A Method for Measuring the Quality of Graphic Transfer to Materials with Variable Dimensions (Wood)

Abstract

:1. Introduction

- A calibration system for dimensional changes during the production process via optical sensing. This system enables the comparison of production input and output even though the output is non-linearly deformed during production. See Section 2.2.

- A quality measurement system for the production of natural and inhomogeneous materials. This system enables the measurement and expressing of the quality for production with variable input materials (every wood veneer is different) and variable production input (every graphic is different). See Section 3.1.

- A study for a compensation system which can predict dimensional changes in the pre-production stage and can deform input graphics to compensate for material deformations and achieve desired results. See Section 2.2.

- A study on an expert system with a database which, with statistical data, can compare every production process (with variable materials and input graphics) and determine the best possible pre-production processing of the material, production parameters, and input graphics. See Section 3.3.

2. Equipment, Materials, and Experimental Procedures

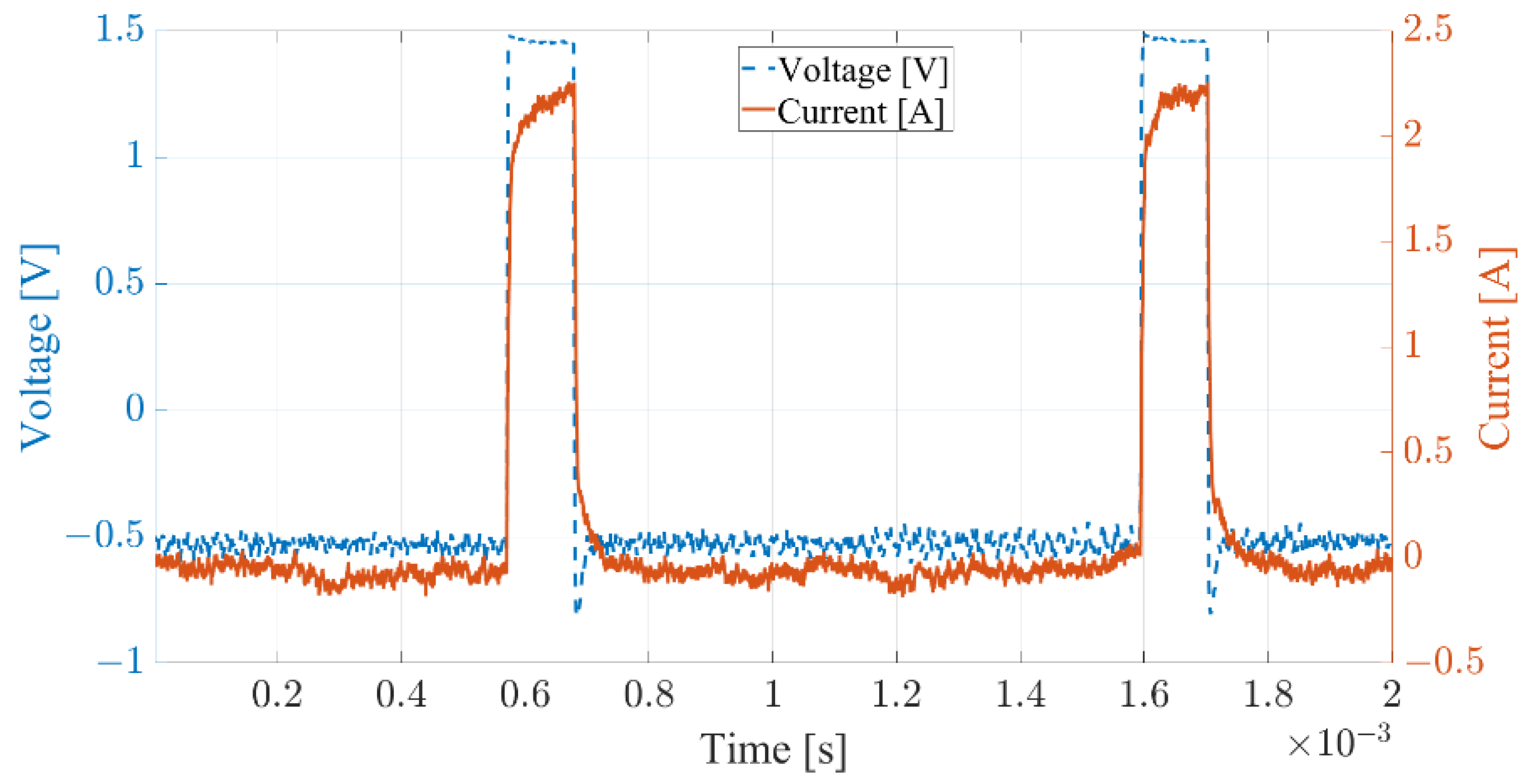

2.1. Laser Machine

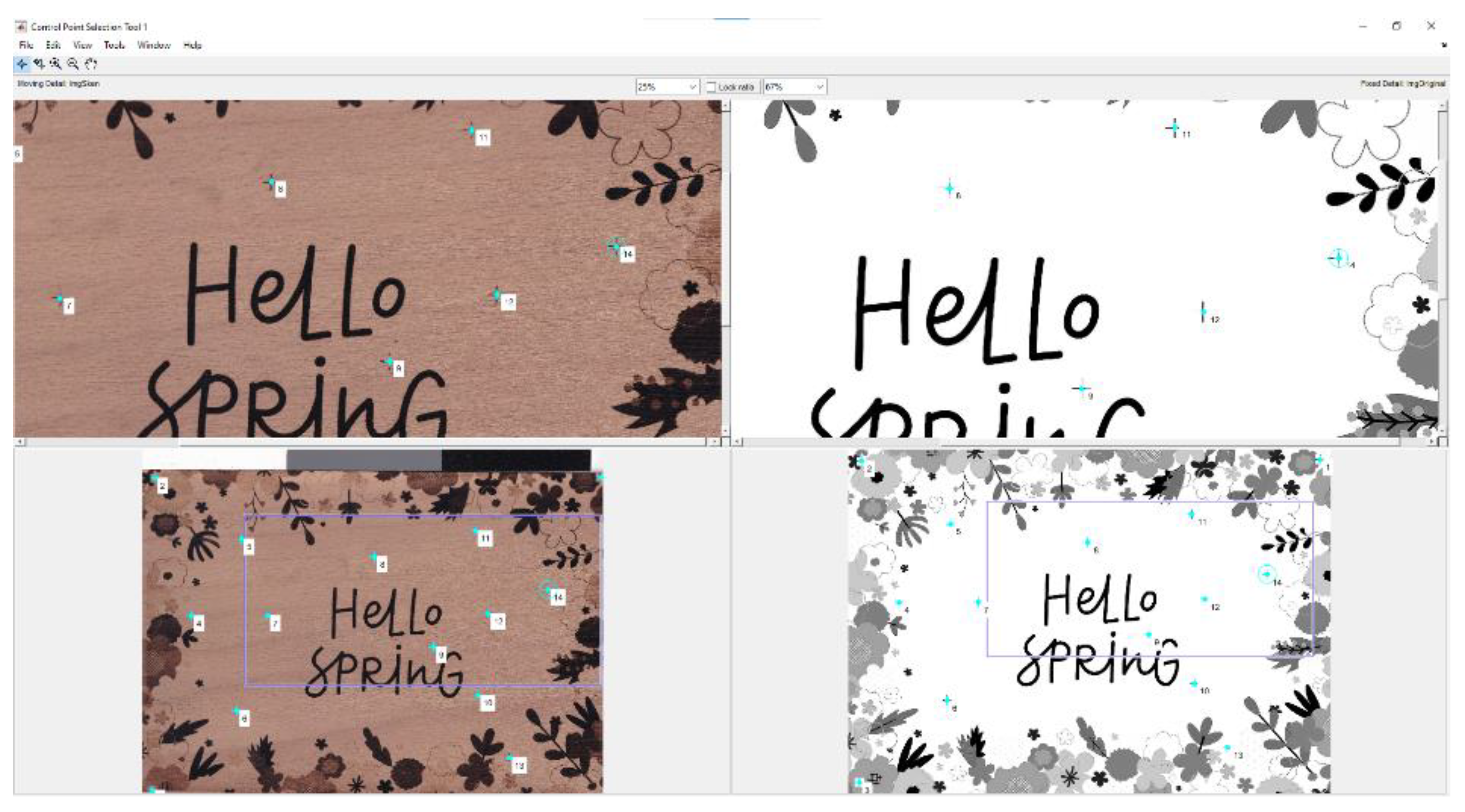

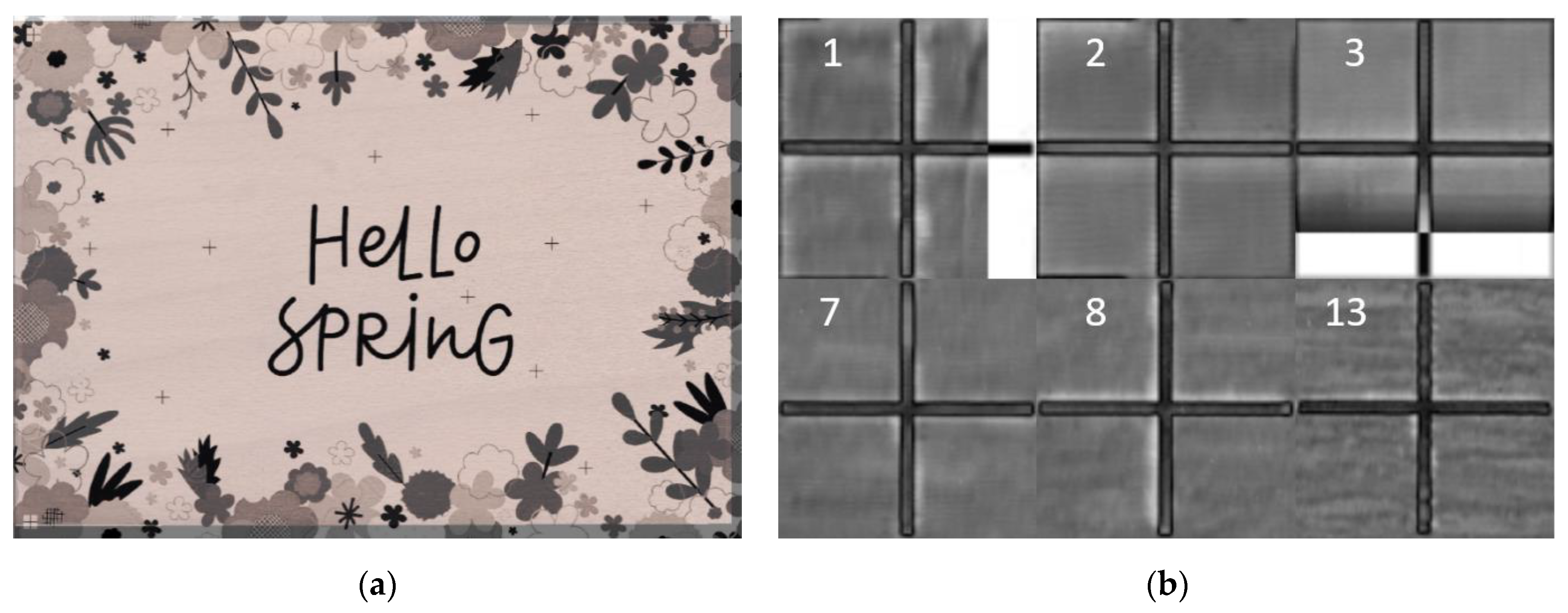

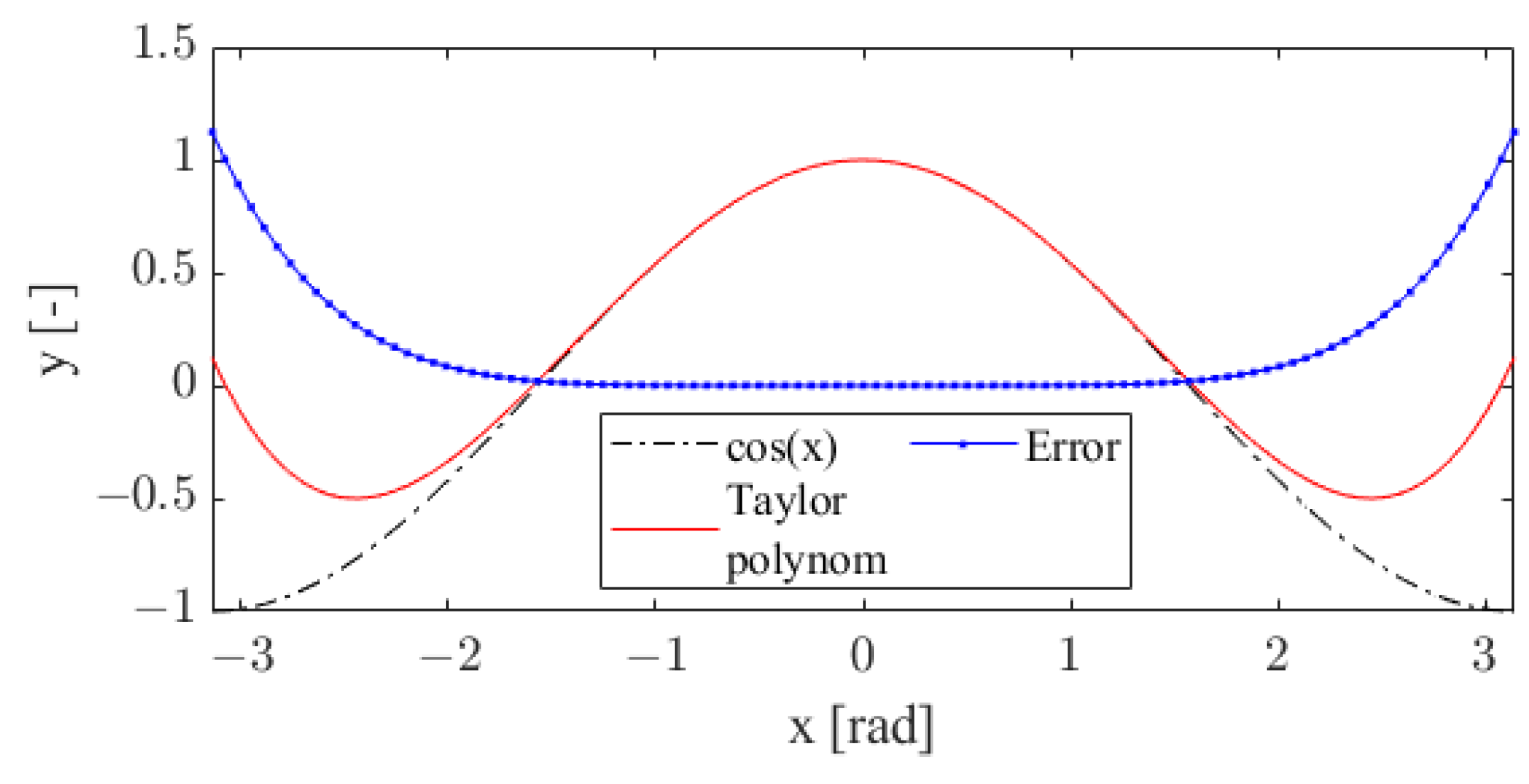

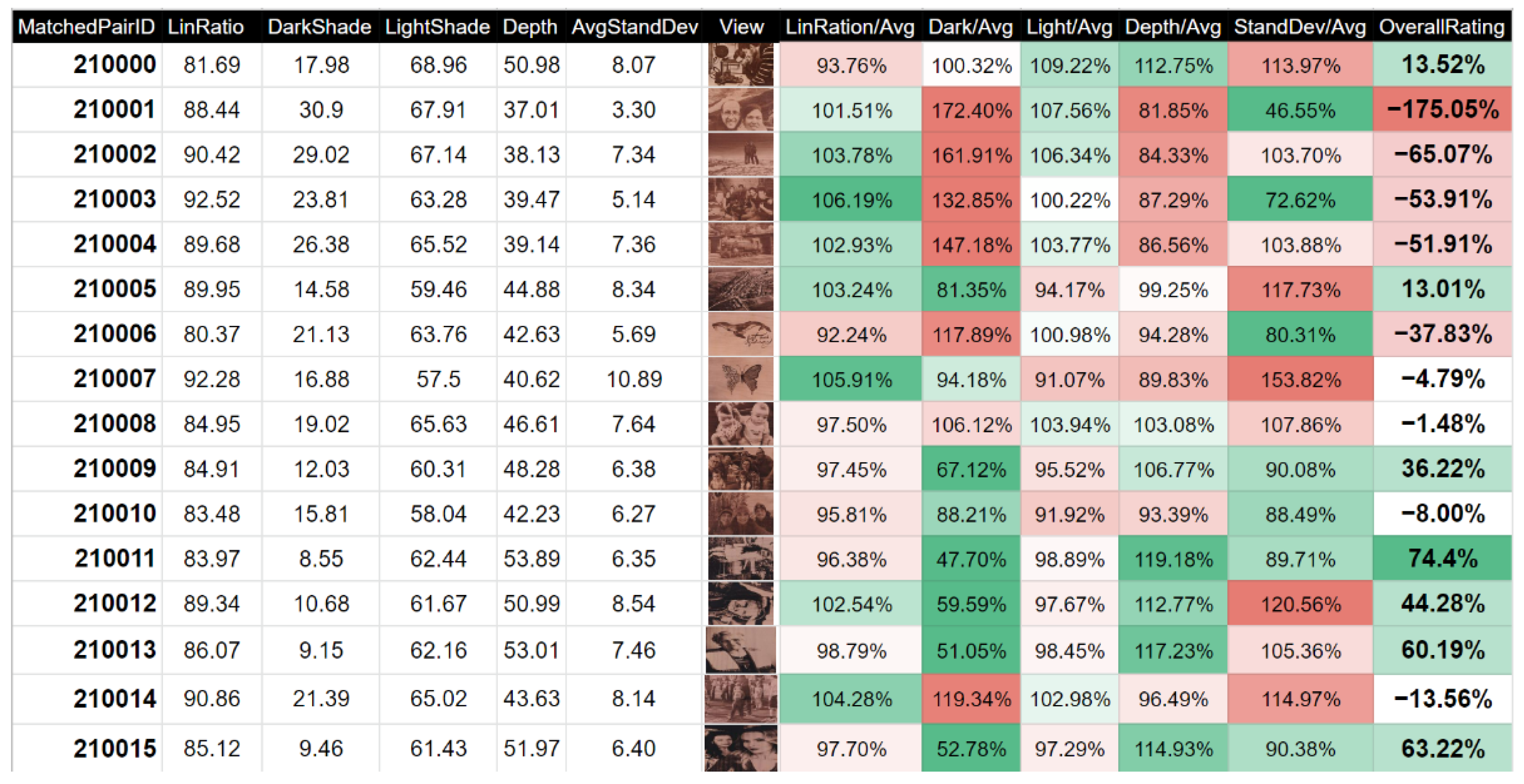

2.2. Affine Transformation

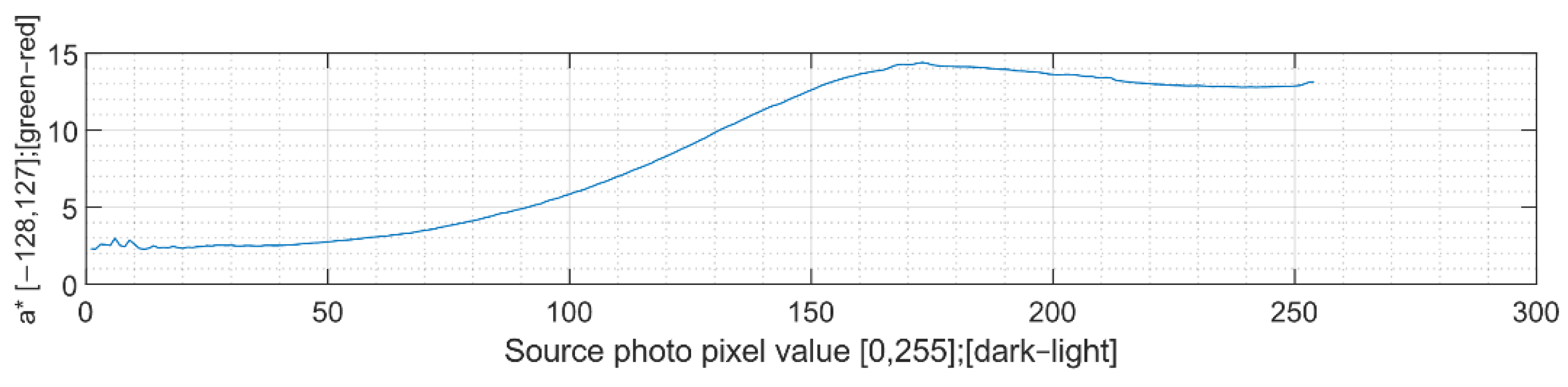

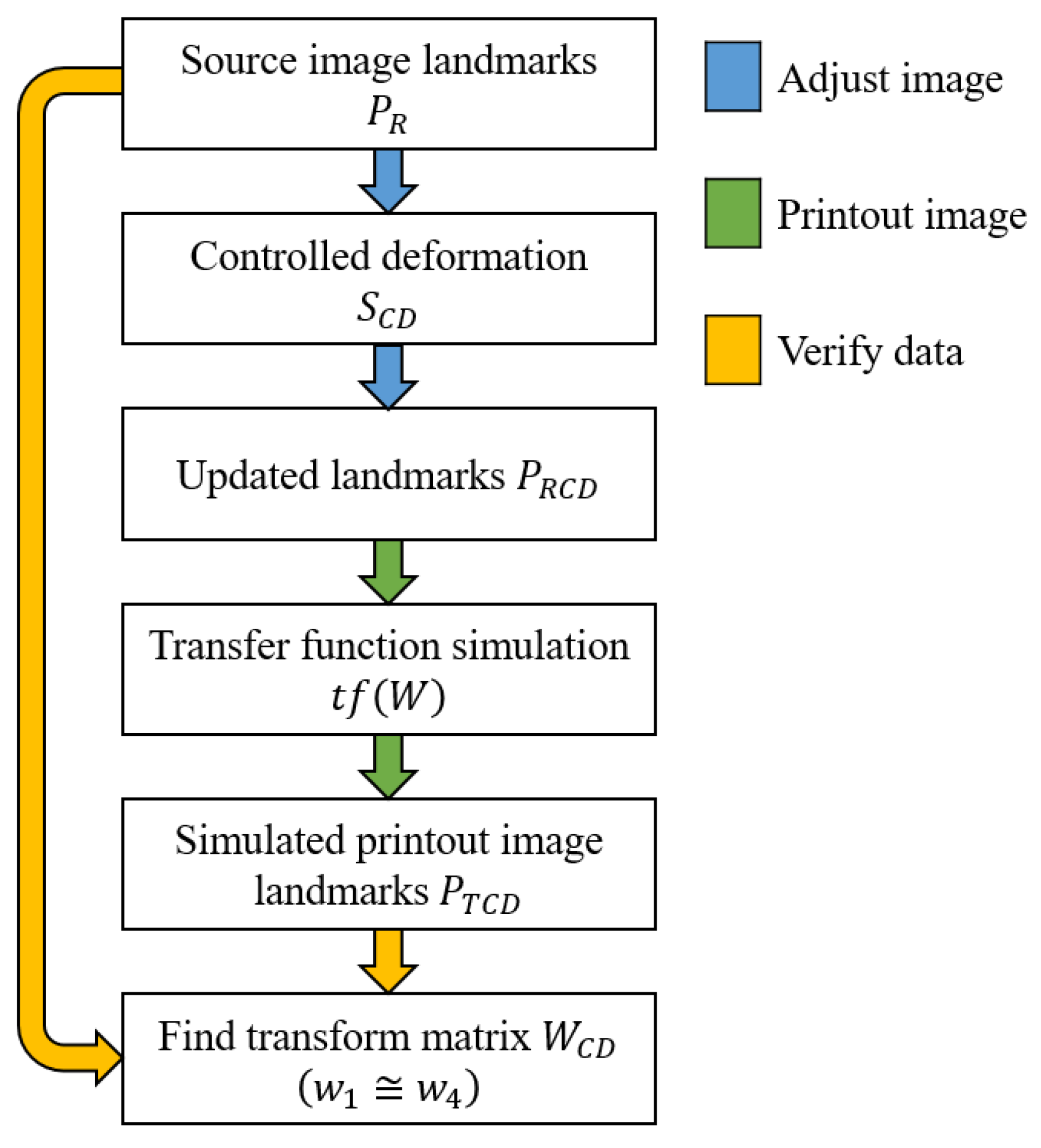

2.3. Quality Measurement Method

3. Results and discussion

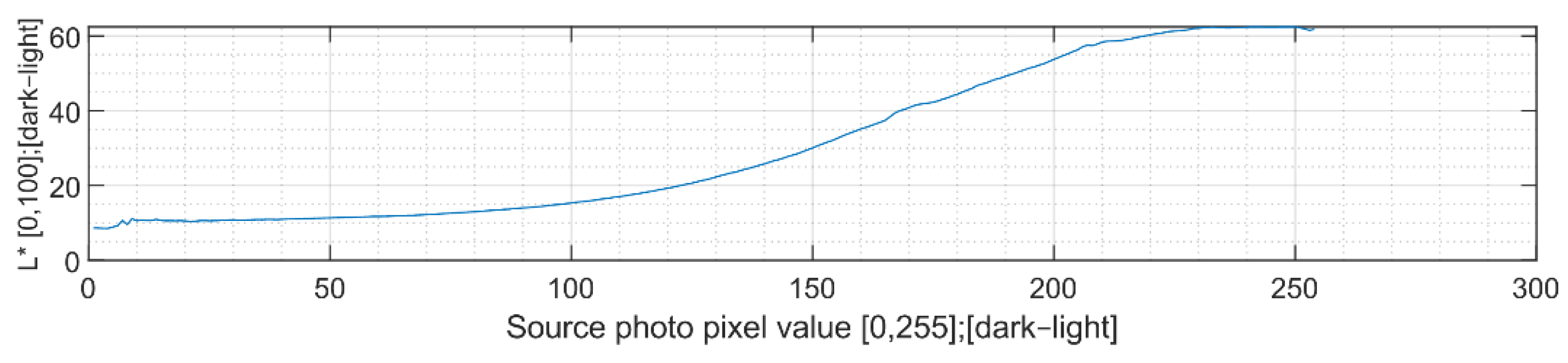

3.1. Quality Measurement Method

3.2. Standard Deviation

3.3. Quality Improvement by Production Parameter Optimisation

3.4. Quality Improvement by Implementing a Calibration Process Based on Affine Transformation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sieka, P.; Magda, K.; Malowany, K.; Rutkiewicz, J.; Styk, A.; Krzesłowski, J.; Kowaluk, T.; Zagórski, A. On-line laser triangulation scanner for wood logs. Sensors 2019, 19, 1074. [Google Scholar]

- Petru, A.; Lunguleasa, A. Effects of the laser power on wood colouration. In Proceedings of the International Conference of Scientific Paper AFASES 2015, Brasov, Romania, 28–30 May 2015; pp. 1–4. [Google Scholar]

- Kubovský, I.; Kačík, F. Changes of the wood surface colour induced by CO2 laser and its durability after the xenon lamp exposure. Wood Res. 2013, 58, 581–590. [Google Scholar]

- Martínez-Conde, A.; Krenke, T.; Frybort, S.; Müller, U. Review: Comparative analysis of CO2 laser and conventional sawing for cutting of lumber and wood-based materials. Wood Sci. Technol. 2017, 51, 943–966. [Google Scholar] [CrossRef]

- Bogosanovic, M.; Al-Anbuky, A.; Emms, G.W. Microwave nondestructive testing of wood anisotropy and scatter. IEEE Sens. J. 2012, 13, 306–313. [Google Scholar] [CrossRef]

- Moron, C.; Garcia-Fuentevilla, L.; Garcia, A.; Moron, A. Measurement of moisture in wood for application in the restoration of old buildings. Sensors 2016, 16, 697. [Google Scholar] [CrossRef]

- Baranski, J.; Suchta, A.; Baranska, S.; Klement, I.; Vilkovská, T.; Vilkovský, P. Wood moisture-content measurement accuracy of impregnated and nonimpregnated wood. Sensors 2021, 21, 7033. [Google Scholar] [CrossRef]

- Häglund, M. Parameter influence on moisture induced eigen-stresses in timber. Eur. J. Wood Wood Prod. 2010, 68, 397–406. [Google Scholar] [CrossRef]

- Hu, X.; Zheng, Y.; Liang, H.; Zhao, Y. Design and test of a microdestructive tree-ring measurement system. Sensors 2020, 20, 3253. [Google Scholar] [CrossRef] [PubMed]

- Kifetew, G. Application of the deformation field measurement method to wood during drying. Wood Sci. Technol. 1996, 30, 455–462. [Google Scholar] [CrossRef]

- Baietto, M.; Wilson, A.D.; Bassi, D.; Ferrini, F. Evaluation of three electronic noses for detecting incipient wood decay. Sensors 2010, 10, 1062–1092. [Google Scholar] [CrossRef]

- Wilson, A.D. Diverse applications of electronic-nose technologies in agriculture and forestry. Sensors 2013, 13, 2295–2348. [Google Scholar] [CrossRef] [PubMed]

- Hernandez-Castaneda, J.C.; Sezer, H.K.; Li, L. The effect of moisture content in fibre laser cutting of pine wood. Opt. Lasers Eng. 2011, 49, 1139–1152. [Google Scholar] [CrossRef]

- Sandak, J.; Sandak, A.; Zitek, A.; Hintestoisser, B.; Picchi, G. Development of low-cost portable spectrometers for detection of wood defects. Sensors 2020, 20, 545. [Google Scholar] [CrossRef]

- Silvennoinen, R.; Wahl, P.; Vidot, J. Inspection of orientation of micro fibres in dried wood by a diffractive optical element. Opt. Lasers Eng. 2000, 33, 29–38. [Google Scholar] [CrossRef]

- Assis, M.R.; Brancheriau, L.; Napoli, A.; Trugilho, P.F. Factors affecting the mechanics of carbonized wood. Wood Sci. Technol. 2016, 50, 519–536. [Google Scholar] [CrossRef]

- Saloni, D.E.; Lemaster, R.L.; Jackson, S.D. Process monitoring evaluation and implementation for the wood abrasive machining process. Sensors 2010, 10, 10401–10412. [Google Scholar] [CrossRef]

- Eltawahni, H.A.; Rossini, N.S.; Dassisti, M.; Alrashed, K.; Aldaham, T.A.; Benyounis, K.Y.; Olabi, A.G. Evalaution and optimization of laser cutting parametersfor plywood materials. Opt. Lasers Eng. 2013, 51, 1029–1043. [Google Scholar] [CrossRef]

- Hung, S.; Chung, Y.; Chen, C.; Chang, K. Optoelectronic angular displacement measurement technology for 2-dimensional mirror galvanometer. Sensors 2022, 22, 872. [Google Scholar] [CrossRef] [PubMed]

- Ramasubramanian, M.K.; Venditti, R.A.; Ammineni, C.; Mallapragada, V. Optical sensor for noncontact measurement of lignin content in high-speed moving paper surfaces. IEEE Sens. J. 2005, 5, 1132–1139. [Google Scholar] [CrossRef]

- Wu, Y.; Tian, G.; Liu, W. Research on moisture content detection of wood components through Wi-Fi channel state information and deep extreme learning machine. IEEE Sens. J. 2020, 20, 9977–9988. [Google Scholar] [CrossRef]

- Kandala, C.V.; Holser, R.; Settaluri, V.; Mani, S.; Puppala, N. Capacitance sensing of moisture content in fuel wood chips. IEEE Sens. J. 2016, 16, 4509–4514. [Google Scholar] [CrossRef]

- Brischke, C.; Meyer-Veltrup, L. Moisture content and decay of differently sized wooden components during 5 years of outdoor exposure. Eur. J. Wood Wood Prod. 2015, 73, 719–728. [Google Scholar] [CrossRef]

- Zhuang, Z.; Liu, Y.; Ding, F.; Wang, Z. Features, online color classification system of solid wood flooring based on characteristic. Sensors 2021, 21, 336. [Google Scholar] [CrossRef]

- Shi, J.; Li, Z.; Zhu, T.; Wang, D.; Ni, C. Defect detection of industry wood veneer based on NAS and multi-channel mask R-CNN. Sensors 2020, 20, 4398. [Google Scholar] [CrossRef] [PubMed]

- Bodirlau, R.; Teaca, C.A.; Spiridon, I. Chemical modification of beech wood: Effect on thermal stability. BioResources 2008, 3, 789–800. [Google Scholar] [CrossRef]

- Rodrigues, G.C.; Pencinovsky, J.; Cuypers, M.; Duflou, J.R. Theoretical and experimental aspects of laser cutting with a direct diode laser. Opt. Lasers Eng. 2014, 61, 31–38. [Google Scholar] [CrossRef]

- Nakamura, S.; Pearton, S.; Fasol, G. The Blue Laser Diode—The Complete Story, 2nd ed.; Springer: Berlin, Germany, 2000; p. 368. ISBN 978-3-540-66505-2. [Google Scholar]

- Andújar, D.; Fernández-Quintanilla, C.; Dorado, J. Matching the best viewing angle in depth cameras for biomass estimation based on poplar seedling geometry. Sensors 2015, 15, 12999–13011. [Google Scholar] [CrossRef] [PubMed]

- Modersitzki, J. Chapter 5-landmark-based registration. FAIR-flexible algorithms for image registration. In Society for Industrial and Applied Mathematics; SIAM: Philadelphia, PA, USA, 2009. [Google Scholar]

- Rehder, J.; Siegwart, R. Camera/IMU calibration revisited. IEEE Sens. J. 2017, 17, 3257–3268. [Google Scholar] [CrossRef]

- Varghese, A.; Jain, S.; Prince, A.A.; Jawahar, M. Digital microscopic image sensing and processing for leather species identification. IEEE Sens. J. 2020, 20, 10045–10056. [Google Scholar] [CrossRef]

- Jabeen, A.; Riaz, M.M.; Iltaf, N.; Ghafoor, A. Image contrast enhancement using weighted transformation function. IEEE Sens. J. 2016, 16, 7534–7536. [Google Scholar] [CrossRef]

- Kaestner, A.P.; Baath, L.B. Microwave polarimetry tomography of wood. IEEE Sens. J. 2005, 5, 209–215. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wagnerova, R.; Jurek, M.; Czebe, J.; Gebauer, J. A Method for Measuring the Quality of Graphic Transfer to Materials with Variable Dimensions (Wood). Sensors 2022, 22, 6030. https://doi.org/10.3390/s22166030

Wagnerova R, Jurek M, Czebe J, Gebauer J. A Method for Measuring the Quality of Graphic Transfer to Materials with Variable Dimensions (Wood). Sensors. 2022; 22(16):6030. https://doi.org/10.3390/s22166030

Chicago/Turabian StyleWagnerova, Renata, Martin Jurek, Jiri Czebe, and Jan Gebauer. 2022. "A Method for Measuring the Quality of Graphic Transfer to Materials with Variable Dimensions (Wood)" Sensors 22, no. 16: 6030. https://doi.org/10.3390/s22166030

APA StyleWagnerova, R., Jurek, M., Czebe, J., & Gebauer, J. (2022). A Method for Measuring the Quality of Graphic Transfer to Materials with Variable Dimensions (Wood). Sensors, 22(16), 6030. https://doi.org/10.3390/s22166030