Design of Compact Mid-Infrared Cooled Echelle Spectrometer Based on Toroidal Uniform-Line-Spaced (TULS) Grating

Abstract

:1. Introduction

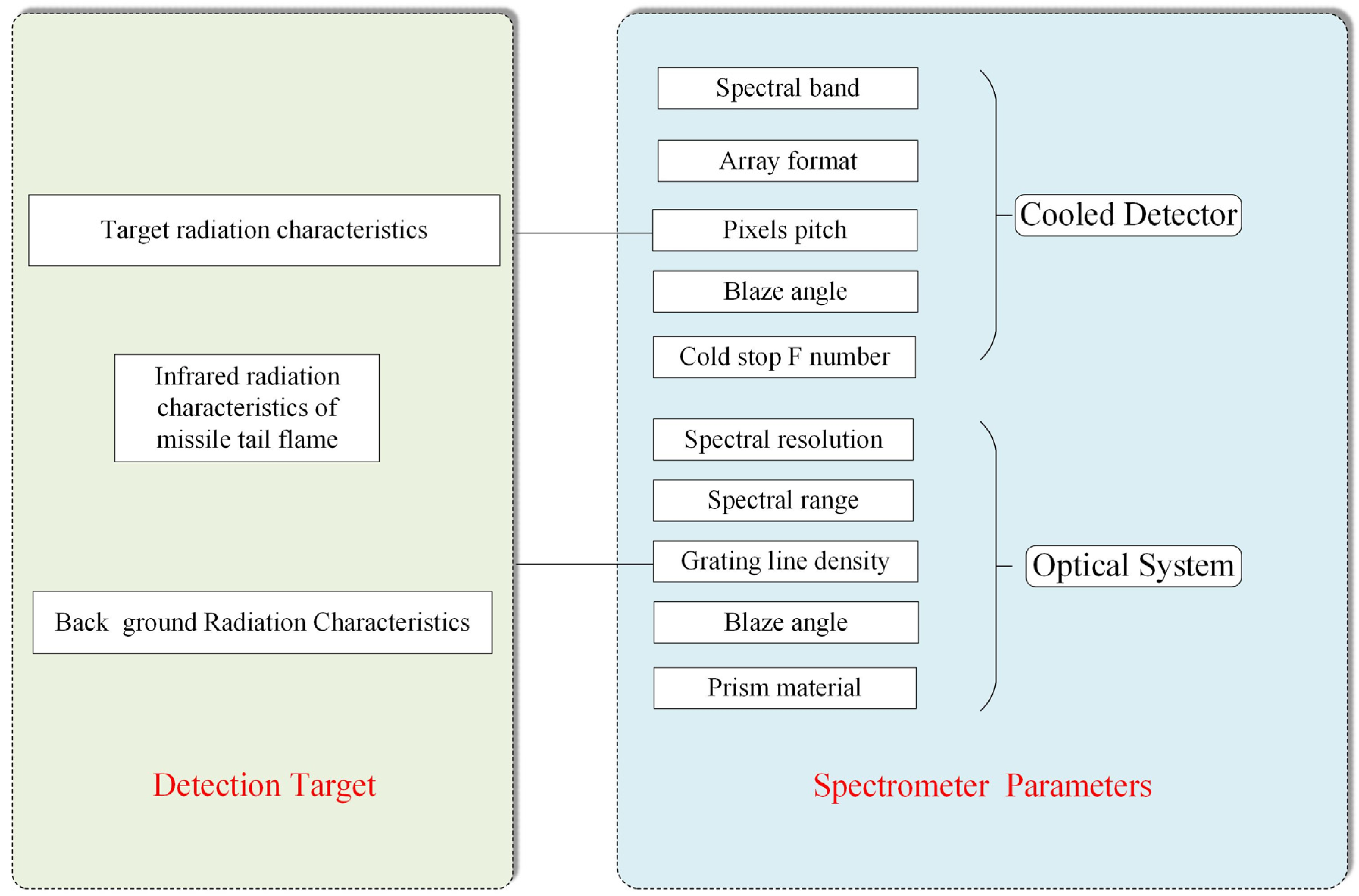

2. Materials and Methods

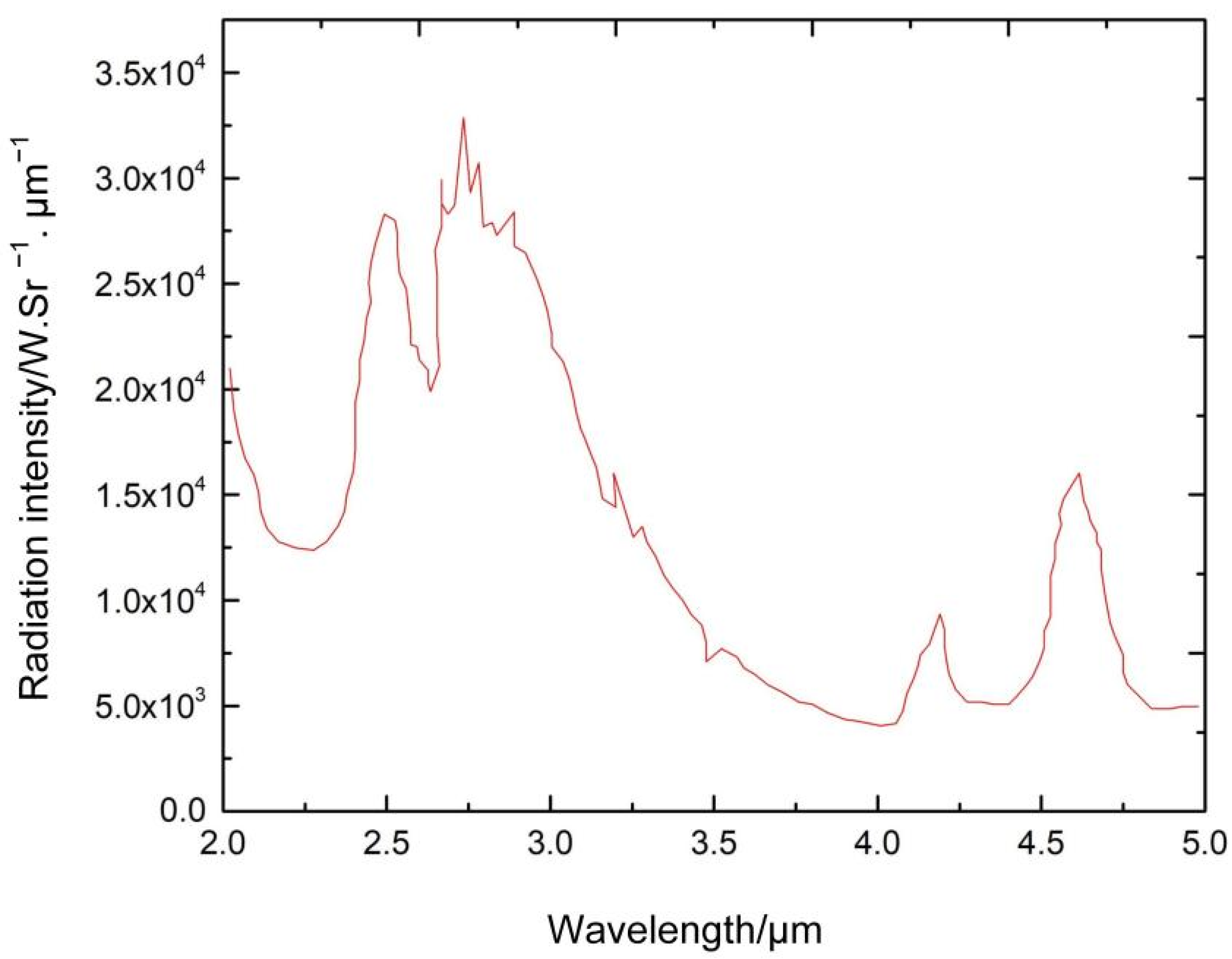

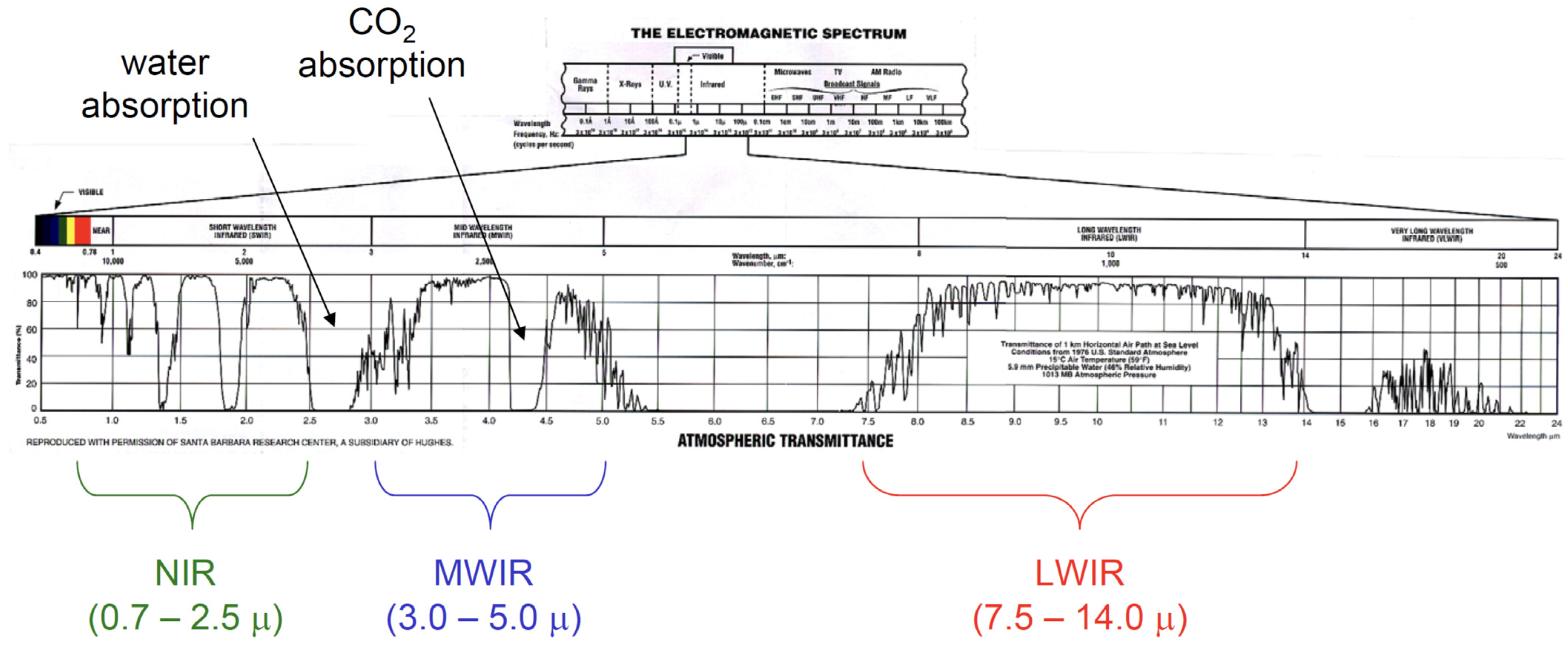

2.1. Infrared Radiation Characteristics of Rocket Plume

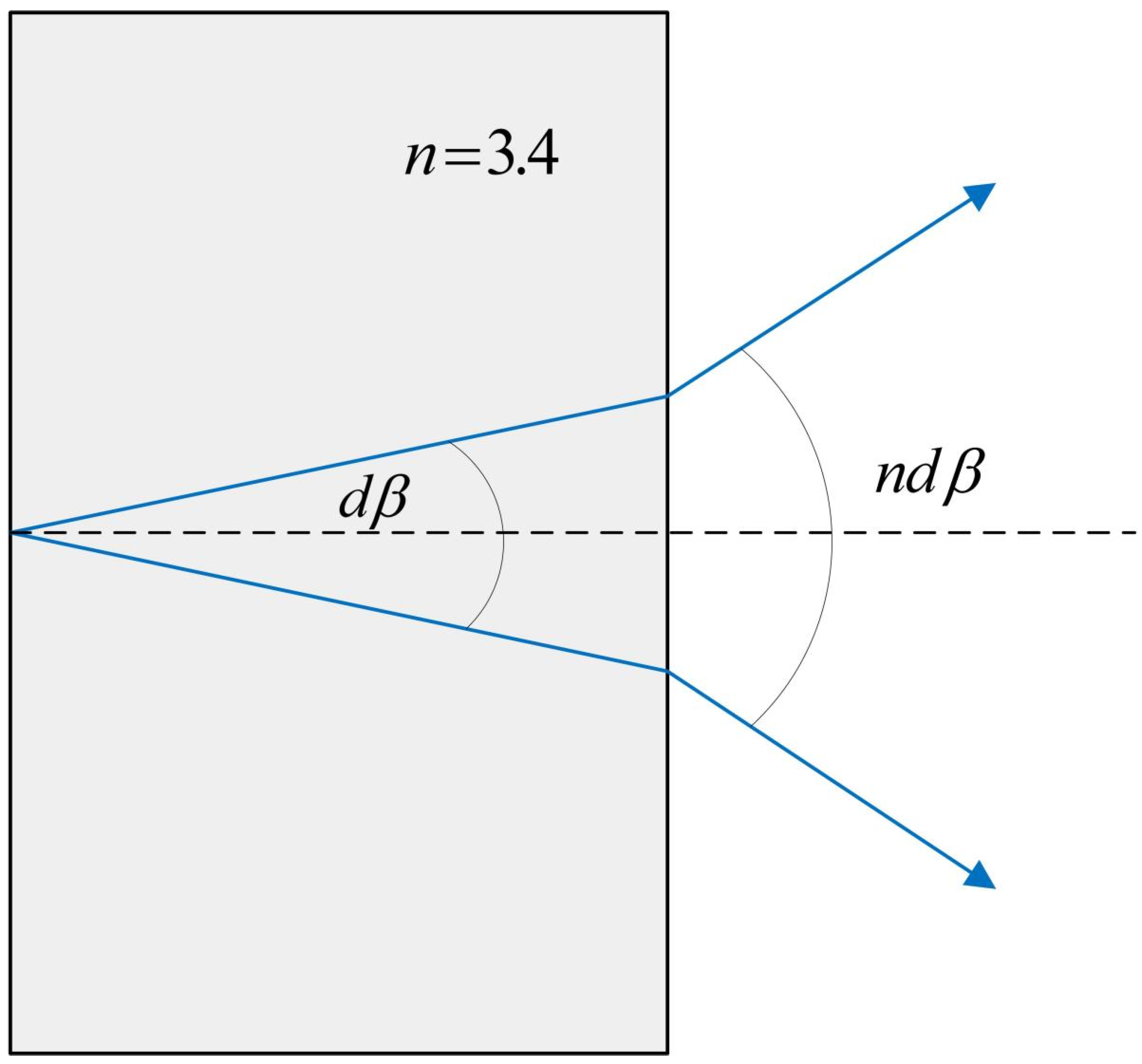

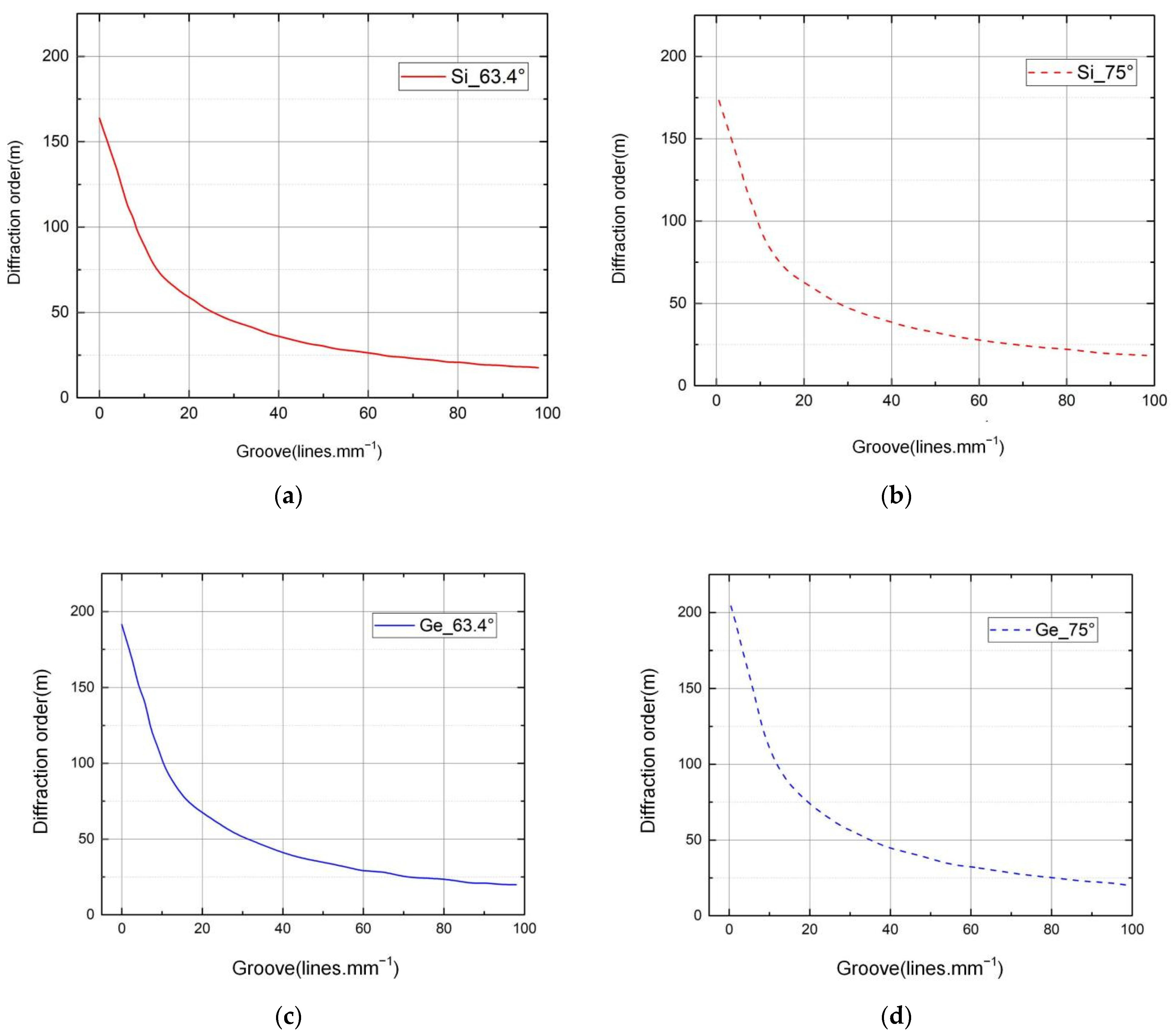

2.2. Immersion Grating Theory

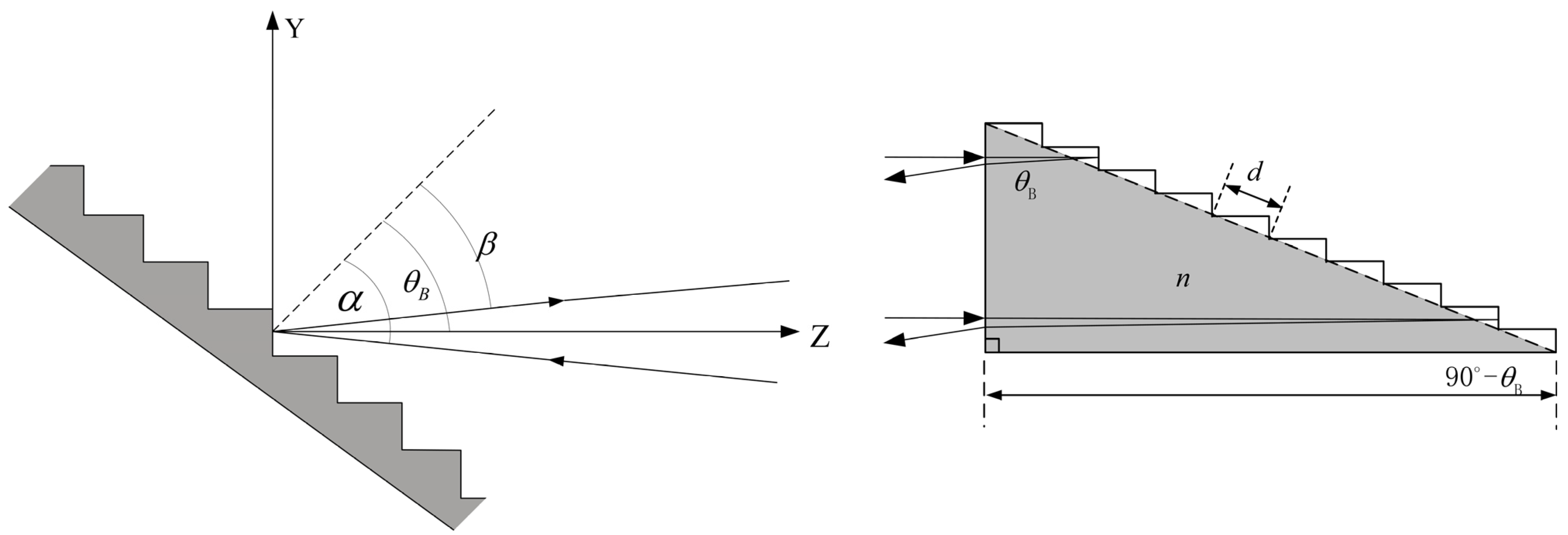

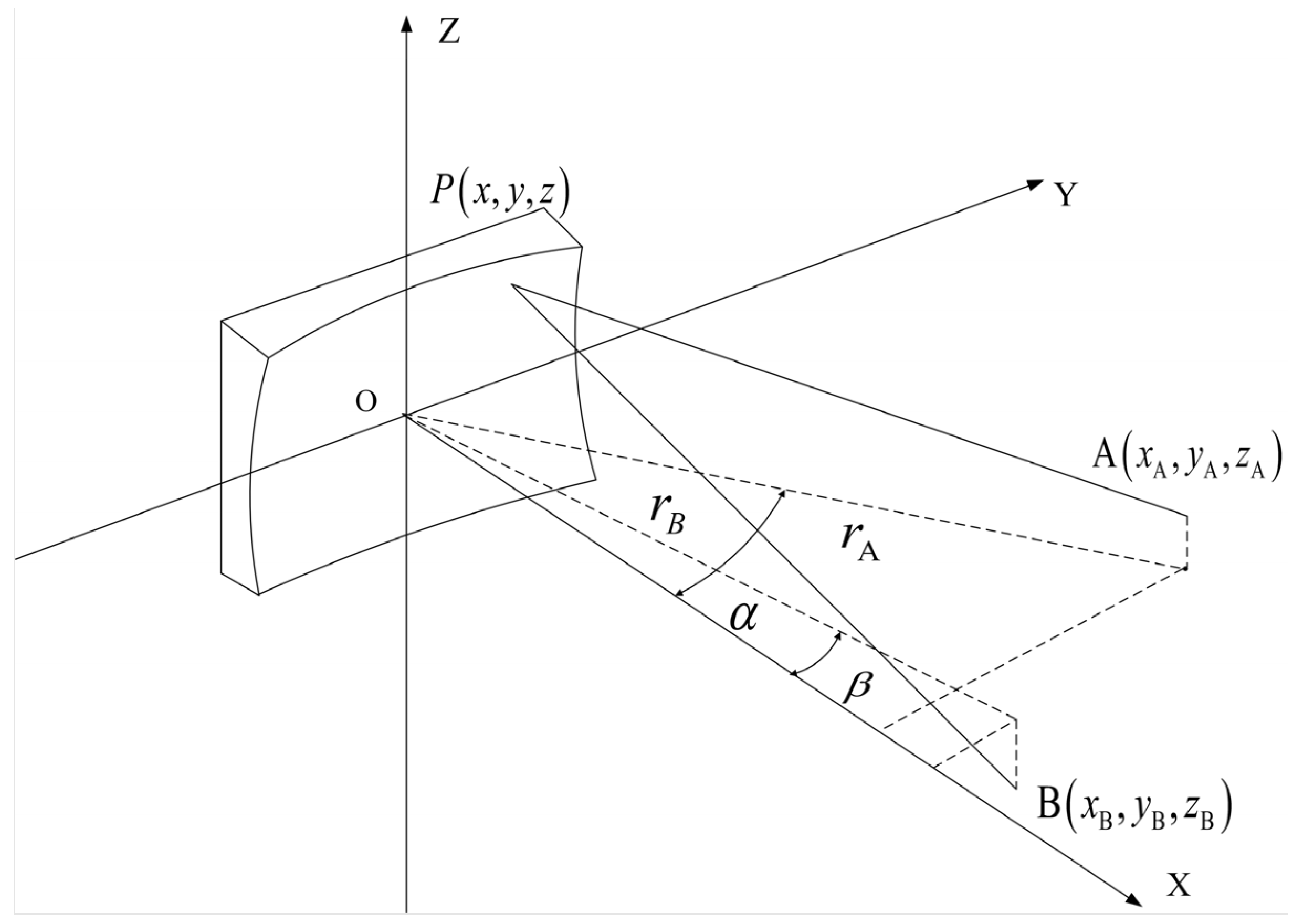

2.3. Dispersion Characteristics of Toroidal Gratings

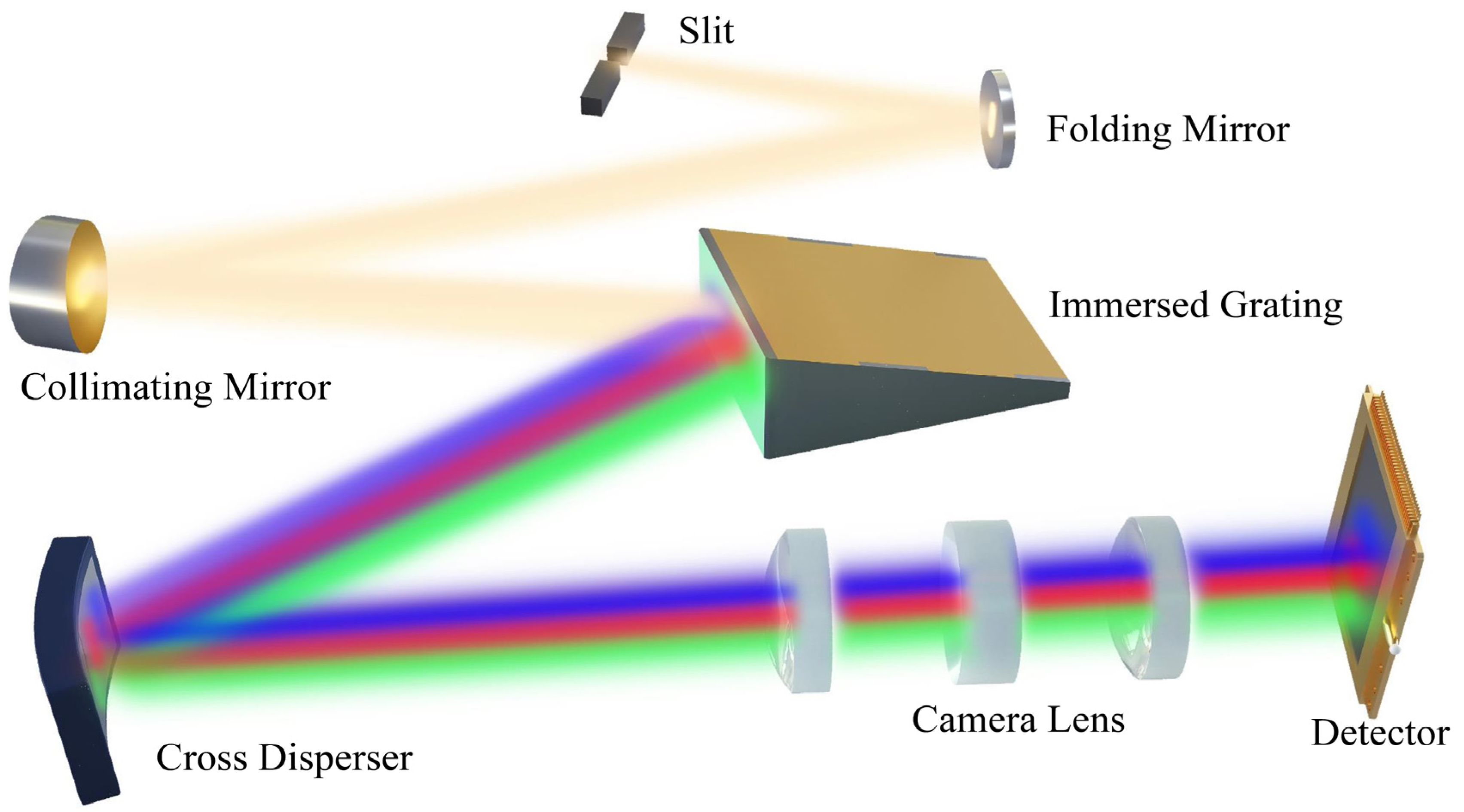

3. Optical System Design Method

4. Results and Discussion

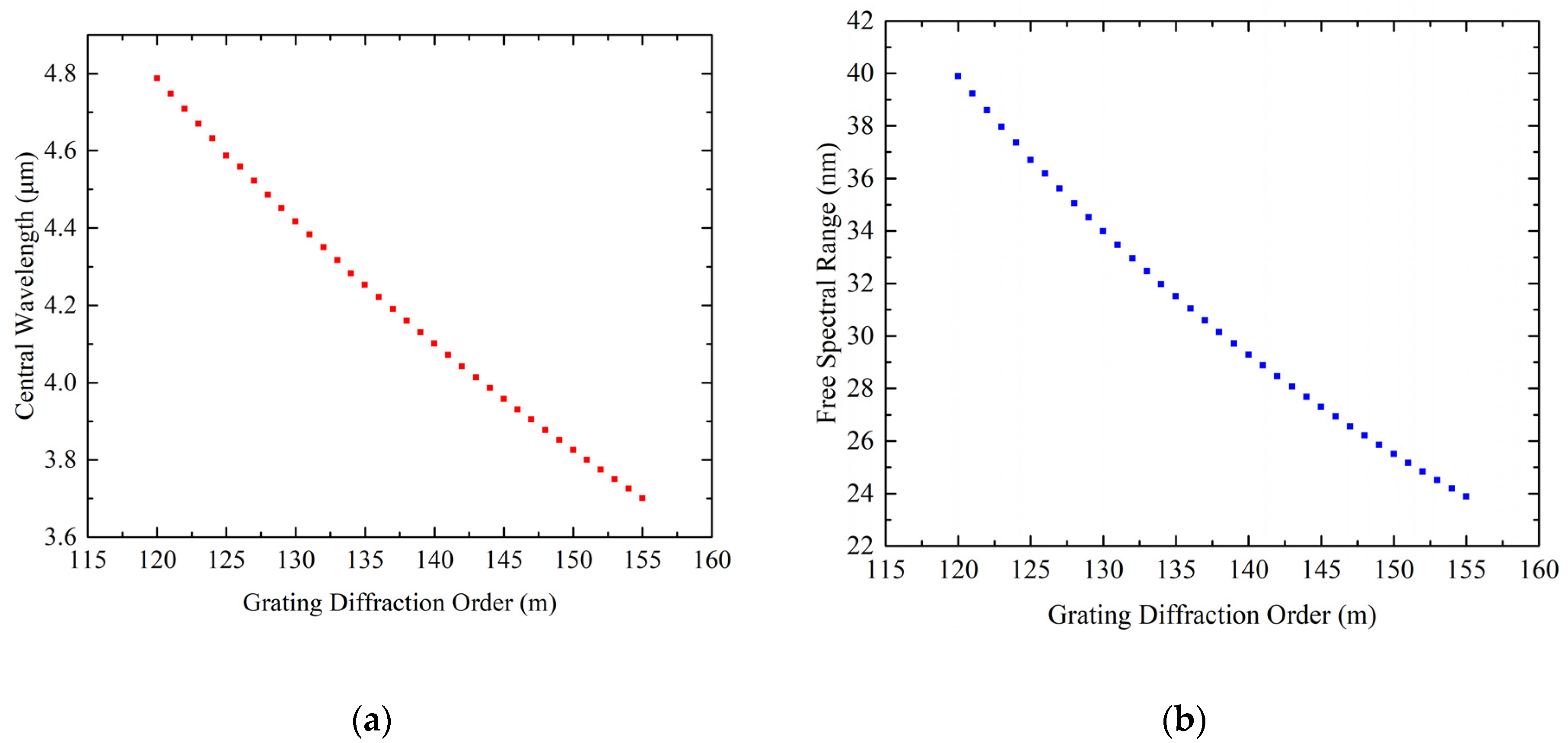

4.1. Analysis of Echelle Grating Characteristics

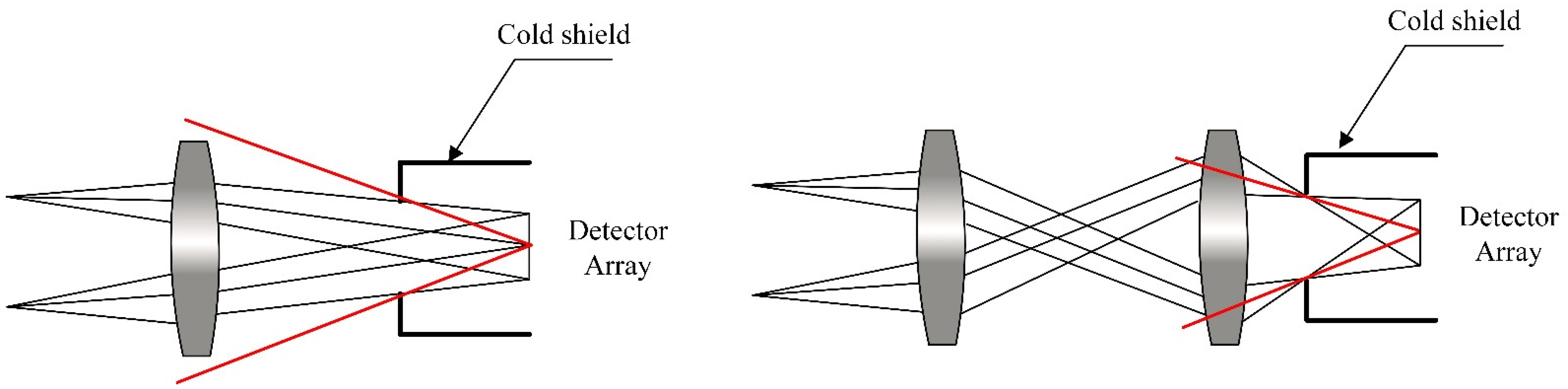

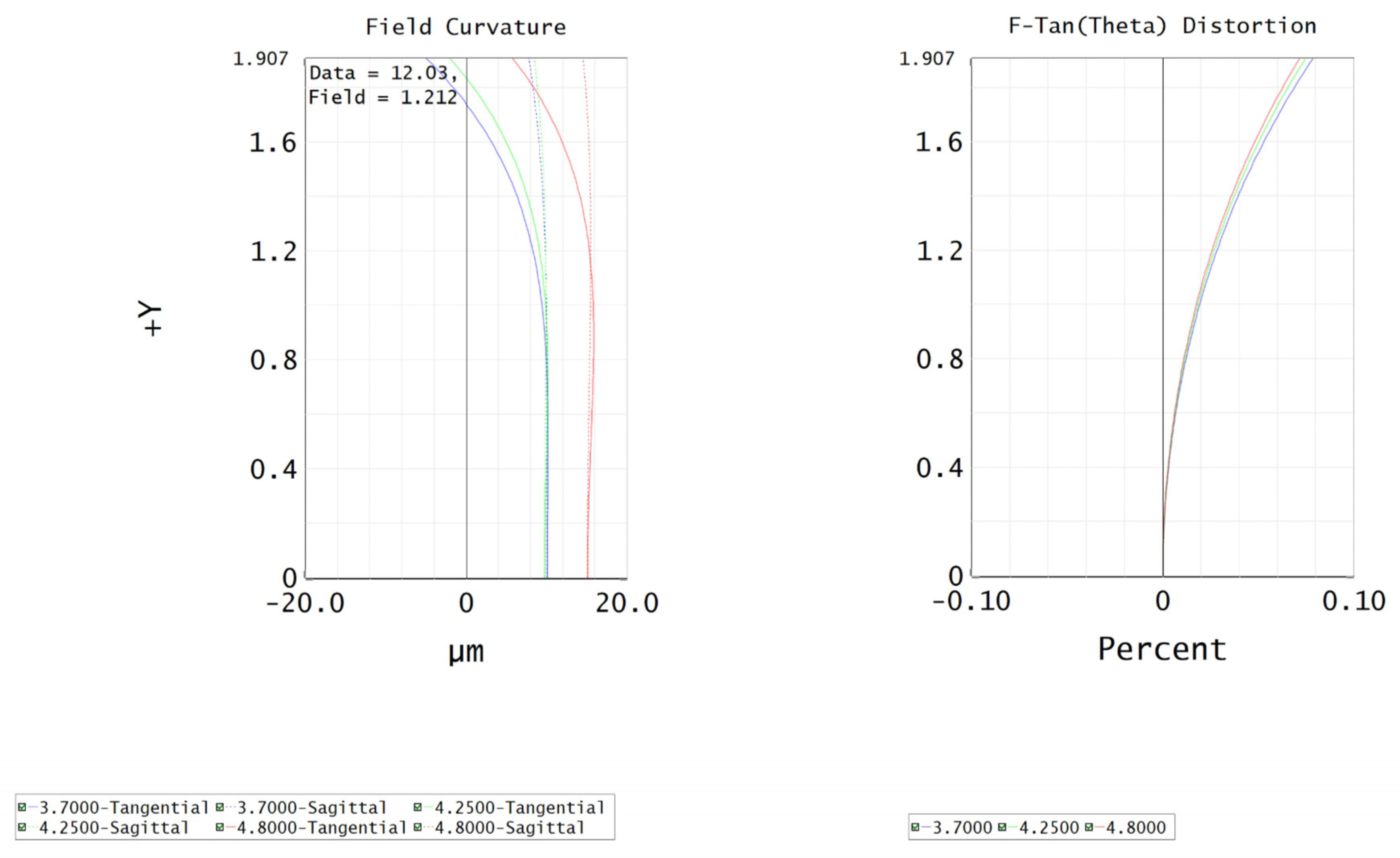

4.2. Thermal Design for Infrared Lens

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sun, L.; Bao, J. Study on Imaging Spectrometer in the Applications of Aviation Imaging Reconnaissance. Remote Sens. Inf. 2010, 6, 115–119. [Google Scholar]

- Wu, X.; Zhu, Y.; Wang, L. Optical design of high resolution echelle spectrograph. Opt. Precis. Eng. 2003, 11, 442–447. [Google Scholar]

- Nana, L.I.; Zhi-yong, A.N.; Ji-cheng, C.U.I. Aligning and testing of optical system of echelle spectrography. Opt. Precis. Eng. 2009, 17, 531–536. [Google Scholar]

- Eversberg, T.; Vollmann, K. Spectroscopic Instrumentation: Fundamentals and Guidelines for Astronomers; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Hearnshaw, J. High Resolution Spectrographs. In Astronomical Spectrographs and Their History; Cambridge University Press: Cambridge, UK, 2009; pp. 72–95. [Google Scholar]

- Harrison, G.R.J.J. The Production of Diffraction Gratings: II. The Design of Echelle Gratings and Spectrographs. J. Opt. Soc. Am. 1949, 39, 522–527. [Google Scholar] [CrossRef]

- Bykov, S.V.; Sharma, B.; Asher, S.A. High-Throughput, High-Resolution Echelle Deep-UV Raman Spectrometer. Appl. Spectrosc. 2013, 67, 873–883. [Google Scholar] [CrossRef]

- Korablev, O.; Montmessin, F.; Trokhimovsky, A.; Fedorova, A.A.; Kiselev, A.V.; Bertaux, J.L.; Goultail, J.P.; Belyaev, D.A.; Stepanov, A.V.; Titov, A.Y.; et al. Compact echelle spectrometer for occultation sounding of the Martian atmosphere: Design and performance. Appl. Opt. 2013, 52, 1054–1065. [Google Scholar] [CrossRef]

- Xu, L.N.; Davenport, M.A.; Turner, M.A.; Sun, T.; Kelly, K.F. Compressive Echelle Spectroscopy. In Proceedings of the Conference on Unconventional Imaging, Wavefront Sensing, and Adaptive Coded Aperture Imaging and Non-Imaging Sensor Systems, San Diego, CA, USA, 21–25 August 2011. [Google Scholar]

- Zhang, R.; Ren, W.Y.; Xu, Z.L.; Wang, H.; Jiang, J.G.; Wang, Y.Y.; Luo, X.B. Single-pixel echelle spectrometer based on compressive sensing. Optik 2021, 240, 7. [Google Scholar] [CrossRef]

- Ning, C.L.; Qi, X.D.; Chen, S.J.; Bayanheshig; Cui, J.C. Optical Design and Performance Analysis of Light and Small Echelle Spectrograph. Spectrosc. Spectr. Anal. 2012, 32, 3406–3410. [Google Scholar] [CrossRef]

- Loewen, E.; Maystre, D.; Popov, E.; Tsonev, L. Echelles—Scalar, Electromagnetic, and Real-Groove Properties. Appl. Opt. 1995, 34, 1707–1727. [Google Scholar] [CrossRef]

- Korablev, O.I.; Bertaux, J.L.; Vinogradov, I.I.; Kalinnikov, Y.K.; Nevejans, D.; Neefs, E.; Le Barbu, T.; Durry, G. Compact high-resolution echelle-AOTF NIR spectrometer for atmospheric measurements. In Proceedings of the 5th International Conference on Space Optics (ICSO 2004), Toulouse, France, 30 March–2 July 2004; pp. 73–80. [Google Scholar]

- Nevejans, D.; Neefs, E.; Van Ransbeeck, E.; Berkenbosch, S.; Clairquin, R.; De Vos, L.; Moelans, W.; Glorieux, S.; Baeke, A.; Korablev, O.; et al. Compact high-resolution spaceborne echelle grating spectrometer with acousto-optical tunable filter based order sorting for the infrared domain from 2.2 to 4.3 mu m. Appl. Opt. 2006, 45, 5191–5206. [Google Scholar] [CrossRef]

- Gao, D.Y.; Ji, H.X.; Cao, C.; Hu, S.M.; Wittenmyer, R.A.; Hu, Z.W.; Grupp, F.; Kellermann, H.; Li, K.; Guo, D.F. WES-Weihai Echelle Spectrograph. Publ. Astron. Soc. Pac. 2016, 128, 16. [Google Scholar] [CrossRef]

- Barnard, T.W.; Crockett, M.I.; Ivaldi, J.C.; Lundberg, P.L. Design and Evaluation of an Echelle Grating Optical-System for Icp-Oes. Anal. Chem. 1993, 65, 1225–1230. [Google Scholar] [CrossRef]

- Chen, S.J.; Tang, Y.G.; Bayanheshig; Qi, X.D.; Zhu, W.Y. A new type of wide spectral coverage echelle spectrometer design for ICP-AES. In Proceedings of the Conference on Optical Design and Testing V, Beijing, China, 5–7 November 2012. [Google Scholar]

- Boumans, P.; Vrakking, J. High-Resolution Spectroscopy using an echelle spectrometer with predisperser.1. Characteristics of the Instrument and Approach for Measuring Physical Line widths in an Inductively Coupled Plasma. Spectroc. Acta Pt. B-Atom. Spectr. 1984, 39, 1239–1260. [Google Scholar] [CrossRef]

- Abbasi, H.; Guzman, R.; Cattin, P.C.; Zam, A. All-fiber-optic LIBS system for tissue differentiation: A prospect for endoscopic smart laser osteotomy. Opt. Lasers Eng. 2022, 148, 106765. [Google Scholar] [CrossRef]

- Shen, M.; Hao, Z.Q.; Li, X.Y.; Li, C.M.; Guo, L.B.; Tang, Y.; Yang, P.; Zeng, X.Y.; Lu, Y.F. New spectral reduction algorithm for echelle spectrometer in laser-induced breakdown spectroscopy. Opt. Express 2018, 26, 34131–34141. [Google Scholar] [CrossRef] [PubMed]

- Fowler, A.M.; Wiedemann, G.R.; Dave, H.H.; Jennings, D.E. Immersion grating and etched gratings for infrared astronomy. In Proceedings of the Infrared Detectors and Instrumentation, Orlando, FL, USA, 20 October 1993; pp. 1176–1178. [Google Scholar]

- HulthÉN, E.; Neuhaus, H. Diffraction Gratings in Immersion. Nature 1954, 173, 442–443. [Google Scholar] [CrossRef]

- Lee, D.; Allington-Smith, J.R. An experimental investigation of immersed gratings. Mon. Not. Roy. Astron. Soc. 2000, 312, 57–69. [Google Scholar] [CrossRef]

- Cugny, B.; Karafolas, N.; Armandillo, E.; Lobb, D.; Bhatti, I.; Fernandez-Saldivar, J.; Guldimann, B.; Desserouer, F.; Touzet, B.; Baister, G.; et al. Efficiency, dispersion and straylight performance tests of immersed gratings for high resolution spectroscopy in the near infrared. In Proceedings of the International Conference on Space Optics—ICSO 2012, Ajaccio, France, 9–12 October 2017. [Google Scholar]

- Tang, Q.; Guo, L.X.; Zhao, B.C. Characteristics of the spectral lines of immersion gratings. J. Infrared Millim. Waves 2017, 36, 569–574. [Google Scholar] [CrossRef]

- Tang, Q.; Guo, L.X. Dispersion nonlinearity analysis of immersed gratings. Appl. Opt. 2018, 57, 1548–1553. [Google Scholar] [CrossRef]

- Tang, Q.; Qiu, Y.; Zhao, B.; Chen, L. Research of the Immersion Grating Diffraction Pattern. Acta Photonica Sin. 2014, 43, 1105002. [Google Scholar] [CrossRef]

- Qian, T.; Min, Z.C.; Chang, Z.B. Effect of refractive index measurement error on immersion grating spectral lines. In Proceedings of the 5th Symposium on Novel Optoelectronic Detection Technology and Application, Xian, China, 24–26 October 2018. [Google Scholar]

- Ikeda, Y.; Kobayashi, N.; Sarugaku, Y.; Sukegawa, T.; Sugiyama, S.; Kaji, S.; Nakanishi, K.; Kondo, S.; Yasui, C.; Kataza, H.; et al. Machined immersion grating with theoretically predicted diffraction efficiency. Appl. Opt. 2015, 54, 5193–5202. [Google Scholar] [CrossRef] [PubMed]

- Ikeda, Y.; Kobayashi, N.; Kuzmenko, P.J.; Little, S.L.; Yasui, C.; Kondo, S.; Minami, A.; Motohara, K. Diamond-machined ZnSe immersion grating for NIR high-resolution spectroscopy. In Proceedings of the International Conference on Advanced Optical and Mechanical Technologies in Telescopes and Instrumentation, Marseille, France, 23–28 June 2008. [Google Scholar]

- Kuzmenko, P.J.; Atad-Ettedgui, E.; Antebi, J.; Davis, P.J.; Little, S.L.; Lemke, D.; Little, L.M.; Bixler, J.V. High efficiency germanium immersion gratings. Optomech. Technol. Astron. 2006, 6273, 1188–1201. [Google Scholar]

- Marsh, J.P.; Mar, D.J.; Jaffe, D.T. Production and evaluation of silicon immersion gratings for infrared astronomy. Appl. Opt. 2007, 46, 3400–3416. [Google Scholar] [CrossRef] [PubMed]

- Navarro, R.; Moon, B.; Cunningham, C.R.; Wang, W.; Park, C.; Prieto, E.; Yuk, I.-s.; Chun, M.-Y.; Jaffe, D.T. Immersion grating mount design for IGRINS and GMTNIRS. In Proceedings of the Modern Technologies in Space- and Ground-based Telescopes and Instrumentation II, Amsterdam, The Netherlands, 1–6 July 2012; p. 854048. [Google Scholar]

- Sodnik, Z.; Cugny, B.; Karafolas, N.; Nakayasu, T.; Okura, Y.; Sukegawa, T. Development of INP immersion grating for the near- to mid-infrared wavelength. In Proceedings of the International Conference on Space Optics—ICSO 2016, Biarritz, France, 18–21 October 2017. [Google Scholar]

- Sarugaku, Y.; Ikeda, Y.; Kobayashi, N.; Sukegawa, T.; Sugiyama, S.; Enya, K.; Kataza, H.; Matsuhara, H.; Nakagawa, T.; Kawakita, H.; et al. Development of CdZnTe immersion grating for spaceborne application. In Proceedings of the SPIE—The International Society for Optical Engineering, Amsterdam, The Netherlands, 16–18 April 2012; Volume 57. [Google Scholar]

- Navarro, R.; Burge, J.H.; Sukegawa, T.; Suzuki, T.; Kitamura, T. Astronomical large Ge immersion grating by Canon. In Proceedings of the Advances in Optical and Mechanical Technologies for Telescopes and Instrumentation II, Edinburgh, UK, 26 June–1 July 2016. [Google Scholar]

- Stevens, C.G.; Kuzmenko, P.J.; Conaway, W.E.; Magnotta, F.; Thomas, N.L.; Galkowski, J.; Lewis, I.T.; Alger, T.W. Cross dispersion infrared spectrometry (CDIRS) for remote chemical sensing. In Proceedings of the 21st Conference on Infrared Technology, San Diego, CA, USA, 9–13 July1995; pp. 284–291. [Google Scholar]

- Navarro, R.; Geyl, R.; Boogert, A.; Sukegawa, T.; Kuzmenko, P.J.; Sandford, S.A.; Greene, T.P.; Santistevan, I.B.; Kaess, K.W.; Montiel, E.J.; et al. Testing of a germanium immersion grating. In Proceedings of the Advances in Optical and Mechanical Technologies for Telescopes and Instrumentation III, Austin, TX, USA, 10–15 June 2018. [Google Scholar]

- Rayner, J.; Tokunaga, A.; Jaffe, D.; Bond, T.; Bonnet, M.; Ching, G.; Connelley, M.; Cushing, M.; Kokubun, D.; Lockhart, C.; et al. iSHELL: A 1–5 micron R = 80,000 Immersion Grating Spectrograph for the NASA Infrared Telescope Facility. Publ. Astron. Soc. Pac. 2022, 134, 015002. [Google Scholar] [CrossRef]

- Rayner, J.; Bond, T.; Bonnet, M.; Jaffe, D.; Muller, G.; Tokunaga, A. iSHELL: A 1-5 micron cross-dispersed R=70,000 immersion grating spectrograph for IRTF. In Proceedings of the Ground-based and Airborne Instrumentation for Astronomy IV, Amsterdam, The Netherlands, 1–6 July 2012; p. 8446. [Google Scholar] [CrossRef]

- Yang, Z.J.; Pan, S.Q.; Pan, Q.; Liu, Q.; Wu, S.L.; Shen, W.M. Design and fabrication of silicon immersion grating. In Proceedings of the 7th Symposium on Novel Photoelectronic Detection Technology and Applications, Kunming, China, 5–7 November 2020. [Google Scholar]

- Pan, S.; Yang, Z.; Pan, Q.; Shen, W. Design of optical system for short-wave infrared silicon immersion grating imaging spectrometer. In Proceedings of the Seventh Symposium on Novel Photoelectronic Detection Technology and Applications, 1 March 2021; p. 1176363. [Google Scholar]

- Loewen, E.G.; Popov, E.J. Diffraction Gratings and Applications; CRC Press: Boca Raton, FL, USA, 1997. [Google Scholar]

- Schroeder, D.J. Chapter 13—Dispersing Elements and Systems. In Astronomical Optics, 2nd ed.; Schroeder, D.J., Ed.; Academic Press: San Diego, CA, USA, 2000; pp. 321–351. [Google Scholar]

- Dekker, H. An Immersion Grating for an Astronomical Spectrograph. In Proceedings of the Instrumentation for Ground-Based Optical Astronomy, New York, NY, USA, 13–24 July 1988; pp. 183–188. [Google Scholar]

- Ramsay, S.K.; McLean, I.S.; Takami, H.; Kaji, S.; Sarugaku, Y.; Ikeda, Y.; Kobayashi, N.; Nakanishi, K.; Kondo, S.; Yasui, C.; et al. The precise measurement of the attenuation coefficients of various IR optical materials applicable to immersion grating. In Proceedings of the Ground-based and Airborne Instrumentation for Astronomy V, Montreal, QC, Canada, 22–26 June 2014. [Google Scholar]

- Kobayashi, N. Zinc sulfide and zinc selenide immersion gratings for astronomical high-resolution spectroscopy: Evaluation of internal attenuation of bulk materials in the short near-infrared region. Opt. Eng. 2009, 48. [Google Scholar] [CrossRef]

- Fan, H.Y.; Becker, M. Infra-Red Absorption of Silicon. Phys. Rev. 1950, 78, 178–179. [Google Scholar] [CrossRef]

- Schroder, D.K.; Thomas, R.N.; Swartz, J.C. Free carrier absorption in silicon. J. Solid-State Circuits 1978, 25, 254–261. [Google Scholar]

- Runyan, W.R. Silicon Semiconductor Technology; McGraw Hill: New York, NY, USA, 1965. [Google Scholar]

- Keller, L.D.; Jaffe, D.T.; Ershov, O.A.; Benedict, T.; Graf, U.U. Fabrication and testing of chemically micromachined silicon echelle gratings. Appl. Opt. 2000, 39, 1094–1105. [Google Scholar] [CrossRef]

- Ge, J.; McDavitt, D.; Miller, S.; Bernecker, J.; Chakraborty, A.; Wang, J. Breakthroughs in silicon grism and immersion grating technology at Penn State. In Proceedings of the Conference on Instrument Design and Performance for Optical/Infrared Ground-based Telescopes, Waikoloa, HI, USA, 25–28 August 2002; pp. 1006–1015. [Google Scholar]

- Graf, U.U.; Jaffe, D.T.; Kim, E.J.; Lacy, J.H.; Ling, H.; Moore, J.T.; Rebeiz, G. Fabrication and Evaluation of an Etched Infrared Diffraction Grating. Appl. Opt. 1994, 33, 96–102. [Google Scholar] [CrossRef]

- Xu, T.; Lu, L. Optimization of Optical System of Extreme Ultra-Violet Spectrometer. Acta Opt. Sin. 2010, 30, 2646–2651. [Google Scholar]

- Harada, T.; Sakuma, H.; Takahashi, K.; Watanabe, T.; Hara, H.; Kita, T. Design of a high-resolution extreme-ultraviolet imaging spectrometer with aberration-corrected concave gratings. Appl. Opt. 1998, 37, 6803–6810. [Google Scholar] [CrossRef] [PubMed]

- Gil, M.A.; Simon, J.M.; Fantino, A.N. Czerny-Turner spectrograph with a wide spectral range. Appl. Opt. 1988, 27, 4069–4072. [Google Scholar] [CrossRef]

- Rosfjord, K.M.; Villalaz, R.A.; Gaylord, T.K. Constant-bandwidth scanning of the Czerny-Turner monochromator. Appl. Opt. 2000, 39, 568. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.; Song, N.; Bayanheshig; Cui, J.; Chen, J. Optical design of cross-dispersed echelle spectrograph. Opt. Precis. Eng. 2010, 18, 1989–1995. [Google Scholar]

- Imaging Spectrometers. In Hyperspectral Imaging Remote Sensing: Physics, Sensors, and Algorithms; Manolakis, D.G.; Lockwood, R.B.; Cooley, T.W. (Eds.) Cambridge University Press: Cambridge, UK, 2016; pp. 154–227. [Google Scholar]

- Rukdee, S.; Vanzi, L.; Schwab, C.; Flores, M.; Valenzuela, A.; Pember, J.; Zapata, A.; Motohara, K.; Yoshii, Y.; Tala Pinto, M. TARdYS: Design and prototype of an exoplanet hunter for TAO using a R6 Echelle grating. Exp. Astron. 2019, 48, 145–169. [Google Scholar] [CrossRef]

| Optical Layout | Advantage | Disadvantage |

|---|---|---|

| Figure 7a Ebert-Fastie | Structure is symmetrical Small residual coma Compact Convenient adjustment | Large volume size Secondary diffraction Multiple diffractions Stray light |

| Figure 7b Czerny-Turner | Avoid multiple diffractions Beneficial to adjustment | None reported |

| Figure 7c Littrow | Simple structure Compact structure | Multiple diffractions High stray light Spectral smile and keystone |

| Figure 7d Chupp-Gtantz | High resolution Low stray light | OAP difficult process |

| Material | Wavelength/μm | Refractive Index | CTE/×10−6 |

|---|---|---|---|

| SiO2 | 0–4.5 | 1.48 | 4–10 |

| MgF2 | 0.45–9.5 | 1.34 | 11.5 |

| MgO | 0.4–10 | 1.7 | 13.9 |

| CaF2 | 0.2–12 | 1.37 | 20 |

| ZnS | 0.6–15 | 2.2 | 7 |

| ZnSe | 0.5–22 | 2.4 | 7.7 |

| Si | 1.3–15 | 3.42 | 4.2 |

| Ge | 1.8–25 | 4.02 | 6.1 |

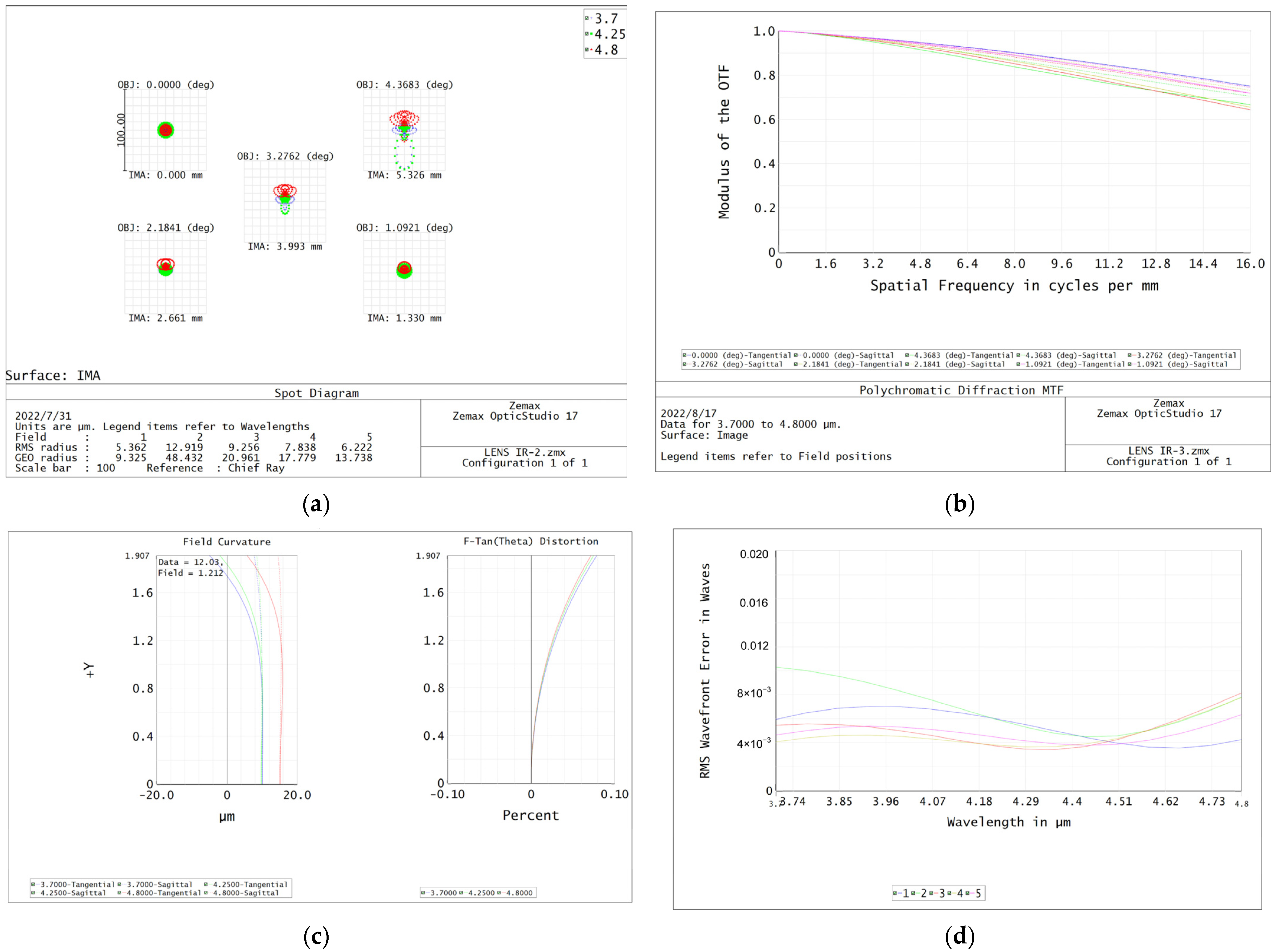

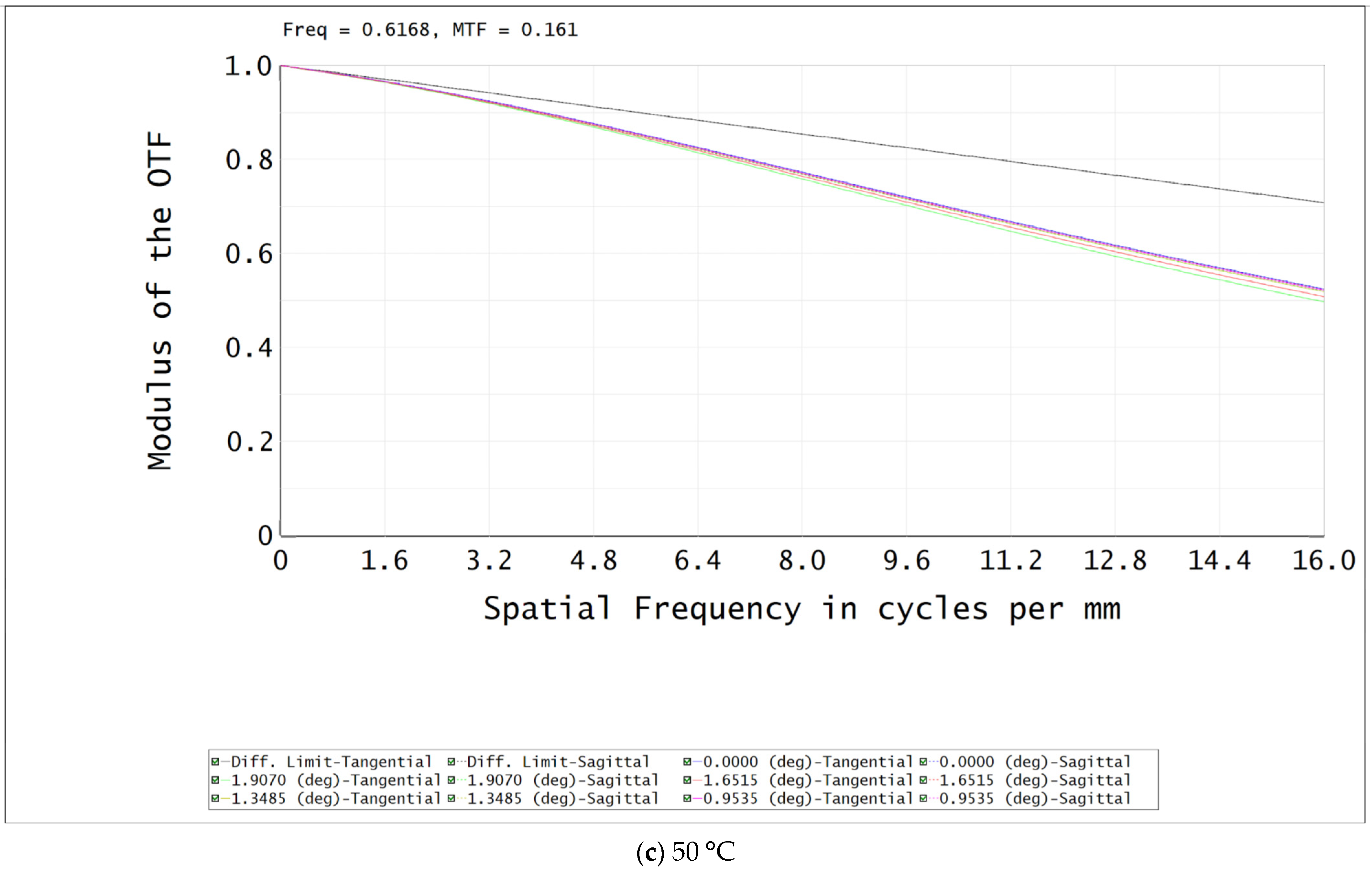

| Parameters | Values |

|---|---|

| Wavelength coverage | ~3.7–4.8 μm |

| Resolving power R | 30,000 |

| Entrance F number | 8 |

| Parabolic mirror | Reflected focal length: 275 mm |

| Main disperser | Immersion grating blaze angle: 63.5° (R2) |

| Cross disperser | Toroidal grating tangential radius: 500 mm; sagittal radius: 484.5 mm |

| Detectors | Array format: 320 × 256 Pixel size: 30 μm × 30 μm |

| Configuration | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| m | 120th | 127th | 135th | 147th | 155th |

| 4.79 | 4.53 | 4.26 | 3.91 | 3.70 | |

| 4.77 | 4.51 | 4.24 | 3.90 | 3.70 | |

| 4.81 | 4.54 | 4.27 | 3.92 | 3.71 | |

| FSR/nm | 39.93 | 35.65 | 31.55 | 26.61 | 23.93 |

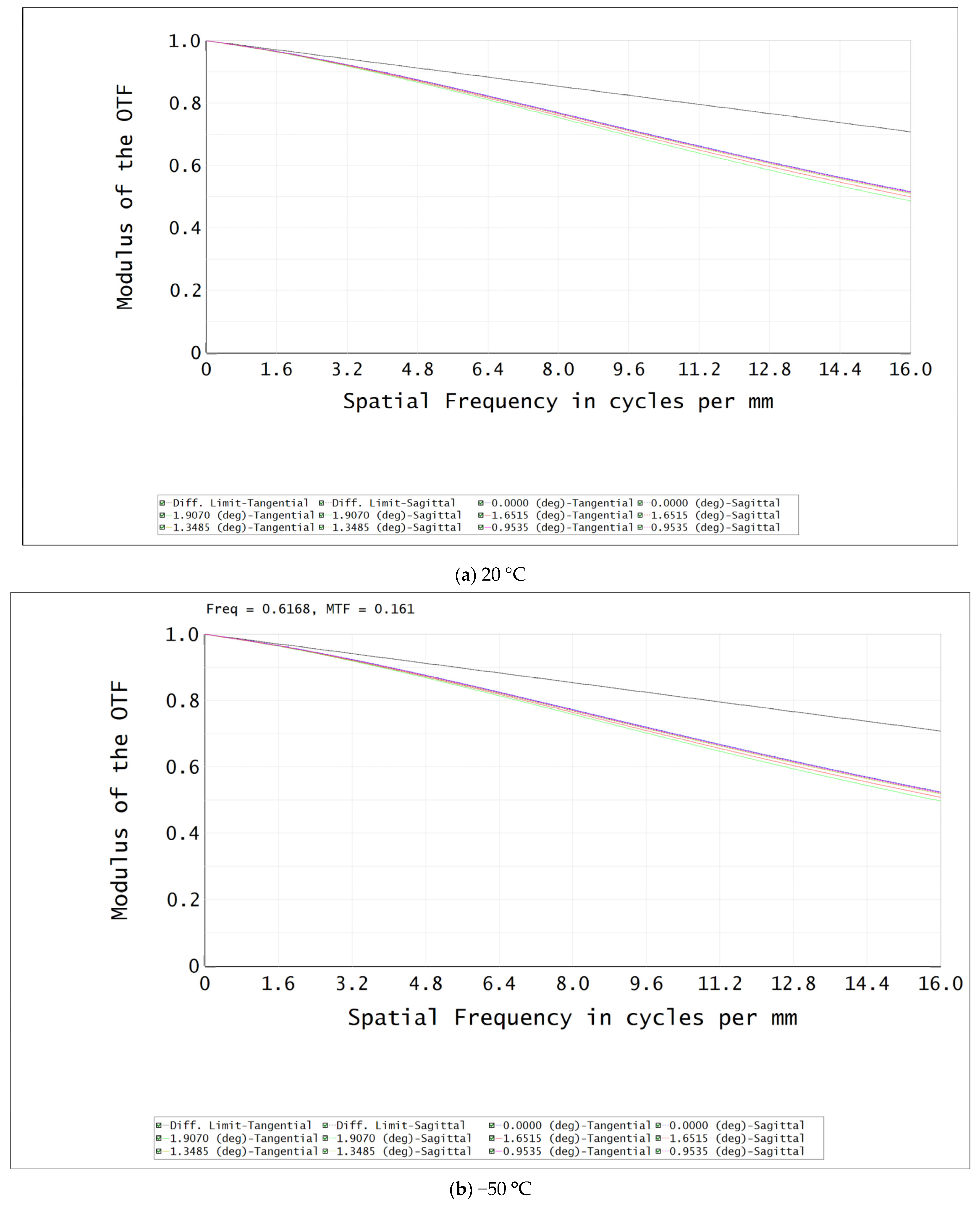

| Temperature/°C | 50 | 20 | 0 | −20 | −50 |

|---|---|---|---|---|---|

| Defocus/μm | 14.2 | 12.1 | 0 | 6.3 | 9.0 |

| Depth of Focal/μm | 40 | ||||

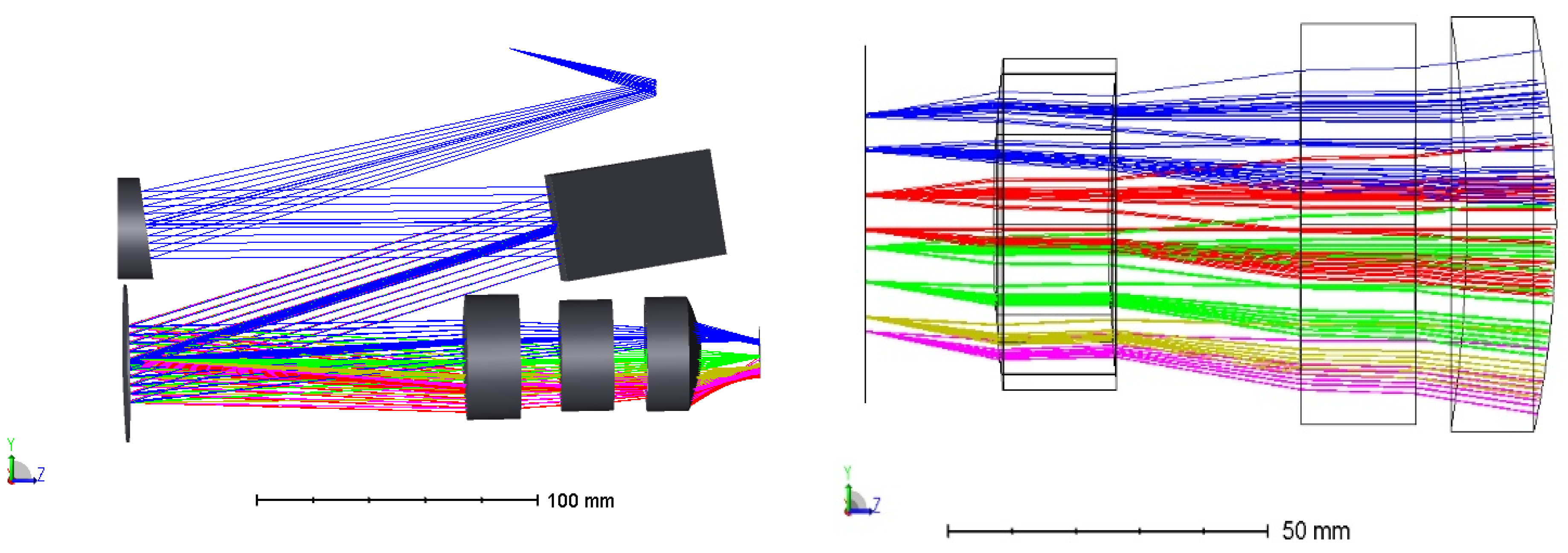

| Wavelength | B1 | B2 | B3 | C1 | C2 | C3 | T1 | T2 | T3 |

|---|---|---|---|---|---|---|---|---|---|

| Figure | (a) | (b) | (c) | (d) | (e) | (f) | (g) | (h) | (i) |

| RMS/μm | 25.2 | 32.3 | 25.8 | 32.8 | 39.7 | 32.5 | 39.8 | 25.6 | 26.2 |

| Resolution | 45,000 | 44,600 | 45,800 | 24,800 | 25,300 | 27,600 | 22,000 | 23,000 | 24,500 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Shen, H.; Liu, W.; Zhang, J.; Meng, L. Design of Compact Mid-Infrared Cooled Echelle Spectrometer Based on Toroidal Uniform-Line-Spaced (TULS) Grating. Sensors 2022, 22, 7291. https://doi.org/10.3390/s22197291

Wang Q, Shen H, Liu W, Zhang J, Meng L. Design of Compact Mid-Infrared Cooled Echelle Spectrometer Based on Toroidal Uniform-Line-Spaced (TULS) Grating. Sensors. 2022; 22(19):7291. https://doi.org/10.3390/s22197291

Chicago/Turabian StyleWang, Qingyu, Honghai Shen, Weiqi Liu, Jingzhong Zhang, and Lingtong Meng. 2022. "Design of Compact Mid-Infrared Cooled Echelle Spectrometer Based on Toroidal Uniform-Line-Spaced (TULS) Grating" Sensors 22, no. 19: 7291. https://doi.org/10.3390/s22197291