Design and Shape Optimization of Strain Gauge Load Cell for Axial Force Measurement for Test Benches

Abstract

:1. Introduction

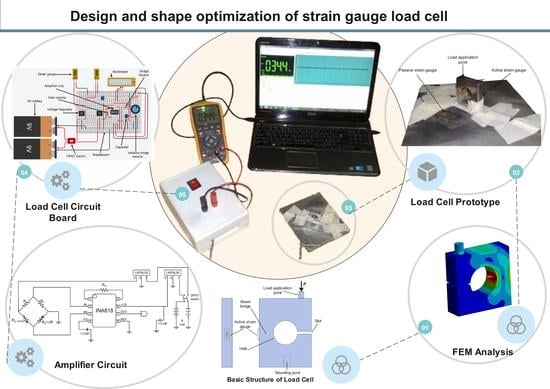

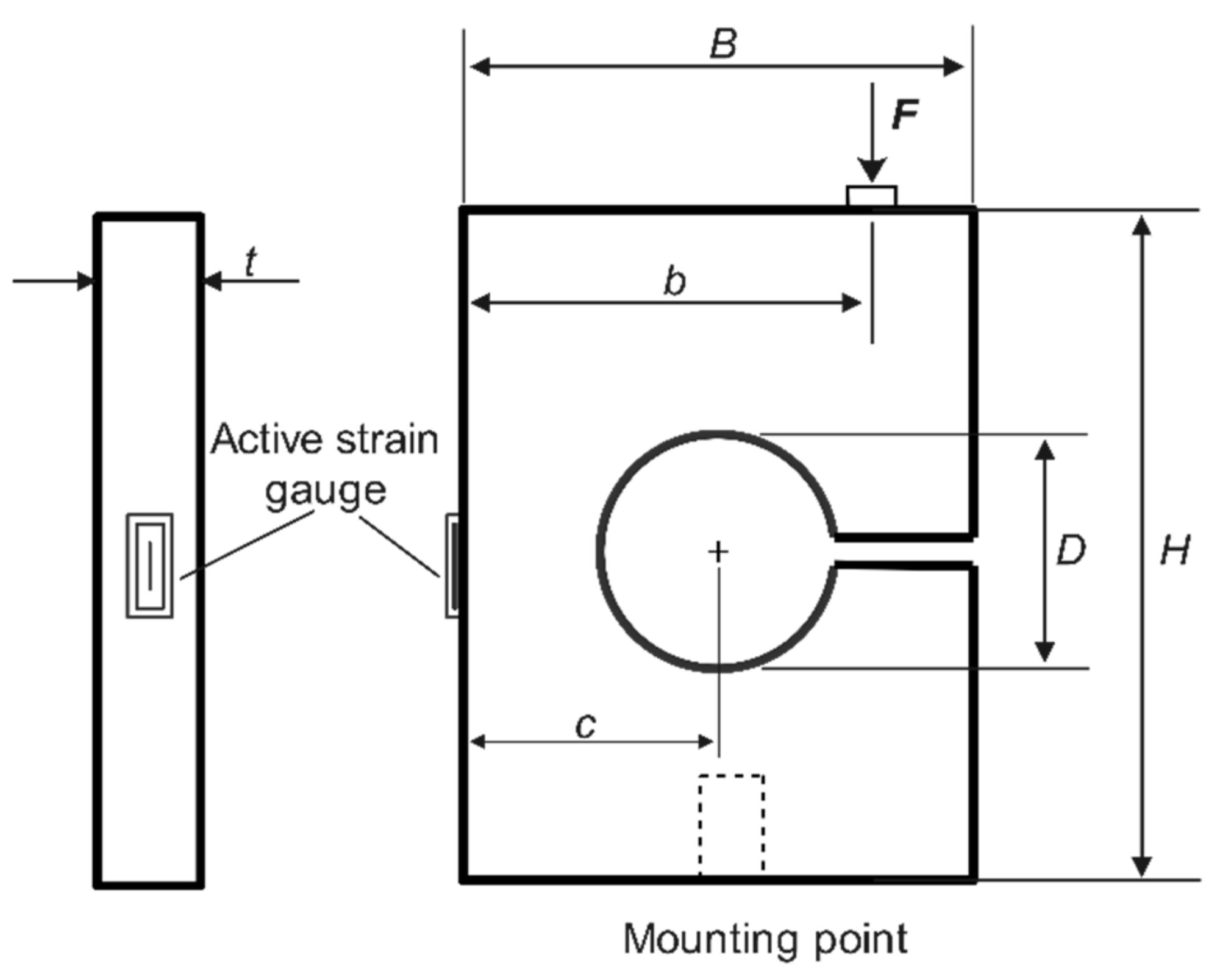

2. Design Concept and Electronic System of the Load Cell

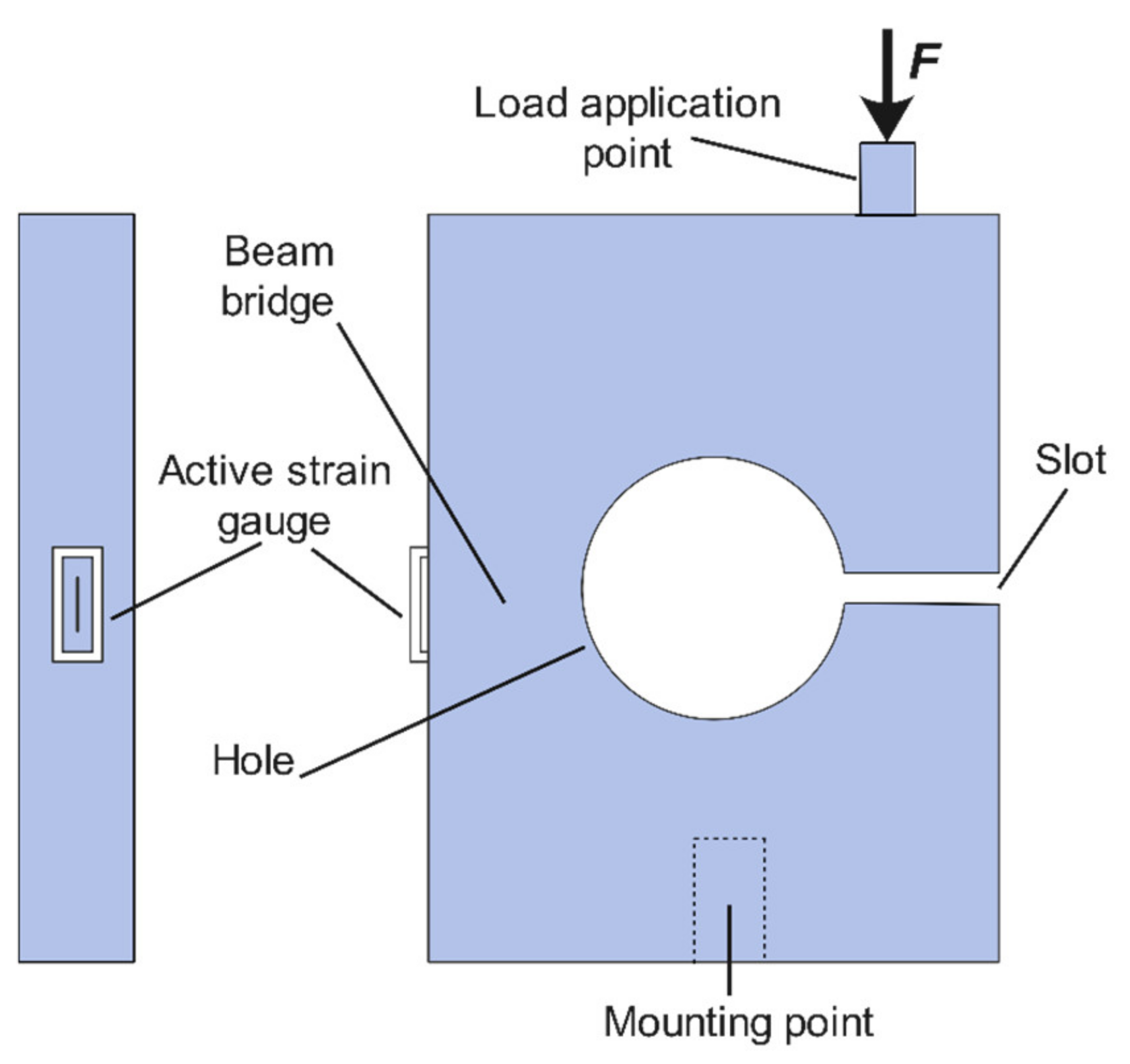

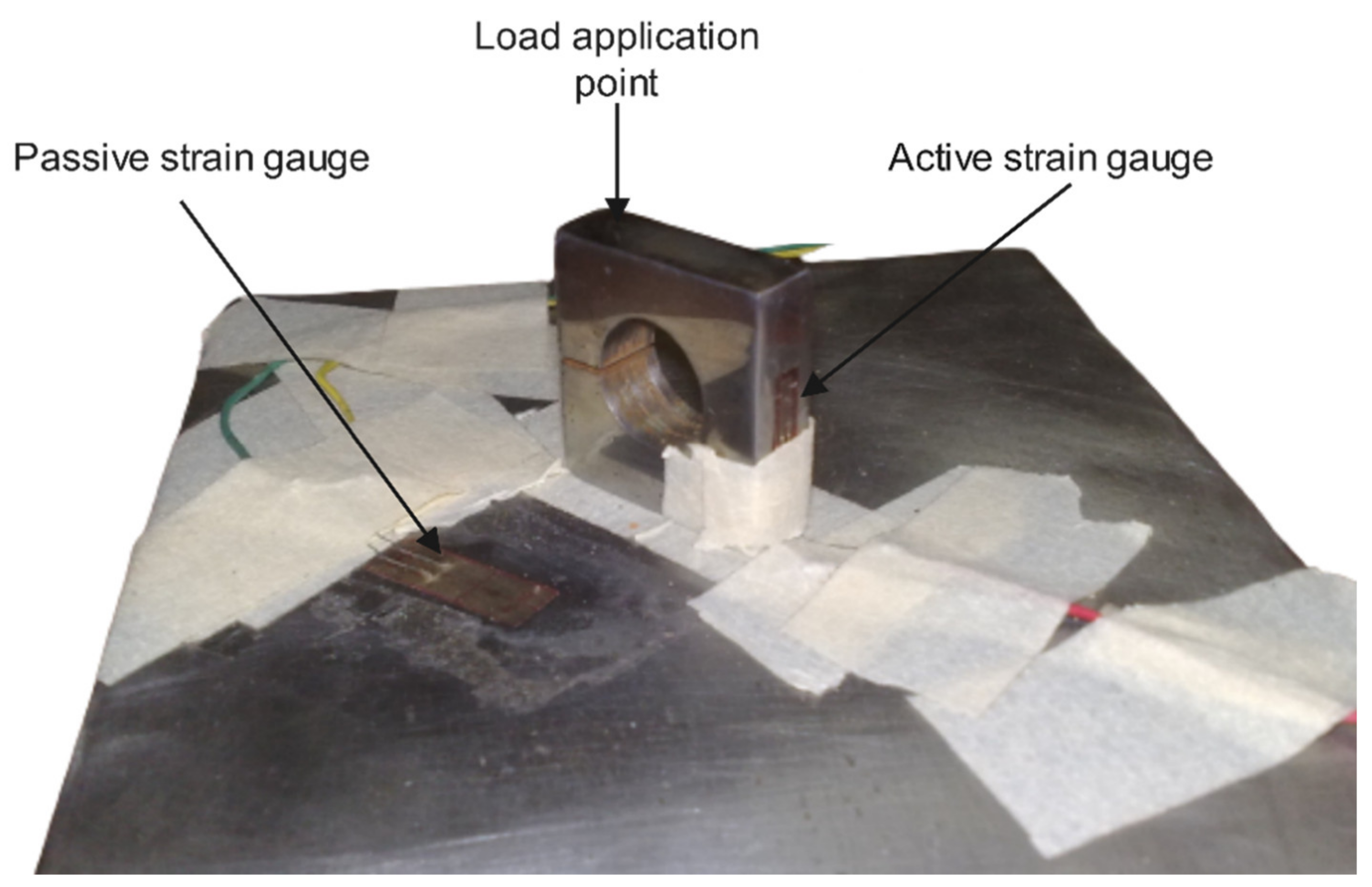

2.1. Prototype Configuration

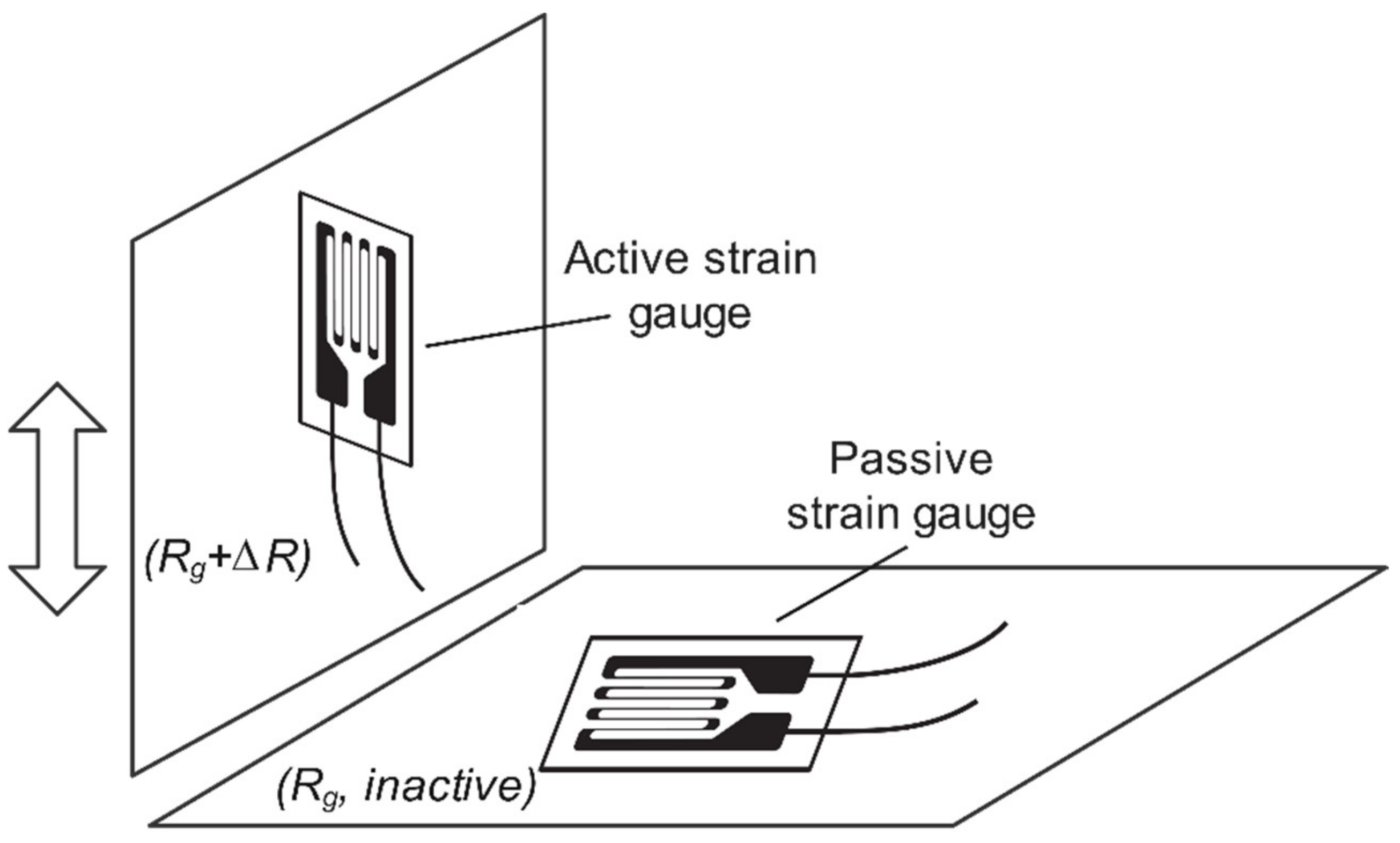

2.2. Working Principles

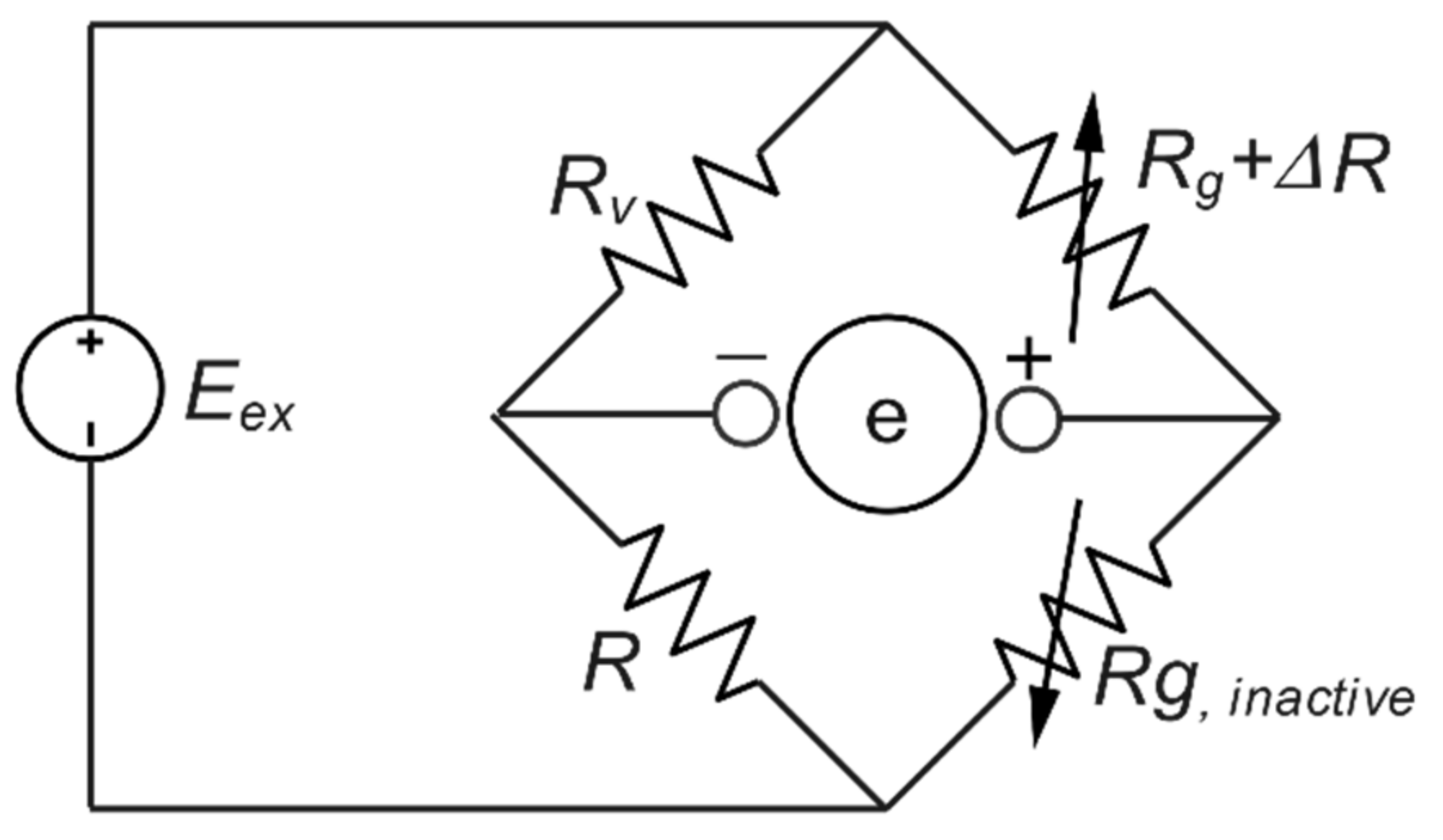

2.3. Wheatstone Bridge Circuit

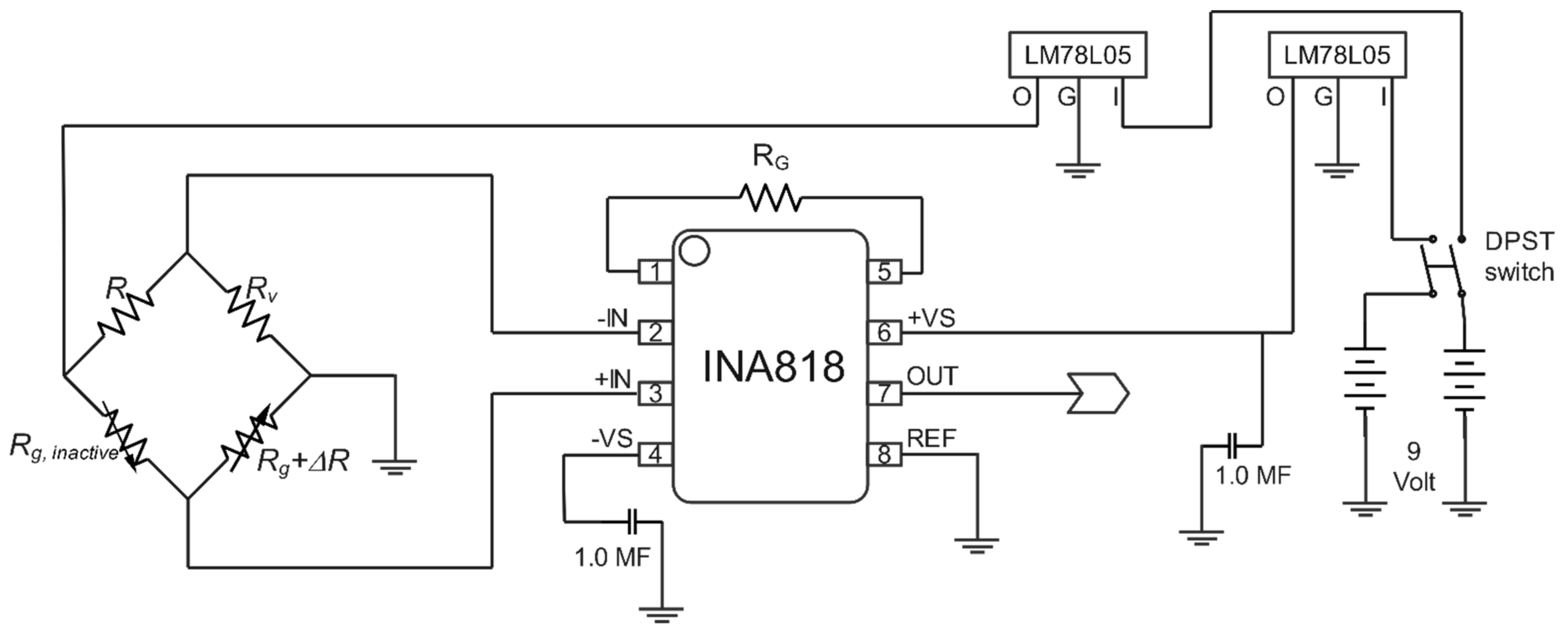

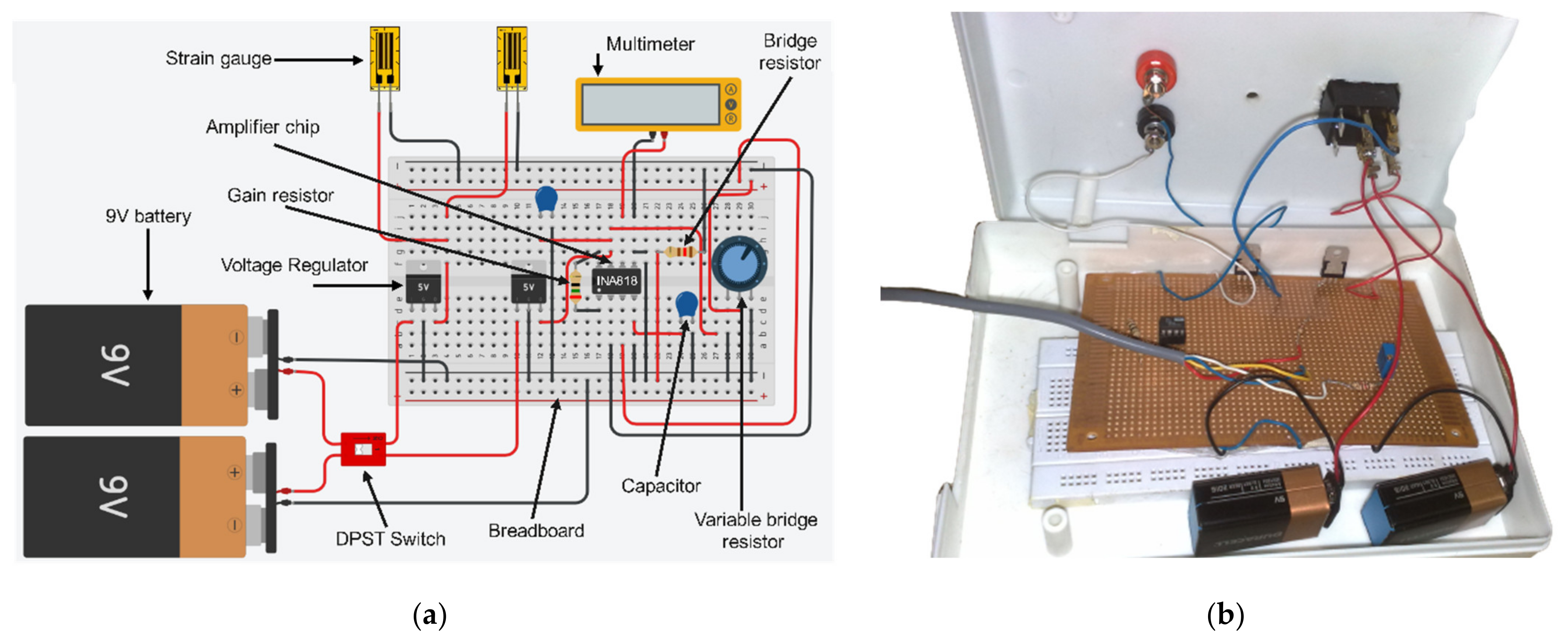

2.4. Amplifier Circuit

Selection of Gain Resistance

3. Shape Design of the Load Cell

3.1. Mathematical Model of the Load Cell Unit

3.2. Design Considerations

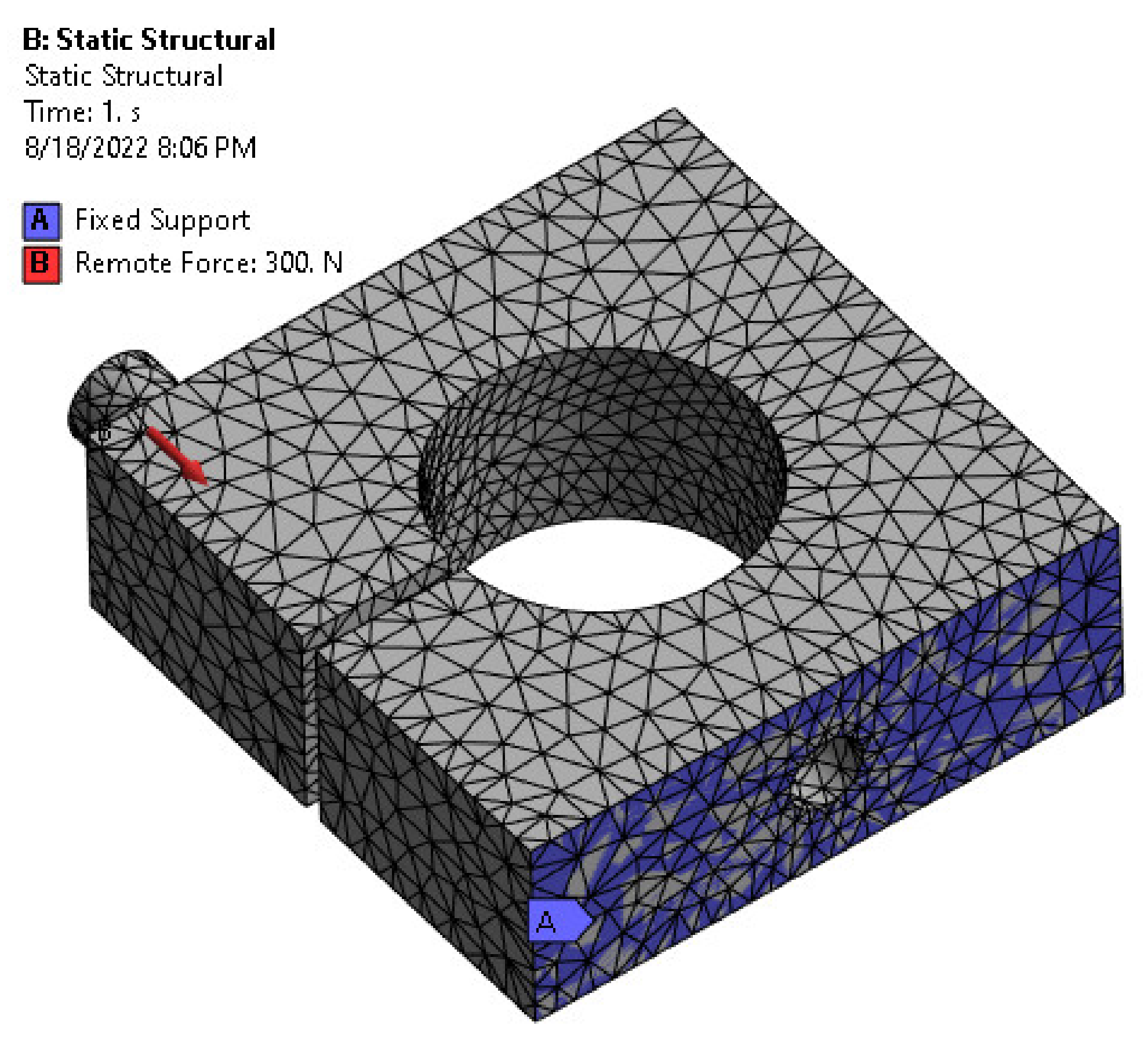

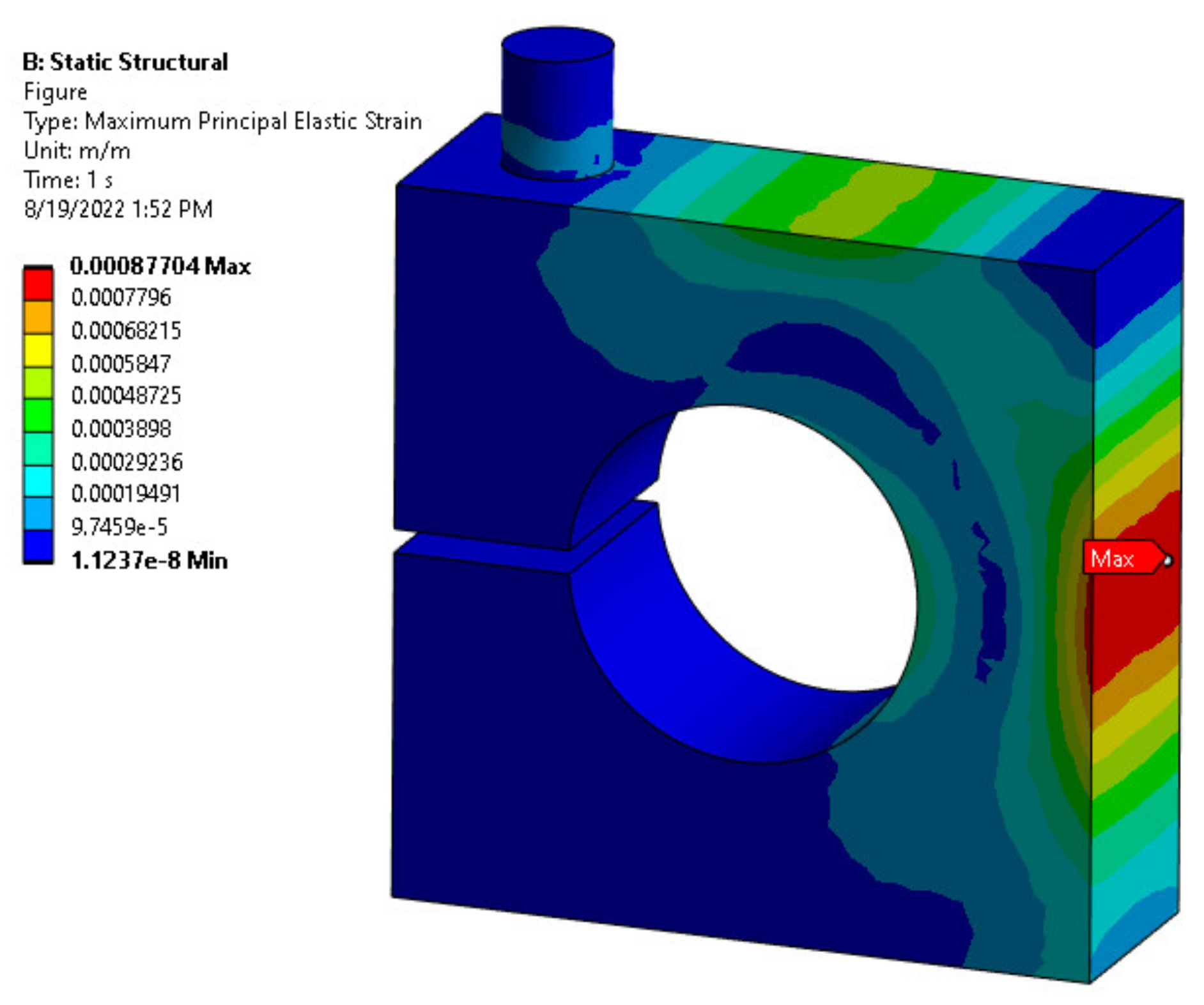

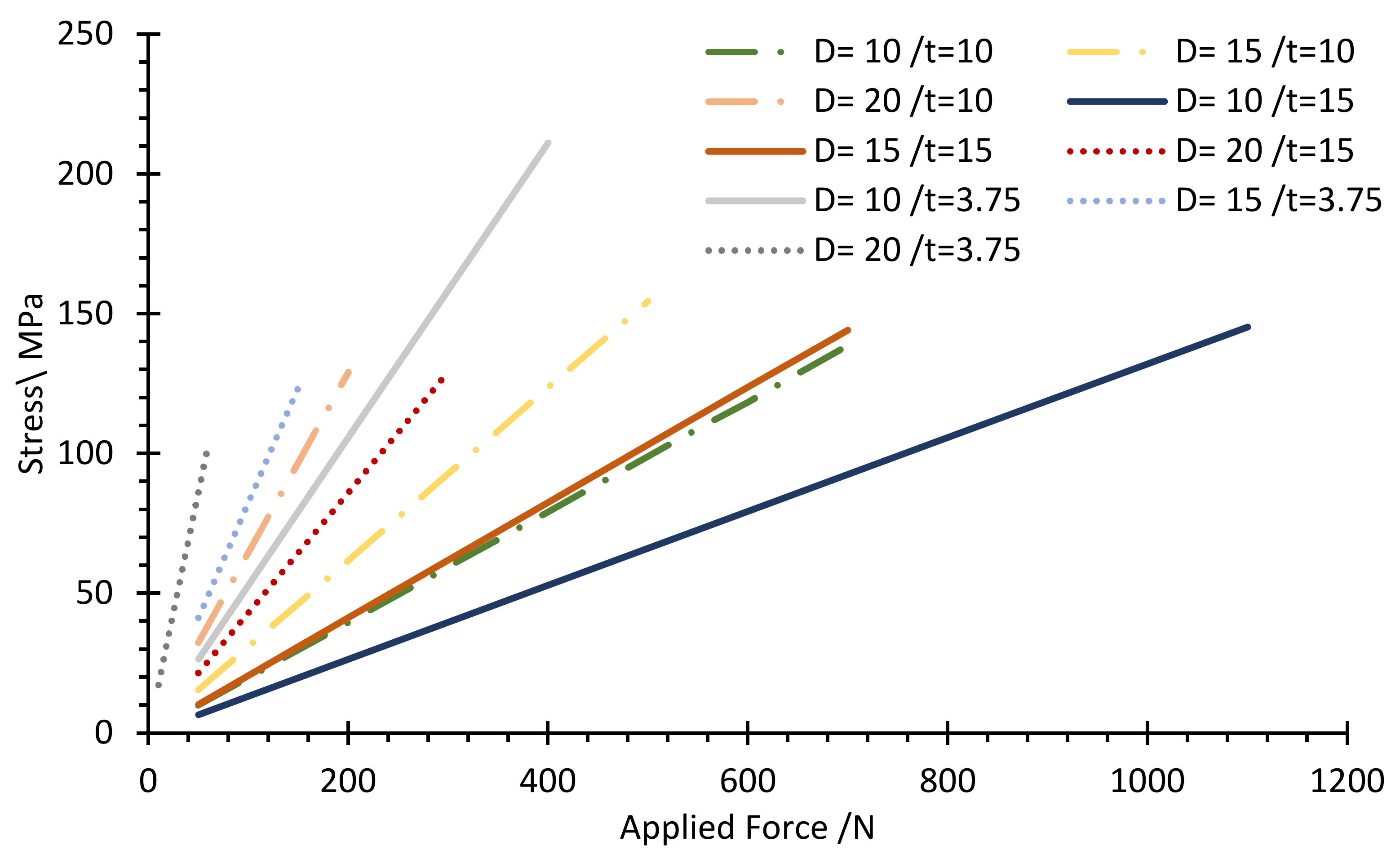

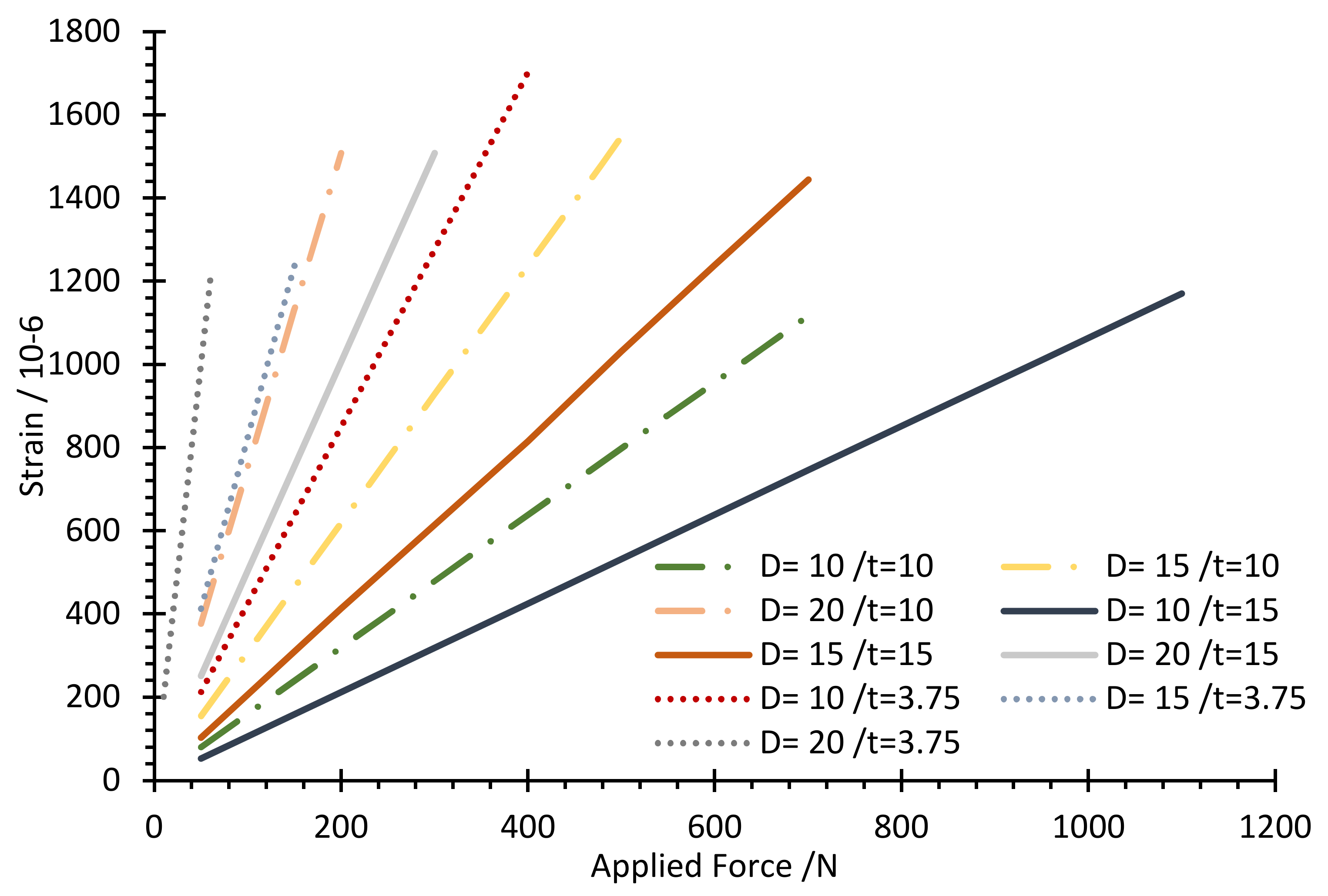

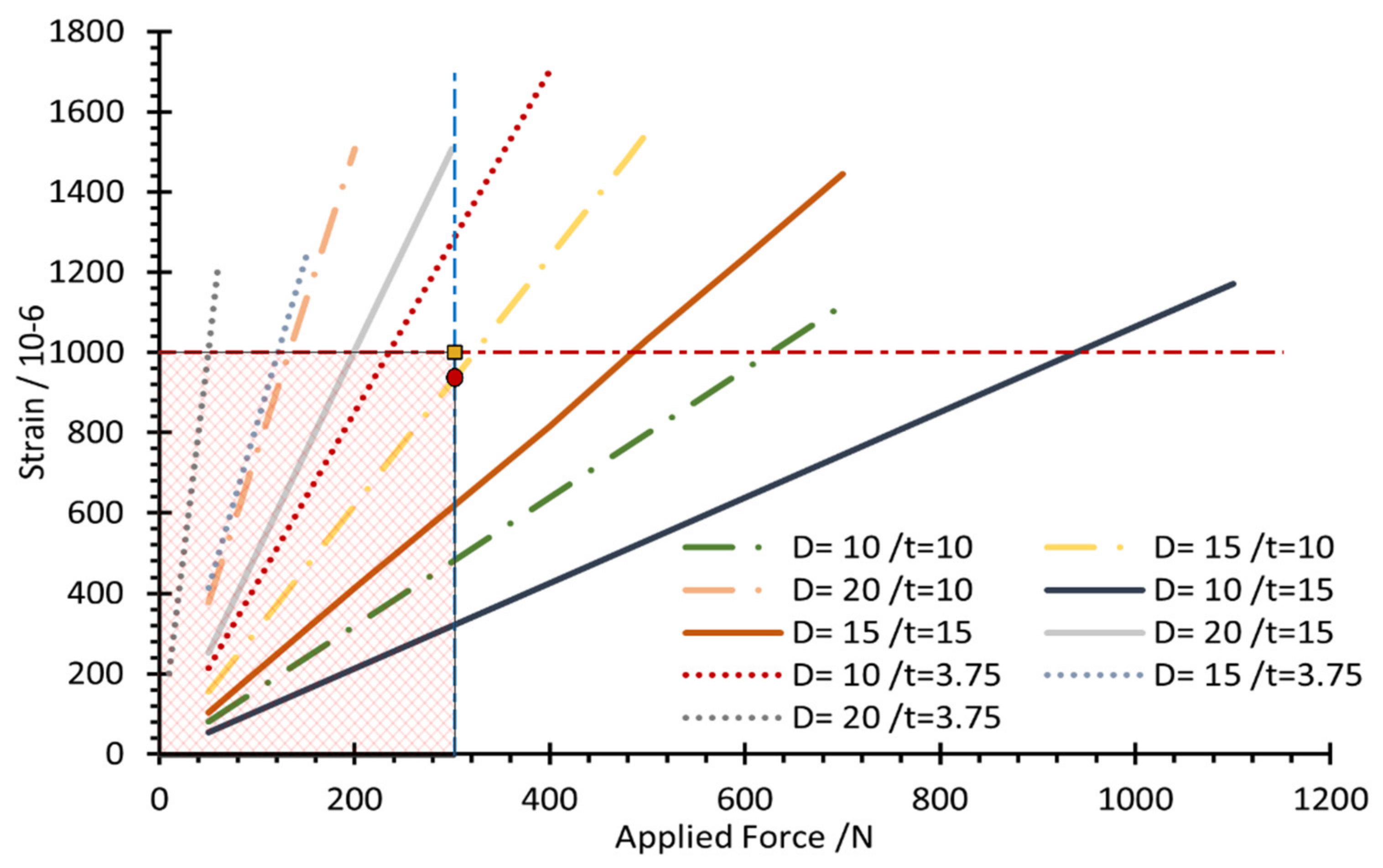

4. Shape Optimization Consistent with the Finite Element Method (FEM)

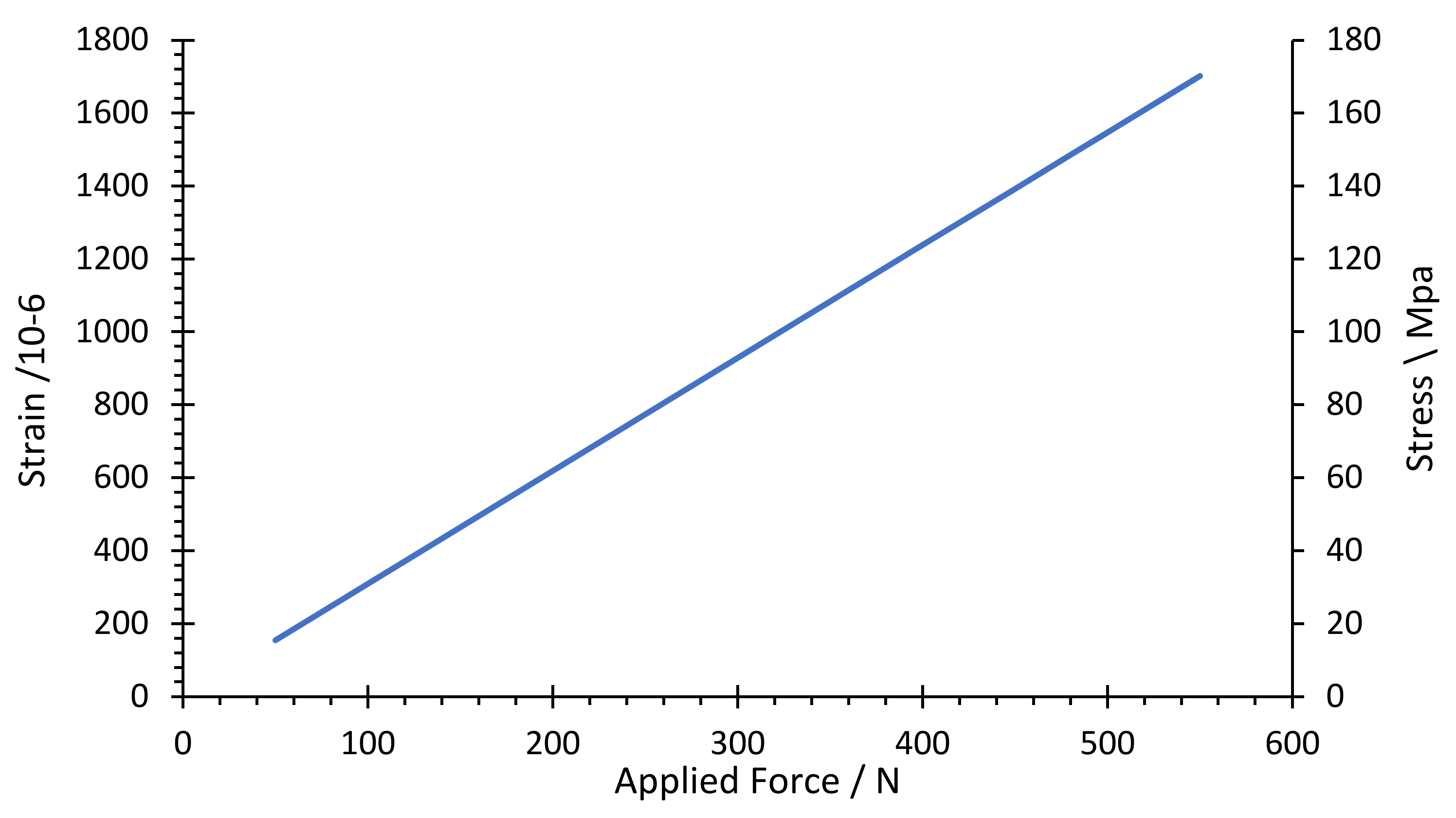

5. Experimental Implementation

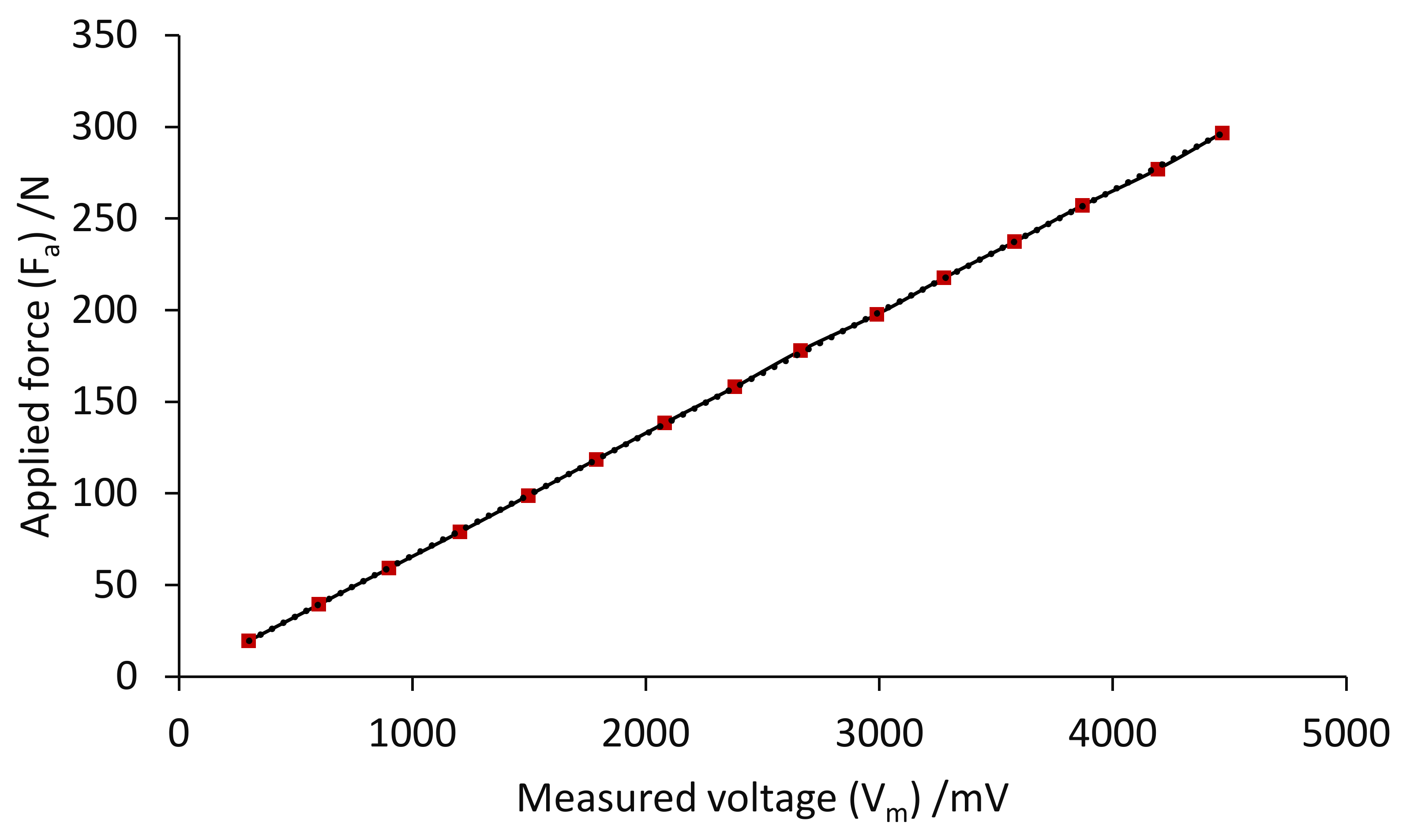

6. Results and Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Olmi, G. Load Cell Training for the Students of Experimental Stress Analysis. Exp. Technol. 2016, 40, 1147–1161. [Google Scholar] [CrossRef]

- Aghili, F. Design of a Load Cell with Large Overload Capacity. Trans. Can. Soc. Mech. Eng. 2010, 34, 449–461. [Google Scholar] [CrossRef]

- Projoth, T.N.; Victor, D.P.M.; Nanthakumar, P. Analysis and prediction of cutting force through lathe tool dynamometer in CNC turning process. Mater. Today Proc. 2021, 46, 4174–4179. [Google Scholar] [CrossRef]

- Abdeetedal, M.; Kermani, M.R. An open-source integration platform for multiple peripheral modules with Kuka robots. CIRP J. Manuf. Sci. Technol. 2019, 27, 46–55. [Google Scholar] [CrossRef]

- Kashiri, N.; Malzahn, J.; Tsagarakis, N.G. On the Sensor Design of Torque Controlled Actuators: A Comparison Study of Strain Gauge and Encoder-Based Principles. IEEE Robot. Autom. Lett. 2017, 2, 1186–1194. [Google Scholar] [CrossRef]

- Zhang, M.; Qiu, B.; Zhu, M.; Qu, X. Novel computation method of reducing ill-posedness for structural static distributed load identification by optimising strain gauge locations. Mech. Syst. Signal Process. 2019, 124, 83–110. [Google Scholar] [CrossRef]

- Byrne, D.T.; Esmonde, H.; Berry, D.P.; McGovern, F.; Creighton, P.; McHugh, N. Sheep lameness detection from individual hoof load. Comput. Electron. Agric. 2019, 158, 241–248. [Google Scholar] [CrossRef]

- Smreczak, M.; Rubbert, L.; Baur, C. Design of a compliant load cell with adjustable stiffness. Precis. Eng. 2021, 72, 259–271. [Google Scholar] [CrossRef]

- Cozzolino, F.; Apicella, D.; Wang, G.; Apicella, A.; Sorrentino, R. Implant-to-bone force transmission: A pilot study for in vivo strain gauge measurement technique. J. Mech. Behav. Biomed. Mater. 2019, 90, 173–181. [Google Scholar] [CrossRef]

- Ramachandran, P.; PradeepKumar, A.R.; Ravishankar, P.; Kishen, A. In Vivo Strain Alterations in Mandibular Molars after Root Canal Treatment Procedures. J. Endod. 2020, 46, 1849–1855. [Google Scholar] [CrossRef]

- Seethaler, R.; Mansour, S.Z.; Ruppert, M.G.; Fleming, A.J. Piezoelectric benders with strain sensing electrodes: Sensor design for position control and force estimation. Sens. Actuators A Phys. 2022, 335, 113384. [Google Scholar] [CrossRef]

- Nuthalapati, S.; Shirhatti, V.; Kedambaimoole, V.; Pandi, N.V.; Takao, H.; Nayak, M.M.; Rajanna, K. Highly sensitive flexible strain and temperature sensors using solution processed graphene palladium nanocomposite. Sens. Actuators A Phys. 2022, 334, 113314. [Google Scholar] [CrossRef]

- Abdulhakim, M.; Hegazy, R.; Abuelezz, A.E.; Abdelhakeem, H.M.; Gaffer, A.M.; Zakaria, H.M. Novel design of a multi-capacity force measurement instrument. Measurement 2021, 173, 108562. [Google Scholar] [CrossRef]

- Templeman, J.O.; Sheil, B.B.; Sun, T. Multi-axis force sensors: A state-of-the-art review. Sens. Actuators A Phys. 2020, 304, 111772. [Google Scholar] [CrossRef]

- Motwani, P.; Perogamvros, N.; Taylor, S.; Laskar, A. Performance of industrial wedge-anchors for pre-stressing BFRP bars: Experimental and numerical studies. Compos. Struct. 2020, 251, 112592. [Google Scholar] [CrossRef]

- Cosentino, I.; Ferro, G.A.; Restuccia, L. An experimental set-up for cyclic loading of concrete. Procedia Struct. Integr. 2020, 25, 413–419. [Google Scholar] [CrossRef]

- Cabboi, A.; Segeren, M.; Hendrikse, H.; Metrikine, A. Vibration-assisted installation and decommissioning of a slip-joint. Eng. Struct. 2020, 209, 109949. [Google Scholar] [CrossRef]

- Bibbo, D.; Gabriele, S.; Scorza, A.; Schmid, M.; Sciuto, S.A.; Conforto, S. A Novel Technique to Design and Optimize Performances of Custom Load Cells for Sport Gesture Analysis. IRBM 2019, 40, 201–210. [Google Scholar] [CrossRef]

- Guo, T.; Chen, Z.; Lu, S.; Yao, R. Monitoring and analysis of long-term prestress losses in post-tensioned concrete beams. Measurement 2018, 122, 573–581. [Google Scholar] [CrossRef]

- Moayedi, H.; Mosallanezhad, M. Uplift resistance of belled and multi-belled piles in loose sand. Measurement 2017, 109, 346–353. [Google Scholar] [CrossRef]

- Kumar, A.A.; Tewari, V.K.; Nare, B. Embedded digital draft force and wheel slip indicator for tillage research. Comput. Electron. Agric. 2016, 127, 38–49. [Google Scholar] [CrossRef]

- Ferreira, J.G.; Branco, F. Measurement of Vertical Deformations in Bridges Using an Innovative Elastic Cell System. Exp. Technol. 2015, 39, 13–20. [Google Scholar] [CrossRef]

- Gonzalez-Mendoza, A.; Quinones-Uriostegui, I.; Salazar-Cruz, S.; Perez-Sanpablo, A.I.; Lopez-Gutierrez, R.; Lozano, R. Design and Implementation of a Rehabilitation Upper-limb Exoskeleton Robot Controlled by Cognitive and Physical Interfaces. J. Bionic Eng. 2022, 19, 1374–1391. [Google Scholar] [CrossRef] [PubMed]

- Hartmann, V.N.; Rinaldi, D.D.M.; Taira, C.; Forner-Cordero, A. Industrial Upper-Limb Exoskeleton Characterization: Paving the Way to New Standards for Benchmarking. Machines 2021, 9, 362. [Google Scholar] [CrossRef]

- Hsieh, M.H.; Huang, Y.H.; Chao, C.L.; Liu, C.H.; Hsu, W.L.; Shih, W.P. Single-Actuator-Based Lower-Limb Soft Exoskeleton for Preswing Gait Assistance. Appl. Bionics Biomech. 2020, 2020, 5927657. [Google Scholar] [CrossRef]

- De Rossi, S.M.; Vitiello, N.; Lenzi, T.; Ronsse, R.; Koopman, B.; Persichetti, A.; Vecchi, F.; Ijspeert, A.J.; van der Kooij, H.; Carrozza, M.C. Sensing pressure distribution on a lower-limb exoskeleton physical human-machine interface. Sensors 2011, 11, 207–227. [Google Scholar] [CrossRef]

- Lovrenovic, Z.; Doumit, M. Development and testing of a passive Walking Assist Exoskeleton. Biocybern. Biomed. Eng. 2019, 39, 992–1004. [Google Scholar] [CrossRef]

- Paulweber, M.; Lebert, K. Measurement and Test Bench Technology, 1st ed.; Springer Vieweg: Wiesbaden, Germany, 2014. [Google Scholar]

- Laidani, A.; Bouhamida, M.; Benghanem, M.; Sammut, K.; Clement, B. A Low-Cost Test Bench for Underwater Thruster Identification. IFAC-PapersOnLine 2019, 52, 254–259. [Google Scholar] [CrossRef]

- Shirazi, A.T.; Nazari, M.R.; Manshadi, M.D. Numerical and experimental investigation of the fluid flow on a full-scale pump jet thruster. Ocean Eng. 2019, 182, 527–539. [Google Scholar] [CrossRef]

- Ozturk, U.E.; Ucar, L.; Zobi, O.; Bagdat, U.; Elmalı, S.; Shahidi, K.; Ersoy, N.; Yanarocak, R. Custom Design Multi-Axial Engine Mount Load-Cell Development for Road Load Identification and Fatigue Life Estimation. SAE Int. J. Mater. Manuf. 2016, 9, 642–648. [Google Scholar] [CrossRef]

- Capobianco, G.; Bohun, N.; Gratton, M.; Serra, R.; Zinbi, A.; Rigollet, N. Both radial and axial load distribution measurement on a V-band clamp by a new load cell design. Insight-Non-Destr. Test. Cond. Monit. 2022, 64, 432–436. [Google Scholar] [CrossRef]

- Torrents, A.; Azgin, K.; Godfrey, S.W.; Topalli, E.S.; Akin, T.; Valdevit, L. MEMS resonant load cells for micro-mechanical test frames: Feasibility study and optimal design. J. Micromechanics Microeng. 2010, 20, 125004. [Google Scholar] [CrossRef] [Green Version]

- Hošek, J.; Frank, O.; Diez, V. Mini-tensile load cell design for diffractometry study of 2d nanostructures. Rom. Rev. Precis. Mech. Opt. Mechatron. 2014, 45, 89–93. Available online: https://www.proquest.com/scholarly-journals/mini-tensile-load-cell-design-diffractometry/docview/1640469803/se-2 (accessed on 29 September 2022).

- Kolhapure, R.; Rawal, M.; Rayjadhav, S.; Kabnure, B.; Mekalke, G.; Patil, R.; Balwan, V. Shape optimization of washer load cell using GRA method. Mater. Today Proc. 2020, 27, 238–243. [Google Scholar] [CrossRef]

- Sun, H.; Zhang, X.; Chen, J. Optimum Design of the Spoke Type Load Cell Based on Fatigue Performance. J. Fail. Anal. Prev. 2017, 17, 717–723. [Google Scholar] [CrossRef]

- Stano, G.; Di Nisio, A.; Lanzolla, A.; Percoco, G. Additive manufacturing and characterization of a load cell with embedded strain gauges. Precis. Eng. 2020, 62, 113–120. [Google Scholar] [CrossRef]

- Kolhapure, R.; Shinde, V.; Kamble, V. Geometrical optimization of strain gauge force transducer using GRA method. Measurement 2017, 101, 111–117. [Google Scholar] [CrossRef]

- Tavakolpour-Saleh, A.R.; Setoodeh, A.R.; Gholamzadeh, M. A novel multi-component strain-gauge external balance for wind tunnel tests: Simulation and experiment. Sens. Actuators A Phys. 2016, 247, 172–186. [Google Scholar] [CrossRef]

- Takezawa, A.; Nishiwaki, S.; Kitamura, M.; Silva, E.C.N. Topology optimization for designing strain-gauge load cells. Struct. Multidiscip. Optim. 2010, 42, 387–402. [Google Scholar] [CrossRef] [Green Version]

- Nakka, R. Strain Gage Load Cell for Thrust Measurement. Available online: http://www.nakka-rocketry.net/strainlc.html (accessed on 9 May 2022).

- Beckwith, T.G.; Buck, N.L.; Marangoni, R.D. Mechanical Measurements; Addison-Wesley: Reading, MA, USA, 1969; Volume 5. [Google Scholar]

- Bolton, W. Chapter 2—Instrumentation System Elements. In Instrumentation and Control Systems, 3rd ed.; Bolton, W., Ed.; Newnes: London, UK, 2021; pp. 17–70. [Google Scholar] [CrossRef]

- Instruments, T. Precision Instrumentation Amplifier Datasheet (Rev. A); Texas Instruments Incorporated: Dallas, TX, USA, 2019. [Google Scholar]

- High and Low Temperature Strain Gauge|Tokyo Measuring Instruments Laboratory Co., Ltd. Available online: https://tml.jp/e/product/strain_gauge/cef_list.html (accessed on 2 September 2022).

- Joo, J.W.; Na, K.S.; Kang, D.I. Design and evaluation of a six-component load cell. Measurement 2002, 32, 125–133. [Google Scholar] [CrossRef]

- Tavakolpour-Saleh, A.R.; Sadeghzadeh, M.R. Design and development of a three-component force/moment sensor for underwater hydrodynamic tests. Sens. Actuators A Phys. 2014, 216, 84–91. [Google Scholar] [CrossRef]

| Parameter | Minimum Limit | Maximum Limit |

|---|---|---|

| Body thickness [t] | 3.75 [mm] | 15 [mm] |

| Hole diameter [D] | 10 [mm] | 20 [mm] |

| Item | Specification |

|---|---|

| Instrumentation Amplifier | INA818 |

| Voltage Regulator, 5 V | LM78L05ACZFS-ND |

| DPST Switch | SW102-ND |

| bridge resistor (R) | 120 Ω |

| Fixed gain resistor (RG) | 25 Ω |

| Variable bridge resistor (Rv, potentiometer) | 120 Ω |

| 9 V battery strap connector | 2243K-ND |

| 1.0 Micro Farad capacitor | P2105-ND |

| Excitation voltage (Eex) | 5 Volt |

| Amplifier Gain (G) | 2001 |

| Load/kg (N) | Output Voltage/mV | Sensitivity µV/V |

|---|---|---|

| 2 (19.7933) | 300.30 | 30.00 |

| 4 (39.5866) | 600.10 | 59.90 |

| 6 (59.3799) | 900.80 | 90.00 |

| 8 (79.1732) | 1205.00 | 120.40 |

| 10 (98.9665) | 1507.00 | 149.60 |

| 12 (118.7598) | 1809.00 | 178.80 |

| 14 (138.5531) | 2101.00 | 207.90 |

| 16 (158.3464) | 2413.00 | 238.20 |

| 18 (178.1397) | 2705.00 | 266.30 |

| 20 (197.933) | 3016.00 | 298.90 |

| 22 (217.7263) | 3328.00 | 327.60 |

| 24 (237.5196) | 3620.00 | 357.80 |

| 26 (257.3129) | 3902.00 | 387.00 |

| 28 (277.1062) | 4224.00 | 419.20 |

| 30 (296.8995) | 4535.00 | 446.80 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Dahiree, O.S.; Tokhi, M.O.; Hadi, N.H.; Hmoad, N.R.; Ghazilla, R.A.R.; Yap, H.J.; Albaadani, E.A. Design and Shape Optimization of Strain Gauge Load Cell for Axial Force Measurement for Test Benches. Sensors 2022, 22, 7508. https://doi.org/10.3390/s22197508

Al-Dahiree OS, Tokhi MO, Hadi NH, Hmoad NR, Ghazilla RAR, Yap HJ, Albaadani EA. Design and Shape Optimization of Strain Gauge Load Cell for Axial Force Measurement for Test Benches. Sensors. 2022; 22(19):7508. https://doi.org/10.3390/s22197508

Chicago/Turabian StyleAl-Dahiree, Omar Sabah, Mohammad Osman Tokhi, Nabil Hassan Hadi, Nassar Rasheid Hmoad, Raja Ariffin Raja Ghazilla, Hwa Jen Yap, and Emad Abdullah Albaadani. 2022. "Design and Shape Optimization of Strain Gauge Load Cell for Axial Force Measurement for Test Benches" Sensors 22, no. 19: 7508. https://doi.org/10.3390/s22197508

APA StyleAl-Dahiree, O. S., Tokhi, M. O., Hadi, N. H., Hmoad, N. R., Ghazilla, R. A. R., Yap, H. J., & Albaadani, E. A. (2022). Design and Shape Optimization of Strain Gauge Load Cell for Axial Force Measurement for Test Benches. Sensors, 22(19), 7508. https://doi.org/10.3390/s22197508