An Arithmetic-Trigonometric Optimization Algorithm with Application for Control of Real-Time Pressure Process Plant

Abstract

:1. Introduction

- 1.

- The proposed ATOA technique avoids premature convergence and accelerates the search mechanism using the trigonometric functions (i.e., sin, cos, and tan).

- 2.

- The different combinations of the proposed trigonometric function quickly relocate its position from one local minimum to another without getting stuck and reducing the computational complexity.

- 3.

- The proposed optimization is simulated and validated with 33 different benchmark functions to determine its rate of convergence and optimal solution zone identification performance.

- 4.

- The ATOA optimized controller is implemented on the real-time pressure process plant to validate the proposed optimization technique.

2. The Arithmetic–Trigonometric Optimization Algorithm

2.1. Sine Cosine Algorithm

- and are the positions of solution at and iterations.

- is the point of destination of solution at iteration.

- , , , and are the random variables.

2.2. Arithmetic Optimization Algorithm

2.2.1. Initialization

2.2.2. Exploration

- is a sensitive parameter that defines the exploitation accuracy.

- t and T are the current and maximum number of iterations, respectively.

2.2.3. Exploitation

2.3. Arithmetic–Trigonometric Optimization Algorithm

- represents the solution in the iteration at the position.

- is best solution obtained at position.

- and are the upper and lower boundaries at position.

- is the constant integer.

- is the search control parameter.

| Algorithm 1 Pseudocode of ATOAcs |

|

3. Performance Analysis on Benchmark Functions

3.1. Selection of Benchmark Functions

3.2. Numerical Analysis on Benchmark Functions

3.3. Convergence Analysis

4. Performance Analysis on Control of Real-time Pressure Process Plant

4.1. Industrial-Scale Setup of Real-Time Pressure Process Plant

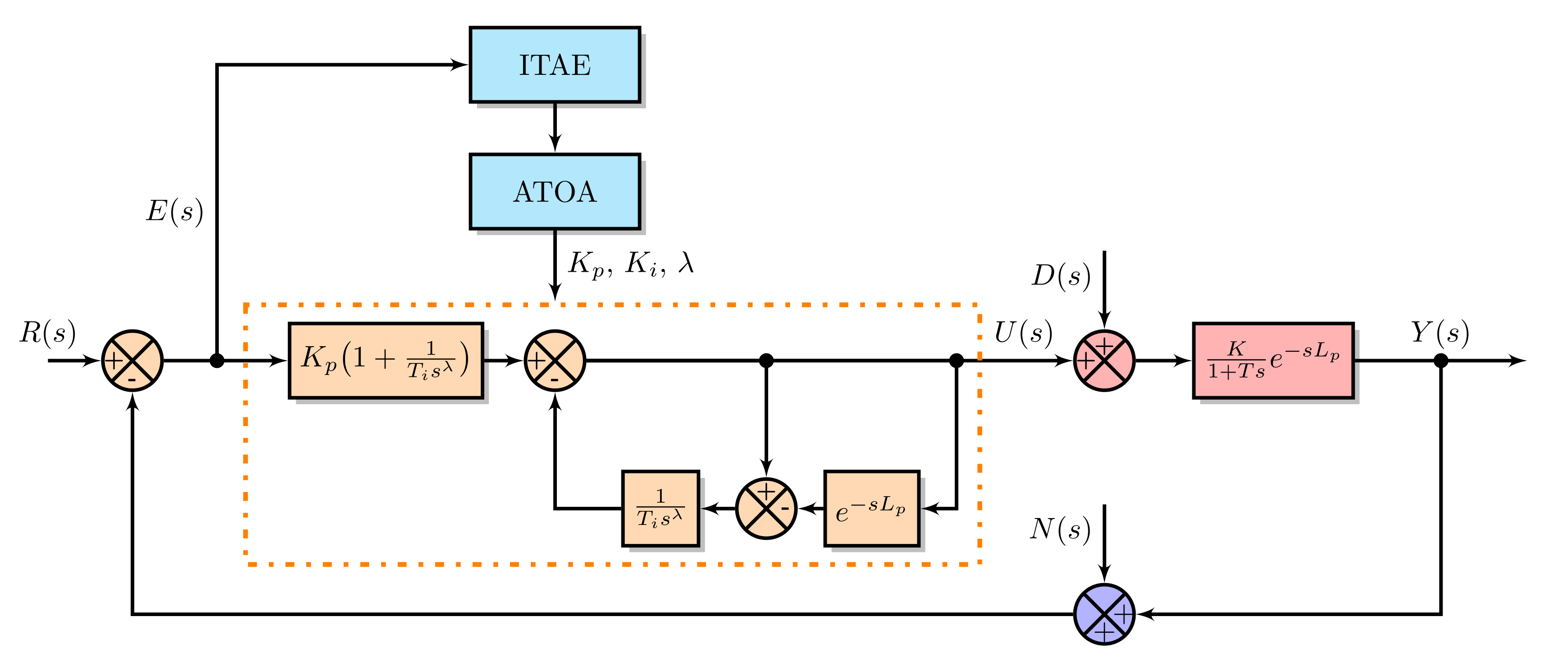

4.2. ATOA-Based Fractional-Order Predictive PI Control of Pressure Process Plant

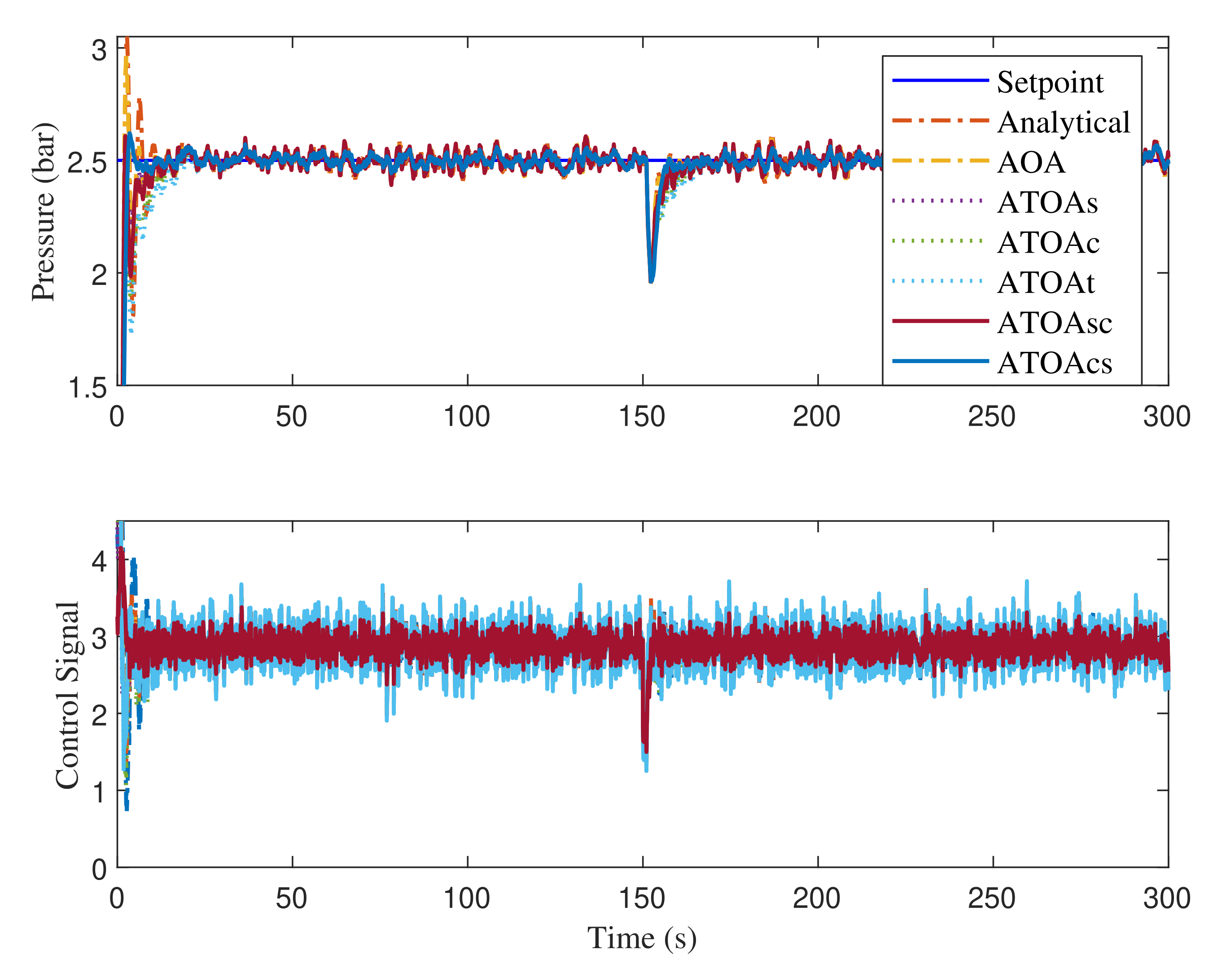

4.3. Performance Analysis

5. Summary and Conclusions

5.1. Summary

- 1.

- The proposed ATOA outperformed all the compared algorithms in most of the benchmark functions in terms of mean, best, and standard deviation.

- 2.

- The proposed ATOA variants produced the best global minima in fewer number of iterations. Among them, ATOAcs achieved phenomenal results in all the comparative research analysis.

- 3.

- The proposed ATOAcs and ATOAs had an efficient global optima search mechanism and yielded better performance, and it is proven by the Friedman ranking test given in Table 4.

- 4.

- The ATOA-optimized FOPPI controller parameters performed effectively by reducing the peak overshoot, actively tracking the set-point, and efficiently minimizing the disturbance impacts on the process.

- 5.

- The control signals of the optimized FOPPI controller greatly smooth the control actions by filtering out the undesired stochastic disturbances.

5.2. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abualigah, L.; Diabat, A.; Mirjalili, S.; Abd Elaziz, M.; Gandomi, A.H. The arithmetic optimization algorithm. Comput. Methods Appl. Mech. Eng. 2021, 376, 113609. [Google Scholar] [CrossRef]

- Huang, H.; Heidari, A.A.; Xu, Y.; Wang, M.; Liang, G.; Chen, H.; Cai, X. Rationalized sine cosine optimization with efficient searching patterns. IEEE Access 2020, 8, 61471–61490. [Google Scholar] [CrossRef]

- Devan, P.; Hussin, F.A.; Ibrahim, R.; Bingi, K.; Khanday, F.A. A Survey on the Application of WirelessHART for Industrial Process Monitoring and Control. Sensors 2021, 21, 4951. [Google Scholar] [CrossRef]

- Meraihi, Y.; Gabis, A.B.; Mirjalili, S.; Ramdane-Cherif, A. Grasshopper optimization algorithm: Theory, variants, and applications. IEEE Access 2021, 9, 50001–50024. [Google Scholar] [CrossRef]

- Fakhar, M.S.; Liaquat, S.; Kashif, S.A.R.; Rasool, A.; Khizer, M.; Iqbal, M.A.; Baig, M.A.; Padmanaban, S. Conventional and metaheuristic optimization algorithms for solving short term hydrothermal scheduling problem: A review. IEEE Access 2021, 9, 25993–26025. [Google Scholar] [CrossRef]

- Bingi, K.; Ibrahim, R.; Karsiti, M.N.; Hassan, S.M. Fractional order set-point weighted PID controller for pH neutralization process using accelerated PSO algorithm. Arab. J. Sci. Eng. 2018, 43, 2687–2701. [Google Scholar] [CrossRef]

- Emambocus, B.A.S.; Jasser, M.B.; Mustapha, A.; Amphawan, A. Dragonfly Algorithm and Its Hybrids: A Survey on Performance, Objectives and Applications. Sensors 2021, 21, 7542. [Google Scholar] [CrossRef]

- Adnan, M.; Razzaque, M.A.; Ahmed, I.; Isnin, I.F. Bio-mimic optimization strategies in wireless sensor networks: A survey. Sensors 2014, 14, 299–345. [Google Scholar] [CrossRef] [PubMed]

- Yue, Z.; Zhang, S.; Xiao, W. A novel hybrid algorithm based on grey wolf optimizer and fireworks algorithm. Sensors 2020, 20, 2147. [Google Scholar] [CrossRef] [Green Version]

- Devan, P.A.M.; Hussin, F.A.; Ibrahim, R.; Bingi, K.; Abdulrab, H. Design of Fractional-Order Predictive PI Controller for Real-time Pressure Process Plant. In Proceedings of the 2021 Australian & New Zealand Control Conference (ANZCC), Gold Coast, Australia, 25–26 November 2021; pp. 86–91. [Google Scholar]

- Dhiman, G. ESA: A hybrid bio-inspired metaheuristic optimization approach for engineering problems. Eng. Comput. 2021, 37, 323–353. [Google Scholar] [CrossRef]

- Rodríguez-Molina, A.; Mezura-Montes, E.; Villarreal-Cervantes, M.G.; Aldape-Pérez, M. Multi-objective meta-heuristic optimization in intelligent control: A survey on the controller tuning problem. Appl. Soft Comput. 2020, 93, 106342. [Google Scholar] [CrossRef]

- Reynoso-Meza, G.; Blasco, X.; Sanchis, J.; Martínez, M. Controller tuning using evolutionary multi-objective optimisation: Current trends and applications. Control Eng. Pract. 2014, 28, 58–73. [Google Scholar] [CrossRef] [Green Version]

- Mirjalili, S. Dragonfly algorithm: A new meta-heuristic optimization technique for solving single-objective, discrete, and multi-objective problems. Neural Comput. Appl. 2016, 27, 1053–1073. [Google Scholar] [CrossRef]

- Antonio, L.M.; Coello, C.A.C. Coevolutionary multiobjective evolutionary algorithms: Survey of the state-of-the-art. IEEE Trans. Evol. Comput. 2017, 22, 851–865. [Google Scholar] [CrossRef]

- Qu, B.Y.; Zhu, Y.; Jiao, Y.; Wu, M.; Suganthan, P.N.; Liang, J.J. A survey on multi-objective evolutionary algorithms for the solution of the environmental/economic dispatch problems. Swarm Evol. Comput. 2018, 38, 1–11. [Google Scholar] [CrossRef]

- Mirjalili, S. SCA: A sine cosine algorithm for solving optimization problems. Knowl.-Based Syst. 2016, 96, 120–133. [Google Scholar] [CrossRef]

- Zou, Q.; Li, A.; He, X.; Wang, X. Optimal operation of cascade hydropower stations based on chaos cultural sine cosine algorithm. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 366, p. 012005. [Google Scholar]

- Liu, S.; Zhao, Q.h.; Chen, S.j. Flower pollination algorithm based on sine cosine algorithm. Microelectron Comput. 2018, 35, 84–87. [Google Scholar]

- El-Shorbagy, M.A.; Farag, M.; Mousa, A.; El-Desoky, I. A hybridization of sine cosine algorithm with steady state genetic algorithm for engineering design problems. In International Conference on Advanced Machine Learning Technologies and Applications; Springer: Berlin/Heidelberg, Germany, 2019; pp. 143–155. [Google Scholar]

- Tawhid, M.A.; Savsani, V. Multi-objective sine-cosine algorithm (MO-SCA) for multi-objective engineering design problems. Neural Comput. Appl. 2019, 31, 915–929. [Google Scholar] [CrossRef]

- Premkumar, M.; Jangir, P.; Kumar, B.S.; Sowmya, R.; Alhelou, H.H.; Abualigah, L.; Yildiz, A.R.; Mirjalili, S. A New Arithmetic Optimization Algorithm for Solving Real-World Multiobjective CEC-2021 Constrained Optimization Problems: Diversity Analysis and Validations. IEEE Access 2021, 9, 84263–84295. [Google Scholar] [CrossRef]

- Panga, N.; Sivaramakrishnan, U.; Abishek, R.; Bingi, K.; Chaudhary, J. An Improved Arithmetic Optimization Algorithm. In 2021 IEEE Madras Section Conference (MASCON); IEEE: Manhattan, NY, USA, 2021; pp. 1–6. [Google Scholar]

- Zheng, R.; Jia, H.; Abualigah, L.; Liu, Q.; Wang, S. An improved arithmetic optimization algorithm with forced switching mechanism for global optimization problems. Math. Biosci. Eng. 2022, 19, 473–512. [Google Scholar] [CrossRef]

- Abualigah, L.; Diabat, A.; Sumari, P.; Gandomi, A.H. A novel evolutionary arithmetic optimization algorithm for multilevel thresholding segmentation of covid-19 ct images. Processes 2021, 9, 1155. [Google Scholar] [CrossRef]

- Zheng, R.; Jia, H.; Abualigah, L.; Liu, Q.; Wang, S. Deep Ensemble of Slime Mold Algorithm and Arithmetic Optimization Algorithm for Global Optimization. Processes 2021, 9, 1774. [Google Scholar] [CrossRef]

- Rizk-Allah, R.M. Hybridizing sine cosine algorithm with multi-orthogonal search strategy for engineering design problems. J. Comput. Des. Eng. 2018, 5, 249–273. [Google Scholar] [CrossRef]

- Ibrahim, R.A.; Abualigah, L.; Ewees, A.A.; Al-Qaness, M.A.; Yousri, D.; Alshathri, S.; Abd Elaziz, M. An Electric Fish-Based Arithmetic Optimization Algorithm for Feature Selection. Entropy 2021, 23, 1189. [Google Scholar] [CrossRef]

- Ewees, A.A.; Al-qaness, M.A.; Abualigah, L.; Oliva, D.; Algamal, Z.Y.; Anter, A.M.; Ali Ibrahim, R.; Ghoniem, R.M.; Abd Elaziz, M. Boosting Arithmetic Optimization Algorithm with Genetic Algorithm Operators for Feature Selection: Case Study on Cox Proportional Hazards Model. Mathematics 2021, 9, 2321. [Google Scholar] [CrossRef]

- Tao, L.; Yang, X.; Zhou, Y.; Yang, L. A Novel Transformers Fault Diagnosis Method Based on Probabilistic Neural Network and Bio-Inspired Optimizer. Sensors 2021, 21, 3623. [Google Scholar] [CrossRef]

- Belazzoug, M.; Touahria, M.; Nouioua, F.; Brahimi, M. An improved sine cosine algorithm to select features for text categorization. J. King Saud Univ.-Comput. Inf. Sci. 2020, 32, 454–464. [Google Scholar] [CrossRef]

- Elkasem, A.H.; Khamies, M.; Magdy, G.; Taha, I.; Kamel, S. Frequency Stability of AC/DC Interconnected Power Systems with Wind Energy Using Arithmetic Optimization Algorithm-Based Fuzzy-PID Controller. Sustainability 2021, 13, 12095. [Google Scholar] [CrossRef]

- Attia, A.F.; El Sehiemy, R.A.; Hasanien, H.M. Optimal power flow solution in power systems using a novel Sine-Cosine algorithm. Int. J. Electr. Power Energy Syst. 2018, 99, 331–343. [Google Scholar] [CrossRef]

- Li, S.; Fang, H.; Liu, X. Parameter optimization of support vector regression based on sine cosine algorithm. Expert Syst. Appl. 2018, 91, 63–77. [Google Scholar] [CrossRef]

- Izci, D.; Ekinci, S.; Kayri, M.; Eker, E. A novel improved arithmetic optimization algorithm for optimal design of PID controlled and Bode’s ideal transfer function based automobile cruise control system. Evol. Syst. 2021, 1–16. [Google Scholar] [CrossRef]

- Abdelsalam, A.A.; Mansour, H.S. Optimal allocation and hourly scheduling of capacitor banks using sine cosine algorithm for maximizing technical and economic benefits. Electr. Power Compon. Syst. 2019, 47, 1025–1039. [Google Scholar] [CrossRef]

- Nenavath, H.; Jatoth, R.K.; Das, S. A synergy of the sine-cosine algorithm and particle swarm optimizer for improved global optimization and object tracking. Swarm Evol. Comput. 2018, 43, 1–30. [Google Scholar] [CrossRef]

- Suid, M.; Tumari, M.; Ahmad, M. A modified sine cosine algorithm for improving wind plant energy production. Indones. J. Electr. Eng. Comput. Sci. 2019, 16, 101–106. [Google Scholar] [CrossRef]

- Bhookya, J.; Jatoth, R.K. Optimal FOPID/PID controller parameters tuning for the AVR system based on sine–cosine-algorithm. Evol. Intell. 2019, 12, 725–733. [Google Scholar] [CrossRef]

- Abualigah, L.; Diabat, A. Advances in sine cosine algorithm: A comprehensive survey. Artif. Intell. Rev. 2021, 54, 2567–2608. [Google Scholar] [CrossRef]

- Singh, K.; Singh, K.; Aziz, A. Congestion control in wireless sensor networks by hybrid multi-objective optimization algorithm. Comput. Netw. 2018, 138, 90–107. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, Q.; Chen, X.; Zhang, D.; Leng, J. A digital twin-based approach for designing and multi-objective optimization of hollow glass production line. Ieee Access 2017, 5, 26901–26911. [Google Scholar] [CrossRef]

- Li, S.; Chen, H.; Wang, M.; Heidari, A.A.; Mirjalili, S. Slime mould algorithm: A new method for stochastic optimization. Future Gener. Comput. Syst. 2020, 111, 300–323. [Google Scholar] [CrossRef]

- Wolpert, D.H.; Macready, W.G. No free lunch theorems for optimization. IEEE Trans. Evol. Comput. 1997, 1, 67–82. [Google Scholar] [CrossRef] [Green Version]

- Carrasco, J.; García, S.; Rueda, M.; Das, S.; Herrera, F. Recent trends in the use of statistical tests for comparing swarm and evolutionary computing algorithms: Practical guidelines and a critical review. Swarm Evol. Comput. 2020, 54, 100665. [Google Scholar] [CrossRef] [Green Version]

- Devan, P.A.M.; Hussin, F.A.; Ibrahim, R.; Bingi, K.; Abdulrab, H. Fractional-order Predictive PI Controller for Process Plants with Deadtime. In Proceedings of the 2020 IEEE 8th R10 Humanitarian Technology Conference (R10-HTC), Kuching, Malaysia, 1–3 December 2020; pp. 1–6. [Google Scholar]

- Hassan, S.M.; Ibrahim, R.; Saad, N.; Asirvadam, V.S.; Bingi, K. Adopting setpoint weighting strategy for WirelessHART networked control systems characterised by stochastic delay. IEEE Access 2017, 5, 25885–25896. [Google Scholar] [CrossRef]

- Mohan, N. Iterative Learning Control Design for a Non-Linear Multivariable System. J. Control Eng. Appl. Inform. 2021, 23, 32–39. [Google Scholar]

- Anitha, T.; Gopu, G.; Nagarajapandian, M.; Devan, P.A.M. Hybrid Fuzzy PID Controller for Pressure Process Control Application. In Proceedings of the 2019 IEEE Student Conference on Research and Development (SCOReD), Bandar Seri Iskandar, Malaysia, 15–17 October 2019; pp. 129–133. [Google Scholar]

- Devan, P.A.M.; Hussin, F.A.B.; Ibrahim, R.; Bingi, K.; Abdulrab, H.Q. Fractional-Order Predictive PI Controller for Dead-Time Processes With Set-Point and Noise Filtering. IEEE Access 2020, 8, 183759–183773. [Google Scholar] [CrossRef]

| Algorithm | Exploration Function | Exploitation Function |

|---|---|---|

| ATOAs | sin | sin |

| ATOAc | cos | cos |

| ATOAt | tan | tan |

| ATOAsc | sin | cos |

| ATOAcs | cos | sin |

| Cat. | Func. | Description | Range |

|---|---|---|---|

| Unimodal | F1 | [−100, 100] | |

| F2 | [−10, 10] | ||

| F3 | [−100, 100] | ||

| F4 | [−30, 30] | ||

| F5 | [−100, 100] | ||

| F6 | [−128, 128] | ||

| Multimodal | F7 | [−500, 500] | |

| F8 | [−32, 32] | ||

| F9 | [−50, 50] | ||

| F10 | [−50, 50] | ||

| F11 | [−65,65] | ||

| F12 | [−5, 5] | ||

| F13 | [−5, 5] | ||

| F14 | [−5, 5] | ||

| F15 | [−4, 5] | ||

| F16 | [−1, 2] | ||

| F17 | [0, 1] | ||

| F18 | [0, 1] | ||

| Hybrid | F19 | [−512, 512] | |

| F20 | [−10, 10] | ||

| Hybrid | F21 | [−5.12, 5.12] | |

| F22 | [−1.5, 4] | ||

| F23 | [−3, 3] | ||

| F24 | [−100, 100] | ||

| F25 | [−5, 10] | ||

| F26 | [−2, 2] | ||

| F27 | [−5, 5] | ||

| F28 | [−10, 10] | ||

| F29 | [−10, 10] | ||

| F30 | [0, 1] | ||

| F31 | [0, 10] | ||

| F32 | [0, 1] | ||

| F33 | [0, ] |

| Function | Global Minima | Measure | AOA | ATOAs | ATOAc | ATOAt | ATOAsc | ATOAcs |

|---|---|---|---|---|---|---|---|---|

| F1 | 0 | Mean | 0.0000 | 4.46 | 9.89 | 0.0000 | 0.0000 | 0.0000 |

| Best | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | ||

| Worst | 0.0000 | 2.10 | 4.95 | 0.0000 | 0.0000 | 0.0000 | ||

| Std. Dev | 0.0000 | 2.97 | 7.00 | 0.0000 | 0.0000 | 0.0000 | ||

| F2 | 0 | Mean | 0.0000 | 8.65 | 4.13 | 1.67 | 5.95 | 0.0000 |

| Best | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | ||

| Worst | 0.0000 | 4.32 | 2.06 | 8.36 | 2.97 | 0.0000 | ||

| Std. Dev | 0.0000 | 6.11 | 2.92 | 0.0000 | 4.21 | 0.0000 | ||

| F3 | 0 | Mean | 0.0000 | 2.03 | 1.07 | 0.0000 | 0.0000 | 0.0000 |

| Best | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | ||

| Worst | 0.0000 | 1.02 | 5.35 | 0.0000 | 0.0000 | 0.0000 | ||

| Std. Dev | 0.0000 | 1.44 | 7.57 | 0.0000 | 0.0000 | 0.0000 | ||

| F4 | 0 | Mean | 5.1652 | 7.7668 | 6.9754 | 23.2905 | 6.8636 | 7.8511 |

| Best | 4.6129 | 6.9030 | 5.2892 | 8.2527 | 5.2644 | 6.6216 | ||

| Worst | 5.8078 | 8.1612 | 7.9103 | 547.483 | 8.4399 | 8.6583 | ||

| Std. Dev | 0.2658 | 0.3346 | 0.499 | 79.9482 | 0.7056 | 0.4639 | ||

| F5 | 0 | Mean | 0.0143 | 0.0018 | 0.3024 | 0.032 | 0.0726 | 0.0014 |

| Best | 0.0054 | 0.0004 | 0.1694 | 0.0161 | 0.0279 | 0.0007 | ||

| Worst | 0.0232 | 0.003 | 0.4172 | 0.0531 | 0.1604 | 0.0027 | ||

| Std. Dev | 0.0041 | 5.23 | 0.056 | 0.0105 | 0.0318 | 0.0005 | ||

| F6 | 0 | Mean | 0.0000 | 3.69 | 7.94 | 0.0211 | 6.11 | 0.0022 |

| Best | 0.0000 | 2.91 | 3.22 | 7.45 | 5.37 | 0.0000 | ||

| Worst | 0.0001 | 0.0018 | 2.29 | 0.0926 | 0.0018 | 0.0173 | ||

| Std. Dev | 0.0000 | 3.83 | 5.79 | 0.0204 | 4.12 | 0.0029 | ||

| F7 | −418.9829 × n | Mean | −3475.0000 | −3.22 | −3069.4000 | −2.18 | −3.08 | −3178.2000 |

| Best | −4071.3000 | −4.00 | −3670.2000 | −3.04 | −3.58 | −3794.9000 | ||

| Worst | −2914.5000 | −2.44 | −2341.0000 | −1.36 | −2.52 | −2620.2000 | ||

| Std. Dev | 252.5026 | 262.4675 | 284.0105 | 368.5892 | 228.423 | 311.1536 | ||

| F8 | 0 | Mean | 0.0000 | 6.32 | 1.98 | 8.88 | 8.88 | 0.0000 |

| Best | 0.0000 | 8.88 | 8.88 | 8.88 | 8.88 | 0.0000 | ||

| Worst | 0.0000 | 3.16 | 9.91 | 8.88 | 8.88 | 0.0000 | ||

| Std. Dev | 0.0000 | 4.47 | 1.40 | 0.0000 | 0.0000 | 0.0000 | ||

| F9 | 0 | Mean | 0.5947 | 8.85 | 5.88 | 0.9595 | 0.4228 | 1.0271 |

| Best | 0.4953 | 1.0361 | 3.2475 | 0.8689 | 0.3078 | 0.9451 | ||

| Worst | 0.6443 | 1.67 | 9.76 | 1.0228 | 0.523 | 1.0944 | ||

| Std. Dev | 0.0337 | 2.94 | 1.52 | 0.0315 | 0.0453 | 0.0317 | ||

| F10 | 0 | Mean | 0.7823 | 0.1646 | 0.1116 | 0.9423 | 0.1327 | 0.8997 |

| Best | 0.3881 | 0.0294 | 0.0554 | 0.5441 | 0.059 | 0.6860 | ||

| Worst | 0.9948 | 0.4447 | 0.1734 | 0.9907 | 0.2184 | 0.9868 | ||

| Std. Dev | 0.1563 | 0.1028 | 0.0245 | 0.0795 | 0.0376 | 0.0639 | ||

| F11 | 1 | Mean | 8.8855 | 5.9519 | 5.5608 | 8.666 | 6.1167 | 5.6534 |

| Best | 0.9980 | 0.998 | 0.998 | 0.998 | 0.998 | 0.9980 | ||

| Worst | 12.6705 | 11.7187 | 12.6705 | 12.6705 | 12.6705 | 11.7187 | ||

| Std. Dev | 3.9075 | 3.3638 | 3.1317 | 3.7149 | 3.6442 | 3.2853 | ||

| F12 | 0.0003 | Mean | 0.0104 | 0.0016 | 0.0043 | 0.008 | 0.0111 | 0.0078 |

| Best | 0.0003 | 4.02 | 3.92 | 6.66 | 3.13 | 0.0004 | ||

| Worst | 0.0863 | 0.0245 | 0.0234 | 0.0569 | 0.0566 | 0.0572 | ||

| Std. Dev | 0.0153 | 0.0037 | 0.0062 | 0.011 | 0.0133 | 0.0111 | ||

| F13 | −1.0316 | Mean | −1.0316 | −1.0313 | −1.0316 | −1.0238 | −1.0316 | −1.0313 |

| Best | −1.0316 | −1.0316 | −1.0316 | −1.0311 | −1.0316 | −1.0316 | ||

| Worst | −1.0316 | −1.0303 | −1.0316 | −1.0063 | −1.0316 | −1.0301 | ||

| Std. Dev | 0.0000 | 3.27 | 9.91 | 0.0066 | 8.16 | 0.0003 | ||

| F14 | 0.398 | Mean | 1.1631 | 0.4233 | 0.3979 | 0.4025 | 0.3979 | 0.4088 |

| Best | 0.4123 | 0.3979 | 0.3979 | 0.398 | 0.3979 | 0.3979 | ||

| Worst | 2.8698 | 0.7824 | 0.398 | 0.4356 | 0.3981 | 0.5690 | ||

| Std. Dev | 0.5939 | 0.0758 | 2.16 | 0.0067 | 3.86 | 0.0259 | ||

| F15 | 3 | Mean | 6.2400 | 3.0005 | 3.0002 | 8.3111 | 6.253 | 3.0005 |

| Best | 3.0000 | 3.0000 | 3.0000 | 3.0000 | 3.0000 | 3.0000 | ||

| Worst | 30.0000 | 3.0028 | 3.0006 | 91.5641 | 84.6034 | 3.0027 | ||

| Std. Dev | 8.8630 | 6.54 | 1.50 | 21.2206 | 16.0971 | 0.0006 | ||

| F16 | −3.86 | Mean | −3.8544 | −3.8563 | −3.8261 | −3.8502 | −3.8445 | −3.8559 |

| Best | −3.8608 | −3.8625 | −3.854 | −3.8616 | −3.8548 | −3.8614 | ||

| Worst | −3.8498 | −3.8515 | −3.0119 | −3.8324 | −3.8202 | −3.8503 | ||

| Std. Dev | 0.0023 | 0.0026 | 0.1181 | 0.0052 | 0.009 | 0.0024 | ||

| F17 | −0.32 | Mean | −3.1259 | −3.1647 | −2.9368 | −3.0409 | −2.8466 | −3.1710 |

| Best | −3.2643 | −3.2551 | −3.2132 | −3.1812 | −3.117 | −3.2631 | ||

| Worst | −2.9339 | −2.9039 | −2.2038 | −2.4088 | −2.3154 | −3.0584 | ||

| Std. Dev | 0.0650 | 0.0595 | 0.1899 | 0.1378 | 0.2263 | 0.0473 | ||

| F18 | −10.1532 | Mean | −4.1529 | −8.2176 | −7.7996 | −6.5441 | −5.3207 | −4.7763 |

| Best | −8.0049 | −10.1471 | −10.0933 | −10.1441 | −10.1435 | −10.1413 | ||

| Worst | −1.9980 | −2.6275 | −2.6046 | −2.6249 | −2.6102 | −2.6253 | ||

| Std. Dev | 1.2108 | 3.251 | 3.1242 | 3.2365 | 2.9748 | 2.7482 | ||

| F19 | −959.6407 | Mean | −800.3974 | −863.6167 | −850.7201 | −706.1923 | −859.4495 | −856.7580 |

| Best | −941.2958 | −959.6407 | −959.6407 | −932.4704 | −959.6406 | −959.6407 | ||

| Worst | −644.2784 | −559.7869 | −559.7868 | −474.3529 | −545.6967 | −575.2190 | ||

| Std. Dev | 89.8151 | 97.5246 | 114.0678 | 116.7106 | 112.0762 | 86.4870 | ||

| F20 | −19.2085 | Mean | −18.7179 | −18.8544 | −18.9728 | −18.7377 | −18.9140 | −18.9721 |

| Best | −19.2083 | −19.2084 | −19.2085 | −19.2085 | −19.2085 | −19.2084 | ||

| Worst | −15.8160 | −16.2678 | −16.2678 | −16.2678 | −16.2678 | −16.2678 | ||

| Std. Dev | 0.7836 | 0.9649 | 0.8057 | 1.0889 | 0.8910 | 0.8055 | ||

| F21 | −186.7309 | Mean | −116.2292 | −176.7813 | −178.8541 | −186.6622 | −176.8742 | −181.4309 |

| Best | −184.3297 | −186.7222 | −186.7259 | −186.7258 | −186.7211 | −186.7294 | ||

| Worst | −50.6600 | −79.3989 | −123.4528 | −186.5087 | −64.6800 | −123.0804 | ||

| Std. Dev | 38.0811 | 25.0093 | 20.6675 | 0.0496 | 29.1740 | 17.3085 | ||

| F22 | −1.9133 | Mean | −1.8773 | −1.9132 | −1.9132 | −1.8676 | −1.9132 | −1.9131 |

| Best | −1.9132 | −1.9132 | −1.9132 | −1.9128 | −1.9132 | −1.9132 | ||

| Worst | −1.4783 | −1.9131 | −1.9132 | −1.6836 | −1.9131 | −1.9127 | ||

| Std. Dev | 0.1158 | 3.84 | 3.64 | 0.0507 | 7.44 | 9.84 | ||

| F23 | −1.0316 | Mean | −1.0091 | −1.0316 | −1.0314 | −1.0316 | −1.0314 | −1.0316 |

| Best | −1.0316 | −1.0316 | −1.0316 | −1.0316 | −1.0316 | −1.0316 | ||

| Worst | −0.9990 | −1.0314 | −1.0310 | −1.0316 | −1.0309 | −1.0314 | ||

| Std. Dev | 0.0135 | 4.68 | 1.50 | 3.78 | 1.65 | 4.25 | ||

| F24 | −1 | Mean | −0.0532 | −0.9400 | −0.8598 | −0.1601 | −0.9998 | −0.9638 |

| Best | −0.9963 | −1.0000 | −1.0000 | −1.0000 | −1.0000 | −1.0000 | ||

| Worst | −2.92 | −8.11 | −8.09 | −8.11 | −0.9994 | −0.9265 | ||

| Std. Dev | 0.1934 | 0.2399 | 0.3504 | 0.3703 | 1.46 | 0.0169 | ||

| F25 | 0.3978 | Mean | 0.7698 | 0.3989 | 0.3980 | 0.4073 | 0.3981 | 0.3993 |

| Best | 0.3985 | 0.3979 | 0.3979 | 0.3982 | 0.3979 | 0.3979 | ||

| Worst | 1.8135 | 0.4045 | 0.3984 | 0.4645 | 0.4000 | 0.4142 | ||

| Std. Dev | 0.3683 | 0.0011 | 9.50 | 0.0103 | 4.03 | 0.0027 | ||

| F26 | 3 | Mean | 21.7513 | 3.0005 | 3.0002 | 6.2811 | 3.0002 | 3.0004 |

| Best | 3.0000 | 3.0000 | 3.0000 | 3.0000 | 3.0000 | 3.0000 | ||

| Worst | 156.2760 | 3.0035 | 3.0010 | 85.6932 | 3.0008 | 3.0016 | ||

| Std. Dev | 27.7673 | 7.45 | 2.02 | 16.2291 | 1.71 | 4.55 | ||

| F27 | −39.1659 | Mean | −72.2967 | −78.3312 | −78.3323 | −76.3317 | −76.3532 | −76.9175 |

| Best | −78.3276 | −78.3323 | −78.3323 | −78.3312 | −78.3323 | −78.3323 | ||

| Worst | −61.4160 | −78.3283 | −78.3322 | −64.1633 | −64.1956 | −64.1936 | ||

| Std. Dev | 5.2366 | 8.32 | 2.35 | 4.9494 | 4.9551 | 4.2841 | ||

| F28 | 0 | Mean | 1.4327 | 0.1547 | 0.1249 | 0.0135 | 0.0647 | 0.0955 |

| Best | 0.2886 | 0.0016 | 6.65 | 2.44 | 3.00 | 3.75 | ||

| Worst | 2.0000 | 0.6345 | 0.4463 | 0.1169 | 0.1157 | 0.1469 | ||

| Std. Dev | 0.5954 | 0.1213 | 0.1332 | 0.0335 | 0.0548 | 0.0438 | ||

| F29 | 0 | Mean | 38.8803 | 8.2303 | 5.4673 | 3.7098 | 3.2438 | 3.5159 |

| Best | 6.4751 | 0.4230 | 0.1357 | 0.0792 | 0.2594 | 0.1630 | ||

| Worst | 42.0000 | 35.4304 | 28.2788 | 8.2784 | 8.2392 | 8.8946 | ||

| Std. Dev | 9.3207 | 8.8018 | 6.1918 | 3.0627 | 2.6992 | 2.6469 | ||

| F30 | −3.8627 | Mean | −3.8545 | −3.8560 | −3.8128 | −3.8366 | −3.8257 | −3.8558 |

| Best | −3.8603 | −3.8621 | −3.8576 | −3.8616 | −3.8562 | −3.8612 | ||

| Worst | −3.8482 | −3.8491 | −3.0234 | −3.0861 | −3.0025 | −3.8497 | ||

| Std. Dev | 0.0029 | 0.0029 | 0.1620 | 0.1084 | 0.1194 | 0.0027 | ||

| F31 | −10.5364 | Mean | −4.6271 | −5.8656 | −4.6245 | −5.9376 | −4.7527 | −6.3397 |

| Best | −8.3487 | −10.5298 | −10.4165 | −10.5222 | −10.4922 | −10.5194 | ||

| Worst | −2.1589 | −1.8533 | −1.8495 | −1.8526 | −1.6908 | −1.8526 | ||

| Std. Dev | 1.3407 | 3.6248 | 2.9955 | 3.2566 | 2.8037 | 2.4718 | ||

| F32 | −3.3223 | Mean | −2.9401 | −2.9589 | −2.8212 | −2.9047 | −2.7873 | −2.9603 |

| Best | −3.0060 | −3.0201 | −2.9447 | −2.9750 | −2.9337 | −3.0257 | ||

| Worst | −2.8450 | −2.8800 | −2.5712 | −2.7635 | −2.5398 | −2.8884 | ||

| Std. Dev | 0.0292 | 0.0268 | 0.1079 | 0.0431 | 0.1204 | 0.0249 | ||

| F33 | −9.6601 | Mean | −3.3874 | −3.7494 | −2.9064 | −3.3626 | −2.9680 | −3.5913 |

| Best | −4.1525 | −4.5626 | −3.3311 | −3.8498 | −3.3714 | −4.2671 | ||

| Worst | −2.6242 | −2.6367 | −2.3804 | −2.3524 | −2.5597 | −2.7726 | ||

| Std. Dev | 0.3532 | 0.4382 | 0.2460 | 0.3167 | 0.2131 | 0.3409 |

| Function | F1 | F2 | F3 | F4 | F5 | F6 | F7 | F8 | F9 | F10 | F11 | F12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AOA | 1 | 1 | 1 | 1 | 3 | 1 | 1 | 1 | 2 | 4 | 1 | 6 |

| AOAs | 2 | 3 | 2 | 4 | 2 | 3 | 2 | 2 | 6 | 3 | 4 | 1 |

| ATOAc | 3 | 4 | 3 | 3 | 6 | 2 | 5 | 3 | 5 | 1 | 6 | 2 |

| ATOAt | 1 | 2 | 1 | 6 | 4 | 6 | 6 | 1 | 3 | 6 | 2 | 4 |

| ATOAsc | 1 | 5 | 1 | 2 | 5 | 4 | 4 | 1 | 1 | 2 | 3 | 5 |

| ATOAcs | 1 | 1 | 1 | 5 | 1 | 5 | 3 | 1 | 4 | 5 | 5 | 3 |

| Function | F13 | F14 | F15 | F16 | F17 | F18 | F19 | F20 | F21 | F22 | F23 | F24 |

| AOA | 1 | 5 | 4 | 5 | 3 | 6 | 5 | 6 | 6 | 3 | 3 | 6 |

| AOAs | 2 | 4 | 2 | 1 | 2 | 1 | 1 | 4 | 5 | 1 | 1 | 3 |

| AOAc | 1 | 1 | 1 | 6 | 5 | 2 | 4 | 1 | 3 | 1 | 2 | 4 |

| ATOAt | 3 | 2 | 5 | 3 | 4 | 3 | 6 | 5 | 1 | 4 | 1 | 5 |

| ATOAsc | 1 | 1 | 3 | 4 | 6 | 4 | 2 | 3 | 4 | 1 | 2 | 1 |

| ATOAcs | 2 | 3 | 2 | 2 | 1 | 5 | 3 | 2 | 2 | 2 | 1 | 2 |

| Function | F25 | F26 | F27 | F28 | F29 | F30 | F31 | F32 | F33 | Final Mean | Final Rank | |

| AOA | 6 | 5 | 6 | 6 | 6 | 3 | 5 | 3 | 6 | 3.696 | 6 | |

| ATOAs | 3 | 3 | 2 | 5 | 5 | 1 | 3 | 2 | 2 | 2.636 | 2 | |

| ATOAc | 1 | 1 | 1 | 4 | 4 | 6 | 6 | 5 | 5 | 3.242 | 4 | |

| ATOAt | 5 | 4 | 5 | 1 | 3 | 4 | 2 | 4 | 3 | 3.484 | 5 | |

| ATOAsc | 2 | 1 | 4 | 2 | 1 | 5 | 4 | 6 | 4 | 2.878 | 3 | |

| ATOAcs | 4 | 2 | 3 | 3 | 2 | 2 | 1 | 1 | 1 | 2.454 | 1 |

| Algorithm | %OS | ITAE | ||||||

|---|---|---|---|---|---|---|---|---|

| Analytical Design | 1.150 | 0.842 | 0.98 | 0.7665 | 83.0137 | 280.4273 | 22.2290 | 3.7159 |

| AOA | 2.167 | 1.197 | 0.97 | 0.8543 | 75.8397 | 276.7360 | 18.0314 | 2.8243 |

| ATOAs | 1.987 | 1.056 | 0.99 | 1.0638 | 65.8043 | 261.9294 | 3.3561 | 1.7391 |

| ATOAc | 1.793 | 0.692 | 0.99 | 2.1729 | 72.1039 | 268.9153 | 2.8020 | 2.2007 |

| ATOAt | 1.983 | 0.592 | 0.98 | 0.9579 | 77.8114 | 274.0171 | 3.1546 | 2.6376 |

| ATOAsc | 2.321 | 1.025 | 0.99 | 0.8301 | 69.5402 | 264.9950 | 3.6644 | 2.0154 |

| ATOAcs | 1.321 | 0.897 | 0.98 | 2.4432 | 61.3744 | 257.7074 | 5.4593 | 1.4224 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Devan, P.A.M.; Hussin, F.A.; Ibrahim, R.B.; Bingi, K.; Nagarajapandian, M.; Assaad, M. An Arithmetic-Trigonometric Optimization Algorithm with Application for Control of Real-Time Pressure Process Plant. Sensors 2022, 22, 617. https://doi.org/10.3390/s22020617

Devan PAM, Hussin FA, Ibrahim RB, Bingi K, Nagarajapandian M, Assaad M. An Arithmetic-Trigonometric Optimization Algorithm with Application for Control of Real-Time Pressure Process Plant. Sensors. 2022; 22(2):617. https://doi.org/10.3390/s22020617

Chicago/Turabian StyleDevan, P. Arun Mozhi, Fawnizu Azmadi Hussin, Rosdiazli B. Ibrahim, Kishore Bingi, M. Nagarajapandian, and Maher Assaad. 2022. "An Arithmetic-Trigonometric Optimization Algorithm with Application for Control of Real-Time Pressure Process Plant" Sensors 22, no. 2: 617. https://doi.org/10.3390/s22020617