Digital Twin for a Multifunctional Technology of Flexible Assembly on a Mechatronics Line with Integrated Robotic Systems and Mobile Visual Sensor—Challenges towards Industry 5.0 †

Abstract

:1. Introduction

- Additive manufacturing: Additive manufacturing, also known as 3D printing, is a process used to create a physical or 3D object by layering materials one by one based on a digital model [20];

- Autodesk software: Advanced manufacturing software allows you to make anything you want;

- Augmented reality: Augmented reality, virtual reality, and mixed reality involve immersive technologies to revolutionize data interaction and project collaboration between team members and how people interact with their data;

- Digital transformation: Digital transformation means convergence for connecting organizations using data, while bridging the gap to bring together different disciplines, such as computer aided design (CAD), computer aided manufacturing (CAM), or computer aided engineering (CAE), collaboration by accessing data via the cloud, for connecting your entire manufacturing ecosystem and automation for removing the delays, and using generative design and robotics to streamline multiple processes and accelerate product development;

- Generative design: Generative design quickly generates high-performing design alternatives and multiple solutions to solve the needs;

- Simulation: Simulation software allows predicting, validating, and optimizing products using accurate analysis.

2. The Hardware Architecture of Multifunctional Flexible Manufacturing Technology Running on A/D/RML Assisted by CAS

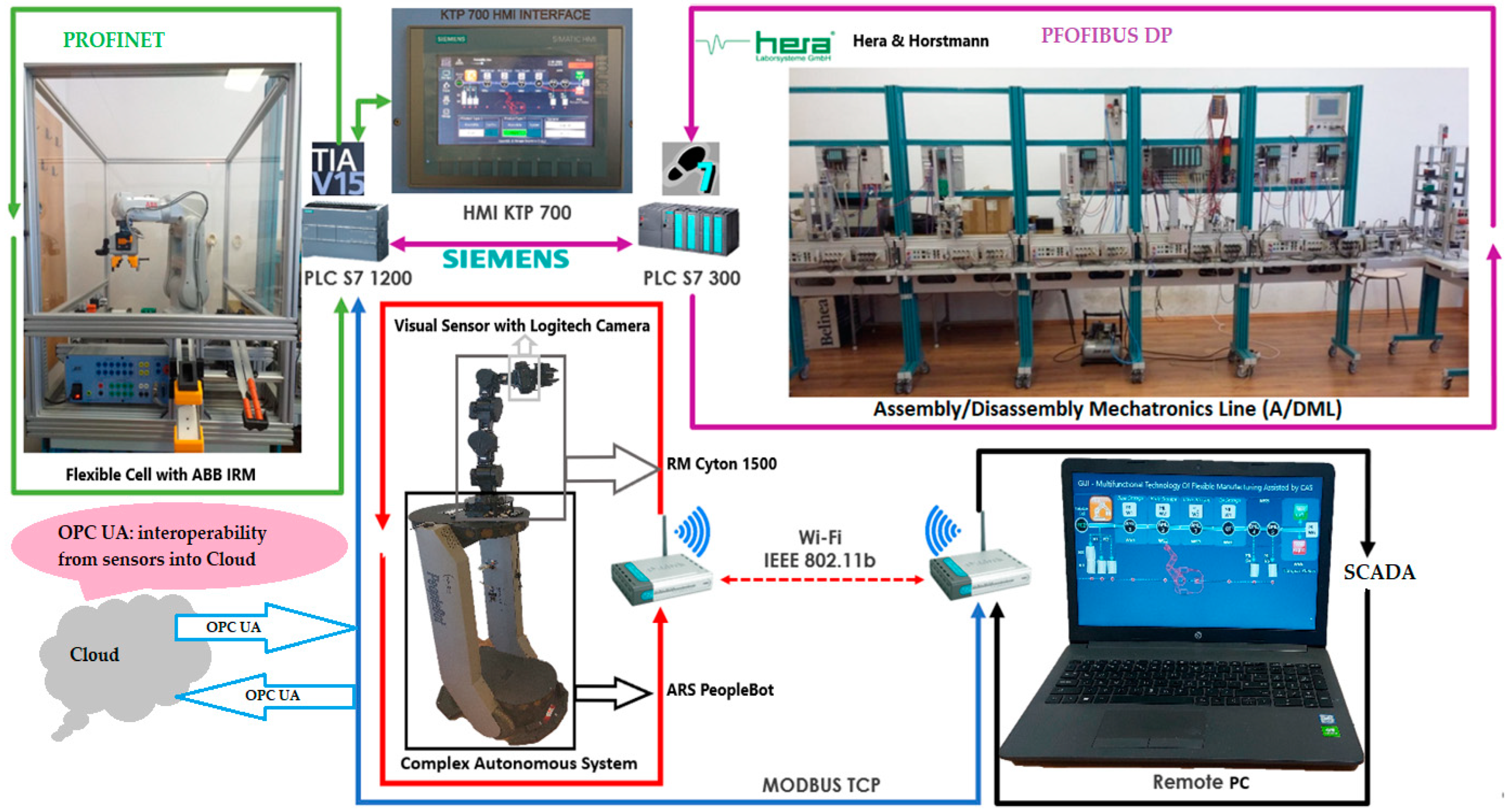

2.1. Hardware Architecture

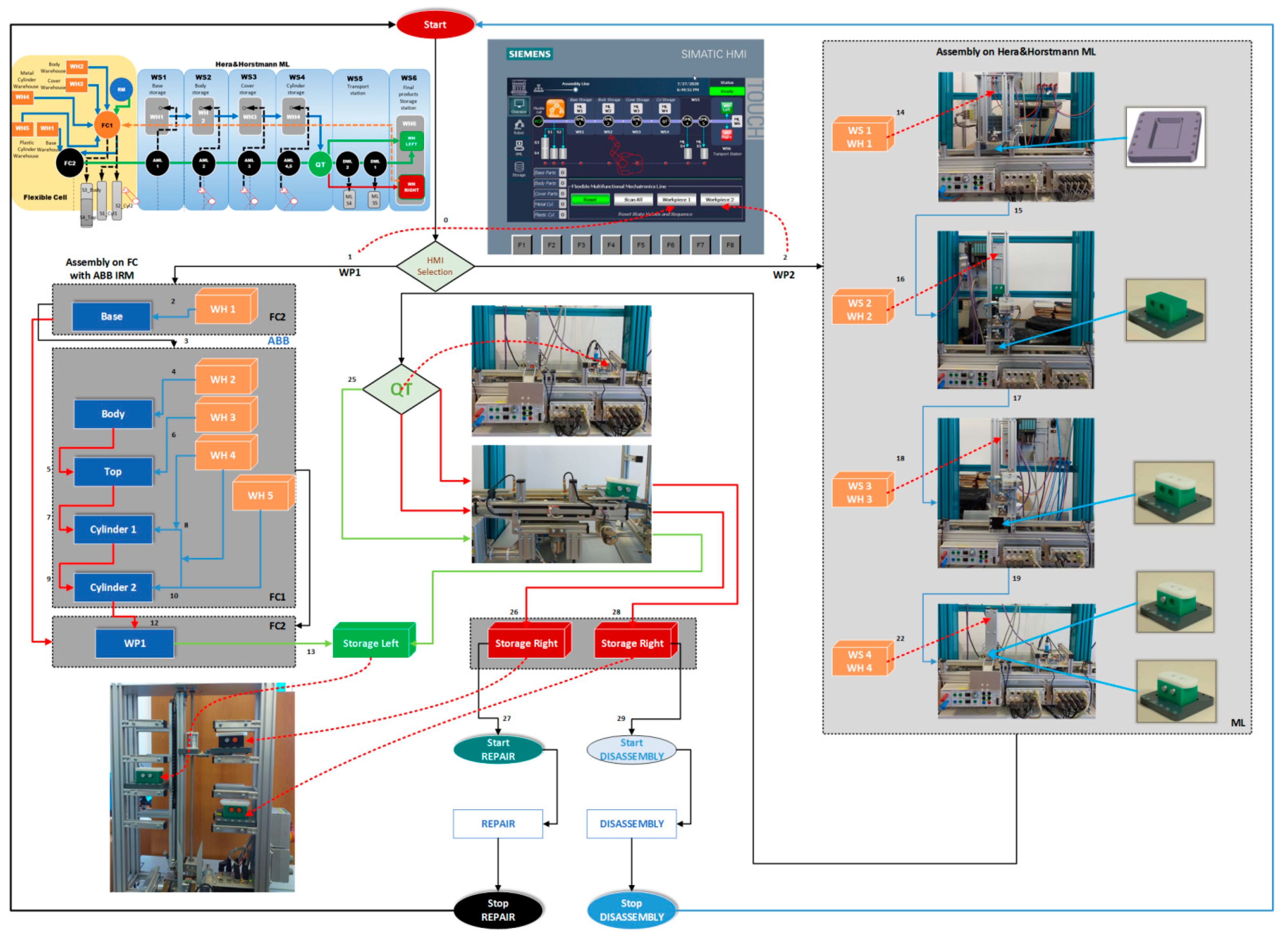

- FC with 6-DOF ABB IRB120 station used for assembly, disassembly, and repair of the workpieces with buffer, handling, processing, and transport capability, Figure 1 and Figure 2a. FC station with 6-DOF ABB RM used for assembly, disassembly, and repair of the workpieces with buffer, handling, processing, and transport capability. FC has as its main components a 6-DOF RM pick-and-place, a Siemens S7-1200 PLC, and a controlled assembly/disassembly unit, which handles the supply of workparts (components) for the workpiece product type 1 (WP1), disassembly, and repair for the second workpiece (WP2);

- A/DML is a 6-workstation (6-WS) Hera & Horstmann ML, which together can perform the following operations: A/D, transport, checking, and storage of assembled workpieces, Figure 1 and Figure 2b. It is a laboratory mechatronic line for didactic and research use. The parts to be assembled are: (1) pallet (base), (2) body, (3) top with triangular edges, (4) top with rounded edges, (5) metal cylinder and (6) plastic cylinder, Figure 3a. The assembled workpieces with metal, plastic, or different material cylinders are shown in Figure 3b–d, respectively. The stations are equipped with inductive sensors that work as position or verification sensors. WS1 is the station where the warehouse with the pallets is located. Base is the support of the workpiece and is equipped with a 6-bit coding system, which offers many large codes, identified by means of inductive sensors. The workpiece that is assembled on the A/DML consists of four parts, (1), (2), (4), (5), and (6), being subjected to assembly, testing, sorting, and storage. The disassembly is not used in this paper. WS2 is the station where the warehouse with component (2), WH2, is located. WS3 is the station where the warehouse with component (4), WH3, is located. Component (3) is assembled only in FC. In WS4, the warehouse with components (5) and (6), WH4, and the test post for the cylinders, QT, are located. WS5 is a multidirectional conveyor station. WS 6 is the final two racks storage station. The stations are equipped with conveyor belts and inductive position sensors, which, by means of pneumatic actuators, perform localization of the workpiece. The control architecture is a distributed one consisting of: SIEMENS S7-300 PLC with a CP 314C-2 DP series processor, CP 343-2 communication module, and ET 200S IM 151-1 distributed on each station, having digital and analog I/O for signals from sensors and commands to actuators. All are connected to PROFIBUS DP. HMI TP 177 is connected to the PROFIBUS DP as terminal, used to select commands and view assembled final products, and stored in WS6.

- CAS is PeopleBot WMR equipped with a 7-DOF Cyton 1500 RM used for recovery and transport/return operation of the disassembled workparts and a mobile VSS [2]. The CAS, shown in Figure 1, is composed of the following elements: a 7-DOF Cyton 1500 RM equipped with an eye-in-hand type of MVSS, using a high-definition camera (visual sensor), both being connected to a computer via USB, and synchronously communicating with the A/D/RML over Wi-Fi. The RM is placed on the PeopleBot, which is a WMR with two driving wheels and one free wheel (2DW/1FW). The CAS is used to transport the recoverable workpart, picked up by the Cyton 1500 RM, to the appropriate storage warehouse if the assembled piece WP2 has failed the quality test and will be disassembled or repaired.

2.2. Assuptions Regarding Hardware Arhitecture

2.3. Flexible Assembly

2.4. Multifunctional Manufacturing Technology, Assembly, Disassembly, and Repair

2.4.1. Assembly

2.4.2. Disassembly

2.4.3. Repair

3. The Virtual World as a Digital Counterpart of Multifunctional Flexible Manufacturing Technology

3.1. Virtual Digital Counterpart Regarding Assembly

3.1.1. Assumptions

3.1.2. Task Assignment, Planning, and Synchronization

3.1.3. SPN Model, Formalism, and Simulation

- is the places set partitioned in:

- is the transitions set partitioned in:

- For WP1 assembly on FC with ABB IRM, the monitoring places in the set (7) monitor the transitions in the set (8) as follows: P43(T1_monitoring), P44(T6_monitoring), P46(T8_monitoring), P47(T10_monitoring), P48(T12_monitoring), P49(T12_monitoring), P50(T16_monitoring), P51(T17_monitoring).

- For WP2 assembly on Hera & Horstmann ML, the monitoring places in the set (7) monitor the transitions in the set (8) as follows: P52(T19_monitoring), P53(T20_monitoring), P54(T22_monitoring), P55(T23_monitoring), P56(T25_monitoring), P57(T26_monitoring), P58(T28_monitoring), P59(T29_monitoring), P60(T30_monitoring), P61(T31_monitoring), P62(T32_monitoring).

- is the input incidence function.

- is the output incidence function.

- is the initial marking of the SPN corresponding to the initial state of the modeled process.

- is a function that defines the timings associated to the transitions.

- Ed1 = Svnc1_A is synchronization signal for: (START assembly of WP1) with (END assembly of WP1).

- Ed2 = Svnc2_A is synchronization signal for: (START assembly of WP2) with (END assembly of WP2).

- Ed3 = Svnc3_D is synchronization signal for: (START assembly of WP1) with (END disassembly of WP2).

- Ed4 = Svnc4_R is synchronization signal for: (START assembly of WP1) with (END repair of WP2).

3.2. Virtual Digital Counterpart Regarding Dissasembly

3.2.1. Assumptions

3.2.2. Task Assignment, Planning, and Synchronization

3.2.3. SHPN Model, Formalism, and Simulation

- T is the transitions set partitioned in:

- P is the places set partitioned in:

- Pre: P × T → Q+ is the input incidence function.

- Pre: P × T → Q+ is the input incidence function.

- Post: P × T → Q+ is the output incidence function.

- is function that defines the timings associated to the transitions.

3.3. Virtual Digital Counterpart Regarding Repair Function

3.3.1. Assumptions

3.3.2. Task Assignment, Planning, and Synchronization

3.3.3. SHPN_2 Model, Formalism, and Simulation

- T is the transitions set partitioned in:

- is the places set partitioned in:

- is the input incidence function.

- is the output incidence function.

- is function that defines the time durations associated to the transitions.

- is a set of external events, where:

- The QT1 and QT2 sequences check the registry of the quality test. Thus, QT1 and QT2 activate one of the and controls that launches the corresponding repair sequence.

- WP2 is transported to the FC1 station of the flexible cell (P15, P18) where the plastic cylinder is replaced with the metal cylinder. In the S1 or S2 trough, the extracted cylinder is released and is then transported by CAS to the WS4 storage on the ML. WP2, thus repaired, will follow the storage sequence in WH Left.

- The presence of the plastic cylinder in S1_Cyl2 or S2_Cyl2 is synchronized with CAS travel for Cylinder 1 recovering or CAS travel for Cylinder 2 recovering, by .

- The completion of the repair process is synchronized with START a new assembly, through the signal , which is found in the SHPN model of the assembly.

- moving from the parking position or to the drawer S1 or S2 , where OA is in red and OC in the blue line, Figure 15a,b, respectively;

- moving from or C to WS4 or , where AB is in green and CB in the blue line, Figure 15a,b, respectively;

- moving from WS4 to the parking position or from WS4 to the parking position , where BO is in blue and in the green line, Figure 15a,b.

3.4. Virtual Digital Counterpart Regarding CAS

4. Real Counterpart Control of Multifunctional Technology Running on A/D/RML Assisted by CAS

4.1. Real Counterpart Communication and Control of A/D/RML

- data acquisition through digital and analogue I/O from FC, A/DML, and CAS for monitoring and control of all sensors;

- data communication, to and from FC, A/DML, and CAS, in which sensors, PLCs, and Remote PC are involved, is necessary for monitoring and remote control of multifunctional technology from a single location through the network of communications. Siemens CM 1242-5 attached to PLC S7-1200 (see Figure 1 and Figure 18) is a device used for communication, having the role of connecting the master PLC (SIEMENS PLC S7-1200), located in FC, with A/DML through Profibus. The SIMATIC S7-1200 module allows connection as a slave to Profibus DP through the CM 1242-5 device that complies with IEC 61158 standards. Thus, it manages traffic autonomously and relieves the main PLC, PLC S7-1200, of communication tasks. CM 1242-5A manages communication data in two directions, one physical and another data link, processing the s signal it receives or sends, and validates the cyclic data transfer between DP master S7-300 PLC from A/DML slave Profibus DP for process data transfer between Profibus DP slaves [3,34];

- displays data and information on SIEMENS HMI SIMATIC KTP 700, HMI TP 177, and Remote PC is performed in a format readable by the human operator through friendly and suggestive GUIs that facilitate a more efficient interaction between the operator and related subsystems: FC, A/DML, and CAS. This represents one of the needs and attributes of Industry 5.0 (see Figure 1);

- remote control, in the network, through SCADA Remote PC, of the devices in the distributed system, of the pending outputs and the synchronization signals from the PLCs, thus facilitating the quick intervention of the operator.

4.2. Real Counterpart Syncronisation and Control of CAS’s Subsystems

- PeopleBot WMR travel control loop is for moving from FC to storage warehouses of disassembled components and from FC to their placement on dedicated storage warehouses on A/DML. The control method is discrete-time TTSMC. The functions from Aria Mobile Robots are called. Communication with the FC is performed wirelessly using a USB over Ethernet 704 adapter and a specific TCP/IP protocol.

- Control loop for eye-in-hand VSS is based on the image moments method, for end effector movement of Cyton RM. Communication is also performed wirelessly between Remote PC and MVSS, for accurate pick-and-place positioning of the robot [3,39,40,41,42,43,44,45]. The control method calls functions from the OpenCV open-source library [46] and MATLAB image processing toolbox [2,47]. All three control loops communicate through Remote PC, which also acts as a SCADA server, controls the CAS, MVSS, and Cyton RM, and manages the synchronization with the FC and A/DML.

4.3. Real Counterpart Control of the MVSS and Cyton RM

- one shoulder type articulation, characterized by three angles;

- one elbow type articulation, characterized by one angle;

- one wrist type articulation, characterized by three angles.

4.4. Real Counterpart Control of CAS PeopleBot Assisting A/D/RML during Disassembly

5. Discussions

- Digital twin with augmented reality (AR) component represents the integration of the virtual and real environments, where objects in the real world are enhanced by computer-generated information or objects that help the multi-functional flexible assembly technology. Thus, SHPN was used for technology modeling in which A/D/RML has a discrete dynamic and MCPS a continuous one;

- The “Digital twin” concept enables optimizing the production line and predictive maintenance that can improve efficiency and detect problems in time. By means of the virtual world model as counterpart of the real one, defects and problems that may appear in the production process can be detected in advance;

- The simulation of SHPN and MCPS models is a powerful tool used for decision-making. By using the simulation results, the monitoring and control methods become easier to apply, together with the developments in the field of digitalization;

- The use of MCPS as an autonomous robotic system, equipped with RM and positioning and navigation sensors, represents a complex, next-generation system with computational and physical capabilities that can interact with humans in new ways;

- Artificial intelligence supports MCPS, A/D/RML PLCs, HMIs, and SCADA by filtering sensor data from the manufacturing system, thus providing data-driven predictive analysis and the ability to assist in decision-making;

- Through OPC UA, access to cloud computing and IoT is facilitated, allowing access to large data sets and their processing to generate new useful information for the manufacturing process and multifunctional technology. As I mentioned above, OPC UA is the communication data structure between SCADA and SIEMENS PLC S7-1200, which, integrated in an industrial manufacturing technology, ensures compatibility and safe data exchange between the industrial equipment of the different providers of software;

- Because the multifunctional technology through disassembly and repair functions allows the recovery and reuse of components, it ensures the sustainability of the production system. Sustainability is an important component of Industry 5.0, which focuses on the reuse and recycling of natural resources and reducing waste and environmental impact;

- Since the hardware configuration and management methods of A/D/RML and MCPS ensure the robustness of all subsystems to defects and uncertainties, the resilience of the production system is conferred, being another concept that is specific to Industry 5.0. Robustness provides support through flexible processes and adaptable manufacturing capabilities, especially when a crisis occurs;

- Last but not least, through the graphic user interfaces on HMIs and remote PC, an approach to multifunctional technology, centered on the human operator, was tried, a concept by which Industry 5.0 places human needs at the center of the process, asking what technology can do better and how it can be useful.

6. Conclusions

- hardware setup, assumptions, flexibility and multifunctionality;

- virtual digital counterpart for each functionality: assumptions, task planning and synchronization, SHPN model and formalism, and simulation results;

- virtual digital counterpart of the CAS: model, control, and simulation results for each component;

- real counterpart control of multifunctional technology: SCADA system, communication and control of A/D/RML, synchronization and control of CAS’s subsystems, real-time results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Guiras, Z.; Turki, S.; Rezg, N.; Dolgui, A. Optimization of Two-Level Disassembly/Remanufacturing/Assembly System with an Integrated Maintenance Strategy. Appl. Sci. 2018, 8, 666. [Google Scholar] [CrossRef] [Green Version]

- Filipescu, A.; Ionescu, D.; Filipescu, A.; Mincă, E.; Simion, G. Multifunctional Technology of Flexible Manufacturing on a Mechatronics Line with IRM and CAS, Ready for Industry 4.0. Processes 2021, 9, 864. [Google Scholar] [CrossRef]

- Ionescu, D.; Filipescu, A.; Simion, G.; Mincă, E.; Cernega, D.; Șolea, R.; Filipescu, A. Communication and Control of an Assembly, Disassembly and Repair Flexible Manufacturing Technology on a Mechatronics Line Assisted by an Autonomous Robotic System. Inventions 2022, 7, 43. [Google Scholar] [CrossRef]

- Segovia, M.; Garcia-Alfaro, J. Design, Modeling and Implementation of Digital Twins. Sensors 2022, 22, 5396. [Google Scholar] [CrossRef]

- Moiceanu, G.; Paraschiv, G. Digital Twin and Smart Manufacturing in Industries: A Bibliometric Analysis with a Focus on Industry 4.0. Sensors 2022, 22, 1388. [Google Scholar] [CrossRef]

- Chryssolouris, G. Manufacturing Systems—Theory and Practice; Springer: New York, NY, USA, 2005. [Google Scholar]

- Tolio, T. Design of Flexible Production Systems—Methodologies and Tools; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Filipescu, A. Contributions to Electric Drive of the Flexible Manufacturing Lines and Integrated Robots. Ph.D. Thesis, University of Galati, Galati, Romania, 2017. [Google Scholar]

- Carlos-Mancilla, M.A.; Luque-Vega, L.F.; Guerrero-Osuna, H.A.; Ornelas-Vargas, G.; Aguilar-Molina, Y.; González-Jiménez, L.E. Educational Mechatronics and Internet of Things: A Case Study on Dynamic Systems Using MEIoT Weather Station. Sensors 2021, 21, 181. [Google Scholar] [CrossRef]

- Florescu, A.; Barabas, S.A. Modeling and Simulation of a Flexible Manufacturing System—A Basic Component of Industry 4.0. Appl. Sci. 2020, 10, 8300. [Google Scholar] [CrossRef]

- Berriche, A.; Mhenni, F.; Mlika, A.; Choley, J.-Y. Towards Model Synchronization for Consistency Management of Mechatronic Systems. Appl. Sci. 2020, 10, 3577. [Google Scholar] [CrossRef]

- Minca, E.; Filipescu, A.; Voda, A. Modelling and control of an assembly/disassembly mechatronics line served by mobile robot with manipulator. Control Eng. Pract. 2014, 31, 50–62. [Google Scholar] [CrossRef]

- Filipescu, A.; Filipescu, A., Jr. Simulated Hybrid Model of an Autonomous Robotic System Integrated into Assembly/Disassembly Mechatronics Line. IFAC Proc. Vol. 2014, 47, 9223–9228. [Google Scholar] [CrossRef]

- Dragomir, F.; Mincă, E.; Dragomir, O.E.; Filipescu, A. Modelling and Control of Mechatronics Lines Served by Complex Autonomous Systems. Sensors 2019, 19, 3266. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Filipescu, A.; Mincă, E.; Filipescu, A.; Coandă, H.-G. Manufacturing Technology on a Mechatronics Line Assisted by Autonomous Robotic Systems, Robotic Manipulators and Visual Servoing Systems. Actuators 2020, 9, 127. [Google Scholar] [CrossRef]

- Filipescu, A.; Minca, E.; Filipescu, A. Mechatronics Manufacturing Line with Integrated Autonomous Robots and Visual Servoing Systems. In Proceedings of the 9th IEEE International Conference on Cybernetics and Intelligent Systems, and Robotics, Automation and Mechatronics (CIS-RAM 2019), Bangkok, Thailand, 18–20 November 2019; pp. 620–625. [Google Scholar]

- Minca, E.; Filipescu, A.; Coanda, H.G.; Dragomir, F.; Dragomir, O.E.; Filipescu, A. Extended Approach for Modeling and Simulation of Mechatronics Lines Served by Collaborative Mobile Robots. In Proceedings of the 22nd International Conference on System Theory, Control and Computing (ICSTCC), Sinaia, Romania, 10–12 October 2018; pp. 335–341. [Google Scholar]

- Martinez, E.M.; Ponce, P.; Macias, I.; Molina, A. Automation Pyramid as Constructor for a Complete Digital Twin, Case Study: A Didactic Manufacturing System. Sensors 2021, 21, 4656. [Google Scholar] [CrossRef] [PubMed]

- Bamunuarachchi, D.; Georgakopoulos, D.; Banerjee, A.; Jayaraman, P.P. Digital Twins Supporting Efficient Digital Industrial Transformation. Sensors 2021, 21, 6829. [Google Scholar] [CrossRef]

- Vachálek, J.; Šišmišová, D.; Vašek, P.; Fiťka, I.; Slovák, J.; Šimovec, M. Design and Implementation of Universal Cyber-Physical Model for Testing Logistic Control Algorithms of Production Line’s Digital Twin by Using Color Sensor. Sensors 2021, 21, 1842. [Google Scholar] [CrossRef]

- Gallala, A.; Kumar, A.A.; Hichri, B.; Plapper, P. Digital Twin for Human–Robot Interactions by Means of Industry 4.0 Enabling Technologies. Sensors 2022, 22, 4950. [Google Scholar] [CrossRef]

- Stączek, P.; Pizoń, J.; Danilczuk, W.; Gola, A. A Digital Twin Approach for the Improvement of an Autonomous Mobile Robots (AMR’s) Operating Environment—A Case Study. Sensors 2021, 21, 7830. [Google Scholar] [CrossRef]

- Abdul Hadi, M.; Kraus, D.; Kajmakovic, A.; Suschnigg, J.; Guiza, O.; Gashi, M.; Sopidis, G.; Vukovic, M.; Milenkovic, K.; Haslgruebler, M.; et al. Towards Flexible and Cognitive Production—Addressing the Production Challenges. Appl. Sci. 2022, 12, 8696. [Google Scholar] [CrossRef]

- Angelopoulos, J.; Mourtzis, D. An Intelligent Product Service System for Adaptive Maintenance of Engineered-to-Order Manufacturing Equipment Assisted by Augmented Reality. Appl. Sci. 2022, 12, 5349. [Google Scholar] [CrossRef]

- Mourtzis, D.; Angelopoulos, J.; Panopoulos, N. A Literature Review of the Challenges and Opportunities of the Transition from Industry 4.0 to Society 5.0. Energies 2022, 15, 6276. [Google Scholar] [CrossRef]

- Zizic, M.C.; Mladineo, M.; Gjeldum, N.; Celent, L. From Industry 4.0 towards Industry 5.0: A Review and Analysis of Paradigm Shift for the People, Organization and Technology. Energies 2022, 15, 5221. [Google Scholar] [CrossRef]

- Nahavandi, S. Industry 5.0—A Human-Centric Solution. Sustainability 2019, 11, 4371. [Google Scholar] [CrossRef] [Green Version]

- Radaschin, A.; Voda, A.; Minca, E.; Filipescu, A. Task Planning Algorithm in Hybrid Assembly/Disassembly Process. In Proceedings of the 14th IFAC Symposium on Information Control Problems in Manufacturing, Bucharest, Romania, 23–25 May 2012. [Google Scholar]

- Kallrath, J. Planning and scheduling in the process industry. In Advance Planning and Scheduling Solution in Process Industry; Springer: Berlin/Heidelberg, Germany, 2003; pp. 201–227. [Google Scholar]

- He, Y.; Stecke, K.E.; Smith, M.L. Robot and machine scheduling with state-dependent part input sequencing in flexible manufacturing systems. Int. J. Prod. Res. 2016, 54, 6736–6746. [Google Scholar] [CrossRef]

- Barczak, A.; Dembińska, I.; Marzantowicz, Ł. Analysis of the Risk Impact of Implementing Digital Innovations for Logistics Management. Processes 2019, 7, 815. [Google Scholar] [CrossRef] [Green Version]

- Sirphyco Simulateur de Réseaux de Petri, Sirphyco-Simulateur-de-Reseaux-de-Petri. Available online: Toucharger.com (accessed on 17 October 2022).

- Mobile Robots Simulator. Available online: https://web.archive.org/web/20180205220201/http://robots.mobilerobots.com/wiki/MobileSim (accessed on 17 October 2022).

- Totally Integrated Automation Portal. Available online: www.siemens.com/tia-portal (accessed on 17 October 2022).

- Gasparetto, A.; Zanotto, V. A new method for smooth trajectory planning of robot manipulators. Mech. Mach. Theory 2007, 42, 455–471. [Google Scholar] [CrossRef]

- Fan, Y.; Lv, X.; Lin, J.; Ma, J.; Zhang, G.; Zhang, L. Autonomous Operation Method of Multi-DOF Robotic Arm Based on Binocular Vision. Appl. Sci. 2019, 9, 5294. [Google Scholar] [CrossRef] [Green Version]

- Ravankar, A.; Ravankar, A.A.; Kobayashi, Y.; Hoshino, Y.; Peng, C.-C. Path Smoothing Techniques in Robot Navigation: State-of-the-Art, Current and Future Challenges. Sensors 2018, 18, 3170. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ciubucciu, G.; Filipescu, A.; Filipescu, A., Jr.; Filipescu, S.; Dumitrascu, B. Control and Obstacle Avoidance of a WMR Based on Sliding-Mode, Ultrasounds and Laser. In Proceedings of the 12th IEEE International Conference on Control and Automation (ICCA), Kathmandu, Nepal, 1–3 June 2016; pp. 779–784. [Google Scholar]

- Corke, P.I.; Spindler, F.; Chaumette, F. Combining Cartesian and polar coordinates in IBVS. In Proceedings of the 2009 IEEE/RSJ International Conference on Intelligent Robots and Systems, St. Louis, MO, USA, 11 December 2009; pp. 5962–5967. [Google Scholar]

- Copot, C. Control Techniques for Visual Servoing Systems. Ph.D. Thesis, Technical University of Iasi, Iasi, Romania, 2012. [Google Scholar]

- Petrea, G.; Filipescu, A.; Solea, R.; Filipescu, A., Jr. Visual Servoing Systems Based Control of Complex Autonomous Systems Serving a P/RML. In Proceedings of the 22nd IEEE, International Conference on System Theory, Control and Computing, (ICSTCC), Sinaia, Romania, 10–12 October 2018; pp. 323–328. [Google Scholar]

- Song, R.; Li, F.; Fu, T.; Zhao, J. A Robotic Automatic Assembly System Based on Vision. Appl. Sci. 2020, 10, 1157. [Google Scholar] [CrossRef] [Green Version]

- Lan, C.-W.; Chang, C.-Y. Development of a Low Cost and Path-free Autonomous Patrol System Based on Stereo Vision System and Checking Flags. Appl. Sci. 2020, 10, 974. [Google Scholar] [CrossRef] [Green Version]

- Deng, L.; Wilson, W.; Janabi-Sharifi, F. Dynamic performance of the position-based visual servoing method in the Cartesian and image spaces. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Las Vegas, NV, USA, 27–31 October 2003; pp. 510–515. [Google Scholar]

- Gans, N.; Hutchinson, S.; Corke, P. Performance tests for visual servo control systems, with application to partitioned approaches to visual servo control. Int. J. Robot. Res. 2003, 22, 955–981. [Google Scholar] [CrossRef]

- OpenCV. Available online: https://opencv.org (accessed on 17 October 2022).

- Mathworks. Available online: https://www.mathworks.com (accessed on 17 October 2022).

- Microsoft Visual Studio. Available online: https://www.visualstudio.com/vs/cplusplus (accessed on 17 October 2022).

- Advanced Robotics Interface for Applications. Available online: https://web.archive.org/web/20180205212122/http://robots.mobilerobots.com/wiki/Aria (accessed on 17 October 2020).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mincă, E.; Filipescu, A.; Cernega, D.; Șolea, R.; Filipescu, A.; Ionescu, D.; Simion, G. Digital Twin for a Multifunctional Technology of Flexible Assembly on a Mechatronics Line with Integrated Robotic Systems and Mobile Visual Sensor—Challenges towards Industry 5.0. Sensors 2022, 22, 8153. https://doi.org/10.3390/s22218153

Mincă E, Filipescu A, Cernega D, Șolea R, Filipescu A, Ionescu D, Simion G. Digital Twin for a Multifunctional Technology of Flexible Assembly on a Mechatronics Line with Integrated Robotic Systems and Mobile Visual Sensor—Challenges towards Industry 5.0. Sensors. 2022; 22(21):8153. https://doi.org/10.3390/s22218153

Chicago/Turabian StyleMincă, Eugenia, Adrian Filipescu, Daniela Cernega, Răzvan Șolea, Adriana Filipescu, Dan Ionescu, and Georgian Simion. 2022. "Digital Twin for a Multifunctional Technology of Flexible Assembly on a Mechatronics Line with Integrated Robotic Systems and Mobile Visual Sensor—Challenges towards Industry 5.0" Sensors 22, no. 21: 8153. https://doi.org/10.3390/s22218153