Low-Cost Laser-Acoustic PVC Identification System Based on a Simple Neural Network

Abstract

1. Introduction

- To show for the first time that laser-ablative sound is also formed by means of a low-power laser diode;

- To investigate the material specificity of these sound signals;

- To demonstrate the identification of PVC in a matrix of extrinsically similar plastics by means of a neural network evaluating these sound signals; and

- To investigate the capabilities of this approach under real-life conditions.

2. Materials and Methods

2.1. General

Laser Diode

2.2. Materials

- Polymethyl methacrylate (PMMA);

- Polypropylene (PP);

- Polystyrene (PS);

- Polyvinyl chloride (PVC);

- Polyurethane (PU);

- Acrylonitrile butadiene styrene (ABS);

- Polyethylene terephthalate (PET);

- Polytetrafluoroethylene (PTFE);

- Polyethylene (PE);

- Polyoxymethylene (POM).

2.3. Physical Investigations of the Laser-Induced Ablation

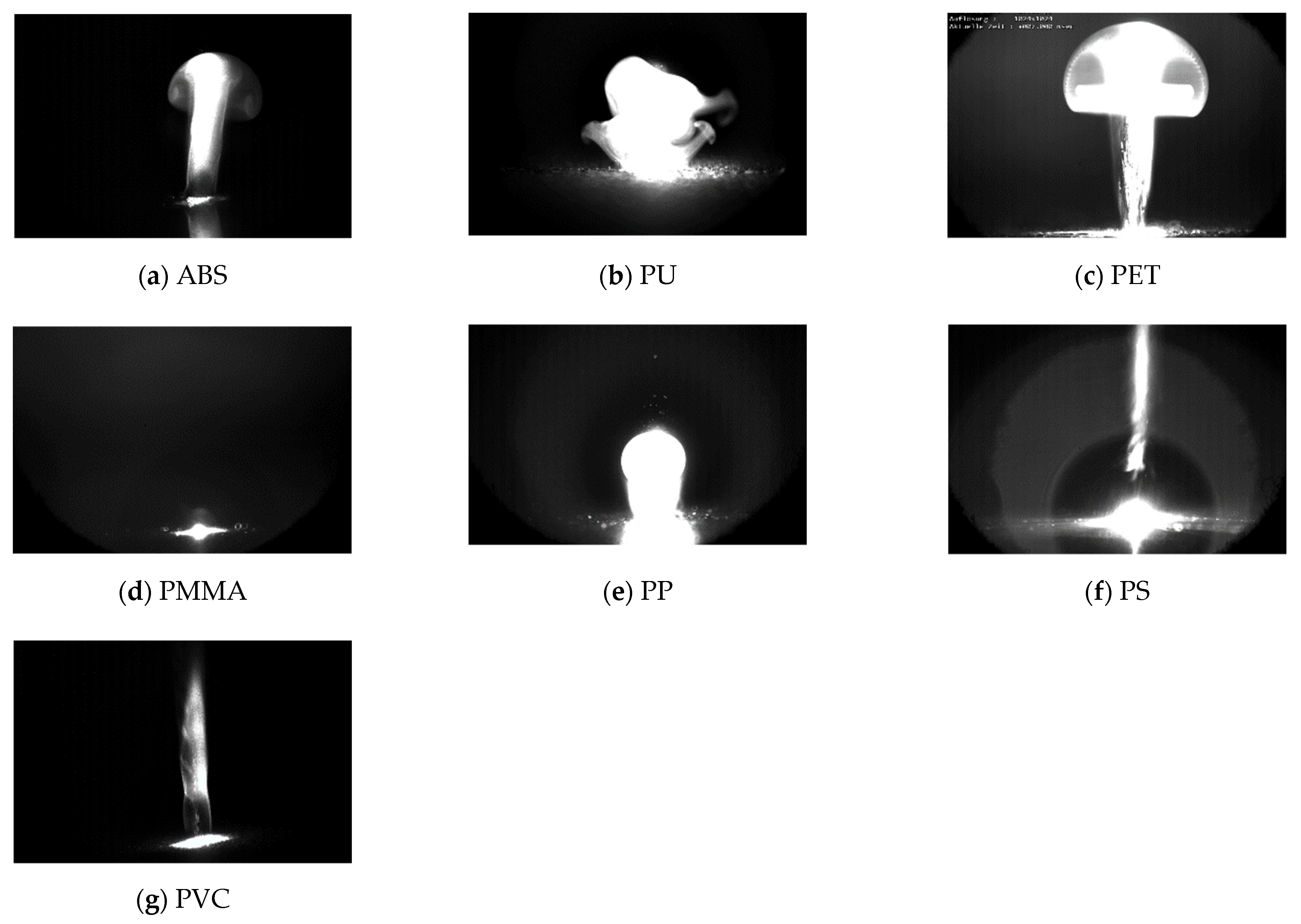

2.3.1. Fast Framing

2.3.2. Amount of Ablated Material

2.3.3. Laser Pulse Energy

2.4. Laser-Acoustic Measurements

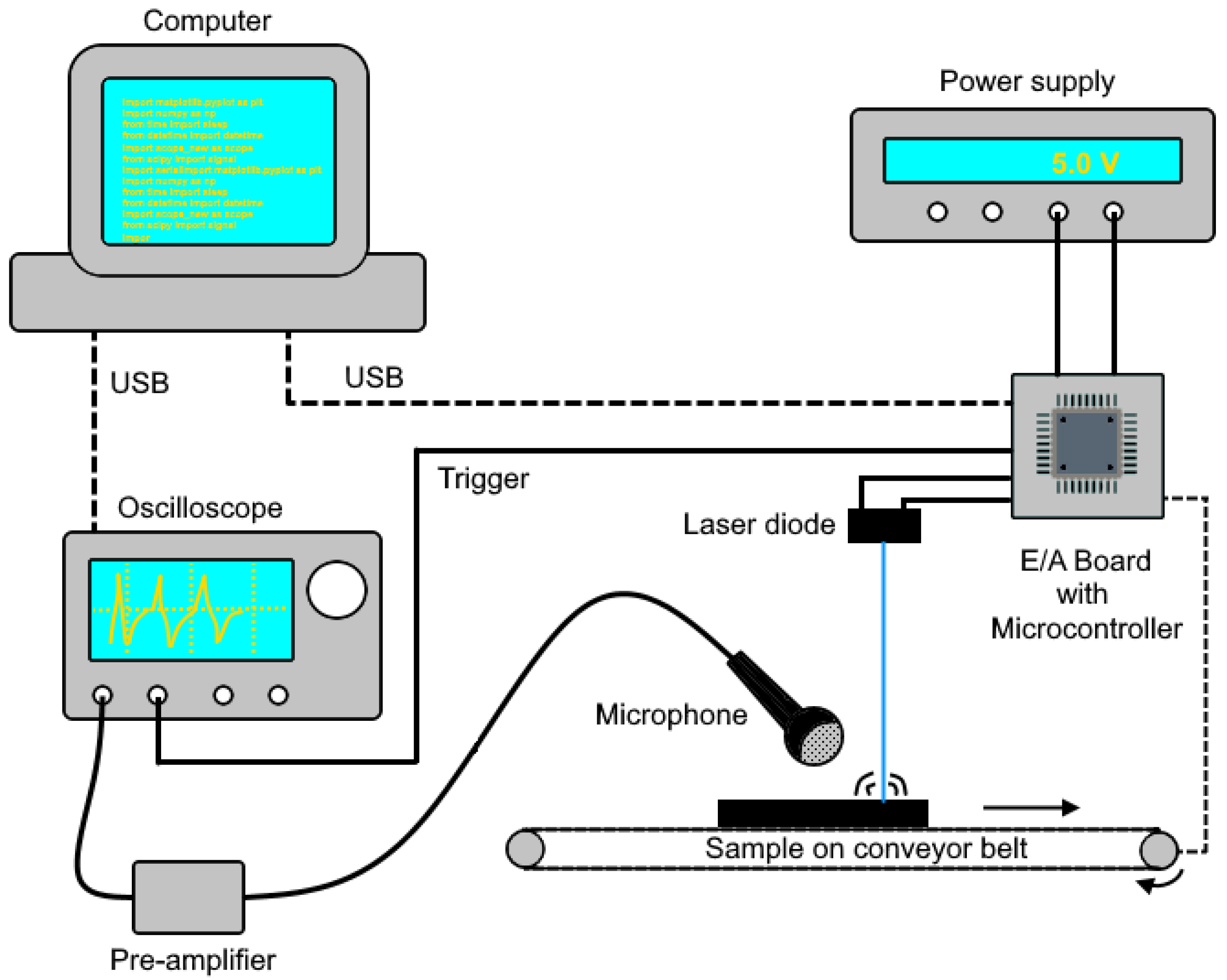

2.4.1. Setup

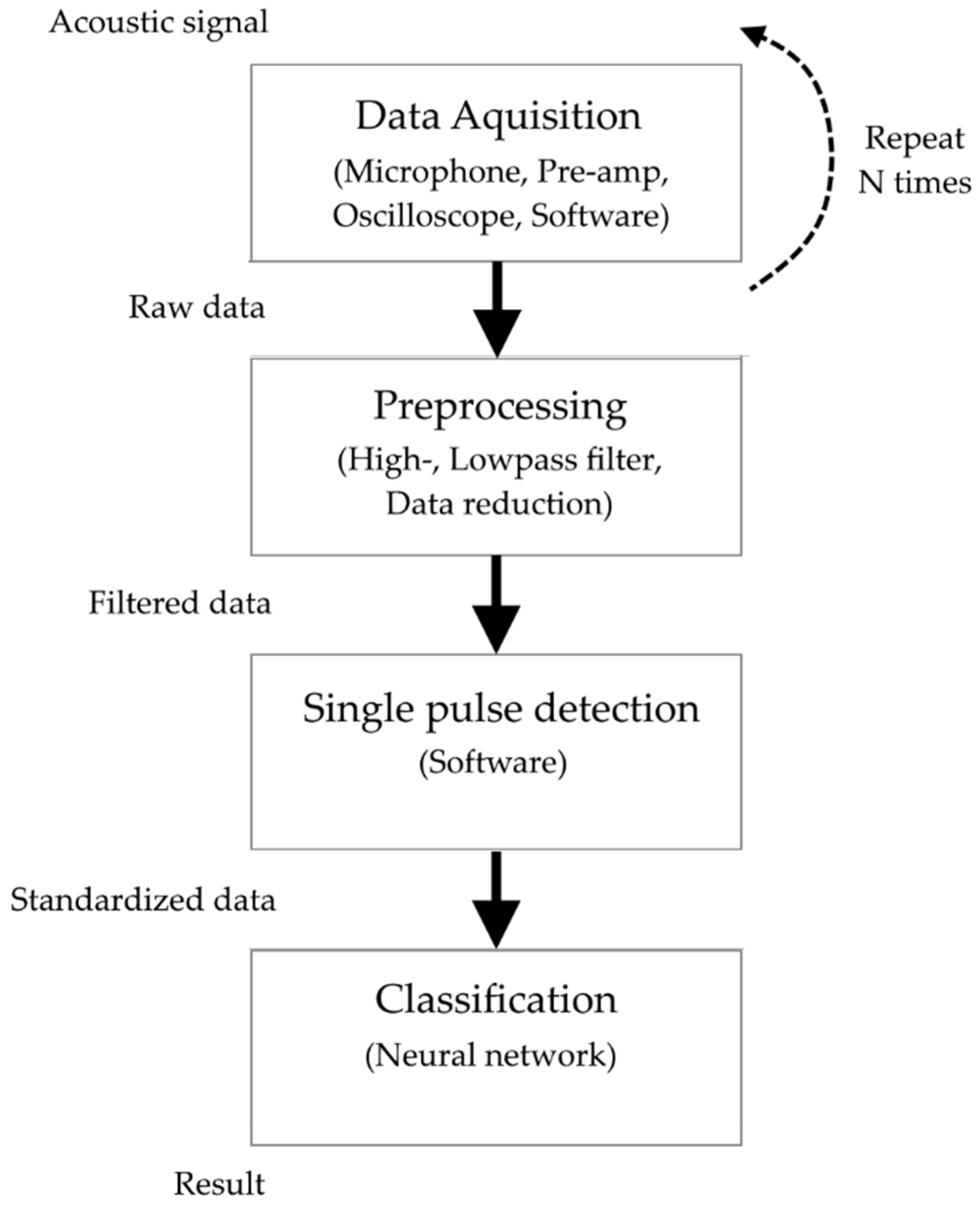

2.4.2. Signal Processing: Data Acquisition and Preprocessing

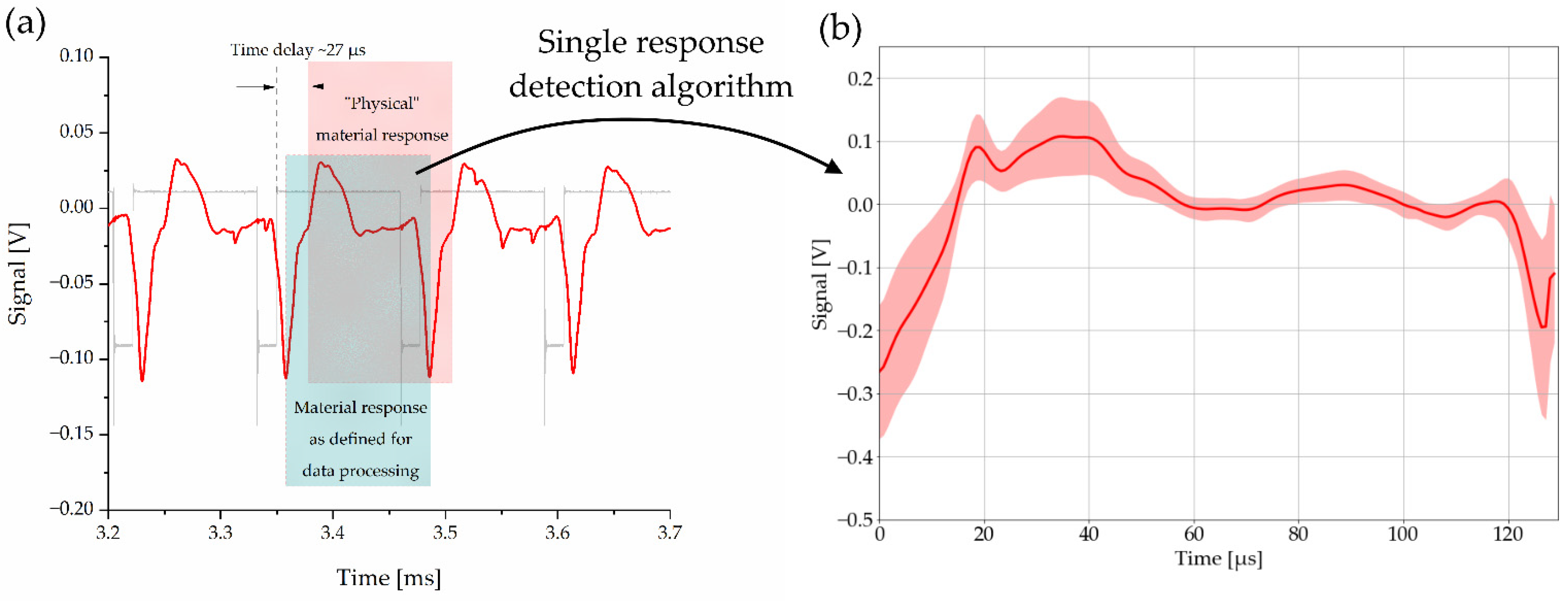

2.4.3. Signal Processing: Detection of LAMR

2.5. Classification

2.5.1. Structure of the Neural Network

2.5.2. Pulse Salvo Classification

2.5.3. Stress Tests

- Increased distance of the microphone (+5 mm);

- Changed angle of the microphone (60° instead of 45°);

- Red instead of black plastic (only for PU, PMMA, PP, PS, and PVC);

- Typical ambient noise during recording.

2.5.4. Confusion Matrices

3. Results

3.1. Physical Background of Laser-Induced Ablation

3.2. Analysis of the Laser-Acoustic Material Responses

3.2.1. General Description

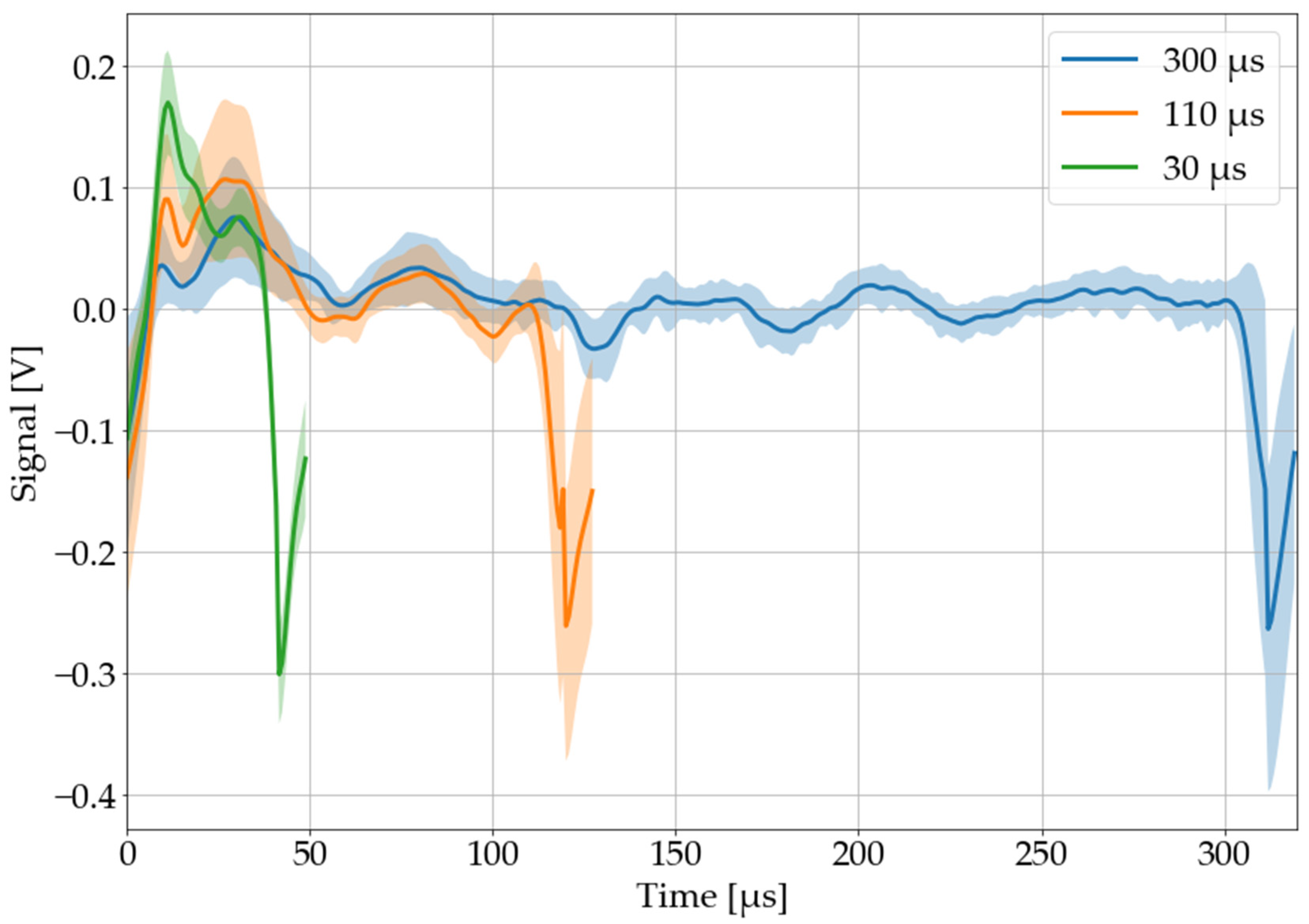

3.2.2. Pulse Length

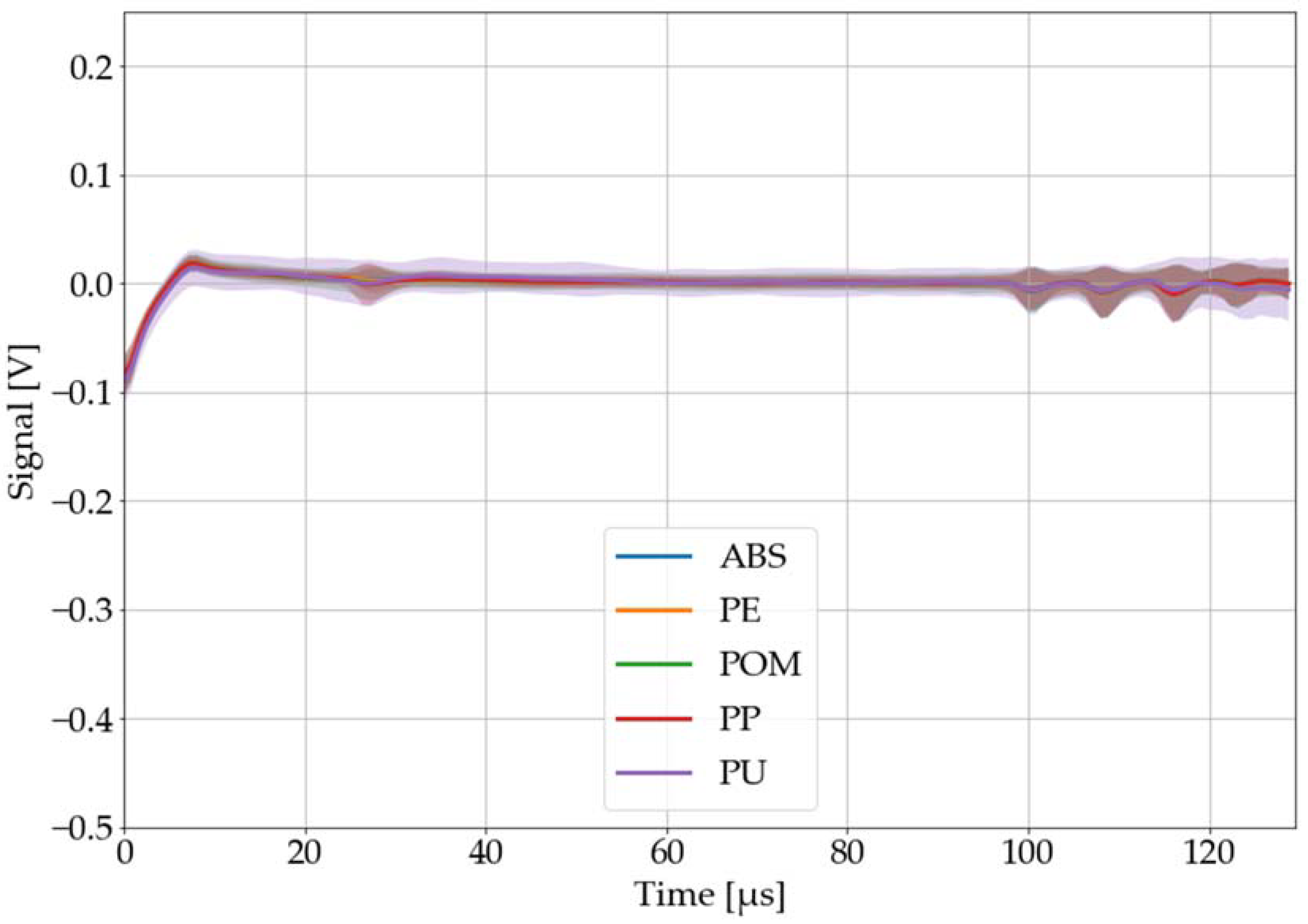

3.2.3. Sample Material

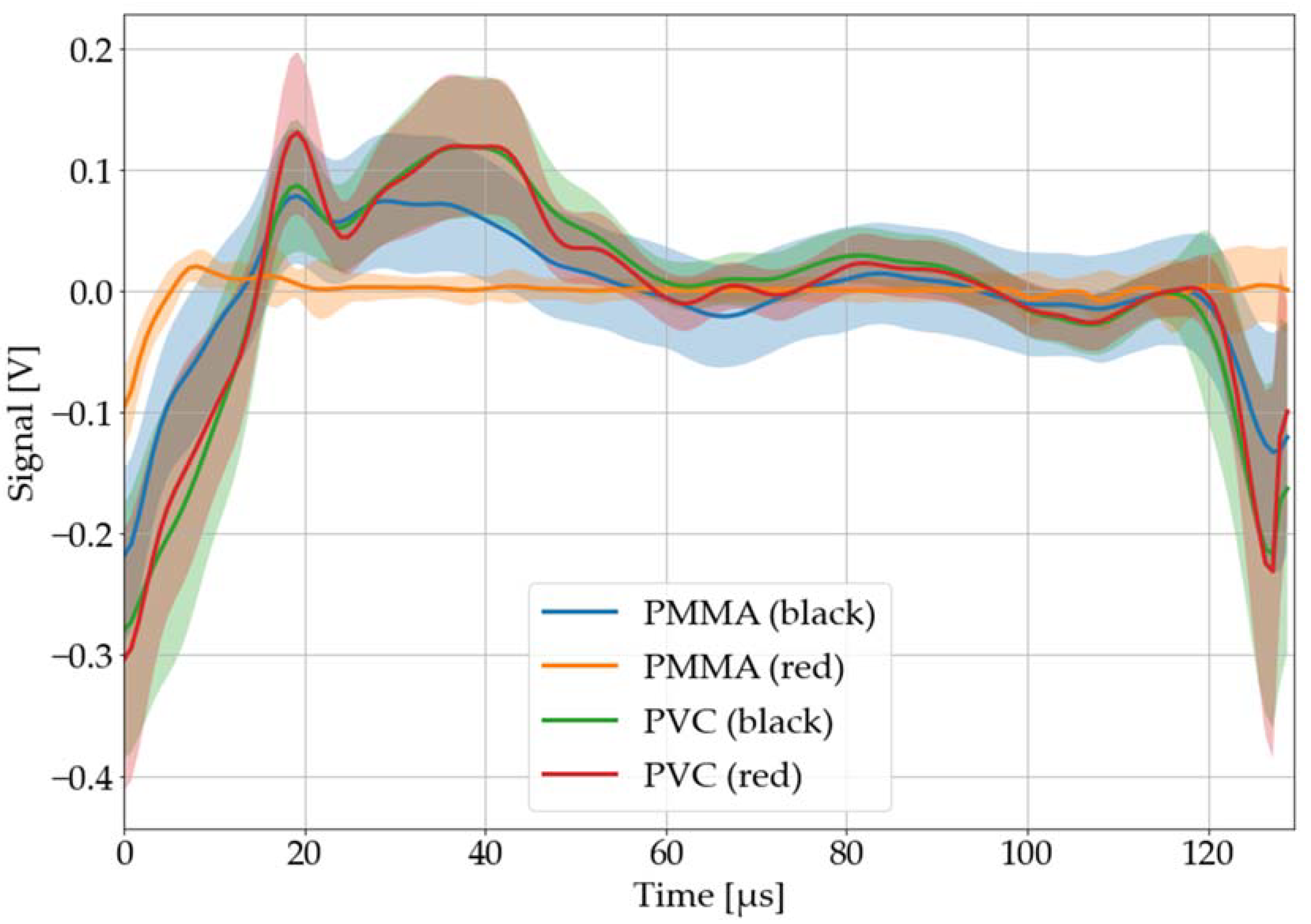

3.2.4. Color of Sample Material

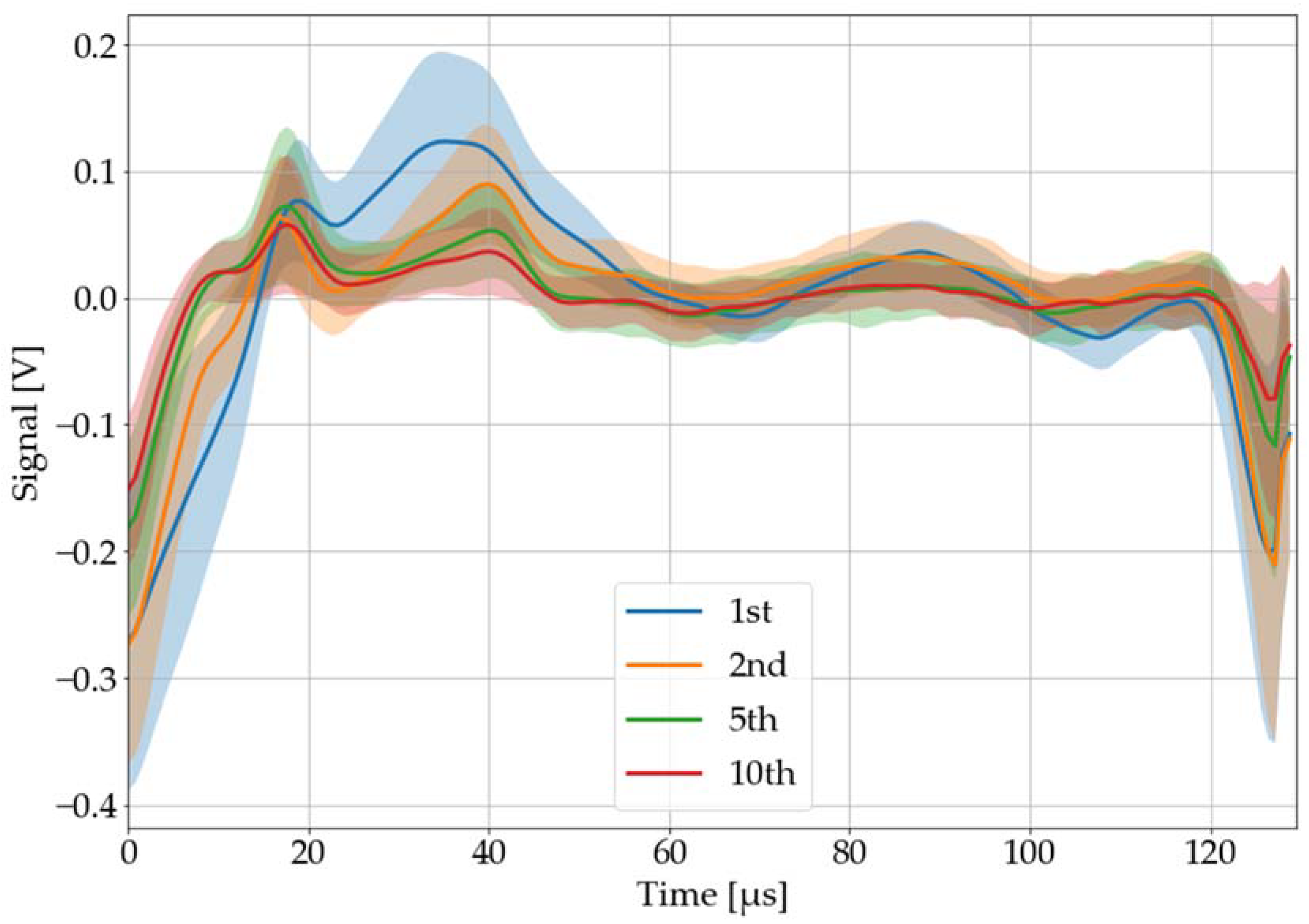

3.2.5. Number of Pulse Salvos

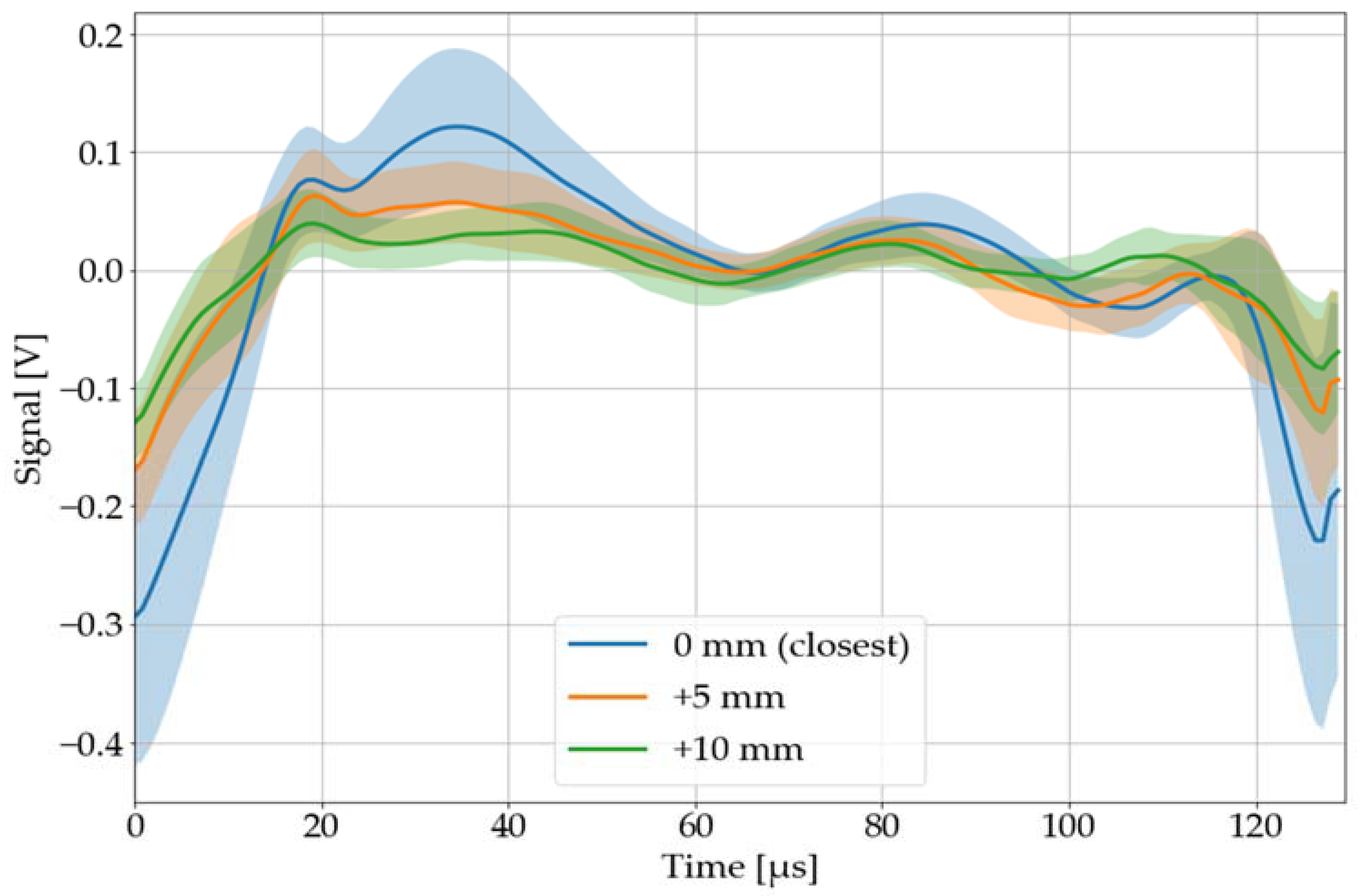

3.2.6. Position of the Microphone

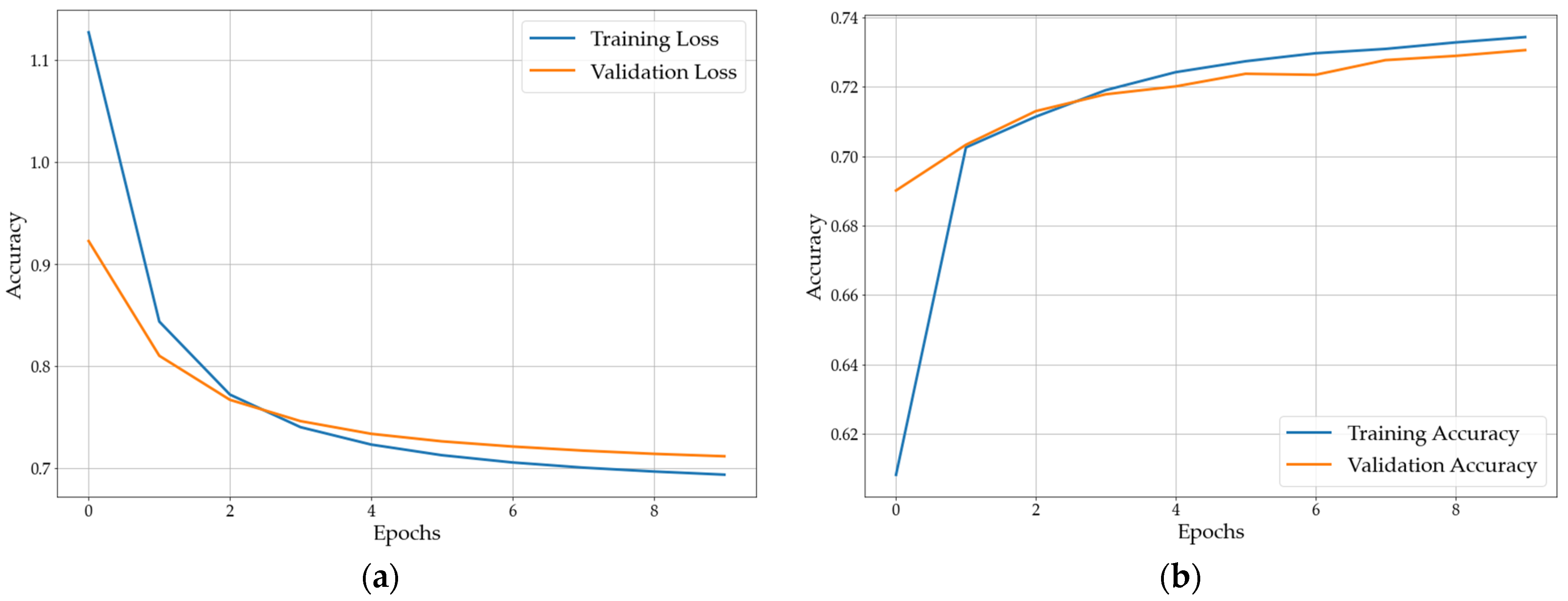

3.3. Performance of the Neural Network

3.3.1. Single Pulse Classification

3.3.2. Pulse Salvo Classification

3.4. PVC Identification under Real-Life Conditions

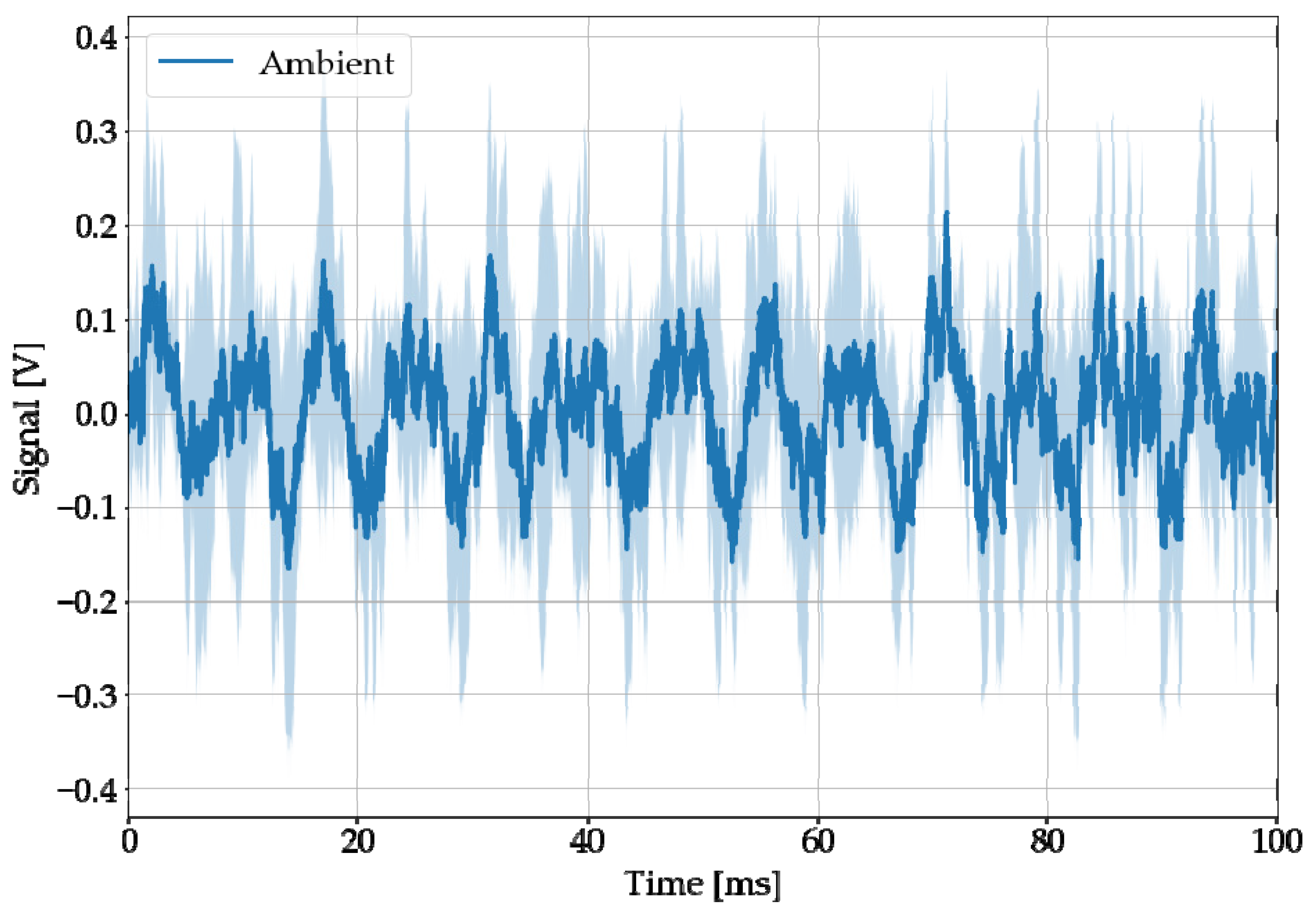

3.4.1. Noise

3.4.2. Position of the Microphone

3.4.3. Color

4. Discussion

4.1. Material-Specific Laseracoustics with a Laser Diode

4.2. PVC Identification by a Neural Network Classification

4.2.1. Strengths

4.2.2. Limits and Areas for Improvement

4.2.3. Impact

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zheng, Y.; Bai, J.; Xu, J.; Li, X.; Zhang, Y. A discrimination model in waste plastics sorting using NIR hyperspectral imaging system. Waste Manag. 2018, 72, 87–98. [Google Scholar] [CrossRef] [PubMed]

- Xia, J.; Huang, Y.; Li, Q.; Xiong, Y.; Min, S. Convolutional neural network with near-infrared spectroscopy for plastic discrimination. Environ. Chem. Lett. 2021, 19, 3547–3555. [Google Scholar] [CrossRef]

- Rozenstein, O.; Puckrin, E.; Adamowski, J. Development of a new approach based on midwave infrared spectroscopy for post-consumer black plastic waste sorting in the recycling industry. Waste Manag. 2017, 68, 38–44. [Google Scholar] [CrossRef] [PubMed]

- Vahid Dastjerdi, M.; Mousavi, S.J.; Soltanolkotabi, M.; Nezarati Zadeh, A. Identification and Sorting of PVC Polymer in Recycling Process by Laser-Induced Breakdown Spectroscopy (LIBS) Combined with Support Vector Machine (SVM) Model. Iran. J. Sci. Technol. Trans. A Sci. 2016, 42, 959–965. [Google Scholar] [CrossRef]

- Zhong, H.; Duan, T.; Lan, H.; Zhou, M.; Gao, F. Review of Low-Cost Photoacoustic Sensing and Imaging Based on Laser Diode and Light-Emitting Diode. Sensor 2018, 18, 2264. [Google Scholar] [CrossRef] [PubMed]

- Leung, W.P.; Tam, A.C. Noncontact monitoring of laser ablation using a miniature piezoelectric probe to detect photoacoustic pulses in air. Appl. Phys. Lett. 1992, 60, 23–25. [Google Scholar] [CrossRef]

- Jean, B.; Bende, T.; Matallana-Kielmann, M. Verfahren und Vorrichtung zur Materialuntersuchung mit Einem Laser (Patent no. DE 43 00 378 A1); German Patent and Trade Mark Office: Munich, Germany, 1993. [Google Scholar]

- Bende, T.; Matallana, M.; Kleffner, B.; Ostertag, M.; Jean, B. Noncontact photoacoustic spectroscopy (NCPAS) during photoablation: A step toward the smart laser? Ophthalmic Technol. V 1995, 2393, 111–119. [Google Scholar]

- Specht, H.; Bende, T.; Jean, B.; Fruehauf, W. Noncontact photoacoustic spectroscopy (NCPAS) for photoablation control: Data acquisition and analysis using cluster analysis. Ophthalmic Technol. IX 1999, 3591, 33–38. [Google Scholar]

- Grieb, N.; Oltrup, T.; Bende, T.; Leitritz, M.A. The Cosine Similarity Technique: A new method for smart EXCIMER laser control. Z. Med. Phys. 2020, 30, 253–258. [Google Scholar] [CrossRef] [PubMed]

- Grad, L.; Možina, J. Acoustic in situ monitoring of excimer laser ablation of different ceramics. Appl. Surf. Sci. 1993, 69, 370–375. [Google Scholar] [CrossRef]

- Stauter, C.; Gérard, P.; Fontaine, J.; Engel, T. Laser ablation acoustical monitoring. Appl. Surf. Sci. 1997, 109–110, 174–178. [Google Scholar] [CrossRef]

- Fischer, B.; Rohringer, W.; Panzer, N.; Hecker, S. Acoustic Process Control for Laser Material Processing. Laser Tech. J. 2017, 14, 21–25. [Google Scholar] [CrossRef]

- Schmidt, L.; Römer, F.; Böttger, D.; Leinenbach, F.; Straß, B.; Wolter, B.; Schricker, K.; Seibold, M.; Pierre Bergmann, J.; Del Galdo, G. Acoustic process monitoring in laser beam welding. Procedia CIRP 2020, 94, 763–768. [Google Scholar] [CrossRef]

- Von Alvensleben, F.; Sheng, P.; Chryssolouris, G. Process Control of Laser Grooving Using Acoustic Sensing. J. Eng. Ind. 1991, 113, 268–275. [Google Scholar]

- Altshuler, G.B.; Belikov, A.V.; Boiko, K.N.; Erofeev, A.V.; Vitiaz, I.V. Acoustic response of hard dental tissues to pulsed laser action. Dent. Appl. Lasers 1993, 2080, 97–103. [Google Scholar]

- Altshuler, G.B.; Belikov, A.V.; Erofeev, A.V.; Scrypnik, A.V. Hard tooth tissue acoustic response under contact of YAG:Er laser radiation processing. In Proceedings of the Laser Applications in Medicine and Dentistry, Vienna, Austria, 3 December 1996; pp. 228–232. [Google Scholar]

- Grad, L.; Možina, J.; Šušterčič, D.; Funduk, N.; Skalerič, U.; Lukač, M.; Cenčič, S.; Nemeš, K. Optoacoustic studies of Er:YAG laser ablation in hard dental tissue. Laser Surg. Adv. Charact. Ther. Syst. IV 1994, 2128, 456–465. [Google Scholar]

- Nahen, K.; Vogel, A. Investigations on acoustic on-line monitoring of IR laser ablation of burned skin. Lasers Surg. Med. 1999, 25, 69–78. [Google Scholar] [CrossRef]

- Gao, F.; Feng, X.; Zhang, R.; Liu, S.; Ding, R.; Kishor, R.; Zheng, Y. Single laser pulse generates dual photoacoustic signals for differential contrast photoacoustic imaging. Sci. Rep. 2017, 7, 626. [Google Scholar] [CrossRef] [PubMed]

| True Values | Guesses | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Total | ABS | PU | PET | PMMA | PP | PS | PVC | Accuracy | |

| ABS | 245 | 113 | 17 | 0 | 3 | 6 | 106 | 0 | 46.1% |

| PU | 376 | 85 | 68 | 1 | 60 | 8 | 140 | 14 | 18.1% |

| PET | 1530 | 50 | 10 | 1355 | 7 | 1 | 71 | 36 | 88.6% |

| PMMA | 1463 | 77 | 24 | 1 | 1028 | 3 | 64 | 266 | 70.3% |

| PP | 333 | 127 | 43 | 0 | 0 | 17 | 146 | 0 | 5.1% |

| PS | 366 | 97 | 24 | 0 | 25 | 8 | 201 | 11 | 54.9% |

| PVC | 1548 | 72 | 17 | 49 | 142 | 4 | 54 | 1210 | 78.2% |

| Specificity | 91.7% | 97.6% | 98.8% | 94.9% | 99.4% | 90.4% | 93.0% | ||

| True Values | Guesses | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Total | ABS | PU | PET | PMMA | PP | PS | PVC | Accuracy | |

| ABS | 5 | 5 | 0 | 0 | 0 | 0 | 0 | 0 | 100% |

| PU | 5 | 1 | 0 | 0 | 0 | 0 | 4 | 0 | 0% |

| PET | 5 | 0 | 0 | 5 | 0 | 0 | 0 | 0 | 100% |

| PMMA | 5 | 0 | 0 | 0 | 5 | 0 | 0 | 0 | 100% |

| PP | 5 | 1 | 0 | 0 | 0 | 0 | 4 | 0 | 0% |

| PS | 5 | 0 | 0 | 0 | 0 | 0 | 5 | 0 | 100% |

| PVC | 5 | 0 | 0 | 0 | 0 | 0 | 0 | 5 | 100% |

| Specificity | 93.7% | 100% | 100% | 100% | 100% | 78.9% | 100% | ||

| True Values | Guesses | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Total | ABS | PU | PET | PMMA | PP | PS | PVC | Accuracy | |

| ABS | 5 | 0 | 0 | 0 | 0 | 0 | 5 | 0 | 0% |

| PU | 5 | 0 | 0 | 0 | 0 | 0 | 5 | 0 | 0% |

| PET | 5 | 0 | 0 | 5 | 0 | 0 | 0 | 0 | 100% |

| PMMA | 5 | 0 | 0 | 0 | 5 | 0 | 0 | 0 | 100% |

| PP | 5 | 0 | 0 | 0 | 0 | 0 | 5 | 0 | 0% |

| PS | 5 | 0 | 0 | 0 | 0 | 0 | 5 | 0 | 100% |

| PVC | 5 | 0 | 0 | 0 | 0 | 0 | 1 | 4 | 80% |

| Specificity | 100% | 100% | 100% | 100% | 100% | 58.8% | 100% | ||

| True Values | Guesses | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Total | ABS | PU | PET | PMMA | PP | PS | PVC | Accuracy | |

| Red PU | 5 | 0 | 1 | 0 | 0 | 0 | 4 | 0 | 20% |

| Red PMMA | 5 | 0 | 0 | 0 | 0 | 0 | 5 | 0 | 0% |

| Red PP | 5 | 2 | 1 | 0 | 0 | 0 | 2 | 0 | 0% |

| Red PS | 5 | 0 | 0 | 0 | 5 | 0 | 0 | 0 | 0% |

| Red PVC | 5 | 0 | 0 | 0 | 0 | 0 | 0 | 5 | 100% |

| Specificity | 92.6% | 96.1% | 100% | 83.3% | 100% | 69.4% | 100% | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Timmermann, E.; Geißler, P.; Bansemer, R. Low-Cost Laser-Acoustic PVC Identification System Based on a Simple Neural Network. Sensors 2022, 22, 8035. https://doi.org/10.3390/s22208035

Timmermann E, Geißler P, Bansemer R. Low-Cost Laser-Acoustic PVC Identification System Based on a Simple Neural Network. Sensors. 2022; 22(20):8035. https://doi.org/10.3390/s22208035

Chicago/Turabian StyleTimmermann, Eric, Philip Geißler, and Robert Bansemer. 2022. "Low-Cost Laser-Acoustic PVC Identification System Based on a Simple Neural Network" Sensors 22, no. 20: 8035. https://doi.org/10.3390/s22208035

APA StyleTimmermann, E., Geißler, P., & Bansemer, R. (2022). Low-Cost Laser-Acoustic PVC Identification System Based on a Simple Neural Network. Sensors, 22(20), 8035. https://doi.org/10.3390/s22208035