Artificial Neurons on Flexible Substrates: A Fully Printed Approach for Neuromorphic Sensing

Abstract

:1. Introduction

1.1. Printed Electronics in Neuromorphic Sensing

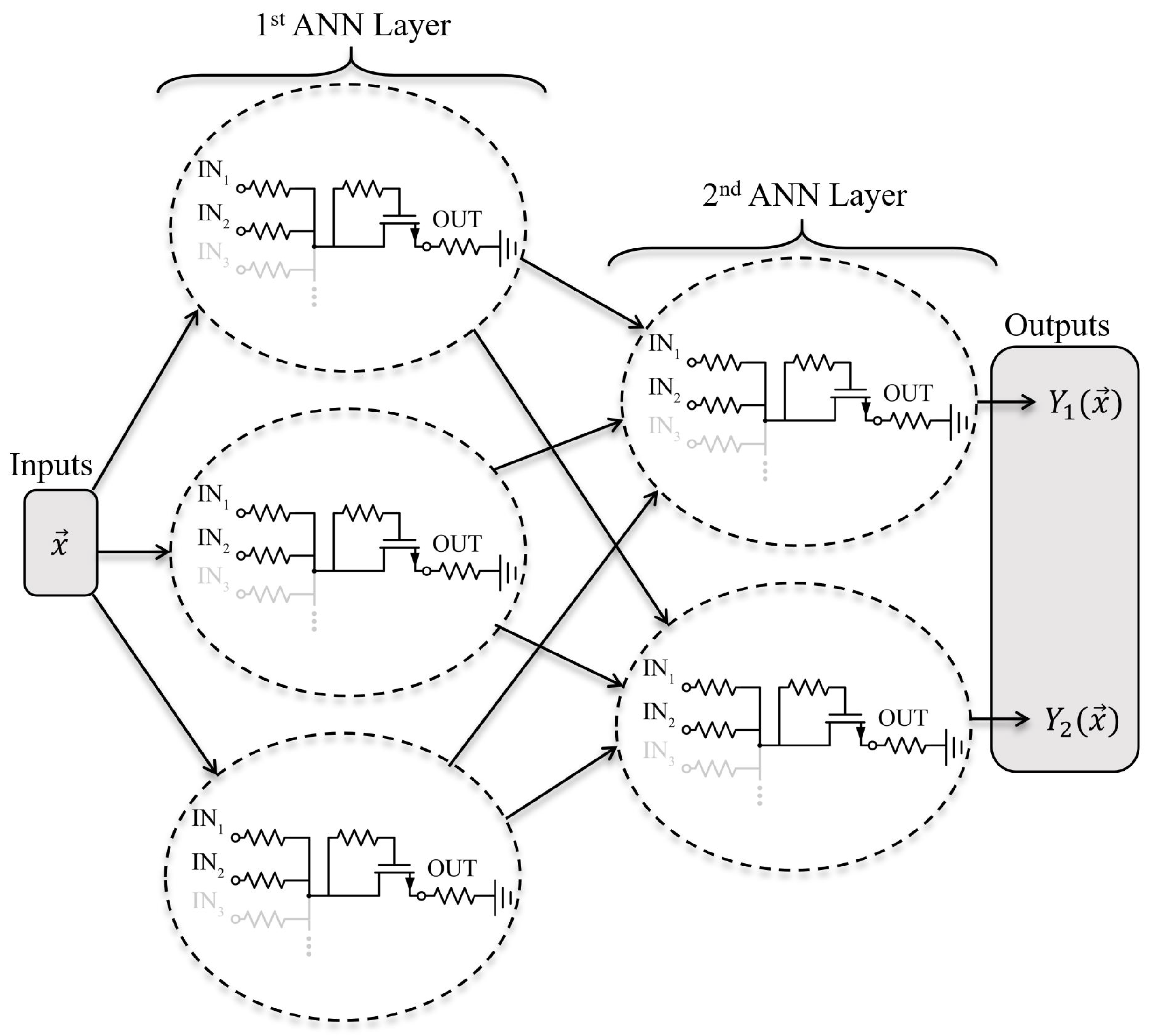

1.2. Device Architecture of Fully Printed Two-Input Neuron

1.3. Proposed Two-Input Neuron

2. Materials and Methods

2.1. Ink Preparation and Characterization

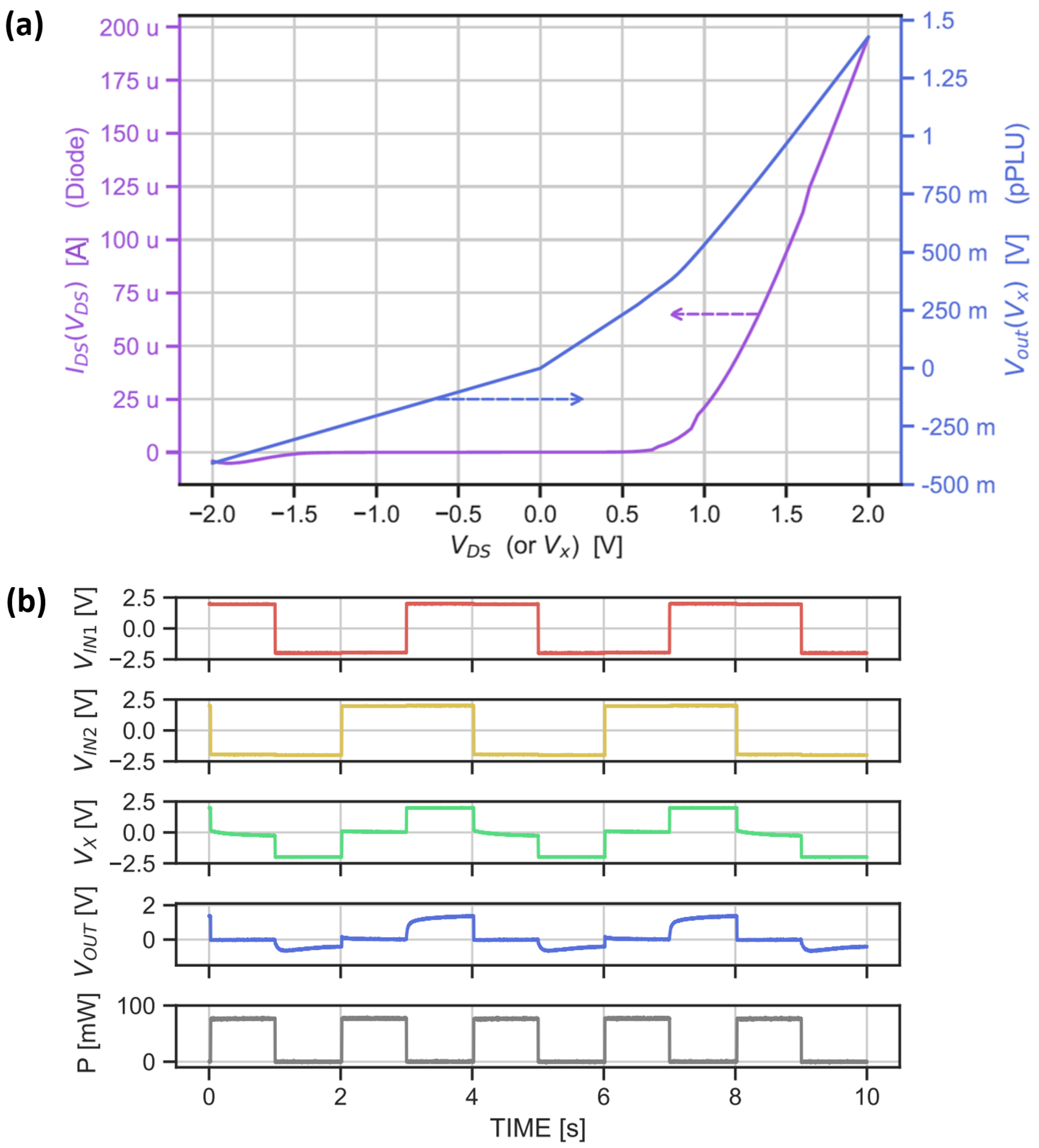

2.2. Electrical Analysis of Printed Two-Input Neuron

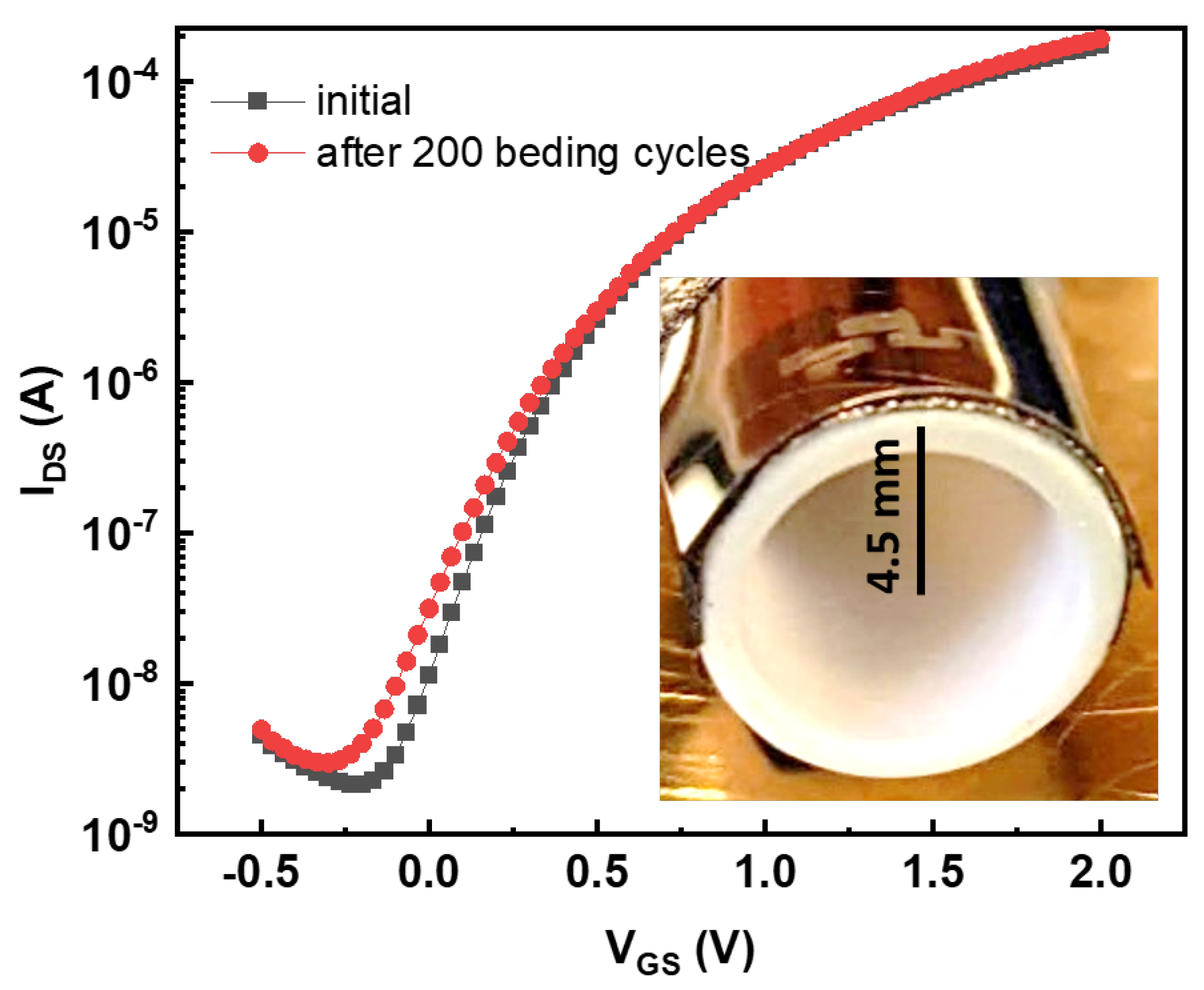

2.3. Bending Tests

3. Results

3.1. Fabrication of EGT on Polyimide

3.2. Printed Flexible 2-Input Neural Network

4. Discussion

4.1. Measurement Results

4.2. Outlook

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ANN | Artificial neural networks |

| CSPE | Composite solid polymer electrolyte |

| DMSO | Dimethyl sulfoxide |

| EGT | Electrolyte gated transistor |

| IoT | Internet of Things |

| NCS | Neuromorphic computing systems |

| PE | Printed electronics |

| PI | Polyimide |

| pPLU | Printed piecewise linear unit |

References

- Kim, Y.J.; Chun, S.E.; Whitacre, J.; Bettinger, C.J. Self-deployable current sources fabricated from edible materials. J. Mater. Chem. B 2013, 1, 3781–3788. [Google Scholar] [CrossRef] [PubMed]

- Maly, W. Cost of silicon viewed from VLSI design perspective. In Proceedings of the 31st Annual Design Automation Conference, San Diego, CA, USA, 6–10 June 1994; pp. 135–142. [Google Scholar]

- Subramanian, V.; Chang, J.B.; de la Fuente Vornbrock, A.; Huang, D.C.; Jagannathan, L.; Liao, F.; Mattis, B.; Molesa, S.; Redinger, D.R.; Soltman, D.; et al. Printed electronics for low-cost electronic systems: Technology status and application development. In Proceedings of the 2008-34th ESSCIRC, Edinburgh, UK, 15–19 September 2008; pp. 17–24. [Google Scholar]

- Lee, Y.; Oh, J.Y.; Xu, W.; Kim, O.; Kim, T.R.; Kang, J.; Kim, Y.; Son, D.; Tok, J.B.H.; Park, M.J.; et al. Stretchable organic optoelectronic sensorimotor synapse. Sci. Adv. 2018, 4, eaat7387. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, Y.; Chortos, A.; Xu, W.; Liu, Y.; Oh, J.Y.; Son, D.; Kang, J.; Foudeh, A.M.; Zhu, C.; Lee, Y.; et al. A bioinspired flexible organic artificial afferent nerve. Science 2018, 360, 998–1003. [Google Scholar] [CrossRef] [Green Version]

- Chortos, A.; Liu, J.; Bao, Z. Pursuing prosthetic electronic skin. Nat. Mater. 2016, 15, 937–950. [Google Scholar] [CrossRef]

- dos Santos, A.; Pinela, N.; Alves, P.; Santos, R.; Farinha, R.; Fortunato, E.; Martins, R.; Águas, H.; Igreja, R. E-Skin Bimodal Sensors for Robotics and Prosthesis Using PDMS Molds Engraved by Laser. Sensors 2019, 19, 899. [Google Scholar] [CrossRef] [Green Version]

- dos Santos, A.; Fortunato, E.; Martins, R.; Águas, H.; Igreja, R. Transduction Mechanisms, Micro-Structuring Techniques, and Applications of Electronic Skin Pressure Sensors: A Review of Recent Advances. Sensors 2020, 20, 4407. [Google Scholar] [CrossRef]

- Kim, J.; Jeerapan, I.; Imani, S.; Cho, T.N.; Bandodkar, A.; Cinti, S.; Mercier, P.P.; Wang, J. Noninvasive alcohol monitoring using a wearable tattoo-based iontophoretic-biosensing system. ACS Sens. 2016, 1, 1011–1019. [Google Scholar] [CrossRef]

- Research and Markets. Global FMCG Market Opportunity Analysis, 2018–2019 & 2025—A Billion New Consumers in Emerging Markets; Research and Markets: Dublin, Ireland, 2019. [Google Scholar]

- Shao, B. Fully Printed Chipless RFID Tags Towards Item-Level Tracking Applications. Ph.D. Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2014. [Google Scholar]

- Khan, Y.; Thielens, A.; Muin, S.; Ting, J.; Baumbauer, C.; Arias, A.C. A new frontier of printed electronics: Flexible hybrid electronics. Adv. Mater. 2020, 32, 1905279. [Google Scholar] [CrossRef]

- Scholz, A.; Gerig, D.; Zimmermann, L.; Seiberlich, M.; Strobel, N.; Hernandez-Sosa, G.; Aghassi-Hagmann, J. A Hybrid Optoelectronic Sensor Platform with an Integrated Solution-Processed Organic Photodiode. Adv. Mater. Technol. 2020, 6, 2000172. [Google Scholar] [CrossRef]

- Tang, Z.; Jia, S.; Zhou, C.; Li, B. 3D Printing of Highly Sensitive and Large-Measurement-Range Flexible Pressure Sensors with a Positive Piezoresistive Effect. ACS Appl. Mater. Interfaces 2020, 12, 28669–28680. [Google Scholar] [CrossRef]

- Cui, Z. Printed Electronics: Materials, Technologies and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Zhao, J.; Gao, Y.; Gu, W.; Wang, C.; Lin, J.; Chen, Z.; Cui, Z. Fabrication and electrical properties of all-printed carbon nanotube thin film transistors on flexible substrates. J. Mater. Chem. 2012, 22, 20747–20753. [Google Scholar] [CrossRef]

- Chen, P.Y.; Chen, C.L.; Chen, C.C.; Tsai, L.; Ting, H.C.; Lin, L.F.; Chen, C.C.; Chen, C.Y.; Chang, L.H.; Shih, T.H.; et al. 30.1: Invited Paper: 65-Inch Inkjet Printed Organic Light-Emitting Display Panel with High Degree of Pixel Uniformity. In Proceedings of the SID Symposium Digest of Technical Papers, San Diego, CA, USA, 7 July 2014; Wiley Online Library: Hoboken, NJ, USA, 2014; Volume 45, pp. 396–398. [Google Scholar]

- Mohammed, M.G.; Kramer, R. All-Printed Flexible and Stretchable Electronics. Adv. Mater. 2017, 29, 1604965. [Google Scholar] [CrossRef] [PubMed]

- Cadilha Marques, G.; Weller, D.; Erozan, A.T.; Feng, X.; Tahoori, M.; Aghassi-Hagmann, J. Progress Report on “From Printed Electrolyte-Gated Metal-Oxide Devices to Circuits”. Adv. Mater. 2019, 31, 1806483. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ling, H.; Koutsouras, D.A.; Kazemzadeh, S.; van de Burgt, Y.; Yan, F.; Gkoupidenis, P. Electrolyte-gated transistors for synaptic electronics, neuromorphic computing, and adaptable biointerfacing. Appl. Phys. Rev. 2020, 7, 011307. [Google Scholar] [CrossRef]

- Yang, C.Y.; Stoeckel, M.A.; Ruoko, T.P.; Wu, H.Y.; Liu, X.; Kolhe, N.B.; Wu, Z.; Puttisong, Y.; Musumeci, C.; Massetti, M.; et al. A high-conductivity n-type polymeric ink for printed electronics. Nat. Commun. 2021, 12, 2354. [Google Scholar] [CrossRef]

- Mubarik, M.; Weller, D.; Bleier, N.; Tomei, M.; Aghassi-Hagmann, J.; Tahoori, M.; Kumar, R. Printed Machine Learning Classifiers. In Proceedings of the 53rd Annual IEEE/ACM International Symposium on Microarchitecture, Athens, Greece, 17–21 October 2020. [Google Scholar]

- Benda, J. Neural adaptation. Curr. Biol. 2021, 31, R110–R116. [Google Scholar] [CrossRef]

- Nawrocki, R.A.; Voyles, R.M.; Shaheen, S.E. Neurons in polymer: Hardware neural units based on polymer memristive devices and polymer transistors. IEEE Trans. Electron Devices 2014, 61, 3513–3519. [Google Scholar] [CrossRef]

- van De Burgt, Y.; Melianas, A.; Keene, S.T.; Malliaras, G.; Salleo, A. Organic electronics for neuromorphic computing. Nat. Electron. 2018, 1, 386–397. [Google Scholar] [CrossRef]

- Liu, B.; Li, H.; Chen, Y.; Li, X.; Wu, Q.; Huang, T. Vortex: Variation-aware training for memristor x-bar. In Proceedings of the 52nd Annual Design Automation Conference, San Francisco, CA, USA, 7–11 June 2015; p. 15. [Google Scholar]

- Leung, C.S.; Wan, W.Y.; Feng, R. A regularizer approach for RBF networks under the concurrent weight failure situation. IEEE Trans. Neural Netw. Learn. Syst. 2016, 28, 1360–1372. [Google Scholar] [CrossRef]

- Schuman, C.D.; Potok, T.E.; Patton, R.M.; Birdwell, J.D.; Dean, M.E.; Rose, G.S.; Plank, J.S. A survey of neuromorphic computing and neural networks in hardware. arXiv 2017, arXiv:1705.06963. [Google Scholar]

- Bishop, C.M. Pattern Recognition and Machine Learning; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- van de Burgt, Y.; Lubberman, E.; Fuller, E.J.; Keene, S.T.; Faria, G.C.; Agarwal, S.; Marinella, M.J.; Talin, A.A.; Salleo, A. A non-volatile organic electrochemical device as a low-voltage artificial synapse for neuromorphic computing. Nat. Mater. 2017, 16, 414–418. [Google Scholar] [CrossRef]

- Douthwaite, M.; García-Redondo, F.; Georgiou, P.; Das, S. A Time-Domain Current-Mode MAC Engine for Analogue Neural Networks in Flexible Electronics. In Proceedings of the 2019 IEEE Biomedical Circuits and Systems Conference (BioCAS), Nara, Japan, 17–19 October 2019; pp. 1–4. [Google Scholar]

- Gkoupidenis, P.; Schaefer, N.; Garlan, B.; Malliaras, G.G. Neuromorphic functions in PEDOT: PSS organic electrochemical transistors. Adv. Mater. 2015, 27, 7176–7180. [Google Scholar] [CrossRef] [PubMed]

- Weller, D.D.; Hefenbrock, M.; Tahoori, M.B.; Aghassi-Hagmann, J.; Beigl, M. Programmable Neuromorphic Circuit based on Printed Electrolyte-Gated Transistors. In Proceedings of the Asia South Pacific Design Automation Conference (ASP-DAC), Beijing, China, 13–16 January 2020. [Google Scholar]

- Weller, D.D.; Hefenbrock, M.; Beigl, M.; Aghassi-Hagmann, J.; Tahoori, M.B. Realization and training of an inverter-based printed neuromorphic computing system. Sci. Rep. 2021, 11, 9554. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Liu, Y.; Li, J.; Lau, C.; Wu, F.; Zhang, A.; Li, Z.; Chen, M.; Fu, H.; Draper, J.; et al. Fully Printed All-Solid-State Organic Flexible Artificial Synapse for Neuromorphic Computing. ACS Appl. Mater. Interfaces 2019, 11, 16749–16757. [Google Scholar] [CrossRef]

- Feng, P.; Xu, W.; Yang, Y.; Wan, X.; Shi, Y.; Wan, Q.; Zhao, J.; Cui, Z. Printed Neuromorphic Devices Based on Printed Carbon Nanotube Thin-Film Transistors. Adv. Funct. Mater. 2017, 27, 1604447. [Google Scholar] [CrossRef]

- Ansari, M.; Fayyazi, A.; Banagozar, A.; Maleki, M.A.; Kamal, M.; Afzali-Kusha, A.; Pedram, M. PHAX: Physical Characteristics AwareEx-SituTraining Framework for Inverter-Based Memristive Neuromorphic Circuits. IEEE Trans. Comput.-Aided Des. Integr. Circuits Syst. 2017, 37, 1602–1613. [Google Scholar] [CrossRef]

- BanaGozar, A.; Maleki, M.A.; Kamal, M.; Afzali-Kusha, A.; Pedram, M. Robust neuromorphic computing in the presence of process variation. In Proceedings of the Design, Automation & Test in Europe Conference & Exhibition (DATE), Lausanne, Switzerland, 27–31 March 2017; pp. 440–445. [Google Scholar]

- Singaraju, S.A.; Marques, G.C.; Gruber, P.; Kruk, R.; Hahn, H.; Breitung, B.; Aghassi-Hagmann, J. Fully Printed Inverters using Metal-Oxide Semiconductor and Graphene Passives on Flexible Substrates. Phys. Status Solidi (RRL) Rapid Res. Lett. 2020, 14, 2000252. [Google Scholar] [CrossRef]

- Singaraju, S.A.; Baby, T.T.; Neuper, F.; Kruk, R.; Hagmann, J.A.; Hahn, H.; Breitung, B. Development of Fully Printed Electrolyte-Gated Oxide Transistors Using Graphene Passive Structures. ACS Appl. Electron. Mater. 2019, 1, 1538–1544. [Google Scholar] [CrossRef]

- Kim, S.H.; Hong, K.; Xie, W.; Lee, K.H.; Zhang, S.; Lodge, T.P.; Frisbie, C.D. Electrolyte-Gated Transistors for Organic and Printed Electronics. Adv. Mater. 2012, 25, 1822–1846. [Google Scholar] [CrossRef]

- DupontResearch. Kapton HN Polyimide Film Specifications; DupontResearch: Wilmington, DE, USA, 2019. [Google Scholar]

- Garlapati, S.K.; Mishra, N.; Dehm, S.; Hahn, R.; Kruk, R.; Hahn, H.; Dasgupta, S. Electrolyte-Gated, High Mobility Inorganic Oxide Transistors from Printed Metal Halides. ACS Appl. Mater. Interfaces 2013, 5, 11498–11502. [Google Scholar] [CrossRef]

- Hwang, Y.H.; Seo, J.S.; Yun, J.M.; Park, H.; Yang, S.; Park, S.H.K.; Bae, B.S. An ‘aqueous route’ for the fabrication of low-temperature-processable oxide flexible transparent thin-film transistors on plastic substrates. NPG Asia Mater. 2013, 5, e45. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.H.; Kim, Y.H.; Ahn, S.J.; Ha, T.H.; Kim, H.S. Grain-size effect on the electrical properties of nanocrystalline indium tin oxide thin films. Mater. Sci. Eng. B 2015, 199, 37–41. [Google Scholar] [CrossRef]

- Ahmed, N.M.; Sabah, F.A.; Abdulgafour, H.; Alsadig, A.; Sulieman, A.; Alkhoaryef, M. The effect of post annealing temperature on grain size of indium-tin-oxide for optical and electrical properties improvement. Results Phys. 2019, 13, 102159. [Google Scholar] [CrossRef]

- Abd, J.A.; Mohammed, W.M. Indium oxide: Synthesis and characterization for future industrial applications. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2019. [Google Scholar] [CrossRef]

- Mypati, S.; Dhanushkodi, S.R.; McLaren, M.; Docoslis, A.; Peppley, B.A.; Barz, D.P.J. Optimized inkjet-printed silver nanoparticle films: Theoretical and experimental investigations. RSC Adv. 2018, 8, 19679–19689. [Google Scholar] [CrossRef] [Green Version]

- Tadesse, M.G.; Mengistie, D.A.; Chen, Y.; Wang, L.; Loghin, C.; Nierstrasz, V. Electrically conductive highly elastic polyamide/lycra fabric treated with PEDOT:PSS and polyurethane. J. Mater. Sci. 2019, 54, 9591–9602. [Google Scholar] [CrossRef] [Green Version]

- Hatamie, A.; Angizi, S.; Kumar, S.; Pandey, C.M.; Simchi, A.; Willander, M.; Malhotra, B.D. Review—Textile Based Chemical and Physical Sensors for Healthcare Monitoring. J. Electrochem. Soc. 2020, 167, 037546. [Google Scholar] [CrossRef]

- Rojas, J.P.; Sevilla, G.A.T.; Hussain, M.M. Can We Build a Truly High Performance Computer Which is Flexible and Transparent? Sci. Rep. 2013, 3, 2609. [Google Scholar] [CrossRef] [Green Version]

| 100 °C | 200 °C | 250 °C | 300 °C | |

|---|---|---|---|---|

| 1 layer | 6 G | 160 M | 12 k | 4000 |

| 2 layers | 5 G | 135 M | 8 k | 1250 |

| 3 layers | 5 G | 114 M | 7 k | 520 |

| 4 layers | 3 G | 96 M | 2 k | 360 |

| 5 layers | 1 G | 55 M | 1 k | 275 |

| R | R | R | R | T-Width | T-Length | Diode V |

|---|---|---|---|---|---|---|

| 250 Ω | 250 Ω | 300 Ω | 3.75 MΩ | 400 μm | 140 μm | 750 mV |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singaraju, S.A.; Weller, D.D.; Gspann, T.S.; Aghassi-Hagmann, J.; Tahoori, M.B. Artificial Neurons on Flexible Substrates: A Fully Printed Approach for Neuromorphic Sensing. Sensors 2022, 22, 4000. https://doi.org/10.3390/s22114000

Singaraju SA, Weller DD, Gspann TS, Aghassi-Hagmann J, Tahoori MB. Artificial Neurons on Flexible Substrates: A Fully Printed Approach for Neuromorphic Sensing. Sensors. 2022; 22(11):4000. https://doi.org/10.3390/s22114000

Chicago/Turabian StyleSingaraju, Surya A., Dennis D. Weller, Thurid S. Gspann, Jasmin Aghassi-Hagmann, and Mehdi B. Tahoori. 2022. "Artificial Neurons on Flexible Substrates: A Fully Printed Approach for Neuromorphic Sensing" Sensors 22, no. 11: 4000. https://doi.org/10.3390/s22114000

APA StyleSingaraju, S. A., Weller, D. D., Gspann, T. S., Aghassi-Hagmann, J., & Tahoori, M. B. (2022). Artificial Neurons on Flexible Substrates: A Fully Printed Approach for Neuromorphic Sensing. Sensors, 22(11), 4000. https://doi.org/10.3390/s22114000