Novel and Simplified Procedure to Test Immunity of Low-Power Voltage Transformers

Abstract

:1. Introduction

2. Low-Power Voltage Transformers

2.1. IEC 61869 Series

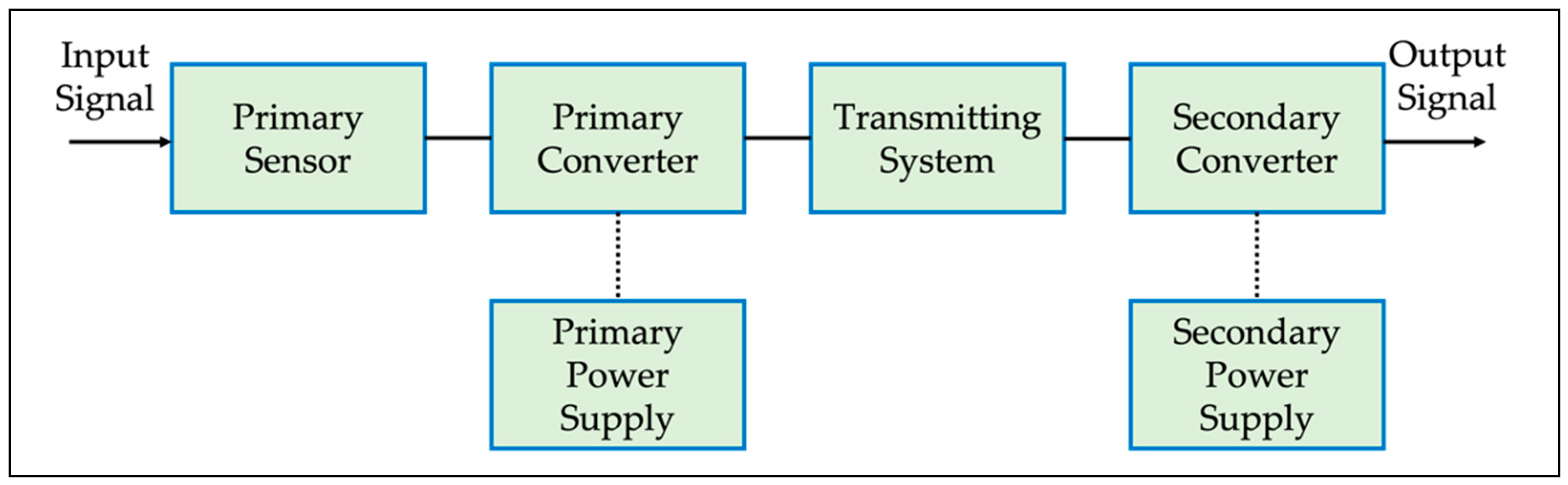

2.2. LPVT Working Principle

3. Standard Test

3.1. Introduction and Setup

3.2. Standard Test Description

- Step 1. The LPVT under test is fed with its rated voltage, and the dummy LPVT—which is connected to the metallic bar—is grounded. The applied primary voltage and the secondary voltage of the LPVT under test are acquired to compute the actual transformation ratio and the phase displacement (referred to as and , respectively).

- Step 2. Both the LPVTs are fed with the rated primary voltage. Again, the secondary voltage of the LPVT under test and the primary voltage are acquired to compute the actual transformation ratio and the phase displacement (referred to as and , respectively).

4. Proposed Procedure

4.1. Introduction

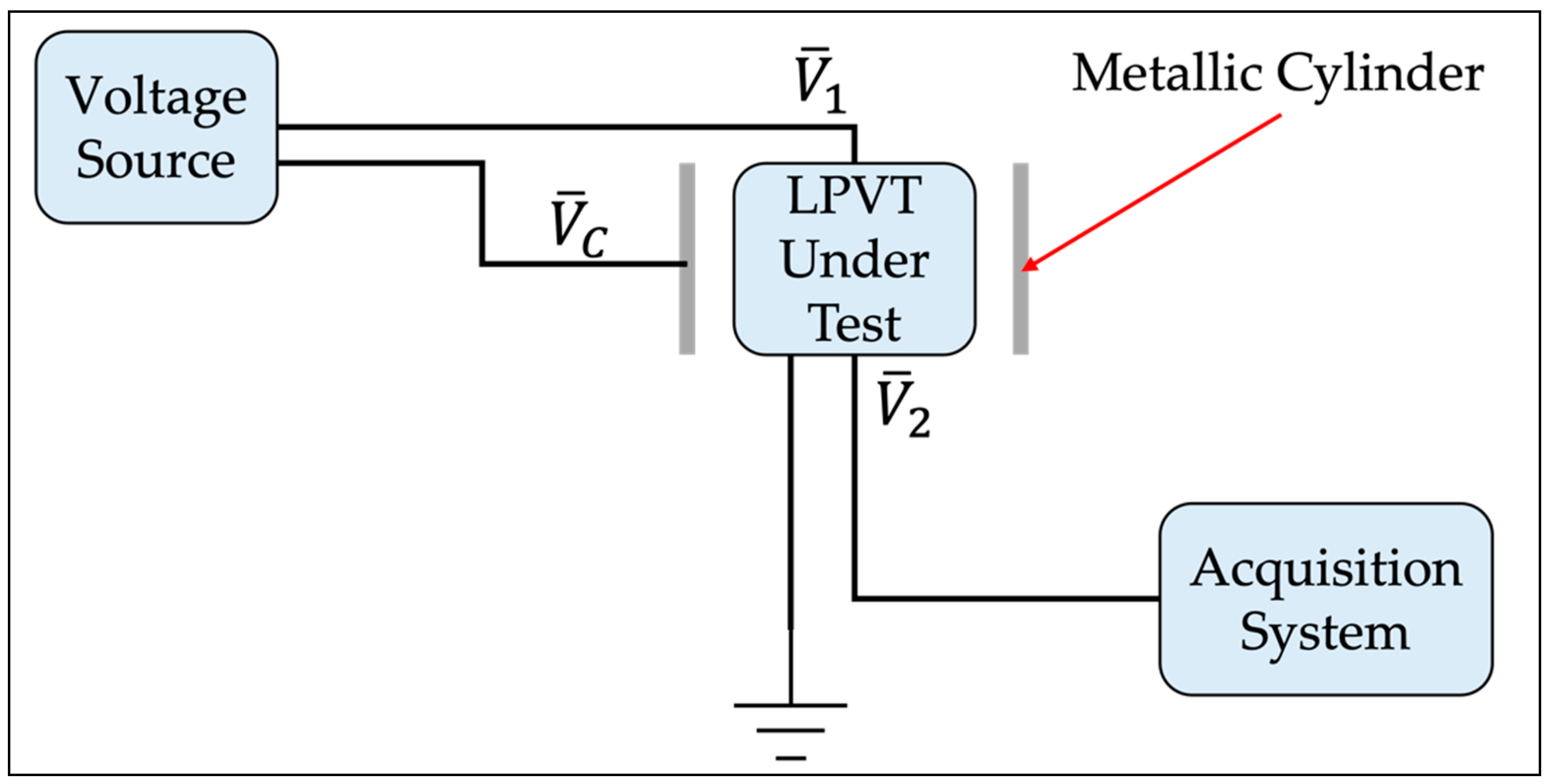

4.2. Simplified and Low-Cost Test Procedure

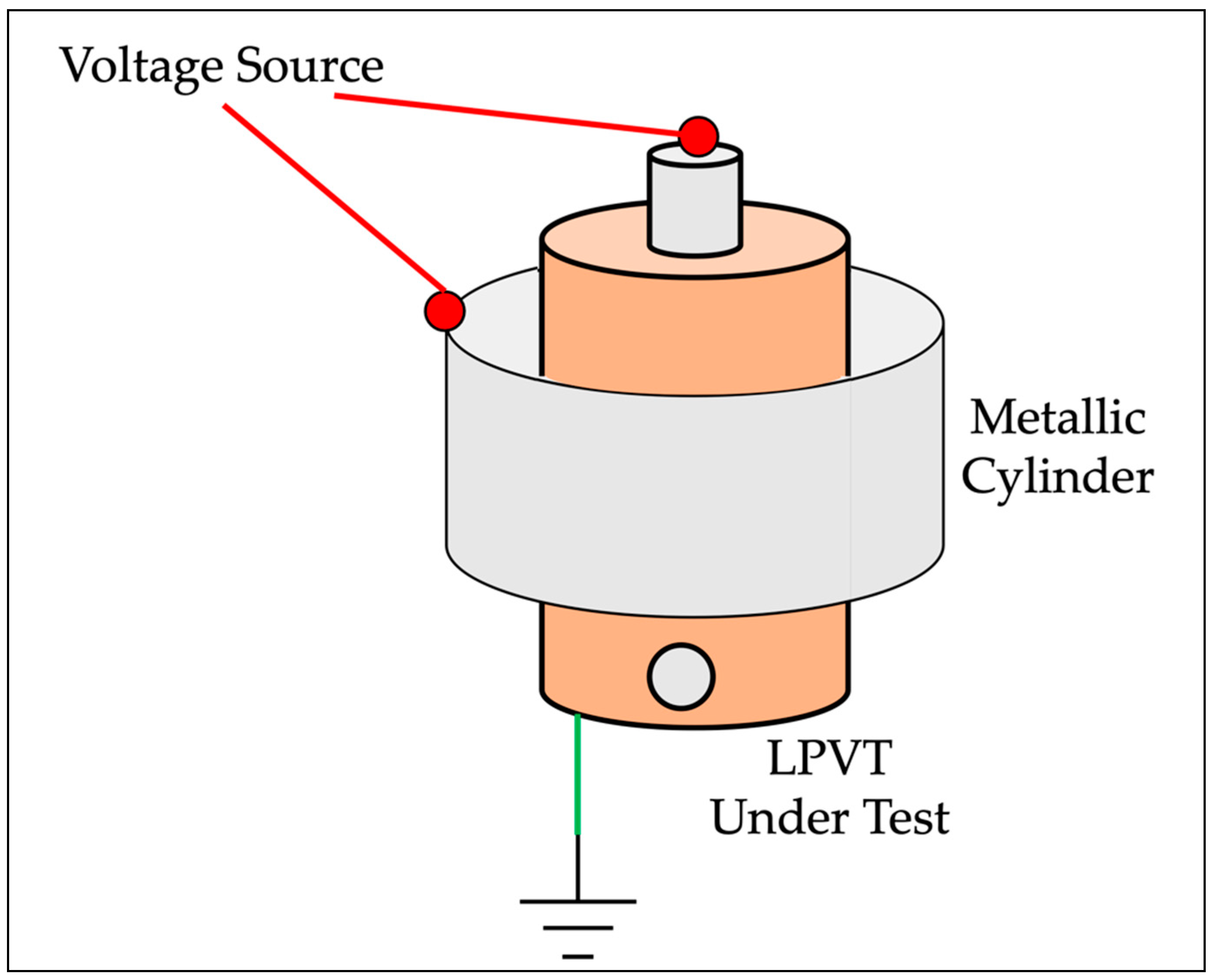

4.3. Experimental Implementation of the Test Procedure

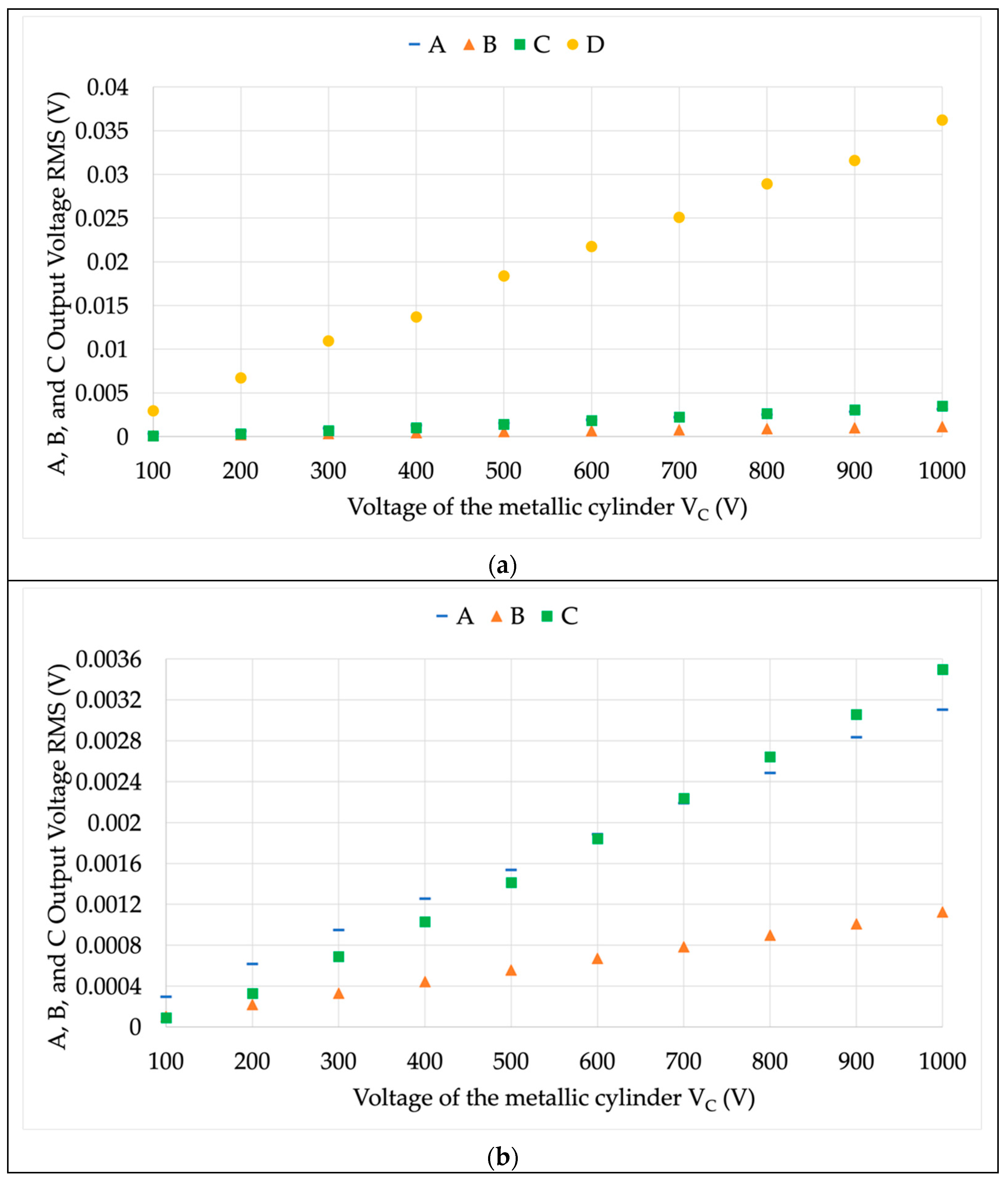

- LPVTs. Four commercial LPVTs are tested. One of them does not include any shielding in its structure. This device is used as further proof of the test validity. The features of the four LPVTs are listed in Table 1. Note that the LPVTs are referred to as A, B, C, and D. A is passive and capacitive, B is active and capacitive, C is passive and resistive, and D, the unshielded, is passive and capacitive. All devices share the same 0.5 accuracy class. This class features a 0.5% limit on the ratio error and a 6 mrad limit on the phase displacement [23]. All LPVTs have an analogue output, which was collected with the data acquisition system.

- Voltage Source. The Fluke 6105A calibrator [29] is used to feed both the LPVT and the metallic cylinder. It is fundamental to mention that the device was not selected for its metrological performance. It was chosen because it is capable of providing two voltage outputs with the same frequency. That is the reason why no accuracy specifications are given here. As for the applied voltage amplitudes, a fixed 7 V amplitude is selected as , whereas the set {100, 200, 300, 400, 500, 600, 700, 800, 900, 1000} V is selected for .

- Metallic cylinder. A 30 cm-diameter aluminum cylinder is used for the tests.

- Data acquisition system (DAQ). A NI 9239 board is used to collect both and . The features of the DAQ are collected in Table 2.

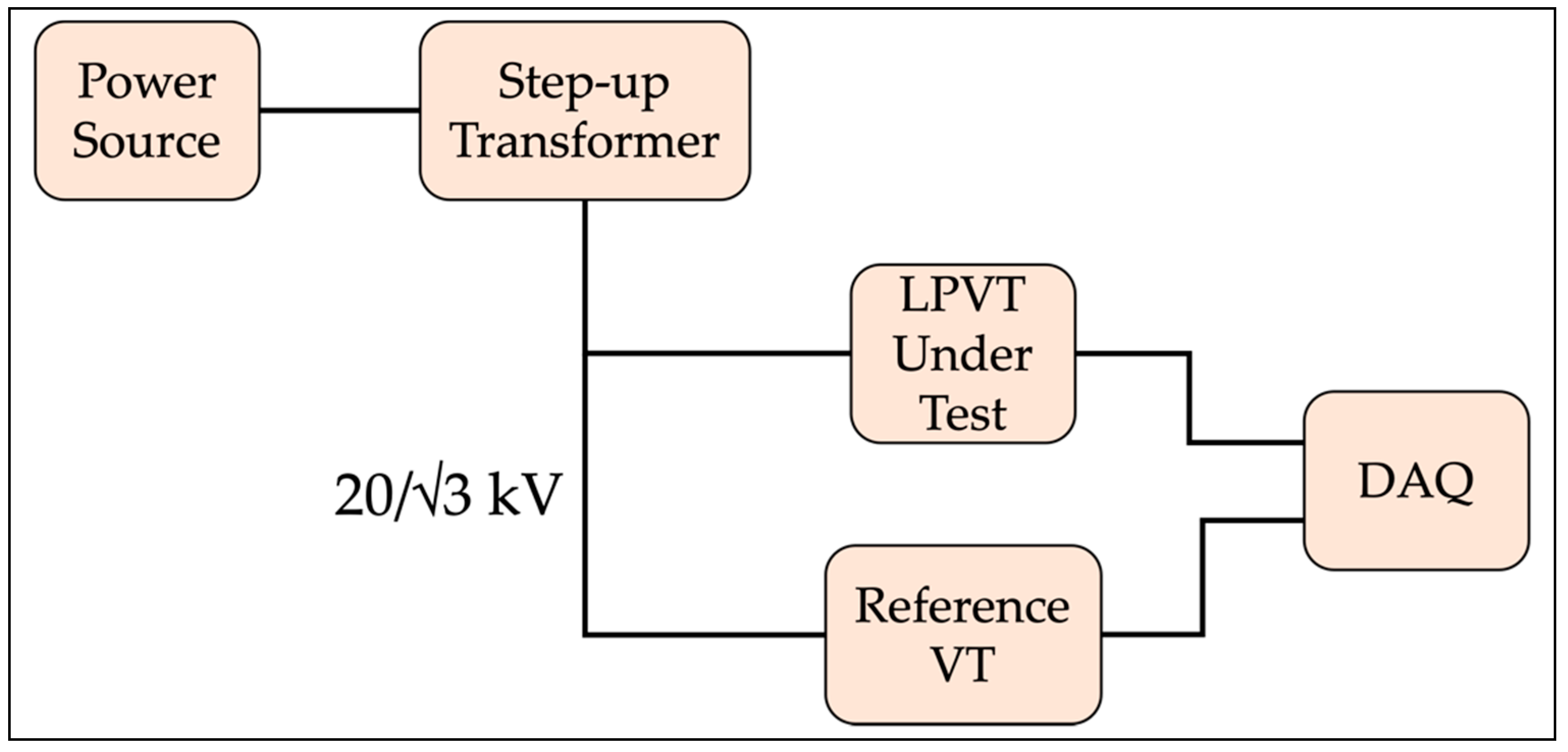

4.4. Validation of the Procedure

- An Agilent 6813B power source. It provides a stable 50 Hz voltage (less than 100 V) to the step-up transformer.

- A step-up transformer. It is used to increase the voltage to the LPVTs’ rated value. For all LPVTs, the rated voltage is 20/√3 kV (see Table 1).

- LPVTs under tests. These were already described.

- A reference voltage transformer (VT). To assess the output of the LPVTs, it is necessary to know the primary voltage applied to them. Hence, a capacitive reference divider with a 5981 ratio is adopted. It features an accuracy of three parts per thousand.

- A DAQ. The same previously described NI 9239 is used. The outputs of the LPVTs and the reference never exceed 10 V.

5. Results

5.1. Results of the Proposed Procedure

- The overall result is that the phase difference behavior is not linear, as in the case of the RMS.

- The applied voltage () is very limited in terms of magnitude; hence, the phase extraction is more complicated.

- As demonstrated by the literature (and in Section 5.2), most influence quantities affect the magnitude of the voltage. Consequently, the phase-angle evaluation becomes secondary, keeping the focus of the procedure on the voltage magnitude.

- The standard deviations associated with the phase-angle measurements are, for all cases, at least one order of magnitude lower than the measured quantity.

5.2. Results of the Test from the Standard

5.3. Discussion

- The test uses LV for both the primary terminals (7 V) and the metallic cylinder (from 100 V to 1000 V). Consequently, no issues associated with the rated voltages apply, resulting in a clear benefit from the MV to the EHV. Note that using an MV may trigger other phenomena that vary the testing conditions. However, such conditions were completely changed with the procedure.

- There is no need for other (dummy) devices to run the test. In the standard procedure, the real configuration of the three-phase system must be replicated.

- The application of two iso-frequency voltages such as and allows for the removal of the contribution from the results. One may comment that the obtained voltages are due to the primary voltage applied at the LPVT. Hence, the results presented in Figure 6 were replicated by removing the = 7 V contribution. The results of this procedure are shown in Figure 8a,b. Note from the graphs how negligible the contribution is, confirming the effectiveness of the procedure.

- It provides useful information on immunity for both the voltage magnitude and the phase-angle.

- The overall test is simpler, cheaper, and faster than the standard one. Such considerations include, for the duration, all the steps needed from the implementation of the measurement setup to the results’ assessment and evaluation. Furthermore, less instrumentation is needed.

- Harmonization of the metallic cylinder. In this study, a fixed metallic cylinder was used. This is because the dimensions of the LPVT under test are almost identical. However, at a commercial level, there is a variety of LPVTs with different dimensions. Hence, the metallic cylinder may become flexible to be adjusted to each LPVT. Furthermore, an interesting study may assess the metallic cylinder’s distance from the LPVT to find that which provides better results in terms of safety and immunity evaluation.Another aspect relevant to the metallic cylinder is its height. Again, each LPVT may have a different height, and this could result in different results during the immunity assessment.

- Type of LPVTs. The current standard prescribes that immunity tests shall be performed only on passive LPVTs. However, from the results, it was demonstrated that active LPVTs may also suffer from immunity. Therefore, a discussion on the types of LPVTs to be tested is needed. In addition, it was also shown that each working principle of an LPVT responds differently to the immunity test. This topic is also another source of discussion.

- Voltage level. The simplicity of the presented procedure allows for it being extended to all voltage levels. It is well known that HV and EHV tests are always critical and require dedicated laboratories and procedures. For this purpose, HV equipment will be tested to understand if the presented procedure may be replicated or if it needs some modifications.

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Available online: https://ec.europa.eu/commission/presscorner/detail/en/IP_22_1511 (accessed on 15 June 2022).

- Abbar, S.; Boumaiza, A.; Mohandes, N.; Sanfilippo, A. Modeling innovation diffusion for renewable energy technologies in city neighborhoods. Presented at the 2018 9th International Renewable Energy Congress, IREC 2018, Hammamet, Tunisia, 20–22 March 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Sweidan, O.D. Is the geopolitical risk an incentive or obstacle to renewable energy deployment? evidence from a panel analysis. Renew. Energy 2021, 178, 377–384. [Google Scholar] [CrossRef]

- Barone, G.; Buonomano, A.; Forzano, C.; Giuzio, G.F.; Palombo, A. Increasing renewable energy penetration and energy independence of island communities: A novel dynamic simulation approach for energy, economic, and environmental analysis, and optimization. J. Clean. Prod. 2021, 311, 127558. [Google Scholar] [CrossRef]

- Dalala, Z.; Al-Omari, M.; Al-Addous, M.; Bdour, M.; Al-Khasawneh, Y.; Alkasrawi, M. Increased renewable energy penetration in national electrical grids constraints and solutions. Energy 2022, 246, 123361. [Google Scholar] [CrossRef]

- Jones, C.B.; Lave, M.; Vining, W.; Garcia, B.M. Uncontrolled electric vehicle charging impacts on distribution electric power systems with primarily residential, commercial or industrial loads. Energies 2021, 14, 1688. [Google Scholar] [CrossRef]

- Perujo, A.; Ciuffo, B. The introduction of electric vehicles in the private fleet: Potential impact on the electric supply system and on the environment. A case study for the province of milan, italy. Energy Policy 2010, 38, 4549–4561. [Google Scholar] [CrossRef]

- Crotti, G.; Gallo, D.; Giordano, D.; Landi, C.; Luiso, M.; Cherbaucich, C.; Mazza, P. Low cost measurement equipment for the accurate calibration of voltage and current transducers. Presented at the Conference Record-IEEE Instrumentation and Measurement Technology Conference, Montevideo, Uruguay, 12–15 May 2014; pp. 202–206. [Google Scholar] [CrossRef]

- Faifer, M.; Laurano, C.; Ottoboni, R.; Toscani, S.; Zanoni, M. Characterization of voltage instrument transformers under nonsinusoidal conditions based on the best linear approximation. IEEE Trans. Instrum. Meas. 2018, 67, 2392–2400. [Google Scholar] [CrossRef]

- Mingotti, A.; Betti, C.; Peretto, L.; Tinarelli, R. Simplified and low-cost characterization of medium-voltage low-power voltage transformers in the power quality frequency range. Sensors 2022, 22, 2274. [Google Scholar] [CrossRef] [PubMed]

- Crotti, G.; Femine, A.D.; Gallo, D.; Giordano, D.; Landi, C.; Letizia, P.S.; Luiso, M. Traceable characterization of low power voltage instrument transformers for PQ and PMU applications. Presented at the CPEM Digest (Conference on Precision Electromagnetic Measurements), Denver, CO, USA, 24–28 August 2020. [Google Scholar] [CrossRef]

- Mingotti, A.; Peretto, L.; Tinarelli, R. A simple modelling procedure of rogowski coil for power systems applications. Presented at the AMPS 2019—2019 10th IEEE International Workshop on Applied Measurements for Power Systems, Proceedings, Aachen, Germany, 25–27 September 2019. [Google Scholar] [CrossRef]

- Wu, Q.; Lu, K.; Li, H. Modeling and analysis of current transformer for fast switching power module current measurement. Presented at the 2016 IEEE 8th International Power Electronics and Motion Control Conference, IPEMC-ECCE Asia 2016, Hefei, China, 22–26 May 2016; pp. 1615–1622. [Google Scholar] [CrossRef]

- Afonso, J.I.; Toscano, P.; Briozzo, I. Current transformer modeling for electromagnetic transient simulation in protection systems. Presented at the 2020 IEEE PES Transmission and Distribution Conference and Exhibition-Latin America, T and D LA, Montevideo, Uruguay, 21 January 2020. [Google Scholar] [CrossRef]

- Mingotti, A.; Peretto, L.; Tinarelli, R.; Angioni, A.; Monti, A.; Ponci, F. A simple calibration procedure for an LPIT plus PMU system under off-nominal conditions. Energies 2019, 12, 4645. [Google Scholar] [CrossRef] [Green Version]

- Juarez-Balderas, E.A.; Medina-Marin, J.; Olivares-Galvan, J.C.; Hernandez-Romero, N.; Seck-Tuoh-Mora, J.C.; Rodriguez-Aguilar, A. Hot-spot temperature forecasting of the instrument transformer using an artificial neural network. IEEE Access 2020, 8, 164392–164406. [Google Scholar] [CrossRef]

- Sivan, V.; Robalino, D.M.; Mahajan, S.M. Measurement of temperature gradients inside a medium voltage current transformer. Presented at the 2007 39th North American Power Symposium, NAPS, Las Cruces, NM, USA, 30 September–2 October 2007; pp. 242–245. [Google Scholar] [CrossRef]

- Mingotti, A.; Bartolomei, L.; Peretto, L.; Tinarelli, R. On the long-period accuracy behavior of inductive and low-power instrument transformers. Sensors 2020, 20, 5810. [Google Scholar] [CrossRef] [PubMed]

- Mingotti, A.; Costa, F.; Peretto, L.; Tinarelli, R. Accuracy type test for rogowski coils subjected to distorted signals, temperature, humidity, and position variations. Sensors 2022, 22, 1397. [Google Scholar] [CrossRef] [PubMed]

- Marinescu, A.; Coatu, S.; Rucinschi, D. About the EMC of non-conventional electronic instrument transformer case study. Presented at the 2012 International Conference on Applied and Theoretical Electricity, ICATE 2012-Proceedings, Craiova, Romania, 25–27 October 2012. [Google Scholar] [CrossRef]

- Razavi SA, H.; Frei, S. Characterization of current transformers for impedance measurements in automotive immunity test setups. Presented at the IEEE International Symposium on Electromagnetic Compatibility, Wroclaw, Poland, 5–9 September 2016; pp. 411–416. [Google Scholar] [CrossRef]

- Wu, H.; Jiao, C.; Cui, X.; Liu, X.; Ji, J. Transient electromagnetic disturbance induced on the ports of intelligent component of electronic instrument transformer due to switching operations in 500 kV GIS substations. IEEE Access 2017, 5, 5104–5112. [Google Scholar] [CrossRef]

- IEC 61869-11:2018; Instrument Transformers-Part 11: Additional Requirements for Low-Power Passive Voltage Transformers. International Standardization Organization: Geneva, Switzerland, 2018.

- IEC 61869-1:2010; Instrument Transformers-Part 1: General Requirements. International Standardization Organization: Geneva, Switzerland, 2010.

- IEC 61869-6; Part 6: Additional General Requirements for Low-Power Instrument Transformers. International Standardization Organization: Geneva, Switzerland, 2016.

- IEC 61869-10; Part 10: Additional Requirements for Low-Power Passive Current Transformers. International Standardization Organization: Geneva, Switzerland, 2018.

- Stankovic, K.; Kovacevic, U. Combined Measuring Uncertainty of Capacitive Divider With Concentrated Capacitance on High-Voltage Scale. IEEE Trans. Plasma Sci. 2018, 46, 2972–2978. [Google Scholar] [CrossRef]

- Hobejogi, T.; Biela, J. Coaxial capacitive voltage divider with high division ratio for high voltage pulses with very fast rise times. Presented at the IEEE Pulsed Power Conference, Chicago, IL, USA, 19–23 June 2011. [Google Scholar]

- Available online: https://eu.flukecal.com/products/electrical-calibration/electrical-calibrators/6105a-6100b-electrical-power-quality-calibrat (accessed on 17 June 2022).

| Feature | A | B | C | D |

|---|---|---|---|---|

| Type of Divider | Capacitive | Capacitive | Resistive | Capacitive |

| Active/Passive | Passive | Active | Passive | Passive |

| Rated Primary Voltage (kV) | 20/√3 | 20/√3 | 20/√3 | 20/√3 |

| Rated Transformation Ratio (V/V) | 8200 | 20,000/√3 | 6153 | 16,800 |

| Accuracy Class (−) | 0.5 | 0.5 | 0.5 | 0.5 |

| Resolution | 24 bit | Max Sampling Frequency | 50 kSa/s/ch |

| Gain Error | ±0.03% | Offset Error | 0.008% |

| LPVT | Bar Potential | Frequency (Hz) | k (V/V) | |||

|---|---|---|---|---|---|---|

| A | GND | 60 | 8160.0720 | 7 × 10−4 | 0.0513622 | 1 × 10−7 |

| HV | 60 | 8149.8043 | 8 × 10−4 | 0.0513455 | 2 × 10−7 | |

| B | GND | 60 | 11,275.164 | 4 × 10−3 | 0.0023404 | 3 × 10−7 |

| HV | 60 | 11,269.789 | 3 × 10−3 | 0.0023600 | 3 × 10−7 | |

| C | GND | 60 | 6241.673 | 1 × 10−3 | 0.00697956 | 5 × 10−7 |

| HV | 60 | 6241.371 | 1 × 10−3 | 0.004380 | 1 × 10−6 | |

| D | GND | 60 | 16,884.7 | 9 × 10−1 | 0.06218 | 7 × 10−5 |

| HV | 60 | 17,906 | 1 | 0.04788 | 7 × 10−5 |

| LPVT | ||

|---|---|---|

| A | −0.126 | −0.0168 |

| B | −0.048 | 0.0196 |

| C | −0.0048 | −2.599 |

| D | 6.051 | −14.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mingotti, A.; Peretto, L.; Tinarelli, R. Novel and Simplified Procedure to Test Immunity of Low-Power Voltage Transformers. Sensors 2022, 22, 5804. https://doi.org/10.3390/s22155804

Mingotti A, Peretto L, Tinarelli R. Novel and Simplified Procedure to Test Immunity of Low-Power Voltage Transformers. Sensors. 2022; 22(15):5804. https://doi.org/10.3390/s22155804

Chicago/Turabian StyleMingotti, Alessandro, Lorenzo Peretto, and Roberto Tinarelli. 2022. "Novel and Simplified Procedure to Test Immunity of Low-Power Voltage Transformers" Sensors 22, no. 15: 5804. https://doi.org/10.3390/s22155804