End-to-End Continuous/Discontinuous Feature Fusion Method with Attention for Rolling Bearing Fault Diagnosis

Abstract

:1. Introduction

- Most current studies still need various signal processing methods to extract features. Therefore, the effectiveness of fault diagnosis heavily depends on the quality of manually extracted features. A suitable intelligent diagnosis algorithm is needed for adaptive feature extraction and selection.

- Some deep learning algorithms still need to cooperate with many complex signal processing methods to adapt to rolling bearing fault detection. These methods have a lot of manual parameters to adjust and are difficult to deploy and train.

- Some deep learning models improve the diagnosis effect by combining overly complex structures, but this usually increases the cost of calculation and the risk of overfitting.

- An end-to-end deep learning model is proposed for rolling bearing fault diagnosis. Without manual design features or complex data processing, this model can accurately extract and screen continuous/discontinuous signal features to diagnose rolling bearing faults.

- Compared with the simple deep learning model, the proposed model has a higher classification accuracy (99.87%), and the inference time does not significantly increase.

- This method could be easily deployed and migrated to a new environment or a new type of rolling bearing because of the absence of complex data processing and manual feature engineering.

- The proposed model can achieve accurate multitype fault diagnosis, and the experiment proved that it could accurately diagnose 10 types of working states of rolling bearings.

2. Materials and Methods

2.1. Types of Rolling Bearing Faults

2.2. Framework of the Proposed C/D-FUSA

2.3. Subnet for Continuous Features

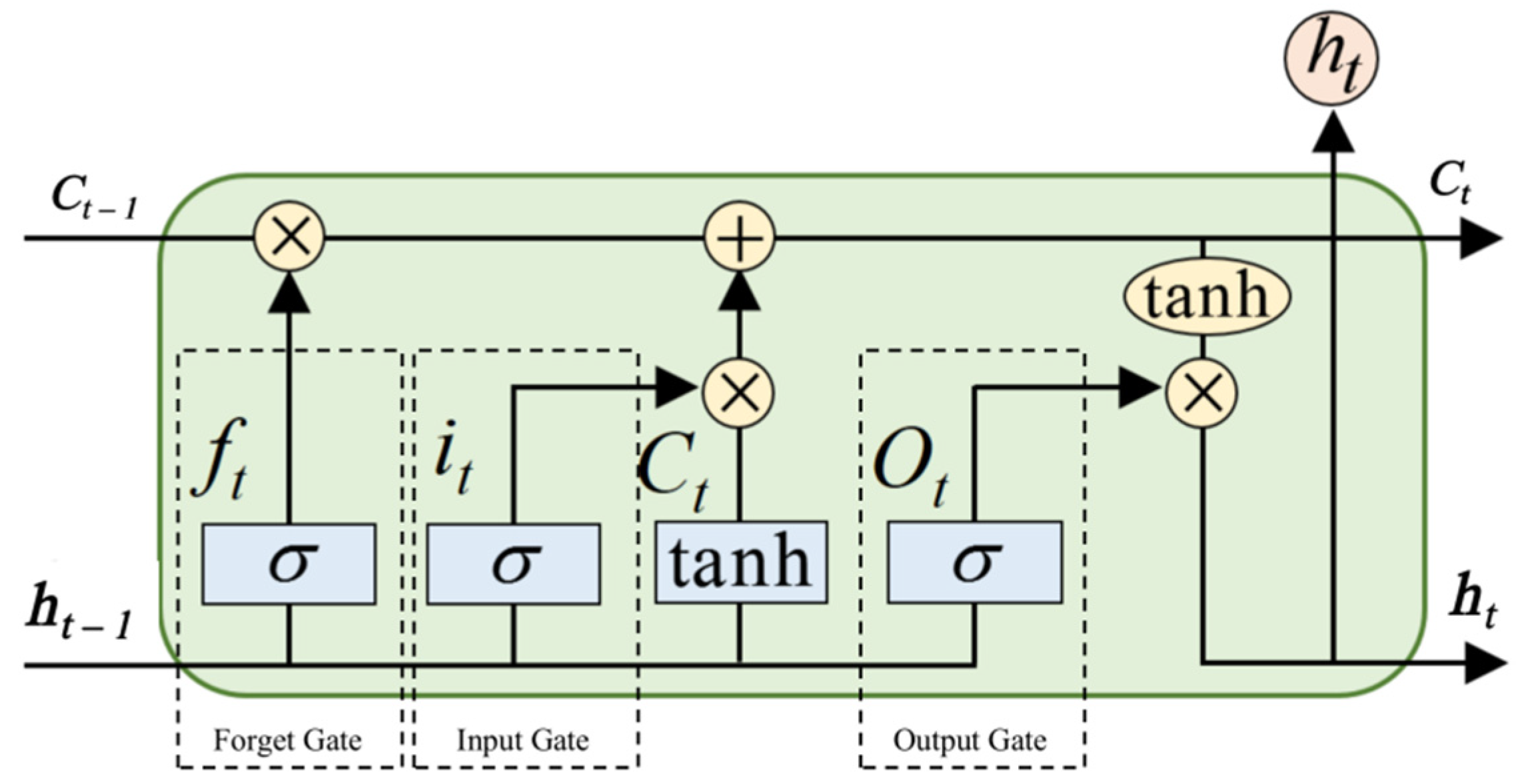

2.3.1. Long Short-Term Memory

2.3.2. Context-Dependent Attention

2.4. Subnet for Discontinuous Features

2.5. Subnet for Classification

3. Experiments and Results

3.1. Experiment Setups

- Normal type: no fault was found in these samples;

- Location = Ball, Diameter = 0.007: the fault occurred on the ball, the fault diameter was 0.007 in;

- Location = Ball, Diameter = 0.014: the fault occurred on the ball, the fault diameter was 0.014 in;

- Location = Ball, Diameter = 0.021: the fault occurred on the ball, the fault diameter was 0.021 in;

- Location = Inner Raceway, Diameter = 0.007: the fault occurred on the inner raceway, the fault diameter was 0.007 in;

- Location = Inner Raceway, Diameter = 0.014: the fault occurred on the inner raceway, the fault diameter was 0.014 in;

- Location = Inner Raceway, Diameter = 0.021: the fault occurred on the inner raceway, the fault diameter was 0.021 in;

- Location = Outer Raceway, Diameter = 0.007: the fault occurred on the outer raceway, the fault diameter was 0.007 in;

- Location = Outer Raceway, Diameter = 0.014: the fault occurred on the outer raceway, the fault diameter was 0.014 in;

- Location = Outer Raceway, Diameter = 0.021: the fault occurred on the outer raceway, the fault diameter was 0.021 in.

3.2. Results

3.2.1. Performance Comparison of Different Models

3.2.2. Performance Comparison with Other Studies

3.2.3. Inference Time Comparison with Other Studies

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, R.; Yang, B.; Zio, E.; Chen, X. Artificial intelligence for fault diagnosis of rotating machinery: A review. Mech. Syst. Signal Process. 2018, 108, 33–47. [Google Scholar] [CrossRef]

- Bediaga, I.; Mendizabal, X.; Arnaiz, A.; Munoa, J. Ball bearing damage detection using traditional signal processing algorithms. IEEE Instrum. Meas. Mag. 2013, 16, 20–25. [Google Scholar] [CrossRef]

- Duan, Z.; Wu, T.; Guo, S.; Shao, T.; Malekian, R.; Li, Z. Development and trend of condition monitoring and fault diagnosis of multi-sensors information fusion for rolling bearings: A review. Int. J. Adv. Manuf. Technol. 2018, 96, 803–819. [Google Scholar] [CrossRef]

- Tandon, N.; Choudhury, A. A review of vibration and acoustic measurement methods for the detection of defects in rolling element bearings. Tribol. Int. 1999, 32, 469–480. [Google Scholar] [CrossRef]

- Frank, P.M.; Ding, S.X.; Marcu, T. Model-based fault diagnosis in technical processes. Trans. Inst. Meas. Control 2000, 22, 57–101. [Google Scholar] [CrossRef]

- Gao, Z.; Cecati, C.; Ding, S.X. A survey of fault diagnosis and fault-tolerant techniques—Part I: Fault diagnosis with model-based and signal-based approaches. IEEE Trans. Ind. Electron. 2015, 62, 3757–3767. [Google Scholar] [CrossRef]

- Ding, Y.; Jia, M.; Miao, Q.; Cao, Y. A novel time–frequency Transformer based on self–attention mechanism and its application in fault diagnosis of rolling bearings. Mech. Syst. Signal Process. 2021, 168, 108616. [Google Scholar] [CrossRef]

- Dong, S.; Xu, X.; Chen, R. Application of fuzzy C-means method and classification model of optimized K-nearest neighbor for fault diagnosis of bearing. J. Braz. Soc. Mech. Sci. Eng. 2015, 38, 2255–2263. [Google Scholar] [CrossRef]

- Yan, X.; Jia, M. A novel optimized SVM classification algorithm with multi-domain feature and its application to fault diagnosis of rolling bearing. Neurocomputing 2018, 313, 47–64. [Google Scholar] [CrossRef]

- Xiao, D.; Ding, J.; Li, X.; Huang, L. Gear Fault Diagnosis Based on Kurtosis Criterion VMD and SOM Neural Network. Appl. Sci. 2019, 9, 5424. [Google Scholar] [CrossRef] [Green Version]

- Antoni, J. The spectral kurtosis: A useful tool for characterising non-stationary signals. Mech. Syst. Signal Process. 2006, 20, 282–307. [Google Scholar] [CrossRef]

- Barszcz, T.; Randall, R. Application of spectral kurtosis for detection of a tooth crack in the planetary gear of a wind turbine. Mech. Syst. Signal Process. 2009, 23, 1352–1365. [Google Scholar] [CrossRef]

- Zimroz, R.; Bartelmus, W. Application of Adaptive Filtering for Weak Impulsive Signal Recovery for Bearings Local Damage Detection in Complex Mining Mechanical Systems Working under Condition of Varying Load. Solid State Phenom. 2011, 180, 250–257. [Google Scholar] [CrossRef]

- Rzeszucinski, P.; Orman, M.; Pinto, C.T.; Tkaczyk, A.; Sulowicz, M. Bearing Health Diagnosed with a Mobile Phone: Acoustic Signal Measurements Can be Used to Test for Structural Faults in Motors. IEEE Ind. Appl. Mag. 2018, 24, 17–23. [Google Scholar] [CrossRef]

- Orman, M.; Rzeszucinski, P.; Tkaczyk, A.; Krishnamoorthi, K.; Pinto, C.T.; Sulowicz, M. Bearing fault detection with the use of acoustic signals recorded by a hand-held mobile phone. In Proceedings of the 2015 International Conference on Condition Assessment Techniques in Electrical Systems (CATCON), Bangalore, India, 10–12 December 2015; pp. 252–256. [Google Scholar]

- Yu, Y.; Dejie, Y.; Junsheng, C. A roller bearing fault diagnosis method based on EMD energy entropy and ANN. J. Sound Vib. 2006, 294, 269–277. [Google Scholar] [CrossRef]

- Seryasat, O.; Shoorehdeli, M.A.; Honarvar, F.; Rahmani, A. Multi-fault diagnosis of ball bearing using FFT, wavelet energy entropy mean and root mean square (RMS). In Proceedings of the 2010 IEEE International Conference on Systems, Man and Cybernetics, Istanbul, Turkey, 10–13 October 2010; pp. 4295–4299. [Google Scholar] [CrossRef]

- Song, L.; Wang, H.; Chen, P. Vibration-Based Intelligent Fault Diagnosis for Roller Bearings in Low-Speed Rotating Machinery. IEEE Trans. Instrum. Meas. 2018, 67, 1887–1899. [Google Scholar] [CrossRef]

- Almounajjed, A.; Sahoo, A.K.; Kumar, M.K.; Alsebai, M.D. Investigation Techniques for Rolling Bearing Fault Diagnosis Using Machine Learning Algorithms. In Proceedings of the 2021 5th International Conference on Intelligent Computing and Control Systems (ICICCS), Madurai, India, 6–8 May 2021; pp. 1290–1294. [Google Scholar] [CrossRef]

- Manikandan, S.; Duraivelu, K. Fault diagnosis of various rotating equipment using machine learning approaches—A review. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2020, 235, 629–642. [Google Scholar] [CrossRef]

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef]

- Wang, Z.; Cao, L.; Zhang, Z.; Gong, X.; Sun, Y.; Wang, H. Short time Fourier transformation and deep neural networks for motor imagery brain computer interface recognition. Concurr. Comput. Pract. Exp. 2018, 30, e4413. [Google Scholar] [CrossRef]

- Wang, Z.; Sun, Y.; Shen, Q.; Cao, L. Dilated 3D Convolutional Neural Networks for Brain MRI Data Classification. IEEE Access 2019, 7, 134388–134398. [Google Scholar] [CrossRef]

- Wang, Z.; Zhu, Y.; Shi, H.; Zhang, Y.; Yan, C. A 3D multiscale view convolutional neural network with attention for mental disease diagnosis on MRI images. Math. Biosci. Eng. 2021, 18, 6978–6994. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Zhang, Y.; Shi, H.; Cao, L.; Yan, C.; Xu, G. Recurrent spiking neural network with dynamic presynaptic currents based on backpropagation. Int. J. Intell. Syst. 2021, 37, 2242–2265. [Google Scholar] [CrossRef]

- Voulodimos, A.; Doulamis, N.; Doulamis, A.; Protopapadakis, E. Deep Learning for Computer Vision: A Brief Review. Comput. Intell. Neurosci. 2018, 2018, 7068349. [Google Scholar] [CrossRef] [PubMed]

- Otter, D.W.; Medina, J.R.; Kalita, J.K. A Survey of the Usages of Deep Learning for Natural Language Processing. IEEE Trans. Neural Netw. Learn. Syst. 2020, 32, 604–624. [Google Scholar] [CrossRef]

- Nassif, A.B.; Shahin, I.; Attili, I.; Azzeh, M.; Shaalan, K. Speech Recognition Using Deep Neural Networks: A Systematic Review. IEEE Access 2019, 7, 19143–19165. [Google Scholar] [CrossRef]

- Chen, X.; Guhl, J. Industrial Robot Control with Object Recognition based on Deep Learning. Procedia CIRP 2018, 76, 149–154. [Google Scholar] [CrossRef]

- Hochreiter, S.; Schmidhuber, J. Long short-term memory. Neural Comput. 1997, 9, 1735–1780. [Google Scholar] [CrossRef]

- Shao, H.; Jiang, H.; Zhang, X.; Niu, M. Rolling bearing fault diagnosis using an optimization deep belief network. Meas. Sci. Technol. 2015, 26, 115002. [Google Scholar] [CrossRef]

- Fuan, W.; Hongkai, J.; Haidong, S.; Wenjing, D.; Shuaipeng, W. An adaptive deep convolutional neural network for rolling bearing fault diagnosis. Meas. Sci. Technol. 2017, 28, 095005. [Google Scholar] [CrossRef]

- Sohaib, M.; Kim, C.-H.; Kim, J.-M. A Hybrid Feature Model and Deep-Learning-Based Bearing Fault Diagnosis. Sensors 2017, 17, 2876. [Google Scholar] [CrossRef]

- Li, X.; Zhang, W.; Ding, Q. Understanding and improving deep learning-based rolling bearing fault diagnosis with attention mechanism. Signal Process. 2019, 161, 136–154. [Google Scholar] [CrossRef]

- Alexakos, C.; Karnavas, Y.; Drakaki, M.; Tziafettas, I. A Combined Short Time Fourier Transform and Image Classification Transformer Model for Rolling Element Bearings Fault Diagnosis in Electric Motors. Mach. Learn. Knowl. Extr. 2021, 3, 228–242. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, B.; Gao, D. Bearing fault diagnosis base on multi-scale CNN and LSTM model. J. Intell. Manuf. 2020, 32, 971–987. [Google Scholar] [CrossRef]

- Daubechies, I.; Lu, J.; Wu, H.-T. Synchrosqueezed wavelet transforms: An empirical mode decomposition-like tool. Appl. Comput. Harmon. Anal. 2011, 30, 243–261. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, S.; Wang, B.; Habetler, T.G. Deep learning algorithms for bearing fault diagnostics—A comprehensive review. IEEE Access 2020, 8, 29857–29881. [Google Scholar] [CrossRef]

- Case Western Reserve University. B.D.C. Seeded Fault Test Data. 2017. Available online: https://engineering.case.edu/bearingdatacenter (accessed on 10 May 2022).

- Yu, X.; Dong, F.; Ding, E.; Wu, S.; Fan, C. Rolling Bearing Fault Diagnosis Using Modified LFDA and EMD with Sensitive Feature Selection. IEEE Access 2017, 6, 3715–3730. [Google Scholar] [CrossRef]

- Jiang, F.; Ding, K.; He, G.; Du, C. Sparse dictionary design based on edited cepstrum and its application in rolling bearing fault diagnosis. J. Sound Vib. 2020, 490, 115704. [Google Scholar] [CrossRef]

- Yu, Y.; Si, X.; Hu, C.; Zhang, J. A Review of Recurrent Neural Networks: LSTM Cells and Network Architectures. Neural Comput. 2019, 31, 1235–1270. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, M.; Zhu, X.; Zhao, L. Attention-based LSTM for aspect-level sentiment classification. In Proceedings of the 2016 Conference on Empirical Methods in Natural Language Processing, Austin, TX, USA, 1–5 November 2016; pp. 606–615. [Google Scholar]

- Hu, J.; Shen, L.; Sun, G. Squeeze-and-excitation networks. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Salt Lake City, UT, USA, 18–23 June 2018; pp. 7132–7141. [Google Scholar]

- Loparo, K.A. Bearings Vibration Data Set; The Case Western Reserve University Bearing Data Center. Available online: http://www.eecs.cwru.edu/laboratory/bearing/download.htm (accessed on 1 May 2022).

- Kingma, D.P.; Ba, J. Adam: A method for stochastic optimization. arXiv 2014, arXiv:1412.6980. Available online: https://arxiv.org/abs/1412.6980 (accessed on 10 May 2022).

- Lei, Y.; Jia, F.; Lin, J.; Xing, S.; Ding, S.X. An Intelligent Fault Diagnosis Method Using Unsupervised Feature Learning towards Mechanical Big Data. IEEE Trans. Ind. Electron. 2016, 63, 3137–3147. [Google Scholar] [CrossRef]

- Wang, J.; Zhan, C.; Yu, D.; Zhao, Q.; Xie, Z. Rolling bearing fault diagnosis method based on SSAE and softmax classifier with improved K-fold cross-validation. Meas. Sci. Technol. 2022, 33. [Google Scholar] [CrossRef]

- Yan, J.; Kan, J.; Luo, H. Rolling Bearing Fault Diagnosis Based on Markov Transition Field and Residual Network. Sensors 2022, 22, 3936. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Gu, Y. A Transfer Learning Framework with a One-Dimensional Deep Subdomain Adaptation Network for Bearing Fault Diagnosis under Different Working Conditions. Sensors 2022, 22, 1624. [Google Scholar] [CrossRef] [PubMed]

- Zhao, K.; Jiang, H.; Wang, K.; Pei, Z. Joint distribution adaptation network with adversarial learning for rolling bearing fault diagnosis. Knowl. Based Syst. 2021, 222, 106974. [Google Scholar] [CrossRef]

- Zou, F.; Zhang, H.; Sang, S.; Li, X.; He, W.; Liu, X. Bearing fault diagnosis based on combined multi-scale weighted entropy morphological filtering and bi-LSTM. Appl. Intell. 2021, 51, 6647–6664. [Google Scholar] [CrossRef]

- Gu, K.; Zhang, Y.; Liu, X.; Li, H.; Ren, M. DWT-LSTM-Based Fault Diagnosis of Rolling Bearings with Multi-Sensors. Electronics 2021, 10, 2076. [Google Scholar] [CrossRef]

| Fault Location | Diameter | Number of Samples | Number of Samples in CWRU-512 | Number of Samples in CWRU-6000 |

|---|---|---|---|---|

| Normal | Normal | 2,182,450 | 4261 | 360 |

| Ball | 0.007 | 487,093 | 950 | 80 |

| 0.014 | 488,109 | 951 | 80 | |

| 0.021 | 487,964 | 951 | 80 | |

| Inner Raceway | 0.007 | 488,309 | 952 | 80 |

| 0.014 | 487,239 | 948 | 80 | |

| 0.021 | 487,529 | 950 | 80 | |

| Outer Raceway | 0.007 | 1,465,051 | 2855 | 240 |

| 0.014 | 487,819 | 950 | 80 | |

| 0.021 | 1,465,487 | 2856 | 240 |

| Data Set | Hyper Parameter | Value |

|---|---|---|

| CWRU-512 | Learning Rate | 0.002 |

| Epoch | 200 | |

| Max length | 512 | |

| Optimizer | Adaptive Moment Estimation (Adam) [46] | |

| Loss Function | Cross-entropy loss | |

| CWRU-6000 | Learning Rate | 0.001 |

| Epoch | 200 | |

| Max length | 6000 | |

| Optimizer | Adam | |

| Loss Function | Cross-entropy loss |

| Data Set | Model | Accuracy (%) | Precision (%) | Recall (%) | F1 Score (%) |

|---|---|---|---|---|---|

| CRWU-512 | C/D-FUSA | 99.85 | 99.84 | 99.90 | 99.87 |

| C/D-FUS | 99.64 | 99.60 | 99.65 | 99.62 | |

| LSTM | 99.58 | 99.51 | 99.58 | 99.54 | |

| CRWU-6000 | C/D-FUSA | 99.69 | 99.65 | 99.72 | 99.68 |

| C/D-FUS | 99.50 | 99.52 | 99.51 | 99.51 | |

| LSTM | 68.75 | 66.67 | 71.69 | 69.09 |

| Method | Type | Number of Fault Classes | Number of Training Samples | Accuracy (%) |

|---|---|---|---|---|

| Sohaib et al., (2017) [33] | Hybrid features + sparse stacked autoencoder | 10 | 710 | 99.10 |

| Li et al., (2019) [34] | Preprocessing + attention + LSTM + CNN | 10 | - | 99.74 |

| Lei et al., (2016) [47] | Signal fraction + deep learning | 10 | 20,000 | 99.66 |

| Wang et al., (2022) [48] | SSAE and softmax classifier | 10 | 4163 | 99.15 |

| Yan et al., (2022) [49] | Markov transition field and residual network | 10 | 6600 | 98.52 |

| Zhang et al., (2022) [50] | Transfer learning | 10 | 9518 | 99.80 |

| Zhao et al., (2021) [51] | Adaptation network with adversarial learning | 10 | 7000 | 99.24 |

| C/D-FUSA | Attention + LSTM + CNN | 10 | 13,299 | 99.85 |

| Data Set | Model | Inference Time (s) |

|---|---|---|

| CRWU-512 | C/D-FUSA | 0.034 |

| C/D-FUS | 0.031 | |

| LSTM | 0.028 | |

| CRWU-6000 | C/D-FUSA | 0.228 |

| C/D-FUS | 0.220 | |

| LSTM | 0.208 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, J.; Liao, J.; Chen, Z. End-to-End Continuous/Discontinuous Feature Fusion Method with Attention for Rolling Bearing Fault Diagnosis. Sensors 2022, 22, 6489. https://doi.org/10.3390/s22176489

Zheng J, Liao J, Chen Z. End-to-End Continuous/Discontinuous Feature Fusion Method with Attention for Rolling Bearing Fault Diagnosis. Sensors. 2022; 22(17):6489. https://doi.org/10.3390/s22176489

Chicago/Turabian StyleZheng, Jianbo, Jian Liao, and Zongbin Chen. 2022. "End-to-End Continuous/Discontinuous Feature Fusion Method with Attention for Rolling Bearing Fault Diagnosis" Sensors 22, no. 17: 6489. https://doi.org/10.3390/s22176489

APA StyleZheng, J., Liao, J., & Chen, Z. (2022). End-to-End Continuous/Discontinuous Feature Fusion Method with Attention for Rolling Bearing Fault Diagnosis. Sensors, 22(17), 6489. https://doi.org/10.3390/s22176489