As-Built Inventory and Deformation Analysis of a High Rockfill Dam under Construction with Terrestrial Laser Scanning

Abstract

:1. Introduction

2. Project Overview

2.1. Site Topography and Geology

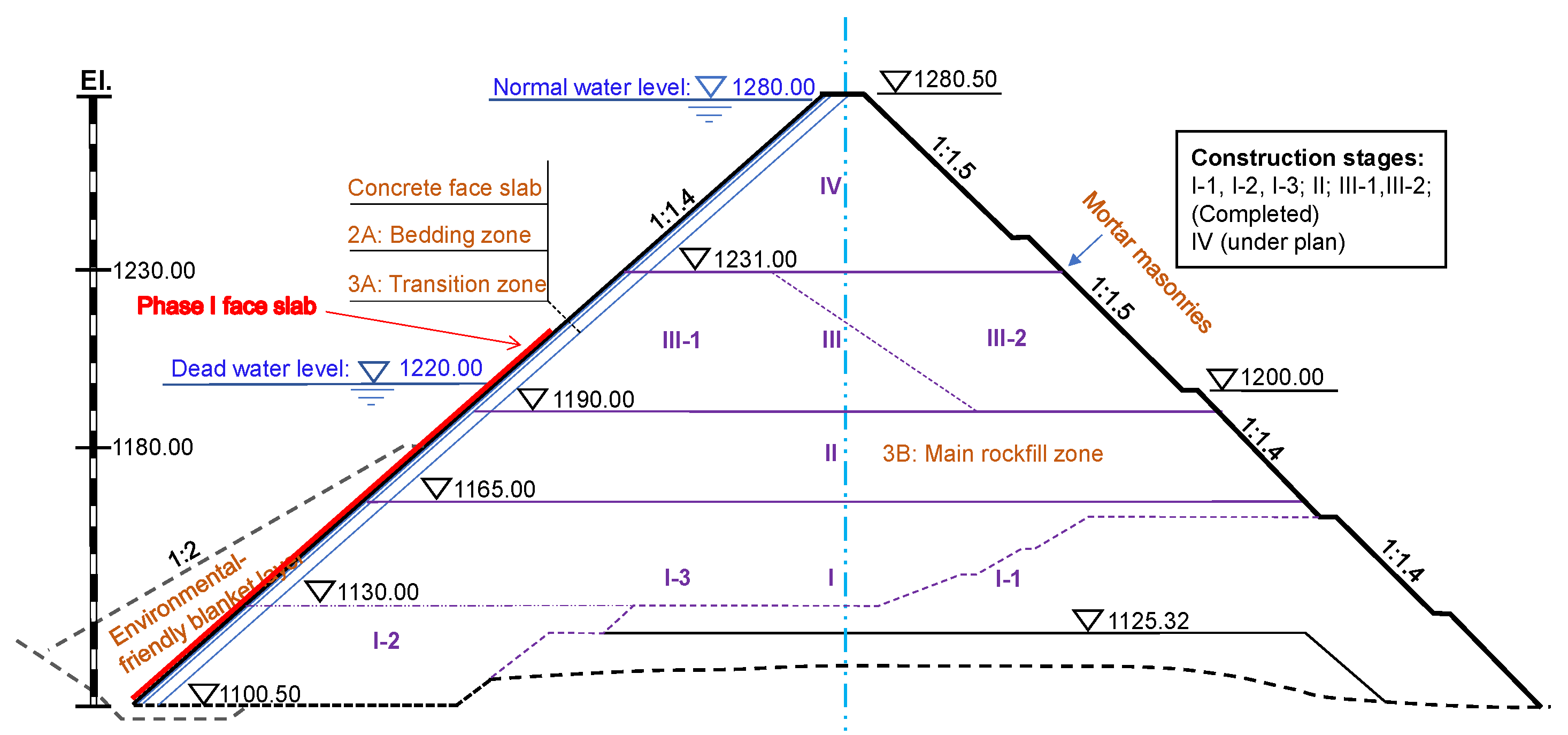

2.2. Dam Design and Filling

3. Field Work and As-Built Inventory

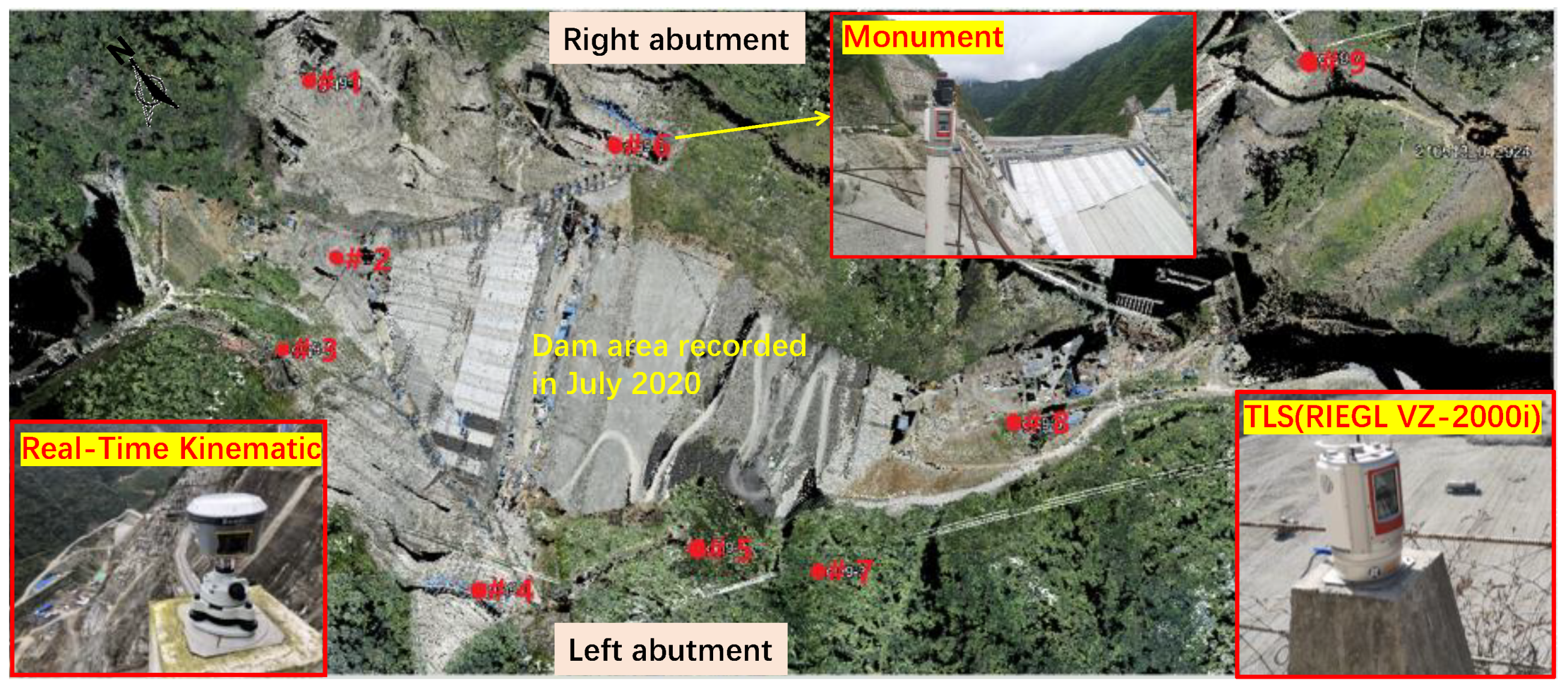

3.1. Instrument Settings

3.2. Geodetic Network

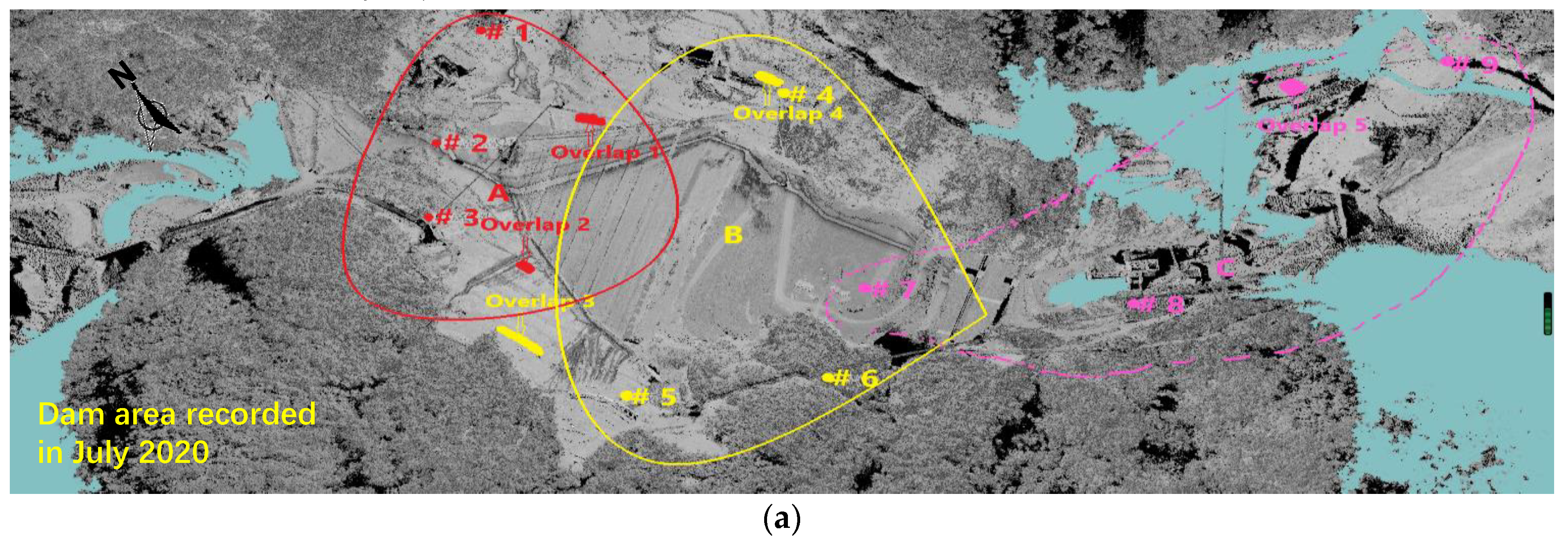

- (a)

- A relatively complete view of the rising compaction face at the dam top can be obtained at any construction period;

- (b)

- A sufficient area of overlap can be achieved from any two adjacent scans. This is essential for splicing neighboring point clouds gathered at the same epoch (i.e., co-registration);

- (c)

- The point cloud from one scan can complement the other from the adjacent scan to yield sufficient data points in the overlapping area. This is because the point resolution in the overlaps from one scan might be largely reduced due to the high incidence angle;

- (d)

- Orientation bias and occlusion could be minimized. Since laser pulses from one point of view might be hidden by local bulge areas in this valley;

- (e)

- Monuments are stable and safe for personnel access, considering the local steep cliff topography (see Figure 1b).

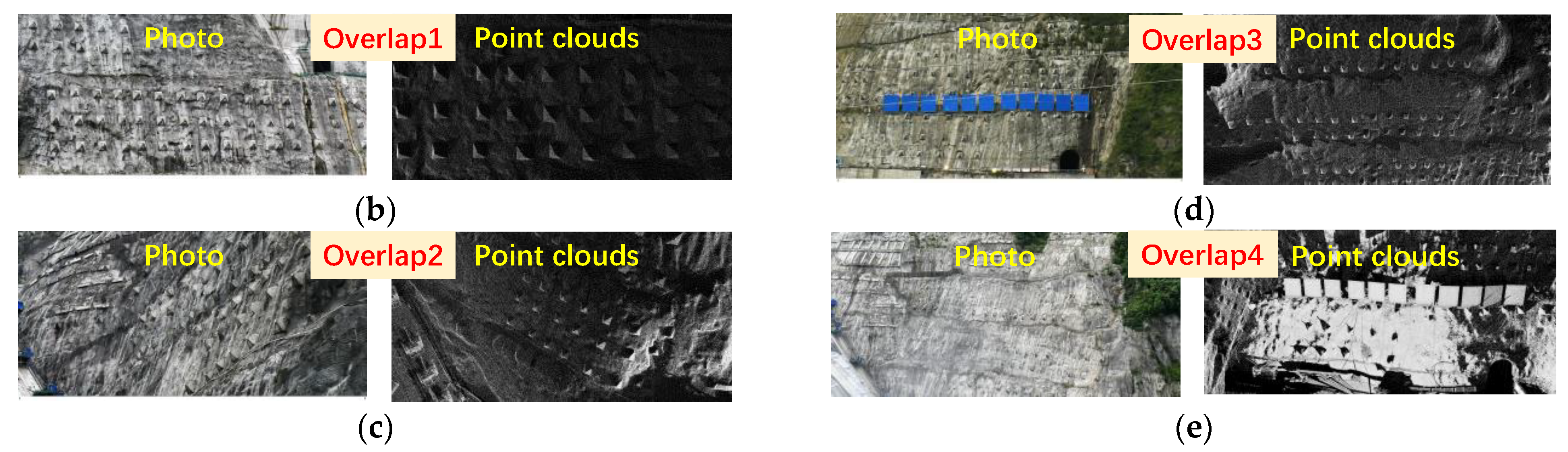

3.3. Scanning Epochs and Co-Registration/Georeferencing

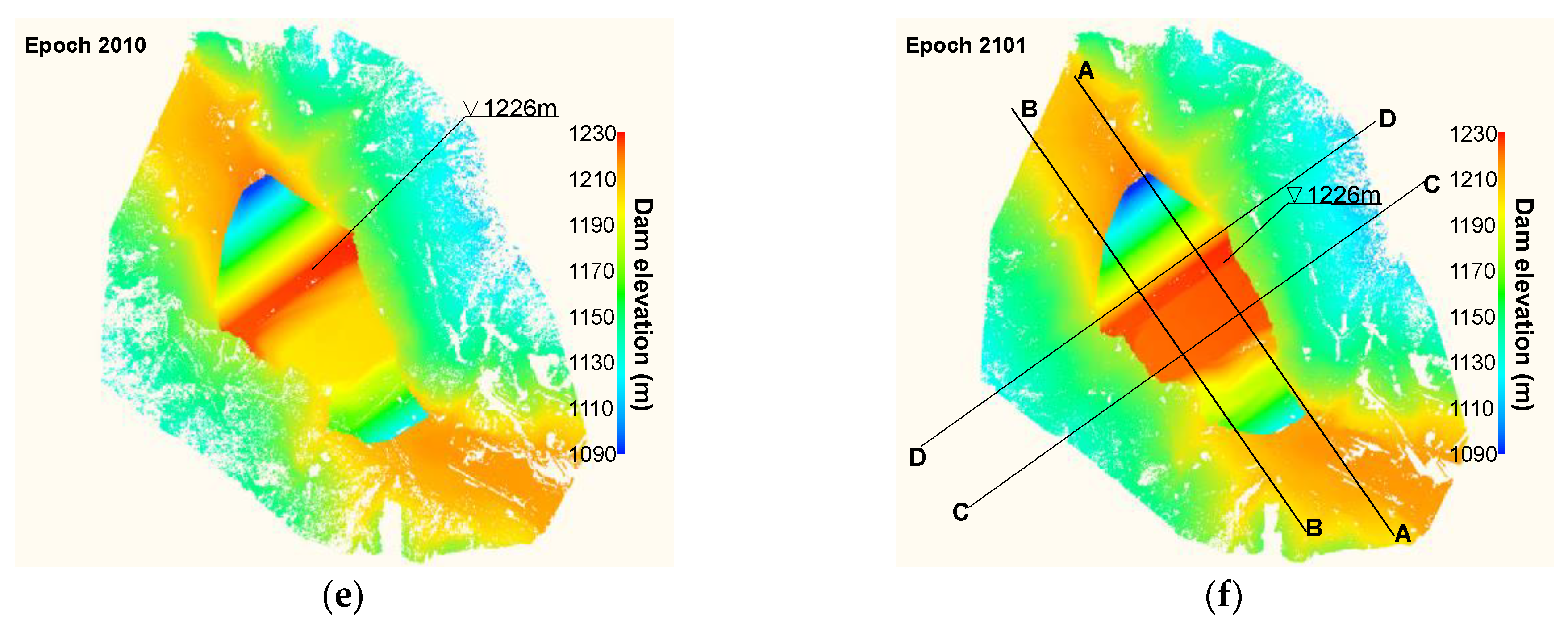

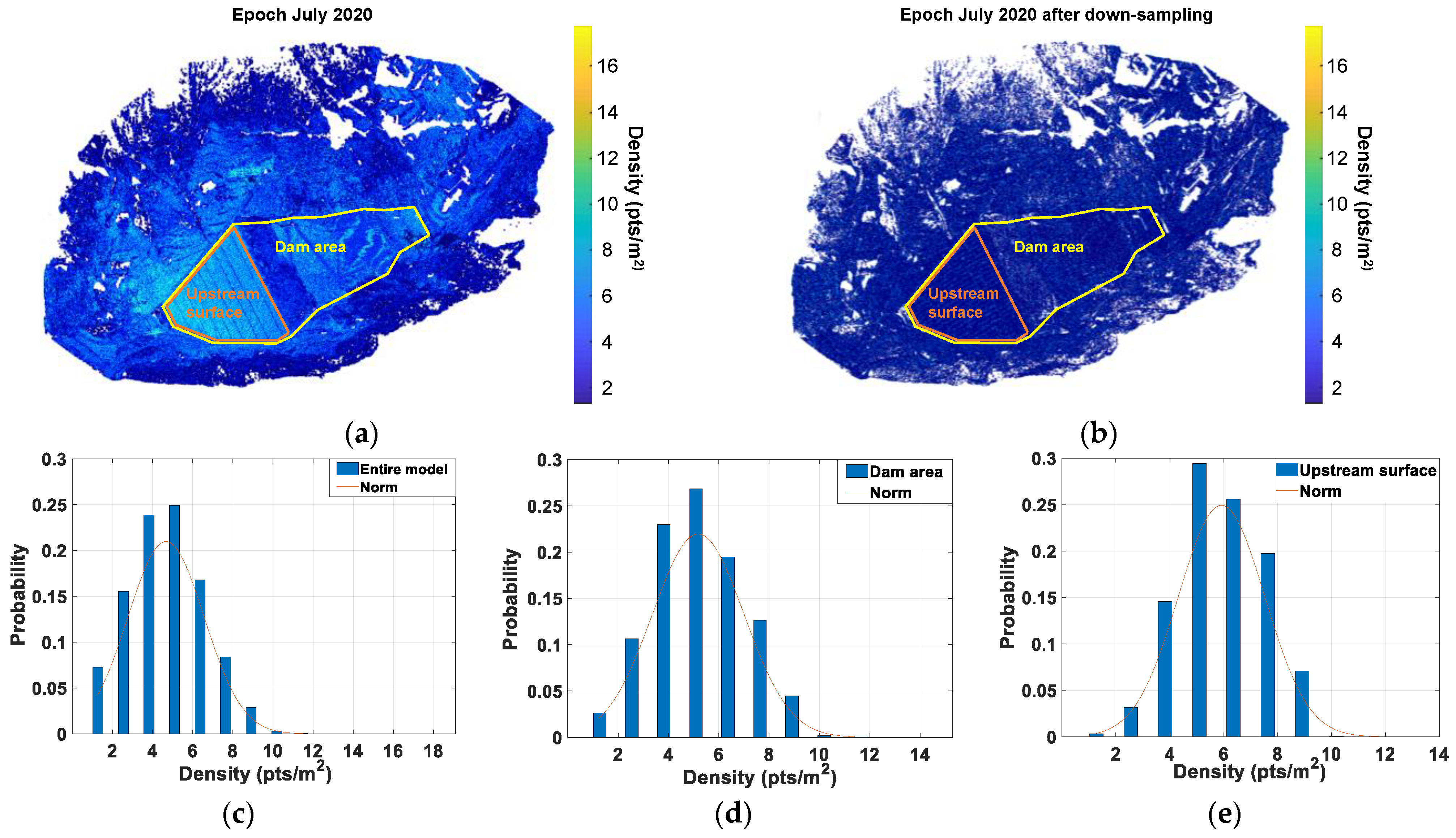

3.4. As-Built Dam Inventory

| Calculate the density based on the KD-tree based search algorithm |

| Require: Cloud: the input point cloud to be searched, e.g., the data for epoch 2007. Require: r: the search radius set to be 0.5 m in our study. Step 1: kdtree.setInputCloud (Cloud); (establish the kdtree for the input cloud) Step 2: for i = 1: N (N is the number of points in the input cloud) kdtree.radiusSearch(Cloud(i), r, pointIdx, pointSquaredDistance) density(i) = pointIdxRadiusSearch.size/() End |

4. Deformation Analysis of the Upstream Face

4.1. Analysis Methodology

4.2. Accuarcy Examination

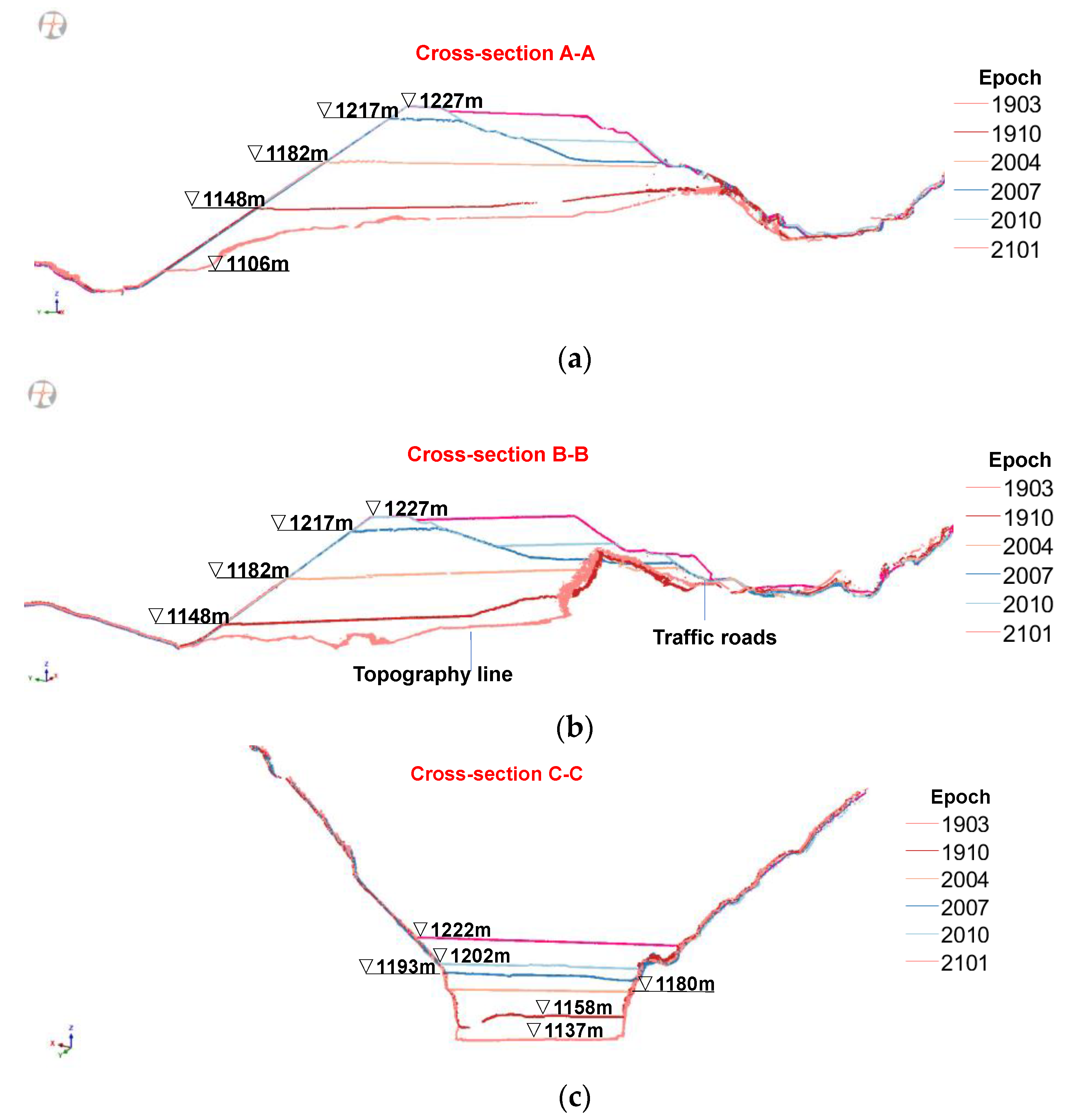

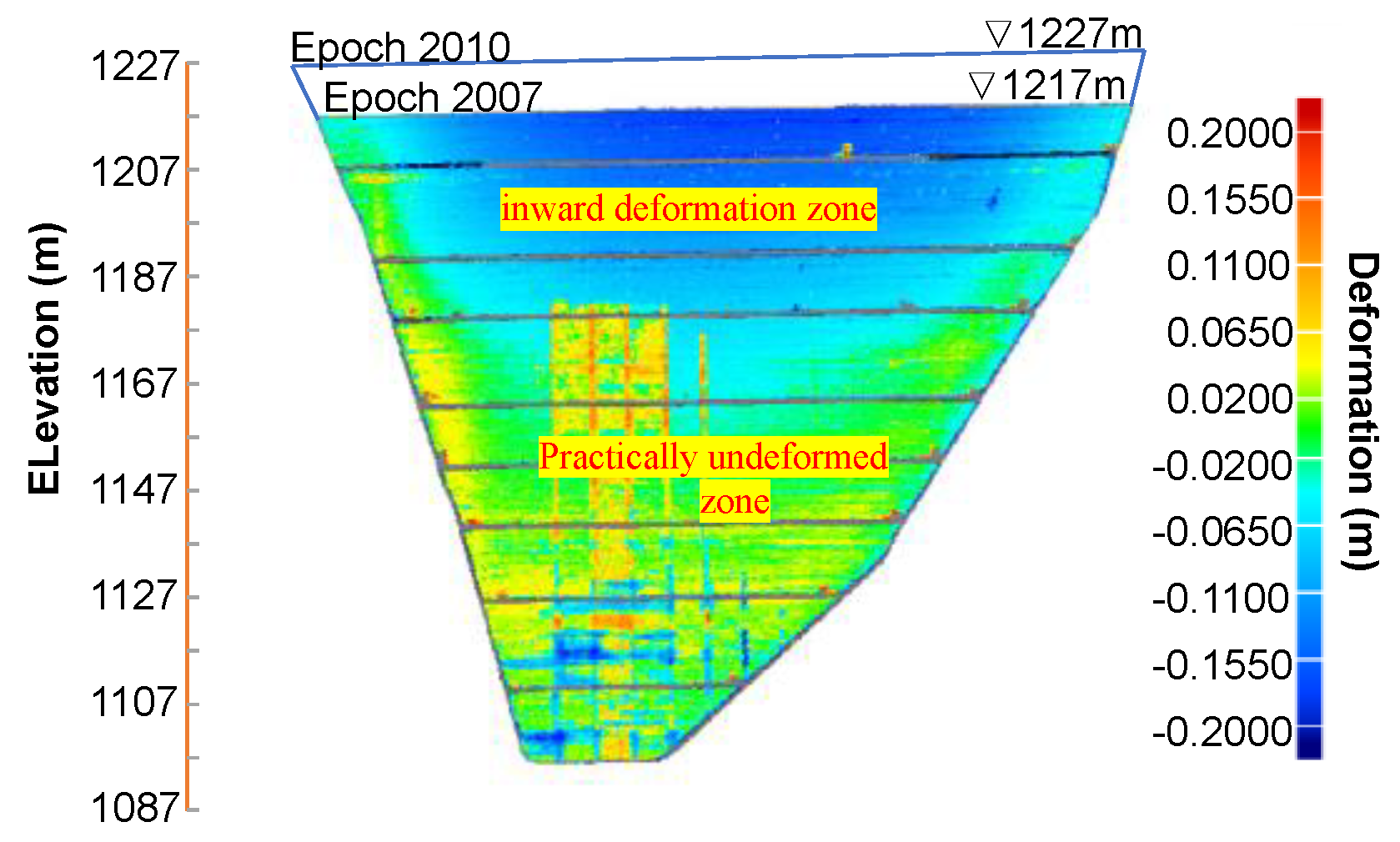

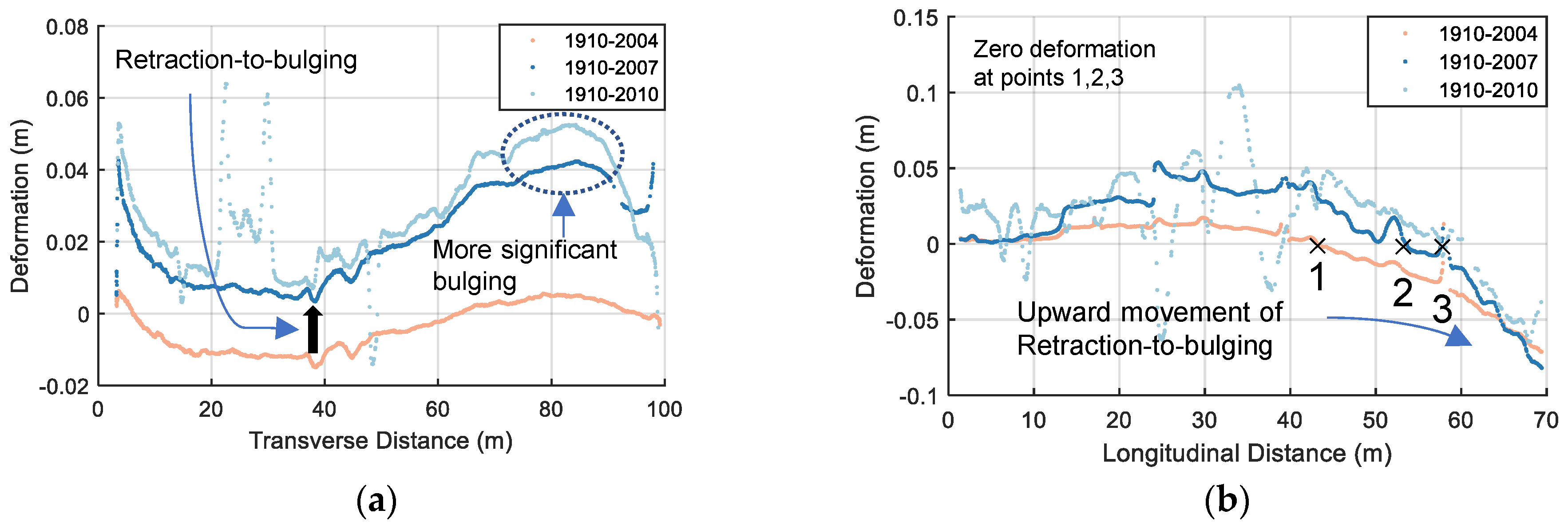

4.3. Results of Deformation Trends

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fahlbusch, H. Early dams. Proc. Inst. Civ. Eng.-Eng. Hist. Herit. 2009, 162, 13–18. [Google Scholar] [CrossRef]

- Cooke, J.B.; Sherard, J.L. Concrete-face rockfill dam: II. Design. J. Geotech. Eng. 1987, 113, 1113–1132. [Google Scholar] [CrossRef]

- Kan, M.E.; Taiebat, H.A. Application of advanced bounding surface plasticity model in static and seismic analyses of Zipingpu Dam. Can. Geotech. J. 2015, 53, 455–471. [Google Scholar] [CrossRef] [Green Version]

- Ma, H.Q.; Chi, F.D. Technical progress on researches for the safety of high concrete-faced rockfill dams. J. Eng. 2016, 2, 332–339. [Google Scholar] [CrossRef] [Green Version]

- Dakoulas, P. Nonlinear seismic response of tall concrete-faced rockfill dams in narrow canyons. Soil Dyn. Earthq. Eng. 2012, 34, 11–24. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, L.; Li, D.; Gao, Y. Evaluation of valley topography effects on the seismic stability of earth-rockfill dams via a modified valley topography coefficient. Comput. Geotech. 2020, 128, 103814. [Google Scholar] [CrossRef]

- Rashidi, M.; Haeri, S.M. Evaluation of behaviors of earth and rockfill dams during construction and initial impounding using instrumentation data and numerical modeling. J. Rock Mech. Geotech. Eng. 2017, 9, 709–725. [Google Scholar] [CrossRef]

- Xiao, Y.; Liu, H.; Zhang, W.G.; Liu, H.L.; Yin, F.; Wang, Y.Y. Testing and modeling of rockfill materials: A review. J. Rock Mech. Geotech. Eng. 2016, 8, 415–422. [Google Scholar]

- Wen, L.; Chai, J.; Xu, Z.; Qin, Y.; Li, Y. A statistical review of the behaviour of concrete-face rockfill dams based on case histories. Geotechnique 2018, 68, 749–771. [Google Scholar] [CrossRef]

- Cruz, P.T.; Materón, B.; Freitas, M. Concrete Face Rockfill Dams; CRC Press: Boca Raton, FL, USA, 2009; Volume 3. [Google Scholar]

- Zhou, M.Z.; Zhang, B.Y.; Peng, C.; Wu, W. Three-dimensional numerical analysis of concrete-faced rockfill dam using dual-mortar finite element method with mixed tangential contact constraints. Int. J. Numer. Anal. Methods Geomech. 2016, 40, 2100–2122. [Google Scholar]

- Da Silva, A.F.; de Assis, A.P.; de Farias, M.M.; Neto, M.P.C. Three-Dimensional Analyses of Concrete Faced Rockfill Dams: Barra Grande Case Study. Electron. J. Geotech. Eng. 2015, 20, 6407–6426. [Google Scholar]

- Materon, B. Alto Anchicaya dam—Ten years performance. In Concrete Face Rockfill Dams—Design, Construction, and Performance; ASCE: Detroit, MI, USA, 1985; pp. 73–87. [Google Scholar]

- White, D.; Take, W.; Bolton, M. Soil deformation measurement using particle image velocimetry (PIV) and photogrammetry. Geotechnique 2003, 53, 619–631. [Google Scholar] [CrossRef]

- Zekkos, D.; Manousakis, J.; Greenwood, W.; Lynch, J. Immediate UAV-enabled infrastructure reconnaissance following recent natural disasters: Case histories from Greece. In Proceedings of the International Conference on Natural Hazards and Infrastructure, Chania, Greece, 28 June–1 July 2016; pp. 28–30. [Google Scholar]

- Alba, M.; Fregonese, L.; Prandi, F.; Scaioni, M.; Valgoi, P. Structural monitoring of a large dam by terrestrial laser scanning. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2006, 36, 6. [Google Scholar]

- González-Aguilera, D.; Gómez-Lahoz, J.; Sánchez, J. A new approach for structural monitoring of large dams with a three-dimensional laser scanner. Sensors 2008, 8, 5866–5883. [Google Scholar] [CrossRef] [Green Version]

- Wang, J. Block-to-point fine registration in terrestrial laser scanning. Remote Sens. 2013, 5, 6921–6937. [Google Scholar] [CrossRef] [Green Version]

- Ramos-Alcázar, L.; Marchamalo-Sacristán, M.; Martínez-Marín, R. Comparing dam movements obtained with Terrestrial Laser Scanner (TLS) data against direct pendulums records. Rev. Fac. Ing. Univ. Antioq. 2015, 76, 99–106. [Google Scholar] [CrossRef]

- Ramos-Alcázar, L.; Marchamalo-Sacristán, M.; Martínez-Marín, R. Estimating and plotting TLS midrange precisions in field conditions: Application to dam monitoring. Int. J. Civ. Eng. 2017, 15, 299–307. [Google Scholar] [CrossRef]

- Scaioni, M.; Marsella, M.; Crosetto, M.; Tornatore, V.; Wang, J. Geodetic and remote-sensing sensors for dam deformation monitoring. Sensors 2018, 18, 3682. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, J.; Zhang, C.C. Deformation monitoring of earth-rock dams based on three-dimensional laser scanning technology. J. Geotech. Eng. 2014, 36, 2345–2350. [Google Scholar] [CrossRef]

- Wan, Z.Y.; Huang, Y.Y.; Zhao, X.R.; Zuo, Q.Y.; Li, X.H. Application of Three-dimensional Laser Scanning Technique in Deformation Monitoring of Extrusion Sidewall of Concrete-faced Rockfill Dam. J. Yangtze River Sci. Res. Inst. 2017, 34, 56–61. [Google Scholar]

- Berberan, A.; Marcelino, J.; Boavida, J.; Oliveira, A.; Laboratório Nacional de Engenharia Civil; Artescan Digitalização Tridimensional. Deformation monitoring of earth dams using laser scanners and digital imagery. In Proceedings of the HYDRO 2007 Symposium, Granada, Spain, 15–17 October 2007. [Google Scholar]

- Xu, H.; Li, H.B.; Yang, X.G.; Qi, S.C.; Zhou, J.W. Integration of terrestrial laser scanning and nurbs modeling for the deformation monitoring of an earth-rock dam. Sensors 2019, 19, 22. [Google Scholar] [CrossRef] [Green Version]

- Vosselman, G.; Maas, H.-G. Airborne and Terrestrial Laser Scanning; CRC press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Fey, C.; Wichmann, V. Long-range terrestrial laser scanning for geomorphological change detection in alpine terrain–handling uncertainties. Earth Surf. Process. Landf. 2017, 42, 789–802. [Google Scholar] [CrossRef]

- Lato, M. Canadian Geotechnical Colloquium: Three-dimensional remote sensing, four-dimensional analysis and visualization in geotechnical engineering—State of the art and outlook. Can. Geotech. J. 2021, 58, 1065–1076. [Google Scholar] [CrossRef]

- Mukupa, W.; Roberts, G.W.; Hancock, C.M.; Al-Manasir, K. A review of the use of terrestrial laser scanning application for change detection and deformation monitoring of structures. Surv. Rev. 2017, 49, 99–116. [Google Scholar] [CrossRef]

- Riegl Laser Measurement Systems GmbH. Technical Documentation Users Instructions of RIEGL VZ-2000i. Horn, Austria, 2014. Available online: http://www.riegl.com/ (accessed on 21 December 2021).

- Chen, Y.; Medioni, G. Object modeling by registration of multiple range images. In Proceedings of the IEEE International Conference on Robotics and Automation, Sacramento, CA, USA, 9–11 April 1991; Volume 3, pp. 2724–2729. [Google Scholar]

- Besl, P.J.; McKay, N.D. A method for registration of 3-D shapes. IEEE Trans. Pattern Anal. Mach. Intell. 1992, 14, 239–256. [Google Scholar] [CrossRef]

- Cacciari, P.P.; Futai, M.M. Mapping and characterization of rock discontinuities in a tunnel using 3D terrestrial laser scanning. Bull. Eng. Geol. Environ. 2016, 75, 223–237. [Google Scholar] [CrossRef]

- Rusu, R.B.; Steve, C. 3d is here: Point cloud library (pcl). In Proceedings of the 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; IEEE: Piscataway, NJ, USA, 2011. [Google Scholar]

- Lovas, T.; Barsi, A.; Detrekoi, A.; Dunai, L.; Csak, Z.; Polgar, A.; Szocs, K. Terrestrial laser scanning in deformation measurements of structures. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2008, 37, 527–531. [Google Scholar]

- Lague, D.; Brodu, N.; Leroux, J. Accurate 3D comparison of complex topography with terrestrial laser scanner: Application to the Rangitikei canyon (N–Z). ISPRS J. Photogramm. Remote Sens. 2013, 82, 10–26. [Google Scholar] [CrossRef] [Green Version]

- Lindenbergh, R.; Pfeifer, N. A statistical deformation analysis of two epochs of terrestrial laser data of a lock. In Proceedings of the International Conference on Optical 3D Measurement Techniques VII, Vienna, Austria, 3–5 October 2005; Volume 2, pp. 61–70. [Google Scholar]

- Chrzanowski, A.; Avella, S.; Chen, Y.Q.; Secord, J.M. Report on Existing Resources, Standards, and Procedures for Precise Monitoring and Analysis of Structural Deformation; Final contract report prepared by Department of Surveying Engineering; University of New Brunswick: Fredericton, NB, Canada; U.S. Army Topographic Engineering Center: Fort Belvoir, VA, USA, 1992; Volume I and II. [Google Scholar]

| Pairwise Comparison | Test (Points) | |||

|---|---|---|---|---|

| References (Surface) | 31 October 2019 | 25 April 2020 | 29 July 2020 | 15 October 2020 |

| 17 March 2019 | √ 1 | √ | √ | √ |

| 31 October 2019 | N.A. 2 | √ | √ | √ |

| 25 April 2020 | N.A. | N.A. | √ | √ |

| 29 July 2020 | N.A. | N.A. | N.A. | √ |

| Epoch | Filling Thickness (m) | Deformation | ||||

|---|---|---|---|---|---|---|

| Reference | Test | Direction | Elevation Range (m) | Maximum Value (cm) | Maximum Value Elevation (m) | |

| 1910 | 2004 | 31 | Inward | 1127–1148 (20) | 7 | 1148 |

| Outward | 1107–1127 (20) | 3–4 | 1117 | |||

| 2007 | 70 | Inward | 1137–1148 (10) | 8 | 1148 | |

| Outward | 1107–1132 (30) | 5–6 | 1117 | |||

| 2010 | 81 | Inward | 1140–1148 (8) | 8.2 | 1148 | |

| Outward | 1107–1136 (30) | 6–7 | 1120 | |||

| 2004 | 2007 | 39 | Inward | 1141–1182 (40) | 12.5 | 1182 |

| Outward | 1107–1139 (30) | 5 | 1130 | |||

| 2010 | 50 | Inward | 1141–1182 (40) | 13 | 1182 | |

| Outward | 1107–1139 (30) | 5.2 | 1130 | |||

| 2007 | 2010 | 11 | Inward | 1152–1217 (65) | 15 | 1217 |

| Outward | / | / | / | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, P.; Zhao, R.; Li, D.; Zeng, Z.; Qi, S.; Yang, X. As-Built Inventory and Deformation Analysis of a High Rockfill Dam under Construction with Terrestrial Laser Scanning. Sensors 2022, 22, 521. https://doi.org/10.3390/s22020521

Xiao P, Zhao R, Li D, Zeng Z, Qi S, Yang X. As-Built Inventory and Deformation Analysis of a High Rockfill Dam under Construction with Terrestrial Laser Scanning. Sensors. 2022; 22(2):521. https://doi.org/10.3390/s22020521

Chicago/Turabian StyleXiao, Peiwei, Ran Zhao, Duohui Li, Zhaogao Zeng, Shunchao Qi, and Xingguo Yang. 2022. "As-Built Inventory and Deformation Analysis of a High Rockfill Dam under Construction with Terrestrial Laser Scanning" Sensors 22, no. 2: 521. https://doi.org/10.3390/s22020521