Lamb Wave-Based Damage Localization and Quantification in Composites Using Probabilistic Imaging Algorithm and Statistical Method

Abstract

:1. Introduction

2. Damage Detection Method

2.1. Damage Localization Algorithm

2.1.1. Probabilistic Imaging Algorithm by TOF

2.1.2. TOF Extraction Method

- (1)

- Construct a dictionary D

- (2)

- Select the best atom α from dictionary D

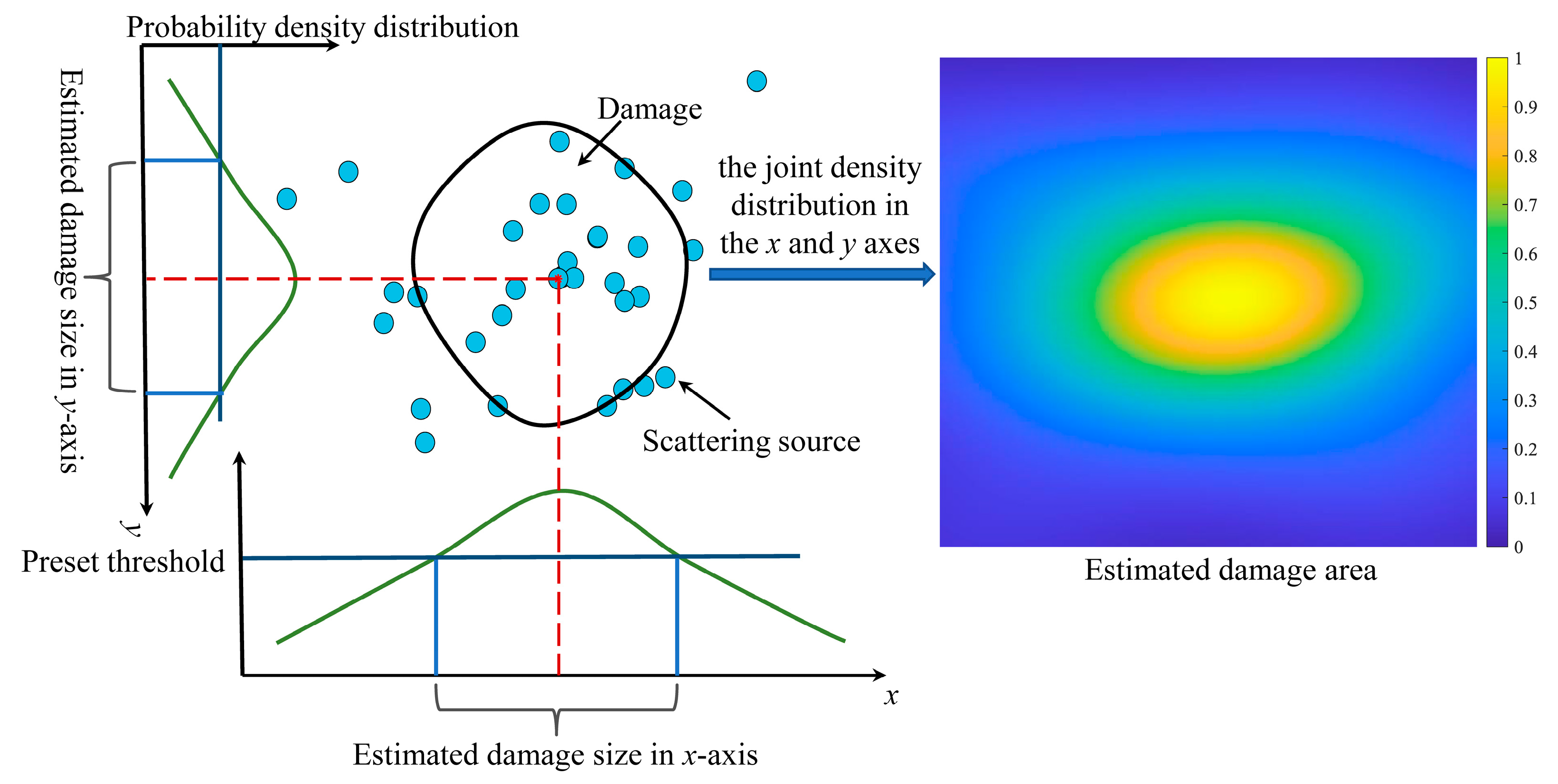

2.2. Kernel Density Probability Distribution Assessment of Damage Size

3. Experiment

3.1. Specimen

3.2. Experimental Setup

4. Results and Discussions

4.1. Damage Location Identification

4.2. Damage Quantification

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mitra, M.; Gopalakrishnan, S. Guided wave based structural health monitoring: A review. Smart Mater. Struct. 2016, 25, 27. [Google Scholar] [CrossRef]

- Zhang, X.; Luo, D.; He, Y.; Zhang, X.; Chen, S.; Xiao, Y. CFRP Barely Visible Impact Damage Inspection Based on Nonlinear Ultrasound Signal Sparse Reconstruction. IEEE Sens. J. 2018, 18, 6303–6310. [Google Scholar] [CrossRef]

- Diamanti, K.; Soutis, C. Structural health monitoring techniques for aircraft composite structures. Prog. Aeosp. Sci. 2010, 46, 342–352. [Google Scholar] [CrossRef]

- Sato, M.; Hasegawa, K.; Koyanagi, J.; Higuchi, R.; Ishida, Y. Residual strength prediction for unidirectional CFRP using a nonlinear viscoelastic constitutive equation considering entropy damage. Compos. Part A Appl. Sci. Manuf. 2021, 141, 106178. [Google Scholar] [CrossRef]

- Tian, Z.; Yu, L.; Leckey, C. Rapid guided wave delamination detection and quantification in composites using global-local sensing. Smart Mater. Struct. 2016, 25, 085042. [Google Scholar] [CrossRef]

- Ramalho, G.M.F.; Lopes, A.M.; da Silva, L.F.M. Structural health monitoring of adhesive joints using Lamb waves: A review. Struct. Control Health Monit. 2022, 29, e2849. [Google Scholar] [CrossRef]

- Agrahari, J.K.; Kapuria, S. Active detection of block mass and notch-type damages in metallic plates using a refined time-reversed Lamb wave technique. Struct. Control Health Monit. 2018, 25, e2064. [Google Scholar] [CrossRef]

- Chang, M.; Yuan, S.F.; Guo, F.Y. Corrosion monitoring using a new compressed sensing-based tomographic method. Ultrasonics 2020, 101, 105988. [Google Scholar] [CrossRef]

- Gonzalez-Jimenez, A.; Lomazzi, L.; Cadini, F.; Beligni, A.; Sbarufatti, C.; Giglio, M.; Manes, A. On the mitigation of the RAPID algorithm uneven sensing network issue employing averaging and Gaussian blur filtering techniques. Compos. Struct. 2021, 278, 114716. [Google Scholar] [CrossRef]

- Liu, L.; Xia, Q.W.; Cao, S.H.; Ma, S.W.; Liu, Y.Y. Damage detection of composite plate based on an improved DAS algorithm by time difference due to anisotropy. J. Vibroeng. 2020, 22, 1747–1757. [Google Scholar] [CrossRef]

- Paixao, J.; da Silva, S.; Figueiredo, E.; Radu, L.; Park, G. Delamination area quantification in composite structures using Gaussian process regression and auto-regressive models. J. Vib. Control 2021, 27, 2778–2792. [Google Scholar] [CrossRef]

- Munian, R.K.; Mahapatra, D.R.; Gopalakrishnan, S. Lamb wave interaction with composite delamination. Compos. Struct. 2018, 206, 484–498. [Google Scholar] [CrossRef]

- Suzuki, M.; Suzuki, Y.; Todoroki, A.; Mizutani, Y. Collision Monitoring of Foreign Object on CFRP Laminate Utilizing Electrostatic Induction. IEEE Sens. J. 2018, 18, 613–622. [Google Scholar] [CrossRef]

- Rizvi, S.H.M.; Abbas, M. An advanced Wigner-Ville time-frequency analysis of Lamb wave signals based upon an autoregressive model for efficient damage inspection. Meas. Sci. Technol. 2021, 32, 16. [Google Scholar] [CrossRef]

- Yan, J.J.; Jin, H.S.; Sun, H.; Qing, X.L. Active Monitoring of Fatigue Crack in the Weld Zone of Bogie Frames Using Ultrasonic Guided Waves. Sensors 2019, 19, 3372. [Google Scholar] [CrossRef] [Green Version]

- Yang, J.S.; He, J.J.; Guan, X.F.; Wang, D.J.; Chen, H.P.; Zhang, W.F.; Liu, Y.M. A probabilistic crack size quantification method using in-situ Lamb wave test and Bayesian updating. Mech. Syst. Signal Process. 2016, 78, 118–133. [Google Scholar] [CrossRef]

- Pillarisetti, L.S.S.; Talreja, R. On quantifying damage severity in composite materials by an ultrasonic method. Compos. Struct. 2019, 216, 213–221. [Google Scholar] [CrossRef]

- Torkamani, S.; Roy, S.; Barkey, M.E.; Sazonov, E.; Burkett, S.; Kotru, S. A novel damage index for damage identification using guided waves with application in laminated composites. Smart Mater. Struct. 2014, 23, 095015. [Google Scholar] [CrossRef]

- He, J.J.; Ran, Y.M.; Liu, B.; Yang, J.S.; Guan, X.F. A Fatigue Crack Size Evaluation Method Based on Lamb Wave Simulation and Limited Experimental Data. Sensors 2017, 17, 2097. [Google Scholar] [CrossRef] [Green Version]

- Jin, H.S.; Yan, J.J.; Liu, X.; Li, W.B.; Qing, X.L. Quantitative defect inspection in the curved composite structure using the modified probabilistic tomography algorithm and fusion of damage index. Ultrasonics 2021, 113, 106358. [Google Scholar] [CrossRef]

- Lu, G.; Li, Y.; Zhou, M.; Feng, Q.; Song, G. Detecting Damage Size and Shape in a Plate Structure Using PZT Transducer Array. J. Aerosp. Eng. 2018, 31, 04018075. [Google Scholar] [CrossRef]

- Gao, F.; Zeng, L.; Lin, J.; Shao, Y. Damage assessment in composite laminates via broadband Lamb wave. Ultrasonics 2018, 86, 49–58. [Google Scholar] [CrossRef] [PubMed]

- Zheng, K.H.; Li, Z.; Ma, Z.Y.; Chen, J.L.; Zhou, J.; Su, X.Y. Damage detection method based on Lamb waves for stiffened composite panels. Compos. Struct. 2019, 225, 111137. [Google Scholar] [CrossRef]

- Li, R.; Luo, J.; Hu, B. Lamb Wave-Based Damage Localization Feature Enhancement and Extraction Method for Stator Insulation of Large Generators Using VMD and Wavelet Transform. Sensors 2020, 20, 4205. [Google Scholar] [CrossRef] [PubMed]

- Gorgin, R.; Wu, Z.; Gao, D.; Wang, Y. Damage size characterization algorithm for active structural health monitoring using the A(0) mode of Lamb waves. Smart Mater. Struct. 2014, 23, 035015. [Google Scholar] [CrossRef]

- Agarwal, S.; Mitra, M. Lamb wave based automatic damage detection using matching pursuit and machine learning. Smart Mater. Struct. 2014, 23, 085012. [Google Scholar] [CrossRef]

- Mu, W.L.; Gao, Y.Q.; Liu, G.J. Ultrasound Defect Localization in Shell Structures with Lamb Waves Using Spare Sensor Array and Orthogonal Matching Pursuit Decomposition. Sensors 2021, 21, 8127. [Google Scholar] [CrossRef]

- Kim, H.; Yuan, F.-G. Adaptive signal decomposition and dispersion removal based on the matching pursuit algorithm using dispersion-based dictionary for enhancing damage imaging. Ultrasonics 2020, 103, 106087. [Google Scholar] [CrossRef]

- Su, C.; Jiang, M.; Lv, S.; Lu, S.; Zhang, L.; Zhang, F.; Sui, Q. Improved Damage Localization and Quantification of CFRP Using Lamb Waves and Convolution Neural Network. IEEE Sens. J. 2019, 19, 5784–5791. [Google Scholar] [CrossRef]

- Yu, Y.H.; Liu, X.; Yan, J.J.; Wang, Y.S.; Qing, X.L. Real-Time Life-Cycle Monitoring of Composite Structures Using Piezoelectric-Fiber Hybrid Sensor Network. Sensors 2021, 21, 8213. [Google Scholar] [CrossRef]

- Migot, A.; Bhuiyan, Y.; Giurgiutiu, V. Numerical and experimental investigation of damage severity estimation using Lamb wave-based imaging methods. J. Intell. Mater. Syst. Struct. 2019, 30, 618–635. [Google Scholar] [CrossRef]

- Lee, Y.; Cho, Y. Defect Imaging Enhancement through Optimized Shape Factors of the RAPID Algorithm Based on Guided Wave Beam Pattern Analysis. Sensors 2021, 21, 4029. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.-W.; Yuan, F.-G. Enhanced damage imaging of a metallic plate using matching pursuit algorithm with multiple wavepaths. Ultrasonics 2018, 89, 84–101. [Google Scholar] [CrossRef] [PubMed]

- Dai, J.; Liu, Y.; Chen, J.; Liu, X. Fast feature selection for interval-valued data through kernel density estimation entropy. Int. J. Mach. Learn. Cybern. 2020, 11, 2607–2624. [Google Scholar] [CrossRef]

- Jerzman, B.; Kicinski, W. Kernel estimation of probability density function: Properties and parameters optimization. Metrol. Meas. Syst. 2009, 16, 85–105. [Google Scholar]

- Qing, X.L.; Li, W.Z.; Wang, Y.S.; Sun, H. Piezoelectric Transducer-Based Structural Health Monitoring for Aircraft Applications. Sensors 2019, 19, 545. [Google Scholar] [CrossRef]

- Lang, Y.-F.; Tian, S.-H.; Yang, Z.-B.; Sun, R.-B.; Zhang, W.; Kong, D.-T.; Chen, X.-F. Array focused Lamb wave Hilbert holographic imaging method. Mech. Adv. Mater. Struct. 2021, 1–15. [Google Scholar] [CrossRef]

| Technical Parameter | Value |

|---|---|

| Excitation Frequency Range | 10–1000 kHz |

| Conversion Rates | 48 MHz |

| Output Voltage Range | Min: ±10 V; Max: ±60 V |

| Memory | 32,000 Samples |

| Sampling Rates | 6, 12, 24, 48 MHz/s |

| Resolution | 12-bit |

| ADC Range | ±1 V |

| Gain Adjustment Range | 10–40 dB, step: 1 dB |

| Actual Damage Location (mm) | Damage Diameter (mm) | Results of Using Hilbert to Extract TOF (mm) | Distance between Predicted and Actual Location (mm) | Relative Error (%) | Results of Using MPD to Extract TOF (mm) | Distance between Predicted and Actual Location (mm) | Relative Error (%) |

|---|---|---|---|---|---|---|---|

| (320, 245) | 4 | (342.9, 245.4) | 22.9 | 5.08 | (309.2, 242.7) | 11.0 | 2.44 |

| (320, 245) | 8 | (334.9, 241.5) | 15.3 | 3.40 | (313.2, 241.6) | 7.6 | 1.69 |

| (320, 245) | 12 | (336.6, 243.7) | 16.6 | 3.69 | (317.9, 252.5) | 7.8 | 1.73 |

| (127, 185) | 4 | (134.8, 179.5) | 9.5 | 2.11 | (134.4, 185.1) | 7.4 | 1.64 |

| (127, 185) | 8 | (135.1, 179.9) | 9.6 | 2.13 | (130.3, 191.9) | 7.6 | 1.69 |

| (127, 185) | 12 | (133.8, 176.2) | 11.4 | 2.53 | (116.1, 187.0) | 11.0 | 2.44 |

| Actual Damage Location (mm) | Damage Diameter (mm) | Actual Damage Size (mm2) | Predicted Damage Size (mm2) | Corresponding Predicted Damage Diameter(mm) | Absolute Error (mm2) |

|---|---|---|---|---|---|

| (320, 245) | 4 | 12.56 | 30.04 | 6.18 | 17.48 |

| (320, 245) | 8 | 50.24 | 47.14 | 7.75 | 3.10 |

| (320, 245) | 12 | 113.04 | 95.69 | 11.04 | 17.35 |

| (127, 185) | 4 | 12.56 | 14.26 | 4.26 | 1.70 |

| (127, 185) | 8 | 50.24 | 45.57 | 7.61 | 4.67 |

| (127, 185) | 12 | 113.04 | 85.53 | 10.43 | 27.51 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, J.; Zeng, X.; Liu, Q.; Qing, X. Lamb Wave-Based Damage Localization and Quantification in Composites Using Probabilistic Imaging Algorithm and Statistical Method. Sensors 2022, 22, 4810. https://doi.org/10.3390/s22134810

Guo J, Zeng X, Liu Q, Qing X. Lamb Wave-Based Damage Localization and Quantification in Composites Using Probabilistic Imaging Algorithm and Statistical Method. Sensors. 2022; 22(13):4810. https://doi.org/10.3390/s22134810

Chicago/Turabian StyleGuo, Jiahui, Xianping Zeng, Qijian Liu, and Xinlin Qing. 2022. "Lamb Wave-Based Damage Localization and Quantification in Composites Using Probabilistic Imaging Algorithm and Statistical Method" Sensors 22, no. 13: 4810. https://doi.org/10.3390/s22134810

APA StyleGuo, J., Zeng, X., Liu, Q., & Qing, X. (2022). Lamb Wave-Based Damage Localization and Quantification in Composites Using Probabilistic Imaging Algorithm and Statistical Method. Sensors, 22(13), 4810. https://doi.org/10.3390/s22134810