Experimental Analysis of Handcart Pushing and Pulling Safety in an Industrial Environment by Using IoT Force and EMG Sensors: Relationship with Operators’ Psychological Status and Pain Syndromes

Abstract

:1. Introduction

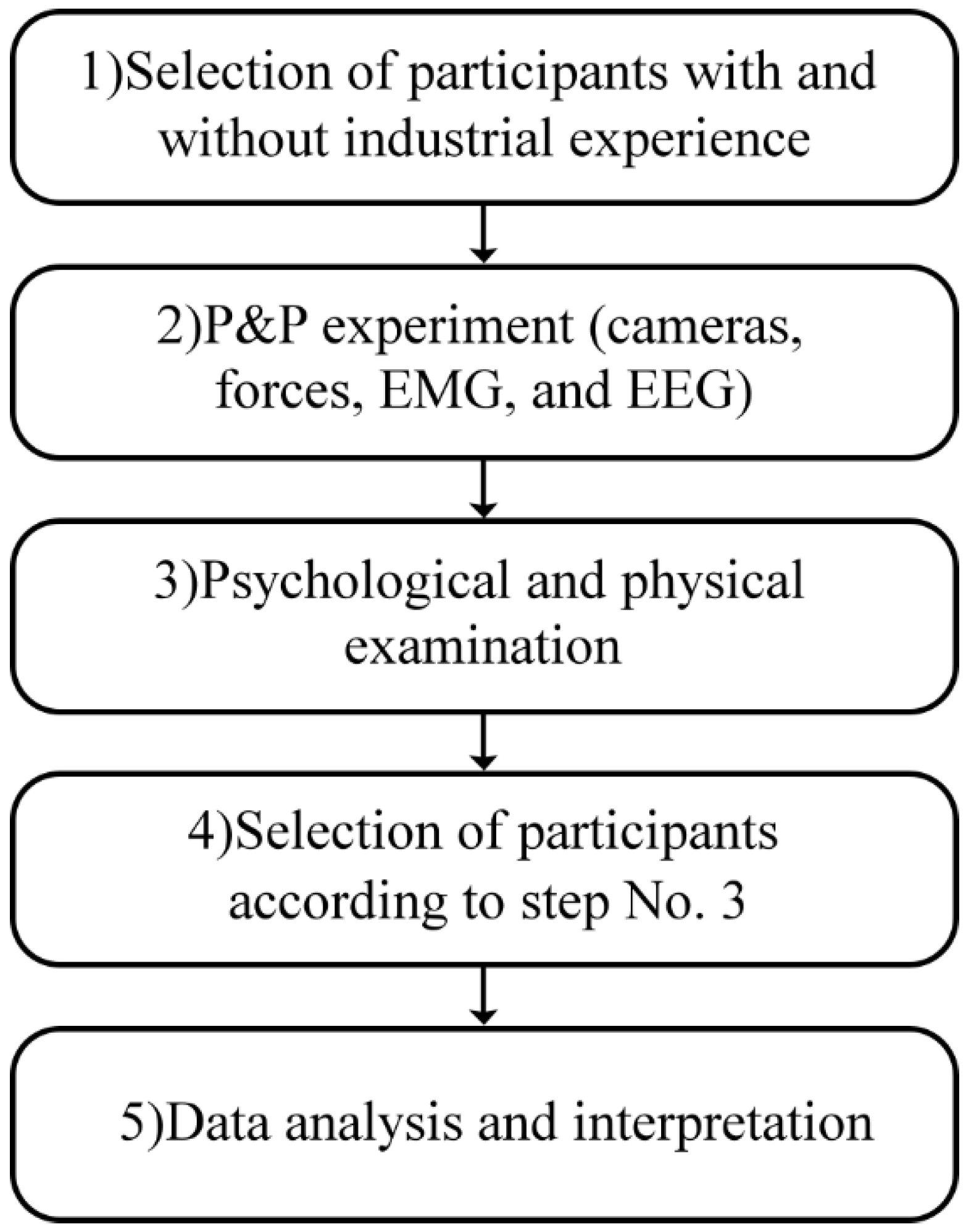

2. Materials and Methods

2.1. Study Participants

2.2. Physical and Psychological Assessment

2.3. Experiment Design

2.4. Data Acquisition

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Abbreviation List

| Abbreviation | Meaning |

| WMSD | Work-related Musculoskeletal Disorder |

| P&P | Pushing and Pulling |

| EMG | Electromyography |

| EEG | Electroencephalography |

| DASS | Depression Anxiety Stress Scales |

| VRSMAV | Verbal Rating ScaleMean Absolute Value |

References

- Zarte, M.; Pechmann, A.; Nunes, I.L. Principles for Human-Centered System Design in Industry 4.0—A Systematic Literature Review. In Proceedings of the Advances in Human Factors and Systems Interaction, San Diego, CA, USA, 16–20 July 2020; Nunes, I.L., Ed.; Springer International Publishing: Cham, Switzerland, 2020; pp. 140–147. [Google Scholar]

- Yaris, C.; Ditchburn, G.; Curtis, G.J.; Brook, L. Combining Physical and Psychosocial Safety: A Comprehensive Workplace Safety Model. Saf. Sci. 2020, 132, 104949. [Google Scholar] [CrossRef]

- Anderson, S.P.; Oakman, J. Allied Health Professionals and Work-Related Musculoskeletal Disorders: A Systematic Review. Saf. Health Work 2016, 7, 259–267. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Antwi-Afari, M.F.; Li, H.; Edwards, D.J.; Pärn, E.A.; Seo, J.; Wong, A.Y.L. Biomechanical Analysis of Risk Factors for Work-Related Musculoskeletal Disorders during Repetitive Lifting Task in Construction Workers. Autom. Constr. 2017, 83, 41–47. [Google Scholar] [CrossRef]

- Eurostat, E.C. Health and Safety at Work in Europe (1999–2007). A Statistical Portrait; Publications Office of the European Union: Luxembourg, 2010. [Google Scholar]

- Chen, D.; Cai, Y.; Cui, J.; Chen, J.; Jiang, H.; Huang, M.-C. Risk Factors Identification and Visualization for Work-Related Musculoskeletal Disorders with Wearable and Connected Gait Analytics System and Kinect Skeleton Models. Smart Health 2018, 7–8, 60–77. [Google Scholar] [CrossRef]

- Antwi-Afari, M.F.; Li, H.; Umer, W.; Yu, Y.; Xing, X. Construction Activity Recognition and Ergonomic Risk Assessment Using a Wearable Insole Pressure System. J. Constr. Eng. Manag. 2020, 146, 4020077. [Google Scholar] [CrossRef]

- Márquez Gómez, M. Prediction of Work-Related Musculoskeletal Discomfort in the Meat Processing Industry Using Statistical Models. Int. J. Ind. Ergon. 2020, 75, 102876. [Google Scholar] [CrossRef]

- Nath, N.D.; Chaspari, T.; Behzadan, A.H. Automated Ergonomic Risk Monitoring Using Body-Mounted Sensors and Machine Learning. Adv. Eng. Inform. 2018, 38, 514–526. [Google Scholar] [CrossRef]

- Marras, W.S. Industrial Electromyography (EMG). Int. J. Ind. Ergon. 1990, 6, 89–93. [Google Scholar] [CrossRef]

- Day, S. Important Factors in Surface EMG Measurement; Bortec Biomedical Publications Ltd.: Calgary, AB, Canada, 2002; pp. 1–17. [Google Scholar]

- Peternel, L.; Tsagarakis, N.; Caldwell, D.; Ajoudani, A. Robot Adaptation to Human Physical Fatigue in Human–Robot Co-Manipulation. Auton. Robot. 2018, 42, 1011–1021. [Google Scholar] [CrossRef]

- Wang, D.; Hu, B.; Dai, F.; Ning, X. Sensor-Based Factorial Experimental Study on Low Back Disorder Risk Factors among. In Proceedings of the International Construction Specialty Conference of the Canadian Society for Civil Engineering (ICSC), Vancouver, BC, Canada, 7–10 June 2015; pp. 238–248. [Google Scholar]

- Salas, E.A.; Vi, P.; Reider, V.L.; Moore, A.E. Factors Affecting the Risk of Developing Lower Back Musculoskeletal Disorders (MSDs) in Experienced and Inexperienced Rodworkers. Appl. Ergon. 2016, 52, 62–68. [Google Scholar] [CrossRef]

- Peppoloni, L.; Filippeschi, A.; Ruffaldi, E.; Avizzano, C.A. A Novel Wearable System for the Online Assessment of Risk for Biomechanical Load in Repetitive Efforts. Int. J. Ind. Ergon. 2016, 52, 1–11. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, Y.; Leng, X.; Han, J.; Xia, F.; Chen, H. Impact of Chronic Stress on Attention Control: Evidence from Behavioral and Event-Related Potential Analyses. Neurosci. Bull. 2020, 36, 1395–1410. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Cheng, G.; Zhang, Y.; Covassin, T.; Heiden, E.O.; Peek-Asa, C. Influence of Symptoms of Depression and Anxiety on Injury Hazard among Collegiate American Football Players. Res. Sports Med. 2014, 22, 147–160. [Google Scholar] [CrossRef]

- Haslam, C.; Atkinson, S.; Brown, S.; Haslam, R.A. Perceptions of the Impact of Depression and Anxiety and the Medication for These Conditions on Safety in the Workplace. Occup. Environ. Med. 2005, 62, 538–545. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gerasimaviciute, V.; Bültmann, U.; Diamond, P.M.; Tullar, J.M.; Delclos, G.L.; de Porras, D.; Amick III, B.C. Reciprocal Associations between Depression, Anxiety and Work-Related Injury. Inj. Prev. 2020, 26, 529–535. [Google Scholar] [CrossRef]

- Pinupong, C.; Jalayondeja, W.; Mekhora, K.; Bhuanantanondh, P.; Jalayondeja, C. The Effects of Ramp Gradients and Pushing–Pulling Techniques on Lumbar Spinal Load in Healthy Workers. Saf. Health Work 2020, 11, 307–313. [Google Scholar] [CrossRef]

- Seo, N.J.; Sindhu, B.S.; Shechtman, O. Influence of Pain Associated with Musculoskeletal Disorders on Grip Force Timing. J. Hand Ther. 2011, 24, 335–344. [Google Scholar] [CrossRef]

- Seo, N.J.; Armstrong, T.J. Biomechanical Analysis for Handle Stability during Maximum Push and Pull Exertions. Ergonomics 2009, 52, 1568–1575. [Google Scholar] [CrossRef]

- Karwowski, W. The Discipline of Ergonomics and Human Factors. In Handbook of Human Factors and Ergonomy; Wiley: Hoboken, NJ, USA, 2006; Volume 3, pp. 3–31. [Google Scholar]

- Iqbal, M.U.; Srinivasan, B.; Srinivasan, R. Dynamic Assessment of Control Room Operator’s Cognitive Workload Using Electroencephalography (EEG). Comput. Chem. Eng. 2020, 141, 106726. [Google Scholar] [CrossRef]

- Iqbal, M.U.; Shahab, M.A.; Choudhary, M.; Srinivasan, B.; Srinivasan, R. Electroencephalography (EEG) Based Cognitive Measures for Evaluating the Effectiveness of Operator Training. Process Saf. Environ. Prot. 2021, 150, 51–67. [Google Scholar] [CrossRef]

- Lovibond, P.F.; Lovibond, S.H. The Structure of Negative Emotional States: Comparison of the Depression Anxiety Stress Scales (DASS) with the Beck Depression and Anxiety Inventories. Behav. Res. Ther. 1995, 33, 335–343. [Google Scholar] [CrossRef]

- Antony, M.M.; Bieling, P.J.; Cox, B.J.; Enns, M.W.; Swinson, R.P. Psychometric Properties of the 42-Item and 21-Item Versions of the Depression Anxiety Stress Scales in Clinical Groups and a Community Sample. Psychol. Assess. 1998, 10, 176. [Google Scholar] [CrossRef]

- The Serbian adaptation of the DASS scale. Available online: http://www2.psy.unsw.edu.au/Groups/Dass/Serbian/DASS-CYR.pdf (accessed on 25 July 2022).

- Pedersen, K.F.; Alves, G.; Larsen, J.P.; Tysnes, O.-B.; Møller, S.G.; Brønnick, K. Psychometric Properties of the Starkstein Apathy Scale in Patients with Early Untreated Parkinson Disease. Am. J. Geriatr. Psychiatry 2012, 20, 142–148. [Google Scholar] [CrossRef] [PubMed]

- Starkstein, S.E.; Migliorelli, R.; Manes, F.; Tesón, A.; Petracca, G.; Chemerinski, E.; Sabe, L.; Leiguarda, R. The Prevalence and Clinical Correlates of Apathy and Irritability in Alzheimer’s Disease. Eur. J. Neurol. 1995, 2, 540–546. [Google Scholar] [CrossRef]

- Starkstein, S.E.; Jorge, R.; Mizrahi, R. The Prevalence, Clinical Correlates and Treatment of Apathy in Alzheimer’s Disease. Eur. J. Psychiatry 2006, 20, 96–106. [Google Scholar] [CrossRef] [Green Version]

- Konrad, P. The Abc of Emg. A Practical Introduction to Kinesiological Electromyography. Electromyography 2005, 1, 30–35. [Google Scholar]

- Park, H.; Sprince, N.L.; Lewis, M.Q.; Burmeister, L.F.; Whitten, P.S.; Zwerling, C. Risk Factors for Work-Related Injury among Male Farmers in Iowa: A Prospective Cohort Study. J. Occup. Environ. Med. 2001, 43, 542–547. [Google Scholar] [CrossRef]

- Huiyun Xiang MD, M.P.H.; PhD, D.L.S.; BS, Y.C.; BS, A.E. Non-Fatal Agricultural Injuries and Risk Factors Among Colorado Female Farmers. J. Agromedicine 1999, 5, 21–33. [Google Scholar] [CrossRef]

- Hoozemans, M.J.M.; Knelange, E.B.; Frings-Dresen, M.H.W.; Veeger, H.E.J.; Kuijer, P.P.F.M. Are Pushing and Pulling Work-Related Risk Factors for Upper Extremity Symptoms? A Systematic Review of Observational Studies. Occup. Environ. Med. 2014, 71, 788–795. [Google Scholar] [CrossRef] [Green Version]

- Kim, J. Depression as a Psychosocial Consequence of Occupational Injury in the US Working Population: Findings from the Medical Expenditure Panel Survey. BMC Public Health 2013, 13, 303. [Google Scholar] [CrossRef] [Green Version]

- Gu, J.K.; Charles, L.E.; Fekedulegn, D.; Ma, C.C.; Violanti, J.M.; Andrew, M.E. Occupational Injury and Psychological Distress among U.S. Workers: The National Health Interview Survey, 2004–2016. J. Saf. Res. 2020, 74, 207–217. [Google Scholar] [CrossRef] [PubMed]

- Glowinski, S.; Krzyzynski, T.; Bryndal, A.; Maciejewski, I. A Kinematic Model of a Humanoid Lower Limb Exoskeleton with Hydraulic Actuators. Sensors 2020, 20, 6116. [Google Scholar] [CrossRef] [PubMed]

- Mehta, R.K.; Parasuraman, R. Neuroergonomics: A Review of Applications to Physical and Cognitive Work. Front. Hum. Neurosci. 2013, 7, 889. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Katona, J. Examination and Comparison of the EEG Based Attention Test with CPT and T.O.V.A. In Proceedings of the 2014 IEEE 15th International Symposium on Computational Intelligence and Informatics (CINTI), Budapest, Hungary, 19–21 November 2014; pp. 117–120. [Google Scholar]

- Katona, J.; Kovari, A. The Evaluation of Bci and Pebl-Based Attention Tests. Acta Polytech. Hung. 2018, 15, 225–249. [Google Scholar]

- Kovari, A.; Katona, J.; Costescu, C. Evaluation of Eye-Movement Metrics in a Software Debbuging Task Using Gp3 Eye Tracker. Acta Polytech. Hung 2020, 17, 57–76. [Google Scholar] [CrossRef]

- Katona, J. Analyse the Readability of LINQ Code Using an Eye-Tracking-Based Evaluation. Acta Polytech. Hung 2021, 18, 193–215. [Google Scholar] [CrossRef]

- Vukicevic, A.M.; Djapan, M.; Stefanovic, M.; Macuzic, I. SafE-Tag Mobile: A Novel Javascript Framework for Real-Time Management of Unsafe Conditions and Unsafe Acts in SMEs. Saf. Sci. 2019, 120, 507–516. [Google Scholar] [CrossRef]

- Vukicevic, A.M.; Djapan, M.; Isailovic, V.; Milasinovic, D.; Savkovic, M.; Milosevic, P. Generic Compliance of Industrial PPE by Using Deep Learning Techniques. Saf. Sci. 2022, 148, 105646. [Google Scholar] [CrossRef]

- Vukicevic, A.M.; Djapan, M.; Todorovic, P.; Erić, M.; Stefanovic, M.; Macuzic, I. Decision Support System for Dimensional Inspection of Extruded Rubber Profiles. IEEE Access 2019, 7, 112605–112616. [Google Scholar] [CrossRef]

- Vukićević, A.; Mladineo, M.; Banduka, N.; Mačužić, I. A Smart Warehouse 4.0 Approach for the Pallet Management Using Machine Vision and Internet of Things (IoT): A Real Industrial Case Study. Adv. Prod. Eng. Manag. 2021, 16, 297–306. [Google Scholar]

- Petrovic, M.; Vukicevic, A.M.; Lukic, B.; Jovanovic, K. Assessment of the Human-Robot Collaborative Polishing Task by Using EMG Sensors and 3D Pose Estimation. In Proceedings of the Advances in Service and Industrial Robotics; RAAD 2022; Müller, A., Brandstötter, M., Eds.; Springer International Publishing: Klagenfurt am Wörthersee, Austria, 2022; pp. 564–570. [Google Scholar] [CrossRef]

- Savković, M.; Caiazzo, C.; Djapan, M.; Vukićević, A.M.; Pušica, M.; Mačužić, I. Development of Modular and Adaptive Laboratory Set-Up for Neuroergonomic and Human-Robot Interaction Research. Front. Neurorobot. 2022, 16, 1–13. [Google Scholar] [CrossRef] [PubMed]

| Participant Number | Age | Body Weight (kg) | Height (cm) | DASS Score Stress | DASS Score Anxiety | DASS Score Depression | Apathy Score | Straight Leg Raise Test + | Reduced Range of Motion of the Thoracolumbar Spine + | Number of Active (Painful) Trigger Points of the Upper Limb # |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 28 | 110 | 185 | 10 | 0 | 0 | 4 | 0 | 0 | 0 |

| 2 | 40 | 100 | 202 | 12 | 6 | 1 | 16 * | 0 | + | 0 |

| 3 | 41 | 102 | 188 | 13 | 4 | 4 | 15 * | 0 | + | 0 |

| 4 | 36 | 92 | 190 | 5 | 1 | 0 | 15 * | 0 | + | 5 |

| 5 | 26 | 65 | 163 | 5 | 5 | 8 | 17 * | 0 | 0 | 0 |

| 6 | 30 | 100 | 194 | 12 | 8 * | 11 * | 11 | 0 | + | 4 |

| 7 | 35 | 92 | 178 | 15 * | 1 | 2 | 15 * | 0 | + | 6 |

| 8 | 37 | 115 | 188 | 13 | 6 | 3 | 16 * | 0 | 0 | 0 |

| 9 | 52 | 94 | 184 | 8 | 6 | 0 | 10 | 0 | 0 | 0 |

| 10 | 38 | 90 | 190 | 15 * | 6 | 5 | 14 * | 0 | 0 | 0 |

| 11 | 35 | 99 | 186 | 11 | 9 * | 4 | 16 * | 0 | + | 5 |

| 12 | 34 | 80 | 175 | 10 | 1 | 1 | 10 | 0 | 0 | 2 |

| 13 | 33 | 92 | 186 | 16 * | 7 | 4 | 16 * | 0 | + | 2 |

| 14 | 38 | 100 | 190 | 6 | 4 | 2 | 13 | 0 | + | 2 |

| 15 | 33 | 105 | 190 | 9 | 1 | 0 | 13 | 0 | + | 0 |

| 16 | 30 | 97 | 193 | 14 | 8 * | 3 | 16 * | 0 | 0 | 0 |

| 17 | 29 | 94 | 192 | 8 | 4 | 5 | 14 * | 0 | + | 1 |

| 18 | 30 | 101 | 198 | 10 | 7 | 8 | 17 * | 0 | 0 | 0 |

| 19 | 34 | 85 | 174 | 16 * | 6 | 4 | 21 * | 0 | + | 0 |

| 20 | 35 | 85 | 187 | 9 | 2 | 1 | 12 | 0 | 0 | 2 |

| Parameters of Force Measurements | Group 1 | Group 2 | % Diff Group 2 vs. Group 1 | % Difference S9–10 vs. S1–2 in Group 1 | % Difference S9–10 vs. S1–2 in Group 2 |

|---|---|---|---|---|---|

| 3.23378 | 3.32861 | 2.932471 | −33.036 | −10.7484 | |

| 3.130066 | 3.361978 | 7.409167 | −13.9833 | −7.16814 | |

| 1.602262 | 1.677908 | 4.721194 | −44.5339 | −4.89131 | |

| 1.636178 | 1.664 | 1.700452 | −38.0757 | 6.912041 | |

| 7.440562 | 7.404284 | −0.48757 | −40.0544 | −4.70138 | |

| 7.207226 | 7.418431 | 2.930461 | −22.9619 | −0.15563 | |

| 1.115157 | 1.093743 | −1.92032 | −8.27834 | −7.12886 | |

| 1.143257 | 1.101681 | −3.63659 | 54.48436 | −16.6559 | |

| 292.9955 | 554.118 | 89.12169 | −16.6674 | −27.9686 | |

| 264.0737 | 553.0317 | 109.4232 | −7.45437 | −25.5471 | |

| relative moment of | −0.18384 | −0.10031 | −45.4335 | 172.9532 | 259.3863 |

| relative moment of | −0.25515 | −0.15481 | −39.3265 | 367.6416 | 17.76975 |

| relative moment of | −0.26997 | −0.1258 | −53.4028 | −29.3991 | 289.4865 |

| relative moment of | −0.26446 | −0.07727 | −70.7802 | 220.8015 | −42.983 |

| maximal difference of consecutive extremums right | 5.751664 | 5.336946 | −7.2104 | −38.65 | −3.86 |

| maximal difference of consecutive extremums left | 5.4427 | 5.5412 | 1.8093 | −33.601 | 6.1558 |

| number of local maxima right | 8.366667 | 10.29444 | 23.04117 | −1.54639 | 0.530504 |

| number of local maxima left | 8.183333 | 9.933333 | 21.38493 | 1.11 × 10−14 | −2.98913 |

| number of local minima right | 8.35 | 10.27222 | 23.02063 | −2.57732 | 0.797872 |

| number of local minima left | 8.15 | 9.911111 | 21.60873 | 1.052632 | −2.74725 |

| position-related task time | 8.944167 | 9.221111 | 3.096369 | −5.62303 | −16.1943 |

| overall duration | 17.73583 | 18.14944 | 2.332065 | −5.31215 | −16.4159 |

| Parameters of EMG Measurements | Group 1 | Group 2 | % Diff Group 2 vs. Group 1 | % Difference S9–10 vs. S1–2 in Group 1 | % Difference S9–10 vs. S1–2 in Group 2 |

|---|---|---|---|---|---|

| 0.022175 | 0.03393 | 53.00936 | −9.24482 | −7.92041 | |

| 0.006357 | 0.032487 | 411.0173 | −21.2933 | −11.0977 | |

| 0.015085 | 0.018502 | 22.65795 | −36.619 | 10.87285 | |

| 0.008021 | 0.018606 | 131.9509 | 24.61576 | −10.82 | |

| 0.029902 | 0.042155 | 40.9753 | −9.45086 | −16.501 | |

| 0.029903 | 0.042155 | 40.9739 | −9.45083 | −16.5009 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petrovic, M.; Vukicevic, A.M.; Djapan, M.; Peulic, A.; Jovicic, M.; Mijailovic, N.; Milovanovic, P.; Grajic, M.; Savkovic, M.; Caiazzo, C.; et al. Experimental Analysis of Handcart Pushing and Pulling Safety in an Industrial Environment by Using IoT Force and EMG Sensors: Relationship with Operators’ Psychological Status and Pain Syndromes. Sensors 2022, 22, 7467. https://doi.org/10.3390/s22197467

Petrovic M, Vukicevic AM, Djapan M, Peulic A, Jovicic M, Mijailovic N, Milovanovic P, Grajic M, Savkovic M, Caiazzo C, et al. Experimental Analysis of Handcart Pushing and Pulling Safety in an Industrial Environment by Using IoT Force and EMG Sensors: Relationship with Operators’ Psychological Status and Pain Syndromes. Sensors. 2022; 22(19):7467. https://doi.org/10.3390/s22197467

Chicago/Turabian StylePetrovic, Milos, Arso M. Vukicevic, Marko Djapan, Aleksandar Peulic, Milos Jovicic, Nikola Mijailovic, Petar Milovanovic, Mirko Grajic, Marija Savkovic, Carlo Caiazzo, and et al. 2022. "Experimental Analysis of Handcart Pushing and Pulling Safety in an Industrial Environment by Using IoT Force and EMG Sensors: Relationship with Operators’ Psychological Status and Pain Syndromes" Sensors 22, no. 19: 7467. https://doi.org/10.3390/s22197467

APA StylePetrovic, M., Vukicevic, A. M., Djapan, M., Peulic, A., Jovicic, M., Mijailovic, N., Milovanovic, P., Grajic, M., Savkovic, M., Caiazzo, C., Isailovic, V., Macuzic, I., & Jovanovic, K. (2022). Experimental Analysis of Handcart Pushing and Pulling Safety in an Industrial Environment by Using IoT Force and EMG Sensors: Relationship with Operators’ Psychological Status and Pain Syndromes. Sensors, 22(19), 7467. https://doi.org/10.3390/s22197467