Development and Applications of a Pressurized Water-Filled Impedance Tube

Abstract

:1. Introduction

2. Theoretical Background

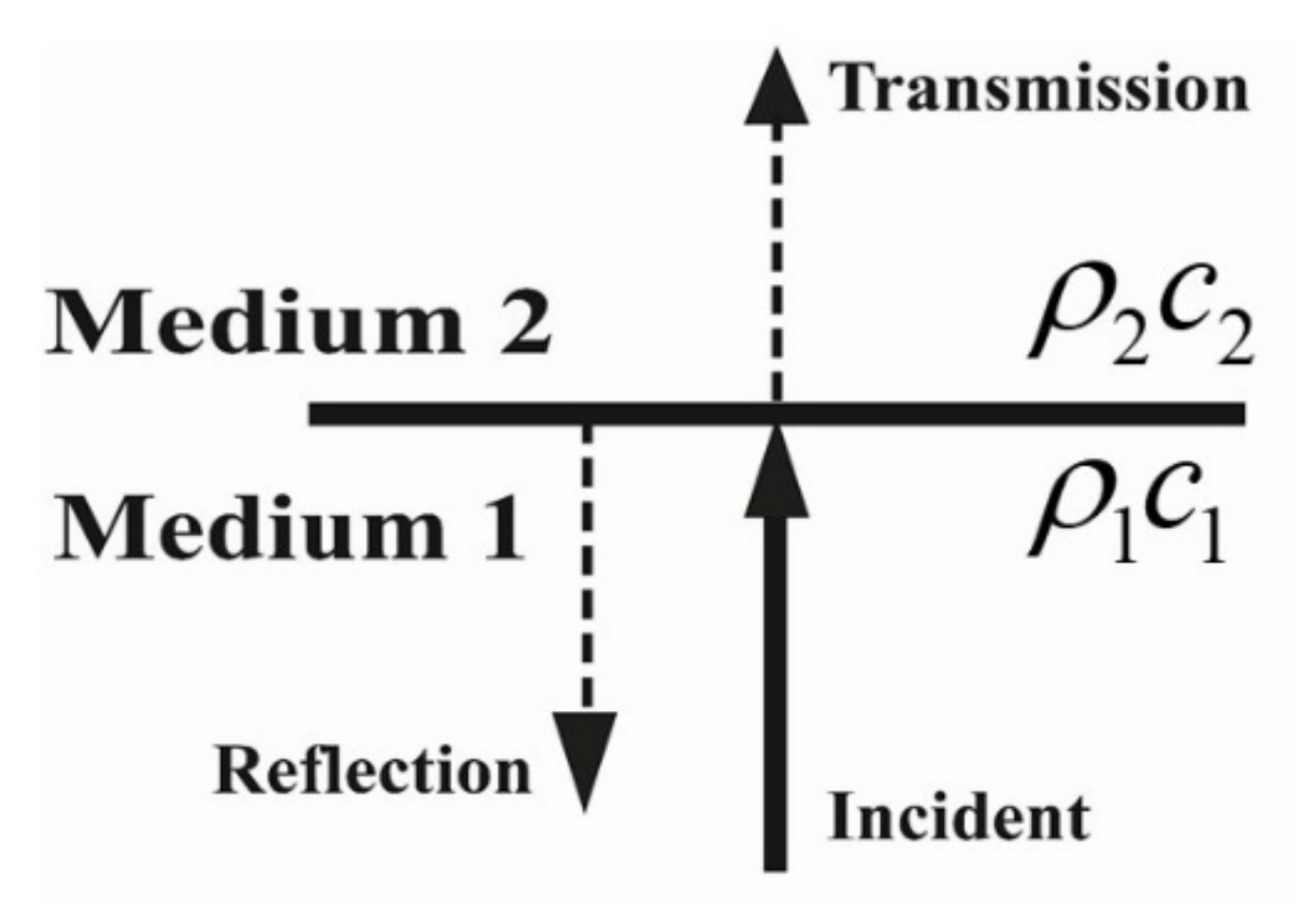

2.1. Acoustic Impedance

2.2. Sound Propagation in a Circular Tube

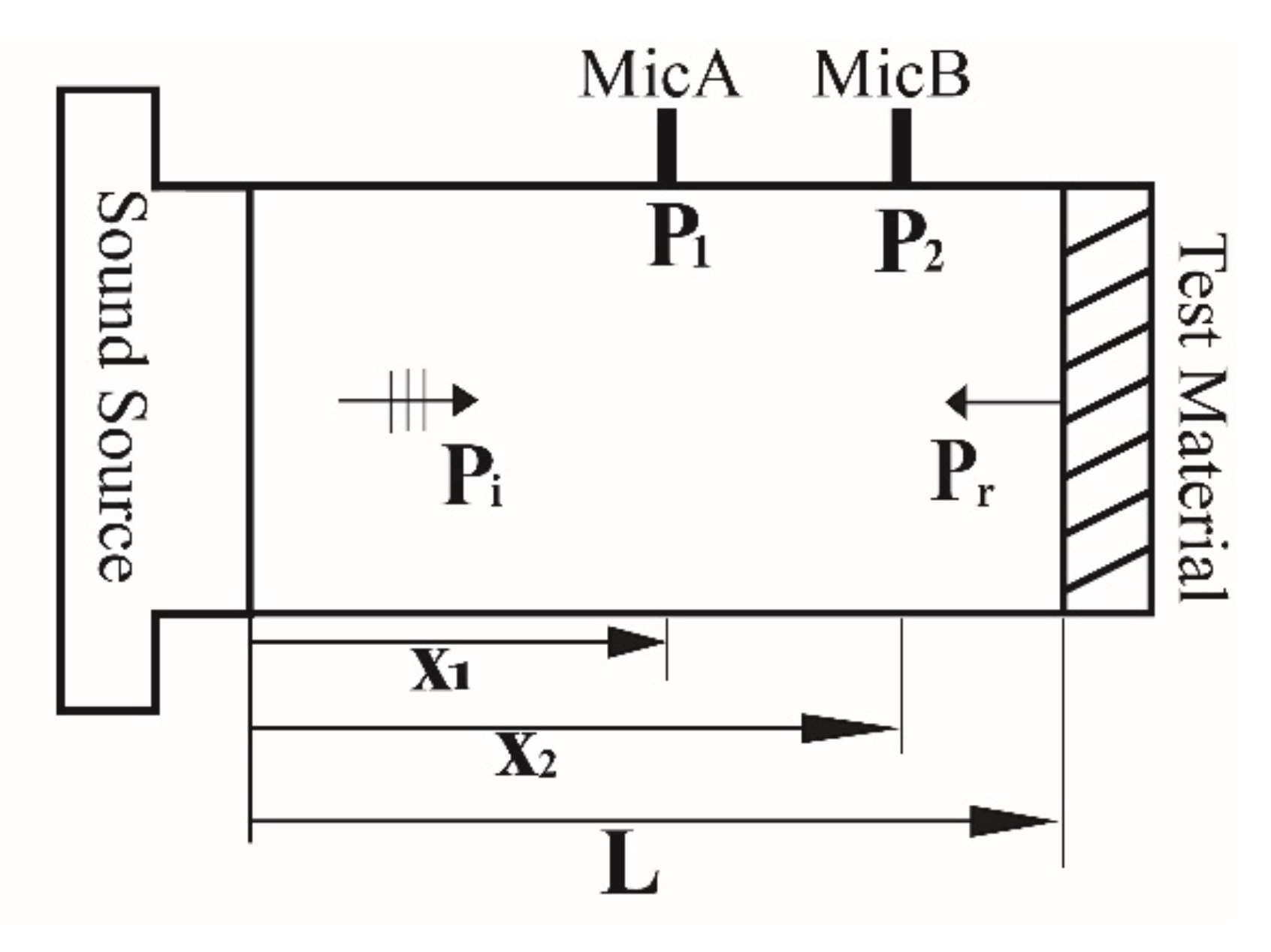

2.3. Transfer Function Method

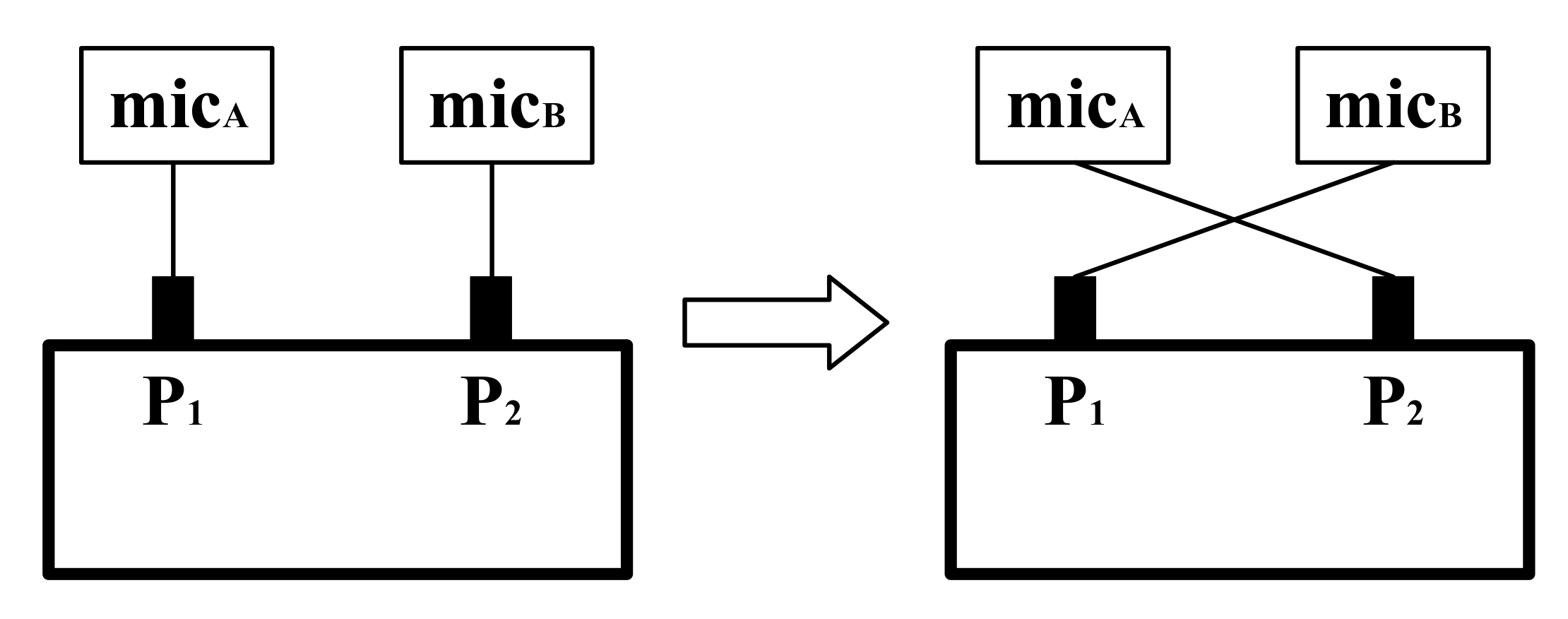

2.4. Sensor-Switching Technique

2.5. Three-Parameter Calibration Method

3. Instrumentation of a WFIT

3.1. Design

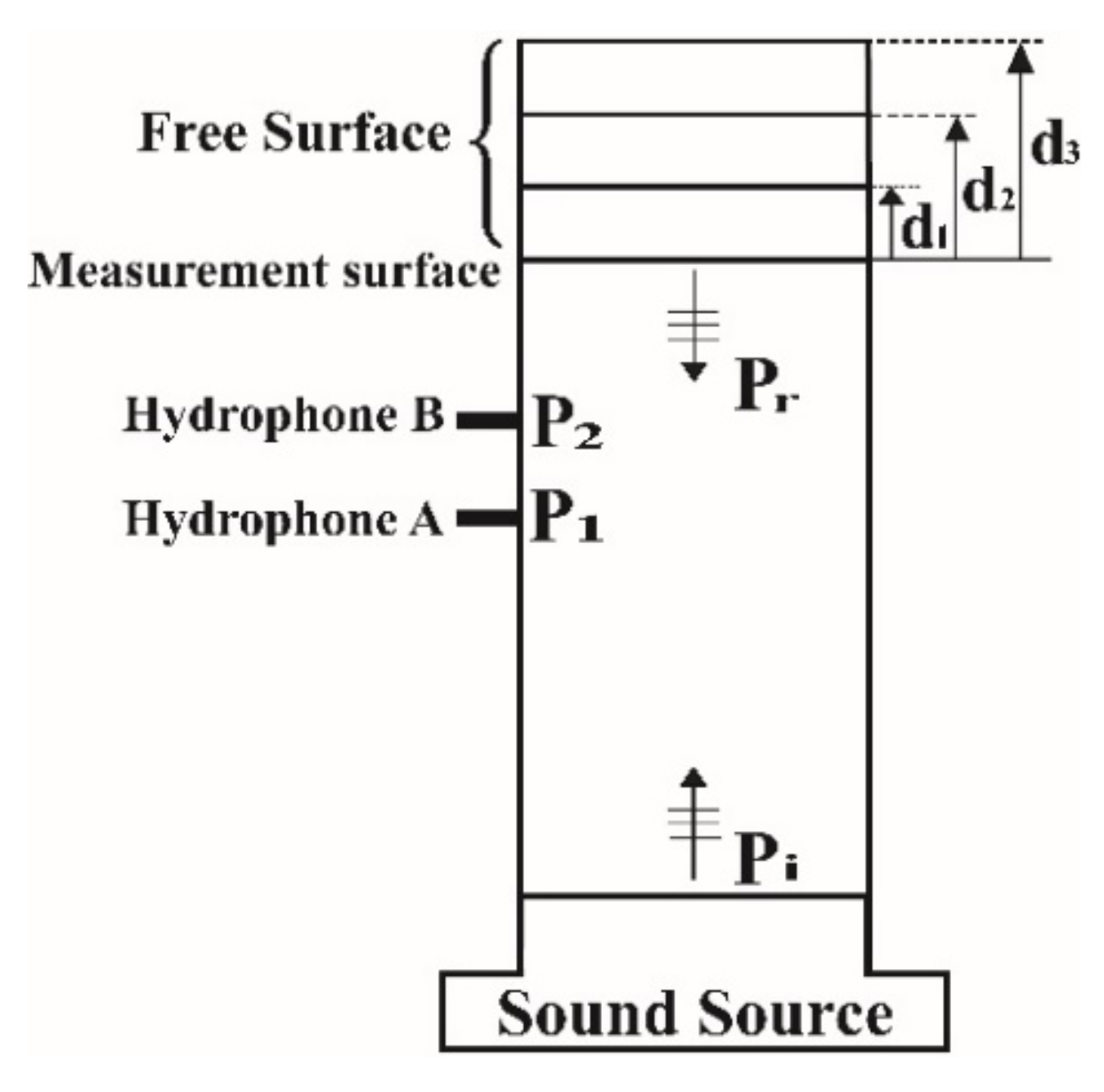

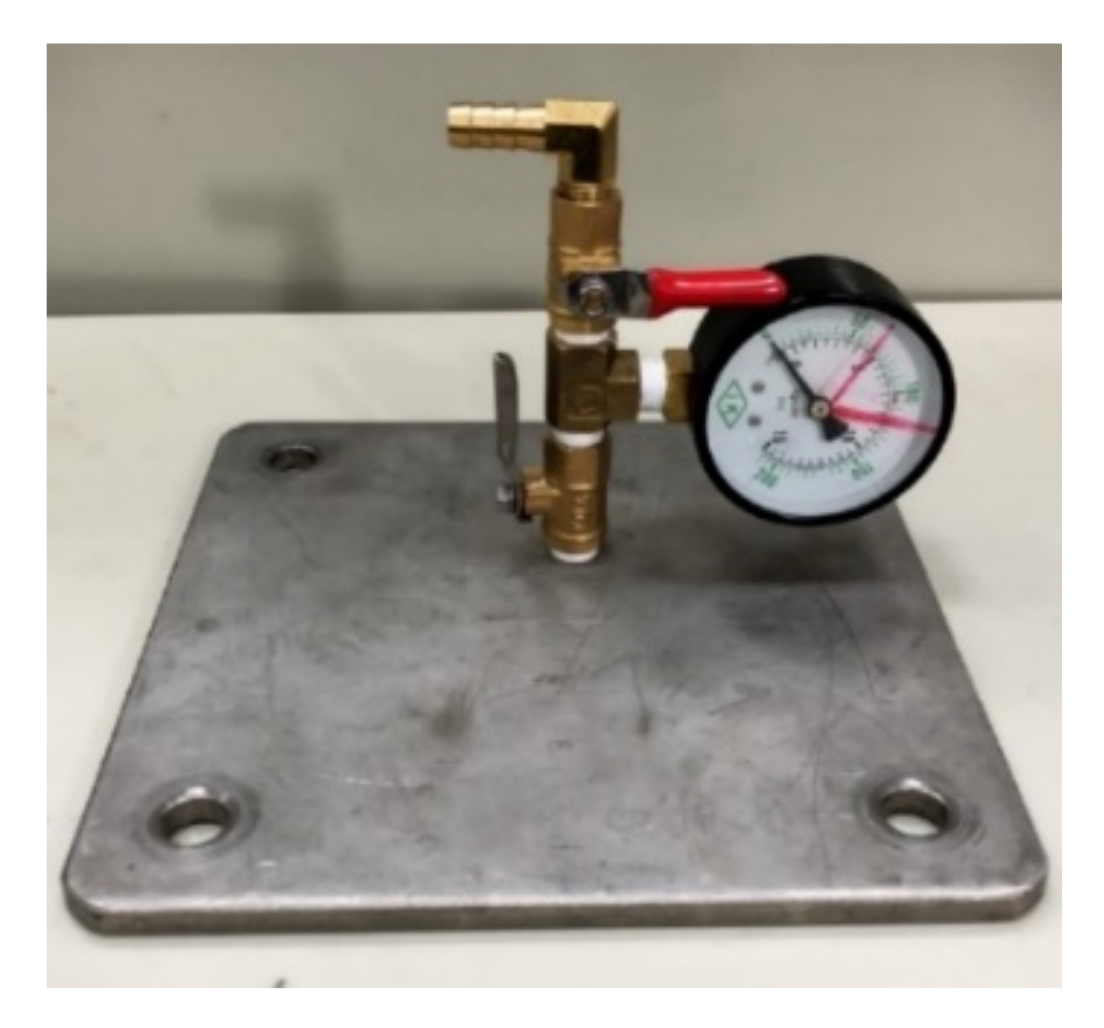

3.2. Pressurized WFIT

3.3. Experimental Setup

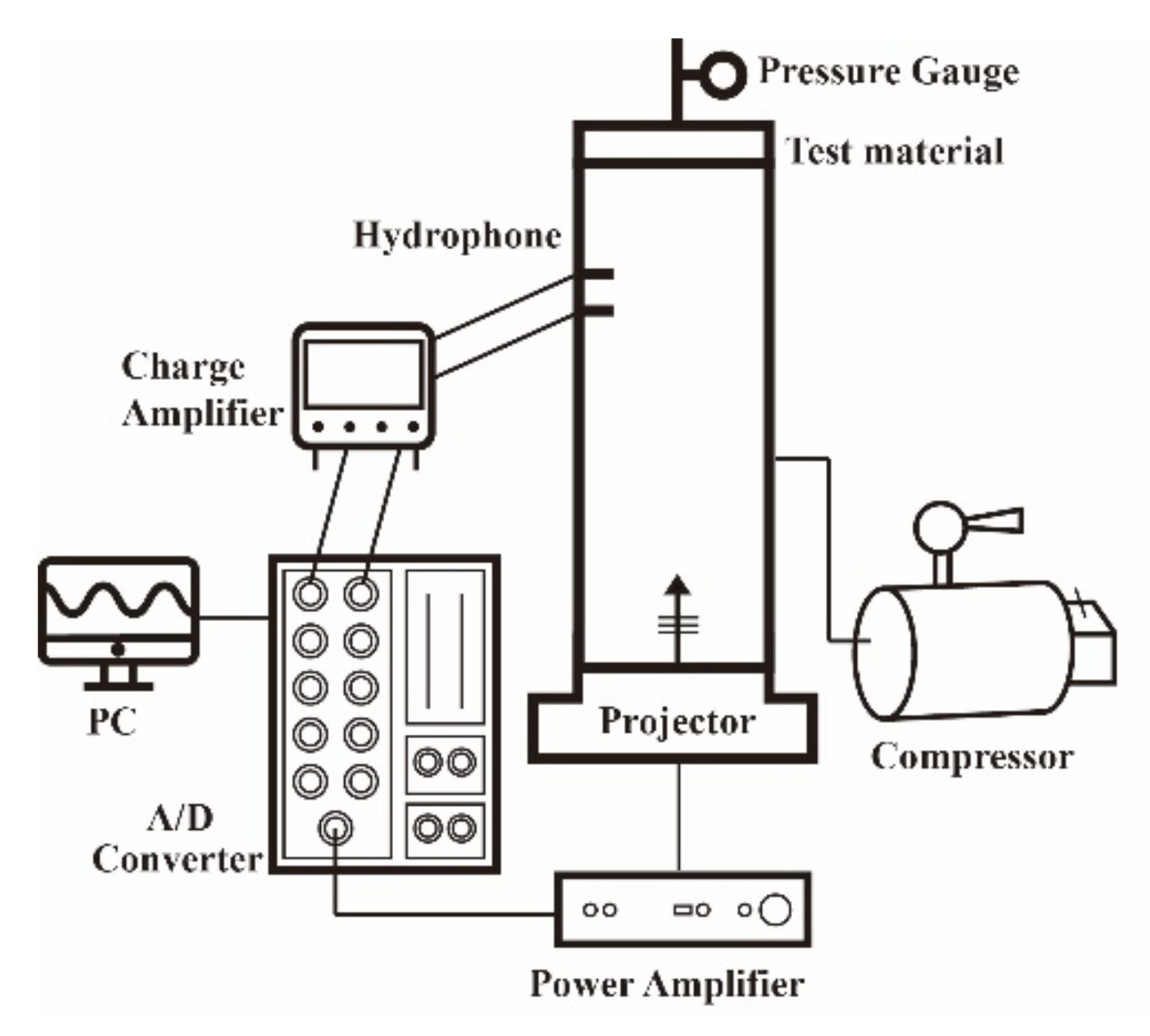

3.4. Measurement Procedure

4. Results and Discussion

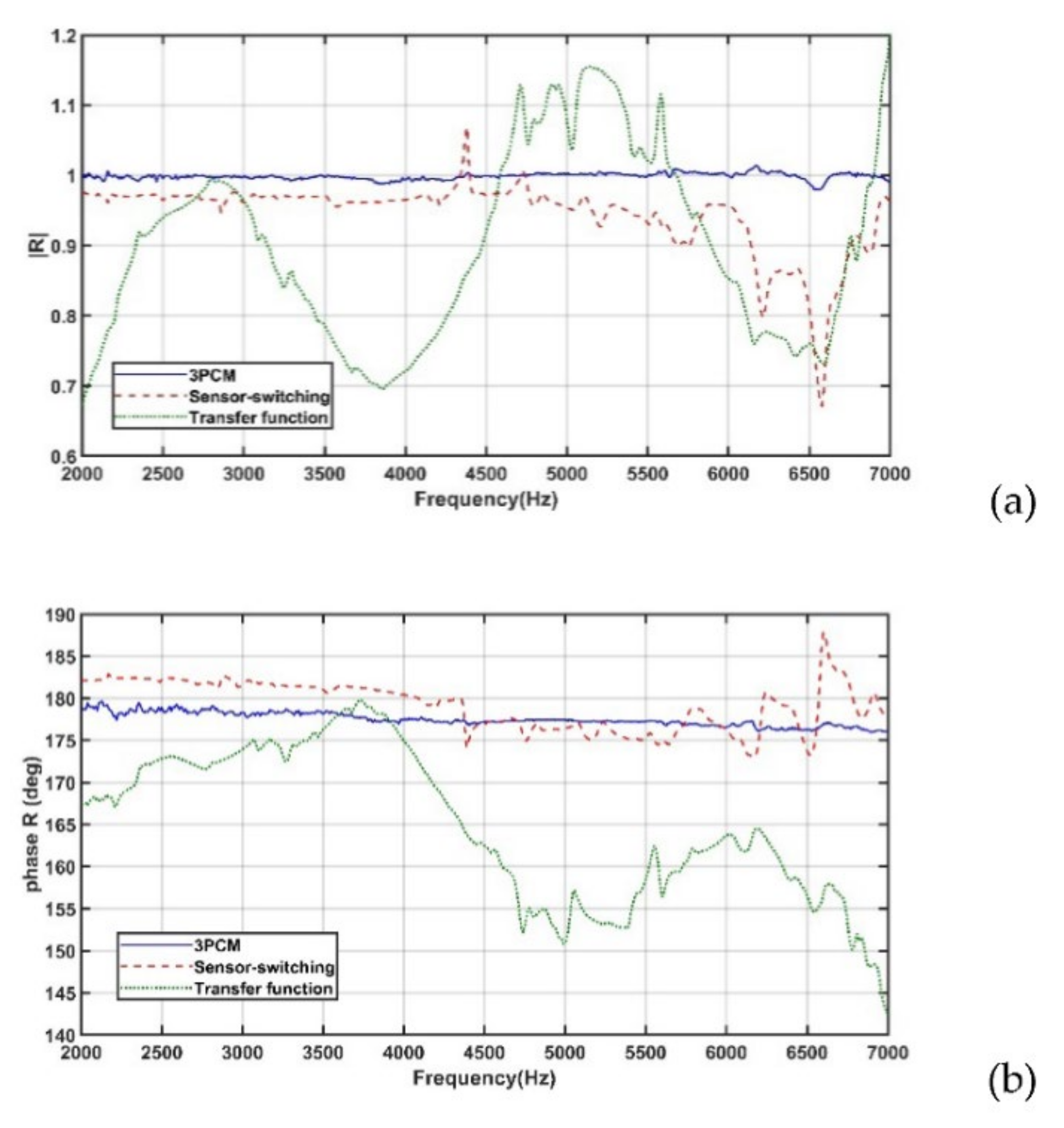

4.1. Reflection Coefficient at the Water–Air Interface

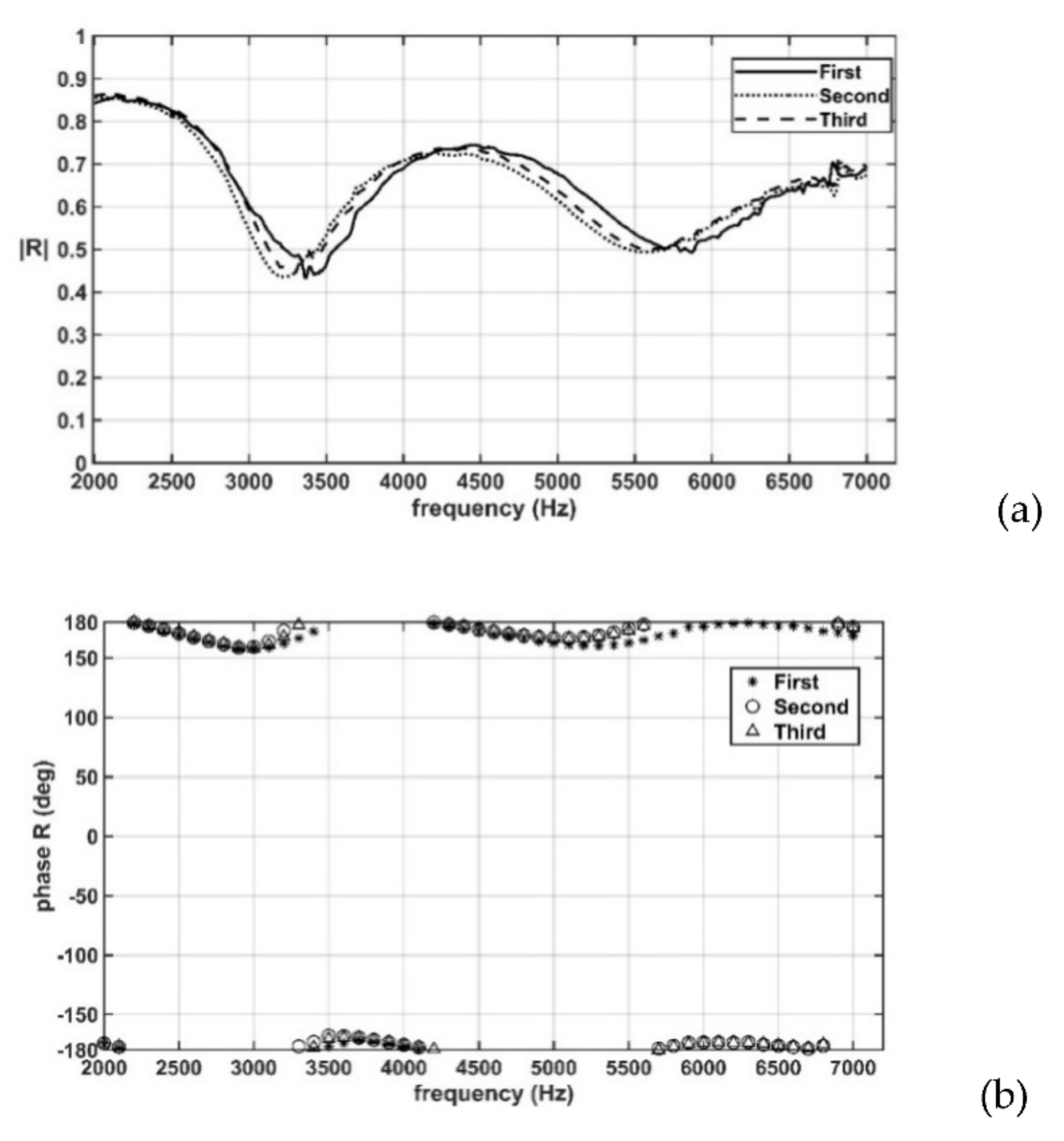

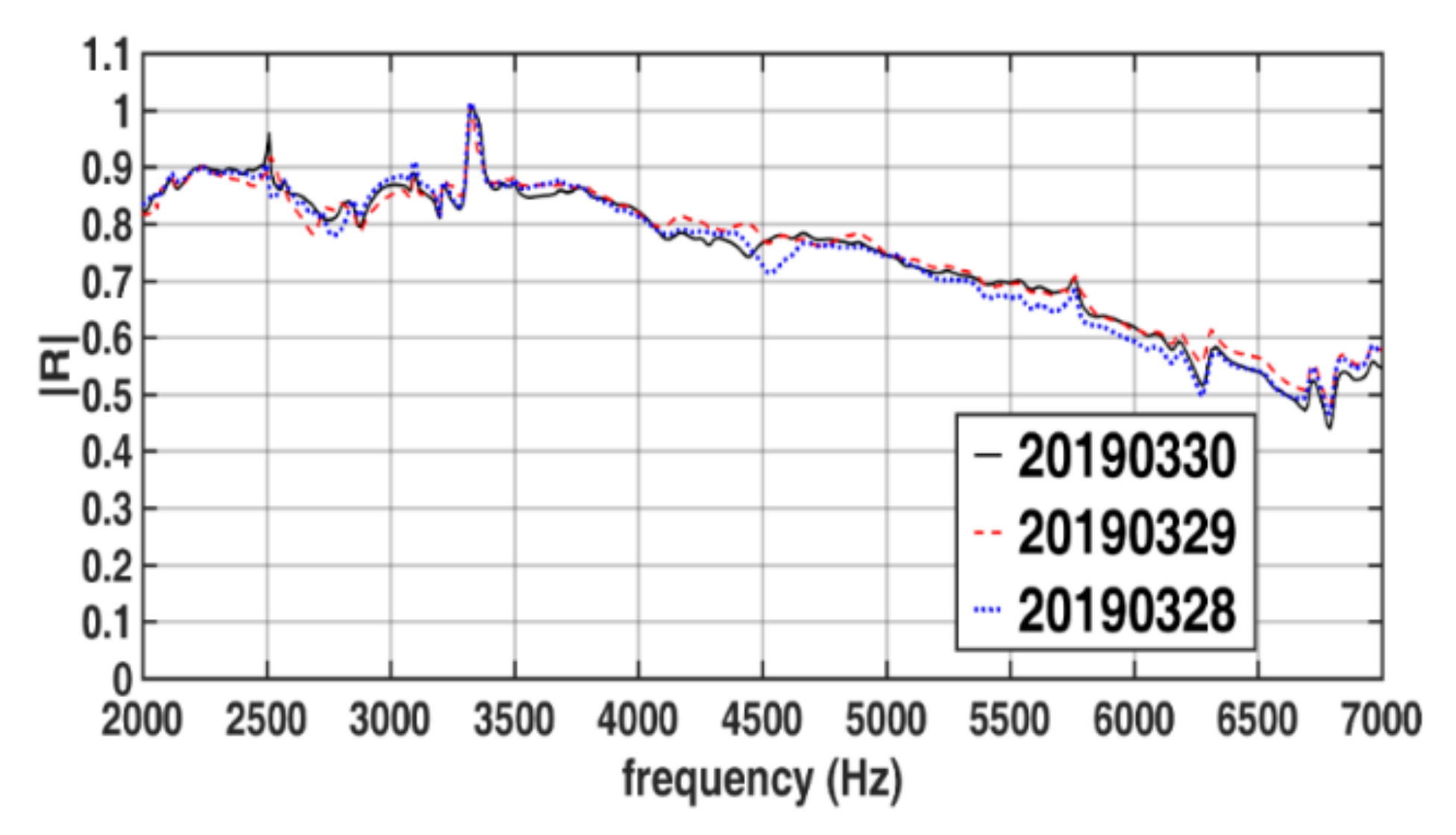

4.2. Repeatability of Reflection Coefficient Measurements for Porous Rubber

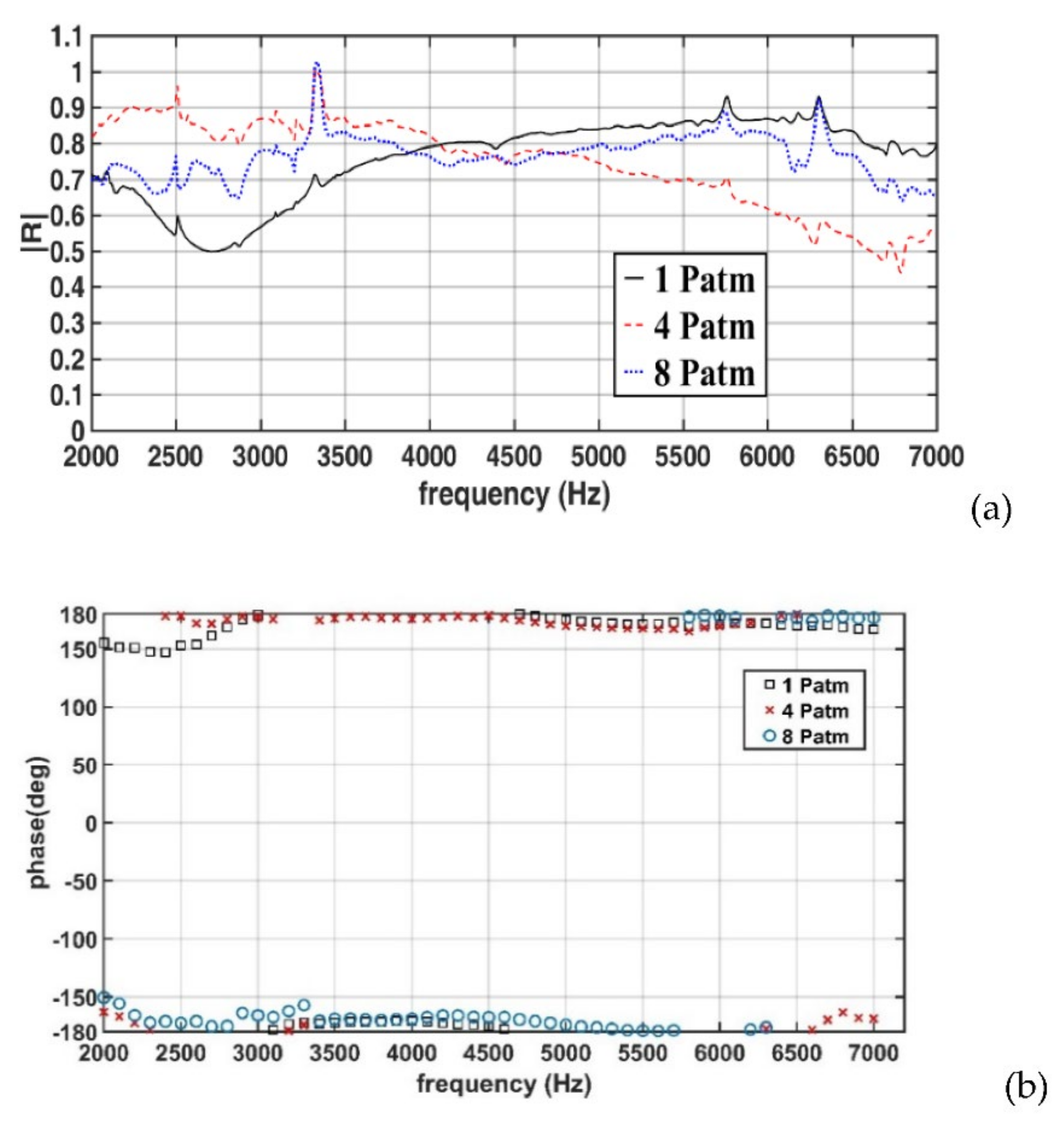

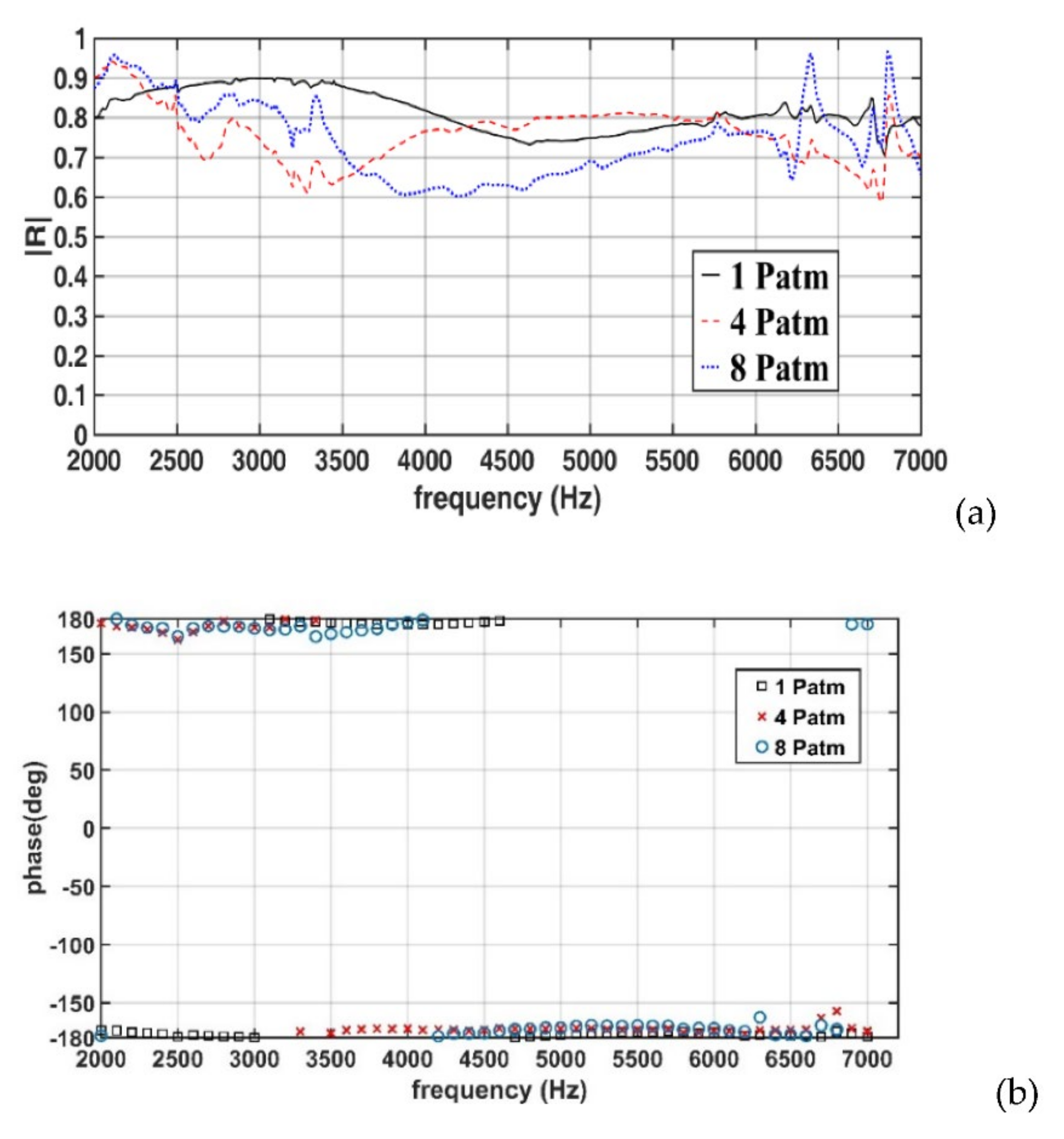

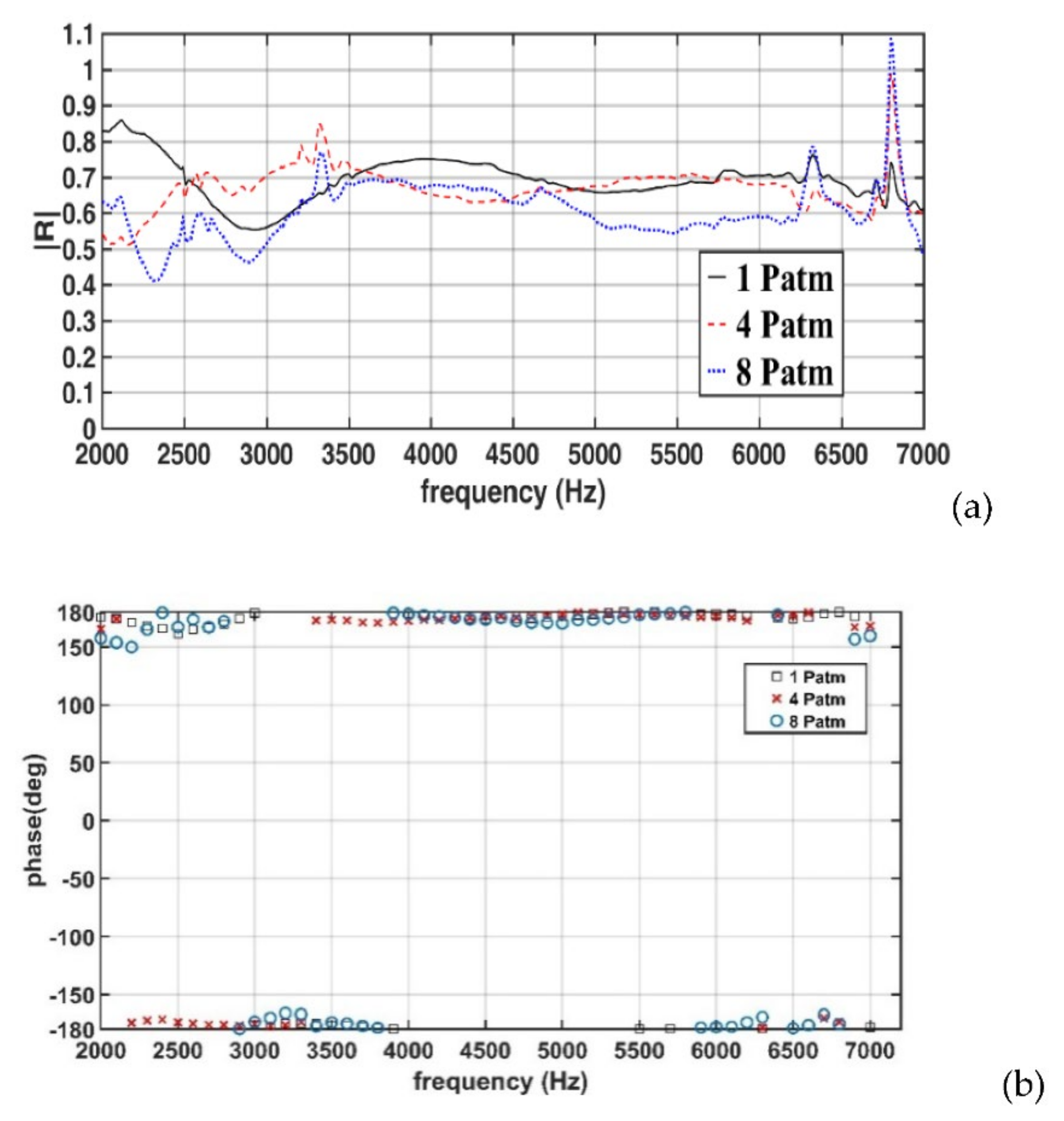

4.3. Reflection Coefficients Obtained for Porous Rubber Specimens under Different Hydrostatic Pressures

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, K.W.; Huang, C.J.; Too, G.P.; Shen, Z.Y.; Sun, Y.D. Underwater sound source localization based on passive time-reversal mirror and ray theory. Sensors 2022, 22, 2420. [Google Scholar] [CrossRef]

- ASTM E1050-12; Standard Test Method for Impedance and Absorption of Acoustical Materials Using a Tube, Two Microphones and a Digital Frequency Analysis System. ASTM Committee: West Conshohocken, PA, USA, 2012.

- ISO 10534-1; Acoustics—Determination of Sound Absorption Coefficient and Impedance in Impedance Tubes–Part I: Method Using Standing Wave Ratio. ISO: Geneva, Switzerland, 1996.

- Seybert, A.F.; Ross, D.F. Experimental determination of acoustic properties using a two-microphone random-excitation technique. J. Acoust. Soc. Am. 1977, 61, 1362–1370. [Google Scholar] [CrossRef] [Green Version]

- Chung, J.Y.; Blaser, D.A. Transfer function method of measuring in-duct acoustic properties, I. Theory. J. Acoust. Soc. Am. 1980, 68, 907–913. [Google Scholar] [CrossRef]

- Chung, J.Y.; Blaser, D.A. Transfer function method of measuring in-duct acoustic properties, II. Experiment. J. Acoust. Soc. Am. 1980, 68, 914–921. [Google Scholar] [CrossRef]

- Corbett, S.S., III. A Two-Hydrophone Technique for Measuring the Complex Reflectivity of Materials in Water-Filled Tubes. Master’s Thesis, Pennsylvania State University, Pennsylvania, PA, USA, 1983. [Google Scholar]

- Wilson, P.S.; Roy, R.A.; Carey, W.M. An improved water-filled impedance tube. J. Acoust. Soc. Am. 2003, 113, 3245–3252. [Google Scholar] [CrossRef]

- Jones, M.G.; Stiede, P.E. Comparison of methods for determining specific acoustic impedance. J. Acoust. Soc. Am. 1997, 101, 2694–2704. [Google Scholar] [CrossRef]

- Bodén, H.; Åbom, M. Influence of errors on the two-microphone method for measuring acoustic properties in ducts. J. Acoust. Soc. Am. 1986, 79, 541–549. [Google Scholar] [CrossRef]

- Del Grosso, V.A. Analysis of multimode acoustic propagation in liquid cylinders with realistic boundary conditions–application to sound speed and absorption measurements. Acta Acust. United Acust. 1971, 24, 299–311. [Google Scholar]

- Lafleur, L.D.; Shields, F.D. Low-frequency propagation modes in a liquid-filled elastic tube waveguide. J. Acoust. Soc. Am. 1995, 97, 1435–1445. [Google Scholar] [CrossRef]

- Wilson, P.S. Sound Propagation and Scattering in Bubbly Liquids. Ph.D. Thesis, Boston University, Boston, MA, USA, 2002. [Google Scholar]

- Jian, Z.Y. The Study on the Measurement of Material’s Underwater Acoustic Properties by Using the Water-Filled Elastic Impedance Tube. Master’s Thesis, National Taiwan University, Taipei, Taiwan, 2005. [Google Scholar]

- Commander, K.W.; Prosperetti, A. Linear pressure waves in bubbly liquids: Comparison between theory and experiments. J. Acoust. Soc. Am. 1989, 85, 732–746. [Google Scholar] [CrossRef]

- Huang, C.-J.; Lin, Y.-T.; Chang, H.-Y.; Tien, T.-M.; Hsu, T.-W. Attenuation of sounds propagating through a bubble screen. J. Coast. Ocean Eng. 2016, 16, 43–53. [Google Scholar] [CrossRef]

- Zhou, C.G.; Bai, G.F.; Liu, B.L.; Li, X.D. Calibration method in measurements of acoustic characteristics of materials in a water filled impedance tube. Acta Acust. 2010, 35, 154–161. [Google Scholar]

- Fu, Y.F.; Fischer, J.; Pan, K.Q.; Yeoh, G.H.; Peng, Z.X. Underwater sound absorption properties of polydimethylsiloxane/carbon nanotube composites with steel plate backing. Appl. Acoust. 2021, 171, 11. [Google Scholar] [CrossRef]

- Sun, L.; Hou, H. Measurement of sound absorption by underwater acoustic material using pulse-separation method. Appl. Acoust. 2014, 85, 106–110. [Google Scholar] [CrossRef]

- ASTM E2611-09; Standard Test Method for Measurement of Normal Incidence Sound Transmission of Acoustical Materials Based on the Transfer Matrix Method. ASTM Committee: West Conshohocken, PA, USA, 2009.

- Oblak, M.; Pirnat, M.; Boltezar, M. An impedance tube submerged in a liquid for the low-frequency transmission-loss measurement of a porous material. Appl. Acoust. 2018, 139, 203–212. [Google Scholar] [CrossRef]

- Sun, Y.; Hua, B. System error calculation and analysis of underwater sound absorption coefficient measurement experiment. Appl. Acoust. 2022, 186, 108489. [Google Scholar] [CrossRef]

- Joshi, D.; Bhatnager, D.; Kumar, A.; Gupta, R. Direct measurement of acoustic impedance in liquids by a new pulse echo technique. MAPAN—J. Metrol. Soc. India 2009, 24, 215–224. [Google Scholar] [CrossRef]

- Joshi, D.; Kumar, A.; Gupta, R.; Yadav, S. Sensitivity Enhancement of Concurrent Technique of Acoustic Impedance Measurement. MAPAN—J. Metrol. Soc. India 2013, 28, 79–83. [Google Scholar] [CrossRef]

- Iwase, T.; Biwa, T.; Yazaki, T. Acoustic impedance measurements of pulse tube refrigerators. J. Appl. Phys. 2010, 107, 6. [Google Scholar] [CrossRef] [Green Version]

- Jin, Y.; Walker, E.; Krokhin, A.; Heo, H.; Choi, T.-Y.; Neogi, A. Enhanced instantaneous elastography in tissues and hard materials using bulk modulus and density determined without externally applied material deformation. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2020, 67, 624–634. [Google Scholar] [CrossRef]

- ASM International. ASM International Metal Handbook, 9th ed.; ASM International: Materials Park, OH, USA, 1989; Volume 17, p. 235. [Google Scholar]

- Jayakumari, V.G.; Shamsudeen, R.K.; Rajeswari, R.; Mukundan, T. Viscoelastic and acoustic characterization of polyurethane-based acoustic absorber panels for underwater applications. J. Appl. Polym. Sci. 2019, 136, 9. [Google Scholar] [CrossRef]

- Guillermic, R.M.; Lanoy, M.; Strybulevych, A.; Page, J.H. A PDMS-based broadband acoustic impedance matched material for underwater applications. Ultrasonics 2019, 94, 152–157. [Google Scholar] [CrossRef] [Green Version]

- Dong, J.; Tian, P. Review of underwater sound absorption materials. IOP Conf. Ser. Earth Environ. Sci. 2020, 508, 012182. [Google Scholar] [CrossRef]

- Wilson, W.D. Speed of sound in distilled water as a function of temperature and pressure. J. Acoust. Soc. Am. 1959, 31, 1067–1072. [Google Scholar] [CrossRef]

| Wave Velocity (m/s) | Density (kg/m3) | Size (cm) | ||

|---|---|---|---|---|

| Water (20 °C) | Inner diam. | |||

| Tube Wall | * | Outer diam. | ||

| * | Length | |||

| Sampling frequency | 50 kHz |

| Amplitude of incident sound | 10.0 mv |

| Sound-transmitting period | 0.21 s |

| Signal duration time | 0.15 s |

| Sound frequency | 2–7 kHz |

| Corbett [7] | Wilson et al. [8] | Jian [14] | Present | |

|---|---|---|---|---|

| Calibration method | Sensor-switching | 3PCM | Sensor-switching | 3PCM |

| Operating frequency | 2–21 kHz | 5–9 kHz | 1–8 kHz | 2–7 kHz |

| Amplitude error | 0.07 | 0.015 | 0.11 | 0.02 |

| Phase error | 30° | 0.7° | 30° | 4° |

| Test | |||

|---|---|---|---|

| Fist | 1.1991 + 0.6836i | 0.9283 − 0.8738i | 0.5510 + 1.0913i |

| Second | 1.2208 + 0.7549i | 0.9191 − 0.7505i | 0.5777 + 0.9940i |

| Third | 1.1044 + 0.7913i | 0.9300 − 0.5589i | 0.5960 + 0.8583i |

| Case | Thickness (mm) | Pressure (Patm) |

|---|---|---|

| Case 1 | 25 | 1, 4, 8 |

| Case 2 | 50 | 1, 4, 8 |

| Case 3 | 75 | 1, 4, 8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, Z.-Y.; Huang, C.-J.; Liu, K.-W. Development and Applications of a Pressurized Water-Filled Impedance Tube. Sensors 2022, 22, 3827. https://doi.org/10.3390/s22103827

Shen Z-Y, Huang C-J, Liu K-W. Development and Applications of a Pressurized Water-Filled Impedance Tube. Sensors. 2022; 22(10):3827. https://doi.org/10.3390/s22103827

Chicago/Turabian StyleShen, Zong-You, Ching-Jer Huang, and Kuan-Wen Liu. 2022. "Development and Applications of a Pressurized Water-Filled Impedance Tube" Sensors 22, no. 10: 3827. https://doi.org/10.3390/s22103827

APA StyleShen, Z.-Y., Huang, C.-J., & Liu, K.-W. (2022). Development and Applications of a Pressurized Water-Filled Impedance Tube. Sensors, 22(10), 3827. https://doi.org/10.3390/s22103827