Algorithms and Methods for the Fault-Tolerant Design of an Automated Guided Vehicle

Abstract

:1. Introduction

1.1. State of the Art in Fault-Tolerant Control

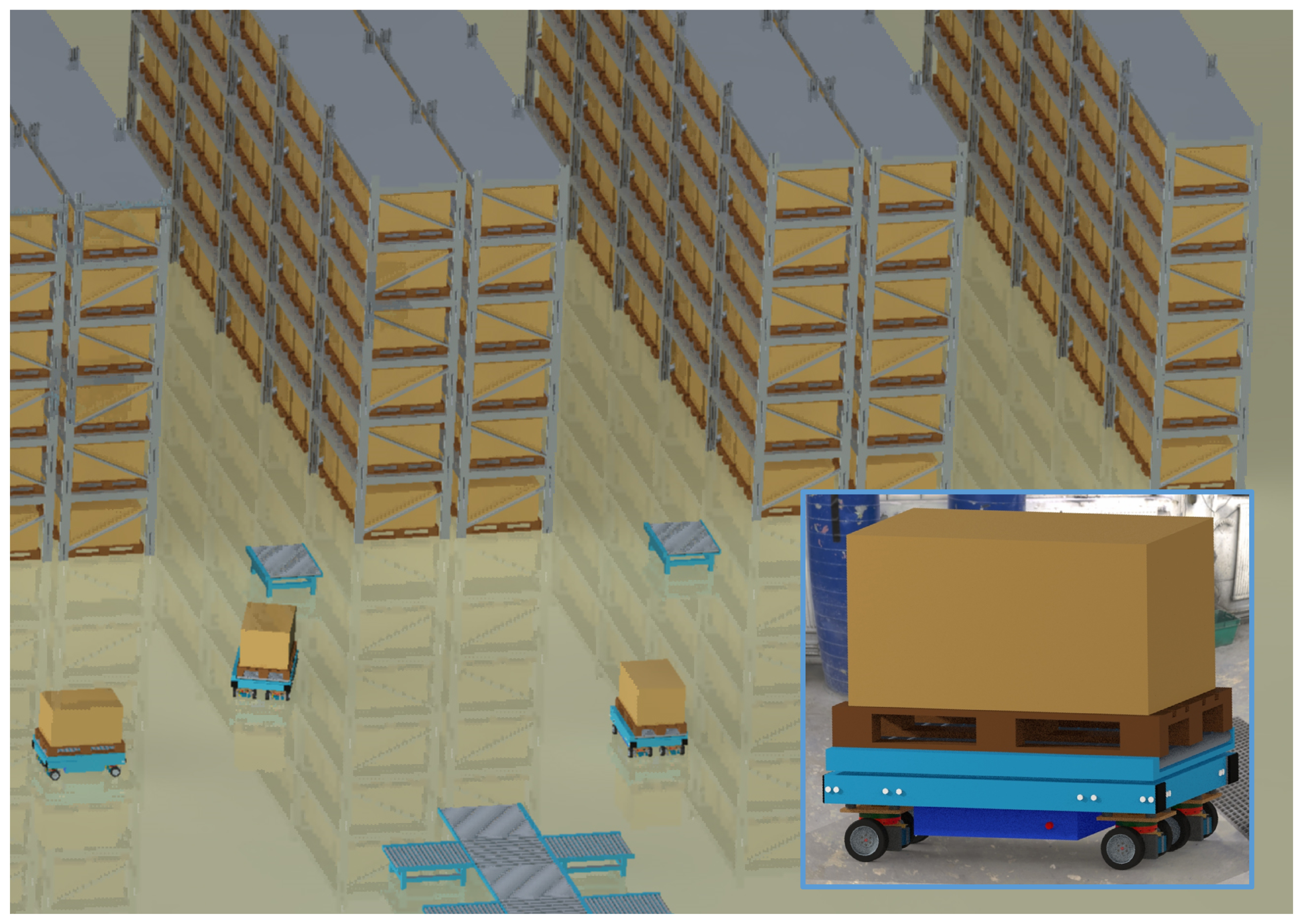

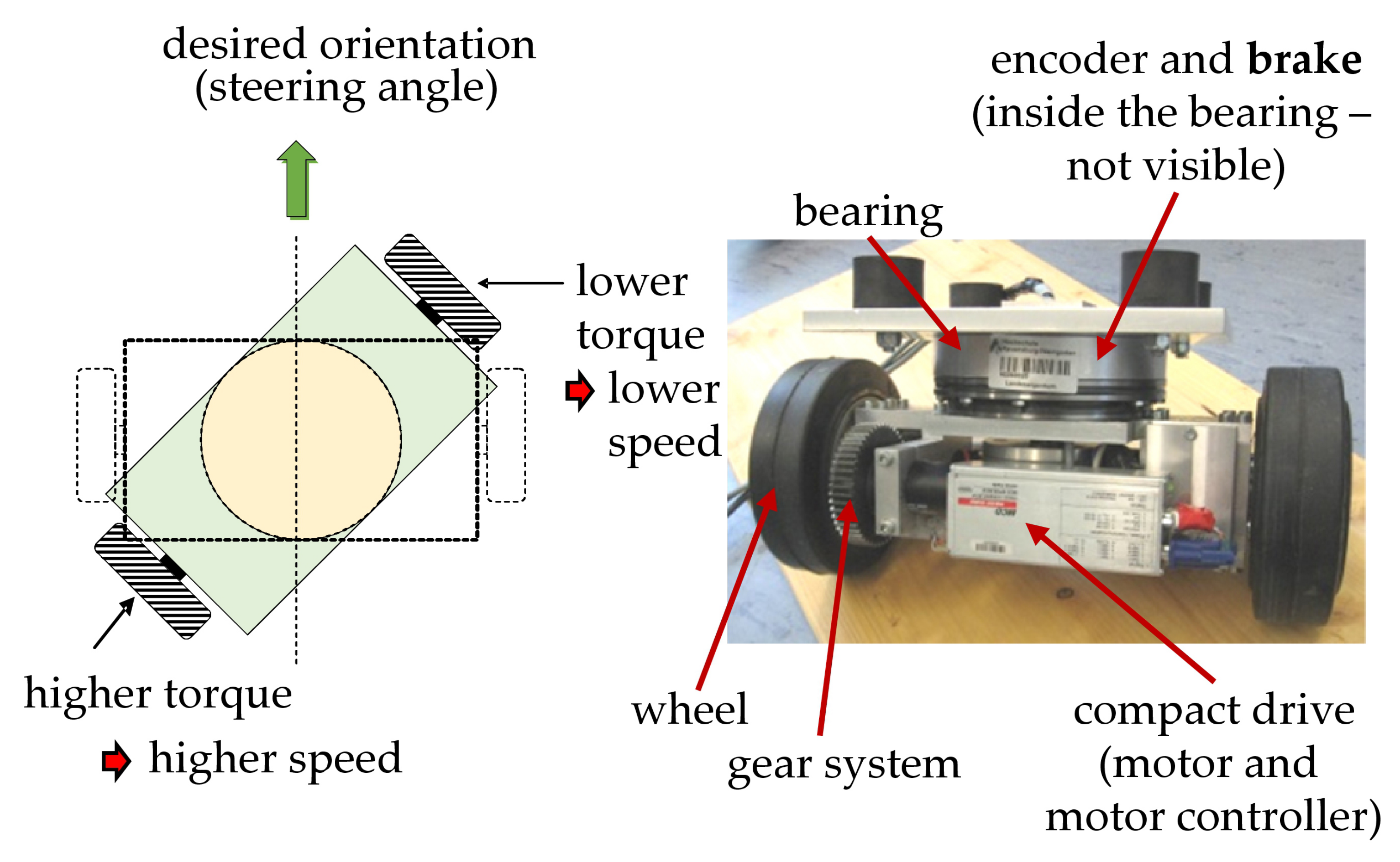

1.2. Application Scenario

1.3. Structure of the Paper

2. Fault-Tolerant Design

- Requirement level: Usually already in the earliest stage certain components, e.g., certain sensors, are already predefined, e.g., because of legal obligations. Usually, possible faults of these components are already known. Additionally, the collection of requirements is accompanied with some kind of benchmark with the predecessor product or competing products. Usually, the benchmark analyses will also produce possible faults.

- Functional level: Frequently, faults are caused by an unfavourable interplay of components. This interplay can be investigated on a functional level and can by employed to search for possible faults.

- Physical structure: Certain faults are connected not only with certain components, but with certain physical phenomena. All kinds of optical sensors, for instance, are susceptible to contamination. Consequently, an analysis of the physical phenomena can also by used for searching for possible faults.

- Geometry, structure and material: On this level, the search for possible faults will concentrate on the applied sensor and actors; even a quantitative evaluation is often possible, because certain values such as the mean time between failure (MTBF) or the reliability in terms of failure rate are known. Detailed investigations are possible employing methods such as failure mode and effects analysis (FMEA), fault tree analysis (FTA) or event tree analysis (ETA).

- Functional level: A technical system can be equipped with redundant entities with functional diversity, i.e., physical and non-physical subsystems, which fulfil the same function. One example can be the combination of a “real” physical sensor and a virtual sensor, which creates a sensor signal by means of a mathematical model, i.e., an analytical redundancy.

- Physical structure: A technical system can be equipped with redundant entities with physical diversity. A typical example is sensors which are based on different physical phenomena, e.g., a combination of a optical sensor with an ultrasonic sensor and the application of a sensor fusion algorithm,

- Geometry, structure and material: On this level, a direct multiplication of components, frequently sensors and actors, is possible.

3. Characteristics of Fault-Tolerant Design

3.1. Fault-Tolerant Design on the Requirements Level

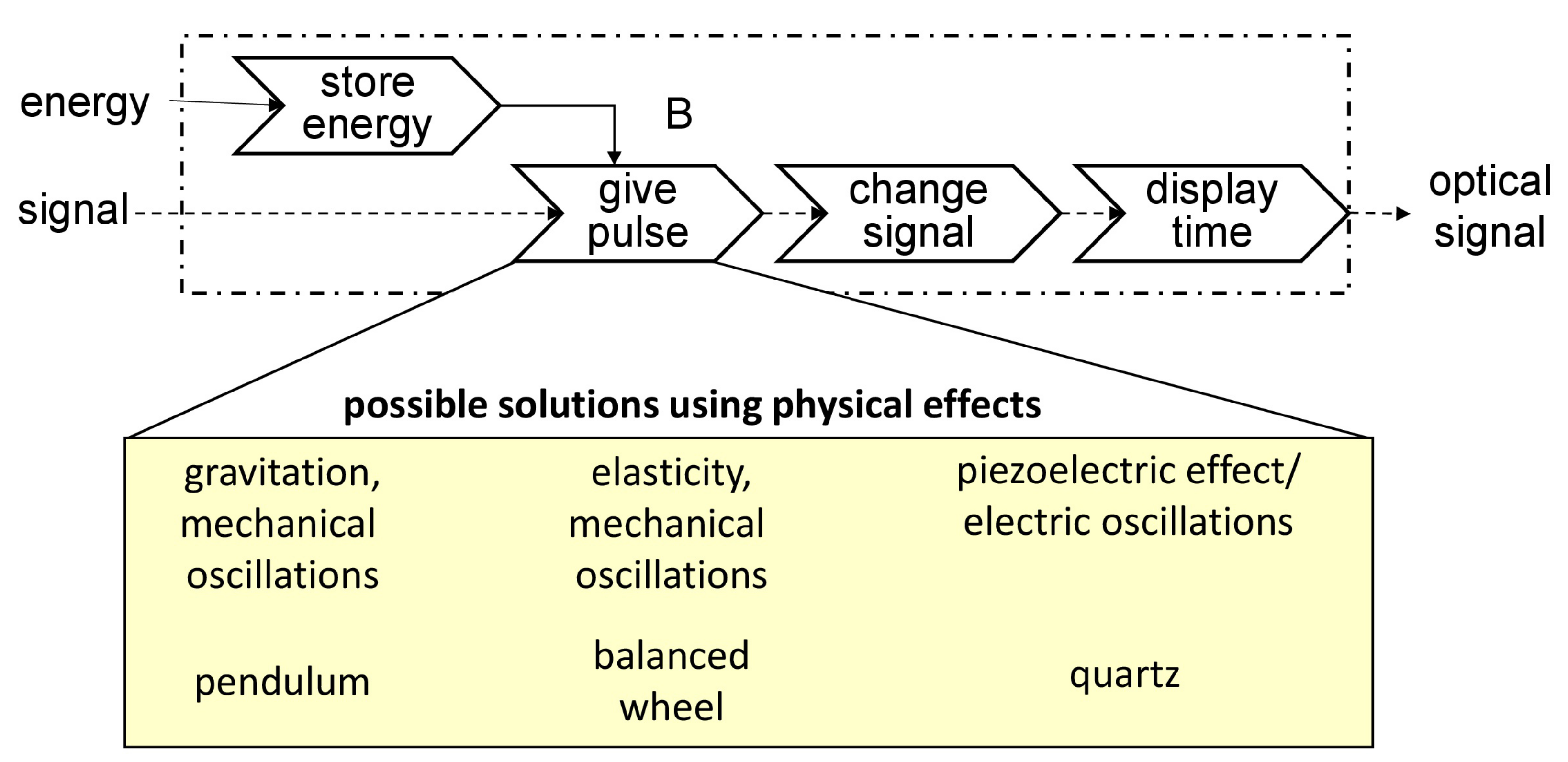

3.2. Design Characteristics on the Functional Level

3.3. Design Characteristics on the Physical Level

3.4. Design Characteristics on the Level of Geometry, Structure and Material

4. Conclusions and Outlook

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Abbreviations

| AGV | Automated guided vehicle |

| CAN | controller area network |

| CPS | Cyber-physical system |

| DC | Direct current |

| ETA | Event tree analysis |

| FMEA | Failure mode and effect analysis |

| FTA | Fault tree analysis |

| FIS | Fuzzy inference system |

| FTC | Fault-tolerant control |

| FTD | Fault-tolerant design |

| IFM | Integrated function modelling |

| MBSE | Model Based Systems Engineering |

| RM | Requirements Management |

| TIPS | Theory of inventive problem solving |

| UIE | Unknown Input Estimator |

| UML | Unified modelling language |

References

- Blanke, M.; Kinnaert, M.; Lunze, J.; Staroswiecki, M. Diagnosis and Fault-Tolerant Control; Springer: New York, NY, USA, 2016. [Google Scholar]

- Witczak, M. Fault Diagnosis and Fault-Tolerant Control Strategies for Non-Linear Systems; Lecture Notes in Electrical Engineering; Springer International Publishing: Heidelberg, Germany, 2014; Volume 266, p. 229. [Google Scholar]

- Ding, S. Model-Based Fault Diagnosis Techniques: Design Schemes, Algorithms, and Tools; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Stetter, R. Fault-Tolerant Design and Control of Automated Vehicles and Processes. Insights for the Synthesis of Intelligent Systems; Springer: Cham, Switzerland, 2020. [Google Scholar]

- Huang, L.; Ren, H.; Chai, Y.; Qu, J. A fault detection method based on stacking the SAE-SRBM for nonstationary and stationary hybrid processes. Int. J. Appl. Math. Comput. Sci. 2021, 31, 29–43. [Google Scholar]

- Montoya, R.; Poudel, B.P.; Bidram, A.; Reno, M.J. DC microgrid fault detection using multiresolution analysis of traveling waves. Int. J. Electr. Power Energy Syst. 2022, 135, 107590. [Google Scholar] [CrossRef]

- Hamdi, H.; Rodrigues, M.; Rabaoui, B.; Braiek, N.B. A fault estimation and fault–tolerant control based sliding mode observer for LPV descriptor systems with time delay. Int. J. Appl. Math. Comput. Sci. 2021, 31, 247–258. [Google Scholar] [CrossRef]

- Farrera, B.; López-Estrada, F.R.; Chadli, M.; Valencia-Palomo, G.; Gómez-Peñate, S. Distributed Fault Estimation of Multi–Agent Systems Using a Proportional–Integral Observer: A Leader–Following Application. Int. J. Appl. Math. Comput. Sci. 2020, 30, 551–560. [Google Scholar] [CrossRef]

- Dimassi, H. A novel fault reconstruction and estimation approach for a class of systems subject to actuator and sensor faults under relaxed assumptions. ISA Trans. 2021, 111, 192–210. [Google Scholar] [CrossRef]

- Straka, O.; Punčochář, I. Decentralized and distributed active fault diagnosis: Multiple model estimation algorithms. Int. J. Appl. Math. Comput. Sci. 2020, 30, 239–249. [Google Scholar] [CrossRef]

- Chen, Q.; Xia, Y.; Wang, J.; Zhao, W.; Liu, G. Short-circuit fault-tolerant control for five-phase fault-tolerant permanent magnet motors with trapezoidal back-EMF. Fundam. Res. 2021, in press. [Google Scholar] [CrossRef]

- Kościelny, J.M.; Syfert, M.; Wnuk, P. Diagnostic Row Reasoning Method Based on Multiple-Valued Evaluation of Residuals and Elementary Symptoms Sequence. Energies 2021, 14, 2476. [Google Scholar] [CrossRef]

- Li, Y.; Hu, Q.; Shao, X. Neural network-based fault diagnosis for spacecraft with single-gimbal control moment gyros. Chin. J. Aeronaut. 2021, 7, 261–273. [Google Scholar] [CrossRef]

- Ali, M.; Din, Z.; Solomin, E.; Cheema, K.M.; Milyani, A.H.; Che, Z. Open switch fault diagnosis of cascade H-bridge multi-level inverter in distributed power generators by machine learning algorithms. Energy Rep. 2021, 7, 8929–8942. [Google Scholar] [CrossRef]

- Eboule, P.S.P.; Pretorius, J.H.C.; Mbuli, N. Machine learning techniques applied on a nine-phase transmission line for faults classification and location. Energy Rep. 2022, 8, 801–810. [Google Scholar] [CrossRef]

- Oh, Y.; Kim, Y.; Na, K.; Youn, B.D. A deep transferable motion-adaptive fault detection method for industrial robots using a residual–convolutional neural network. ISA Trans. 2021. [Google Scholar] [CrossRef]

- Mao, W.; Ding, L.; Liu, Y.; Afshari, S.S.; Liang, X. A new deep domain adaptation method with joint adversarial training for online detection of bearing early fault. ISA Trans. 2021, 122, 444–458. [Google Scholar] [CrossRef]

- Zuev, A.; Zhirabok, A.; Filaretov, V. Fault identification in underwater vehicle thrusters via sliding mode observers. Int. J. Appl. Math. Comput. Sci. 2020, 30, 679–688. [Google Scholar] [CrossRef]

- Salazar, J.C.; Sanjuan, A.; Nejjari, F.; Sarrate, R. Health–Aware and Fault–Tolerant Control of an Octorotor UAV System Based on Actuator Reliability. Int. J. Appl. Math. Comput. Sci. 2020, 30, 47–59. [Google Scholar] [CrossRef]

- Liu, Y.; Hong, S.; Zoi, E.; Liu, J. Integrated fault estimation and fault-tolerant control for a flexible regional aircraft. Chin. J. Aeronaut. 2021, 35, 390–399. [Google Scholar] [CrossRef]

- Mejdi, S.; Messaoud, A.; Abdennour, R.B. Fault Tolerant Multicontrollers for Nonlinear Systems: A Real Validation on a Chemical Process. Int. J. Appl. Math. Comput. Sci. 2020, 30, 61–74. [Google Scholar] [CrossRef]

- Zare, S.; Ayati, M. Simultaneous fault diagnosis of wind turbine using multichannel convolutional neural networks. ISA Trans. 2021, 108, 230–239. [Google Scholar] [CrossRef]

- Chen, M.; Zhou, Z.; Zhang, B.; Hu, G.; Cao, Y. A novel combination belief rule base model for mechanical equipment fault diagnosis. Chin. J. Aeronaut. 2021, in press. [Google Scholar] [CrossRef]

- Su, X.; Xiao, B. Actuator-Integrated Fault Estimation and Fault Tolerant Control for Electric Power Steering System of Forklift. Appl. Sci. 2021, 11, 7236. [Google Scholar] [CrossRef]

- Zhang, T.; Chen, J.; Li, F.; Zhang, K.; Lv, H.; He, S.; Xu, E. Intelligent fault diagnosis of machines with small and imbalanced data: A state-of-the-art review and possible extensions. ISA Trans. 2022, 119, 152–171. [Google Scholar] [CrossRef]

- Dashti, R.; Daisy, M.; Mirshekali, H.; Shaker, H.R.; Hosseini Aliabadi, M. A survey of fault prediction and location methods in electrical energy distribution networks. Measurement 2021, 184, 109947. [Google Scholar] [CrossRef]

- Zhang, S.; Su, L.; Gu, J.; Li, K.; Zhou, L.; Pecht, M. Rotating machinery fault detection and diagnosis based on deep domain adaptation: A survey. Chin. J. Aeronaut. 2021. [Google Scholar] [CrossRef]

- Cheng, C.; Wang, J.; Chen, H.; Chen, Z.; Luo, H.; Xie, P. A Review of Intelligent Fault Diagnosis for High-Speed Trains: Qualitative Approaches. Entropy 2021, 23, 1. [Google Scholar] [CrossRef]

- Bejarano, R.; Pääkkönen, R.; Blech, J.O.; Peake, I.; Herrmann, P.; Vyatkin, V. Evaluating Architectural Patterns for Remote Control of AGVs. In Proceedings of the IEEE International Conference on Emerging Technologies and Factory Automation ETFA 2020, Vienna, Austria, 8–11 September 2020. [Google Scholar]

- Bejarano, R.; Atmojo, U.D.; Blech, J.O.; Vyatkin, V. Towards enhanced live visualization based on communication delay prediction for remote AGV operation. In Proceedings of the 2021 26th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Vasteras, Sweden, 7–10 September 2021; pp. 1–4. [Google Scholar] [CrossRef]

- Sedghi, L.; John, J.; Noor-A-Rahim, M.; Pesch, D. Formation Control of Automated Guided Vehicles in the Presence of Packet Loss. Sensors 2022, 22, 3552. [Google Scholar] [CrossRef] [PubMed]

- Teh, X.X.; Aijaz, A.; Portelli, A.; Jones, S. Communications-based Formation Control of Mobile Robots: Modeling, Analysis and Performance Evaluation. In Proceedings of the 23rd International ACM Conference on Modeling, Analysis and Simulation of Wireless and Mobile Systems, Alicante, Spain, 16–20 November 2020. [Google Scholar]

- Manoharan, S.H.; Chiu, W.Y. Consensus Based Formation Control of Automated Guided Vehicles Using Dynamic Destination Approach. In Proceedings of the 2019 58th Annual Conference of the Society of Instrument and Control Engineers of Japan (SICE), Hiroshima, Japan, 10–13 September 2019; pp. 902–907. [Google Scholar] [CrossRef]

- Zhuang, H.; Dong, K.; Wang, N.; Dong, L. Multi-Robot Leader Grouping Consistent Formation Control Method Research with Low Convergence Time Based on Nonholonomic Constraints. Appl. Sci. 2022, 12, 2300. [Google Scholar] [CrossRef]

- Pahl, G.; Beitz, W.; Feldhusen, J.; Grote, K.H. Engineering Design: A Systematic Approach; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Ehrlenspiel, K.; Meerkamm, H. Integrierte Produktentwicklung. Denkabläufe, Methodeneinsatz, Zusammenarbeit; Carl Hanser Verlag: München, Germany, 2013. [Google Scholar]

- Lindemann, U. Methodische Entwicklung Technischer Produkte; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Ponn, J.; Lindemann, U. Konzeptentwicklung und Gestaltung Technischer Produkte; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Cross, N. Engineering Design Methods: Strategies for Product Design; John Wiley and Sons Ltd.: Hoboken, NJ, USA, 2008. [Google Scholar]

- Rouissi, F.; Hoblos, G. Fault Tolerant Sensor Network Design with Respect to Diagnosability Properties. In Proceedings of the 8th IFAC Symposium on Fault Detection, Supervision and Safety of Technical Processes (SAFEPROCESS), Mexico City, Mexico, 29–31 August 2012; pp. 1120–1124. [Google Scholar]

- Dubrova, E. Fault-Tolerant Design; Springer: New York, NY, USA, 2013. [Google Scholar]

- Shirazipourazad, S.; Sen, A.; Bandyopadhyay, S. Fault-tolerant design of wireless sensor networks with directional antennas. Pervasive Mob. Comput. 2014, 13, 258–271. [Google Scholar] [CrossRef]

- Oh, Y.; Jeong, J.; Lee, J.; Lee, Y.; Baek, S.; Lee, S. Fault-Tolerant Design for Advanced Diverse Protection System. Nucl. Eng. Technol. 2013, 45, 795–802. [Google Scholar] [CrossRef] [Green Version]

- Hsieh, T.Y.; Li, K.H.; Chung, C.C. A fault-analysis oriented re-design and cost-effectiveness evaluation methodology for error tolerant applications. Microelectron. J. 2017, 66, 48–57. [Google Scholar] [CrossRef]

- Vedachalam, N.; Umapathy, A.; Ramadass, G. Fault-tolerant design approach for reliable offshore multi-megawatt variable frequency converters. J. Ocean Eng. Sci. 2016, 1, 226–237. [Google Scholar] [CrossRef] [Green Version]

- Porter, R.; Ronen, A.; Shoham, Y.; Tennenholtz, M. Fault tolerant mechanism design. Artif. Intell. 2013, 45, 1783–1799. [Google Scholar] [CrossRef] [Green Version]

- VDI/VDE. VDI/VDE 2006: Development of Cyber-Physical Mechatronic Systems (CPMS); Beuth: Berlin, Germany, 2020. [Google Scholar]

- Buehne, S.; Herrmann, A. Handbuch Requirements Management nach IREB Standard. Aus- und Weiterbildung zum IREB Certified Professional for Requirements Engineering Advanced Level Requirements Management.; IREB e.V.: Fürth, Germany, 2015. [Google Scholar]

- Bernard, R.; Irlinger, R. About watches and cars: Winning R and D strategies in two branches. In Proceedings of the International Symposium “Engineering Design—The Art of Building Networks”, München, Germany, 4 April 2016. [Google Scholar]

- Hruschka, P. Business Analysis und Requirements Engineering: Produkte und Prozesse Nachhaltig Verbessern; Hanser: München, Germany, 2014. [Google Scholar]

- Ebert, C.; Jastram, M. ReqIF: Seamless Requirements Interchange Format between Business Partners. IEEE Softw. 2012, 29, 82–87. [Google Scholar] [CrossRef]

- Sharif Ullah, A.M.M.; Sato, M.; Watanabe, M.; Mamunur Rashid, M. Analysis of Kano-Model-Based Customer Needs for Product Development. Int. J. Autom. Technol. 2016, 10, 132–143. [Google Scholar] [CrossRef]

- Carrillo de Gea, J.M.; Nicolas, J.; Fernandez Aleman, J.L.; Toval, A.; Ebert, C.; Vizca, A. Requirements engineering tools: Capabilities, survey and assessment. Inf. Softw. Technol. 2012, 54, 1142–1157. [Google Scholar] [CrossRef]

- IBM. Rational DOORS. 2021. Available online: https://www.ibm.com/de-de/marketplace/requirements-management (accessed on 16 June 2022).

- Stetter, R. Approaches for Modelling the Physical Behavior of Technical Systems on the Example of Wind Turbines. Energies 2020, 13, 2087. [Google Scholar] [CrossRef]

- Eisenbart, B.; Gericke, K.; Blessing, L.; McAloone, T. A DSM-based framework for integrated function modelling: Concept, application and evaluation. Res. Eng. Des. 2016, 28, 25–41. [Google Scholar] [CrossRef] [Green Version]

- Elwert, M.; Ramsaier, M.; Eisenbart, B.; Stetter, R. Holistic Digital Function Modelling with Graph-Based Design Languages. In Proceedings of the 22nd International Conference on Engineering Design (ICED 19), Delft, The Netherlands, 5–8 August 2019; Volume 1. [Google Scholar]

- Elwert, M.; Ramsaier, M.; Eisenbart, B.; Stetter, R.; Till, M.; Rudolph, S. Digital Function Modeling in Graph-Based Design Languages. Appl. Sci. 2022, 12, 5301. [Google Scholar] [CrossRef]

- Banciu, F.; Drăghici, G.; Pămîntaş, E.; Grozav, I. Identify Functions, Failure Modes, Causes and Effects Using the Triz Functional Modeling. In Proceedings of the International Conference on Manufacturing Science and Education, (MSE 2011), Sibiu, Romania, 2–5 June 2011. [Google Scholar]

- Stetter, R. A Fuzzy Virtual Actuator for Automated Guided Vehicles. Sensors 2020, 20, 4154. [Google Scholar] [CrossRef]

- Gillijns, S.; De Moor, B. Unbiased minimum-variance input and state estimation for linear discrete-time systems. Automatica 2007, 43, 111–116. [Google Scholar] [CrossRef]

- Stetter, R.; Witczak, M.; Till, M. Fault-Tolerant Design of a Balanced Two-Wheel Scooter. In Advanced, Contemporary Control; Bartoszewicz, A., Kabziński, J., Kacprzyk, J., Eds.; Springer: Berlin, Germany, 2020; pp. 1399–1410. [Google Scholar]

- Mendonca, L.F.; Sousa, J.; da Costa, J.M.G. Fault Isolation using Fuzzy Model-Based Observers. IFAC Proc. Vol. 2006, 39, 735–740. [Google Scholar] [CrossRef]

- Albers, A.; Wintergerst, E. The Contact and Channel Approach: Relating a system’s physical structure to its functionality. In An Anthology of Theories and Models of Design: Philosophy, Approaches and Empirical Explorations; Springer: London, UK, 2014; pp. 61–72. [Google Scholar]

- Ryll, M.; Buelthoff, H.; Giordano, P. Overactuation in UAVs for Enhanced Aerial Manipulation: A Novel Quadrotor Concept with Tilting Propellers. In Proceedings of the 6th International Workshop on Human-Friendly Robotics, Rome, Italy, 25–26 September 2013. [Google Scholar]

- Schneider, M.; van de Molengraft, M.; Steinbuch, M. Benefits of over-actuation in motion systems. In Proceedings of the 2004 American Control Conference, Boston, MA, USA, 30 June–2 July 2004. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stetter, R. Algorithms and Methods for the Fault-Tolerant Design of an Automated Guided Vehicle. Sensors 2022, 22, 4648. https://doi.org/10.3390/s22124648

Stetter R. Algorithms and Methods for the Fault-Tolerant Design of an Automated Guided Vehicle. Sensors. 2022; 22(12):4648. https://doi.org/10.3390/s22124648

Chicago/Turabian StyleStetter, Ralf. 2022. "Algorithms and Methods for the Fault-Tolerant Design of an Automated Guided Vehicle" Sensors 22, no. 12: 4648. https://doi.org/10.3390/s22124648

APA StyleStetter, R. (2022). Algorithms and Methods for the Fault-Tolerant Design of an Automated Guided Vehicle. Sensors, 22(12), 4648. https://doi.org/10.3390/s22124648