Analysis of Pressure Fluctuation Characteristics of Central Swirl Combustors Based on Empirical Mode Decomposition

Abstract

:1. Introduction

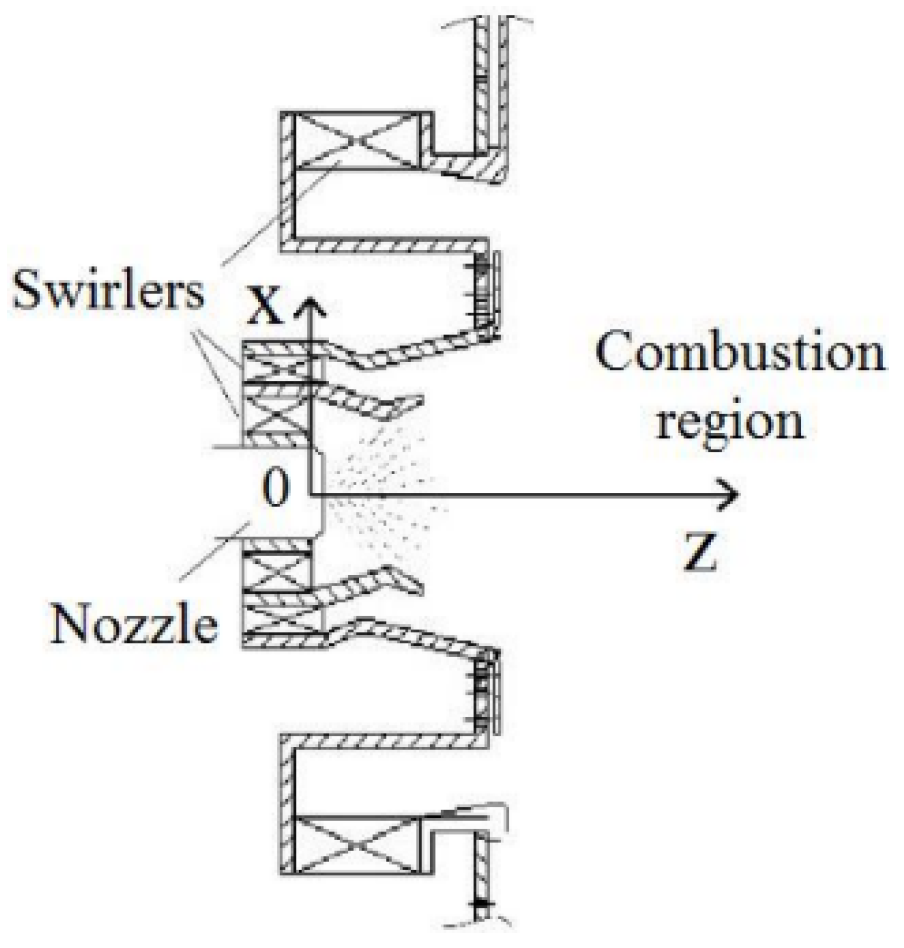

2. Experimental Facilities and Test Conditions

2.1. Test Structure and Measurement System

2.2. Test Conditions

- is the fluid density;

- is the kinematic viscosity of a fluid;

- is the characteristic linear dimension;

- is the dynamic viscosity of a fluid;

3. Introduction of Data Processing Method

3.1. Introduction to Empirical Mode Decomposition

- (1)

- All local maximum points and all local minimum points in the original signal are obtained;

- (2)

- The upper envelope and the lower envelope are obtained by fitting the extreme points with cubic spline interpolation, so that contents:

- (3)

- The mean value is calculated for the upper envelope and the lower envelope:

- (4)

- Obtain signal local details :

- (5)

- If contents the conditions are defined by IMF, take as the first IMF , then . If not, is regarded as the original signal and the above steps are carried out until of the m-th time contents the conditions. Namely:where is the mean value of upper and lower envelope; contents the definition of IMF, that is the first IMF component screened, then:

- (6)

- The first IMF is eliminated from the original signal to obtain the residue , namely:

- (7)

- Take as the original signal and repeat the above steps to obtain multiple IMF and final residue :

- (8)

- When the decomposition process is completed, the original signal can be expressed as:

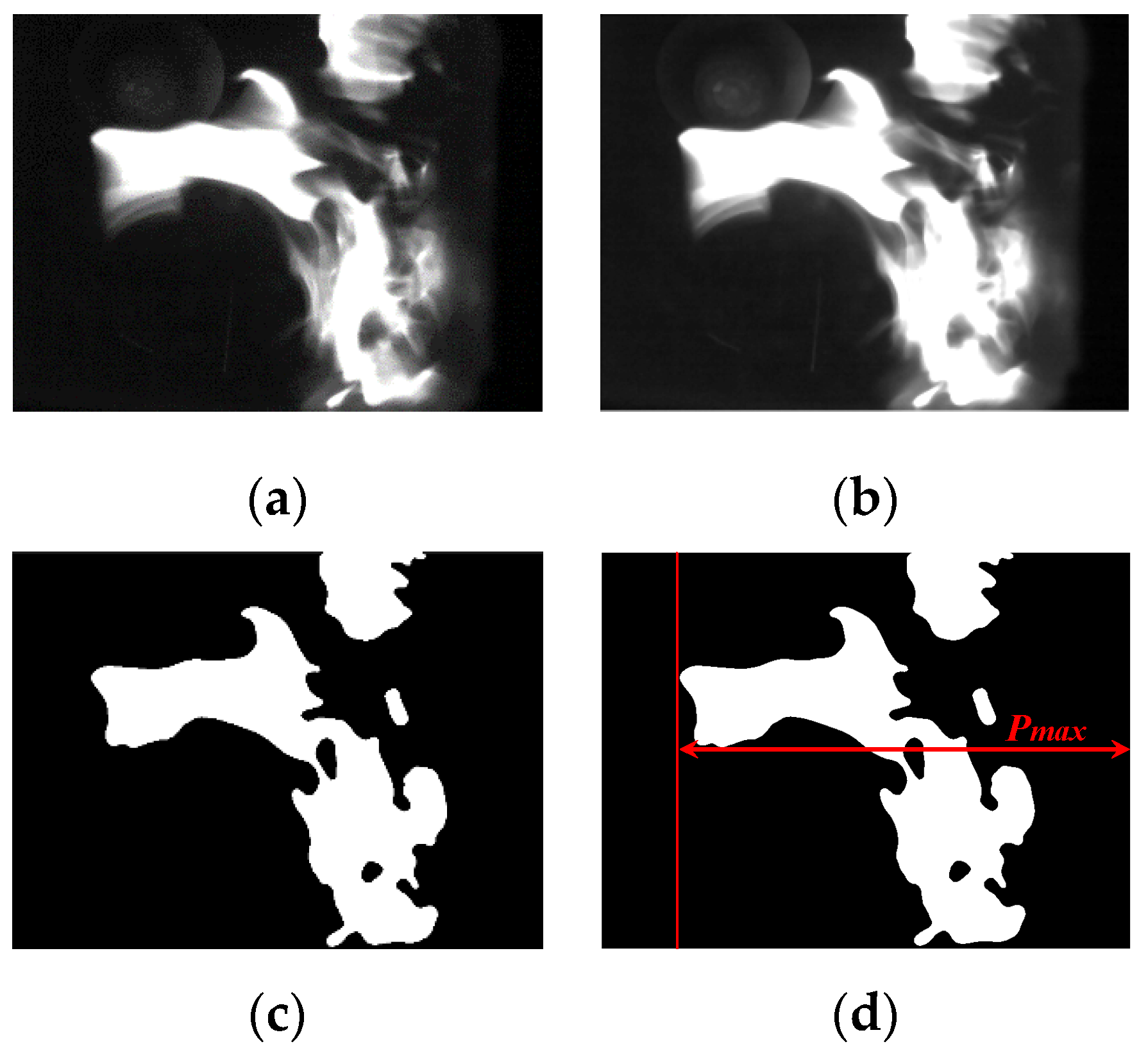

3.2. Introduction to Flame Image Boundary Identification Method

4. Analysis of Test Results

4.1. Analysis of Test Results of M Combustor

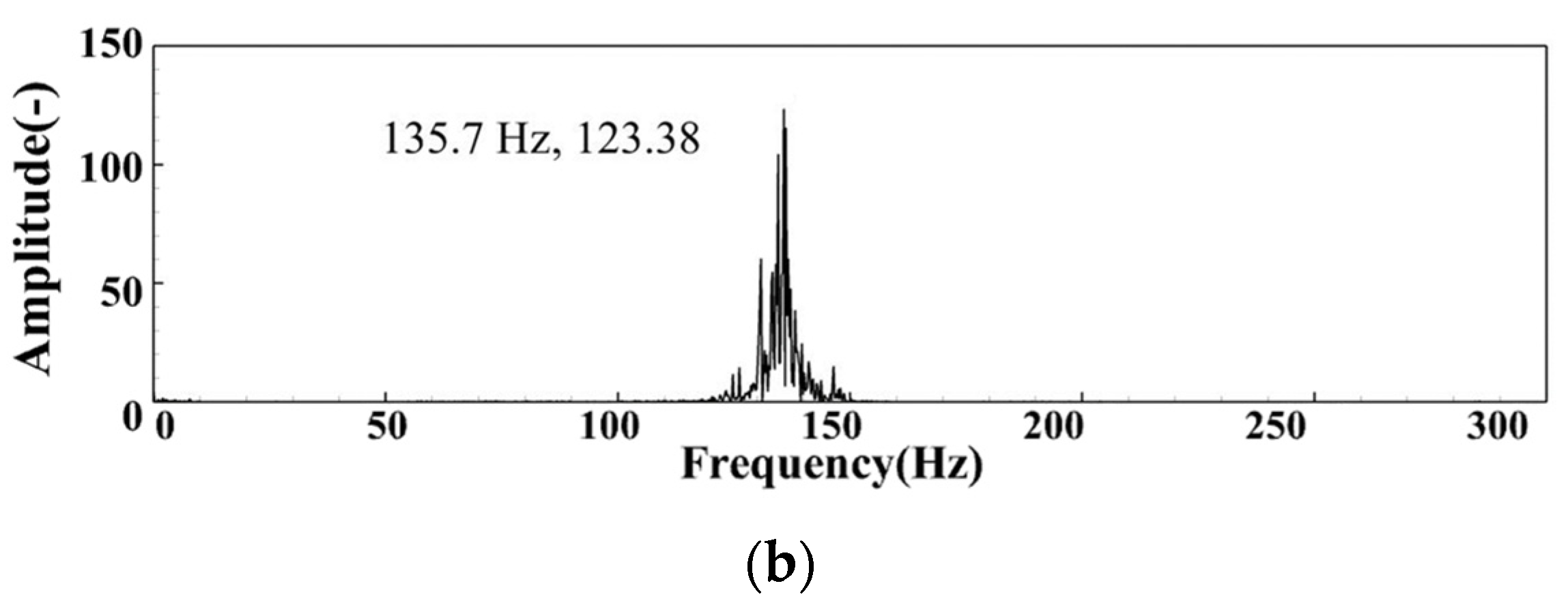

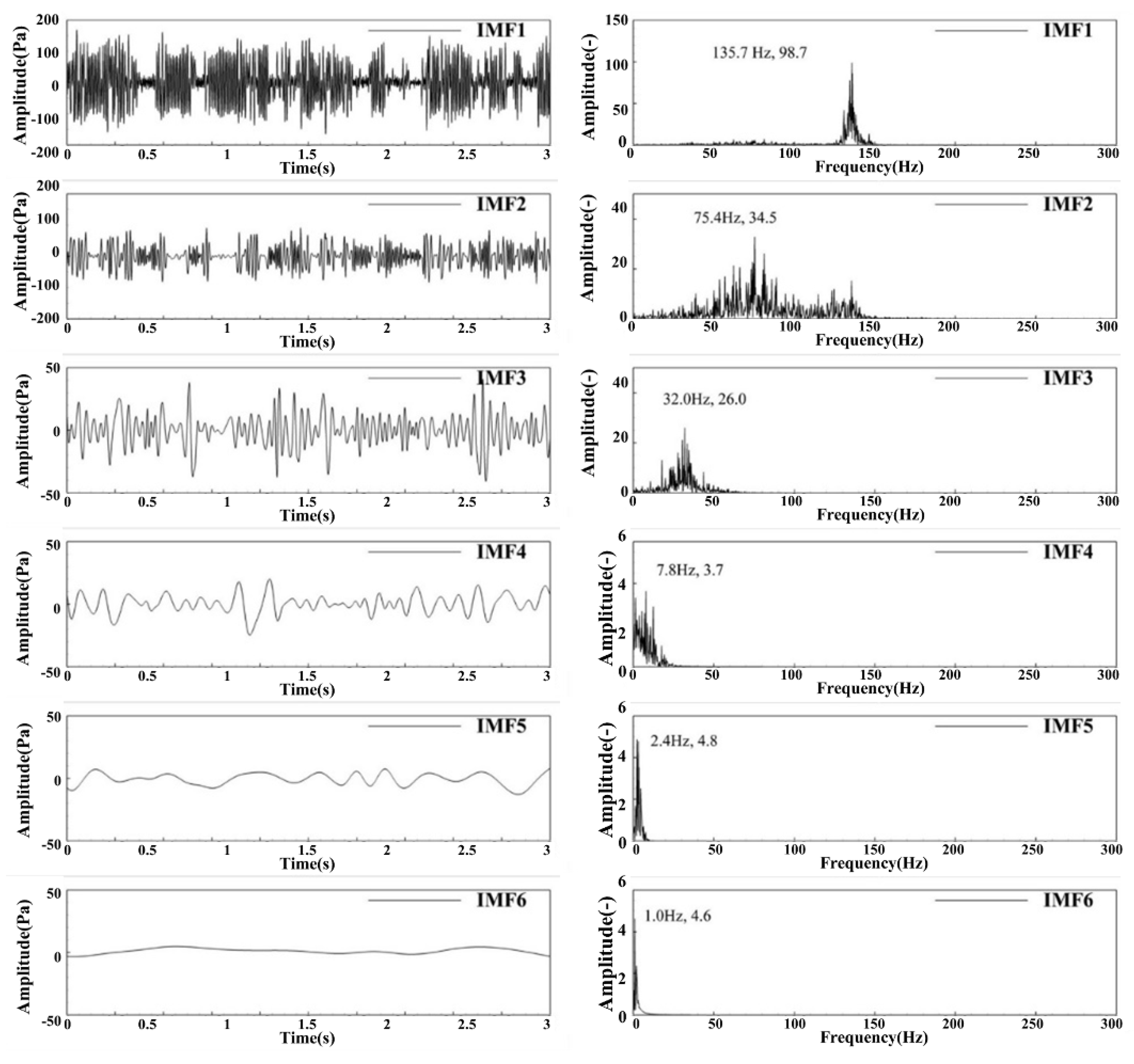

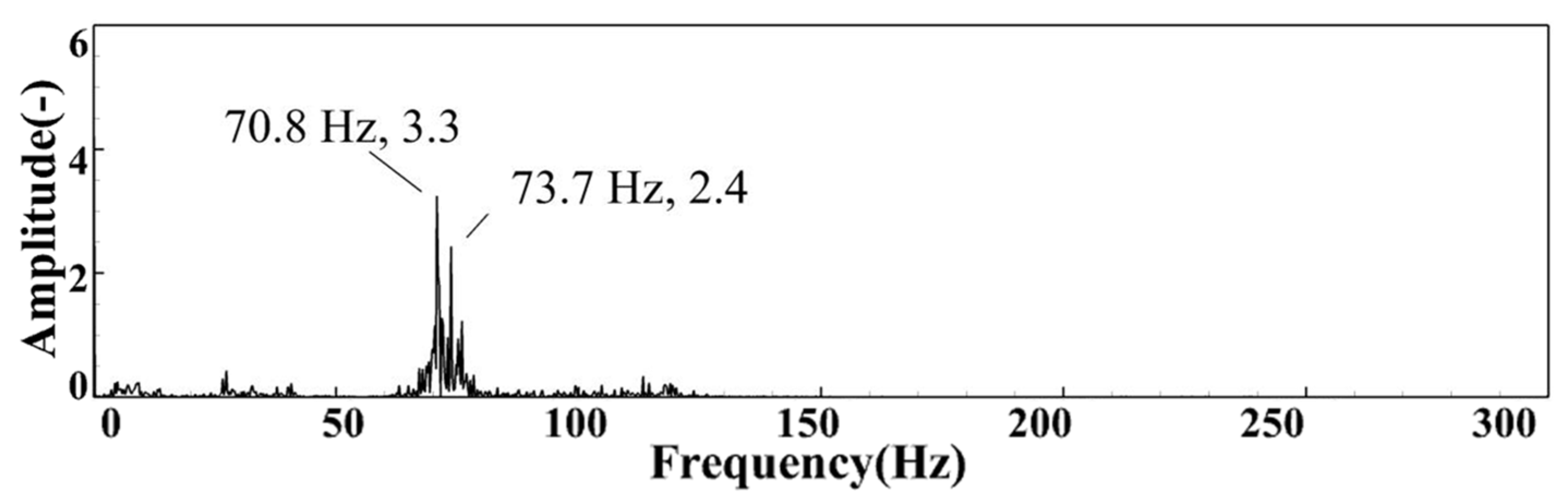

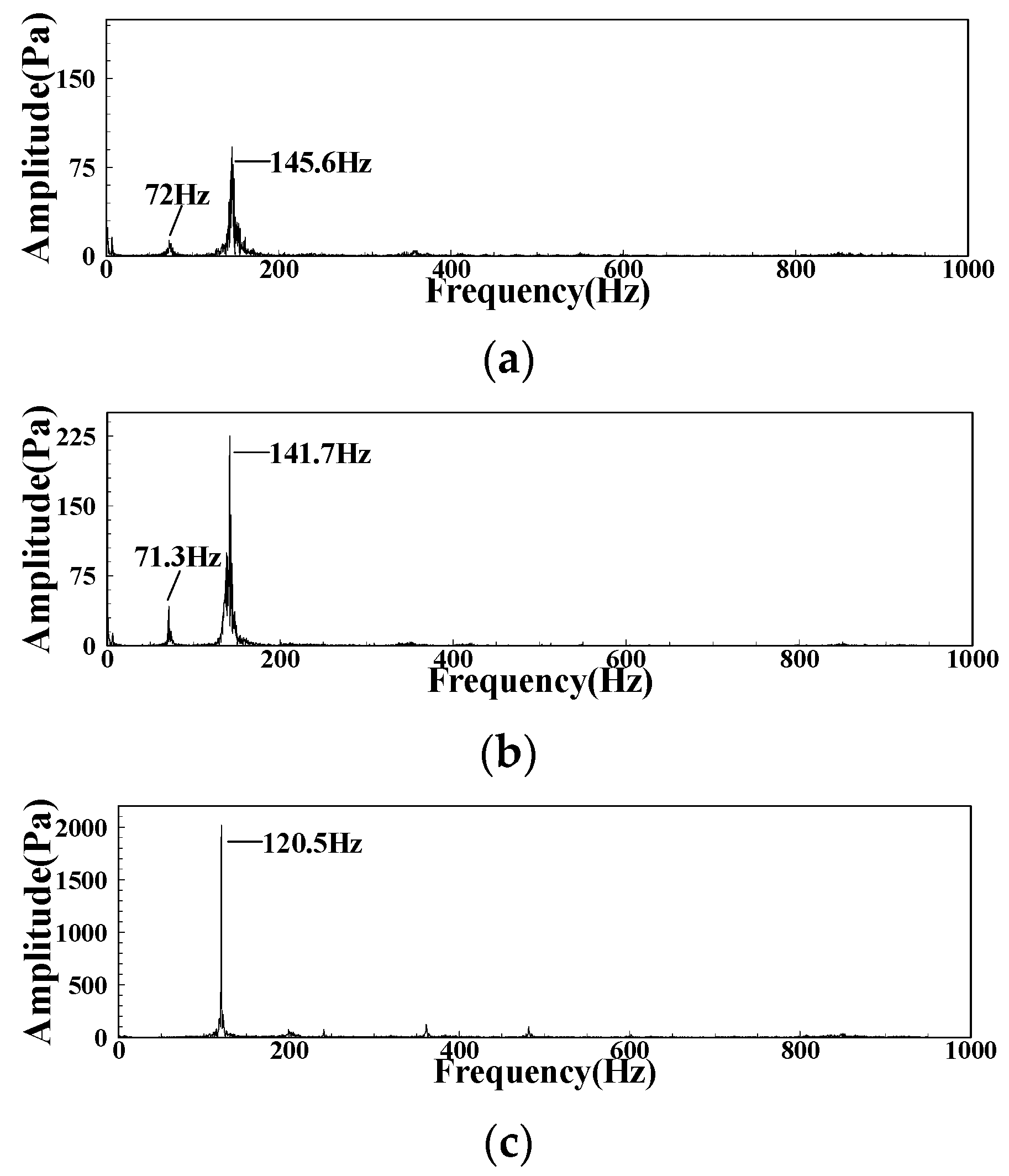

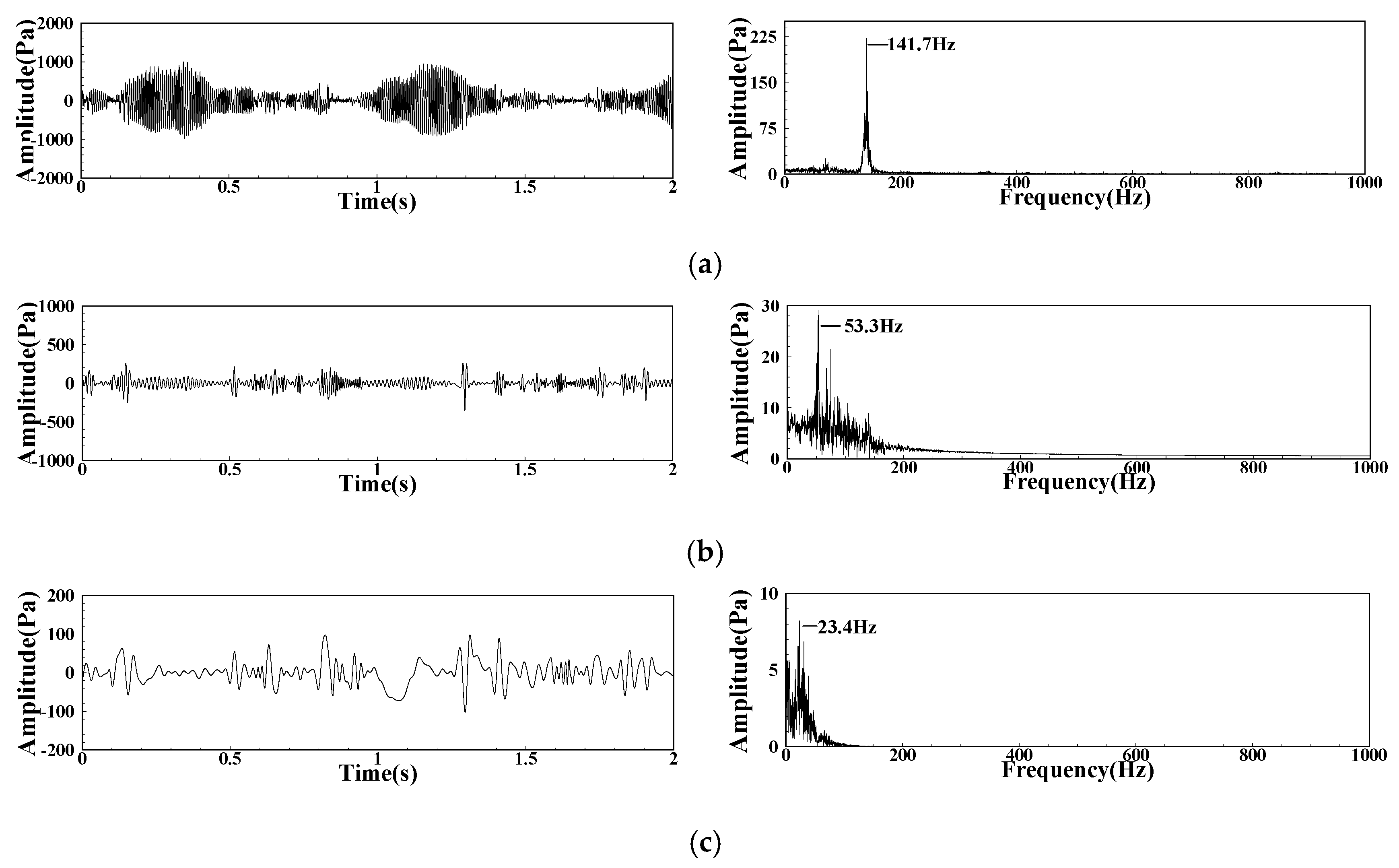

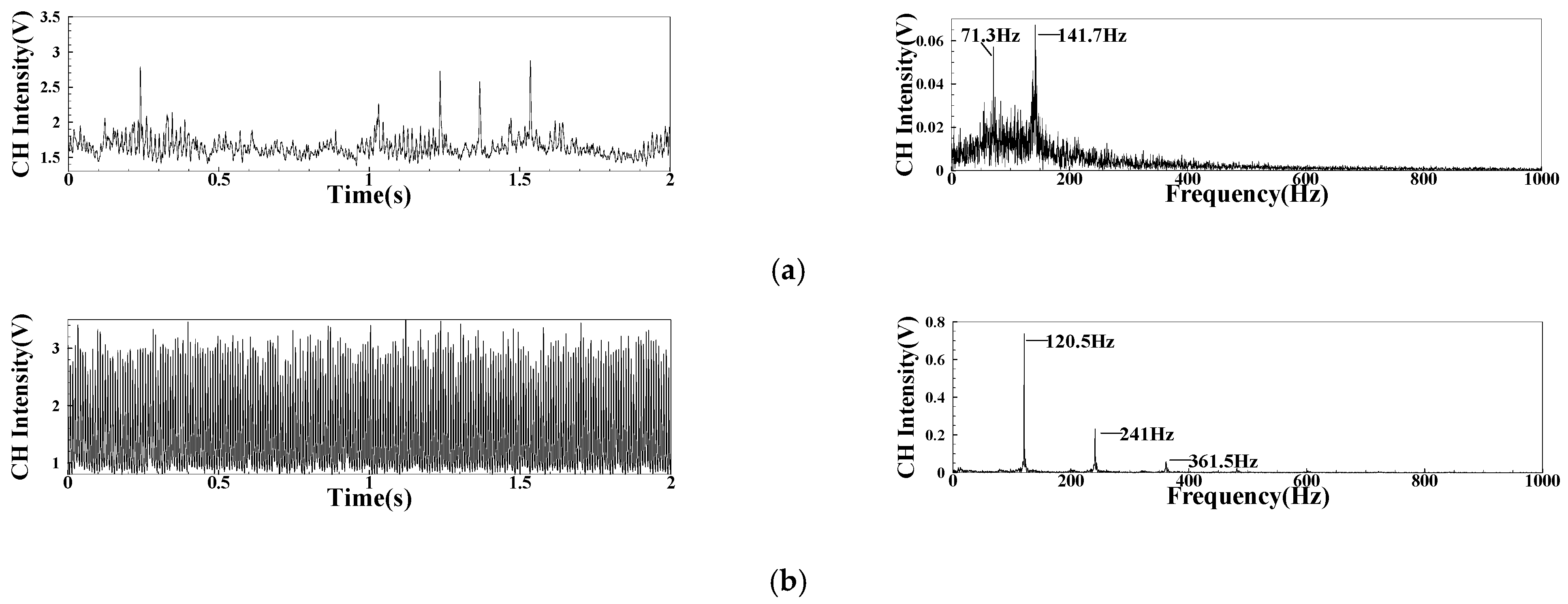

4.1.1. Analysis of Dynamic Pressure Signal under Combustion

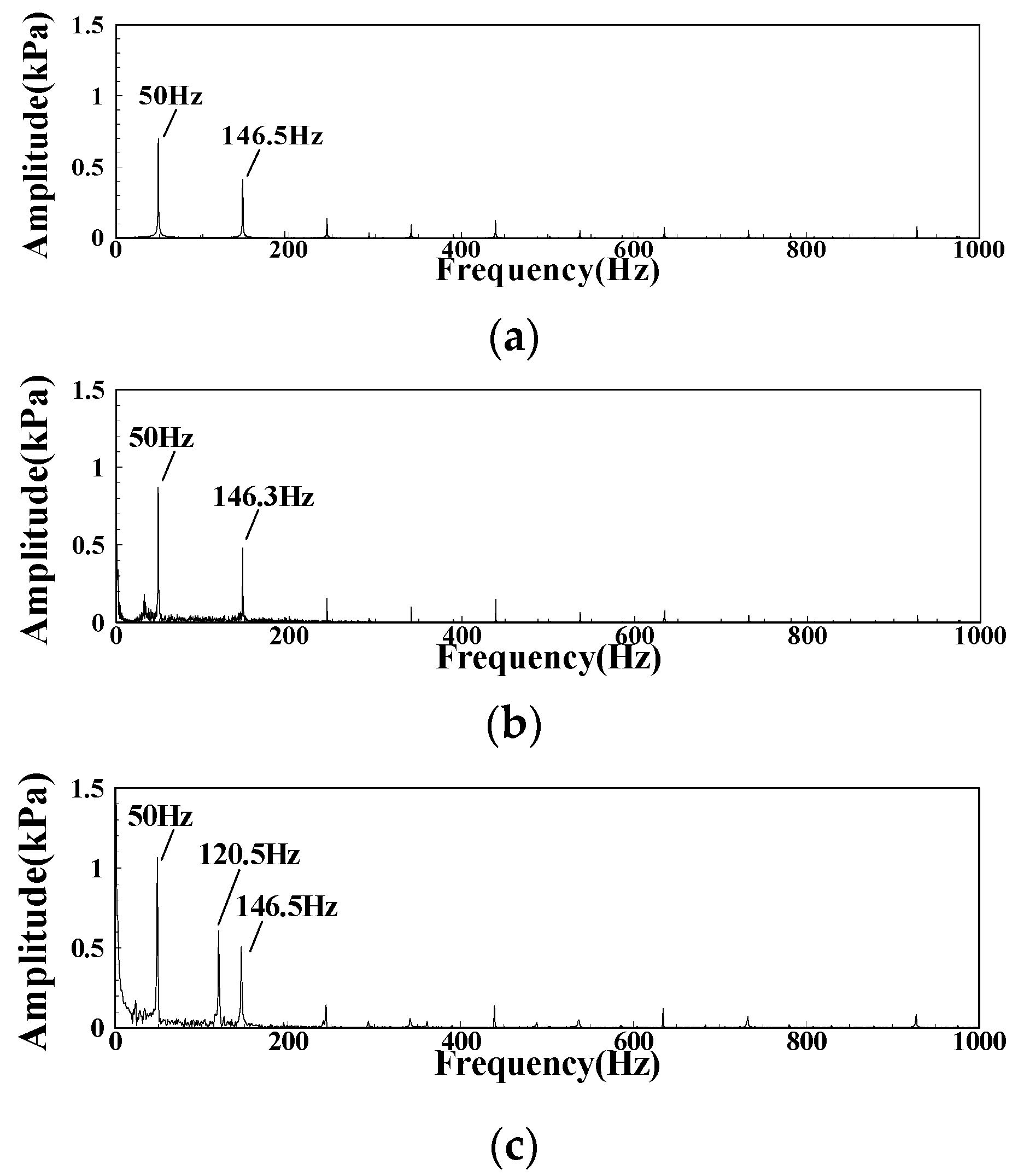

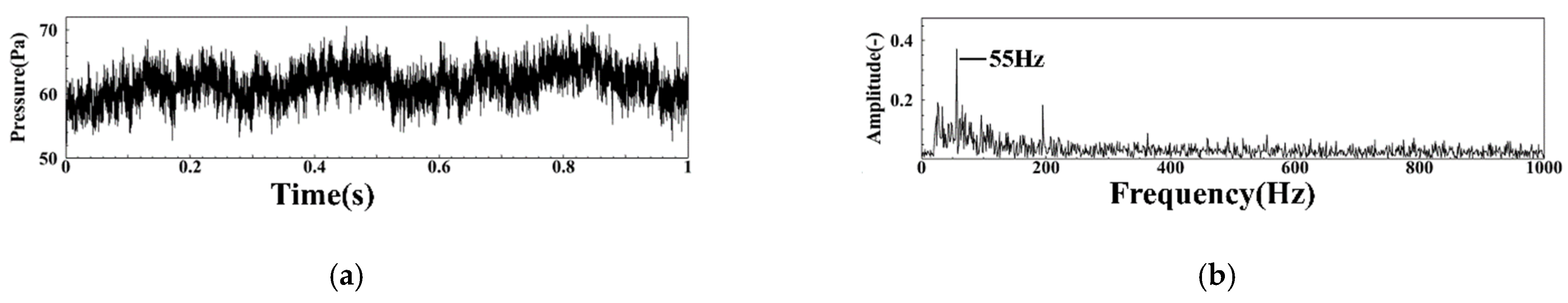

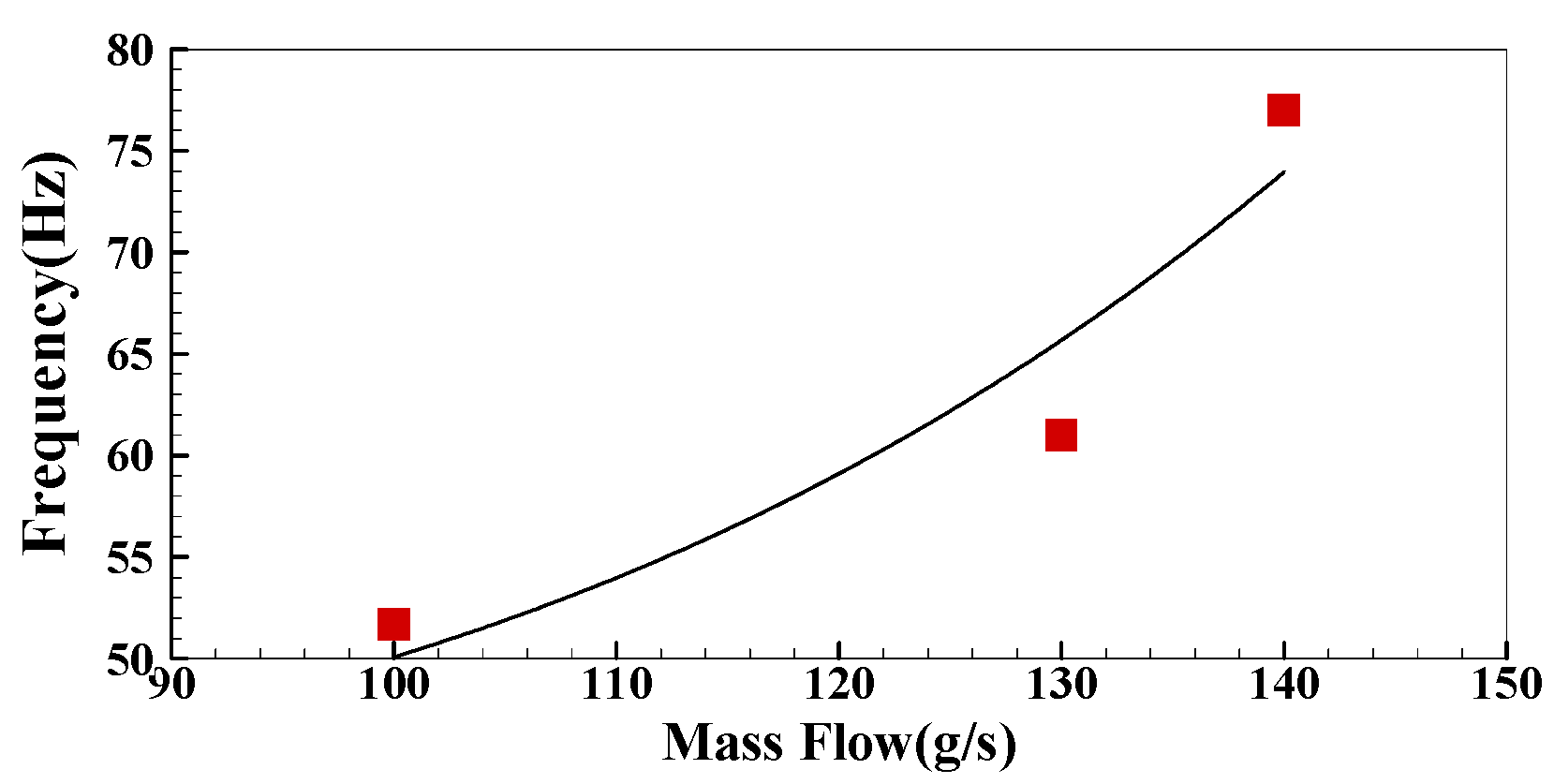

4.1.2. Analysis of Dynamic Pressure Signal under Cold State

4.1.3. Analysis of CH*

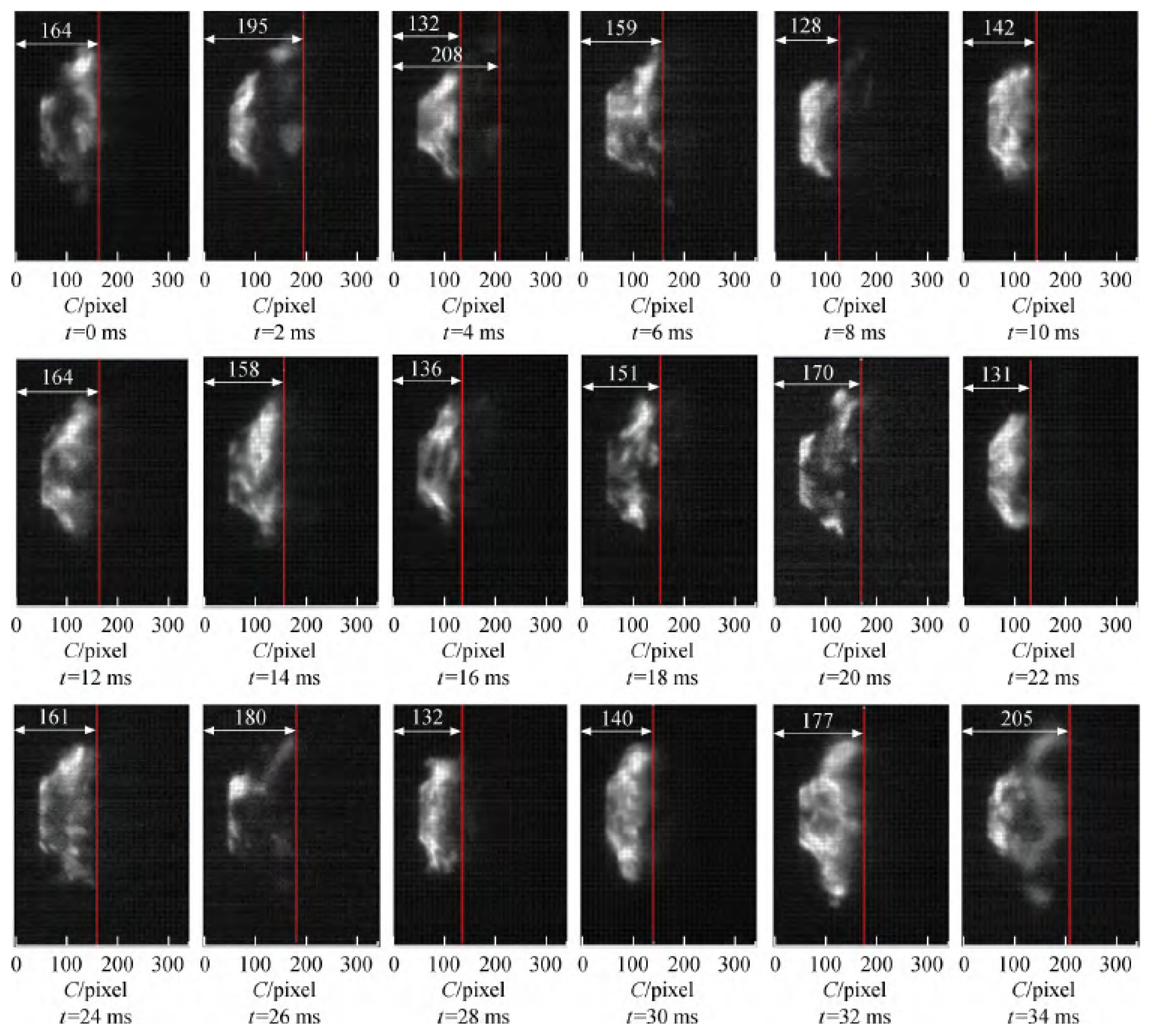

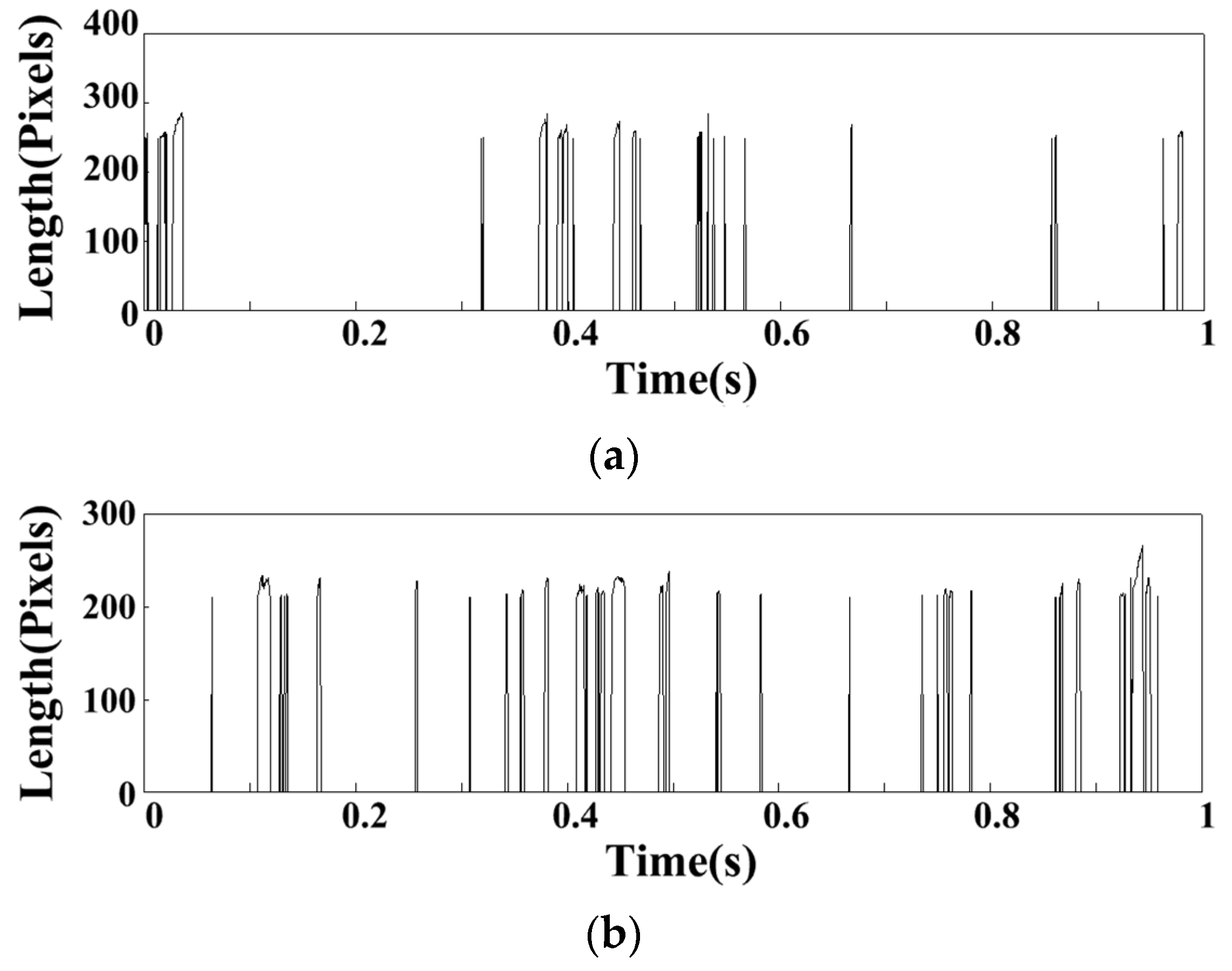

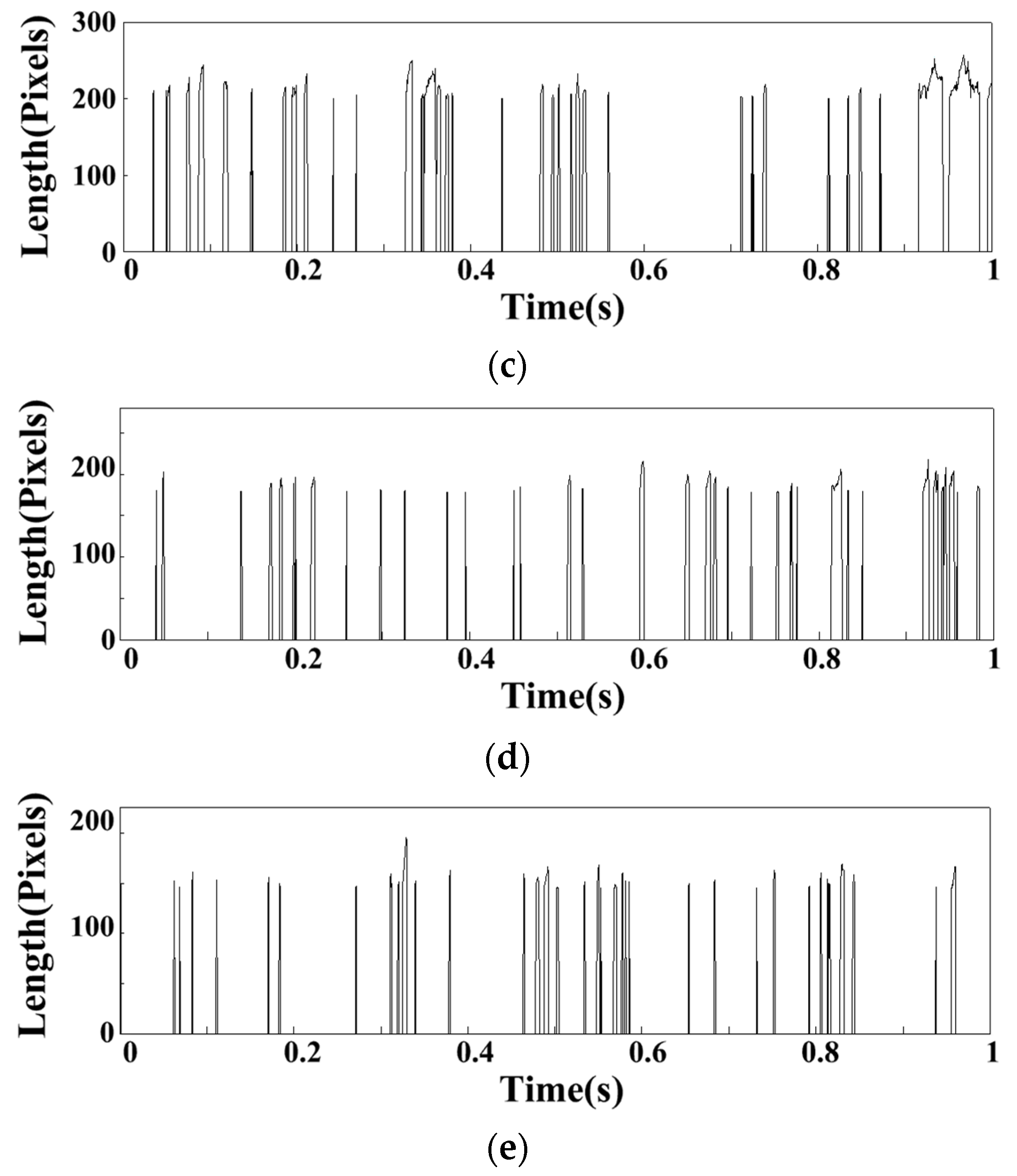

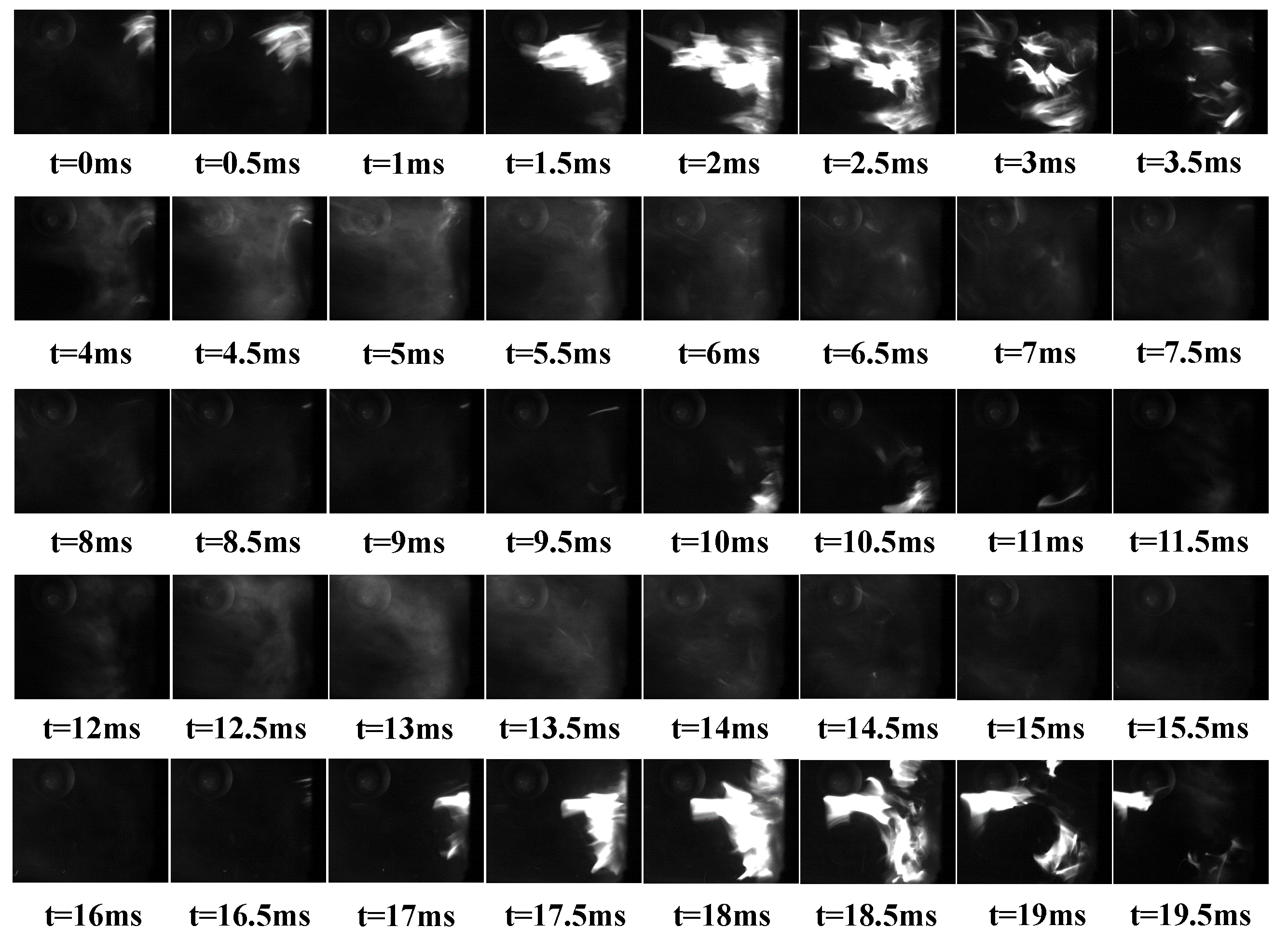

4.1.4. Analysis of Flame Images

4.2. Analysis of Test Results of L Combustor

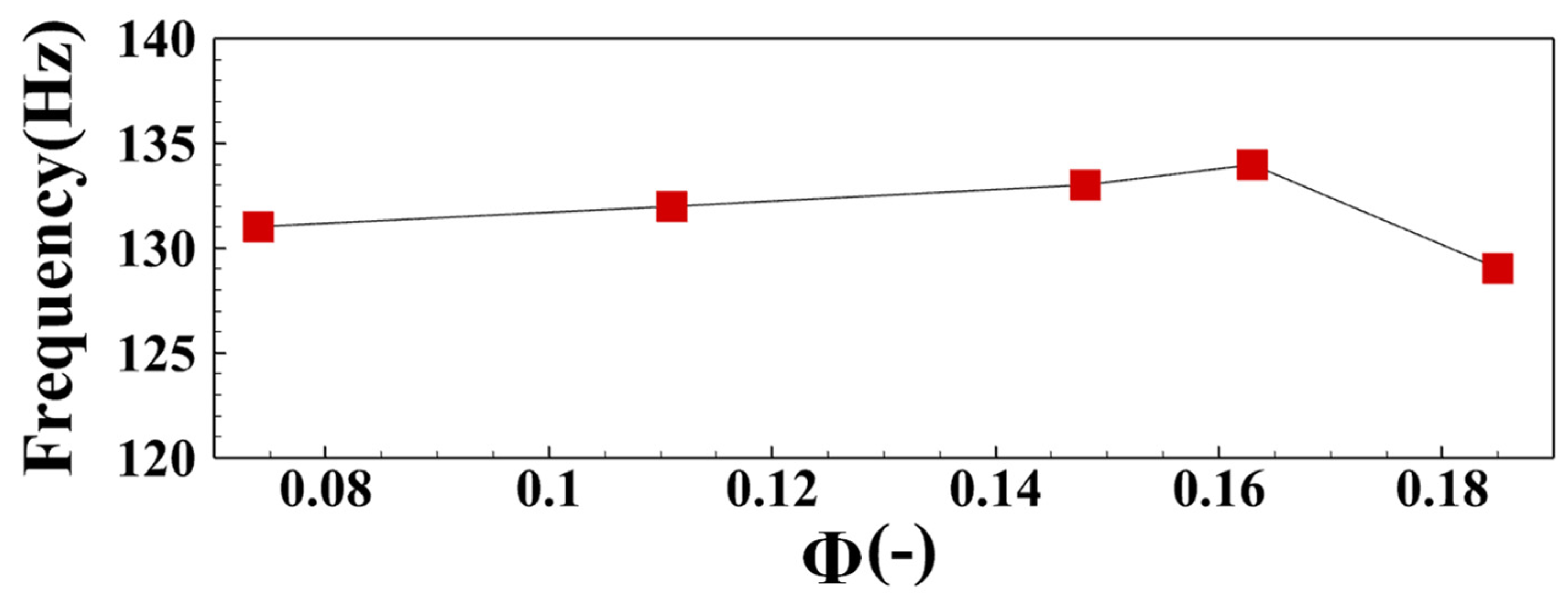

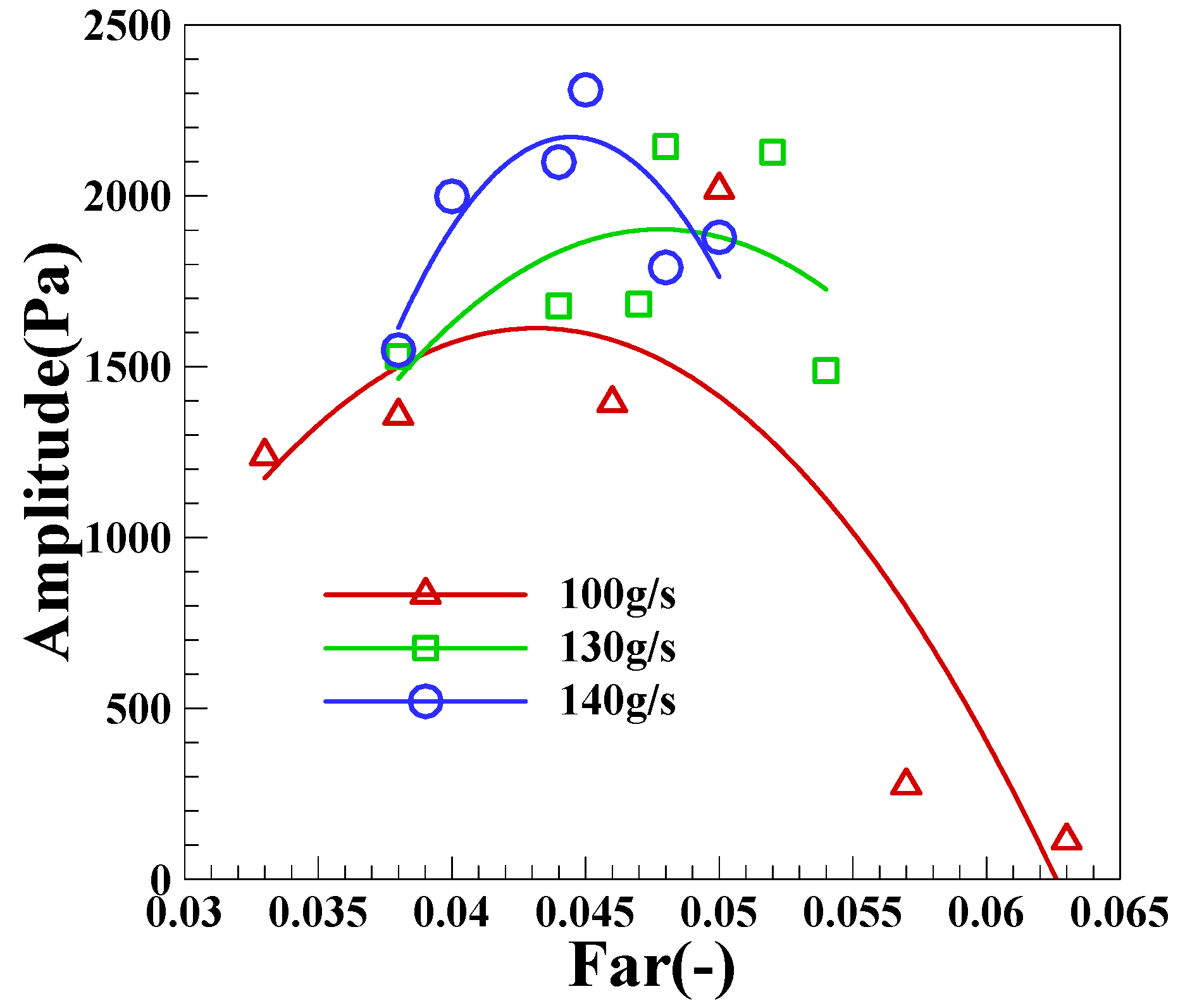

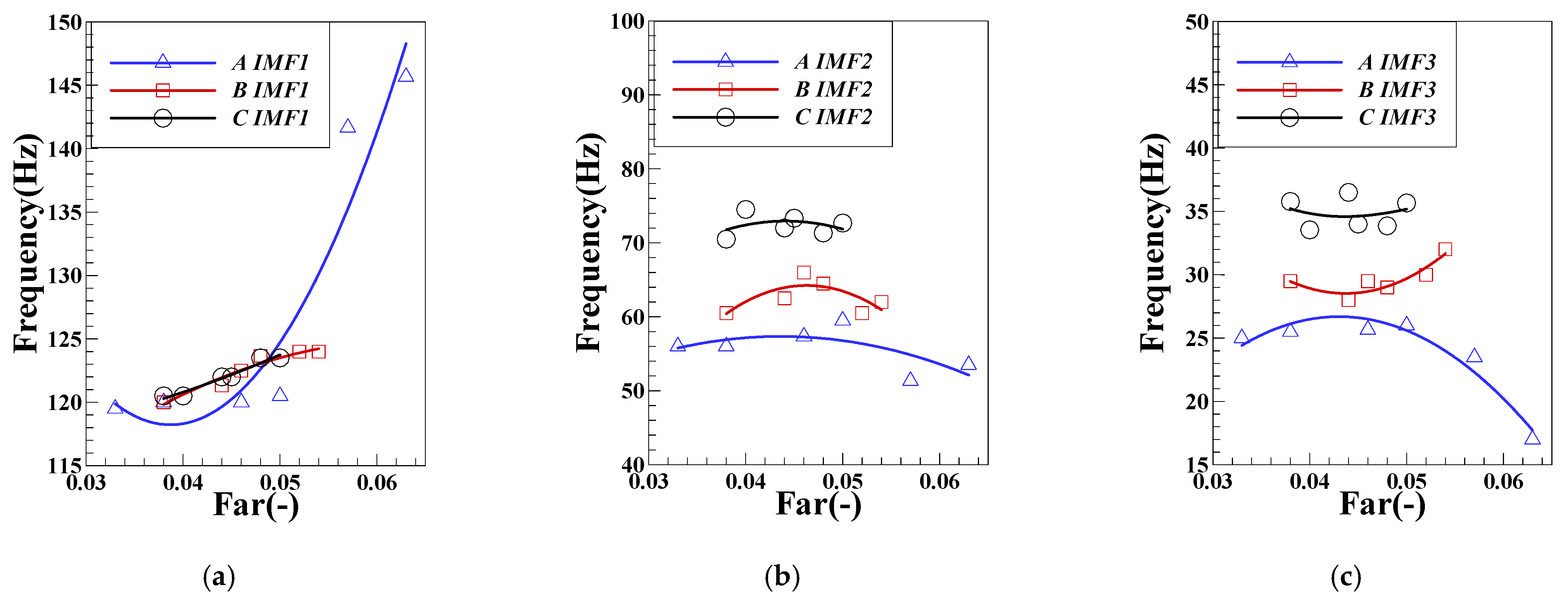

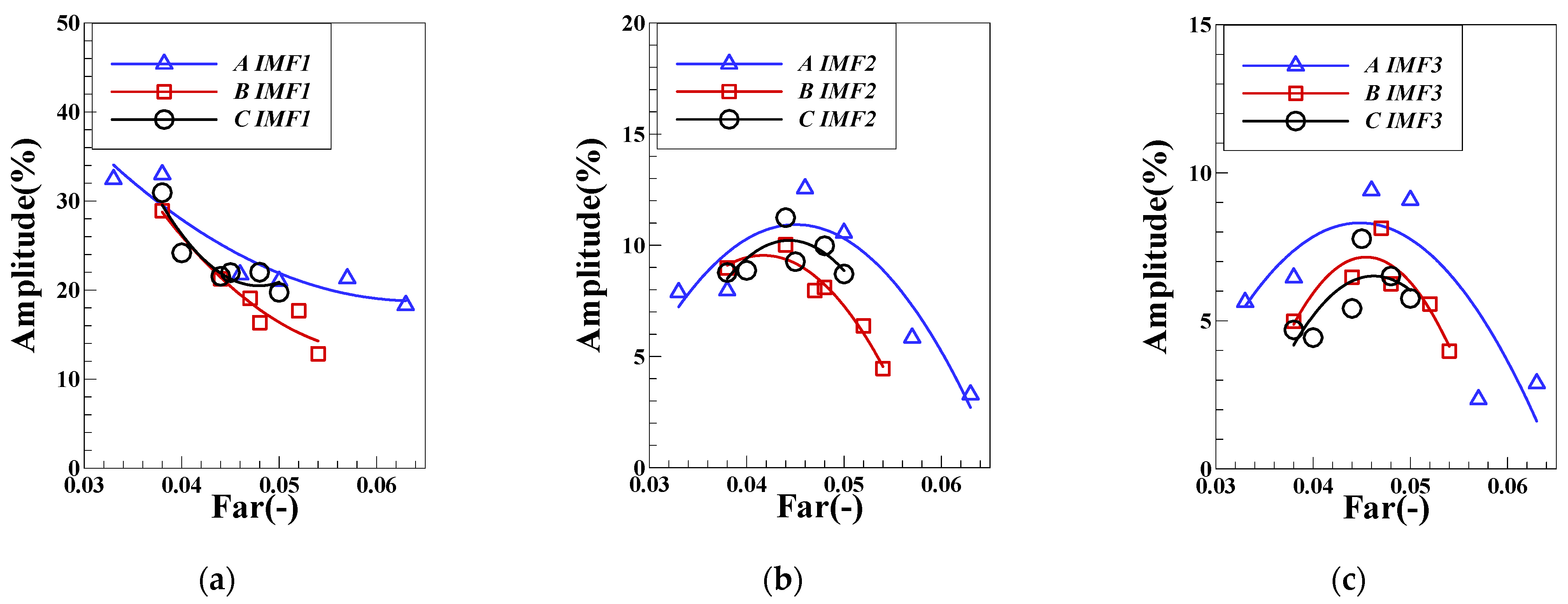

4.2.1. Analysis of Dynamic Pressure Signal under Combustion

4.2.2. Analysis of Dynamic Pressure Signal under Cold State

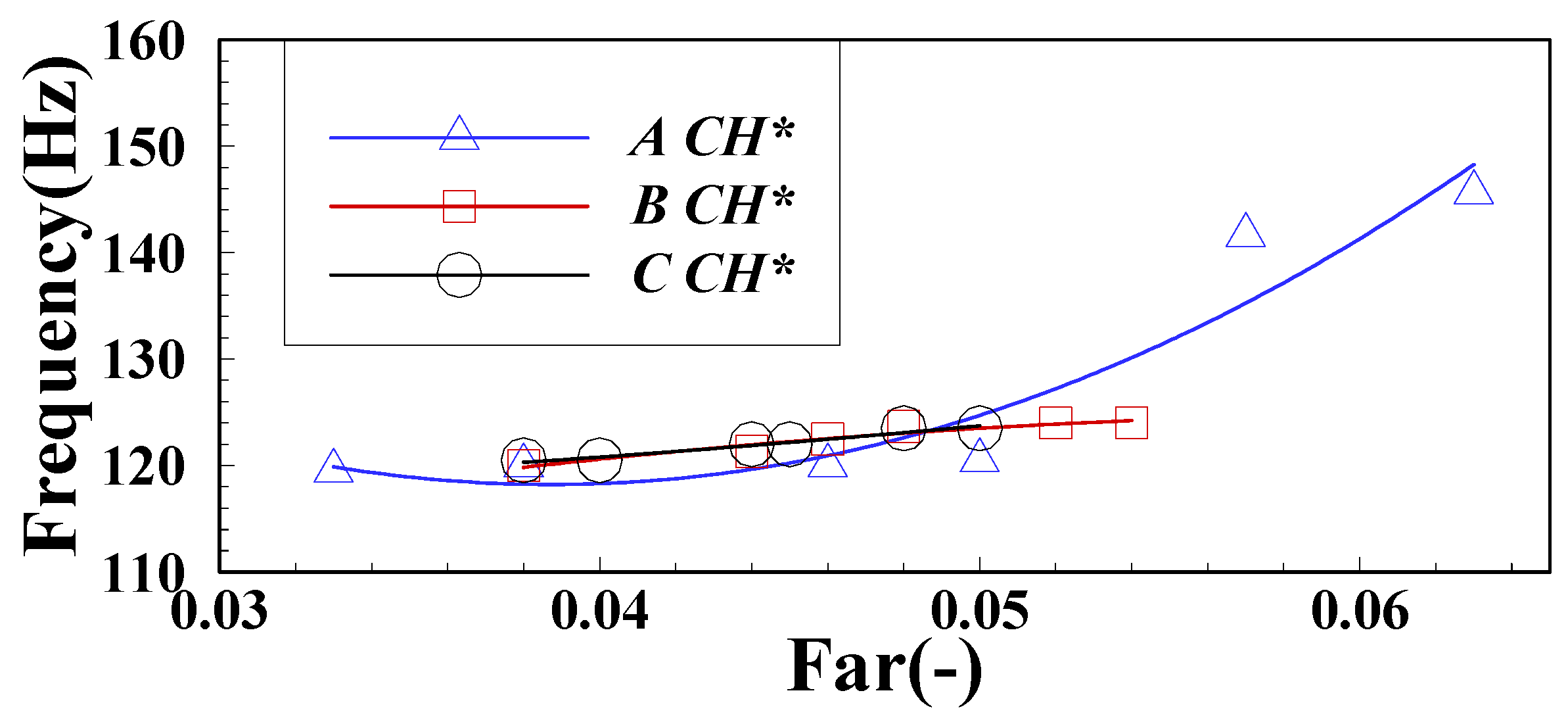

4.2.3. Analysis of CH* Signal

4.2.4. Analysis of Flame Images

5. Conclusions

- (1)

- There are two kinds combustion states in an industrial combustor (flame instability and combustion instability). The diversities of the amplitude and waveform of dynamic pressure are obviously different in the two combustion states. The intermittence decreases gradually with the state changing from flame instability to combustion instability.

- (2)

- The characteristics of the dynamic pressure pulsation under cold state mainly is influenced by swirler, which increases with the increases of the mass flow of intake air.

- (3)

- In two kinds of non-premixed swirl combustors, it is found that the pulsating energy of the dynamic pressure concentrated in the first three order IMF after EMD decomposition. The main frequency of heat release rate pulsation, pressure pulsation characteristics under cold state, and flame shedding correspond to the main frequency of IMF1-3 pulsation, respectively. The frequency of flame shedding is below 40 Hz [30]. By contrasting the peak value of IMF1-3 and the proportion of pulsation peak energy of each order component of DP, the most important factor affecting the pressure pulsation is the contribution of the pulsation of heat release rate and the influence of flame flameout and the flow field pulsation is small.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ducruix, S.; Schuller, T.; Durox, D.; Candel, S. Combustion dynamics and instabilities: Elementary coupling and driving mechanisms. J. Propuls. Power 2003, 19, 722–734. [Google Scholar] [CrossRef]

- Lieuwen, T.C.; Yang, V. Combustion Instabilities in Gas Turbine Engines; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2005. [Google Scholar]

- Prakash, S.; Neumeier, Y.; Zinn, B. Investigation of Mode Shift Dynamics of Lean, Premixed Flames. In Proceedings of the 44th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 9–12 January 2006. [Google Scholar]

- Natanzon, M.S.; Culick, F. The acoustic response of the combustion chamber. In Combustion Instability; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2005; pp. 61–94. [Google Scholar]

- Ying, H.; Yang, V. Dynamics and stability of lean-premixed swirl-stabilized combustion. Prog. Energy Combust. Sci. 2009, 35, 293–364. [Google Scholar]

- Hiroaki, K.; Hiroshi, G.; Shigeru, T. Nonlinear determinism in degenerated combustion instability in a gas turbine model combustor. Stat. Mech. Appl. 2018, 510, 345–354. [Google Scholar]

- Song, W.J.; Cha, D.J. Temporal kurtosis of dynamic pressure signal as a quantitative measure of combustion instability. Appl. Therm. Eng. 2016, 104, 577–586. [Google Scholar] [CrossRef]

- Laera, D.; Campa, G.; Camporeale, M.S.; Bertolotto, E.; Rizzo, S.; Bonzani, F.; Ferrante, A.; Saponaro, A. Modelling of Thermoacoustic Combustion Instabilities Phenomena: Application to an Experimental Test Rig. Energy Procedia 2014, 45, 1392–1401. [Google Scholar] [CrossRef] [Green Version]

- Balusamy, S.; Li, L.K.B.; Han, Z.; Juniper, M.P.; Hochgreb, S. Nonlinear dynamics of a self-excited thermoacoustic system subjected to acoustic forcing. Proc. Combust. Inst. 2015, 35, 3229–3236. [Google Scholar] [CrossRef] [Green Version]

- Worth, N.A.; Dawson, J.R. Effect of equivalence ratio on the modal dynamics of azimuthal combustion instabilities. Proc. Combust. Inst. 2017, 36, 3743–3751. [Google Scholar] [CrossRef]

- Hale, A.A.; Cothran, W.D.; Sabo, K.M. Analysis Technique to Determine the Underlying Wave Structure of Combustion Instabilities from Surface Mounted High Response Static Pressure Sensors. In Proceedings of the ASME Turbo Expo 2018: Turbomachinery Technical Conference and Exposition, Oslo, Norway, 11–15 June 2018. [Google Scholar]

- Huang, N.E.; Shen, Z.; Long, S.R.; Wu, M.C.; Shih, H.H.; Zheng, Q.; Yen, N.-C.; Tung, C.C.; Liu, H.H. The empirical mode decomposition and the Hilbert spectrum for nonlinear and non-stationary time series analysis. Proc. R. Soc. Lond. 1998, 454, 903–995. [Google Scholar] [CrossRef]

- Marchant, B.P. Time-frequency Analysis for Biosystems Engineering. Biosyst. Eng. 2003, 85, 261–281. [Google Scholar] [CrossRef]

- Zhao, X.; Patel, T.H.; Zuo, M.J. Multivariate EMD and full spectrum based condition monitoring for rotating machinery. Mech. Syst. Signal Process. 2012, 27, 712–728. [Google Scholar] [CrossRef]

- Singh, D.S.; Zhao, Q. Pseudo-fault signal assisted EMD for fault detection and isolation in rotating machines. Mech. Syst. Signal Process. 2016, 81, 202–218. [Google Scholar] [CrossRef]

- Yang, D.; Yang, K. Multi-step prediction of strong earthquake ground motions and seismic responses of SDOF systems based on EMD-ELM method. Soil Dyn. Earthq. Eng. 2016, 85, 117–129. [Google Scholar] [CrossRef]

- Amoura, S.; Gaci, S.; Barbosa, S.; Farfour, M.; Bounif, M.A. Investigation of lithological heterogeneities from velocity logs using EMD-Hlder technique combined with multifractal analysis and unsupervised statistical methods. J. Pet. Sci. Eng. 2022, 208, 109588. [Google Scholar] [CrossRef]

- Boda, S.; Mahadevappa, M.; Dutta, P.K. A hybrid method for removal of power line interference and baseline wander in ECG signals using EMD and EWT. Biomed. Signal Process. Control 2021, 67, 102466. [Google Scholar] [CrossRef]

- Yadav, S.K.; Kalra, P.K. Condition Monitoring of Internal Combustion Engine Using EMD and HMM. In Intelligent Autonomous Systems. Studies in Computational Intelligence; Pratihar, D.K., Jain, L.C., Eds.; Springer: Berlin/Heidelberg, Germany, 2010; Volume 275, pp. 167–185. [Google Scholar]

- Lu, A.; Zhang, C.; Ren, Y.; Li, Y.; Li, S.; Yin, P. Research on knock recognition of coal-based naphtha homogeneous charge compression ignition engine based on combined feature extraction and classification. Fuel 2021, 300, 120997. [Google Scholar] [CrossRef]

- Yao, Z.; Liu, X.; Yang, W.; Wang, C.; Chang, S. A coarse-to-fine denoising method for dynamic calibration signals of pressure sensor based on adaptive mode decompositions. Measurement 2020, 163, 107935. [Google Scholar] [CrossRef]

- Bian, X.; Li, S.; Lin, L.; Tan, X.; Fan, Q.; Li, M. High and low frequency unfolded partial least squares regression based on empirical mode decomposition for quantitative analysis of fuel samples. Anal. Chim. Acta 2016, 925, 16–22. [Google Scholar] [CrossRef]

- Yan, S.; Liang, Q.; Guo, Q.; Zhou, Z.; Yu, G. Analysis on acoustic characteristics of opposed multi-burner gasifier. Appl. Acoust. 2011, 72, 43–47. [Google Scholar] [CrossRef]

- Konle, M.; Sattelmayer, T. Interaction of heat release and vortex breakdown during flame flashback driven by combustion induced vortex breakdown. Exp. Fluids 2009, 47, 627–635. [Google Scholar] [CrossRef]

- Xu, L.L.; Zheng, J.Y.; Wang, G.Q.; Li, L.; Qi, F. Effects of swirler position on flame response and combustion instabilities. Chin. J. Aeronaut. 2022, 35, 345–355. [Google Scholar] [CrossRef]

- Steinberg, A.M.; Arndt, C.M.; Meier, W. Parametric study of vortex structures and their dynamics in swirl-stabilized combustion. Proc. Combust. Inst. 2013, 34, 3117–3125. [Google Scholar] [CrossRef] [Green Version]

- Jin, U.; Kim, K.T. Influence of radial fuel staging on combustion instabilities and exhaust emissions from lean-premixed multi-element hydrogen/methane/air flames. Combust. Flame 2022, 242, 112184. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Gupta, B.; Hansda, S.; Haque, Z.; Sen, S. Lean Blowout Phenomena and Prior Detection of Lean Blowout in a Premixed Model Annular Combustor. In Proceedings of the ASME 2019 Gas Turbine India Conference, Chennai, India, 5–6 December 2019. [Google Scholar]

- Dhanuka, S.K.; Temme, J.E.; Driscoll, J.F.; Mongia, H.C. Vortex-shedding and mixing layer effects on periodic flashback in a lean premixed prevaporized gas turbine combustor. Proc. Combust. Inst. 2009, 32, 2901–2908. [Google Scholar] [CrossRef]

- Nair, S.; Lieuwen, T. Acoustic Detection of Imminent Blowout in Pilot and Swirl Stabilized Combustors. In Proceedings of the ASME Turbo Expo 2003, Atlanta, GA, USA, 16–19 June 2003. [Google Scholar]

| Case | Re/(-) | Φ |

|---|---|---|

| MA01 | 3802 | 0.185 |

| MA02 | 3802 | 0.163 |

| MA03 | 3802 | 0.148 |

| MA04 | 3802 | 0.111 |

| MA05 | 3802 | 0.074 |

| Case | Wa/(g/s) | Far |

|---|---|---|

| LA01 | 100.2 | 0.063 |

| LA02 | 100.2 | 0.057 |

| LA03 | 100.2 | 0.050 |

| LA04 | 100.2 | 0.046 |

| LA05 | 100.2 | 0.038 |

| LA06 | 100.2 | 0.033 |

| LB01 | 130.1 | 0.054 |

| LB02 | 130.1 | 0.052 |

| LB03 | 130.1 | 0.048 |

| LB04 | 130.1 | 0.046 |

| LB05 | 130.1 | 0.044 |

| LB06 | 130.1 | 0.038 |

| LC01 | 140.0 | 0.050 |

| LC02 | 140.0 | 0.048 |

| LC03 | 140.0 | 0.045 |

| LC04 | 140.0 | 0.044 |

| LC05 | 140.0 | 0.040 |

| LC06 | 140.0 | 0.038 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Zhang, X.; Yang, C.; Li, H.; Liu, Y. Analysis of Pressure Fluctuation Characteristics of Central Swirl Combustors Based on Empirical Mode Decomposition. Sensors 2022, 22, 5615. https://doi.org/10.3390/s22155615

Wang X, Zhang X, Yang C, Li H, Liu Y. Analysis of Pressure Fluctuation Characteristics of Central Swirl Combustors Based on Empirical Mode Decomposition. Sensors. 2022; 22(15):5615. https://doi.org/10.3390/s22155615

Chicago/Turabian StyleWang, Xuhuai, Xiang Zhang, Chen Yang, Hao Li, and Yong Liu. 2022. "Analysis of Pressure Fluctuation Characteristics of Central Swirl Combustors Based on Empirical Mode Decomposition" Sensors 22, no. 15: 5615. https://doi.org/10.3390/s22155615

APA StyleWang, X., Zhang, X., Yang, C., Li, H., & Liu, Y. (2022). Analysis of Pressure Fluctuation Characteristics of Central Swirl Combustors Based on Empirical Mode Decomposition. Sensors, 22(15), 5615. https://doi.org/10.3390/s22155615