Development of Smart Weighing Lysimeter for Measuring Evapotranspiration and Developing Crop Coefficient for Greenhouse Chrysanthemum

Abstract

:1. Introduction

2. Materials and Methods

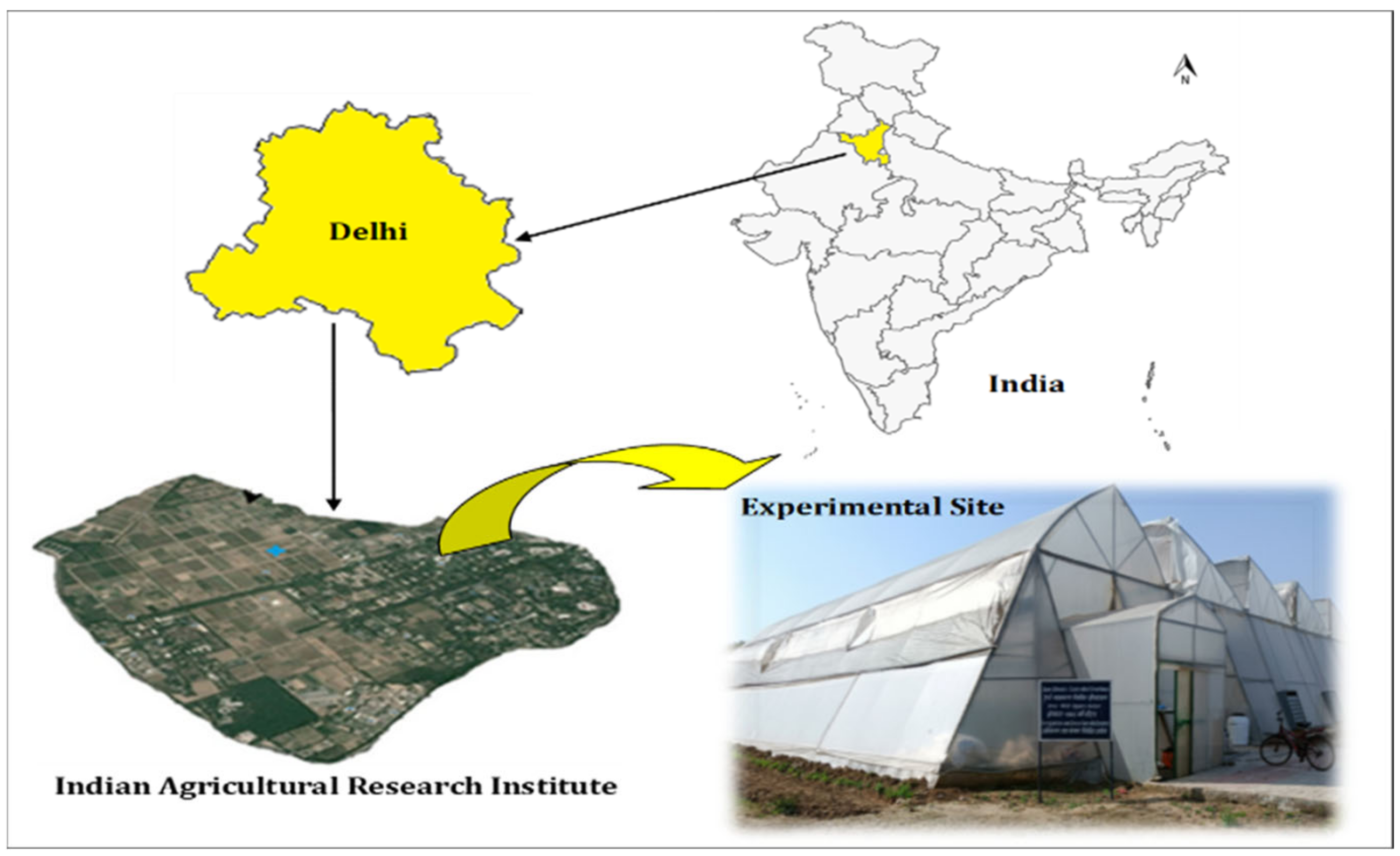

2.1. Descriptions of the Study Area

2.2. Moisture Characteristics of Soil

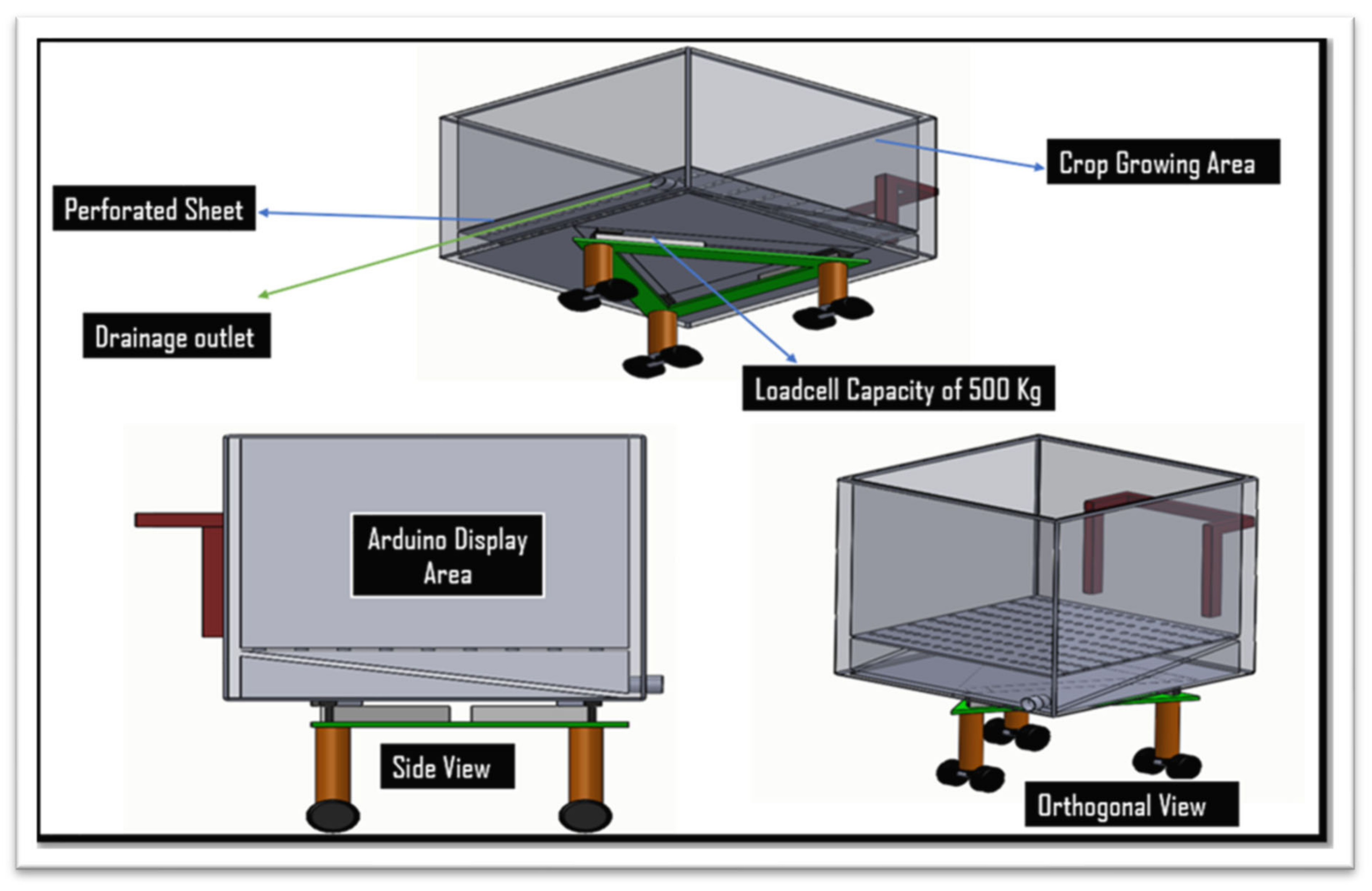

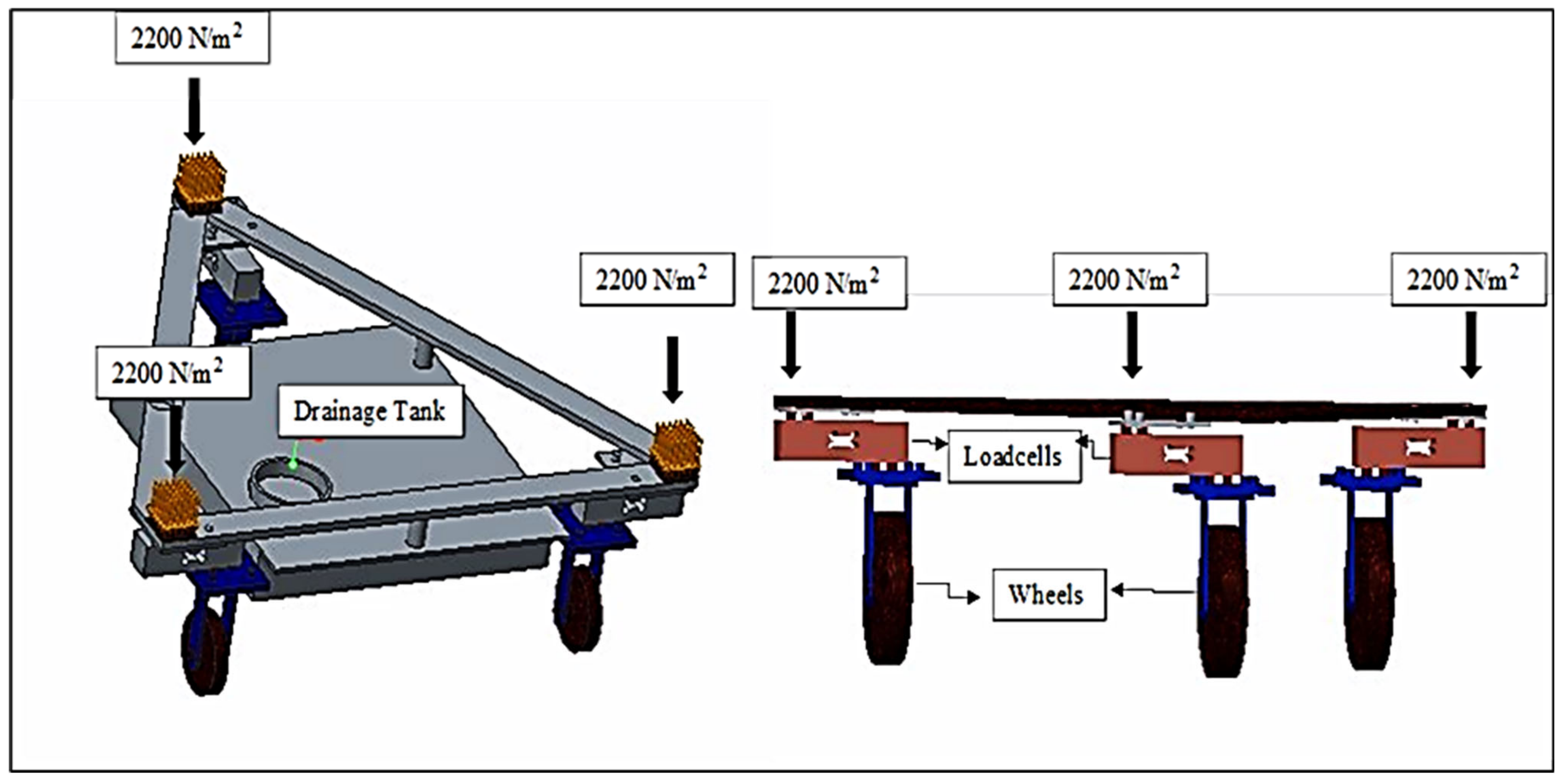

2.3. Components of the Weighing Lysimeter

- A cultivation tank that contains soil from the same plot to replicate natural conditions, as well as to calculate the crop’s coefficient (Kc) and evapotranspiration throughout different growth stages of the crop.

- A collection tank for collecting and measuring the water that has percolated through the media.

- Three wheels are assembled with three loadcells on which the lysimeter’s total load (soil + own weight) acts and determines the weight variation of the soil mass and the drainage tank.

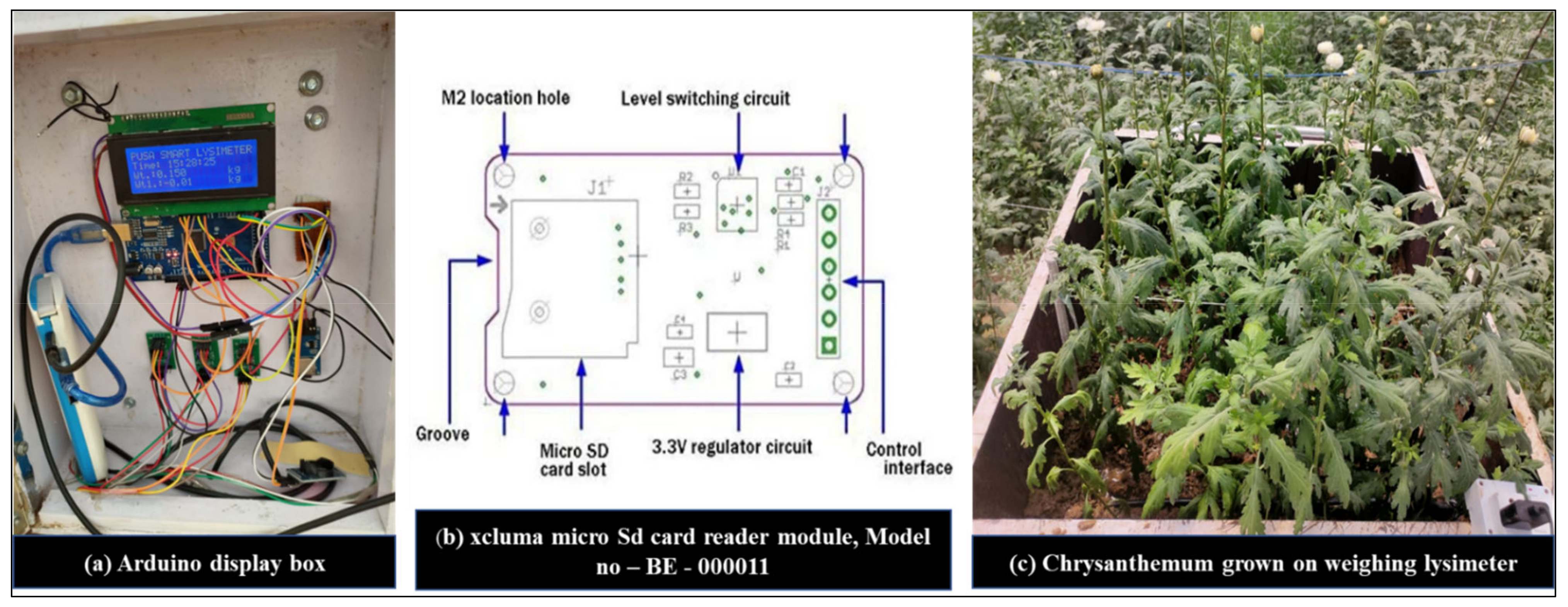

- An Arduino display assembly with a data logger was used to obtain the measured data.

2.3.1. Design and Construction of a Weighing Lysimeter

2.3.2. Selection of Crop Type

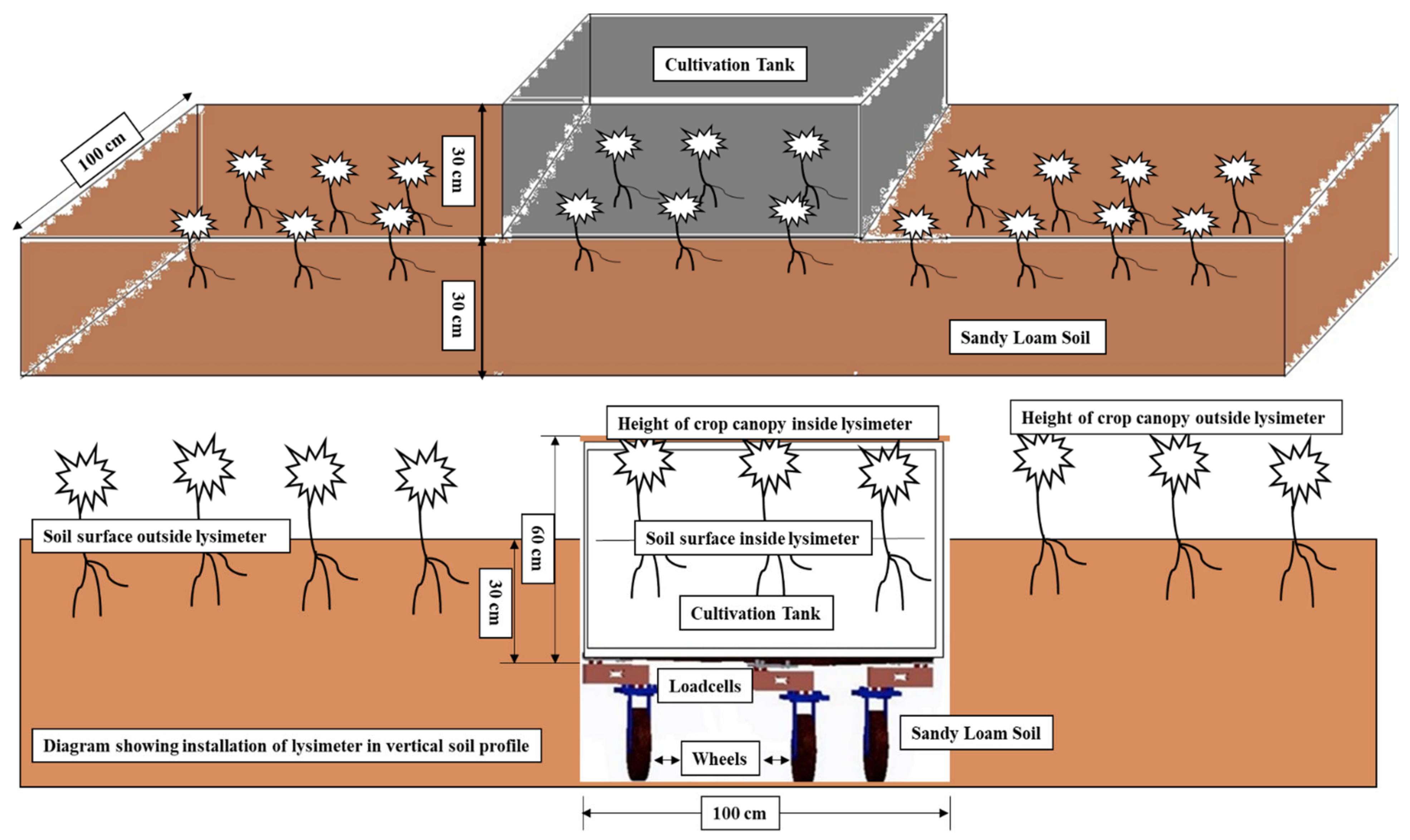

2.3.3. Installation

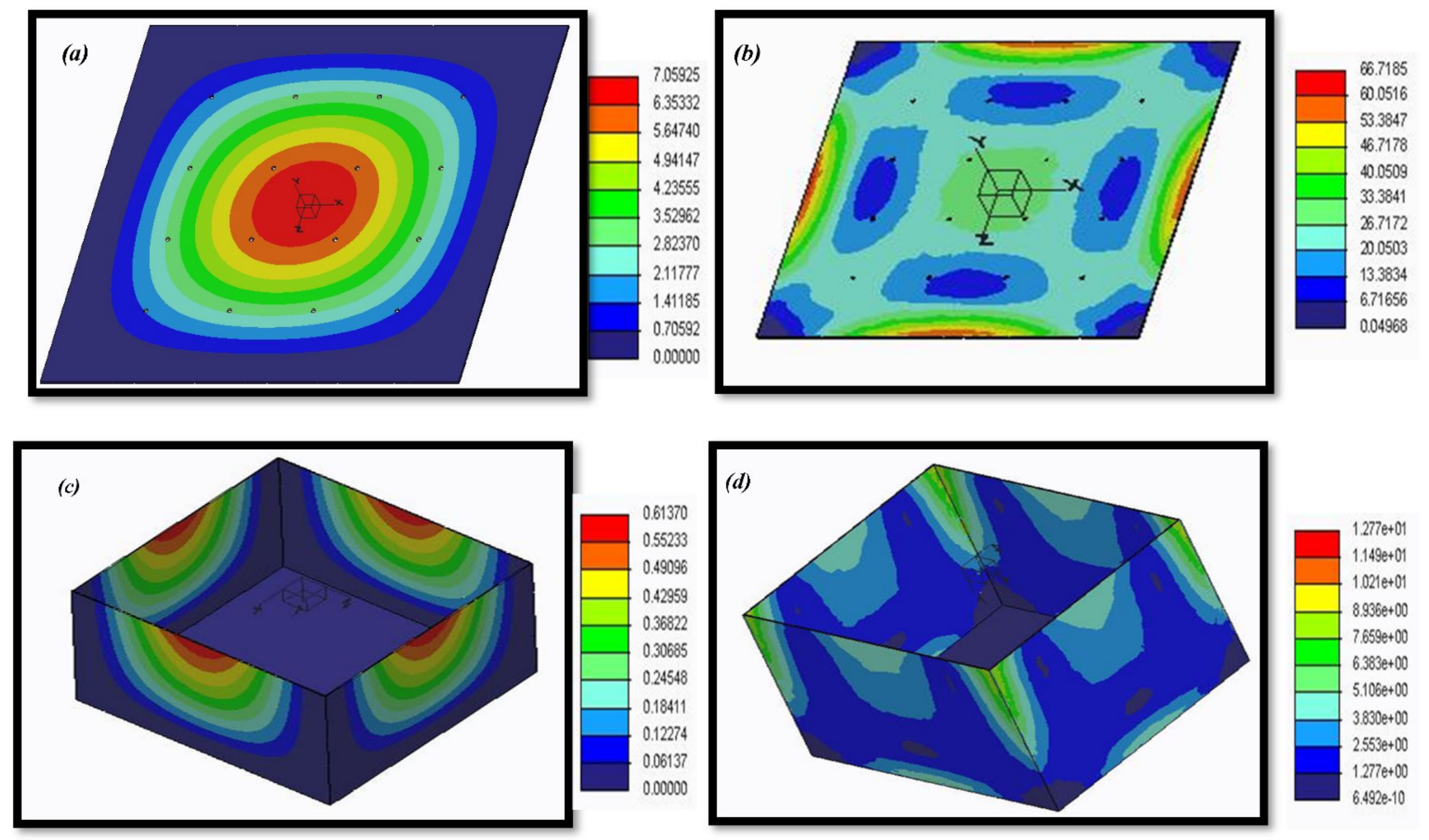

2.3.4. Structural Analysis

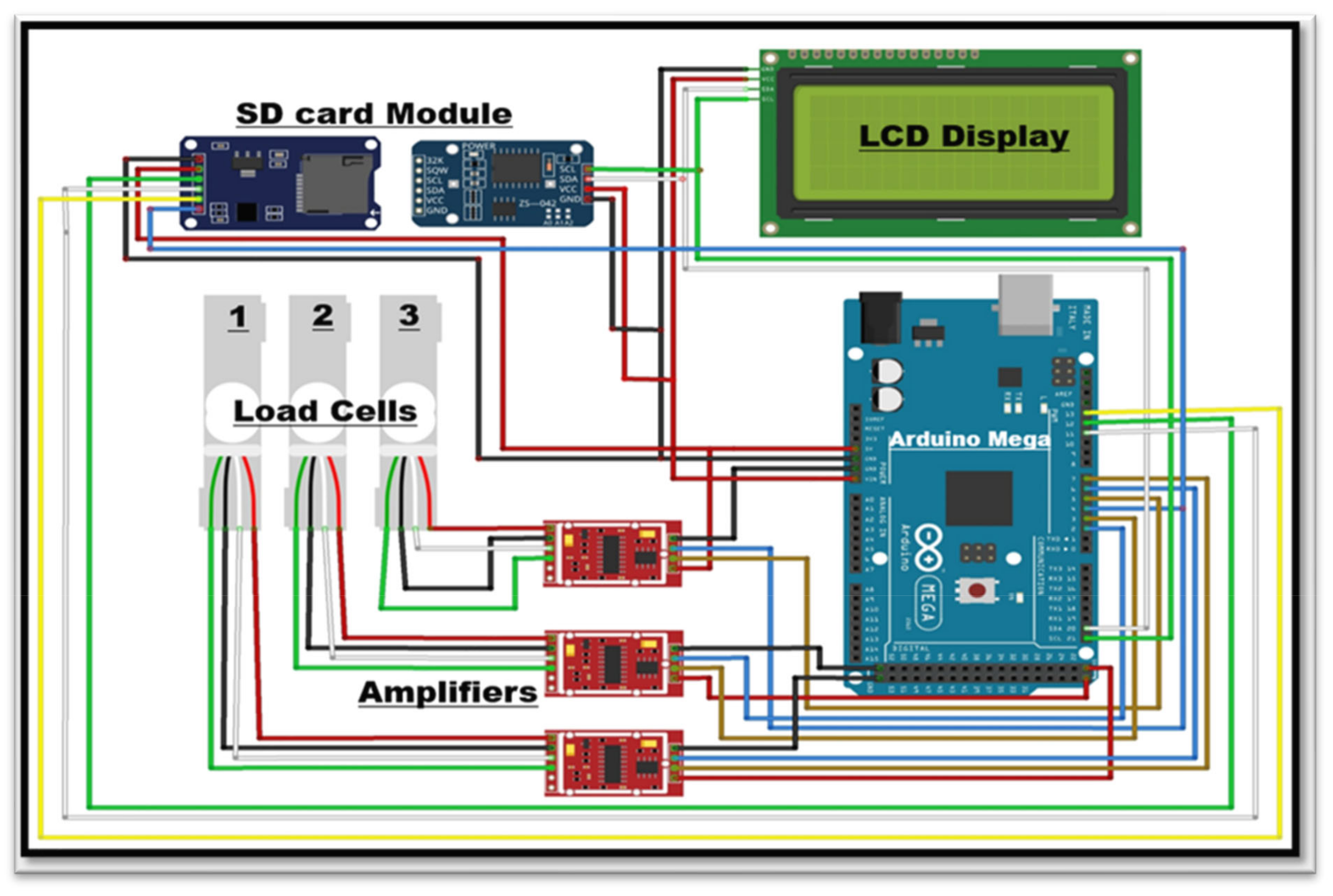

2.3.5. Acquisition of Data and Control System

2.4. Operation

3. Results

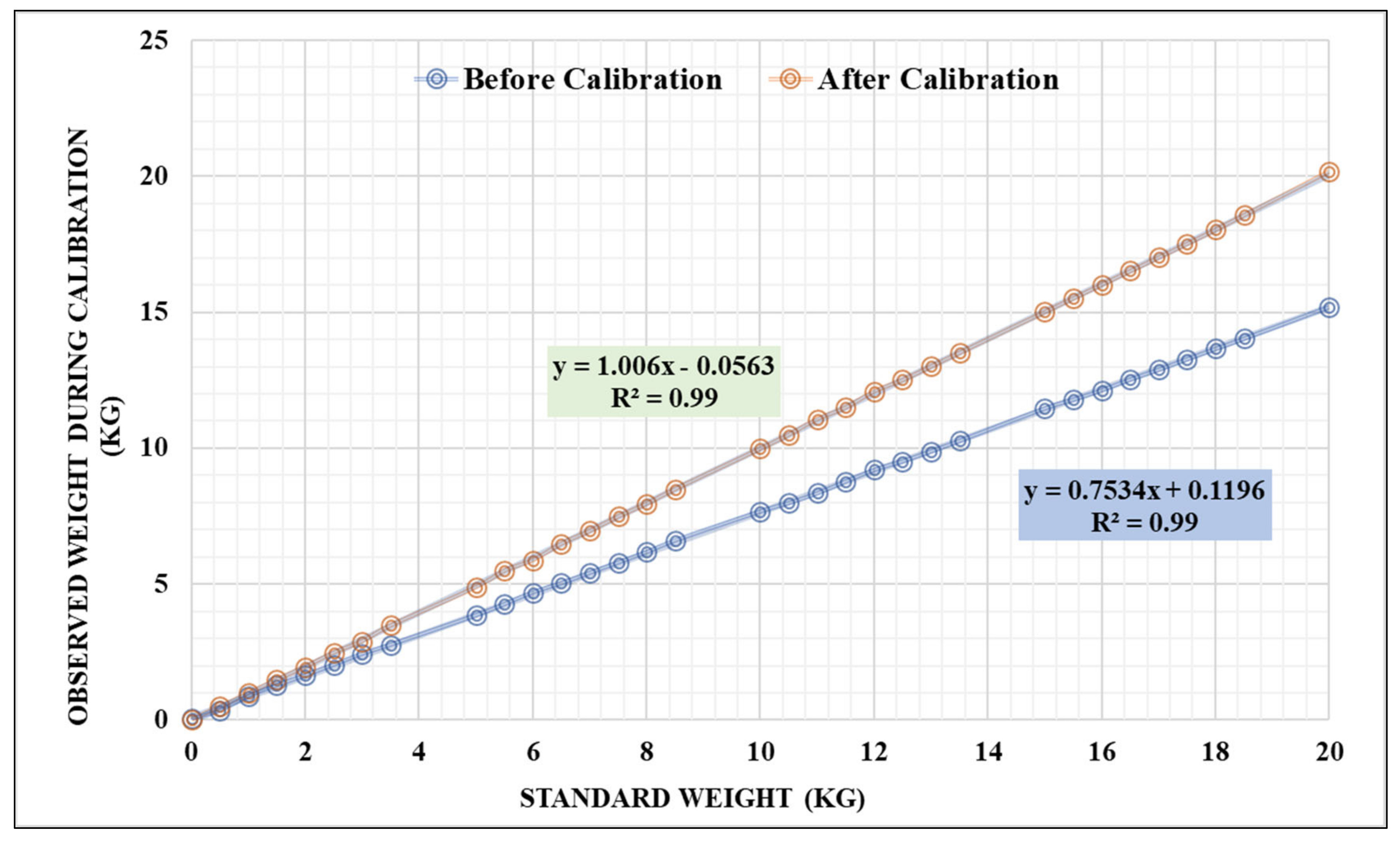

3.1. Calibration Process for Lysimeters

3.2. Structural Analysis of Lysimeter

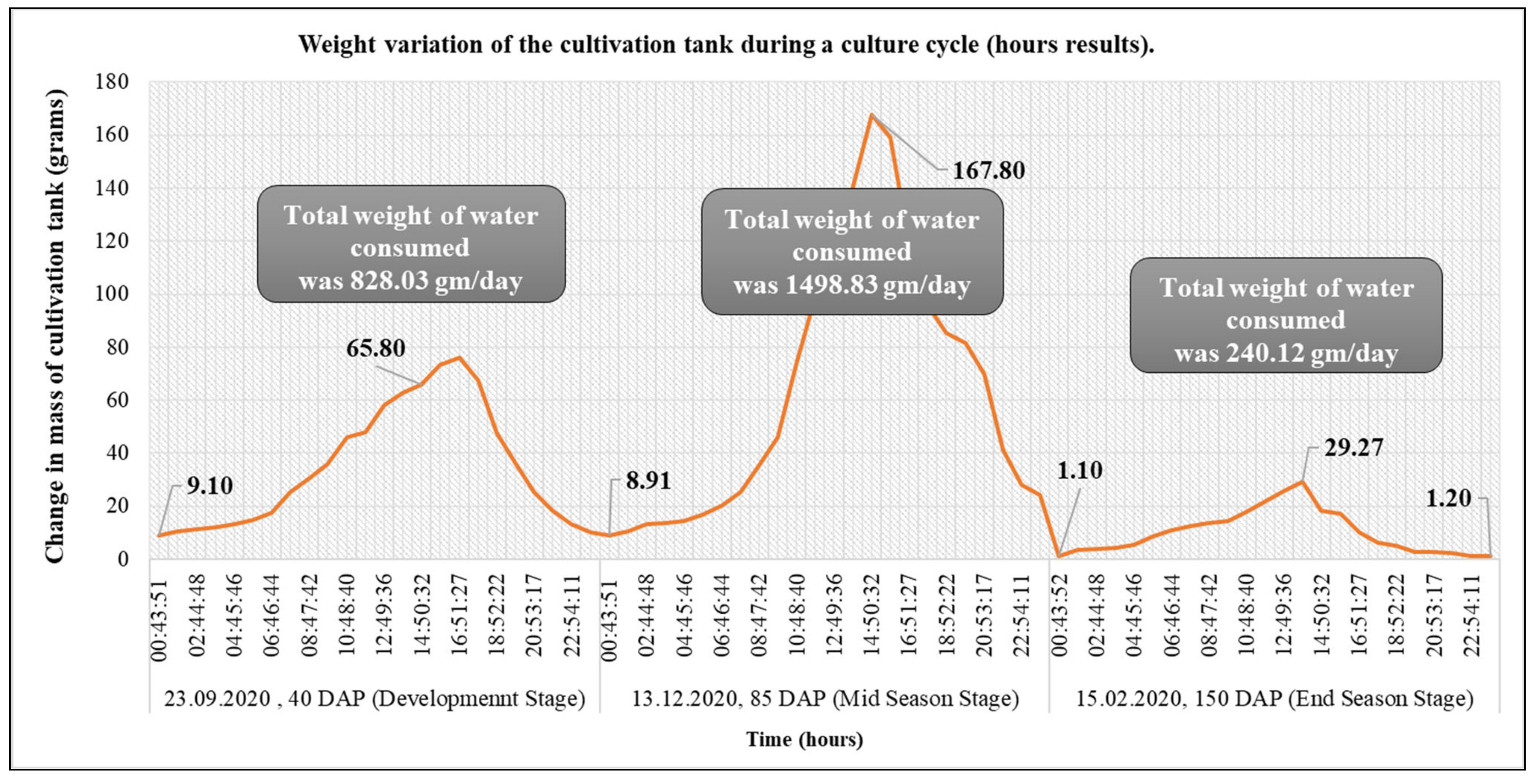

3.3. Operation Results

3.4. Crop Evapotranspiration (ETc)

3.5. Crop Coefficient of Chrysanthemum

4. Discussion

5. Conclusions

- The developed weighing type lysimeter is cheap, lightweight, portable and has automation features.

- It can be adopted by local greenhouse farmers to grow shallow-rooted crops for efficient water and nutrient management.

- The developed lysimeter is sensitive to sudden load variations. Uncertainty of the weight measurement due to sudden abrupt external forces might disturb the readings.

- It has generated crop coefficient (Kc) for greenhouse chrysanthemum crops, which was missing in the existing literature.

- The development of a temperature gradient at the lysimeter sides and edge is a cause for concern. However, since the growth of flowers in this region is done during the winter months in a greenhouse with relatively uniform temperatures under structure, it has no significant impact on the results of the crop grown in this lysimeter.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Allen, R.G.; Pereira, L.S.; Raes, D.; Smith, M. Crop Evapotranspiration—Guidelines for Computing Crop Water Requirements; FAO Irrigation and Drainage Paper 56; FAO: Rome, Italy, 1998; Volume 300, p. D05109. [Google Scholar]

- Doorenbos, J. Guidelines for Predicting Crop Water Requirements; FAO Irrigation and Drainage Paper 24; Food and Agriculture Organization: Rome, Italy, 1975. [Google Scholar]

- Allen, R.G.; Howell, T.A.; Pruitt, W.O.; Walter, I.A.; Jensen, M.E. Lysimeters for evapotranspiration and environmental measurements. In Proceedings of the International Symposium on Lysimetry, Honolulu, HI, USA, 23–25 July 1991; American Society of Civil Engineers: New York, NY, USA, 1991; p. 456. [Google Scholar]

- Kumari, N.; Srivastava, A. An Approach for Estimation of Evapotranspiration by Standardizing Parsimonious Method. Agric. Res. 2020, 9, 301–309. [Google Scholar] [CrossRef]

- Martínez-Cob, A. Use of thermal units to estimate corn crop coefficients under semiarid climatic conditions. Irrig. Sci. 2008, 26, 335–345. [Google Scholar] [CrossRef]

- Pandey, P.K.; Pandey, V. Lysimeter based crop coefficients for estimation of crop evapotranspiration of black gram (Vigna mungo L.) in sub-humid region. Int. J. Agric. Biol. Eng. 2011, 4, 50–58. [Google Scholar] [CrossRef]

- Tyagi, N.; Sharma, D.; Luthra, S. Determination of evapotranspiration and crop coefficients of rice and sunflower with lysimeter. Agric. Water Manag. 2000, 45, 41–54. [Google Scholar] [CrossRef]

- Ko, J.; Piccinni, G.; Marek, T.; Howell, T. Determination of growth-stage-specific crop coefficients (Kc) of cotton and wheat. Agric. Water Manag. 2009, 96, 1691–1697. [Google Scholar] [CrossRef]

- Liu, Y.; Luo, Y. A consolidated evaluation of the FAO-56 dual crop coefficient approach using the lysimeter data in the North China Plain. Agric. Water Manag. 2010, 97, 31–40. [Google Scholar] [CrossRef]

- Payero, J.O.; Neale, C.M.U.; Wright, J.L.; Allen, R.G. Guidelines for validating Bowen ratio data. Trans. ASAE 2003, 46, 1051–1060. [Google Scholar] [CrossRef]

- Todd, R.W.; Evett, S.R.; Howell, T.A. The Bowen ratio-energy balance method for estimating latent heat flux of irrigated alfalfa evaluated in a semi-arid, advective environment. Agric. For. Meteorol. 2000, 103, 335–348. [Google Scholar] [CrossRef]

- Verhoef, A.; Allen, S.J.; Lloyd, C.R. Seasonal variation of surface energy balance over two Sahelian surfaces. Int. J. Climatol. 1999, 19, 1267–1277. [Google Scholar] [CrossRef]

- Liu, J.; Kotoda, K. Estimation of Regional Evapotranspiration from Arid and Semi-Arid Surfaces. J. Am. Water Resour. Assoc. 1998, 34, 27–41. [Google Scholar] [CrossRef]

- Laubach, J.; Raschendorfer, M.; Kreilein, H.; Gravenhorst, G. Determination of heat and water vapour fluxes above a spruce forest by eddy correlation. Agric. For. Meteorol. 1994, 71, 373–401. [Google Scholar] [CrossRef]

- Vishwakarma, D.K.; Pandey, K.; Kaur, A.; Kushwaha, N.L.; Kumar, R.; Ali, R.; Elbeltagi, A.; Kuriqi, A. Methods to estimate evapotranspiration in humid and subtropical climate conditions. Agric. Water Manag. 2022, 261, 107378. [Google Scholar] [CrossRef]

- Dylla, A.S.; Cox, L.M. An Economical Hydraulic Weighing Evapotranspiration Tank. Trans. ASAE 1973, 16, 0294–0295. [Google Scholar] [CrossRef]

- Kumari, N.; Srivastava, A.; Dumka, U.C. A Long-Term Spatiotemporal Analysis of Vegetation Greenness over the Himalayan Region Using Google Earth Engine. Climate 2021, 9, 109. [Google Scholar] [CrossRef]

- Marek, T.; Piccinni, G.; Schneider, A.; Howell, T.; Jett, M.; Dusek, D. Weighing Lysimeters for the Determination of Crop Water Requirements and Crop Coefficients. Appl. Eng. Agric. 2006, 22, 851–856. [Google Scholar] [CrossRef]

- Malone, R.W.; Bonta, J.V.; Stewardson, D.J.; Nelsen, T. Error analysis and quality improvement of the Coshocton weighing lysimeters. Trans. ASAE 2000, 43, 271–280. [Google Scholar] [CrossRef]

- Klocke, N.L.; Heermann, D.F.; Duke, H.R. Measurement of Evaporation and Transportation with Lysimeters. Trans. ASAE 1985, 28, 183–189. [Google Scholar] [CrossRef]

- Tyagi, N.K.; Sharma, D.K.; Luthra, S.K. Determination of evapotranspiration for maize and berseem clover. Irrig. Sci. 2003, 21, 173–181. [Google Scholar] [CrossRef]

- Yang, S.; Aydin, M.; Yano, T.; Li, X. Evapotranspiration of orange trees in greenhouse lysimeters. Irrig. Sci. 2003, 21, 145–149. [Google Scholar] [CrossRef]

- Marek, T.H.; Schneider, A.D.; Howell, T.A.; Lynn, L. Ebeling Design and Construction of Large Weighing Monolithic Lysimeters. Trans. ASAE 1988, 31, 0477–0484. [Google Scholar] [CrossRef]

- Schneider, A.D.; Howell, T.A.; Moustafa, A.T.A.; Evett, S.R.; Abou-Zeid, W. A simplified weighing lysimeter for monolithic or reconstructed soils. Appl. Eng. Agric. 1998, 14, 267–273. [Google Scholar] [CrossRef]

- Jiménez-Carvajal, C.; Ruiz-Peñalver, L.; Vera-Repullo, J.A.; Jiménez-Buendía, M.; Antolino-Merino, A.; Molina-Martínez, J.M. Weighing lysimetric system for the determination of the water balance during irrigation in potted plants. Agric. Water Manag. 2017, 183, 78–85. [Google Scholar] [CrossRef]

- Burman, R.D.; Cuenca, R.H.; Weiss, A. Techniques for estimating irrigation water requirements. In Advances in Irrigation; Hillel, D., Ed.; Academic Press: New York, NY, USA, 1983; pp. 335–393. [Google Scholar]

- Burman, R.; Pochop, L.O. Evaporation, evapotranspiration and climatic data. In Developments in Atmospheric Science; Elsevier: Amsterdam, The Netherlands, 1994; Volume 22, p. 278. [Google Scholar]

- Soler-Méndez, M.; Parras-Burgos, D.; Cisterne-López, A.; Mas-Espinosa, E.; Intrigliolo, D.S.; Molina-Martínez, J.M. Development of an Algorithm for an Automatic Determination of the Soil Field Capacity Using of a Portable Weighing Lysimeter. Sensors 2021, 21, 7203. [Google Scholar] [CrossRef]

- Sagar, A.; Singh, P.K. Study of Different Evapotranspiration Models under Polyhouse and Open Environment in Tarai Region of Uttarakhand. Int. J. Environ. Clim. Chang. 2019, 9, 832–840. [Google Scholar] [CrossRef]

- Srivastava, A.; Saco, P.M.; Rodriguez, J.F.; Kumari, N.; Chun, K.P.; Yetemen, O. The role of landscape morphology on soil moisture variability in semi-arid ecosystems. Hydrol. Process. 2021, 35, e13990. [Google Scholar] [CrossRef]

- Howell, T.A.; Schneider, A.D.; Jensen, M.E. History of lysimeter design and use for evapotranspiration measurements. In Grouting in Geotechnical Engineering; Allen, R.G., Howell, T.A., Pruitt, W.O., Walter, I.A., Jensen, M.E., Eds.; American Society of Civil Engineers: Reston, VA, USA, 1991; pp. 1–9. [Google Scholar]

- Nicolás-Cuevas, J.A.; Parras-Burgos, D.; Soler-Méndez, M.; Ruiz-Canales, A.; Molina-Martínez, J.M. Removable Weighing Lysimeter for Use in Horticultural Crops. Appl. Sci. 2020, 10, 4865. [Google Scholar] [CrossRef]

- Doležal, F.; Hernandez-Gomis, R.; Matula, S.; Gulamov, M.; Miháliková, M.; Khodjaev, S. Actual Evapotranspiration of Unirrigated Grass in a Smart Field Lysimeter. Vadose Zone J. 2018, 17, 170173. [Google Scholar] [CrossRef]

- Allen, R.G.; Fisher, D.K. Low-Cost Electronic Weighing Lysimeters. Trans. ASAE 1990, 33, 1823–1833. [Google Scholar] [CrossRef]

- Farzaneh Zardoshti, F.; Bakhtiari, B.; Qaderi, K.; Khanjani, M.J.; Banayan, M. Design and construction of a portable smart weighing lysimeter for accurate measurement of crop water requirement. Iran. J. Soil Water Res. 2018, 49, 695–704. [Google Scholar] [CrossRef]

- Allen, R.G.; Fisher, D.K. Direct load cell-based weighing lysimeter system. In Grouting in Geotechnical Engineering; Allen, R.G., Howell, T.A., Pruitt, W.O., Eds.; American Society of Civil Engineers: Reston, VA, USA, 1991; pp. 114–124. [Google Scholar]

- Gómez González, S. Solidworks Simulation; Alfaomega: Santiago de Querétaro, Mexico, 2010. [Google Scholar]

- Libardi, L.G.P.; de Faria, R.T.; Dalri, A.B.; de Souza Rolim, G.; Palaretti, L.F.; Coelho, A.P.; Martins, I.P. Evapotranspiration and crop coefficient (Kc) of pre-sprouted sugarcane plantlets for greenhouse irrigation management. Agric. Water Manag. 2019, 212, 306–316. [Google Scholar] [CrossRef]

- Ruiz-Peñalver, L.; Vera-Repullo, J.A.; Jiménez-Buendía, M.; Guzmán, I.; Molina-Martínez, J.M. Development of an innovative low cost weighing lysimeter for potted plants: Application in lysimetric stations. Agric. Water Manag. 2015, 151, 103–113. [Google Scholar] [CrossRef]

| Properties | 2019–2020 | 2020–2021 |

|---|---|---|

| Planting Date | 20-09-2019 | 10-10-2020 |

| Last Harvesting Date | 16-02-2020 | 07-03-2021 |

| Mean Air Temperature (°C) | 20.8 | 19.8 |

| Mean Relative Humidity (%) | 72.4 | 73.0 |

| Mean Solar Short-wave radiation (Watt/m2) | 275.5 | 278.9 |

| Total Rainfall (mm) | Zero | Zero |

| Lysimeter ETc (mm) | 152.6 | 147.8 |

| Class-A Pan ETo (mm) | 153.9 | 147.9 |

| Load Case | Value of the Load (N/m2) | Load Distribution | |

|---|---|---|---|

| Cultivation tank | Self—weight of lysimeter excluding wheels weight | 784.8 | Uniform |

| Lateral earth Pressure | 1650 | ||

| Base structure | Self—weight including wheels weight | 1027 | Triangular |

| Total Earth weight on perforated sheet at bottom | 6600 |

| Statistical Indices | D | RMSE | RMAE | MBE | MSE | MAE | RE |

|---|---|---|---|---|---|---|---|

| Before Calibration | 0.99 | 2.02 | 0.20 | −1.33 | 4.18 | 1.33 | 0.10 |

| After Calibration | 1.00 | 0.04 | 0.02 | 0.00 | 0.00 | 0.02 | 0.00 |

| Load Case | VMS (MPa) | URES: R.D (mm) | F.S |

|---|---|---|---|

| Lateral earth pressure on cultivation tank | 12.7 | 0.6 | 19.2 |

| Total earth weight on perforated sheet at bottom | 66.7 | 7.1 | 3.7 |

| Components | 2019–2020 | 2020–2021 | |||||

|---|---|---|---|---|---|---|---|

| Water Film (mm) | Mass (g) | Difference In-O (g, mm) | Water Film (mm) | Mass (g) | Difference In-O (g, mm) | ||

| In | R | 0 | 0 | +8976 +8.9 | 0 | 0 | +7410 +7.4 |

| I | 153.9 | 153,961 | 147.8 | 147,967 | |||

| C | 7.7 | 7698 | 7.4 | 7391 | |||

| O | ETc | 152.6 | 152,683 | 147.9 | 147,948 | ||

| D | 0 | 0 | 0 | 0 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sagar, A.; Hasan, M.; Singh, D.K.; Al-Ansari, N.; Chakraborty, D.; Singh, M.C.; Iquebal, M.A.; Kumar, A.; Malkani, P.; Vishwakarma, D.K.; et al. Development of Smart Weighing Lysimeter for Measuring Evapotranspiration and Developing Crop Coefficient for Greenhouse Chrysanthemum. Sensors 2022, 22, 6239. https://doi.org/10.3390/s22166239

Sagar A, Hasan M, Singh DK, Al-Ansari N, Chakraborty D, Singh MC, Iquebal MA, Kumar A, Malkani P, Vishwakarma DK, et al. Development of Smart Weighing Lysimeter for Measuring Evapotranspiration and Developing Crop Coefficient for Greenhouse Chrysanthemum. Sensors. 2022; 22(16):6239. https://doi.org/10.3390/s22166239

Chicago/Turabian StyleSagar, Atish, Murtaza Hasan, Dhirendra Kumar Singh, Nadhir Al-Ansari, Debashis Chakraborty, Mam Chand Singh, Mir Asif Iquebal, Amit Kumar, Pankaj Malkani, Dinesh Kumar Vishwakarma, and et al. 2022. "Development of Smart Weighing Lysimeter for Measuring Evapotranspiration and Developing Crop Coefficient for Greenhouse Chrysanthemum" Sensors 22, no. 16: 6239. https://doi.org/10.3390/s22166239

APA StyleSagar, A., Hasan, M., Singh, D. K., Al-Ansari, N., Chakraborty, D., Singh, M. C., Iquebal, M. A., Kumar, A., Malkani, P., Vishwakarma, D. K., & Elbeltagi, A. (2022). Development of Smart Weighing Lysimeter for Measuring Evapotranspiration and Developing Crop Coefficient for Greenhouse Chrysanthemum. Sensors, 22(16), 6239. https://doi.org/10.3390/s22166239