A Study on the Applicability of the Impact-Echo Test Using Semi-Supervised Learning Based on Dynamic Preconditions

Abstract

:1. Introduction

2. Theoretical Background

2.1. Impact-Echo

2.2. Dynamic Behavior of Concrete Defects

2.3. Principal Component Analysis

2.4. Semi-Supervised Learning

3. Materials and Test Procedure

3.1. Materials and Preparation of Specimens

3.2. IE Test Procedure

4. Results and Discussion

4.1. Experimental Results of the Impact Resonance Test for Flexural and Thickness Modes

4.1.1. Analysis of FFT Domains

4.1.2. Feature Extraction with PCA

4.2. Prediction and Visualization of Controlled Delaminations with SL and SSL

4.2.1. Analysis of SL Model Training and Prediction

4.2.2. Analysis of SSL Model Training and Prediction

4.2.3. C-Scan Images Predicted with SL and SSL for Principal Components

4.3. Field Application and Validation of Two Methods

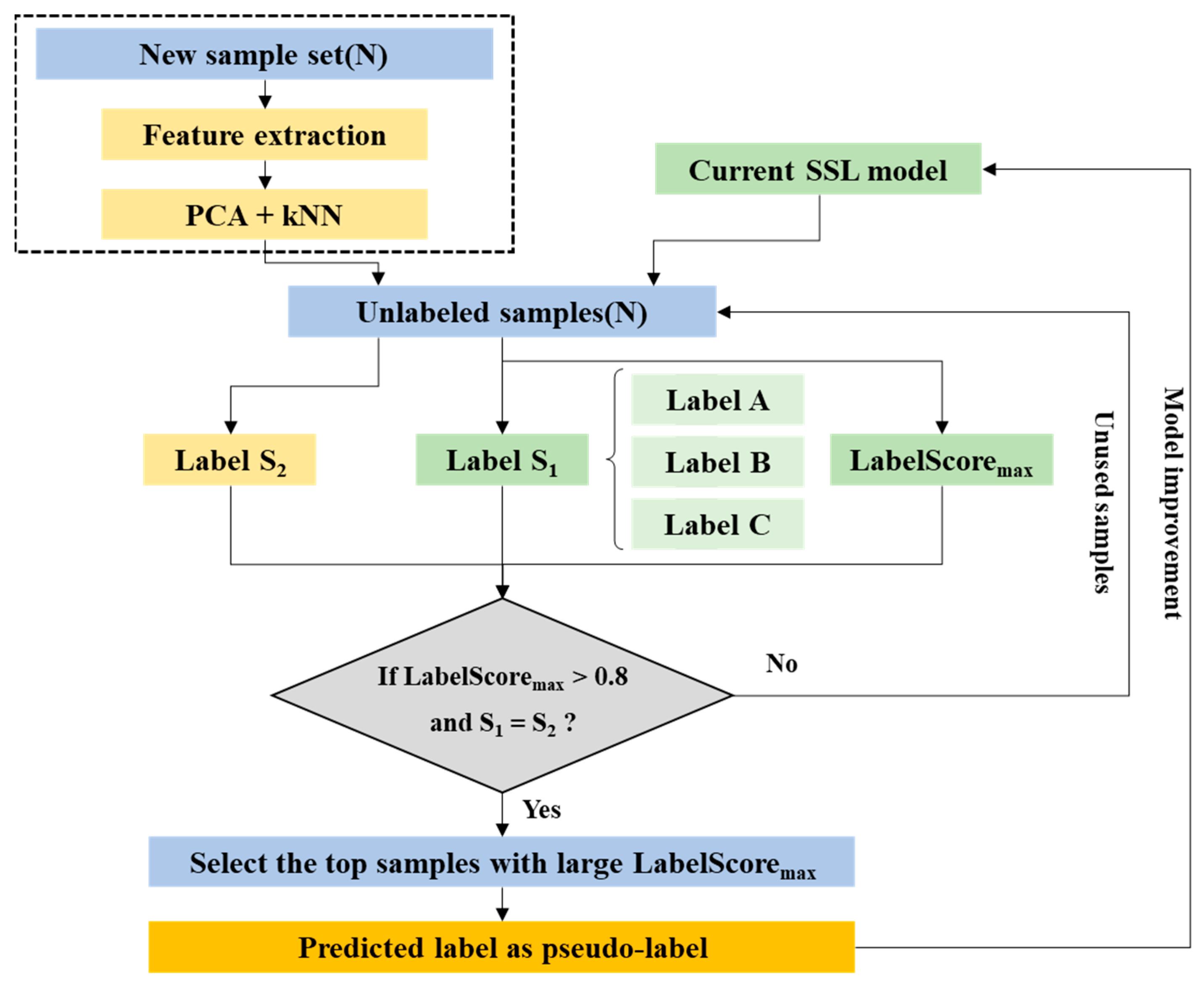

4.4. Flowchart for Using the SSL Model in a Concrete Field

5. Conclusions

- The limitations of previous studies that could not reflect various physical characteristics from valuable cases without synthetic data were resolved using verified reliable data.

- PCA efficiently and clearly extracted frequency domain features from typical IE data that reflect dynamic behavior based on repetitive body waves.

- Non-experts can readily use a conventional SSL algorithm, which can also be applied to actual bridge data.

- Moreover, an SSL model was developed in advance in this study using the specimens with simulated defects as unlabeled data, the unlabeled field data were verified, and the following summaries were derived.

- In comparison with the previous model, which used the entire frequency domain, an algorithm that can quickly and accurately determine the presence or absence of defects through dynamic preconditions was proposed.

- Compared with SL, the proposed SSL model can accurately determine the presence or absence of defects by about 7–8% or more through domain correction of inaccurate label data and updating of new specimen characteristics.

- In the future, the field data that is difficult to label can be applied by reflecting the characteristics of the new specimen.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| ELM | Extreme learning machine |

| EMD | Empirical mode decomposition |

| FFT | Fast Fourier transform |

| GPR | Ground penetrating radar |

| HHT | Hilbert–Huang Transform |

| IE | Impact Echo |

| IRT | Infrared thermography |

| MASW | Multichannel Analysis of Surface Waves |

| NDE | Nondestructive evaluation |

| PC | Principal component |

| PCA | Principal component analysis |

| RMS | Root mean square |

| SASW | Spectral Analysis of Surface Waves |

| SL | Supervised learning |

| SSL | Semi supervised learning |

| STFT | Short-time Fourier transform |

| a | Plate width |

| b | Plate height |

| Cp | P-wave velocity |

| DT | Transpose matrix |

| E | Young’s modulus |

| f | Frequency |

| h | Plate thickness |

| t | Time |

| v | Poisson’s ratio |

| The two-dimensional differential Laplace operator | |

| β | Shape factor |

| μ | Average |

| Mass density per unit area of plate surface | |

| λ | Eigenvalue |

References

- Dunker, K.F.; Rabbat, B.G. Performance of highway bridges. Concr. Int. 1990, 12, 40–42. [Google Scholar]

- Madanat, S. Incorporating inspection decisions in pavement management. Transp. Res. B Methodol. 1993, 27, 425–438. [Google Scholar] [CrossRef]

- Alamayreh, M.I.; Alahmer, A.; Younes, M.B.; Bazlamit, S.M. Pre-Cooling Concrete System in Massive Concrete Production: Energy Analysis and Refrigerant Replacement. Energies 2022, 15, 1129. [Google Scholar] [CrossRef]

- Li, P.; Li, W.; Sun, Z.; Shen, L.; Sheng, D. Development of sustainable concrete incorporating seawater: A critical review on cement hydration. microstructure and mechanical strength. Cem. Concr. Compos. 2021, 121, 104100. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J.M. Concrete-Microstructure, Properties, and Materials, 3rd ed.; McGraw-Hill: New York, NY, USA, 1993. [Google Scholar]

- Gucunski, N. Nondestructive Testing to Identify Concrete Bridge Deck Deterioration; Transportation Research Board: Washington, DC, USA, 2013. [Google Scholar]

- Rhee, J.Y.; Choi, J.J.; Kee, S.H. Evaluation of the depth of deteriorations in concrete bridge decks with asphalt overlays using air-coupled GPR: A case study from a pilot bridge on Korean expressway. Int. J. Concr. Struct. Mater. 2019, 13, 399–415. [Google Scholar] [CrossRef] [Green Version]

- American Society of Civil Engineers (ASCE). ASCE Report Card for America’s Infrastructure. 2017. Available online: https://www.infrastructurereportcard.org/ (accessed on 30 June 2022).

- Huston, D.; Cui, J.; Burns, D.; Hurley, D. Concrete bridge deck condition assessment with automated multisensor techniques. Struct. Infrastruct. Eng. 2011, 7, 613–623. [Google Scholar] [CrossRef]

- Oh, T.; Kee, S.-H.; Arndt, R.W.; Popovics, J.S.; Zhu, J. Comparison of NDT methods for assessment of a concrete bridge deck. J. Eng. Mech. 2013, 139, 305–314. [Google Scholar] [CrossRef]

- Ghahremani, B.; Enshaeian, A.; Rizzo, P. Bridge Health Monitoring Using Strain Data and High-Fidelity Finite Element Analysis. Sensors 2022, 22, 5172. [Google Scholar] [CrossRef]

- Romanevich, K.V.; Lebedeb, M.O.; Andrianov, S.V.; Mulev, S.N. Integrated Interpretation of the Results of Long-Term Geotechnical Monitoring in Underground Tunnels Using the Electromagnetic Radiation Method. Foundations 2022, 2, 562–580. [Google Scholar] [CrossRef]

- Zhong, B.; Zhu, J. Applications of Stretching Technique and Time Window Effects on Ultrasonic Velocity Monitoring in Concrete. Appl. Sci. 2022, 12, 7130. [Google Scholar] [CrossRef]

- Carino, N.J.; Sansalone, M.; Hsu, N.N. Flaw detection in concrete by frequency spectrum analysis of impact-echo waveforms. In International Advances in Nondestructive Testing; McGonnagle, W.J., Ed.; Gordon & Breach Science Publishers: New York, NY, USA, 1985; Volume 11, pp. 117–146. [Google Scholar]

- Carino, N.J.; Sansalone, M. Impact-Echo: A New method for inspecting construction materials. In Proceeding of Nondestructive Testing and Evaluation of Materials for Construction; University of Illinois Urbana–Champaign: Urbana, IL, USA, 1988; pp. 209–223. [Google Scholar]

- Sansalone, M.; Carino, N.J. Detecting delaminations in concrete slabs with and without overlays using the impact-echo method. ACI Mater. J. 1989, 86, 175–184. [Google Scholar]

- Kee, S.-H.; Oh, T.; Popovics, J.S.; Arndt, R.W.; Zhu, J. Nondestructive bridge deck testing with air-coupled impact-echo and infrared thermography. J. Bridge Eng. 2012, 17, 928–939. [Google Scholar] [CrossRef]

- Kim, D.S.; Seo, W.S.; Lee, K.M. IE-SASW method for nondestructive evaluation of concrete structure. NDT E Int. 2006, 39, 143–154. [Google Scholar] [CrossRef]

- Baggens, O.; Ryden, N. Systematic errors in Impact-echo thickness estimation due to near field e_ects. NDT E Int. 2015, 69, 16–27. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.K.; Yan, W.; Cui, D.M. Concrete condition assessment using impact-echo method and extreme learning machines. Sensors 2016, 16, 447. [Google Scholar] [CrossRef]

- Farrar, C.R.; Worden, K. Structural Health Monitoring: A Machine Learning Perspective; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Baek, S.; Yoon, H.S.; Kim, D.Y. Abnormal vibration detection in the bearing-shaft system via semi-supervised classification of accelerometer signal patterns. Procedia Manuf. 2020, 51, 316–323. [Google Scholar] [CrossRef]

- Igual, J.; Salazar, A.; Safont, G.; Vergara, L. Semi-supervised Bayesian classification of materials with impact-echo signals. Sensors 2015, 15, 11528–11550. [Google Scholar] [CrossRef]

- Shen, W.; Li, D.; Ou, J. Modeling dispersive waves in cracked rods using the wavelet-based higher-order rod elements. Int. J. Mech. Sci. 2020, 166, 105236. [Google Scholar] [CrossRef]

- Tolstoy, I.; Usdin, E. Dispersive properties of stratified elastic and liquid media: A ray theory. Geophysics 1953, 18, 844–870. [Google Scholar] [CrossRef]

- Caliendo, C.; Hamidullah, M. Zero-group-velocity acoustic waveguides for high-frequency resonators. J. Phys. D Appl. Phys. 2017, 50, 474002. [Google Scholar] [CrossRef]

- Gibson, A.; Popovics, J.S. Lamb wave basis for impact-echo method analysis. J. Eng. Mech. 2005, 131, 438–443. [Google Scholar] [CrossRef]

- Ryden, N.; Park, C. A combined multichannel impact-echo and surface wave analysis scheme for nondestructive thickness and sti_ness evaluation of concrete slabs. In Proceedings of the 6th International Symposium on NDT in Civil Engineering, Saint Louis, MO, USA, 14–18 August 2006; pp. 247–253. [Google Scholar]

- Joglekar, D.M.; Mitra, M. Nonlinear analysis of flexural wave propagation through 1D waveguides with a breathing crack. J. Sound Vib. 2015, 344, 242–257. [Google Scholar] [CrossRef]

- Kim, D.S.; Kim, N.R.; Seo, W.S. Time-frequency analysis for impact echo-SASW (IE-SASW) method. Key Eng. Mater. 2004, 270–273, 1529–1534. [Google Scholar] [CrossRef]

- Lin, C.C.; Liu, P.L.; Yeh, P.L. Application of empirical mode decomposition in the impact-echo test. NDT E Int. 2009, 42, 589–598. [Google Scholar] [CrossRef]

- Zhang, Y.; Xie, Z.H. Ensemble empirical mode decomposition of impact-echo data for testing concrete structures. NDT E Int. 2012, 51, 74–84. [Google Scholar] [CrossRef]

- Bouden, T.; Djerfi, F.; Dib, S.; Nibouche, M. Hilbert Huang Transform for enhancing the impact-echo method of nondestructive testing. J. Autom. Syst. Eng. 2012, 6, 172–184. [Google Scholar]

- Daubechies, I. Ten Lectures on Wavelets; Society for Industrial and Applied Mathematics: Philadelphia, PA, USA, 1992. [Google Scholar]

- Gucunski, N.; Romero, F.; Kruschwitz, S.; Feldmann, R.; Abu-Hawash, A.; Dunn, M. Multiple complementary nondestructive evaluation technologies for condition assessment of concrete bridge decks. Transp. Res. Rec. 2010, 2201, 34–44. [Google Scholar] [CrossRef]

- Lim, M.K.; Cao, H. Combining multiple NDT methods to improve testing effectiveness. Constr. Build. Mater. 2013, 38, 1310–1315. [Google Scholar] [CrossRef]

- Varnavina, A.V.; Sneed, L.H.; Khamzin, A.K.; Torgashov, E.V.; Anderson, N.L. An attempt to describe a relationship between concrete deterioration quantities and bridge deck condition assessment techniques. J. Appl. Geophys. 2017, 142, 38–48. [Google Scholar] [CrossRef]

- Senin, S.F.; Hamid, R. Ground penetrating radar wave attenuation models for estimation of moisture and chloride content in concrete slab. Constr. Build. Mater. 2016, 106, 659–669. [Google Scholar] [CrossRef]

- Tarighat, A.; Miyamoto, A. Fuzzy concrete bridge deck condition rating method for practical bridge management system. Expert Syst. Appl. 2009, 36, 12077–12085. [Google Scholar] [CrossRef]

- Ying, Y.; Garrett, J.H.; Oppenheim, I.J.; Soibelman, L.; Harley, J.B.; Shi, J.; Jin, Y. Toward data-driven structural health monitoring: Application of machine learning and signal processing to damage detection. J. Comput. Civ. Eng. 2013, 27, 667–680. [Google Scholar] [CrossRef]

- Park, J.Y.; Yoon, Y.G.; Oh, T.K. Prediction of Concrete Strength with P-, S-, R-Wave Velocities by Support Vector Machine (SVM) and Artificial Neural Network (ANN). Appl. Sci. 2019, 9, 4053. [Google Scholar] [CrossRef] [Green Version]

- Sadowski, Ł.; Nikoo, M.; Nikoo, M. Principal component analysis combined with a self organization feature map to determine the pull-off adhesion between concrete layers. Constr. Build. Mater. 2015, 78, 386–396. [Google Scholar] [CrossRef]

- Li, B.; Cao, J.; Xiao, J.Z.; Zhang, X.; Wang, H.F. Robotic impact-echo non-destructive evaluation based on FFT and SVM. In Proceedings of the 11th World Congress on Intelligent Control and Automation, Shenyang, China, 29 June–4 July 2014; pp. 2854–2859. [Google Scholar]

- He, B.; Xu, D.; Nian, R.; van Heeswijk, M.; Yu, Q.; Miche, Y.; Lendasse, A. Fast face recognition via sparse coding and extreme learning machine. Cognit. Comput. 2014, 6, 264–277. [Google Scholar] [CrossRef] [Green Version]

- Bazi, Y.; Alajlan, N.; Melgani, F.; AlHichri, H.; Malek, S.; Yager, R.R. Differential evolution extreme learning machine for the classification of hyperspectral images. IEEE Geosci. Remote Sens. Lett. 2014, 11, 1066–1070. [Google Scholar] [CrossRef]

- Kaya, Y.; Uyar, M. A hybrid decision support system based on rough set and extreme learning machine for diagnosis of hepatitis disease. Appl. Soft Comput. 2013, 13, 3429–3438. [Google Scholar] [CrossRef]

- Yang, X.; Mao, K. Reduced ELMs for causal relation extraction from unstructured text. IEEE Intell. Syst. 2013, 28, 48–52. [Google Scholar]

- Huang, G.; Song, S.; Gupta, J.N.; Wu, C. Semi-supervised and unsupervised extreme learning machines. IEEE Trans Cybern. 2014, 44, 2405–2417. [Google Scholar] [CrossRef]

- Seliya, N.; Khoshgoftaar, T.M. Software quality estimation with limited fault data: A semi-supervised learning perspective. Softw. Qual. J. 2007, 15, 327–344. [Google Scholar] [CrossRef]

- Schwenker, F.; Trentin, E. Pattern classification and clustering: A review of partially supervised learning approaches. Pattern Recognit. Lett. 2014, 37, 4–14. [Google Scholar] [CrossRef]

- Wu, H.; Yu, Z.; Wang, Y. Real-time FDM machine condition monitoring and diagnosis based on acoustic emission and hidden semi-markov model. Int. J. Adv. Manuf. Technol. 2017, 90, 2027–2036. [Google Scholar] [CrossRef]

- Zhao, Y.; Ball, R.; Mosesian, J.; de Palma, J.F.; Lehman, B. Graph-based semi-supervised learning for fault detection and classification in solar photovoltaic arrays. IEEE Trans. Power Electron. 2014, 30, 2848–2858. [Google Scholar] [CrossRef]

- Jiang, L.; Xuan, J.; Shi, T. Feature extraction based on semi-supervised kernel marginal fisher analysis and its application in bearing fault diagnosis. Mech. Syst. Signal Process. 2013, 41, 113–126. [Google Scholar] [CrossRef]

- Igual, J. Hierarchical clustering of materials with defects using impact-echo testing. IEEE Trans. Instrum. Meas. 2020, 69, 5316–5324. [Google Scholar] [CrossRef]

- Sansalone, M. Impact-echo: The complete story. ACI Struct. J. 1996, 94, 777–786. [Google Scholar]

- Tawhed, W.F.; Gassman, S.L. Damage assessment of concrete bridge decks using impact-echo method. ACI Mater. J. 2002, 99, 273–281. [Google Scholar]

- Sansalone, M.J.; Streett, W.B. Impact-Echo: Nondestructive Evaluation for Concrete and Masonry; Bullbrier Press: Ithaca, NY, USA, 1997. [Google Scholar]

- Zhu, J.; Popovics, J.S. Noncontact detection of surfacewaves in concrete using an air-coupled sensor. Rev. Progr. Quant. Non-Destruct. Eval. 2002, 20, 1261–1268. [Google Scholar]

- Zhu, J.; Popovics, J.S. Imaging concrete structures using aircoupled impact-echo. J. Eng. Mech. 2007, 133, 628–640. [Google Scholar] [CrossRef]

- Ventsel, E.S.; Krauthammer, T. Thin Plates and Shells: Theory, Analysis, and Application; Marcel Dekker, Inc.: New York, NY, USA, 2001. [Google Scholar]

- Mindlin, R.D. Influence of rotary inertia and shear on flexural motions of isotropic, elastic plates. J. Appl. Mech. 1951, 18, 31–38. [Google Scholar] [CrossRef]

- Oh, T.K.; Popovics, J.S. Application of impact resonance C-scan stack images to evaluate bridge deck conditions. J. Infrastruct. Syst. 2015, 21, 04014029. [Google Scholar] [CrossRef]

- Hotelling, H. Analysis of a complex of statistical variables into principal components. J. Educ. Psychol. 1933, 24, 417–441. [Google Scholar] [CrossRef]

- Jollie, I.T. Principal Component Analysis, 2nd ed.; Springer Science+Business Media: New York, NY, USA, 2002; pp. 1–27. [Google Scholar]

- Choi, I.H.; Son, J.A.; Koo, J.B.; Yoon, Y.G.; Oh, T.K. Damage assessment of porcelain insulators through principal component analysis associated with frequency response signals. Appl. Sci. 2019, 9, 3150. [Google Scholar] [CrossRef] [Green Version]

- Chapelle, O.; Schölkopf, B.; Zien, A. Semi-Supervised Learning; MIT Press: Cambridge, MA, USA, 2006; Available online: https://mitpress.mit.edu/books/semi-supervised-learning (accessed on 30 March 2022).

- Van Engelen, J.E.; Hoos, H.H. A survey on semi-supervised learning. Mach. Learn. 2020, 109, 373–440. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Ko, B.; Choi, H.J. Naive semi-supervised deep learning using pseudo-label. Peer-to-Peer Netw. Appl. 2019, 12, 1358–1368. [Google Scholar] [CrossRef]

| Slab | Delamination | Width (mm) | Height (mm) | Depth (mm) | Type |

|---|---|---|---|---|---|

| Slab A | DL-A1 | 200 | 200 | 60 | Plastic sheet |

| DL-A2 | ø300 | - | 60 | Soft form | |

| DL-A3 | ø200 | - | 60 | Soft form | |

| DL-A4 | 400 | 600 | 60 | Plastic sheet | |

| DL-A5 | 300 | 300 | 60 | Plastic sheet | |

| Slab B | DL-B1 | 500 | 500 | 25 | Plastic sheet |

| DL-B2 | 750 | 750 | 25 | Plastic sheet | |

| DL-B3 | 1000 | 1000 | 25 | Plastic sheet | |

| DL-B4 | 1000 | 1000 | 50 | Plastic sheet | |

| DL-B5 | 750 | 750 | 50 | Plastic sheet | |

| DL-B6 | 500 | 500 | 50 | Plastic sheet | |

| Slab C | DL-C1 | 300 | 300 | 65 | Thin form (2 mm) |

| DL-C2 | 300 | 300 | 65 | Thin form (1 mm) | |

| DL-C3 | 600 | 600 | 65 | Thin form (1 mm) | |

| DL-C4 | 600 | 600 | 65 | Thin form (2 mm) | |

| DL-C5 | 600 | 600 | 65 | Thin form (2 mm) | |

| DL-C6 | 600 | 450 | 65 | Thin form (2 mm) | |

| DL-C7 | 600 | 450 | 150 | Thin form (1 mm) |

| Type | a/h | Dominant Flexural Mode | Type | a/h | Dominant Flexural Mode |

|---|---|---|---|---|---|

| Sound region | - | x | - | - | - |

| DL-A1 | 3.33 | x | DL-A2 | 5 | x |

| DL-A3 | 3.33 | x | DL-A4 | 10 | o |

| DL-A5 | 5 | x | DL-B1 | 20 | o |

| DL-B2 | 30 | o | DL-B3 | 40 | o |

| DL-B4 | 20 | o | DL-B5 | 15 | o |

| DL-B6 | 10 | o | DL-C1 | 4.62 | x |

| DL-C2 | 4.62 | x | DL-C3 | 9.23 | o |

| DL-C4 | 9.23 | o | DL-C5 | 9.23 | o |

| DL-C6 | 9.23 | o | DL-C7 | 4 | x |

| Types | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 |

|---|---|---|---|---|---|---|---|---|

| Oh and Popovics | Good | Good | Poor | Poor | Fair | Good | Good | Poor |

| SL model | Fair | Poor | Poor | Poor | Fair | Good | Fair | Poor |

| SSL model | Good | Fair | Poor | Poor | Fair | Good | Good | Poor |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoon, Y.-G.; Kim, C.-M.; Oh, T.-K. A Study on the Applicability of the Impact-Echo Test Using Semi-Supervised Learning Based on Dynamic Preconditions. Sensors 2022, 22, 5484. https://doi.org/10.3390/s22155484

Yoon Y-G, Kim C-M, Oh T-K. A Study on the Applicability of the Impact-Echo Test Using Semi-Supervised Learning Based on Dynamic Preconditions. Sensors. 2022; 22(15):5484. https://doi.org/10.3390/s22155484

Chicago/Turabian StyleYoon, Young-Geun, Chung-Min Kim, and Tae-Keun Oh. 2022. "A Study on the Applicability of the Impact-Echo Test Using Semi-Supervised Learning Based on Dynamic Preconditions" Sensors 22, no. 15: 5484. https://doi.org/10.3390/s22155484

APA StyleYoon, Y.-G., Kim, C.-M., & Oh, T.-K. (2022). A Study on the Applicability of the Impact-Echo Test Using Semi-Supervised Learning Based on Dynamic Preconditions. Sensors, 22(15), 5484. https://doi.org/10.3390/s22155484