Automatically Controlled Dust Generation System Using Arduino †

Abstract

:1. Introduction

1.1. Dust Generation Methods

1.2. Dust Sensing Technology

2. Materials and Methods

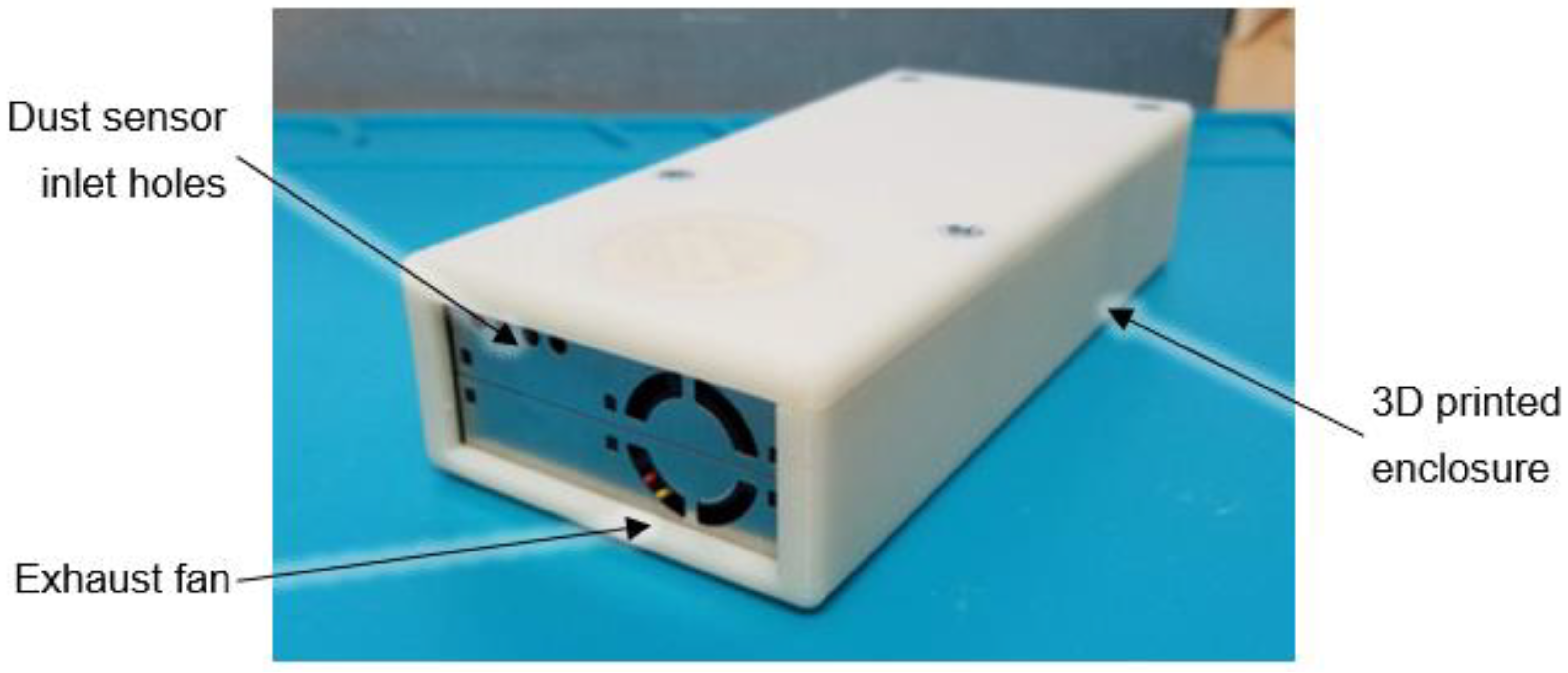

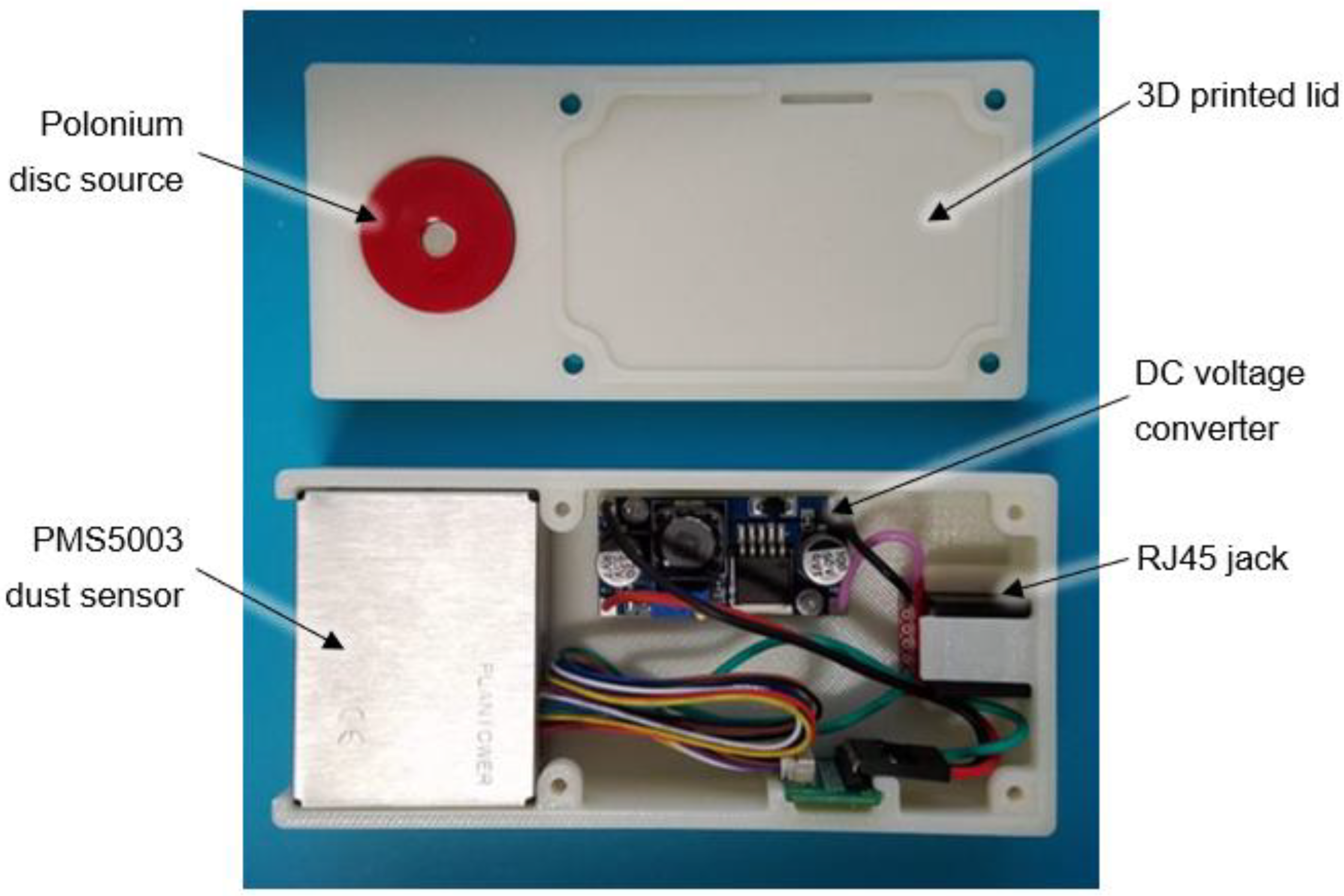

2.1. Air Quality Monitor and Datalogger

2.2. Dust Sensor

2.3. Conveyor Body

2.4. Dust Hopper

2.5. Vibratory Shaker, Hopper Extension, Blower

2.6. Dust Generator Conveyor Motor Operation

2.7. Preliminary Testing

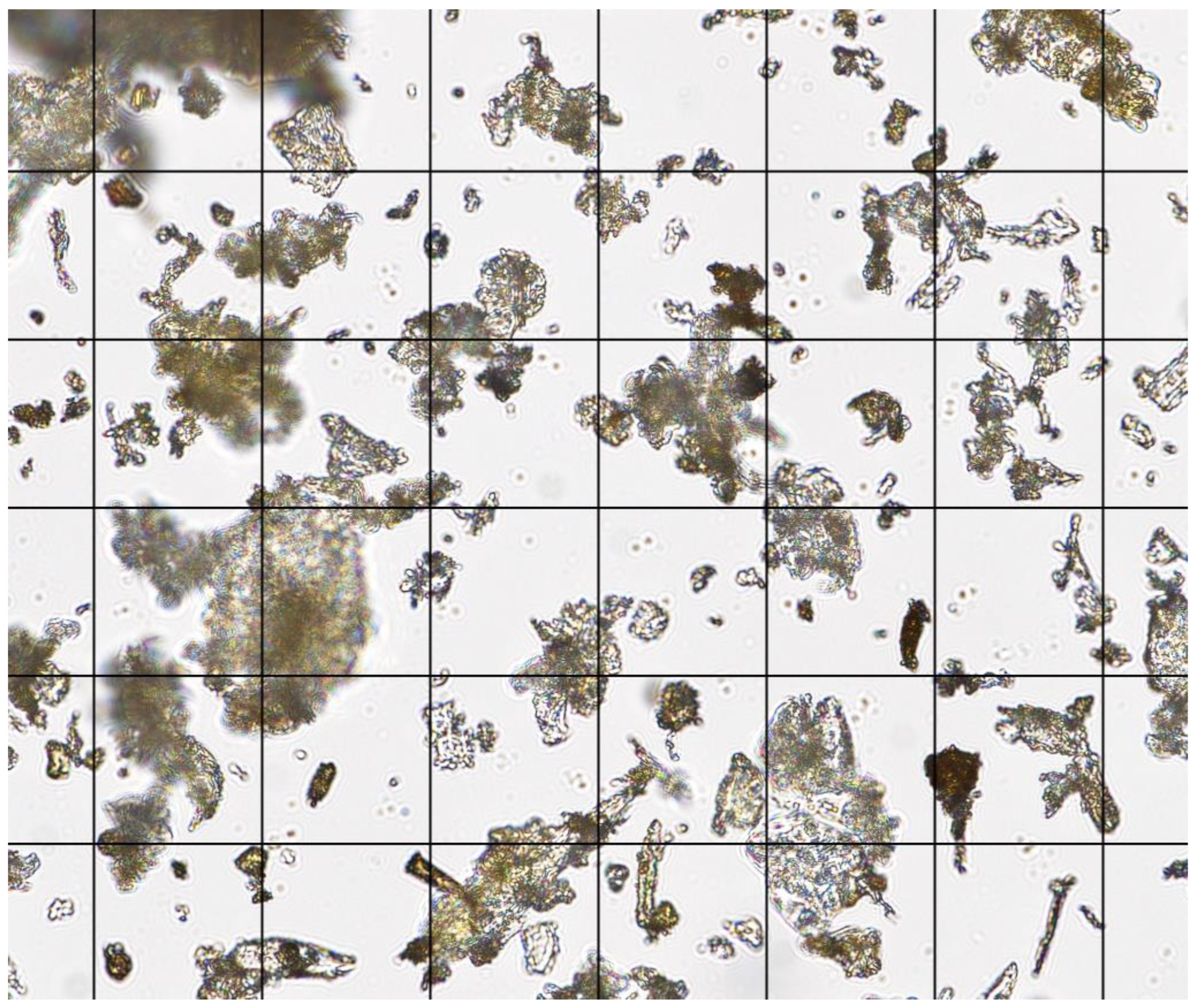

2.8. Dust Characteristics

2.9. Controlled Environment Chamber

2.10. Dust Generator Usage and Evaluation

3. Results

4. Discussion

4.1. Dust Generator Conveyor Motor Operation

4.2. Advantages of Automatic Control

4.3. Control of the Dust Generator Output

4.4. Generated Dust Levels in Test Chamber Compared with Control

4.5. Challenges

4.6. Operation in High Humidity Environments

4.7. Dust Feed from Hopper

4.8. Conveyor Quality

4.9. Dust Sensing Technology

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Quantity | Component |

|---|---|

| 1 | Ryobi BD4601G belt sander |

| 1 | 375H400 timing belt |

| 2 | 18-tooth 3D printed drive pulley half |

| 2 | 18-tooth 3D printed idler pulley half |

| 2 | RJ45 jack (1 for generator, 1 for dust sensor) |

| 2 | RJ45 breakout board |

| 1 | 12 VDC 1800 rpm vibratory shaker motor |

| 1 | 5 VDC relay |

| 1 | Delta model BFB1012VH-7P03 centrifugal fan |

| 1 | 9 VDC 1.5 A power adapter |

| 1 | 3.5 RPM 12 VDC gearmotor |

| 1 | 37 mm L-shaped motor mount for torque arm |

| 6 | 18–8 stainless steel flanged button head screw, M3 × 0.5 mm thread size, 6 mm long |

| 2 | Flanged Philips head screws for torque arm stops |

| 2 | ¼ in.–20 square nuts for torque arm stops |

| 1 | 12 mm to 6 mm stainless steel set screw shaft coupler |

| 1 | L293N motor controller |

| 1 | 3D printed motor controller housing |

| 4 | M3.5 × 6 mm thread forming screws |

| 2 | Female blade terminal plugs |

| 1 | 2-pin JST-XH male plug |

| 2 | JST-XH female crimp pins |

| 1 | 6-pin 2.54 mm pitch female connector housing |

| 1 | 1-pin 2.5 mm pitch female connector housing |

| 7 | Female crimp pins |

| 2 | Plywood sides for conveyor hopper |

| 2 | Polycarbonate sides for hopper |

| 2 | UHMW polyethylene film adhesive-backed, 1 in. wide strip, 0.005 in. thick, 12 in. length for side skirting |

| 1 | UHMW polyethylene film adhesive-backed, 1 in. wide strip, 0.005 in. thick, 4 in. length for side skirting |

| 1 box | Flanged Philips head screws |

| 1 tube | E6000 adhesive |

| 1 | Slippery white UHMW polyethylene sheet, 4 in. × 12 in. × 1/16 in. for slider bed liner |

| 4 | 1/8 in. diameter × 1/4 in. grip range medium steel pop rivets to attach liner to slider bed |

| 1 | Arduino MEGA 2560 R3 microcontroller |

| 1 | DS3231 real-time clock module |

| 1 | MicroSD card module |

| 1 | Plantower PMS5003 laser particle counter |

| 1 | 3D printed dust sensor housing and lid |

| 1 | Polonium-210 disc source |

| 1 | LM2596 DC-DC voltage converter module |

| multiple | 22-gauge silicone stranded wires |

| 1 box | M2 × 4 mm thread forming screws |

| 1 box | M3.5 × 6 mm thread forming screws |

References

- Guarino, M.; Caroli, A.; Navarotto, P. Dust Concentration and Mortality Distribution in an Enclosed Laying House. Trans. ASAE 1999, 42, 1127. [Google Scholar] [CrossRef]

- Willis, W.L.; Ouart, M.D.; Quarles, C.L. Effect of an Evaporative Cooling and Dust Control System on Rearing Environment and Performance of Male Broiler Chickens. Poult. Sci. 1987, 66, 1590–1593. [Google Scholar] [CrossRef] [PubMed]

- O’connor, J.; Mcquitty, J.B.; Clark, P. Air Quality and Contaminant Loads in Three Commercial Broiler Breeder Barns. Can. Agric. Eng. 1987, 30, 273–276. [Google Scholar]

- Madelin, T.M.; Wathes, C.M. Air Hygiene in a Broiler House: Comparison of Deep Litter with Raised Netting Floors. Br. Poult. Sci. 1989, 30, 23–37. [Google Scholar] [CrossRef]

- David, B.; Moe, R.O.; Michel, V.; Lund, V.; Mejdell, C. Air Quality in Alternative Housing Systems May Have an Impact on Laying Hen Welfare. Part I—Dust. Animals 2015, 5, 495–511. [Google Scholar] [CrossRef] [Green Version]

- Wolfe, R.R.; Anderson, D.P.; Cherms Jr, F.L.; Roper, W.E. Effect of Dust and Ammonia Air Contamination on Turkey Response. Trans. ASAE 1968, 11, 0515–0518. [Google Scholar] [CrossRef]

- Riddell, C.; Schwean, K.; Classen, H.L. Inflammation of the Bronchi in Broiler Chickens, Associated with Barn Dust and the Influence of Barn Temperature. Avian Dis. 1998, 42, 225–229. [Google Scholar] [CrossRef]

- Oyetunde, O.O.; Thomson, R.G.; Carlson, H.C. Aerosol Exposure of Ammonia, Dust and Escherichia Coli in Broiler Chickens. Can. Vet. J. 1978, 19, 187. [Google Scholar]

- Anderson, D.P.; Wolfe, R.R.; Cherms, F.L.; Roper, W.E. Influence of Dust and Ammonia on the Development of Air Sac Lesions in Turkeys. Am. J. Vet. Res. 1968, 29, 1049–1058. [Google Scholar]

- Donham, K.J.; Cumro, D.; Reynolds, S. Synergistic Effects of Dust and Ammonia on the Occupational Health Effects of Poultry Production Workers. J. Agromed. 2002, 8, 57–76. [Google Scholar] [CrossRef]

- Reynolds, S.J.; Thorne, P.S.; Donham, K.J.; Croteau, E.A.; Kelly, K.M.; Lewis, D.; Whitmer, M.; Heederik, D.J.J.; Douwes, J.; Connaughton, I. Comparison of Endotoxin Assays Using Agricultural Dusts. AIHA J. 2002, 63, 430–438. [Google Scholar] [CrossRef] [PubMed]

- Patterson, P.H.; Adrizal, A. Management Strategies to Reduce Air Emissions: Emphasis—Dust and Ammonia. J. Appl. Poult. Res. 2005, 14, 638–650. [Google Scholar] [CrossRef]

- Hartung, J.; Saleh, M. Composition of Dust and Effects on Animals. Landbauforsch Volk 2007, 308, 111–116. [Google Scholar]

- Skóra, J.; Matusiak, K.; Wojewódzki, P.; Nowak, A.; Sulyok, M.; Ligocka, A.; Okrasa, M.; Hermann, J.; Gutarowska, B. Evaluation of Microbiological and Chemical Contaminants in Poultry Farms. Int. J. Environ. Res. Public Health 2016, 13, 192. [Google Scholar] [CrossRef] [PubMed]

- Corbanie, E.A.; Matthijs, M.G.; van Eck, J.H.; Remon, J.P.; Landman, W.J.; Vervaet, C. Deposition of Differently Sized Airborne Microspheres in the Respiratory Tract of Chickens. Avian Pathol. 2006, 35, 475–485. [Google Scholar] [CrossRef]

- David, B.; Mejdell, C.; Michel, V.; Lund, V.; Moe, R.O. Air Quality in Alternative Housing Systems May Have an Impact on Laying Hen Welfare. Part II—Ammonia. Animals 2015, 5, 886–896. [Google Scholar] [CrossRef] [Green Version]

- Van Harn, J.; Aarnink, A.J.A.; Mosquera, J.; Van Riel, J.W.; Ogink, N.W.M. Effect of Bedding Material on Dust and Ammonia Emission from Broiler Houses. Trans. ASABE 2012, 55, 219–226. [Google Scholar] [CrossRef]

- Le Bouquin, S.; Huneau-Salaün, A.; Huonnic, D.; Balaine, L.; Martin, S.; Michel, V. Aerial Dust Concentration in Cage-Housed, Floor-Housed, and Aviary Facilities for Laying Hens. Poult. Sci. 2013, 92, 2827–2833. [Google Scholar] [CrossRef]

- Mendez, M.J.; Panebianco, J.E.; Buschiazzo, D.E. A New Dust Generator for Laboratory Dust Emission Studies. Aeolian Res. 2013, 8, 59–64. [Google Scholar] [CrossRef]

- Gill, T.E.; Zobeck, T.M.; Stout, J.E. Technologies for Laboratory Generation of Dust from Geological Materials. J. Hazard. Mater. 2006, 132, 1–13. [Google Scholar] [CrossRef]

- Wright, B.M. A New Dust-Feed Mechanism. J. Sci. Instrum. 1950, 27, 12. [Google Scholar] [CrossRef]

- Hinds, W.C. Aerosol Technology: Properties, Behavior, and Measurement of Airborne Particles; John Wiley & Sons: Hoboken, NJ, USA, 1999; ISBN 0-471-19410-7. [Google Scholar]

- Hemenway, D.R.; Boudreau, K.; Miller, J. Retrofitting of a Wright Dustfeed. Am. Ind. Hyg. Assoc. J. 1986, 47, 301–307. [Google Scholar]

- O’Shaughnessy, P.T.; Hemenway, D.R. Computer Automation of a Dry-Dust Generating System. Inhal. Toxicol. 1994, 6, 95–113. [Google Scholar] [CrossRef]

- O’Shaughnessy, P.T.; Hemenway, D.R.; Absher, R.G. System Identification and Feedback Control of an Aerosol Production Process. Aerosol Sci. Technol. 1996, 25, 292–304. [Google Scholar] [CrossRef]

- Crider, W.L.; Barkley, N.P.; Strong, A.A. Dry-Powder Aerosol Dispersing Device with Long-Time Output Stability. Rev. Sci. Instrum. 1968, 39, 152–155. [Google Scholar] [CrossRef]

- McKinney, W.; Chen, B.; Schwegler-Berry, D.; Frazer, D.G. Computer-Automated Silica Aerosol Generator and Animal Inhalation Exposure System. Inhal. Toxicol. 2013, 25, 363–372. [Google Scholar] [CrossRef] [PubMed]

- Domingo, R.A.; Southard, R.J.; Lee, K. Laboratory System for Dust Generation from Soils. J. Environ. Qual. 2010, 39, 1254–1261. [Google Scholar] [CrossRef]

- Alfano, B.; Barretta, L.; Del Giudice, A.; De Vito, S.; Di Francia, G.; Esposito, E.; Formisano, F.; Massera, E.; Miglietta, M.L.; Polichetti, T. A Review of Low-Cost Particulate Matter Sensors from the Developers’ Perspectives. Sensors 2020, 20, 6819. [Google Scholar] [CrossRef]

- Austin, E.; Novosselov, I.; Seto, E.; Yost, M.G. Laboratory Evaluation of the Shinyei PPD42NS Low-Cost Particulate Matter Sensor. PLoS ONE 2015, 10, e0137789. [Google Scholar]

- Yu, X.; Shi, Y.; Wang, T.; Sun, X. Dust-Concentration Measurement Based on Mie Scattering of a Laser Beam. PLoS ONE 2017, 12, e0181575. [Google Scholar] [CrossRef] [Green Version]

- Bulot, F.M.J.; Russell, H.S.; Rezaei, M.; Johnson, M.S.; Ossont, S.J.J.; Morris, A.K.R.; Basford, P.J.; Easton, N.H.C.; Foster, G.L.; Loxham, M. Laboratory Comparison of Low-Cost Particulate Matter Sensors to Measure Transient Events of Pollution. Sensors 2020, 20, 2219. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kumar, P.; Skouloudis, A.N.; Bell, M.; Viana, M.; Carotta, M.C.; Biskos, G.; Morawska, L. Real-Time Sensors for Indoor Air Monitoring and Challenges Ahead in Deploying Them to Urban Buildings. Sci. Total Environ. 2016, 560, 150–159. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hofstetter, D.; Fabian, E.; Lorenzoni, A.G. Ammonia Generation System for Poultry Health Research Using Arduino. Sensors 2021, 21, 6664. [Google Scholar] [CrossRef] [PubMed]

- Cambra-López, M.; Winkel, A.; Mosquera, J.; Ogink, N.W.; Aarnink, A.J. Comparison between Light Scattering and Gravimetric Samplers for PM10 Mass Concentration in Poultry and Pig Houses. Atmos. Environ. 2015, 111, 20–27. [Google Scholar] [CrossRef]

| Location | PM10 | Average Particle Count, Particles/L | ||||||

|---|---|---|---|---|---|---|---|---|

| µg/m3 | 0.3 µm | 0.5 µm | 1.0 µm | 2.5 µm | 5.0 µm | 10.0 µm | ||

| Test Chamber | Mean | 52.72 | 44,617 | 13,537 | 3168 | 653 | 128 | 38 |

| SD 1 | 4.68 | 5736 | 1720 | 430 | 151 | 54 | 25 | |

| Control Chamber | Mean | 5.67 | 8534 | 2227 | 315 | 27 | 9 | 4 |

| SD 1 | 1.86 | 1711 | 455 | 102 | 25 | 12 | 7 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hofstetter, D.; Fabian, E.; Dominguez, D.; Lorenzoni, A.G. Automatically Controlled Dust Generation System Using Arduino. Sensors 2022, 22, 4574. https://doi.org/10.3390/s22124574

Hofstetter D, Fabian E, Dominguez D, Lorenzoni AG. Automatically Controlled Dust Generation System Using Arduino. Sensors. 2022; 22(12):4574. https://doi.org/10.3390/s22124574

Chicago/Turabian StyleHofstetter, Dan, Eileen Fabian, Dorian Dominguez, and A. Gino Lorenzoni. 2022. "Automatically Controlled Dust Generation System Using Arduino" Sensors 22, no. 12: 4574. https://doi.org/10.3390/s22124574

APA StyleHofstetter, D., Fabian, E., Dominguez, D., & Lorenzoni, A. G. (2022). Automatically Controlled Dust Generation System Using Arduino. Sensors, 22(12), 4574. https://doi.org/10.3390/s22124574