Giant Magnetoresistance Biosensors for Food Safety Applications

Abstract

:1. Introduction

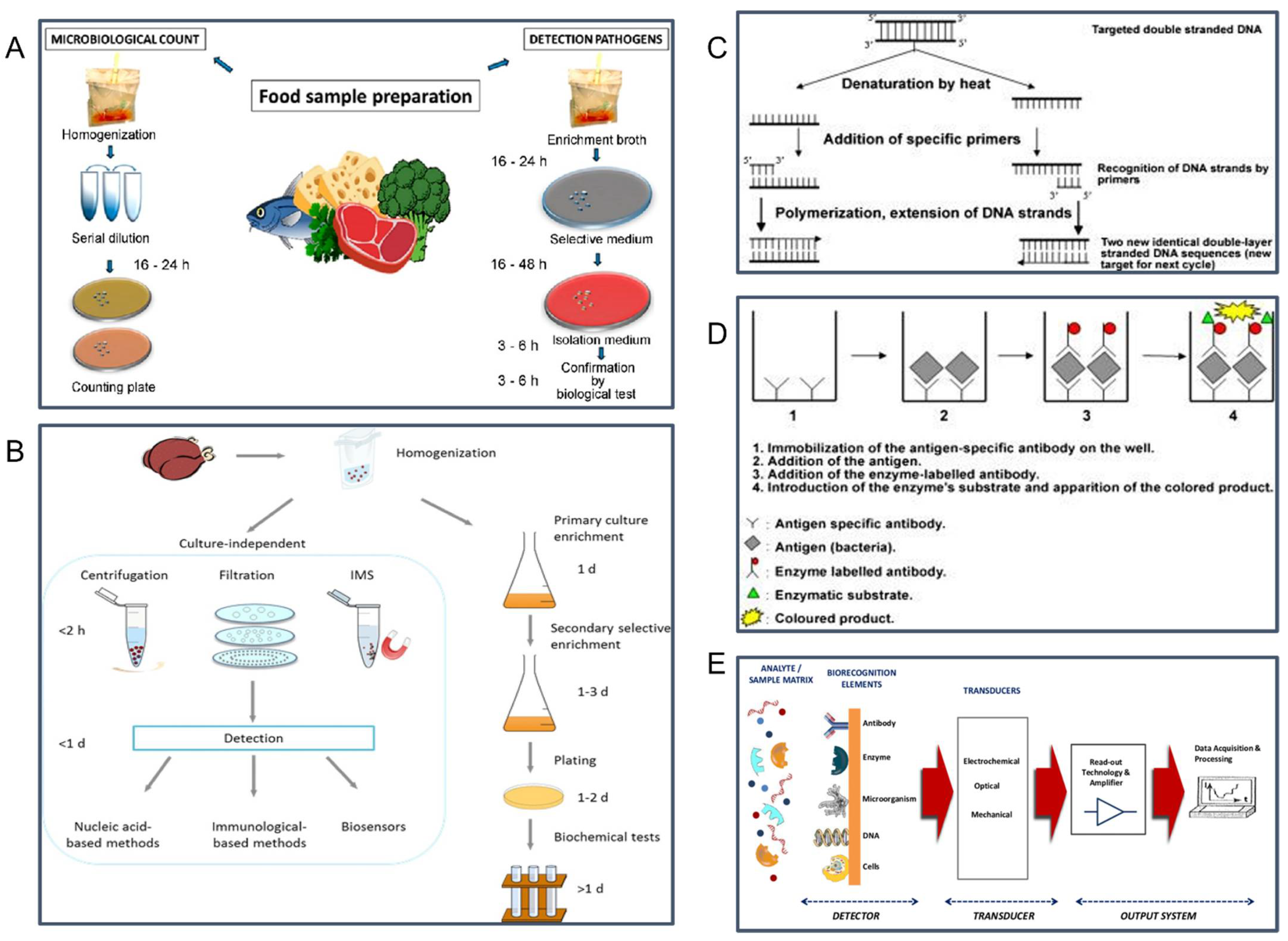

2. Current Technologies for Food Safety Applications

2.1. The Conventional Culture Methods

2.2. Polymerase Chain Reaction (PCR)

2.3. Immunological Methods

2.4. New Types of Biosensors

2.4.1. Optical Biosensors

2.4.2. Electrochemical Biosensors

2.4.3. Mechanical Biosensors

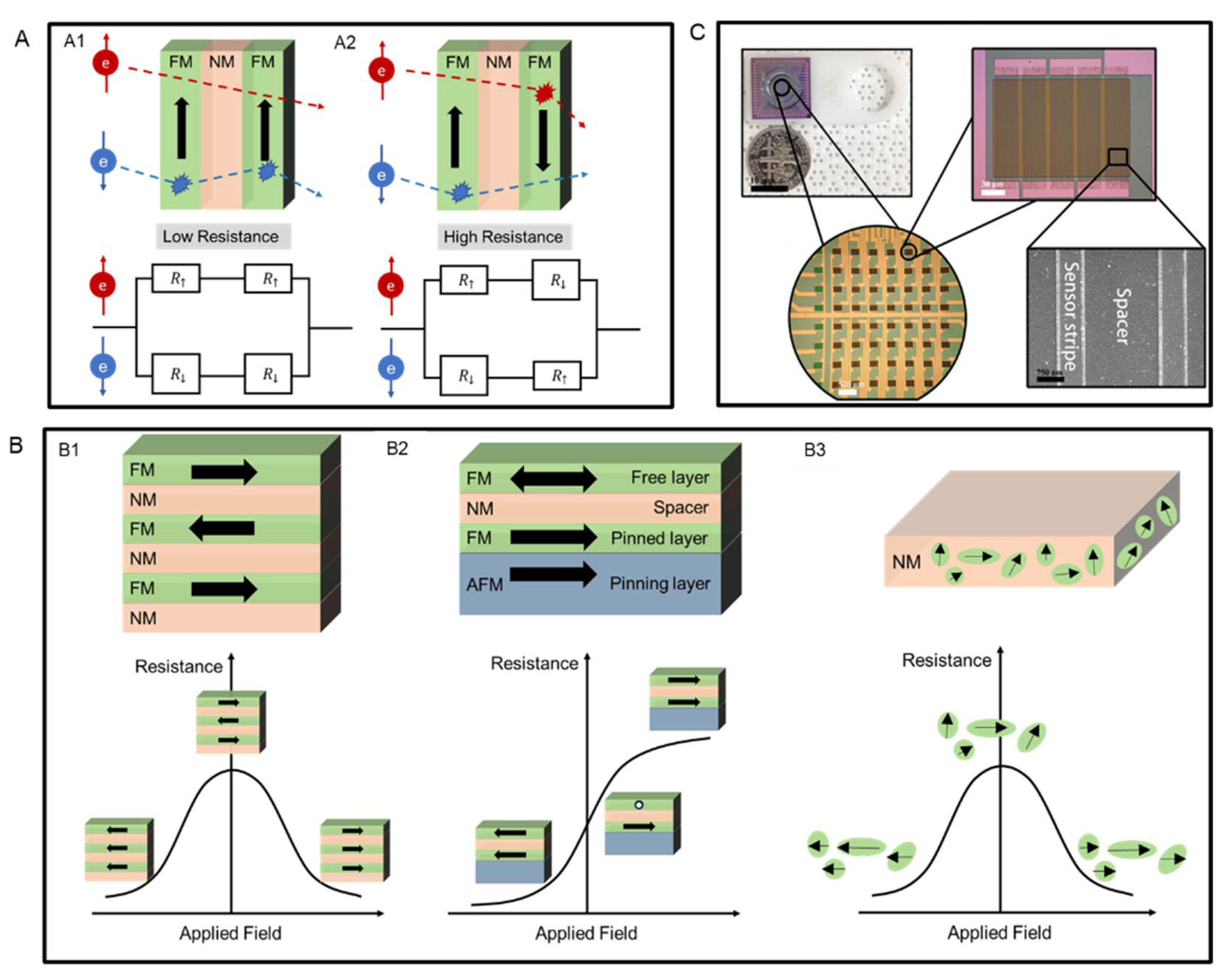

3. Giant Magnetoresistance (GMR)

3.1. GMR Effect and Devices

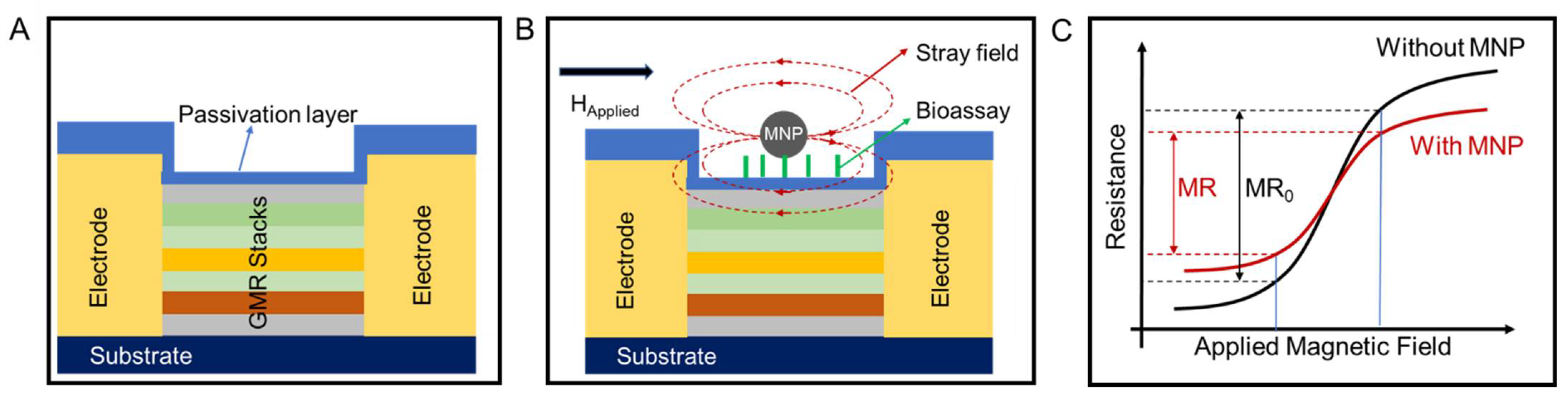

3.2. GMR Biosensors: Surface Modifications and Bioassay Strategies

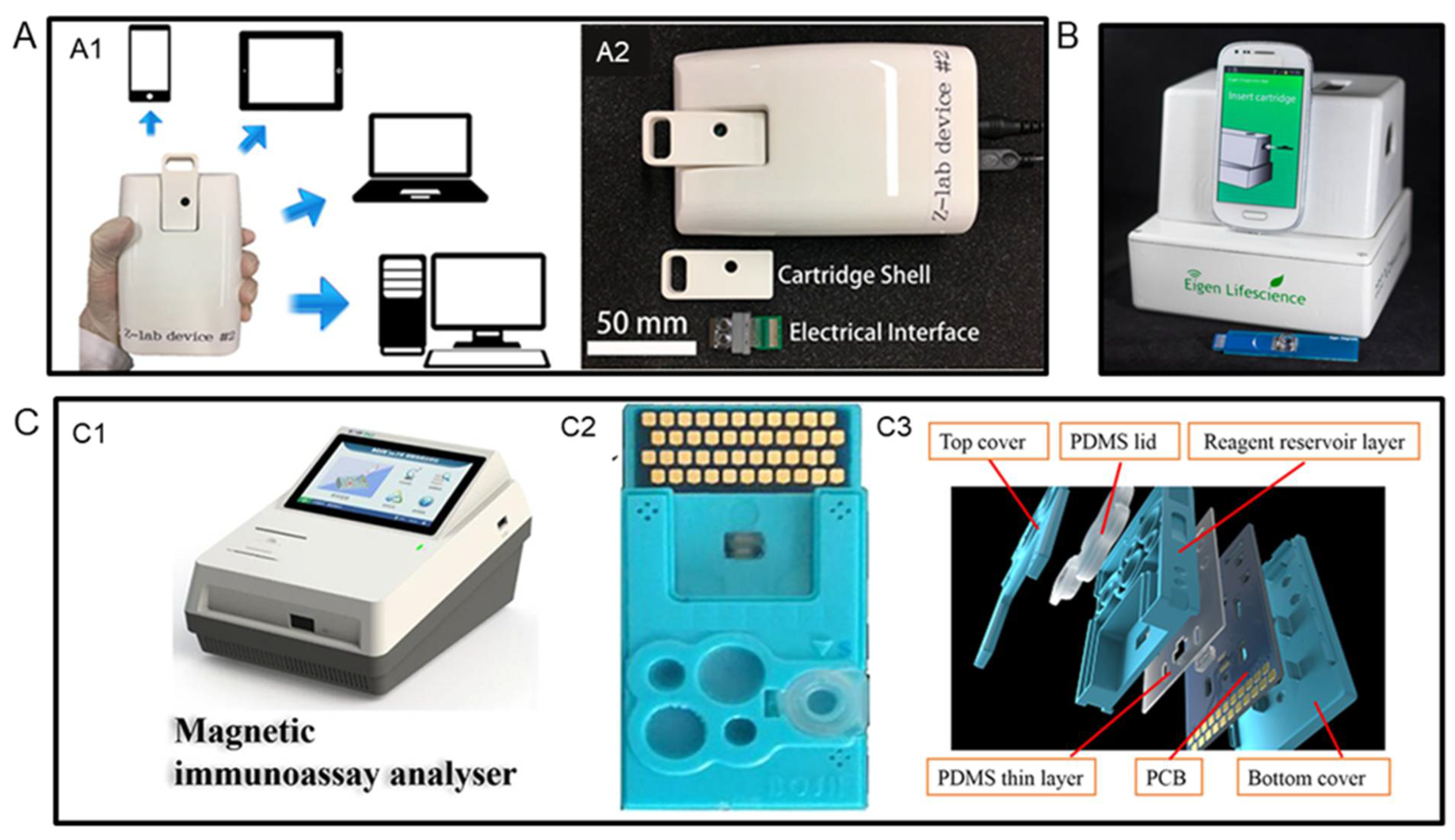

3.3. Portable GMR Bioassay Platforms for Field Test

4. GMR for Food Safety Applications

4.1. GMR for Foodborne Pathogen Detection

4.2. GMR for Foodborne Toxin Detection

4.3. GMR for Other Food-Related Biomarker Detection

5. Conclusions

6. Future Prospects

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Zhao, X.; Lin, C.-W.; Wang, J.; Oh, D.H. Advances in Rapid Detection Methods for Foodborne Pathogens. J. Microbiol. Biotechnol. 2014, 24, 297–312. [Google Scholar] [CrossRef] [Green Version]

- Umesha, S.; Manukumar, H.M. Advanced molecular diagnostic techniques for detection of food-borne pathogens: Current applications and future challenges. Crit. Rev. Food Sci. Nutr. 2018, 58, 84–104. [Google Scholar] [CrossRef] [PubMed]

- Scallan, E.; Hoekstra, R.M.; Angulo, F.J.; Tauxe, R.V.; Widdowson, M.-A.; Roy, S.L.; Jones, J.L.; Griffin, P.M. Foodborne Illness Acquired in the United States—Major Pathogens. Emerg. Infect. Dis. 2011, 17, 7–15. [Google Scholar] [CrossRef]

- Mandal, P.K.; Biswas, A.K.; Choi, K.; Pal, U.K. Methods for rapid detection of foodborne pathogens: An overview. Am. J. Food Technol. 2011, 6, 87–102. [Google Scholar] [CrossRef] [Green Version]

- Carvalho, F.; George, J.; Sheikh, H.M.A.; Selvin, R. Advances in screening, detection and enumeration of Escherichia coli using nanotechnology-based methods: A review. J. Biomed. Nanotechnol. 2018, 14, 829–846. [Google Scholar] [CrossRef]

- Pillai, S.D. Molecular Methods for Microbial Detection. In Preharvest and Postharvest Food Safety; Blackwell Publishing: Ames, IA, USA, 2004; pp. 289–302. [Google Scholar] [CrossRef]

- Alahi, M.E.E.; Mukhopadhyay, S.C. Detection methodologies for pathogen and toxins: A review. Sensors 2017, 17, 1885. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Maurer, J.J. Rapid detection and limitations of molecular techniques. Annu. Rev. Food Sci. Technol. 2011, 2, 259–279. [Google Scholar] [CrossRef] [Green Version]

- Xie, C.; Wang, R.; Saeed, A.F.U.H.; Yang, Q.; Chen, H.; Ling, S.; Xiao, S.; Zeng, L.; Wang, S. Preparation of anti-human podoplanin monoclonal antibody and its application in immunohistochemical diagnosis. Sci. Rep. 2018, 8, 1–10. [Google Scholar] [CrossRef]

- Woan-Fei Law, J.; Ab Mutalib, N.-S.; Chan, K.-G.; Lee, L.-H.; Matthews Ciira, K.; Cheah, J. Rapid methods for the detection of foodborne bacterial pathogens: Principles, applications, advantages and limitations. Front. Microbiol. 2015, 5, 770. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Jasim, I.; Shen, Z.; Zhao, L.; Dweik, M.; Zhang, S.; Almasri, M. A microfluidic based biosensor for rapid detection of Salmonella in food products. PLoS ONE 2019, 14, e0216873. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ahmed, W.; Gyawali, P.; Toze, S. Quantitative PCR measurements of Escherichia coli including Shiga Toxin-Producing E. coli (STEC) in Animal Feces and Environmental Waters. Environ. Sci. Technol. 2015, 49, 3084–3090. [Google Scholar] [CrossRef] [PubMed]

- Mead, P.S.; Griffin, P.M. Escherichia coli O157:H7. Lancet 1998, 352, 1207–1212. [Google Scholar] [CrossRef]

- Nesvet, J.C.; Antilla, K.A.; Pancirer, D.S.; Lozano, A.X.; Preiss, J.S.; Ma, W.; Fu, A.; Park, S.M.; Gambhir, S.S.; Fan, A.C.; et al. Giant Magnetoresistive Nanosensor Analysis of Circulating Tumor DNA Epidermal Growth Factor Receptor Mutations for Diagnosis and Therapy Response Monitoring. Clin. Chem. 2021, 67, 534–542. [Google Scholar] [CrossRef]

- Mujika, M.; Arana, S.; Castaño, E.; Tijero, M.; Vilares, R.; Ruano-López, J.M.; Cruz, A.; Sainz, L.; Berganza, J. Magnetoresistive immunosensor for the detection of Escherichia coli O157:H7 including a microfluidic network. Biosens. Bioelectron. 2009, 24, 1253–1258. [Google Scholar] [CrossRef]

- Binasch, G.; Grünberg, P.; Saurenbach, F.; Zinn, W. Enhanced magnetoresistance in layered magnetic structures with antiferromagnetic interlayer exchange. Phys. Rev. B 1989, 39, 4828–4830. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Baibich, M.N.; Broto, J.M.; Fert, A.; Nguyen, F.; Dau, V.; Petroff, F.; Eitenne, P.; Creuzet, G.; Friederich, A.; Chazelas, J. Giant Magnetoresistance of (001)Fel(001) Cr Magnetic Snperlattices. Phys. Rev. Lett. 1988, 61, 2472–2475. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, L.; Hu, Z.; Zhu, Y.; Xian, D.; Cai, J.; Guan, M.; Wang, C.; Duan, J.; Wu, J.; Wang, Z.; et al. Electric Field-Tunable Giant Magnetoresistance (GMR) Sensor with Enhanced Linear Range. ACS Appl. Mater. Interfaces 2020, 12, 8855–8861. [Google Scholar] [CrossRef] [PubMed]

- Khunkitti, P.; Kruesubthaworn, A.; Kaewrawang, A.; Siritaratiwat, A. Unstable Playback Response of CPP-GMR Read Head Induced by Electromagnetic Interference: Structural Dependence. IEEE Trans. Magn. 2019, 55, 1–6. [Google Scholar] [CrossRef]

- Baselt, D.R.; Lee, G.U.; Natesan, M.; Metzger, S.W.; Sheehan, P.E.; Colton, R.J. A biosensor based on magnetoresistance technology. Biosens. Bioelectron. 1998, 13, 731–739. [Google Scholar] [CrossRef]

- Gani, A.W.; Wei, W.; Shi, R.Z.; Ng, E.; Nguyen, M.; Chua, M.S.; So, S.; Wang, S.X. An Automated, Quantitative, and Multiplexed Assay Suitable for Point-of-Care Hepatitis B Virus Diagnostics. Sci. Rep. 2019, 9, 15615. [Google Scholar] [CrossRef]

- Pannetier-Lecoeur, M.; Parkkonen, L.; Sergeeva-Chollet, N.; Polovy, H.; Fermon, C.; Fowley, C. Magnetocardiography with sensors based on giant magnetoresistance. Appl. Phys. Lett. 2011, 98, 153705. [Google Scholar] [CrossRef] [Green Version]

- Gao, Y.; Huo, W.; Zhang, L.; Lian, J.; Tao, W.; Song, C.; Tang, J.; Shi, S.; Gao, Y. Multiplex measurement of twelve tumor markers using a GMR multi-biomarker immunoassay biosensor. Biosens. Bioelectron. 2019, 123, 204–210. [Google Scholar] [CrossRef] [PubMed]

- Chopin, C.; Torrejon, J.; Solignac, A.; Fermon, C.; Jendritza, P.; Fries, P.; Pannetier-Lecoeur, M. Magnetoresistive Sensor in Two-Dimension on a 25 μm Thick Silicon Substrate for in Vivo Neuronal Measurements. ACS Sens. 2020, 5, 3493–3500. [Google Scholar] [CrossRef] [PubMed]

- Rife, J.C.; Miller, M.M.; Sheehan, P.E.; Tamanaha, C.R.; Tondra, M.; Whitman, L.J. Design and performance of GMR sensors for the detection of magnetic microbeads in biosensors. Sens. Actuators A Phys. 2003, 107, 209–218. [Google Scholar] [CrossRef]

- Ferreira, H.A.; Graham, D.L.; Freitas, P.P.; Cabral, J.M.S. Biodetection using magnetically labeled biomolecules and arrays of spin valve sensors (invited). J. Appl. Phys. 2003, 93, 7281–7286. [Google Scholar] [CrossRef]

- Tondra, M.; Porter, M.; Lipert, R.J. Model for detection of immobilized superparamagnetic nanosphere assay labels using giant magnetoresistive sensors. J. Vac. Sci. Technol. A Vac. Surf. Film. 2000, 18, 1125–1129. [Google Scholar] [CrossRef] [Green Version]

- Damsgaard, C.D.; Hansen, M.F. Theoretical study of in-plane response of magnetic field sensor to magnetic beads in an in-plane homogeneous field. J. Appl. Phys. 2008, 103, 64512. [Google Scholar] [CrossRef] [Green Version]

- Song, S.H.; Gao, Z.F.; Guo, X.; Chen, G.H. Aptamer-based detection methodology studies in food safety. Food Anal. Methods 2019, 12, 966–990. [Google Scholar] [CrossRef]

- Cao, Y.; Feng, T.; Xu, J.; Xue, C. Recent advances of molecularly imprinted polymer-based sensors in the detection of food safety hazard factors. Biosens. Bioelectron. 2019, 141, 111447. [Google Scholar] [CrossRef]

- Lv, M.; Liu, Y.; Geng, J.; Kou, X.; Xin, Z.; Yang, D. Engineering nanomaterials-based biosensors for food safety detection. Biosens. Bioelectron. 2018, 106, 122–128. [Google Scholar] [CrossRef]

- Su, D.; Wu, K.; Saha, R.; Peng, C.; Wang, J.P. Advances in magnetoresistive biosensors. Micromachines 2020, 11, 34. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ren, C.; Bayin, Q.; Feng, S.; Fu, Y.; Ma, X.; Guo, J. Biomarkers detection with magnetoresistance-based sensors. Biosens. Bioelectron. 2020, 165, 112340. [Google Scholar] [CrossRef] [PubMed]

- Wu, K.; Tonini, D.; Liang, S.; Saha, R.; Chugh, V.K.; Wang, J.-P. Giant Magnetoresistance Biosensors in Biomedical Applications. ACS Appl. Mater. Interfaces 2022, 14, 9945–9969. [Google Scholar] [CrossRef]

- Ricke, S.C.; Feye, K.M.; Chaney, W.E.; Shi, Z.; Pavlidis, H.; Yang, Y. Developments in rapid detection methods for the detection of foodborne campylobacterin the United States. Front. Microbiol. 2019, 10, 3280. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Carlson, K.; Misra, M.; Mohanty, S. Developments in Micro- and Nanotechnology for Foodborne Pathogen Detection. Foodborne Pathog. Dis. 2018, 15, 16–25. [Google Scholar] [CrossRef]

- Vaisocherová-Lísalová, H.; Víšová, I.; Ermini, M.L.; Špringer, T.; Song, X.C.; Mrázek, J.; Lamačová, J.; Scott Lynn, N.; Šedivák, P.; Homola, J. Low-fouling surface plasmon resonance biosensor for multi-step detection of foodborne bacterial pathogens in complex food samples. Biosens. Bioelectron. 2016, 80, 84–90. [Google Scholar] [CrossRef] [PubMed]

- Velusamy, V.; Arshak, K.; Korostynska, O.; Oliwa, K.; Adley, C. An overview of foodborne pathogen detection: In the perspective of biosensors. Biotechnol. Adv. 2010, 28, 232–254. [Google Scholar] [CrossRef] [PubMed]

- Lazcka, O.; Del Campo, F.J.; Muñoz, F.X. Pathogen detection: A perspective of traditional methods and biosensors. Biosens. Bioelectron. 2007, 22, 1205–1217. [Google Scholar] [CrossRef]

- Mangal, M.; Bansal, S.; Sharma, S.K.; Gupta, R.K. Molecular Detection of Foodborne Pathogens: A Rapid and Accurate Answer to Food Safety. Crit. Rev. Food Sci. Nutr. 2016, 56, 1568–1584. [Google Scholar] [CrossRef]

- Chiang, Y.C.; Tsen, H.Y.; Chen, H.Y.; Chang, Y.H.; Lin, C.K.; Chen, C.Y.; Pai, W.Y. Multiplex PCR and a chromogenic DNA macroarray for the detection of Listeria monocytogens, Staphylococcus aureus, Streptococcus agalactiae, Enterobacter sakazakii, Escherichia coli O157:H7, Vibrio parahaemolyticus, Salmonella spp. and Pseudomonas fluoresc. J. Microbiol. Methods 2012, 88, 110–116. [Google Scholar] [CrossRef]

- Alves, J.; Marques, V.V.; Pereira, L.F.P.; Hirooka, E.Y.; De Oliveira, T.C.R.M. Multiplex pcr for the detection of Campylobacter spp. and Salmonella spp. in chicken meat. J. Food Saf. 2012, 32, 345–350. [Google Scholar] [CrossRef]

- Wei, C.; Zhong, J.; Hu, T.; Zhao, X. Simultaneous detection of Escherichia coli O157:H7, Staphylococcus aureus and Salmonella by multiplex PCR in milk. 3 Biotech 2018, 8, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Jasson, V.; Jacxsens, L.; Luning, P.; Rajkovic, A.; Uyttendaele, M. Alternative microbial methods: An overview and selection criteria. Food Microbiol. 2010, 27, 710–730. [Google Scholar] [CrossRef]

- Ellingson, J.L.E.; Anderson, J.L.; Carlson, S.A.; Sharma, V.K. Twelve hour real-time PCR technique for the sensitive and specific detection of Salmonella in raw and ready-to-eat meat products. Mol. Cell. Probes 2004, 18, 51–57. [Google Scholar] [CrossRef]

- Malorny, B.; Bunge, C.; Helmuth, R. A real-time PCR for the detection of Salmonella Enteritidis in poultry meat and consumption eggs. J. Microbiol. Methods 2007, 70, 245–251. [Google Scholar] [CrossRef]

- Zhou, B.; Xiao, J.; Liu, S.; Yang, J.; Wang, Y.; Nie, F.; Zhou, Q.; Li, Y.; Zhao, G. Simultaneous detection of six food-borne pathogens by multiplex PCR with a GeXP analyzer. Food Control 2013, 32, 198–204. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, Y.; Bie, S.; Suo, T.; Jia, G.; Liu, B.; Ye, R.; Li, Z. Development of an electrochemical biosensor for rapid and effective detection of pathogenic Escherichia coli in licorice extract. Appl. Sci. 2019, 9, 295. [Google Scholar] [CrossRef] [Green Version]

- Chapman, P.A.; Cerdan Malo, A.T.; Siddons, C.A.; Harkin, M. Use of commercial enzyme immunoassays and immunomagnetic separation systems for detecting Escherichia coli O157 in bovine fecal samples. Appl. Environ. Microbiol. 1997, 63, 2549–2553. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rozand, C.; Feng, P.C.H. Specificity Analysis of a Novel Phage-Derived Ligand in an Enzyme-Linked Fluorescent Assay for the Detection of Escherichia coli O157:H7. J. Food Prot. 2009, 72, 1078–1081. [Google Scholar] [CrossRef] [PubMed]

- Vázquez, F.; González, E.A.; Garabal, J.I.; Valderrama, S.; Blanco, J.; Baloda, S.B. Development and evaluation of an ELISA to detect Escherichia coli K88 (F4) fimbrial antibody levels. J. Med. Microbiol. 1996, 44, 453–463. [Google Scholar] [CrossRef]

- Kim, J.H.; Yoo, J.G.; Ham, J.S.; Oh, M.H. Direct detection of Escherichia coli, staphylococcus aureus, and Salmonella spp. in animal-derived foods using a magnetic bead-based immunoassay. Korean J. Food Sci. Anim. Resour. 2018, 38, 727–736. [Google Scholar]

- Sun, F.; Zhang, J.; Yang, Q.; Wu, W. Quantum dot biosensor combined with antibody and aptamer for tracing food-borne pathogens. Food Qual. Saf. 2021, 5, fyab019. [Google Scholar] [CrossRef]

- Magliulo, M.; Simoni, P.; Guardigli, M.; Michelini, E.; Luciani, M.; Lelli, R.; Roda, A. A rapid multiplexed chemiluminescent immunoassay for the detection of Escherichia coli O157:H7, Yersinia enterocolitica, Salmonella typhimurium, and Listeria monocytogenes pathogen bacteria. J. Agric. Food Chem. 2007, 55, 4933–4939. [Google Scholar] [CrossRef]

- Chen, C.; Luo, J.; Li, C.; Ma, M.; Yu, W.; Shen, J.; Wang, Z. Molecularly Imprinted Polymer as an Antibody Substitution in Pseudo-immunoassays for Chemical Contaminants in Food and Environmental Samples. J. Agric. Food Chem. 2018, 66, 2561–2571. [Google Scholar] [CrossRef]

- Turner, A.P.F. Biosensors: Sense and sensibility. Chem. Soc. Rev. 2013, 42, 3184–3196. [Google Scholar] [CrossRef] [Green Version]

- Chircov, C.; Bîrcă, A.C.; Grumezescu, A.M.; Andronescu, E. Biosensors-on-Chip: An Up-to-Date Review. Molecules 2020, 25, 6013. [Google Scholar] [CrossRef]

- Mohd Said, N.A. Electrochemical Biosensor Based on Microfabricated Electrode Arrays for Life Sciences Applications; University College Cork: Cork, Ireland, 2014. [Google Scholar] [CrossRef]

- Singh, A.; Poshtiban, S.; Evoy, S. Recent advances in bacteriophage based biosensors for food-borne pathogen detection. Sensors 2013, 13, 1763–1786. [Google Scholar] [CrossRef] [Green Version]

- Tilton, L.; Das, G.; Yang, X.; Wisuthiphaet, N.; Kennedy, I.M.; Nitin, N. Nanophotonic Device in Combination with Bacteriophages for Enhancing Detection Sensitivity of Escherichia coli in Simulated Wash Water. Anal. Lett. 2019, 52, 2203–2213. [Google Scholar] [CrossRef]

- Ali, A.A.; Altemimi, A.B.; Alhelfi, N.; Ibrahim, S.A. Application of biosensors for detection of pathogenic food bacteria: A review. Biosensors 2020, 10, 58. [Google Scholar] [CrossRef]

- Vidic, J.; Vizzini, P.; Manzano, M.; Kavanaugh, D.; Ramarao, N.; Zivkovic, M.; Radonic, V.; Knezevic, N.; Giouroudi, I.; Gadjanski, I. Point-of-need DNA testing for detection of foodborne pathogenic bacteria. Sensors 2019, 19, 1100. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Salazar, J.K. Culture-Independent Rapid Detection Methods for Bacterial Pathogens and Toxins in Food Matrices. Compr. Rev. Food Sci. Food Saf. 2016, 15, 183–205. [Google Scholar] [CrossRef]

- Hosseini, S.; Ibrahim, F.; Djordjevic, I.; Koole, L.H. Recent advances in surface functionalization techniques on polymethacrylate materials for optical biosensor applications. Analyst 2014, 139, 2933–2943. [Google Scholar] [CrossRef]

- Rubab, M.; Shahbaz, H.M.; Olaimat, A.N.; Oh, D.H. Biosensors for rapid and sensitive detection of Staphylococcus aureus in food. Biosens. Bioelectron. 2018, 105, 49–57. [Google Scholar] [CrossRef]

- Alamer, S.; Eissa, S.; Chinnappan, R.; Herron, P.; Zourob, M. Rapid colorimetric lactoferrin-based sandwich immunoassay on cotton swabs for the detection of foodborne pathogenic bacteria. Talanta 2018, 185, 275–280. [Google Scholar] [CrossRef] [Green Version]

- Krishna, V.D.; Wu, K.; Su, D.; Cheeran, M.C.J.; Wang, J.P.; Perez, A. Nanotechnology: Review of concepts and potential application of sensing platforms in food safety. Food Microbiol. 2018, 75, 47–54. [Google Scholar] [CrossRef]

- Campbell, C.T.; Kim, G. SPR microscopy and its applications to high-throughput analyses of biomolecular binding events and their kinetics. Biomaterials 2007, 28, 2380–2392. [Google Scholar] [CrossRef]

- Chen, S.; Svedendahl, M.; Käll, M.; Gunnarsson, L.; Dmitriev, A. Ultrahigh sensitivity made simple: Nanoplasmonic label-free biosensing with an extremely low limit-of-detection for bacterial and cancer diagnostics. Nanotechnology 2009, 20, 434015. [Google Scholar] [CrossRef] [PubMed]

- Yoo, S.M.; Lee, S.Y. Optical Biosensors for the Detection of Pathogenic Microorganisms. Trends Biotechnol. 2016, 34, 7–25. [Google Scholar] [CrossRef]

- Wang, J. Electrochemical nucleic acid biosensors. Anal. Chim. Acta 2002, 469, 63–71. [Google Scholar] [CrossRef]

- Lim, J.W.; Ha, D.; Lee, J.; Lee, S.K.; Kim, T. Review of micro/nanotechnologies for microbial biosensors. Front. Bioeng. Biotechnol. 2015, 3, 61. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bansod, B.K.; Kumar, T.; Thakur, R.; Rana, S.; Singh, I. A review on various electrochemical techniques for heavy metal ions detection with different sensing platforms. Biosens. Bioelectron. 2017, 94, 443–455. [Google Scholar] [CrossRef]

- Pal, S.; Ying, W.; Alocilja, E.C.; Downes, F.P. Sensitivity and specificity performance of a direct-charge transfer biosensor for detecting Bacillus cereus in selected food matrices. Biosyst. Eng. 2008, 99, 461–468. [Google Scholar] [CrossRef]

- De Ávila, B.E.F.; Pedrero, M.; Campuzano, S.; Escamilla-Gómez, V.; Pingarrón, J.M. Sensitive and rapid amperometric magnetoimmunosensor for the determination of Staphylococcus aureus. Anal. Bioanal. Chem. 2012, 403, 917–925. [Google Scholar] [CrossRef] [PubMed]

- Yamada, K.; Choi, W.; Lee, I.; Cho, B.K.; Jun, S. Rapid detection of multiple foodborne pathogens using a nanoparticle-functionalized multi-junction biosensor. Biosens. Bioelectron. 2016, 77, 137–143. [Google Scholar] [CrossRef]

- Sobhan, A.; Lee, J.; Park, M.K.; Oh, J.H. Rapid detection of Yersinia enterocolitica using a single–walled carbon nanotube-based biosensor for Kimchi product. LWT 2019, 108, 48–54. [Google Scholar] [CrossRef]

- Ben Haddada, M.; Salmain, M.; Boujday, S. Gold colloid-nanostructured surfaces for enhanced piezoelectric immunosensing of staphylococcal enterotoxin A. Sens. Actuators B Chem. 2018, 255, 1604–1613. [Google Scholar] [CrossRef] [Green Version]

- Yu, X.; Chen, F.; Wang, R.; Li, Y. Whole-bacterium SELEX of DNA aptamers for rapid detection of E. coli O157:H7 using a QCM sensor. J. Biotechnol. 2018, 266, 39–49. [Google Scholar] [CrossRef]

- Liu, F.; Li, Y.; Su, X.-L.; Slavik, M.F.; Ying, Y.; Wang, J. QCM immunosensor with nanoparticle amplification for detection of Escherichia coli O157:H7. Sens. Instrum. Food Qual. Saf. 2007, 1, 161–168. [Google Scholar] [CrossRef]

- Salmain, M.; Ghasemi, M.; Boujday, S.; Spadavecchia, J.; Técher, C.; Val, F.; Le Moigne, V.; Gautier, M.; Briandet, R.; Pradier, C.M. Piezoelectric immunosensor for direct and rapid detection of staphylococcal enterotoxin A (SEA) at the ng level. Biosens. Bioelectron. 2011, 29, 140–144. [Google Scholar] [CrossRef]

- Bayramoglu, G.; Ozalp, V.C.; Oztekin, M.; Arica, M.Y. Rapid and label-free detection of Brucella melitensis in milk and milk products using an aptasensor. Talanta 2019, 200, 263–271. [Google Scholar] [CrossRef] [PubMed]

- Butler, W.H.; Zhang, X.G.; Nicholson, D.M.C.; MacLaren, J.M. Spin-dependent scattering and giant magnetoresistance. J. Magn. Magn. Mater. 1995, 151, 354–362. [Google Scholar] [CrossRef]

- Mott, N.F. The electrical conductivity of transition metals. Proc. R. Soc. London. Ser. A Math. Phys. Sci. 1936, 153, 699–717. [Google Scholar]

- Nogués, J.; Schuller, I.K. Exchange bias. J. Magn. Magn. Mater. 1999, 192, 203–232. [Google Scholar] [CrossRef]

- Xiao, J.Q.; Jiang, J.S.; Chien, C.L. Giant magnetoresistance in nonmultilayer magnetic systems. Phys. Rev. Lett. 1992, 68, 3749–3752. [Google Scholar] [CrossRef] [PubMed]

- Berkowitz, A.E.; Mitchell, J.R.; Carey, M.J.; Young, A.P.; Zhang, S.; Spada, F.E.; Parker, F.T.; Hutten, A.; Thomas, G. Giant magnetoresistance in heterogeneous Cu-Co alloys. Phys. Rev. Lett. 1992, 68, 3745–3748. [Google Scholar] [CrossRef] [PubMed]

- Hylton, T.L. Limitations of magnetoresistive sensors based on the giant magnetoresistive effect in granular magnetic composites. Appl. Phys. Lett. 1993, 62, 2431–2433. [Google Scholar] [CrossRef]

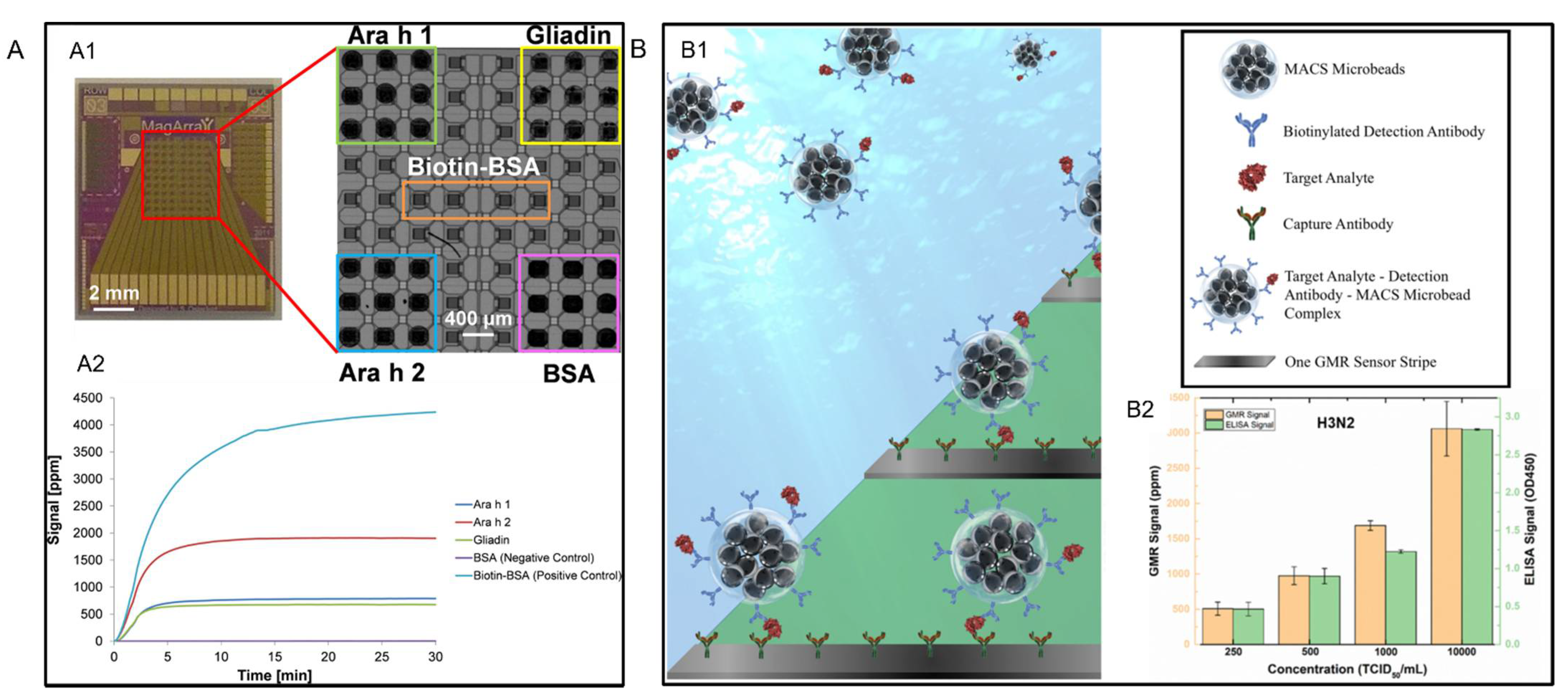

- Krishna, V.D.; Wu, K.; Perez, A.M.; Wang, J.P. Giant magnetoresistance-based biosensor for detection of influenza A virus. Front. Microbiol. 2016, 7, 400. [Google Scholar] [CrossRef] [Green Version]

- De Palma, R.; Liu, C.; Barbagini, F.; Reekmans, G.; Bonroy, K.; Laureyn, W.; Borghs, G.; Maes, G. Magnetic Particles as Labels in Bioassays: Interactions between a Biotinylated Gold Substrate and Streptavidin Magnetic Particles. J. Phys. Chem. C 2007, 111, 12227–12235. [Google Scholar] [CrossRef]

- Hall, D.A.; Gaster, R.S.; Lin, T.; Osterfeld, S.J.; Han, S.; Murmann, B.; Wang, S.X. GMR biosensor arrays: A system perspective. Biosens. Bioelectron. 2010, 25, 2051–2057. [Google Scholar] [CrossRef] [Green Version]

- Bechstein, D.J.B.; Lee, J.-R.; Ooi, C.C.; Gani, A.W.; Kim, K.; Wilson, R.J.; Wang, S.X. High performance wash-free magnetic bioassays through microfluidically enhanced particle specificity. Sci. Rep. 2015, 5, 11693. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.; Wang, Y.; Tu, L.; Klein, T.; Feng, Y.; Wang, J.P. Surface modification for protein and DNA immobilization onto GMR biosensor. IEEE Trans. Magn. 2013, 49, 296–299. [Google Scholar] [CrossRef]

- Yao, C.; Ng, E.; Wang, S.X. An automated and mobile magnetoresistive biosensor system for early hepatocellular carcinoma diagnosis. Biosens. Bioelectron. 2022, 202, 113982. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.; Gani, A.W.; Bechstein, D.J.B.; Lee, J.R.; Utz, P.J.; Wang, S.X. Portable, one-step, and rapid GMR biosensor platform with smartphone interface. Biosens. Bioelectron. 2016, 85, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Wu, K.; Klein, T.; Krishna, V.D.; Su, D.; Perez, A.M.; Wang, J.P. Portable GMR Handheld Platform for the Detection of Influenza A Virus. ACS Sens. 2017, 2, 1594–1601. [Google Scholar] [CrossRef]

- Meng, F.; Zhang, L.; Huo, W.; Lian, J.; Jesorka, A.; Shi, X.; Gao, Y. Dynamic Range Expansion of the C-Reactive Protein Quantification with a Tandem Giant Magnetoresistance Biosensor. ACS Omega 2021, 6, 12923–12930. [Google Scholar] [CrossRef]

- Meng, F.; Huo, W.; Lian, J.; Zhang, L.; Shi, X.; Jesorka, A.; Gao, Y. A tandem giant magnetoresistance assay for one-shot quantification of clinically relevant concentrations of N-terminal pro-B-type natriuretic peptide in human blood. Anal. Bioanal. Chem. 2021, 413, 2943–2949. [Google Scholar] [CrossRef]

- Sun, X.; Lei, C.; Guo, L.; Zhou, Y. Separable detecting of Escherichia coli O157H:H7 by a giant magneto-resistance-based bio-sensing system. Sens. Actuators B Chem. 2016, 234, 485–492. [Google Scholar] [CrossRef]

- Koets, M.; van der Wijk, T.; van Eemeren, J.T.W.M.; van Amerongen, A.; Prins, M.W.J. Rapid DNA multi-analyte immunoassay on a magneto-resistance biosensor. Biosens. Bioelectron. 2009, 24, 1893–1898. [Google Scholar] [CrossRef]

- Mak, A.C.; Osterfeld, S.J.; Yu, H.; Wang, S.X.; Davis, R.W.; Jejelowo, O.A.; Pourmand, N. Sensitive giant magnetoresistive-based immunoassay for multiplex mycotoxin detection. Biosens. Bioelectron. 2010, 25, 1635–1639. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, W.; Wang, Y.; Tu, L.; Klein, T.; Feng, Y.; Li, Q.; Wang, J.-P. Magnetic Detection of Mercuric Ion Using Giant Magnetoresistance-Based Biosensing System. Anal. Chem. 2014, 86, 3712–3716. [Google Scholar] [CrossRef]

- Su, D.; Wu, K.; Krishna, V.D.; Klein, T.; Liu, J.; Feng, Y.; Perez, A.M.; Cheeran, M.C.J.; Wang, J.-P. Detection of Influenza a Virus in Swine Nasal Swab Samples With a Wash-Free Magnetic Bioassay and a Handheld Giant Magnetoresistance Sensing System. Front. Microbiol. 2019, 10, 1077. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ng, E.; Nadeau, K.C.; Wang, S.X. Giant magnetoresistive sensor array for sensitive and specific multiplexed food allergen detection. Biosens. Bioelectron. 2016, 80, 359–365. [Google Scholar] [CrossRef] [Green Version]

- Feng, M.; Yong, Q.; Wang, W.; Kuang, H.; Wang, L.; Xu, C. Development of a monoclonal antibody-based ELISA to detect Escherichia coli O157:H7. Food Agric. Immunol. 2013, 24, 481–487. [Google Scholar] [CrossRef]

- Wang, Z.; Cai, R.; Gao, Z.; Yuan, Y.; Yue, T. Immunomagnetic separation: An effective pretreatment technology for isolation and enrichment in food microorganisms detection. Compr. Rev. Food Sci. Food Saf. 2020, 19, 3802–3824. [Google Scholar] [CrossRef]

- Shigemura, K.; Shirakawa, T.; Okada, H.; Tanaka, K.; Kamidono, S.; Arakawa, S.; Gotoh, A. Rapid detection and differentiation of Gram-negative and Gram-positive pathogenic bacteria in urine using TaqMan probe. Clin. Exp. Med. 2005, 4, 196–201. [Google Scholar] [CrossRef] [PubMed]

- Fricke, C.; Harms, H.; Maskow, T. Rapid Calorimetric Detection of Bacterial Contamination: Influence of the Cultivation Technique. Front. Microbiol. 2019, 10, 2530. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Giouroudi, I.; Kokkinis, G. Recent advances in magnetic microfluidic biosensors. Nanomaterials 2017, 7, 171. [Google Scholar] [CrossRef] [Green Version]

| Technique | Advantages | Disadvantages |

|---|---|---|

| Traditional Culture and Colony-based Methods | Low cost High sensitivity High credibility | Time-consuming Labor-intensiveness |

| Polymerase Chain Reaction (PCR) | High sensitivity High specificity High accuracy | Nucleic acid extraction Expensive equipment Requiring trained technicians No distinction between dead or live cells |

| Immunological Methods | High sensitivity High specificity Real-time analysis | Requiring trained technicians Expensive |

| Optical Biosensors | Easy to use Miniaturizable Low costs High sensitivity | Need for high energy sources Interference of incident light Narrow concentration range |

| Electrochemical Biosensors | Rapid Simple operation Miniaturizable | Low selectivity |

| Mechanical Biosensors | High sensitivity Rapid Simple operation Stable output | Low sensitivity with liquid samples Interference induces by nonspecific binding |

| MNPs | Target Analytes | Matrices | Assay Time | LOD | Detection Range | Ref. |

|---|---|---|---|---|---|---|

| Dynabeads | E. coli O157:H7 | Pure culture | N/A | N/A | N/A | [15] |

| Streptavidin-coated magnetic particles | LamB gene of E. coli | Pure culture | 3 min | 4 pM | 4 to 250 pM | [100] |

| MACS | Aflatoxins B1 | Pure culture | 15 min | 50 pg/mL | N/A | [101] |

| MACS | Zearalenone | Pure culture | 15 min | 50 pg/mL | N/A | [101] |

| MACS | HT-2 | Pure culture | 15 min | 50 pg/mL | 50 pg/mL–50 ng/mL | [101] |

| Dynabeads | E. coli O157:H7 | Orange juice | N/A | 100 CFU/mL | N/A | [99] |

| MACS | Mercuric ion | Natural water | 30 min | 10 nM | 10 nM to 10 μM | [102] |

| MACS | IAV nucleoprotein | Pure culture | N/A | 0.3 nM | N/A | [103] |

| MACS | IAV H3N2v | IAV-spiked nasal swab | N/A | 250 TCID50/mL | N/A | [103] |

| MACS | Ara h 1 | Pure culture | 15 min | 7.0 ng/mL | 7.0 to 2000 ng/mL | [104] |

| MACS | Ara h 2 | Pure culture | 15 min | 0.2 ng/mL | 0.2 to 250 ng/mL | [104] |

| MACS | Gliadin | Pure culture | 15 min | 1.5 ng/mL | 1.5 to 4000 ng/mL | [104] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, S.; Sutham, P.; Wu, K.; Mallikarjunan, K.; Wang, J.-P. Giant Magnetoresistance Biosensors for Food Safety Applications. Sensors 2022, 22, 5663. https://doi.org/10.3390/s22155663

Liang S, Sutham P, Wu K, Mallikarjunan K, Wang J-P. Giant Magnetoresistance Biosensors for Food Safety Applications. Sensors. 2022; 22(15):5663. https://doi.org/10.3390/s22155663

Chicago/Turabian StyleLiang, Shuang, Phanatchakorn Sutham, Kai Wu, Kumar Mallikarjunan, and Jian-Ping Wang. 2022. "Giant Magnetoresistance Biosensors for Food Safety Applications" Sensors 22, no. 15: 5663. https://doi.org/10.3390/s22155663

APA StyleLiang, S., Sutham, P., Wu, K., Mallikarjunan, K., & Wang, J.-P. (2022). Giant Magnetoresistance Biosensors for Food Safety Applications. Sensors, 22(15), 5663. https://doi.org/10.3390/s22155663