Smart Insole Based on Flexi Force and Flex Sensor for Monitoring Different Body Postures

Abstract

:1. Introduction

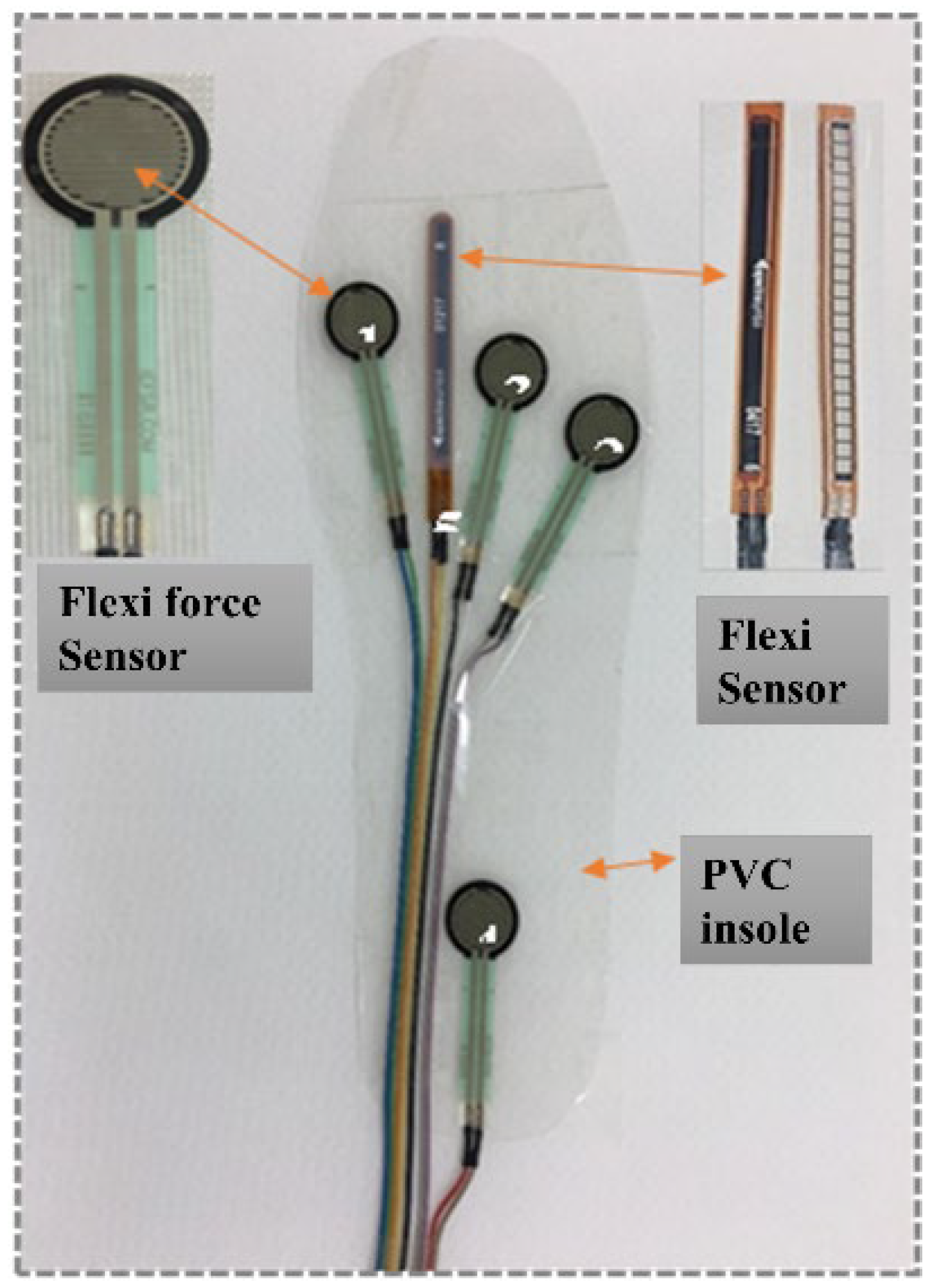

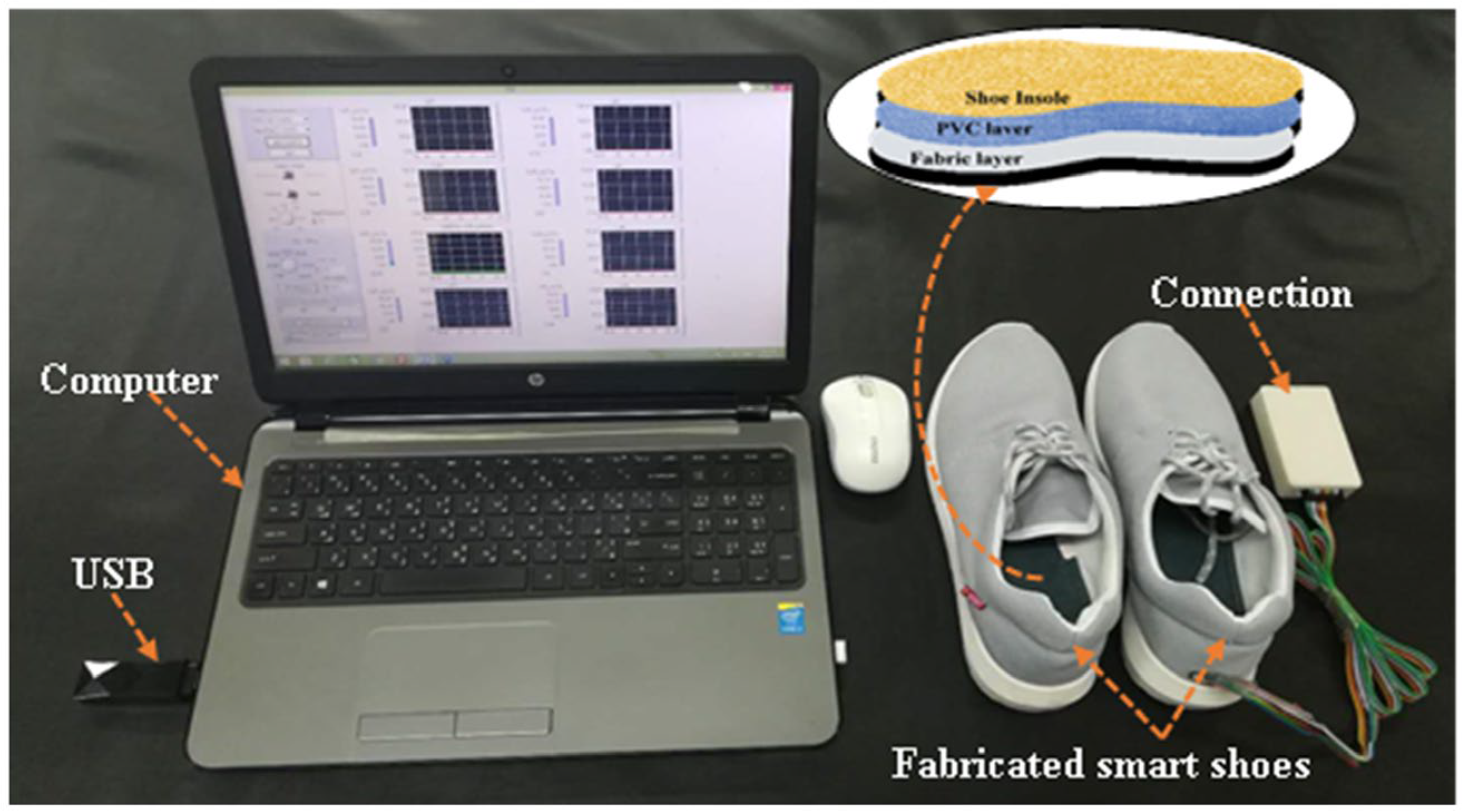

2. Smart Insole Development

2.1. Flexi Force Sensor

2.2. Flex Sensor

2.3. Smart Insole and Monitoring System

2.4. Metrological Characterization

3. Sensors’ Postural Monitoring Methods and Experimental Results

4. Postural Assessment Using the Smart Insole

5. Discussion and Comparison with Previous Related Studies

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Masud, M.; Gaba, G.S.; Alqahtani, S.; Muhammad, G.; Gupta, B.B.; Kumar, P.; Ghoneim, A. A lightweight and robust secure key establishment protocol for internet of medical things in COVID-19 patients care. IEEE Internet Things J. 2020, 8, 15694–15703. [Google Scholar] [CrossRef] [PubMed]

- Cisotto, G.; Casarin, E.; Tomasin, S. Requirements and enablers of advanced healthcare services over future cellular systems. IEEE Commun. Mag. 2020, 58, 76–81. [Google Scholar] [CrossRef] [Green Version]

- Donisi, L.; Pagano, G.; Cesarelli, G.; Coccia, A.; Amitrano, F.; D’Addio, G. Benchmarking between two wearable inertial systems for gait analysis based on a different sensor placement using several statistical approaches. Measurement 2021, 173, 108642. [Google Scholar] [CrossRef]

- Gao, L.; Zhang, G.; Yu, B.; Qiao, Z.; Wang, J. Wearable human motion posture capture and medical health monitoring based on wireless sensor networks. Measurement 2020, 166, 108252. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Hong, C.Y.; Ahmed, R.; Ahmed, Z. A fiber Bragg grating based sensing platform fabricated by fused deposition modeling process for plantar pressure measurement. Measurement 2017, 112, 74–79. [Google Scholar] [CrossRef]

- Hong, C.Y.; Zhang, Y.F.; Zhang, M.X.; Leung, L.M.G.; Liu, L.Q. Application of FBG sensors for geotechnical health monitoring, a review of sensor design, implementation methods and packaging techniques. Sens. Actuators A Phys. 2016, 244, 184–197. [Google Scholar] [CrossRef]

- Titianova, E.B.; Mateev, P.S.; Tarkka, I.M. Footprint analysis of gait using a pressure sensor system. J. Electromyogr. Kinesiol. 2004, 14, 275–281. [Google Scholar] [CrossRef]

- Patil, S.L.; Thatte, M.A.; Chaskar, U.M. Development of planter foot pressure distribution system using flexi force sensors. Sens. Transducers 2009, 108, 73. [Google Scholar]

- Chatwin, K.E.; Abbott, C.A.; Boulton, A.J.; Bowling, F.L.; Reeves, N.D. The role of foot pressure measurement in the prediction and prevention of diabetic foot ulceration—A comprehensive review. Diabetes/Metab. Res. Rev. 2020, 36, e3258. [Google Scholar] [CrossRef]

- Boulton, A.J.; Franks, C.I.; Betts, R.P.; Duckworth, T.; Ward, J.D. Reduction of abnormal foot pressures in diabetic neuropathy using a new polymer insole material. Diabetes Care 1984, 7, 42–46. [Google Scholar] [CrossRef]

- Lakho, R.A.; Yi-Fan, Z.; Jin-Hua, J.; Cheng-Yu, H.; Ahmed Abro, Z. A smart insole for monitoring plantar pressure based on the fiber Bragg grating sensing technique. Text. Res. J. 2019, 89, 3433–3446. [Google Scholar] [CrossRef]

- Valldecabres, R.; Richards, J.; De Benito, A.M. The effect of match fatigue in elite badminton players using plantar pressure measurements and the implications to injury mechanisms. Sports Biomech. 2020, 19, 1–18. [Google Scholar] [CrossRef]

- Konings-Pijnappels, A.P.M.; Tenten-Diepenmaat, M.; Dahmen, R.; Verberne, S.K.; Dekker, J.; Twisk, J.W.R.; Roorda, L.D.; van der Leeden, M. Forefoot pathology in relation to plantar pressure distribution in patients with rheumatoid arthritis: A cross-sectional study in the Amsterdam Foot cohort. Gait Posture 2019, 68, 317–322. [Google Scholar] [CrossRef]

- Montero-Odasso, M.; Hachinski, V. Preludes to brain failure: Executive dysfunction and gait disturbances. Neurol. Sci. 2014, 35, 601–604. [Google Scholar] [CrossRef]

- Melvin, J.M.; Price, C.; Preece, S.; Nester, C.; Howard, D. An investigation into the effects of, and interaction between, heel height and shoe upper stiffness on plantar pressure and comfort. Footwear Sci. 2019, 11, 25–34. [Google Scholar] [CrossRef] [Green Version]

- Bonato, P. Wearable sensors/systems and their impact on biomedical engineering. IEEE Eng. Med. Biol. Mag. 2003, 22, 18–20. [Google Scholar] [CrossRef]

- Patel, S.; Park, H.; Bonato, P.; Chan, L.; Rodgers, M. A review of wearable sensors and systems with application in rehabilitation. J. Neuroeng. Rehabil. 2012, 9, 21. [Google Scholar] [CrossRef] [Green Version]

- Suresh, R.; Singh, C.; Hao, J.; Anand, S. Fibre Bragg grating sensors for plantar pressure monitoring at different walking speeds. Int. J. Biomed. Eng. Technol. 2014, 14, 34–45. [Google Scholar] [CrossRef]

- Lee, Y.C.; Lin, G.; Wang, M.J.J. Evaluating insole design with joint motion, plantar pressure and rating of perceived exertion measures. Work 2012, 41 (Suppl. 1), 1114–1117. [Google Scholar] [CrossRef] [Green Version]

- Ho, I.J.; Hou, Y.Y.; Yang, C.H.; Wu, W.L.; Chen, S.K.; Guo, L.Y. Comparison of plantar pressure distribution between different speed and incline during treadmill jogging. J. Sports Sci. Med. 2010, 9, 154. [Google Scholar]

- Komi, E.R.; Roberts, J.R.; Rothberg, S.J. Evaluation of thin, flexible sensors for time-resolved grip force measurement. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2007, 221, 1687–1699. [Google Scholar] [CrossRef] [Green Version]

- Vecchi, F.; Freschi, C.; Micera, S.; Sabatini, A.M.; Dario, P.; Sacchetti, R. Experimental evaluation of two commercial force sensors for applications in biomechanics and motor control. In Proceedings of the 5th Annual Conference of International Functional Electrical Simulation Society, Aalorg, Denmark, 18–24 June 2000. [Google Scholar]

- Ferguson-Pell, M.; Hagisawa, S.; Bain, D. Evaluation of a sensor for low interface pressure applications. Med. Eng. Phys. 2000, 22, 657–663. [Google Scholar] [CrossRef]

- Lebosse, C.; Bayle, B.; de Mathelin, M.; Renaud, P. Nonlinear modeling of low cost force sensors. In Proceedings of the 2008 IEEE International Conference on Robotics and Automation, Pasadena, CA, USA, 19–23 May 2008; IEEE: Piscataway, NJ, USA, 2008; pp. 3437–3442. [Google Scholar]

- Freschi, C.; Vecchi, F.; Micera, S.; Sabatini, A.M.; Dario, P. Force control during grasp using FES techniques: Preliminary results. In Proceedings of the 5th Annual Conference of the International Functional Electrical Stimulation Society (IFESS 2000), Aalborg, Denmark, 18–20 June 2000; pp. 17–24. [Google Scholar]

- Ali, S.; Osman, N.A.A.; Mortaza, N.; Eshraghi, A.; Gholizadeh, H.; Abas, W.A.B.B.W. Clinical investigation of the interface pressure in the trans-tibial socket with Dermo and Seal-In X5 liner during walking and their effect on patient satisfaction. Clin. Biomech. 2012, 27, 943–948. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kwon, J.; Park, J.H.; Ku, S.; Jeong, Y.; Paik, N.J.; Park, Y.L. A soft wearable robotic ankle-foot-orthosis for post-stroke patients. IEEE Robot. Autom. Lett. 2019, 4, 2547–2552. [Google Scholar] [CrossRef]

- Ponukumati, A.S.; Wu, X.; Kahng, P.W.; Skinner, J.; Paydarfar, J.A.; Halter, R.J. A system for characterizing intraoperative force distribution during operative laryngoscopy. IEEE Trans. Biomed. Eng. 2020, 67, 2616–2627. [Google Scholar] [CrossRef]

- Lao, S.; Edher, H.; Saini, U.; Sixt, J.; Salehian, A. A novel capacitance-based in-situ pressure sensor for wearable compression garments. Micromachines 2019, 10, 743. [Google Scholar] [CrossRef] [Green Version]

- Middleton, S.D.; Jenkins, P.J.; Muir, A.Y.; Anakwe, R.E.; McEachan, J.E. Variability in local pressures under digital tourniquets. J. Hand Surg. (Eur. Vol.) 2014, 39, 637–641. [Google Scholar] [CrossRef]

- Ouckama, R.; Pearsall, D.J. Evaluation of a flexible force sensor for measurement of helmet foam impact performance. J. Biomech. 2011, 44, 904–909. [Google Scholar] [CrossRef]

- Razak, A.H.A.; Zayegh, A.; Begg, R.K.; Wahab, Y. Foot plantar pressure measurement system: A review. Sensors 2012, 12, 9884–9912. [Google Scholar] [CrossRef] [Green Version]

- Buldt, A.K.; Forghany, S.; Landorf, K.B.; Levinger, P.; Murley, G.S.; Menz, H.B. Foot posture is associated with plantar pressure during gait: A comparison of normal, planus and cavus feet. Gait Posture 2018, 62, 235–240. [Google Scholar] [CrossRef]

- Park, J.W.; Kim, T.; Kim, D.; Hong, Y.; Gong, H.S. Measurement of finger joint angle using stretchable carbon nanotube strain sensor. PLoS ONE 2019, 14, e0225164. [Google Scholar] [CrossRef]

- Li, L.; He, R.; Soares, M.S.; Savović, S.; Hu, X.; Marques, C.; Min, R.; Li, X. Embedded FBG-based sensor for joint movement monitoring. IEEE Sens. J. 2021, 21, 26793–26798. [Google Scholar] [CrossRef]

- Zhang, B.; Lu, Q. A current review of foot disorder and plantar pressure alternation in the elderly. Phys. Act. Health 2020, 4, 95–106. [Google Scholar] [CrossRef]

- Saggio, G.; Orengo, G. Flex sensor characterization against shape and curvature changes. Sens. Actuators A Phys. 2018, 273, 221–231. [Google Scholar] [CrossRef]

- Saggio, G.; Riillo, F.; Sbernini, L.; Quitadamo, L.R. Resistive flex sensors: A survey. Smart Mater. Struct. 2015, 25, 013001. [Google Scholar] [CrossRef]

- Orengo, G.; Lagati, A.; Saggio, G. Modeling wearable bend sensor behavior for human motion capture. IEEE Sens. J. 2014, 14, 2307–2316. [Google Scholar] [CrossRef]

- Saggio, G. A novel array of flex sensors for a goniometric glove. Sens. Actuators A Phys. 2014, 205, 119–125. [Google Scholar] [CrossRef]

- Abro, Z.A.; Yi-Fan, Z.; Nan-Liang, C.; Cheng-Yu, H.; Lakho, R.A.; Halepoto, H. A novel flex sensor-based flexible smart garment for monitoring body postures. J. Ind. Text. 2019, 49, 262–274. [Google Scholar] [CrossRef]

- Wang, L.; Jones, D.; Chapman, G.J.; Siddle, H.J.; Russell, D.A.; Alazmani, A.; Culmer, P. A review of wearable sensor systems to monitor plantar loading in the assessment of diabetic foot ulcers. IEEE Trans. Biomed. Eng. 2019, 67, 1989–2004. [Google Scholar] [CrossRef] [Green Version]

- Dipietro, L.; Sabatini, A.M.; Dario, P. A survey of glove-based systems and their applications. IEEE Trans. Syst. Man Cybern. Part C 2008, 38, 461–482. [Google Scholar] [CrossRef]

- Saggio, G.; Bianchi, L.; Castelli, S.; Santucci, M.B.; Fraziano, M.; Desideri, A. In vitro analysis of pyrogenicity and cytotoxicity profiles of flex sensors to be used to sense human joint postures. Sensors 2014, 14, 11672–11681. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Papi, E.; Bo, Y.N.; McGregor, A.H. A flexible wearable sensor for knee flexion assessment during gait. Gait Posture 2018, 62, 480–483. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Zhao, Y.; Zhang, X. Design and fabrication of a thin and soft tactile force sensor array based on conductive rubber. Sens. Rev. 2012, 32, 273–279. [Google Scholar] [CrossRef]

- Nag, A.; Menzies, B.; Mukhopadhyay, S.C. Performance analysis of flexible printed sensors for robotic arm applications. Sens. Actuators A Phys. 2018, 276, 226–236. [Google Scholar] [CrossRef]

- Almassri, A.M.; Wan Hasan, W.Z.; Ahmad, S.A.; Ishak, A.J.; Ghazali, A.M.; Talib, D.N.; Wada, C. Pressure sensor: State of the art, design, and application for robotic hand. J. Sens. 2015, 2015, 846487. [Google Scholar] [CrossRef] [Green Version]

- Abro, Z.A.; Zhang, Y.F.; Hong, C.Y.; Lakho, R.A.; Chen, N.L. Development of a smart garment for monitoring body postures based on FBG and flex sensing technologies. Sens. Actuators A Phys. 2018, 272, 153–160. [Google Scholar] [CrossRef]

- Shu, L.; Hua, T.; Wang, Y.; Li, Q.; Feng, D.D.; Tao, X. In-shoe plantar pressure measurement and analysis system based on fabric pressure sensing array. IEEE Trans. Inf. Technol. Biomed. 2010, 14, 767–775. [Google Scholar]

- Lin, F.; Wang, A.; Zhuang, Y.; Tomita, M.R.; Xu, W. Smart insole: A wearable sensor device for unobtrusive gait monitoring in daily life. IEEE Trans. Ind. Inform. 2016, 12, 2281–2291. [Google Scholar] [CrossRef]

- Roth, N.; Martindale, C.F.; Eskofier, B.M.; Gaßner, H.; Kohl, Z.; Klucken, J. Synchronized sensor insoles for clinical gait analysis in home-monitoring applications. Curr. Dir. Biomed. Eng. 2018, 4, 433–437. [Google Scholar] [CrossRef]

- Jung, P.G.; Oh, S.; Lim, G.; Kong, K. A mobile motion capture system based on inertial sensors and smart shoes. J. Dyn. Syst. Meas. Control 2014, 136, 011002. [Google Scholar] [CrossRef]

- Lee, S.S.; Choi, S.T.; Choi, S.I. Classification of gait type based on deep learning using various sensors with smart insole. Sensors 2019, 19, 1757. [Google Scholar] [CrossRef] [Green Version]

| (a) Flexi Force Sensor | |||

|---|---|---|---|

| Particular | Typical Performance | Evaluation Conditions | |

| Thickness | 0.008″ (0.208 mm) | N/A | |

| Sensing Area | 0.375″ (9.53 mm) | N/A | |

| Connector | 3-pin male square pin | N/A | |

| Force ranges | Sensor A201-1(4.4 N) Sensor A201-25(110 N) Sensor A201-100(440 N) | N/A | |

| Linearity | ±3% of full scale | Line drawn from 0 to 50% load | |

| Hysteresis | <4.5% of the full scale | Conditioned sensor, 80% of full force applied | |

| Repeatability | <±2.5% | Conditioned sensor, 80% of full force applied | |

| Drift | <5% per logarithmic time scale | Constant load of 111 N (25 lb) | |

| Response time | <5 µs | Impact load put recorded on an oscilloscope | |

| Operating temperature | −9 °C to 60 °C | The time required for the sensor to respond to an input force | |

| (b) Flex Sensor | |||

| Flex Sensor Length | Flex Sensor Frequency | Maximum Output | Measurement Sensitivity |

| 110 (mm) | 30 (Hz) | 240 (Vout) | 0.56–0.94 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lakho, R.A.; Abro, Z.A.; Chen, J.; Min, R. Smart Insole Based on Flexi Force and Flex Sensor for Monitoring Different Body Postures. Sensors 2022, 22, 5469. https://doi.org/10.3390/s22155469

Lakho RA, Abro ZA, Chen J, Min R. Smart Insole Based on Flexi Force and Flex Sensor for Monitoring Different Body Postures. Sensors. 2022; 22(15):5469. https://doi.org/10.3390/s22155469

Chicago/Turabian StyleLakho, Rafique Ahmed, Zamir Ahmed Abro, Jun Chen, and Rui Min. 2022. "Smart Insole Based on Flexi Force and Flex Sensor for Monitoring Different Body Postures" Sensors 22, no. 15: 5469. https://doi.org/10.3390/s22155469