Detection of Mechanical Failures in Industrial Machines Using Overlapping Acoustic Anomalies: A Systematic Literature Review

Abstract

:1. Introduction

- Classifying acoustic mechanical failure analysis approaches and techniques;

- Analyzing the existing work conducted in this area of research;

- Recognizing the main issues that need to be handled;

- Identifying the potential areas of research in the future.

2. Related Work

3. Research Methodology

3.1. Research Design

3.1.1. Literature Review Questions

- What types of failures in industrial machines can be detected by acoustic methods?

- What are the existing solutions and possible technologies for the detection of mechanical failures by acoustic methods?

- What are the challenges faced by acoustical failure detection?

- What are the future research trends and directions in mechanical failure detection using acoustic methods?

3.1.2. Research Process

3.1.3. Search Terms

- “Acoustic Mechanical Failure Detection Industrial Machine” OR “Acoustic Mechanical Fault Detection Industrial Machine”

- “Acoustic Mechanical Failure”

- “Acoustic Detection”

- “Acoustic”

- “Mechanic Failure”

- Detection

- Failure

- Machine

(((((“Industrial Machine”) AND “mechanical”) AND “Failure” OR “Fault”) AND “Acoustic”) AND “Detection”)

3.2. Review Conduction

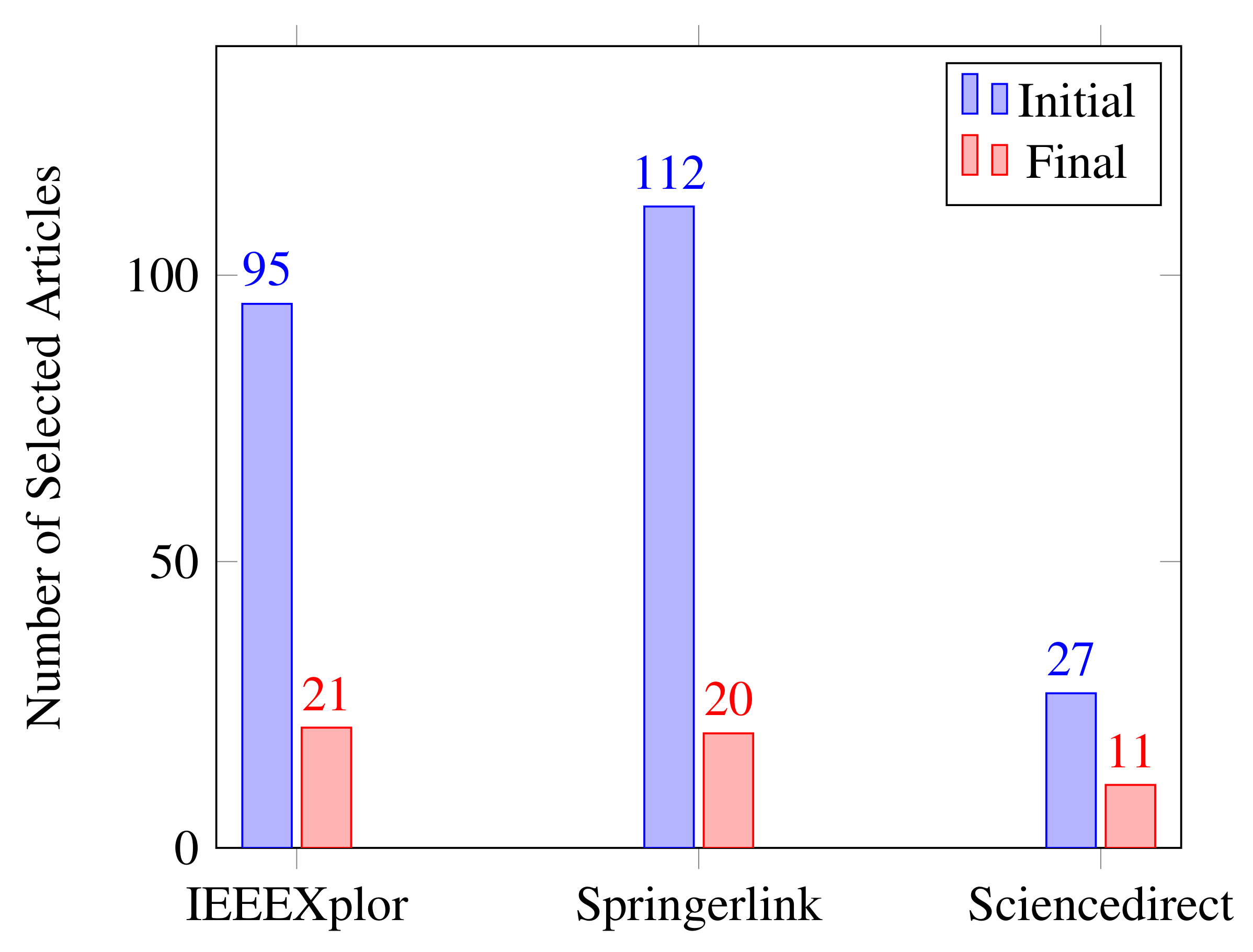

3.2.1. Selection of Relevant Papers

- Find the database and identify previous works related to the study using the defined terms.

- Ignore papers that are not related to the given search criteria.

- Exclude papers that have no clear relationship between title or abstract.

- Evaluate the papers by reading the full context.

- Evaluate the bibliography

- Perform the initial study.

3.2.2. Inclusion and Exclusion Criteria

3.2.3. Data Extraction

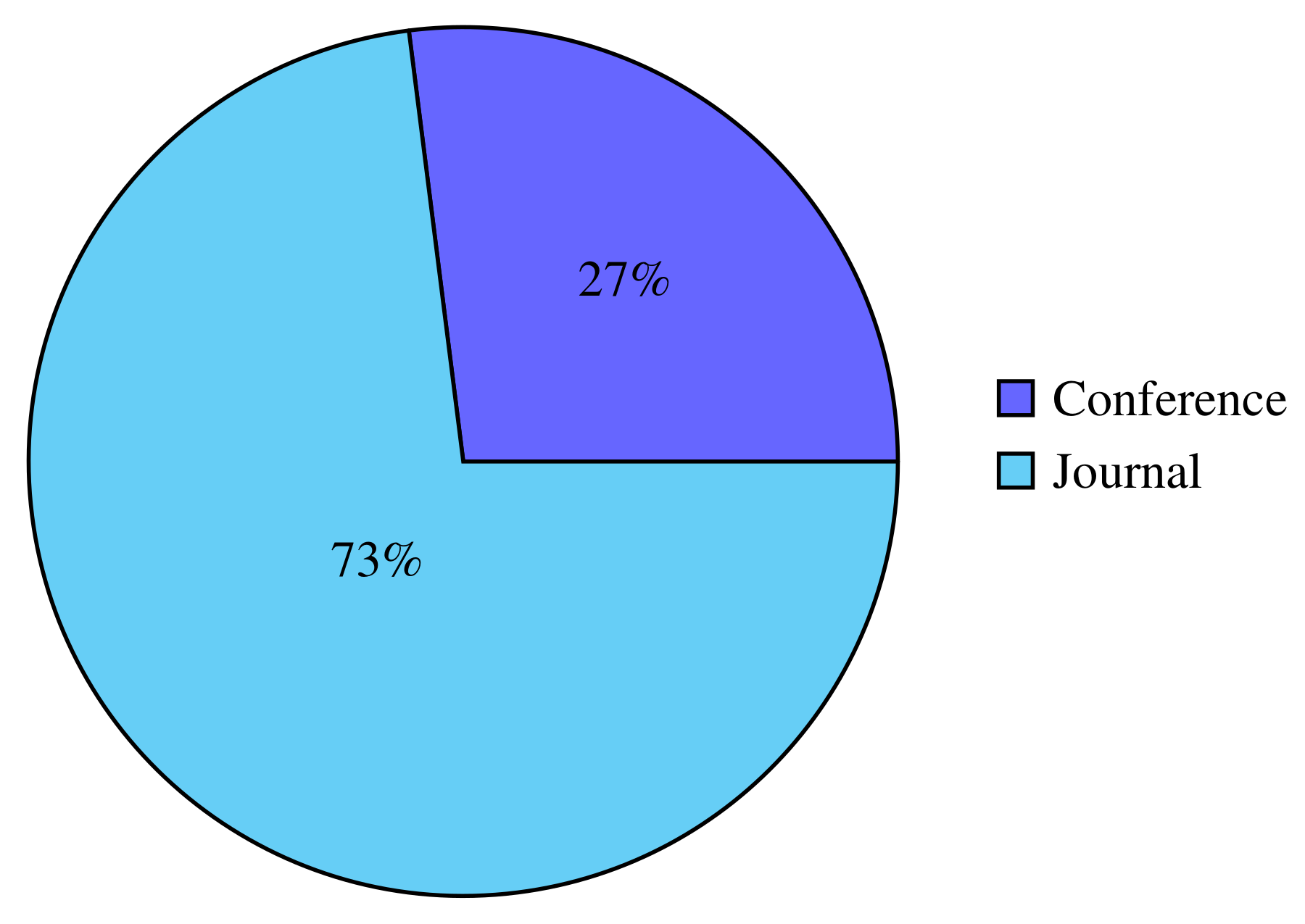

3.3. Demographic Data and Overview

4. Results and Discussion

4.1. Results Obtained from Answering the Research Questions

4.1.1. What Types of Failures in Industrial Machines Can Be Detected by Acoustic Methods?

4.1.2. What Are the Existing Solutions and Possible Technologies for the Detection of Mechanical Failures by Acoustic Methods?

- Acoustic Emission-BasedAcoustic emission (AE) is the term given to describe a physical phenomenon that occurs when a small amount of elastic energy is released into a structure through a mechanical process [20]. In simple terms, the acoustic emission signal is a combination of the deterministic signal and the failure signal. A deterministic signal is a signal that appears when the engine is running normally. Meanwhile, the failure signal is a signal that appears when there is an abnormality or disturbance when the engine is operating. Assuming that the deterministic signal and the failure signal are unrelated, Liu et al. [50] write the acoustic emission signal as Equation (1), where , , and are, respectively, acoustic emission signals, deterministic signals, and fault signals.

- Microphone-BasedApart from the acoustic emission approach, there are various other ways to retrieve the acoustic signal from the component to be inspected. In general, acoustic signal retrieval involves using a microphone to pick up the signal. The microphone used can stand alone [22,47], with additional equipment involvement (such as a stethoscope) [78], or a microphone may be used that is installed on certain devices (such as cellphones) [60,67]. The use of a microphone is intended to take sound samples from the device under test when the equipment is working in accordance with its function. The frequency of the sound picked up by the microphone can be in the range of 10 Hz–10 kHz (the range of sound that can be heard by humans) [59], as well as the signals picked up by the microphone on a mobile phone sampling frequency of 44.1 kHz [47,67]. The advantage of using a microphone over other methods is the ease of installation and data collection [22]. However, careless placement of the microphone will affect the measurement results.

- Ultrasonic-BasedAnother method used to detect faults is to utilize ultrasonic signals. Jo et al. [45] conducted research on failure detection on turbine blades by the ultrasonic method at a frequency of 300 kHz. They found that partially lost and distorted blades can be detected by acoustic diagnosis during the turbine’s operation.

4.1.3. What Are the Challenges Faced by Acoustical Failure Detection?

4.1.4. What Are the Future Research Trends and Directions in Mechanical Failure Detection Using the Acoustic Method?

4.2. Threats to Validity

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Fan, L.; Zhang, F.; Fan, H.; Zhang, C. Brief review of image denoising techniques. Vis. Comput. Ind. Biomed. Art 2019, 2, 7. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ali, M.H.; Jaber, M.M.; Abd, S.K.; Rehman, A.; Awan, M.J.; Vitkutė-Adžgauskienė, D.; Damaševičius, R.; Bahaj, S.A. Harris Hawks Sparse Auto-Encoder Networks for Automatic Speech Recognition System. Appl. Sci. 2022, 12, 1091. [Google Scholar] [CrossRef]

- Butkeviciute, E.; Bikulciene, L.; Sidekerskiene, T.; Blazauskas, T.; Maskeliunas, R.; Damasevicius, R.; Wei, W. Removal of Movement Artefact for Mobile EEG Analysis in Sports Exercises. IEEE Access 2019, 7, 7206–7217. [Google Scholar] [CrossRef]

- Damasevicius, R.; Napoli, C.; Sidekerskiene, T.; Wozniak, M. IMF mode demixing in EMD for jitter analysis. J. Comput. Sci. 2017, 22, 240–252. [Google Scholar] [CrossRef]

- Picaut, J.; Can, A.; Fortin, N.; Ardouin, J.; Lagrange, M. Low-cost sensors for urban noise monitoring networks—A literature review. Sensors 2020, 20, 2256. [Google Scholar] [CrossRef]

- Kantová, R. Evaluation of Construction Site Noise to Allow the Optimisation of Construction Processes and Construction Machinery Selection. Appl. Sci. 2021, 11, 4389. [Google Scholar] [CrossRef]

- Ahmed, S.S.; Gadelmoula, A.M. Industrial noise monitoring using noise mapping technique: A case study on a concrete block-making factory. Int. J. Environ. Sci. Technol. 2022, 19, 851–862. [Google Scholar] [CrossRef]

- Lv, Y.; Liu, Y.; Jing, W.; Woźniak, M.; Damaševičius, R.; Scherer, R.; Wei, W. Quality control of the continuous hot pressing process of medium density fiberboard using fuzzy failure mode and effects analysis. Appl. Sci. 2020, 10, 4627. [Google Scholar] [CrossRef]

- Araújo Alves, J.; Neto Paiva, F.; Torres Silva, L.; Remoaldo, P. Low-Frequency Noise and Its Main Effects on Human Health—A Review of the Literature between 2016 and 2019. Appl. Sci. 2020, 10, 5205. [Google Scholar] [CrossRef]

- Paar, R.; Marendić, A.; Jakopec, I.; Grgac, I. Vibration monitoring of civil engineering structures using contactless vision-based low-cost iats prototype. Sensors 2021, 21, 7952. [Google Scholar] [CrossRef]

- Weintroub, S. Noise in Factories and its Control. Nature 1960, 187, 1085. [Google Scholar] [CrossRef]

- Bi, X. Infrared Sensors and Ultrasonic Sensors; Springer: Berlin/Heidelberg, Germany, 2020; pp. 143–168. [Google Scholar] [CrossRef]

- Silva, C.W. Sensors and Actuators: Control System Instrumentation; CRC Press: Boca Raton, FL, USA, 2007; pp. 1–674. [Google Scholar] [CrossRef]

- Leukel, J.; González, J.; Riekert, M. Adoption of machine learning technology for failure prediction in industrial maintenance: A systematic review. J. Manuf. Syst. 2021, 61, 87–96. [Google Scholar] [CrossRef]

- Hua, X.; Ono, Y.; Peng, L.; Cheng, Y.; Wang, H. Target Detection Within Nonhomogeneous Clutter Via Total Bregman Divergence-Based Matrix Information Geometry Detectors. IEEE Trans. Signal Process. 2021, 69, 4326–4340. [Google Scholar] [CrossRef]

- Maio, A. Invariance Theory for Adaptive Radar Detection in Heterogeneous Environment. IEEE Signal Process. Lett. 2019, 26, 996–1000. [Google Scholar] [CrossRef]

- Levikari, S.; Kärkkäinen, T.; Andersson, C.; Tamminen, J.; Nykyri, M.; Silventoinen, P. Nondestructive Acoustic Testing of Ceramic Capacitors Using One-Class Support Vector Machine With Automated Hyperparameter Selection. IEEE Access 2020, 8, 226337–226351. [Google Scholar] [CrossRef]

- Simonovic, M.; Kovandzic, M.; Ciric, I.; Nikolic, V. Acoustic Recognition Of Noise-like Environmental Sounds by Using Artificial Neural Network. Expert Syst. Appl. 2021, 184, 115484. [Google Scholar] [CrossRef]

- Molina Vicuna, C.; Howeler, C. A method for reduction of Acoustic Emission (AE) data with application in machine failure detection and diagnosis. Mech. Syst. Signal Process. 2017, 97, 44–58. [Google Scholar] [CrossRef]

- Holford, K.; Eaton, M.; Hensman, J.; Pullin, R.; Evans, S.; Dervilis, N.; Worden, K. A new methodology for automating acoustic emission detection of metallic fatigue fractures in highly demanding aerospace environments: An overview. Prog. Aerosp. Sci. 2017, 90, 1–11. [Google Scholar] [CrossRef]

- Cooper, C.; Wang, P.; Zhang, J.; Gao, R.; Roney, T.; Ragai, I.; Shaffer, D. Convolutional neural network-based tool condition monitoring in vertical milling operations using acoustic signals. Procedia Manuf. 2020, 49, 105–111. [Google Scholar] [CrossRef]

- Tagawa, Y.; Maskeliunas, R.; Damasevicius, R. Acoustic Anomaly Detection of Mechanical Failures in Noisy Real-Life Factory Environments. Electronics 2021, 10, 2329. [Google Scholar] [CrossRef]

- Reubens, J.; Verhelst, P.; van der Knaap, I.; Deneudt, K.; Moens, T.; Hernandez, F. Environmental factors influence the detection probability in acoustic telemetry in a marine environment: Results from a new setup. Hydrobiologia 2019, 845, 81–94. [Google Scholar] [CrossRef] [Green Version]

- Bonfiglio, P.; Pompoli, F.; Delvecchio, S. Vibro-acoustic condition monitoring of Internal Combustion Engines: A critical review of existing techniques. Mech. Syst. Signal Process. 2018, 99, 661–683. [Google Scholar] [CrossRef]

- Leaman, F.; Clausen, E.; Molina Vicuna, C. A Review of Gear Fault Diagnosis of Planetary Gearboxes Using Acoustic Emissions. Acoust. Aust. / Aust. Acoust. Soc. 2021, 49, 265–272. [Google Scholar] [CrossRef]

- Lukonge, A.; Cao, X. Leak Detection System for Long-Distance Onshore and Offshore Gas Pipeline Using Acoustic Emission Technology. A Review. Trans. Indian Inst. Met. 2020, 73, 1715–1727. [Google Scholar] [CrossRef]

- Raghav, M.; Sharma, R. A Review on Fault Diagnosis and Condition Monitoring of Gearboxes by Using AE Technique. Arch. Comput. Methods Eng. 2020, 28, 2845–2859. [Google Scholar] [CrossRef]

- Al-Obaidi, S.; Hui, K.H.; Hee, L.; Leong, M. Automated valve fault detection based on acoustic emission parameters and support vector machine. Alex. Eng. J. 2017, 57, 491–498. [Google Scholar] [CrossRef]

- Altaf, M.; Khan, M.; Ahmad, A.; Badshah, S.; Shah, J.; Anjum, M.A. Automatic and Efficient Fault Detection in Rotating Machinery using Sound Signals. Acoust. Aust. 2019, 47, 125–139. [Google Scholar] [CrossRef]

- Cruz, R.; Silva, F.; Fileti, A. Machine learning and acoustic method applied to leak detection and location in low-pressure gas pipelines. Clean Technol. Environ. Policy 2020, 22, 627–638. [Google Scholar] [CrossRef]

- Daraz, A.; Alabied, S.; Smith, A.; Gu, F.; Ball, A. Detection and Diagnosis of Centrifugal Pump Bearing Faults Based on the Envelope Analysis of Airborne Sound Signals. In Proceedings of the 2018 24th International Conference on Automation and Computing (ICAC), Newcastle Upon Tyne, UK, 6–7 September 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Delgado-Prieto, M.; Zurita Millan, D. Chromatic Monitoring of Gear Mechanical Degradation Based on Acoustic Emission. IEEE Trans. Ind. Electron. 2017, 64, 8707–8717. [Google Scholar] [CrossRef] [Green Version]

- Eftekharnejad, B.; Mba, D. Seeded fault detection on helical gears with acoustic emission. Appl. Acoust. 2009, 70, 547–555. [Google Scholar] [CrossRef] [Green Version]

- Fezari, M.; Taif, F.; Lafifi, M.M. Noise emission analysis a way for early detection and classification faults in rotating machines. In Proceedings of the 2014 16th International Power Electronics and Motion Control Conference and Exposition, Antalya, Turkey, 21–24 September 2014. [Google Scholar] [CrossRef]

- Firmino, J.; Neto, J.; Oliveira, A.; Silva, J.; Mishina, K.; Rodrigues, M. Misfire detection of an internal combustion engine based on vibration and acoustic analysis. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 336. [Google Scholar] [CrossRef]

- Gao, Z.; Lin, J.; Wang, X.; Yuhe, L. Grinding Burn Detection Based on Cross Wavelet and Wavelet Coherence Analysis by Acoustic Emission Signal. Chin. J. Mech. Eng. 2019, 32, 68. [Google Scholar] [CrossRef] [Green Version]

- Gil, D.; Grochowina, M.; Leniowska, L. Detecting of the rolling bearing state based on acoustic signal and the k-NN classifier. In Proceedings of the 2019 Signal Processing: Algorithms, Architectures, Arrangements, and Applications (SPA), Poznan, Poland, 18–20 September 2019; pp. 246–249. [Google Scholar] [CrossRef]

- Glowacz, A.; Glowacz, Z. Diagnosis of stator faults of the single-phase induction motor using acoustic signals. Appl. Acoust. 2017, 117, 20–27. [Google Scholar] [CrossRef]

- Glowacz, A.; Tadeusiewicz, R.; Legutko, S.; Caesarendra, W.; Irfan, M.; Liu, H.; Brumercik, F.; Gutten, M.; Sułowicz, M.; Antonino-Daviu, J.; et al. Fault diagnosis of angle grinders and electric impact drills using acoustic signals. Appl. Acoust. 2021, 179, 108070. [Google Scholar] [CrossRef]

- Griffin, J.; Shanbhag, V.; Pereira, M.; Rolfe, B. Application of machine learning for acoustic emissions waveform to classify galling wear on sheet metal stamping tools. Int. J. Adv. Manuf. Technol. 2021, 116, 579–596. [Google Scholar] [CrossRef]

- Gu, D.; Kim, J.; An, Y.; Choi, B.K. Detection of faults in gearboxes using acoustic emission signal. J. Mech. Sci. Technol. 2011, 25, 1279–1286. [Google Scholar] [CrossRef]

- Heydarzadeh, M.; Nourani, M.; Hansen, J.; Kia, S. Non-invasive Gearbox Fault Diagnosis Using Scattering Transform of Acoustic Emission. In Proceedings of the 2017 IEEE International Conference on Acoustics, Speech and Signal Processing (ICASSP), New Orleans, LA, USA, 5–9 March 2017. [Google Scholar] [CrossRef]

- Ibarra, D.; Tamayo, O.; Vallejo-Guevara, A. Bearing fault diagnosis in rotating machinery based on cepstrum pre-whitening of vibration and acoustic emission. Int. J. Adv. Manuf. Technol. 2019, 104, 4155–4168. [Google Scholar] [CrossRef]

- Jian, H.; Lee, H.R.; Ahn, J.H. Detection of Bearing/Rail Defects for Linear Motion Stage Using Acoustic Emission. Int. J. Precis. Eng. Manuf. 2013, 14, 2043–2046. [Google Scholar] [CrossRef]

- Jo, H.; Kim, Y.; Jo, D. Acoustically monitoring defects on rotating turbine blades. J. Mech. Sci. Technol. 2020, 34, 1913–1923. [Google Scholar] [CrossRef]

- Karabacak, Y.; Ozmen, N. Common Spatial Pattern-based Feature Extraction and Worm Gear Fault Detection through Vibration and Acoustic Measurements. Measurement 2021, 187, 110366. [Google Scholar] [CrossRef]

- Kothuru, A.; Nooka, S.; Liu, R. Application of audible sound signals for tool wear monitoring using machine learning techniques in end milling. Int. J. Adv. Manuf. Technol. 2018, 95, 3797–3808. [Google Scholar] [CrossRef]

- Liu, L.; Chen, L.; Wang, Z.; Liu, D. Early Fault Detection of Planetary Gearbox Based on Acoustic Emission and Improved Variational Mode Decomposition. IEEE Sens. J. 2020, 21, 1735–1745. [Google Scholar] [CrossRef]

- Liu, X.; Pei, D.; Lodewijks, G.; Zhao, Z.; Mei, J. Acoustic signal based fault detection on belt conveyor idlers using machine learning. Adv. Powder Technol. 2020, 31, 2689–2698. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, B.; Wang, X.; Zhang, L. Acoustic Emission Analysis for Wind Turbine Blade Bearing Fault Detection Under Time-Varying Low-Speed and Heavy Blade Load Conditions. IEEE Trans. Ind. Appl. 2021, 57, 2791–2800. [Google Scholar] [CrossRef]

- Lu, K.; Gu, J.; Fan, H.; Sun, X.; Li, B.; Gu, F. Acoustics Based Monitoring and Diagnostics for the Progressive Deterioration of Helical Gearboxes. Chin. J. Mech. Eng. 2021, 34, 82. [Google Scholar] [CrossRef]

- Mad Juhani, J.; Ibrahim, R. Acoustic emission technique for early leakage detection of in-service control valve. In Proceedings of the 2016 6th International Conference on Intelligent and Advanced Systems (ICIAS), Kuala Lumpur, Malaysia, 15–17 August 2016; pp. 1–5. [Google Scholar] [CrossRef]

- Medina, R.; Cerrada, M.; Cabrera, D.; Sánchez, R.; Li, C.; de Oliveira, J. Deep Learning-Based Gear Pitting Severity Assessment Using Acoustic Emission, Vibration and Currents Signals. In Proceedings of the 2019 Prognostics and System Health Management Conference (PHM-Paris), Paris, France, 2–5 May 2019; pp. 210–216. [Google Scholar] [CrossRef]

- Merizio, I.; Chavarette, F.; Moro, T.; Outa, R.; Mishra, V. Machine Learning Applied in the Detection of Faults in Pipes by Acoustic Means. J. Inst. Eng. India Ser. C 2021, 102, 975–980. [Google Scholar] [CrossRef]

- Motahari Nezhad, M.; Jafari, S. ANFIS System for Prognosis of Dynamometer High-Speed Ball Bearing Based on Frequency Domain Acoustic Emission Signals. Measurement 2020, 166, 108154. [Google Scholar] [CrossRef]

- Nirwan, N.; Ramani, H.B. Condition monitoring and fault detection in roller bearing used in rolling mill by acoustic emission and vibration analysis. Mater. Today Proc. 2021, 9, 238. [Google Scholar] [CrossRef]

- Oh, S.W.; Lee, C.; You, W. Gear Reducer Fault Diagnosis Using Learning Model for Spectral Density of Acoustic Signal. In Proceedings of the 2019 International Conference on Information and Communication Technology Convergence (ICTC), Jeju, Korea, 16–18 October 2019; pp. 1027–1029. [Google Scholar] [CrossRef]

- Omoregbee, H.; Heyns, S. Fault Classification of Low-Speed Bearings Based on Support Vector Machine for Regression and Genetic Algorithms Using Acoustic Emission. J. Vib. Eng. Technol. 2019, 7, 455–464. [Google Scholar] [CrossRef]

- Ono, Y.; Onishi, Y.; Koshinaka, T.; Takata, S.; Hoshuyama, O. Anomaly detection of motors with feature emphasis using only normal sounds. In Proceedings of the 2013 IEEE International Conference on Acoustics, Speech and Signal Processing, Vancouver, BC, Canada, 26–31 May 2013; pp. 2800–2804. [Google Scholar] [CrossRef]

- Orman, M.; Rzeszucinski, P.; Tkaczyk, A.; Krishnamoorthi, K.; Pinto, C.; Sułowicz, M. Bearing fault detection with the use of acoustic signals recorded by a hand-held mobile phone. In Proceedings of the 2015 International Conference on Condition Assessment Techniques in Electrical Systems (CATCON), Bangalore, India, 10–12 December 2015. [Google Scholar] [CrossRef]

- Pandya, D.; Upadhyay, S.; HARSHA, S. Fault diagnosis of rolling element bearing with intrinsic mode function of acoustic emission data using APF-KNN. Expert Syst. Appl. 2013, 40, 4137–4145. [Google Scholar] [CrossRef]

- Pan, Q.; Zhou, R.; Su, J.; He, T.; Zhang, Z. Automatic localization of the rotor-stator rubbing fault based on acoustic emission method and higher-order statistics. J. Mech. Sci. Technol. 2019, 33, 513–524. [Google Scholar] [CrossRef]

- Park, K.C.; Motai, Y.; Yoon, J. Acoustic Fault Detection Technique for High Power Insulators. IEEE Trans. Ind. Electron. 2017, 64, 9699–9708. [Google Scholar] [CrossRef]

- Qiao, M.; Yan, S.; Tang, X.; Xu, C. Deep Convolutional and LSTM Recurrent Neural Networks for Rolling Bearing Fault Diagnosis Under Strong Noises and Variable Loads. IEEE Access 2020, 8, 66257–66269. [Google Scholar] [CrossRef]

- Qu, A.; Zhu, J.; He, D.; Qiu, B.; Bechhoefer, E. Development of a new acoustic emission based fault diagnosis tool for gearbox. In Proceedings of the 2013 IEEE International Conference on Prognostics and Health Management, PHM 2013, Gaithersburg, MD, USA, 24–27 June 2013; pp. 1–9. [Google Scholar] [CrossRef]

- Ramteke, S.; Chelladurai, H.; Muniyappa, A. Diagnosis of Liner Scuffing Fault of a Diesel Engine via Vibration and Acoustic Emission Analysis. J. Vib. Eng. Technol. 2019, 8, 815–833. [Google Scholar] [CrossRef]

- Rzeszucinski, P.; Orman, M.; Pinto, C.; Tkaczyk, A.; Sulowicz, M. A signal processing approach to bearing fault detection with the use of a mobile phone. In Proceedings of the 2015 IEEE 10th International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives (SDEMPED), Guarda, Portugal, 1–4 September 2015. [Google Scholar] [CrossRef]

- Seemuang, N.; Lim, J.; Kaewkongka, T. Shaft Crack Monitoring by Using Acoustic Emission Technique. In Proceedings of the 2018 2nd International Conference on Engineering Innovation (ICEI), Bangkok, Thailand, 5–6 July 2018; pp. 30–34. [Google Scholar] [CrossRef]

- Shang, Y.; Liu, Q.; Niu, B.; Zhang, M.; Qi, W.; Wu, J. Mechanical fault diagnosis system based on acoustic feature analysis in gas insulated switchgear. In Proceedings of the 2017 1st International Conference on Electrical Materials and Power Equipment (ICEMPE), Xi’an, China, 14–17 May 2017; pp. 610–615. [Google Scholar] [CrossRef]

- Shukri, I.; Mun, G.; Ibrahim, R. A study on control valve fault incipient detection monitoring system using Acoustic Emission technique. In Proceedings of the 2011 3rd International Conference on Computer Research and Development, Shanghai, China, 11–13 March 2011; Volume 4, pp. 365–370. [Google Scholar] [CrossRef]

- Sun, S.; Hu, X.; Zhang, W. Detection of tool breakage during milling process through acoustic emission. Int. J. Adv. Manuf. Technol. 2020, 109, 1409–1418. [Google Scholar] [CrossRef]

- Taha, Z.; Widiyati, K. Artificial neural network for bearing defect detection based on acoustic emission. Int. J. Adv. Manuf. Technol. 2010, 50, 289–296. [Google Scholar] [CrossRef]

- Tang, L.; Liu, X.; Wu, X.; Wang, Z.; Hou, K. Defect localization on rolling element bearing stationary outer race with acoustic emission technology. Appl. Acoust. 2021, 182, 108207. [Google Scholar] [CrossRef]

- Toutountzakis, T.; Tan, C.; Mba, D. Application of Acoustic Emission to Seeded Gear Fault Detection. NDT E Int. 2005, 38, 27–36. [Google Scholar] [CrossRef] [Green Version]

- Volkovas, V.; Dulevicius, J. Acoustic emission used for detection of crack generation in propellers of turbine-pump units. Russ. J. Nondestruct. Test. 2006, 42, 248–254. [Google Scholar] [CrossRef]

- Wu, F.; Meng, G. Feature extraction based on the 3D spectrum analysis of acoustic signals to identify rotor malfunction. Int. J. Adv. Manuf. Technol. 2006, 28, 1146–1151. [Google Scholar] [CrossRef]

- Yao, Y.; Gui, G.; Yang, S.; Zhang, S. A Recursive Denoising Learning for Gear Fault Diagnosis Based on Acoustic Signal in Real-Industrial Noise Condition. IEEE Trans. Instrum. Meas. 2021, 70, 3524015. [Google Scholar] [CrossRef]

- Yun, H.; Kim, H.; Jeong, Y.; Jun, M. Autoencoder-based anomaly detection of industrial robot arm using stethoscope based internal sound sensor. J. Intell. Manuf. 2021, 1–18. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, J.; Litak, G.; Hu, E. Feature extraction under bounded noise background and its application in low speed bearing fault diagnosis. J. Mech. Sci. Technol. 2019, 33, 3193–3204. [Google Scholar] [CrossRef]

- Yang, C.; Mariton, M. Machine failure detection in manufacturing systems. In Proceedings of the 1994 33rd IEEE Conference on Decision and Control, Lake Buena Vista, FL, USA, 14–16 December 1994. [Google Scholar] [CrossRef]

| References | Research Method | Year | Citations | Timeline | Focus of Study |

|---|---|---|---|---|---|

| Delvecchio et al. [24] | Traditional Review | 2017 | 179 | No | The state-of-the-art strategies and techniques based on vibroacoustic signals that can monitor and diagnose malfunctions in internal combustion engines (ICEs) under both test bench and vehicle operating conditions. |

| Leaman et al. [25] | Traditional Review | 2021 | 34 | No | The use of acoustic emission technology to detect failures in planetary gearboxes |

| Lukonge and Cao [26] | Traditional Review | 2020 | 77 | No | Utilization of acoustic emissions technology to detect offshore and onshore pipeline leaks |

| Raghav and Sharma [27] | Traditional Review | 2020 | 99 | No | The techniques for the condition monitoring and fault diagnosis of gearboxes based on acoustic emissions (AE) |

| No | Database | URL |

|---|---|---|

| 1 | IEEE Xplore | https://ieeexplore.ieee.org/, (accessed on 24 December 2021) |

| 2 | Science Direct | https://sciencedirect.com/, (accessed on 24 December 2021) |

| 3 | Springer Link | https://link.springer.com/, (accessed on 24 December 2021) |

| Inclusion Criteria | |

|---|---|

| 1 | Peer-reviewed original articles |

| 2 | Articles proposing an acoustical method for mechanical failure detection |

| 3 | Articles that utilize acoustical method for failure detection |

| 4 | Recency of articles in case of multiple repeated studies |

| Exclusion Criteria | |

| 1 | Articles that are not written in English |

| 2 | Studies with unvalidated techniques and algorithms |

| 3 | Articles that utilize acoustical approach for other purposes |

| 4 | Articles that do not utilize acoustical methods |

| 5 | Articles that do not clearly mention acoustic/sound/noise approaches in the title |

| 6 | Articles providing unclear results or findings |

| 7 | Duplicated studies |

| Data Item | Description |

|---|---|

| Title | Article title |

| Year | Year of publication |

| Author(s) | The article author(s) |

| Publication type | Journal, proceeding, etc. |

| Publication medium | The medium via which the article is published |

| Country | Researchers’ affiliation country |

| Contribution | The major contribution of the article |

| Summary | Summary of the article from our perspective |

| No | Authors | Year | Publication Type | Case |

|---|---|---|---|---|

| 1 | Al-Obaidi et al. [28] | 2017 | Journal | Valve |

| 2 | Altaf et al. [29] | 2019 | Journal | Rotating machine |

| 3 | Cruz et al. [30] | 2020 | Journal | Gas pipeline |

| 4 | Daraz et al. [31] | 2018 | Conference | Centrifugal Pump |

| 5 | Delgado-Prieto and Zurita Millan [32] | 2017 | Journal | Gear |

| 6 | Eftekharnejad and Mba [33] | 2009 | Journal | Gear |

| 7 | Fezari et al. [34] | 2014 | Conference | Rotating machine |

| 8 | Firmino et al. [35] | 2021 | Journal | ICE |

| 9 | Gao et al. [36] | 2019 | Journal | Grinder |

| 10 | Gil et al. [37] | 2019 | Conference | Bearing |

| 11 | Glowacz and Glowacz [38] | 2017 | Journal | Induction Motor |

| 12 | Glowacz et al. [39] | 2021 | Journal | Grinder |

| 13 | Griffin et al. [40] | 2021 | Journal | Metal Stamping |

| 14 | Gu et al. [41] | 2011 | Journal | Gearbox |

| 15 | Heydarzadeh et al. [42] | 2017 | Conference | Gearbox |

| 16 | Ibarra et al. [43] | 2019 | Journal | Bearing |

| 17 | Jian et al. [44] | 2013 | Journal | Bearing |

| 18 | Jo et al. [45] | 2020 | Journal | Turbine blade |

| 19 | Karabacak and Ozmen [46] | 2021 | Journal | Gear |

| 20 | Kothuru et al. [47] | 2018 | Journal | End Milling |

| 21 | Liu et al. [48] | 2020 | Journal | Gearbox |

| 22 | Liu et al. [49] | 2020 | Journal | Belt conveyor |

| 23 | Liu et al. [50] | 2021 | Journal | Turbine blade |

| 24 | Lu et al. [51] | 2021 | Journal | Gearbox |

| 25 | Mad Juhani and Ibrahim [52] | 2016 | Conference | Control valve |

| 26 | Medina et al. [53] | 2019 | Conference | Gear |

| 27 | Merizio et al. [54] | 2021 | Journal | Pipe |

| 28 | Motahari Nezad and Jafari [55] | 2020 | Journal | Bearing |

| 29 | Nirwan and Ramani [56] | 2021 | Journal | Bearing |

| 30 | Oh et al. [57] | 2019 | Conference | Gear Reducer |

| 31 | Omoregbee and Heyns [58] | 2019 | Journal | Bearing |

| 32 | Ono et al. [59] | 2013 | Conference | Motor |

| 33 | Orman et al. [60] | 2015 | Conference | Bearing |

| 34 | Pandya et al. [61] | 2013 | Journal | Bearing |

| 35 | Pan et al. [62] | 2019 | Journal | Motor |

| 36 | Park et al. [63] | 2017 | Journal | Insulator |

| 37 | Qiao et al. [64] | 2020 | Journal | Bearing |

| 38 | Qu et al. [65] | 2013 | Conference | Gearbox |

| 39 | Ramteke et al. [66] | 2019 | Journal | Diesel engine |

| 40 | Rzeszucinski et al. [67] | 2015 | Conference | Bearing |

| 41 | Seemuang et al. [68] | 2018 | Conference | Shaft |

| 42 | Shang et al. [69] | 2017 | Conference | Switchgear |

| 43 | Shukri et al. [70] | 2011 | Conference | Control valve |

| 44 | Sun et al. [71] | 2020 | Journal | Mill |

| 45 | Taha and Widiyati [72] | 2010 | Journal | Bearing |

| 46 | Tang et al. [73] | 2021 | Journal | Bearing |

| 47 | Toutountzakis et al. [74] | 2005 | Journal | Gear |

| 48 | Volkovas and Dulevicius [75] | 2006 | Journal | Turbine pump |

| 49 | Wu and Meng [76] | 2006 | Journal | Rotor |

| 50 | Yao et al. [77] | 2021 | Journal | Gear |

| 51 | Yun et al. [78] | 2021 | Journal | Robot arm |

| 52 | Zhang et al. [79] | 2019 | Journal | Bearing |

| Medium of Publication | Reference |

|---|---|

| 1st International Conference on Electrical Materials and Power Equipment | [69] |

| 2nd International Conference on Engineering Innovation | [68] |

| 3rd International Conference on Computer Research and Development | [70] |

| 4th International Conference on Intelligent and Automation Systems | [52] |

| 10th IEEE International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives | [67] |

| 10th International Conference on Information and Communication Technology Convergence | [57] |

| 16th International Power Electronics and Motion Control Conference and Exposition | [34] |

| 24th International Conference on Automation & Computing | [31] |

| 42nd IEEE International Conference on Acoustics, Speech and Signal Processing | [42] |

| 2013 IEEE International Conference on Prognostics and Health Management | [65] |

| 2nd International Conference on Condition Assessment Techniques in Electrical Systems | [60] |

| 2019 Signal Processing Algorithms, Architectures, Arrangements, and Applications | [37] |

| 2019 Prognostics and System Health Management Conference | [53] |

| Acoustics, Speech, and Signal Processing | [59] |

| Acoustic Australia | [29] |

| Advance Powder Technology | [49] |

| Alexandria Engineering Journal | [28] |

| Applied Acoustic | [33,38,39,73] |

| Chinese Journal of Mechanical Engineering | [36,51] |

| Clean Technologies and Environmental Policy | [30] |

| Expert Systems with Application | [61] |

| IEEE Access | [64] |

| IEEE Sensors Journal | [48] |

| IEEE Transactions on Industrial Electronics | [32,63] |

| IEEE Transactions on Industry Applications | [50] |

| IEEE Transactions on Instrumentation and Measurement | [77] |

| International Journal of Advanced Manufacturing Technology | [76] |

| International Journal of Precision Engineering and Manufacturing | [44] |

| Journal of Intelligent Manufacturing | [78] |

| Journal of Mechanical Science and Technology | [41,45,62,79] |

| Journal of the Brazilian Society of Mechanical Sciences and Engineering | [35] |

| Journal of The Institution of Engineers (India): Series C | [54] |

| Journal of Vibration Engineering & Technologies | [58,66] |

| Material Today: Proceedings | [56] |

| Measurement | [46,55] |

| NDT & E International | [74] |

| Russian Journal of Nondestructive Testing | [75] |

| The International Journal of Advanced Manufacturing Technology | [40,43,47,71,72] |

| Failure | Location | Accuracy | Reference |

|---|---|---|---|

| Burn | Grinder | ≤100% | [36] |

| Breakage | Milling Machine | 91.18% | [71] |

| Corrosion | Valve | 98% | [28] |

| Crack | Bearing | 80–100% | [72] |

| - | [44] | ||

| Gear | 97% | [57] | |

| - | [48] | ||

| Propeller | - | [75] | |

| Shaft | - | [68] | |

| Fracture | Gear | ≥90% | [77] |

| 72% | [32] | ||

| Leakage | Pipeline | 99.6% | [30] |

| Control Valve | - | [52] | |

| Misfire | Combustion Engine | 98.7–99.3% | [35] |

| Pitting | Gear | 97.0–99.9% | [53] |

| Rubbing | Motor | 80% | [62] |

| Wear | Bearing | 56.3–100% | [55] |

| - | [43] | ||

| Gear | 48.4–99.9% | [46] | |

| - | [51,65] | ||

| Metal Stamping | 96% | [40] | |

| Other | 97% | [47] | |

| Seeded | Bearing | 96.67% | [61] |

| - | [60] | ||

| Gear | - | [33,74] | |

| Spall | Bearing | - | [67] |

| Another Failure | Bearing | 89.33–100% | [39] |

| 87.2–99.48% | [64] | ||

| - | [29,37,50,56,58,73,76,79] | ||

| Pipe | 100% | [54] | |

| Turbine Blade | - | [45] | |

| Insulator | 96.7–100% | [63] | |

| Belt Conveyor | 94.53% | [49] | |

| Diesel Engine | - | [66] | |

| Centrifugal Pump | - | [31] | |

| Control Valve | - | [70] | |

| Motor | 82–100% | [59] | |

| - | [38] | ||

| Robot Arm | 85% | [78] | |

| Rotataing Machine | 91.5–94.5% | [34] | |

| Gear | 97% | [42] | |

| - | [41] | ||

| Switchgear | - | [69] |

| Detection Method | Analysis | Reference |

|---|---|---|

| Acoustic Emission | Adaptive Neuro-Fuzzy Inference System | [55] |

| Akaike Information Criterion | [73] | |

| Cepstrum | [43,44] | |

| Chromatic monitoring | [32] | |

| Envelope | [41] | |

| Frequency | [52] | |

| Machine Learning | [28,34,40,42,53,58,61,71,72] | |

| Root Mean Square | [33,56,68,74] | |

| Sparse Augmented Lagrangian | [50] | |

| Statistic | [62,66,70,75] | |

| Time Synchronous Average | [65] | |

| Variational Mode Decomposition | [48] | |

| Wavelet | [36] | |

| Microphone | Envelope | [31] |

| Modulation Signal Bispectrum | [51] | |

| Machine Learning | [29,30,35,37,38,46,47,49,54,57,63,64,77,78] | |

| Reverse Spectrum | [69] | |

| Shortened Method of Frequency Selection Nearest Frequency Components | [39] | |

| Special Kurtosis | [60,67] | |

| Statistic | [59] | |

| Stochastic Resonance | [79] | |

| Time-frequency | [76] | |

| Ultrasonic | Quantitative | [45] |

| Intelligent | Clasical |

|---|---|

| Adaptive Neuro-Fuzzy Inference System | High-Order Statistics |

| Support Vector Machine (SVM) | Akaike Information Criterion |

| Decision Tree | Mel-Frequency Cepstral Coefficients |

| Classification and Regression Tree | Sparse Augmented Lagrangian |

| Genetic Algorithm | Variational Mode Decomposition |

| k-Nearest Neighbors (KNN) | Cepstrum Pre-Whitening |

| Kernel Liner Discriminant Analysis | Special Kurtosis |

| Negative Selection Algorithm | Envelope Analysis |

| Recursive Denoising Learning | Time-Frequency Analysis |

| Random Forest (RF) | Modulation Signal Bispectrum |

| Neural Network | |

| Sparse Discriminant Analysis |

| Author | Failure Location | Algorithm | Dataset | Environment |

|---|---|---|---|---|

| Al-Obaidi et al. [28] | Valve | SVM | 142,035 samples of AE signal statistical parameters | Laboratory |

| Altaf et al. [29] | Rotating Machine | SVM, kernel liner discriminant analysis, KNN, sparse discriminant analysis | Audible sound frequency ranges from 20 Hz to 20 KHz | Laboratory |

| Cruz et al. [30] | Gas Pipeline | Logistic regression, KNN, SVM with linear kernel, SVM with radial basis kernel, random forest, adaptive boosting, extreme gradient boosting | 1680 samples (120 samples for each of the 14 experiments) and for regression of 840 samples (120 samples for each of the leakage experiments) in 7 orifices | Laboratory |

| Fezari et al. [34] | Rotating Machine | K-Nearest Neighbors | 10 recordings of 5 s duration with frequency sampling 10,000 Hz | Laboratory |

| Firmino et al. [35] | Internal Combustion Engine | Artificial neural network | Frequencies, amplitudes, and energy data gathered using acoustic acquisition system | Laboratory |

| Griffin et al. [40] | Metal Stamping | Classification and regression tree | A reduced short-time Fourier transform of top 10 absolute maximum component AE feature sets that correlates to wear measurement data | Laboratory |

| Heydarzadeh et al. [42] | Gearbox | SVM | Recording of gearbox acoustic emissions using an open field microphone at the rate of 5 KHz for 5 load conditions and four classes corresponding to fault-free, pinion, wheel, and simultaneous faults | Laboratory |

| Karabacak and Ozmeri [46] | Gear | Artificial neural network | Artificially produced acoustic signal samples on machines that have failures caused by wear, pitting, and breakage | Laboratory |

| Kothuru et al. [47] | End Milling | SVM | Audio signal related to wear level | Laboratory |

| Liu et al. [49] | Belt Conveyor | Decision tree | 42 sets of acoustic data acquired from experiments with a belt velocity of 1 m/s, which is equivalent to 2.9 rpm for the idler rolls | Laboratory |

| Medina et al. [53] | Gear | Long short-term memory | Acoustic emission signal datasets | Laboratory |

| Merizio et al. [54] | Pipe | Negative selection algorithm | Collection of sound pressure data in positions inside the tube using ISO10534-1(1996) standard | Laboratory |

| Motahari Nezad and Jafari [55] | Bearing | Adaptive neuro-fuzzy inference system | Acoustic emission signals | Laboratory |

| Oh et al. [57] | Gear Reducer | SVM | A balanced data set of 300 acoustic signals to accommodate four cases of 60 signals and 60 signals each in normal operation | Laboratory |

| Omoregbee and Heyns [58] | Bearing | SVM, and genetic algorithm | A GA-based feature extractor from a raw acoustic emission dataset | Laboratory |

| Pandya et al. [61] | Bearing | Asymmetric proximity function KNN | 180 data samples of the five bearing conditions | Laboratory |

| Park et al. [63] | Insulator | Neural network | Samples of noise measurement results on insulators | Laboratory |

| Qiao et al. [64] | Bearing | CNN, long short-term memory | Data of 10 different fault levels, including inner race, outer race, ball, and normal. Each fault type collects 800 samples, and 1200 signal points make a group of samples | Noisy |

| Sun et al. [71] | Mill | SVM | Acoustic signal samples from the engine during operation for normal and abnormal conditions | Laboratory |

| Taha and Widiyati [72] | Bearing | Artificial neural network | Acoustic signal samples from five bearing defect conditions | Laboratory |

| Yao et al. [77] | Gear | Recursive denoising learning | The collection of clean acoustic signal and noise-disturbed acoustic signal | Laboratory |

| Yun et al. [78] | Robot Arm | Neural network | A collection of acoustic signal samples measured at each joint | Laboratory |

| Challenges | Explanation |

|---|---|

| Environmental noise | The type of noise is very influential on the measurement results. Noise dominated by impulse signals will certainly make failure analysis difficult because the spectrum of the signal will be present and affect all observed frequencies. |

| Fragility | Failure is very likely to occur in components that are already fragile. Failures such as defects or leaks can be detected, but because there is a tendency to change the size of the defect level in a short time, the measurement results will vary. |

| Multivariate failures | Failures that occur in a machine can come from several points and occur at the same time. In addition, the type of failure that occurs can also be a mixture of defects, cracks, leaks, wear, and others. Each failure will affect the measurement signal received and will affect the failure analysis method used. |

| Concurrent failure | Failure may occur on more than one machine running at the same time. The sensor will be very easily affected by interference signals from equipment around the measuring object that also fails, especially for microphone-based measurements. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qurthobi, A.; Maskeliūnas, R.; Damaševičius, R. Detection of Mechanical Failures in Industrial Machines Using Overlapping Acoustic Anomalies: A Systematic Literature Review. Sensors 2022, 22, 3888. https://doi.org/10.3390/s22103888

Qurthobi A, Maskeliūnas R, Damaševičius R. Detection of Mechanical Failures in Industrial Machines Using Overlapping Acoustic Anomalies: A Systematic Literature Review. Sensors. 2022; 22(10):3888. https://doi.org/10.3390/s22103888

Chicago/Turabian StyleQurthobi, Ahmad, Rytis Maskeliūnas, and Robertas Damaševičius. 2022. "Detection of Mechanical Failures in Industrial Machines Using Overlapping Acoustic Anomalies: A Systematic Literature Review" Sensors 22, no. 10: 3888. https://doi.org/10.3390/s22103888

APA StyleQurthobi, A., Maskeliūnas, R., & Damaševičius, R. (2022). Detection of Mechanical Failures in Industrial Machines Using Overlapping Acoustic Anomalies: A Systematic Literature Review. Sensors, 22(10), 3888. https://doi.org/10.3390/s22103888