Design and Optimization for a New XYZ Micropositioner with Embedded Displacement Sensor for Biomaterial Sample Probing Application

Abstract

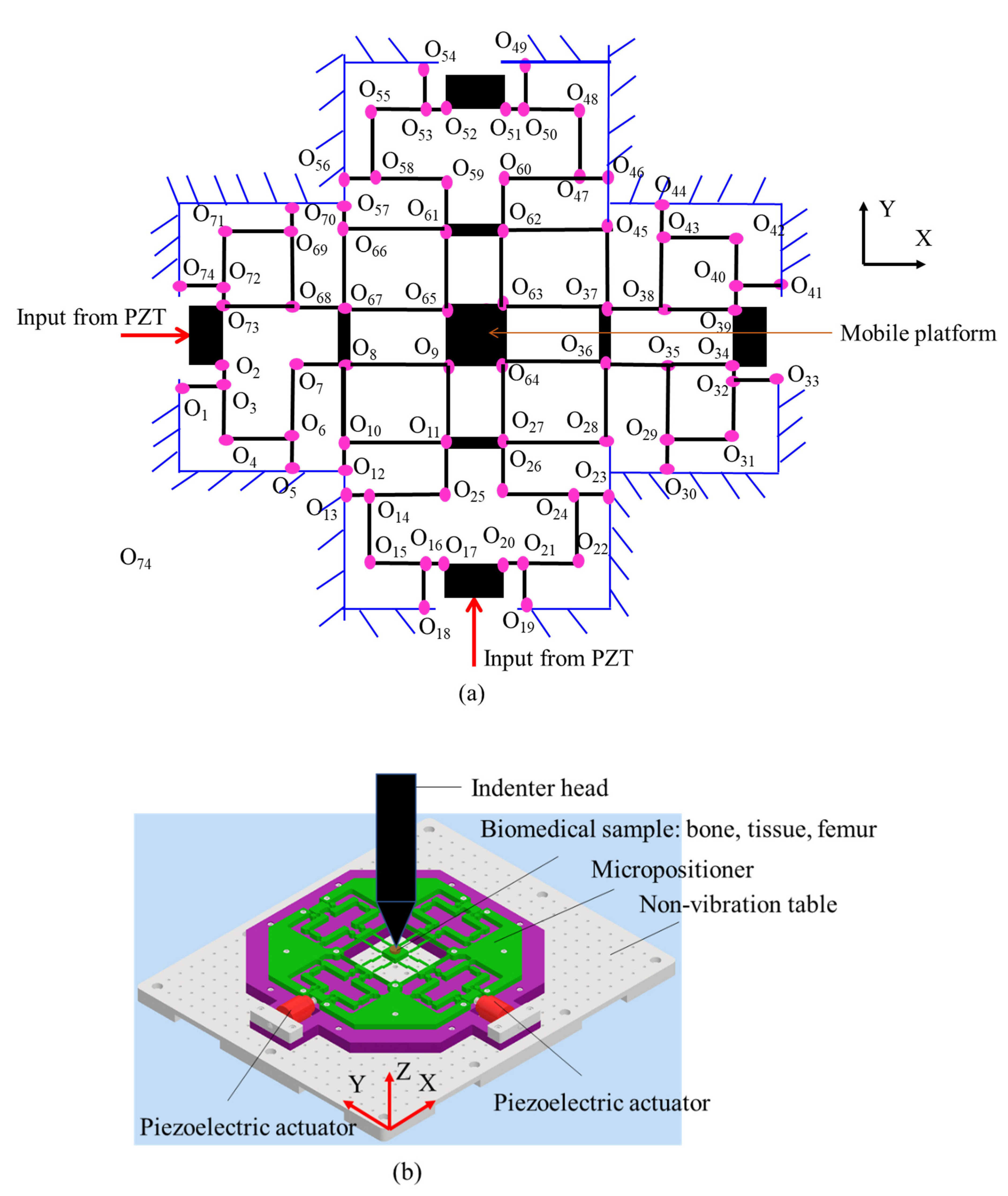

1. Introduction

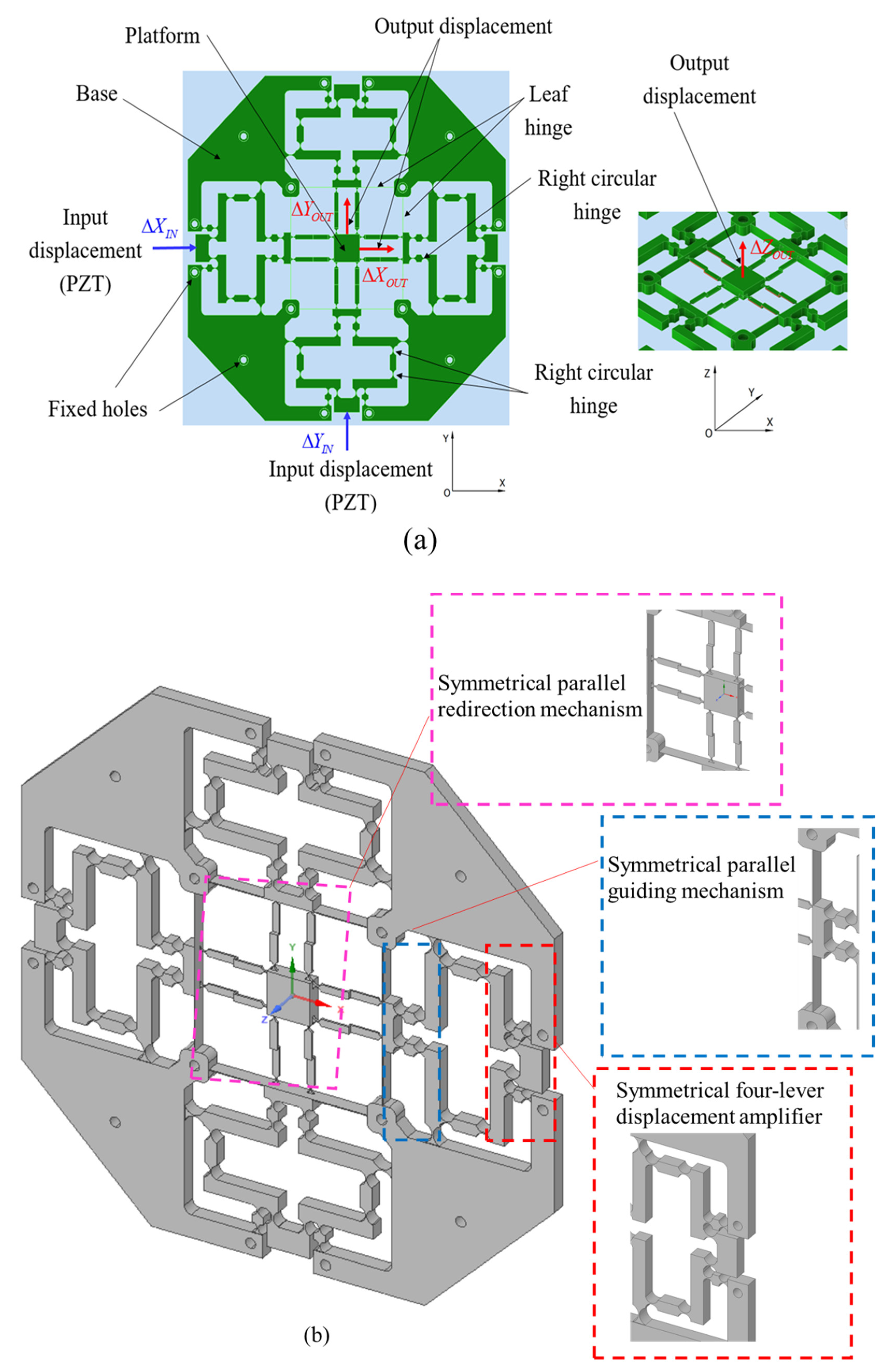

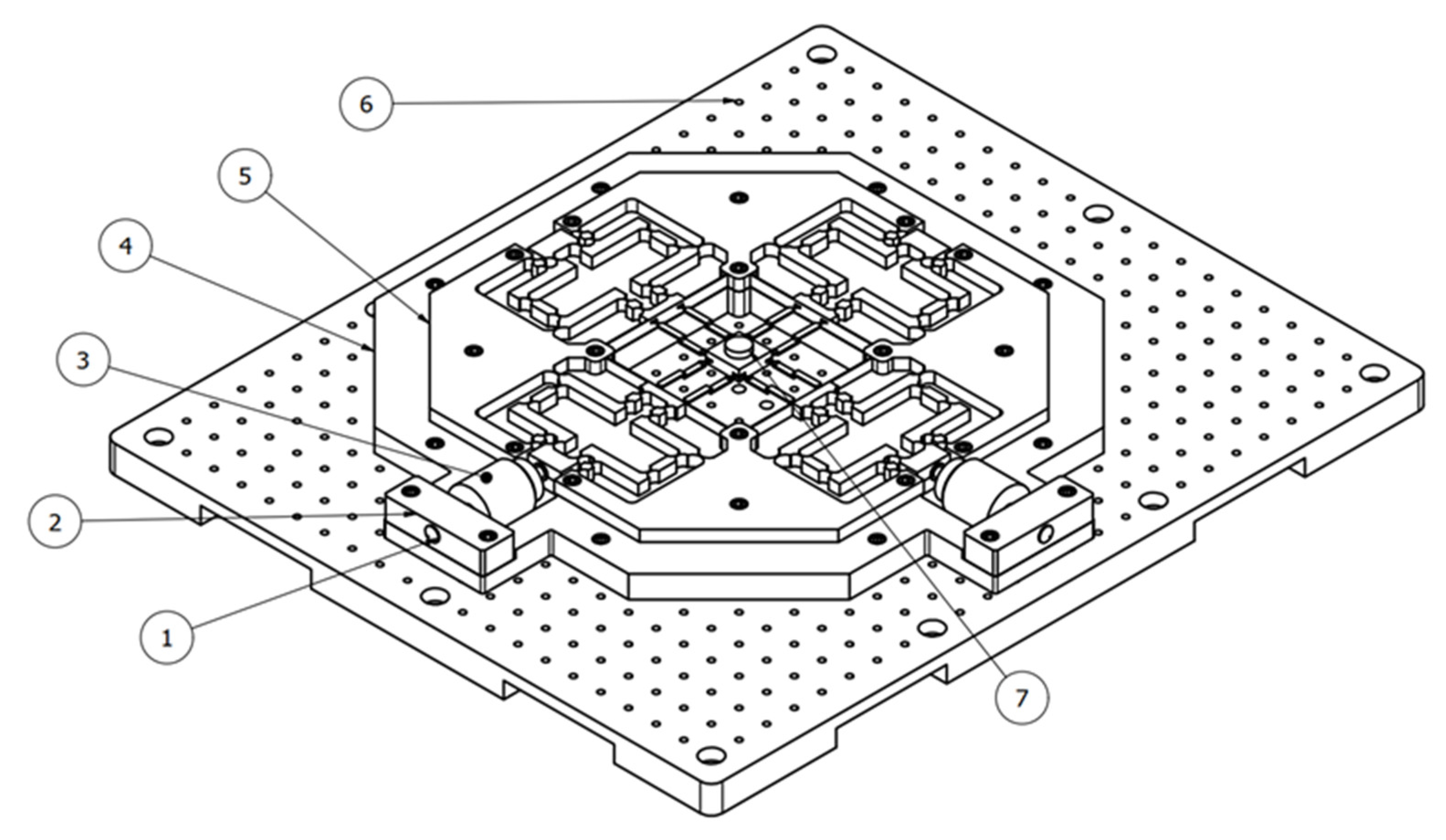

2. Conceptual Design of XYZ Micropositioner with Embedded Displacement Sensor

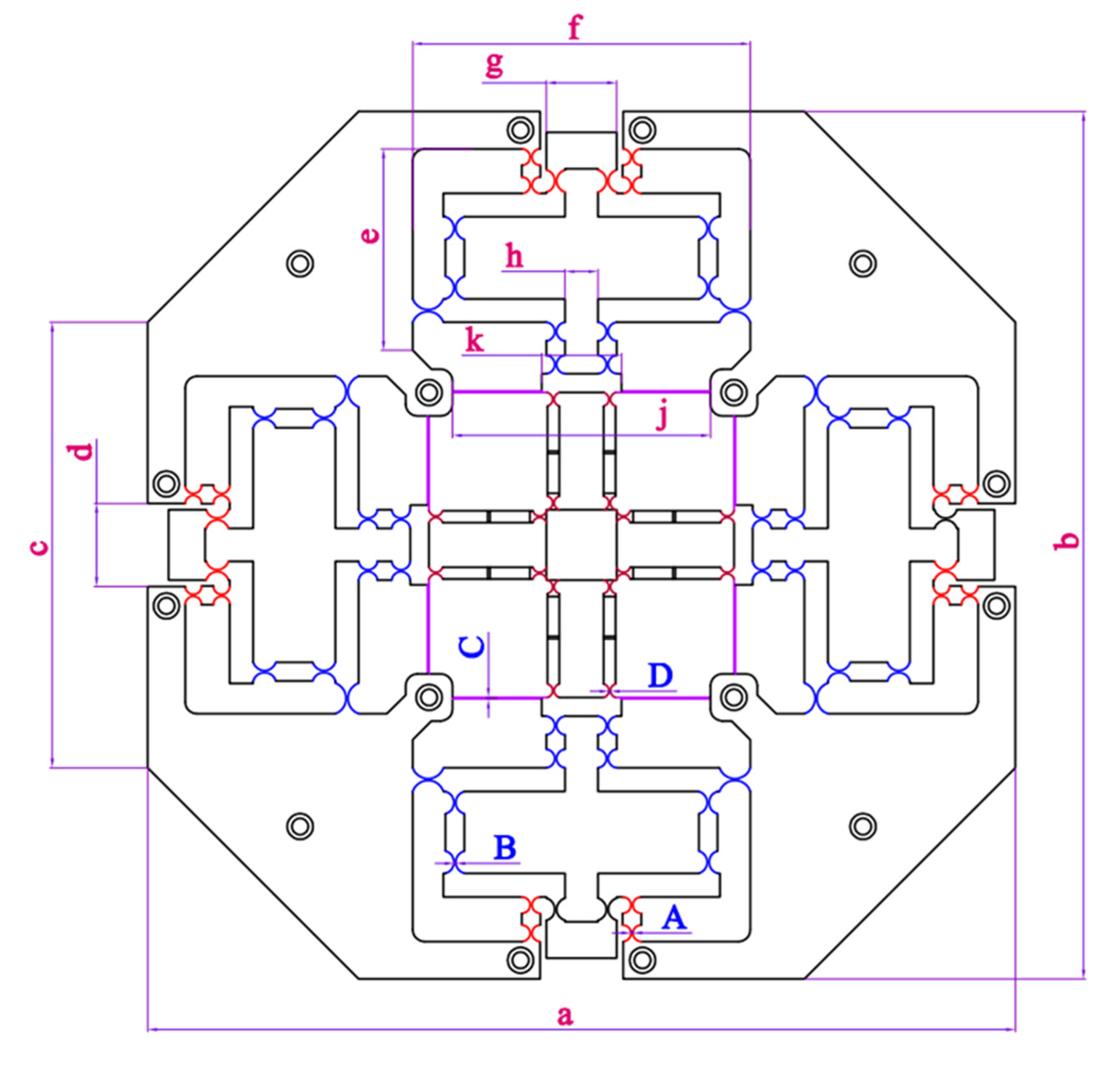

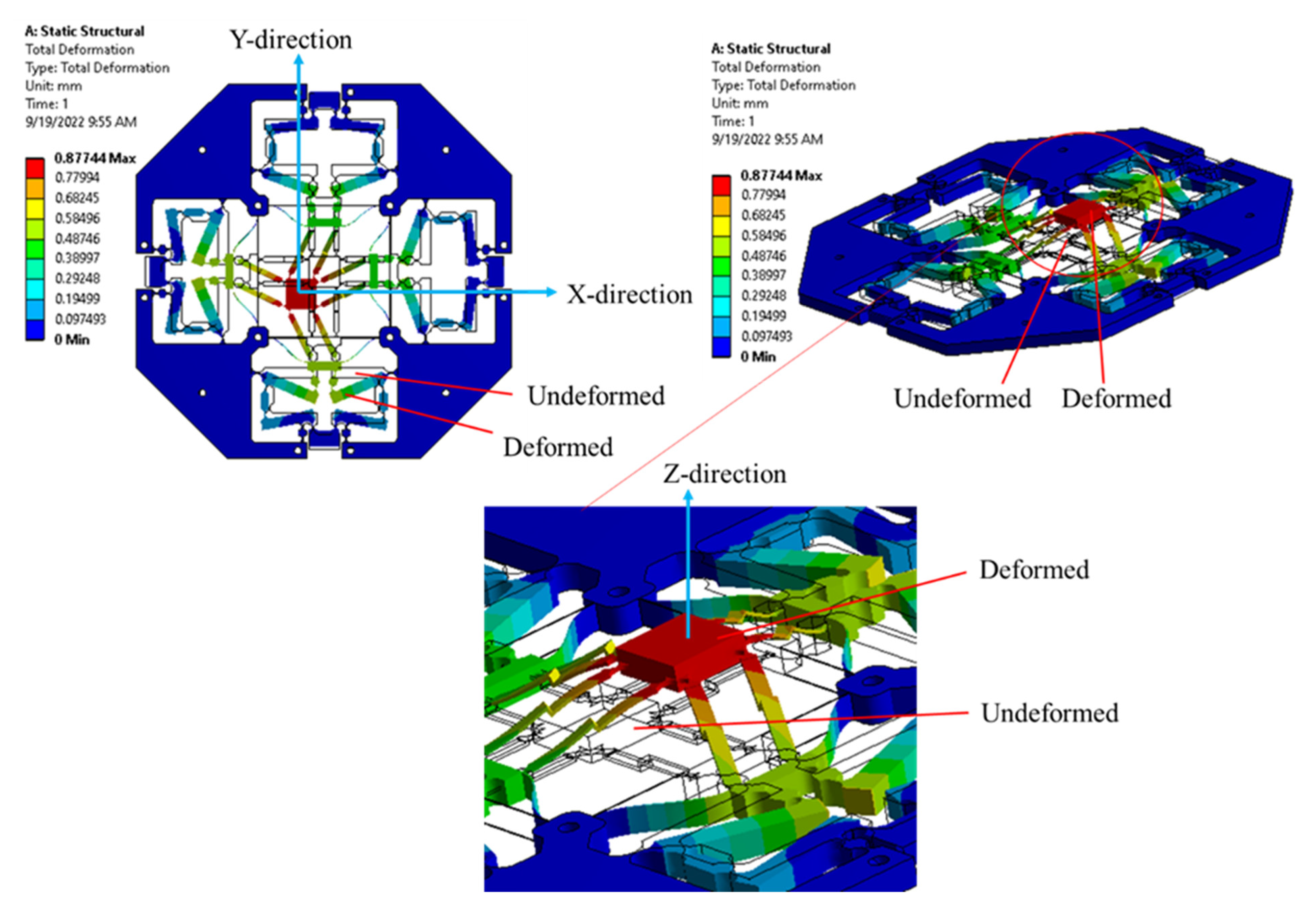

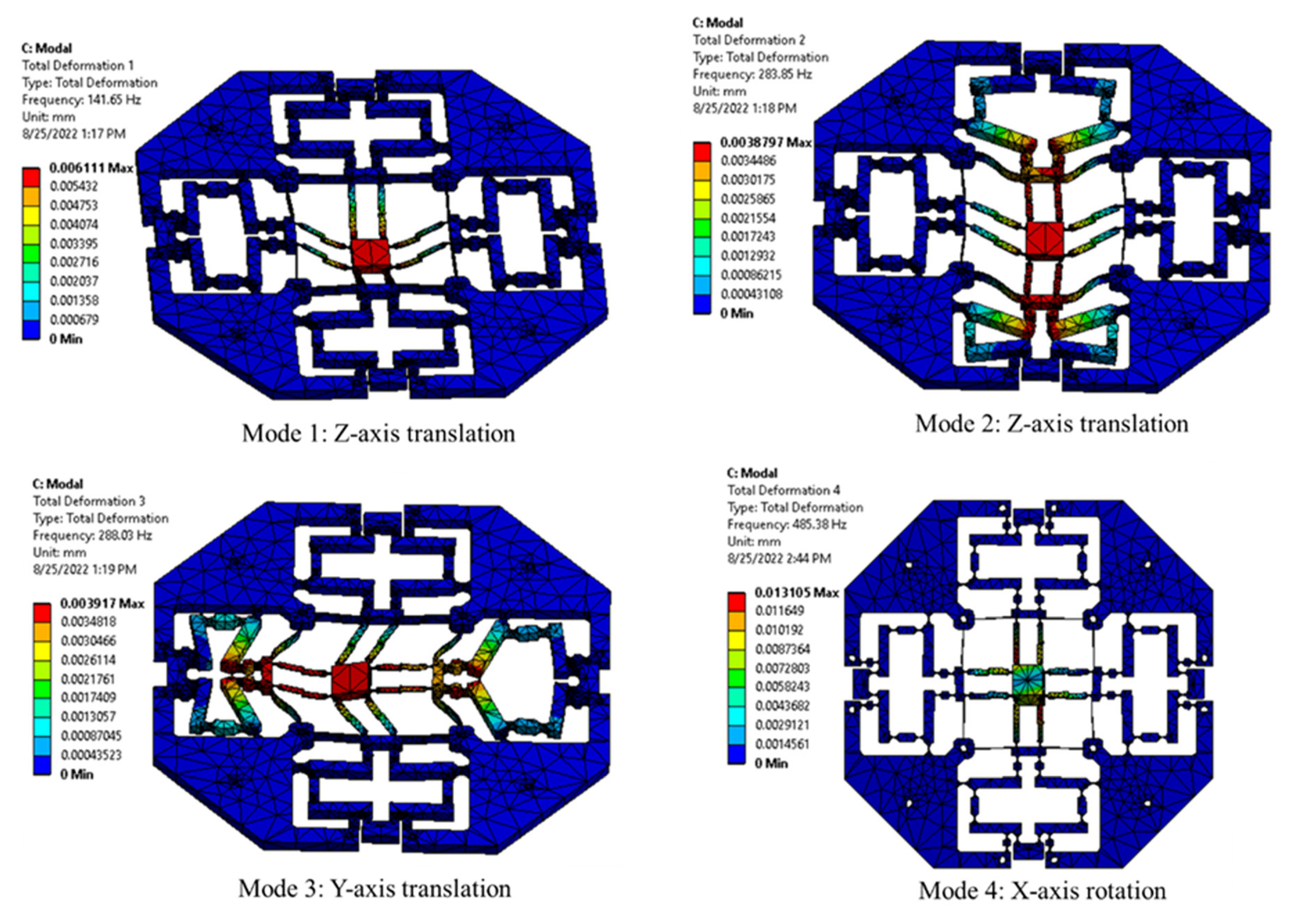

2.1. Design of XYZ Micropositioner

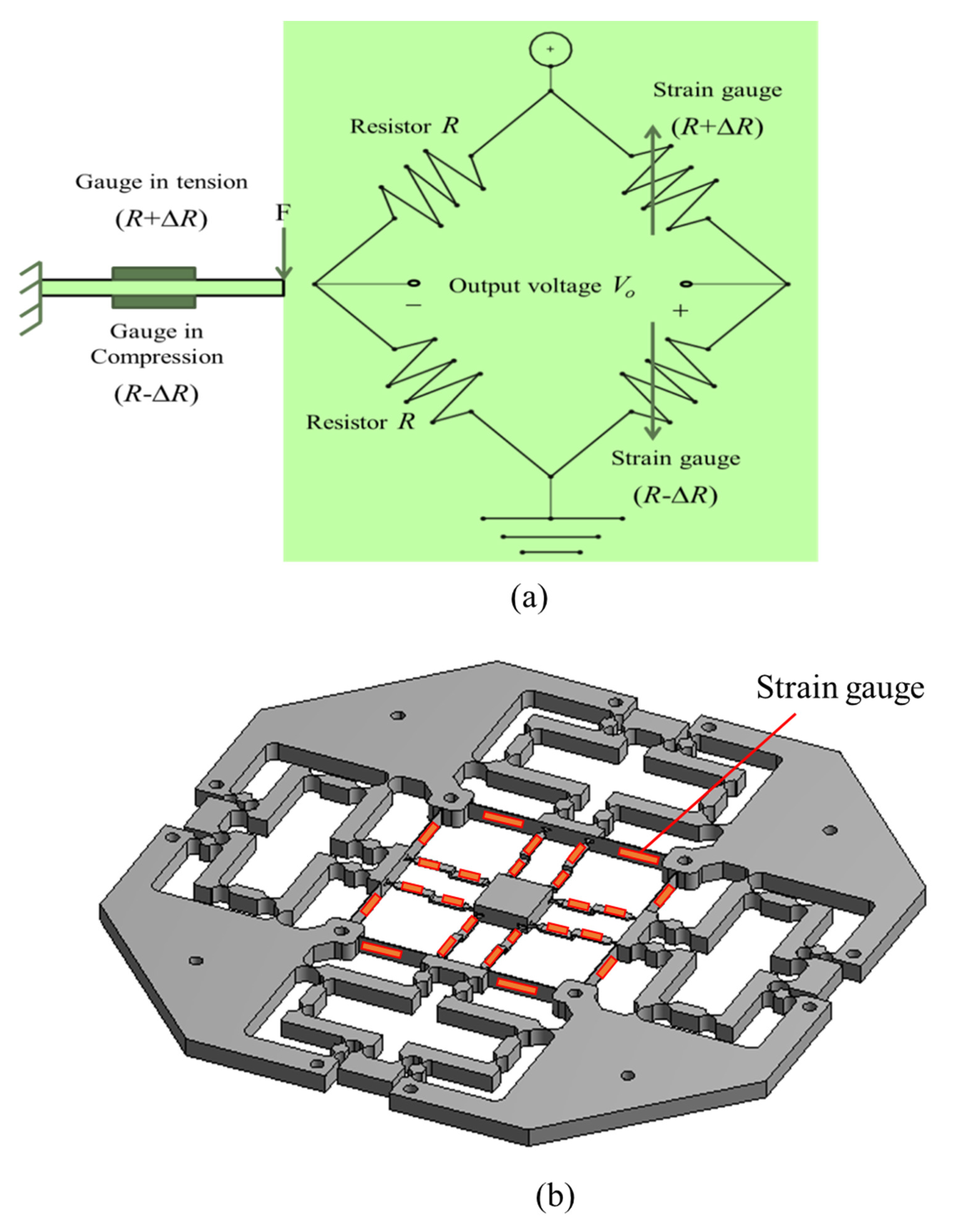

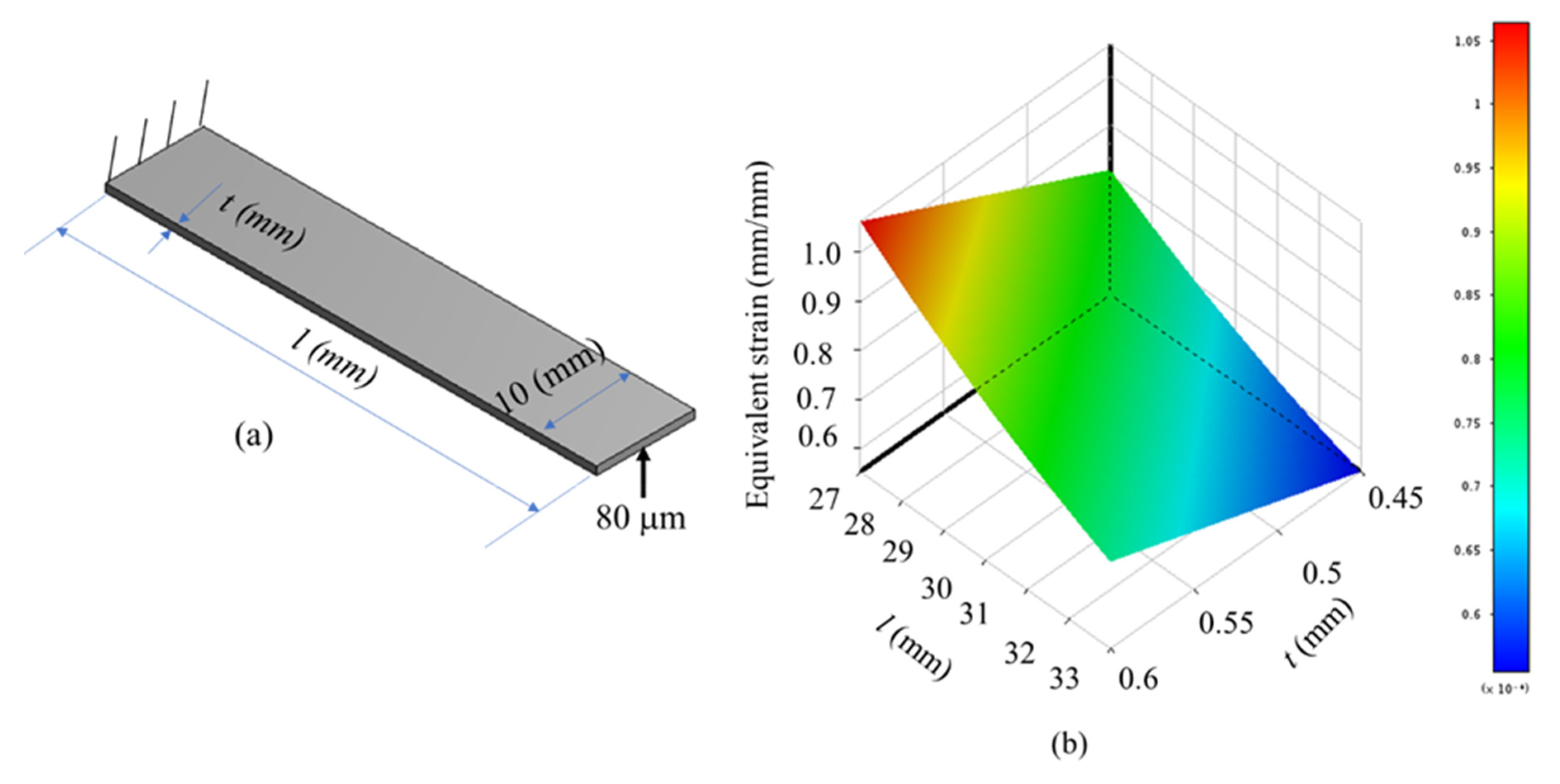

2.2. Determination Analysis of Embedded Displacement Sensor

2.3. Initial Calculations

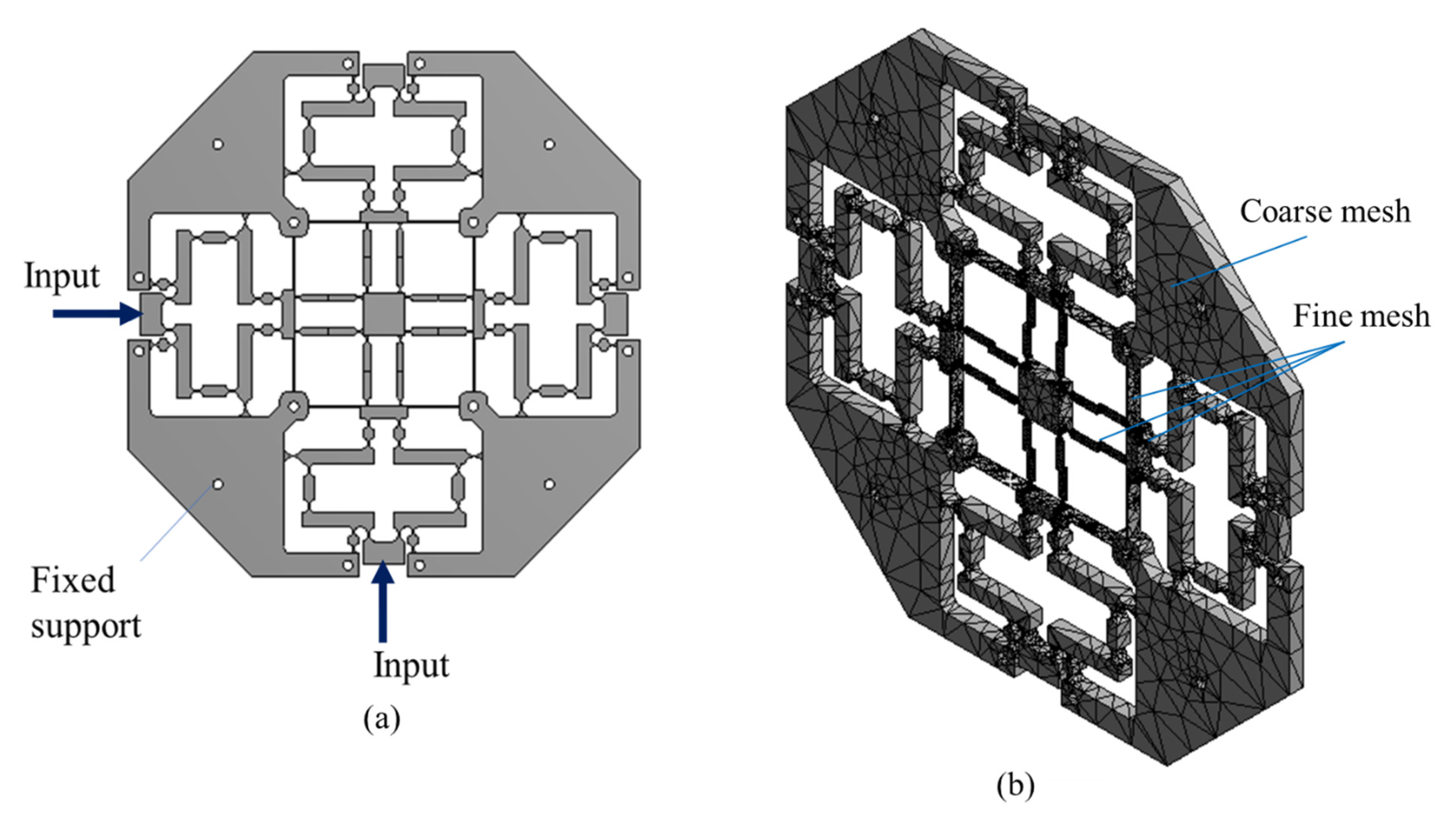

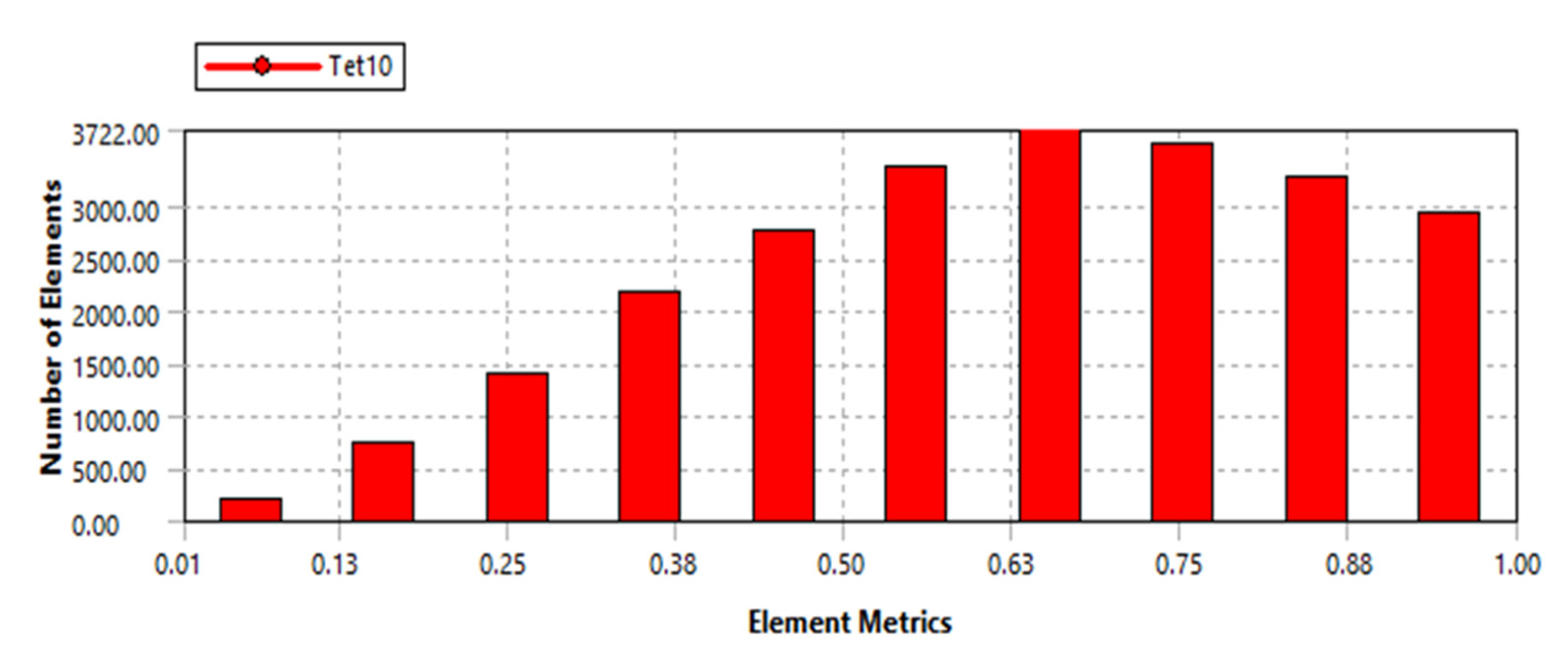

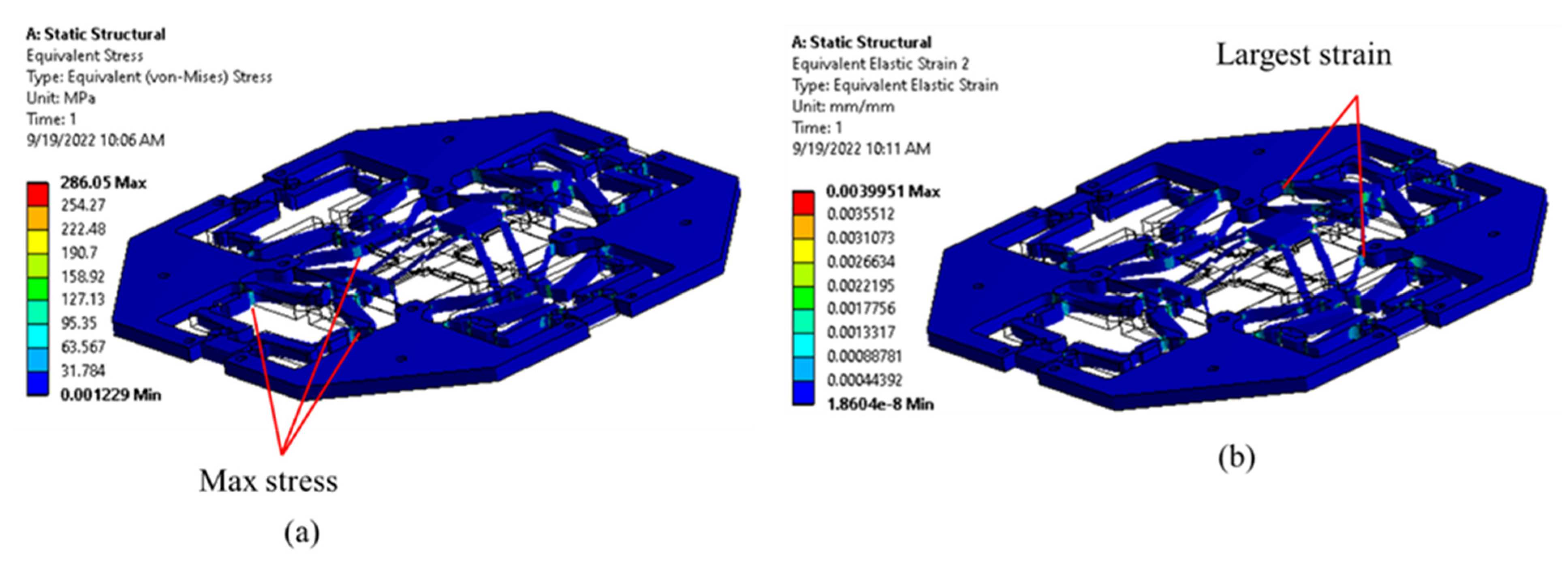

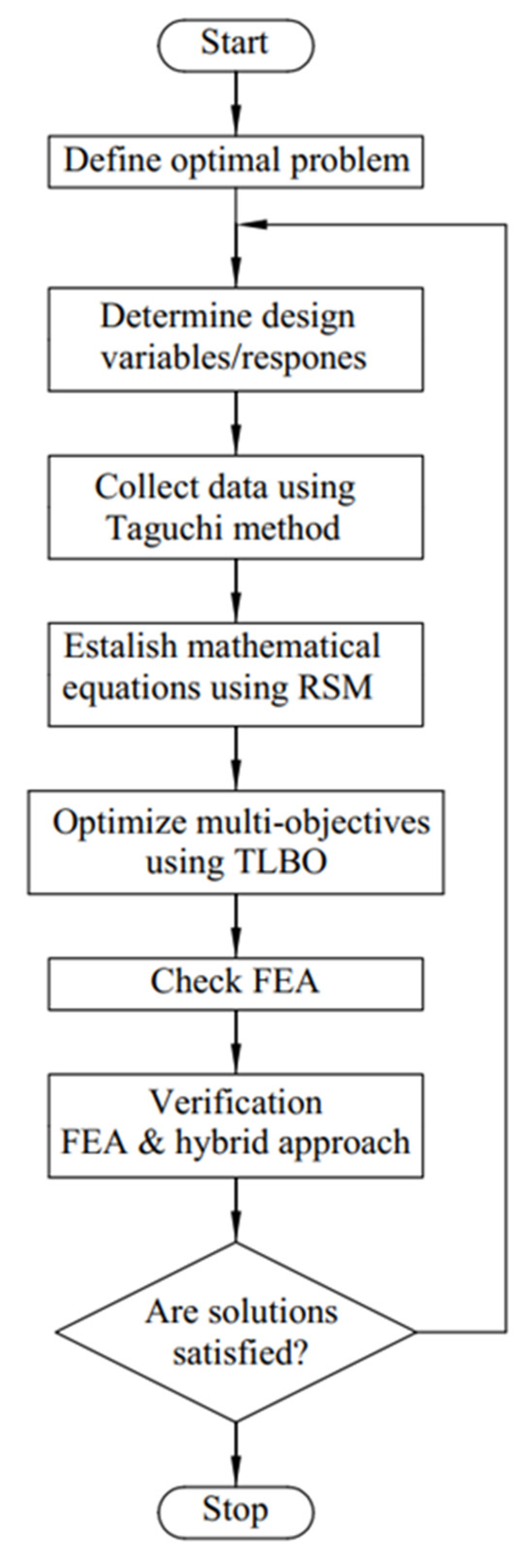

3. Parameter Optimization of XYZ Micropositioner

3.1. Statement of Optimization Problem

3.2. Proposed Methodology

- -

- βi (i = 0, 1, 2, …, n): the unknown coefficients;

- -

- βij (i < j): the collaboration coefficients;

- -

- x1, x2,…, xn: the predicted variables;

- -

- ɛ: an error.

3.3. Teaching–Learning-Based Optimization

3.3.1. Teaching Operation

- Looking for the teacher to achieve the best solution.

- Calculating the mean results of the learners (Mj,i) in a specific course.

- The quality of the teacher has a strong effect on the students through the following formula.

3.3.2. Learning Operation

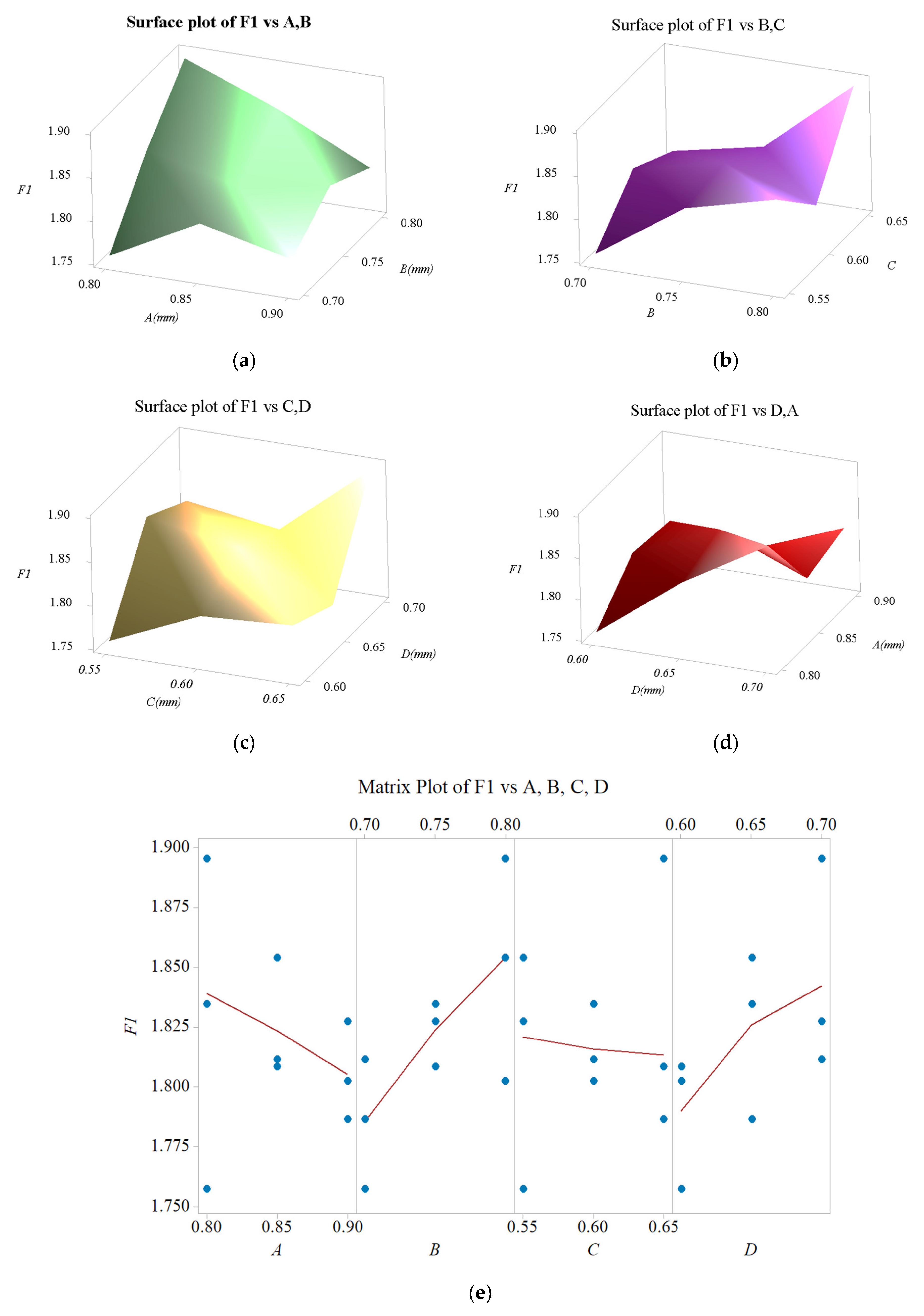

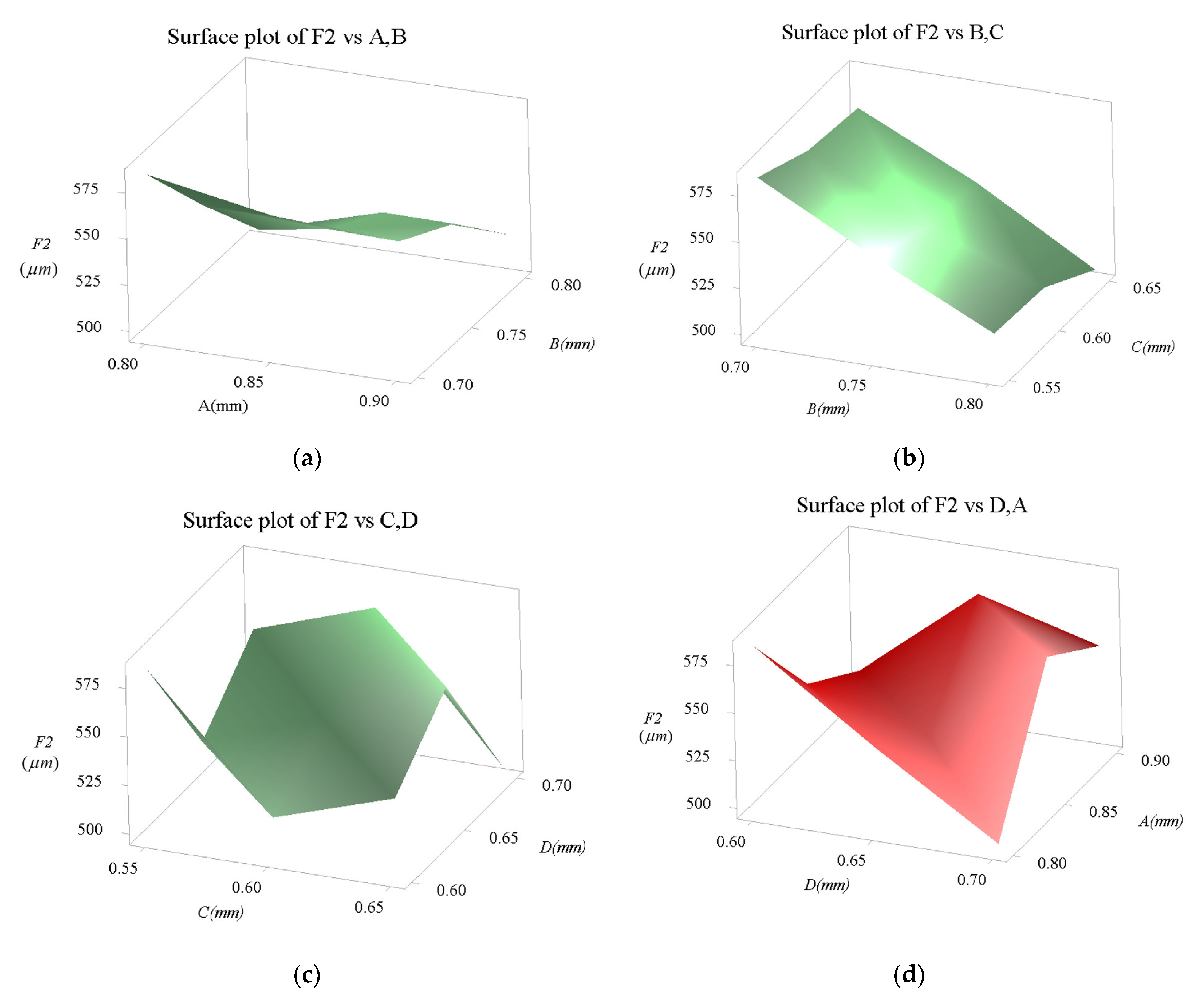

3.4. Influent Analysis of Design Parameters

3.5. Sensitivity Analysis

3.6. Results of Optimization

4. Verification and Comparison

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, Q.; Zhang, X.; Zhang, H.; Zhu, B.; Chen, B. Topology optimization of bistable mechanisms with maximized differences between switching forces in forward and backward direction. Mech. Mach. Theory 2019, 139, 131–143. [Google Scholar] [CrossRef]

- Le Chau, N.; Tran, N.T.; Dao, T.-P. A multi-response optimal design of bistable compliant mechanism using efficient approach of desirability, fuzzy logic, ANFIS and LAPO algorithm. Appl. Soft Comput. 2020, 94, 106486. [Google Scholar] [CrossRef]

- Otrokov, M.M.; Klimovskikh, I.I.; Calleja, F.; Shikin, A.M.; Vilkov, O.; Rybkin, A.G.; Estyunin, D.; Muff, S.; Dil, J.H.; Vázquez de Parga, A.L.; et al. Evidence of large spin-orbit coupling effects in quasi-free-standing graphene on Pb/Ir(1 1 1). 2D Mater. 2018, 5, 035039. [Google Scholar] [CrossRef]

- Bharanidaran, R.; Ramesh, T. A modified post-processing technique to design a compliant based microgripper with a plunger using topological optimization. Int. J. Adv. Manuf. Technol. 2015, 93, 103–112. [Google Scholar] [CrossRef]

- Ma, X.; Wilson, A.; Rahn, C.D.; Trolier-McKinstry, S. Efficient Energy Harvesting Using Piezoelectric Compliant Mechanisms: Theory and Experiment. J. Vib. Acoust. Trans. ASME 2016, 138, 021005. [Google Scholar] [CrossRef]

- Odhner, L.U.; Dollar, A.M. The Smooth Curvature Model: An Efficient Representation of Euler–Bernoulli Flexures as Robot Joints. IEEE Trans. Robot. 2012, 28, 761–772. [Google Scholar] [CrossRef]

- Le Chau, N.; Dang, M.P.; Prakash, C.; Buddhi, D.; Dao, T.-P. Structural optimization of a rotary joint by hybrid method of FEM, neural-fuzzy and water cycle–moth flame algorithm for robotics and automation manufacturing. Robot. Auton. Syst. 2022, 156, 104199. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, X. Preload characteristics identification of the piezoelectric-actuated 1-DOF compliant nanopositioning platform. Front. Mech. Eng. 2015, 10, 20–36. [Google Scholar] [CrossRef]

- Wang, F.; Zhao, X.; Huo, Z.; Shi, B.; Liang, C.; Tian, Y.; Zhang, D. A 2-DOF nano-positioning scanner with novel compound decoupling-guiding mechanism. Mech. Mach. Theory 2021, 155, 104066. [Google Scholar] [CrossRef]

- Xi, X.; Clancy, T.; Wu, X.; Sun, Y.; Liu, X. A MEMSXY-stage integrating compliant mechanism for nanopositioning at sub-nanometer resolution. J. Micromech. Microeng. 2016, 26, 25014. [Google Scholar] [CrossRef]

- Clark, L.; Shirinzadeh, B.; Tian, Y.; Yao, B. Development of a Passive Compliant Mechanism for Measurement of Micro/Nanoscale Planar 3-DOF Motions. IEEE/ASME Trans. Mechatron. 2016, 21, 1222–1232. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, X. Optimal design of a planar parallel 3-DOF nanopositioner with multi-objective. Mech. Mach. Theory 2017, 112, 61–83. [Google Scholar] [CrossRef]

- Tian, Y.; Shirinzadeh, B.; Zhang, D. Design and dynamics of a 3-DOF flexure-based parallel mechanism for micro/nano manipulation. Microelectron. Eng. 2010, 87, 230–241. [Google Scholar] [CrossRef]

- Tian, Y.; Cai, K.; Zhang, D.; Liu, X.; Wang, F.; Shirinzadeh, B. Development of a XYZ scanner for home-made atomic force microscope based on FPAA control. Mech. Syst. Signal Process. 2019, 131, 222–242. [Google Scholar] [CrossRef]

- Iqbal, S.; Malik, A. A review on MEMS based micro displacement amplification mechanisms. Sens. Actuators A Phys. 2019, 300, 111666. [Google Scholar] [CrossRef]

- Shiryayev, O.; Vahdati, N.; Yap, F.F.; Butt, H. Compliant Mechanism-Based Sensor for Large Strain Measurements Employing Fiber Optics. Sensors 2022, 22, 3987. [Google Scholar] [CrossRef]

- Zhu, W.-L.; Zhu, Z.; To, S.; Liu, Q.; Ju, B.-F.; Zhou, X. Redundantly piezo-actuated XYθz compliant mechanism for nano-positioning featuring simple kinematics, bi-directional motion and enlarged workspace. Smart Mater. Struct. 2016, 25, 125002. [Google Scholar] [CrossRef]

- Li, H.; Hao, G. Constraint-force-based approach of modelling compliant mechanisms: Principle and application. Precis. Eng. 2017, 47, 158–181. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, Q. Design of a new flexure-based XYZ parallel nanopositioning stage. In Proceedings of the 2015 IEEE International Conference on Robotics and Biomimetics (ROBIO), Zhuhai, China, 6–9 December 2015; pp. 1962–1966. [Google Scholar] [CrossRef]

- Tang, X.; Chen, I.-M. Robust control of XYZ flexure-based micromanipulator with large motion. Front. Mech. Eng. China 2009, 4, 25–34. [Google Scholar] [CrossRef]

- Li, Y.; Xu, Q. A Totally Decoupled Piezo-Driven XYZ Flexure Parallel Micropositioning Stage for Micro/Nanomanipulation. IEEE Trans. Autom. Sci. Eng. 2011, 8, 265–279. [Google Scholar] [CrossRef]

- Tang, X.; Chen, I.-M.; Li, Q. Design and nonlinear modeling of a large-displacement XYZ flexure parallel mechanism with decoupled kinematic structure. Rev. Sci. Instrum. 2006, 77, 115101. [Google Scholar] [CrossRef]

- Ling, M.; Cao, J.; Li, Q.; Zhuang, J. Design, Pseudostatic Model, and PVDF-Based Motion Sensing of a Piezo-Actuated XYZ Flexure Manipulator. IEEE/ASME Trans. Mechatron. 2018, 23, 2837–2848. [Google Scholar] [CrossRef]

- Awtar, S.; Ustick, J.; Sen, S. An XYZ Parallel-Kinematic Flexure Mechanism with Geometrically Decoupled Degrees of Freedom. J. Mech. Robot. 2012, 5, 015001. [Google Scholar] [CrossRef]

- Tang, C.; Zhang, M.; Cao, G. Design and testing of a novel flexure-based 3-degree-of-freedom elliptical micro/nano-positioning motion stage. Adv. Mech. Eng. 2017, 9, 1–10. [Google Scholar] [CrossRef]

- Li, Y.; Xu, Q. Design and Optimization of an XYZ Parallel Micromanipulator with Flexure Hinges. J. Intell. Robot. Syst. 2009, 55, 377–402. [Google Scholar] [CrossRef]

- Ghafarian, M.; Shirinzadeh, B.; Al-Jodah, A.; Das, T.K.; Wei, W.; Tian, Y.; Zhang, D. An XYZ micromanipulator for precise positioning applications. J. Micro-Bio Robot. 2020, 16, 53–63. [Google Scholar] [CrossRef]

- Tian, Y.; Ma, Y.; Wang, F.; Lu, K.; Zhang, D. A novel XYZ micro/nano positioner with an amplifier based on L-shape levers and half-bridge structure. Sens. Actuators A Phys. 2020, 302, 111777. [Google Scholar] [CrossRef]

- Alcheikh, N.; Coutier, C.; Giroud, S.; Poulain, C.; Rey, P. Characterization and modeling of a piezoresistive three-axial force micro sensor. Sens. Actuators A Phys. 2013, 201, 188–192. [Google Scholar] [CrossRef]

- Tran, A.V.; Zhang, X.; Zhu, B. The Development of a New Piezoresistive Pressure Sensor for Low Pressures. IEEE Trans. Ind. Electron. 2018, 65, 6487–6496. [Google Scholar] [CrossRef]

- Al Cheikh, N.; Coutier, C.; Brun, J.; Poulain, C.; Blanc, H.; Rey, P. Characterization of a highly sensitive silicon based three-axial piezoresistive force sensor. In Proceedings of the IEEE 2012 International Semiconductor Conference Dresden-Grenoble (ISCDG), Grenoble, France, 24–26 September 2012; pp. 183–186. [Google Scholar] [CrossRef]

- Maroufi, M.; Bazaei, A.; Mohammadi, A.; Moheimani, S.O.R. Tilted Beam Piezoresistive Displacement Sensor: Design, Modeling, and Characterization. J. Microelectromech. Syst. 2015, 24, 1594–1605. [Google Scholar] [CrossRef]

- Patkar, R.S.; Vinchurkar, M.; Ashwin, M.; Rao, V.R. A Novel PET-Based Piezoresistive MEMS Sensor Platform for Agricultural Applications. J. Microelectromech. Syst. 2017, 26, 746–748. [Google Scholar] [CrossRef]

- Yi, Y.; Wang, B.; Bermak, A. A Low-Cost Strain Gauge Displacement Sensor Fabricated via Shadow Mask Printing. Sensors 2019, 19, 4713. [Google Scholar] [CrossRef]

- Shishkovski, D.; Petreski, Z.; Tasevski, G. Development of System for Displacement Measurement of a Cantilever Beam with Strain Gauge Sensor. Mech. Eng.–Sci. J. 2015, 33, 115–120. [Google Scholar]

- Wang, H.; Zhang, X. Input coupling analysis and optimal design of a 3-DOF compliant micro-positioning stage. Mech. Mach. Theory 2008, 43, 400–410. [Google Scholar] [CrossRef]

- Pham, M.T.; Teo, T.J.; Yeo, S.H.; Wang, P.; Nai, M.L.S. A 3-D Printed Ti-6Al-4V 3-DOF Compliant Parallel Mechanism for High Precision Manipulation. IEEE/ASME Trans. Mechatron. 2017, 22, 2359–2368. [Google Scholar] [CrossRef]

- Li, Y.; Wu, Z. Design, analysis and simulation of a novel 3-DOF translational micromanipulator based on the PRB model. Mech. Mach. Theory 2016, 100, 235–258. [Google Scholar] [CrossRef]

- Niknam, T.; Azizipanah-Abarghooee, R.; Narimani, M.R. A new multi objective optimization approach based on TLBO for location of automatic voltage regulators in distribution systems. Eng. Appl. Artif. Intell. 2012, 25, 1577–1588. [Google Scholar] [CrossRef]

- Rao, R.V.; Savsani, V.; Balic, J. Teaching–learning-based optimization algorithm for unconstrained and constrained real-parameter optimization problems. Eng. Optim. 2012, 44, 1447–1462. [Google Scholar] [CrossRef]

| Symbol | Value | Symbol | Value | Unit |

|---|---|---|---|---|

| a | 370 | h | 14 | mm |

| b | 370 | j | 110 | mm |

| c | 190 | k | 34 | mm |

| d | 35 | A | 0.8 ≤ A ≤ 0.9 | mm |

| e | 86 | B | 0.7 ≤ B ≤ 0.8 | mm |

| f | 144 | C | 0.55 ≤ C ≤ 0.65 | mm |

| g | 30 | D | 0.6 ≤ D ≤ 0.7 | mm |

| No. | Input Displacement (µm) | XA | XB | XC | XD | F1 | F2 (µm) | Stress (MPa) |

|---|---|---|---|---|---|---|---|---|

| 1 | 77 | 0.8 | 0.7 | 0.55 | 0.6 | 1.8029 | X: 568.86 Y:567.8 Z: 568.33 | 278.99 |

| 2 | 77 | 0.8 | 0.75 | 0.6 | 0.65 | 1.8822 | X: 525.54 Y: 526.24 Z: 525.89 | 267.24 |

| 3 | 77 | 0.8 | 0.8 | 0.65 | 0.7 | 1.9447 | X: 486.12 Y: 487.44 Z: 486.78 | 258.65 |

| 4 | 77 | 0.85 | 0.7 | 0.6 | 0.7 | 1.8584 | X: 556.19 Y: 556.4 Z: 556.295 | 270.66 |

| 5 | 77 | 0.85 | 0.75 | 0.65 | 0.6 | 1.8553 | X: 522.57 Y: 523.41 Z: 522.99 | 271.12 |

| 6 | 77 | 0.85 | 0.8 | 0.55 | 0.65 | 1.902 | X: 504.49 Y: 506.45 Z: 505.47 | 264.46 |

| 7 | 77 | 0.9 | 0.7 | 0.65 | 0.65 | 1.833 | X: 552.78 Y: 552.39 Z: 552.585 | 274.41 |

| 8 | 77 | 0.9 | 0.75 | 0.55 | 0.7 | 1.8745 | X: 535.28 Y: 536.05 Z: 535.665 | 268.34 |

| 9 | 77 | 0.9 | 0.8 | 0.6 | 0.6 | 1.8492 | X: 503.05 Y: 503.93 Z: 503.49 | 272.01 |

| No. | Input Displacement (µm) | XA | XB | XC | XD | F1 | F2 (µm) | Stress (MPa) |

|---|---|---|---|---|---|---|---|---|

| 1 | 78 | 0.8 | 0.7 | 0.55 | 0.6 | 1.7798 | X: 576.25 Y:575.18 Z: 575.715 | 282.62 |

| 2 | 78 | 0.8 | 0.75 | 0.6 | 0.65 | 1.8581 | X: 532.47 Y: 533.07 Z: 532.77 | 270.71 |

| 3 | 78 | 0.8 | 0.8 | 0.65 | 0.7 | 1.9197 | X: 492.43 Y: 493.77 Z: 493.1 | 262.02 |

| 4 | 78 | 0.85 | 0.7 | 0.6 | 0.7 | 1.8345 | X: 563.42 Y: 563.63 Z: 563.525 | 274.19 |

| 5 | 78 | 0.85 | 0.75 | 0.65 | 0.6 | 1.8315 | X: 529.36 Y: 530.21 Z: 529.785 | 274.64 |

| 6 | 78 | 0.85 | 0.8 | 0.55 | 0.65 | 1.8776 | X: 511.04 Y: 513.03 Z: 512.035 | 267.9 |

| 7 | 78 | 0.9 | 0.7 | 0.65 | 0.65 | 1.8095 | X: 559.96 Y: 559.56 Z: 559.76 | 277.98 |

| 8 | 78 | 0.9 | 0.75 | 0.55 | 0.7 | 1.8505 | X: 542.23 Y: 543.01 Z: 543.12 | 271.82 |

| 9 | 78 | 0.9 | 0.8 | 0.6 | 0.6 | 1.8255 | X: 509.58 Y: 510.48 Z: 510.035 | 275.54 |

| No. | Input Displacement (µm) | XA | XB | XC | XD | F1 | F2 (µm) | Stress (MPa) |

|---|---|---|---|---|---|---|---|---|

| 1 | 79 | 0.8 | 0.7 | 0.55 | 0.6 | 1.7573 | X: 583.64 Y:582.55 Z: 583.095 | 286.23 |

| 2 | 79 | 0.8 | 0.75 | 0.6 | 0.65 | 1.8345 | X: 539.29 Y: 539.9 Z: 539.595 | 274.19 |

| 3 | 79 | 0.8 | 0.8 | 0.65 | 0.7 | 1.8954 | X: 498.74 Y: 500.1 Z: 499.42 | 265.38 |

| 4 | 79 | 0.85 | 0.7 | 0.6 | 0.7 | 1.8113 | X: 570.64 Y: 570.85 Z: 570.745 | 277.7 |

| 5 | 79 | 0.85 | 0.75 | 0.65 | 0.6 | 1.8083 | X: 536.14 Y: 537.01 Z: 536.575 | 278.16 |

| 6 | 79 | 0.85 | 0.8 | 0.55 | 0.65 | 1.8539 | X: 517.59 Y: 519.61 Z: 518.68 | 271.32 |

| 7 | 79 | 0.9 | 0.7 | 0.65 | 0.65 | 1.7866 | X: 567.13 Y: 566.74 Z: 566.935 | 281.54 |

| 8 | 79 | 0.9 | 0.75 | 0.55 | 0.7 | 1.8271 | X: 549.18 Y: 549.97 Z: 549.575 | 275.3 |

| 9 | 79 | 0.9 | 0.8 | 0.6 | 0.6 | 1.8024 | X: 516.12 Y: 517.02 Z: 516.66 | 279.07 |

| No. | Input Displacement (µm) | XA | XB | XC | XD | F1 | F2 (µm) | Stress (MPa) |

|---|---|---|---|---|---|---|---|---|

| 1 | 80 | 0.8 | 0.7 | 0.55 | 0.6 | 1.7353 | X: 591.03 Y:589.92 Z: 590.475 | 289.86 |

| 2 | 80 | 0.8 | 0.75 | 0.6 | 0.65 | 1.8116 | X: 546.12 Y: 546.74 Z: 546.43 | 277.66 |

| 3 | 80 | 0.8 | 0.8 | 0.65 | 0.7 | 1.8717 | X: 505.06 Y: 506.43 Z: 508.43 | 268.74 |

| 4 | 80 | 0.85 | 0.7 | 0.6 | 0.7 | 1.7887 | X: 577.86 Y: 578.08 Z: 577.97 | 281.21 |

| 5 | 80 | 0.85 | 0.75 | 0.65 | 0.6 | 1.7857 | X: 542.93 Y: 543.8 Z: 543.365 | 281.68 |

| 6 | 80 | 0.85 | 0.8 | 0.55 | 0.65 | 1.8307 | X: 524.14 Y: 526.19 Z: 525.165 | 274.76 |

| 7 | 80 | 0.9 | 0.7 | 0.65 | 0.65 | 1.7643 | X: 574.31 Y: 573.91 Z: 574.11 | 285.1 |

| 8 | 80 | 0.9 | 0.75 | 0.55 | 0.7 | 1.8042 | X: 556.13 Y: 556.93 Z: 556.53 | 278.79 |

| 9 | 80 | 0.9 | 0.8 | 0.6 | 0.6 | 1.7799 | X: 522.65 Y: 523.57 Z: 523.11 | 282.6 |

| Source | DF | Seq SS | Contribution | Adj SS | Adj MS | p-Value |

|---|---|---|---|---|---|---|

| Model | 8 | 0.012663 | 100.00% | 0.012663 | 0.001583 | significant |

| Linear | 4 | 0.012310 | 97.21% | 0.012310 | 0.003078 | significant |

| A | 1 | 0.000843 | 6.65% | 0.000843 | 0.000843 | significant |

| B | 1 | 0.006435 | 50.82% | 0.006435 | 0.006435 | significant |

| C | 1 | 0.000451 | 3.56% | 0.000451 | 0.000451 | significant |

| D | 1 | 0.004582 | 36.18% | 0.004582 | 0.004582 | significant |

| Square | 4 | 0.000353 | 2.79% | 0.000353 | 0.000088 | significant |

| A*A | 1 | 0.000106 | 0.84% | 0.000106 | 0.000106 | significant |

| B*B | 1 | 0.000060 | 0.47% | 0.000060 | 0.000060 | significant |

| C*C | 1 | 0.000058 | 0.45% | 0.000058 | 0.000058 | significant |

| D*D | 1 | 0.000129 | 1.02% | 0.000129 | 0.000129 | significant |

| Error | 0 | - | - | - | - | |

| Total | 8 | 0.012663 | 100.00% |

| Source | DF | Seq SS | Contribution | Adj SS | Adj MS | p-Value |

| Model | 8 | 6227.22 | 100.00% | 6227.22 | 778.40 | significant |

| Linear | 4 | 6223.94 | 99.95% | 6223.94 | 1555.98 | significant |

| A | 1 | 20.39 | 0.33% | 20.39 | 20.39 | significant |

| B | 1 | 5766.93 | 92.61% | 5766.93 | 5766.93 | significant |

| C | 1 | 390.75 | 6.27% | 390.75 | 390.75 | significant |

| D | 1 | 45.87 | 0.74% | 45.87 | 45.87 | significant |

| Square | 4 | 3.28 | 0.05% | 3.28 | 0.82 | significant |

| A*A | 1 | 0.60 | 0.01% | 0.60 | 0.60 | significant |

| B*B | 1 | 0.91 | 0.01% | 0.91 | 0.91 | significant |

| C*C | 1 | 0.00 | 0.00% | 0.00 | 0.00 | significant |

| D*D | 1 | 1.77 | 0.03% | 1.77 | 1.77 | significant |

| Error | 0 | - | - | - | - | |

| Total | 8 | 6227.22 | 100.00% |

| Characteristics | Anticipation | Confirmation | Error (%) |

|---|---|---|---|

| F1 | 1.8548 | 1.8364 | 1.001 |

| F2 (mm) | 515.7278 | 516.58 | 0.165 |

| XYZ Micropositioner | Workspace (X, Y, Z-Travels) | DOF | Number of Actuators |

|---|---|---|---|

| This design | 516.58 μm × 516.58 μm × 516.58 μm | XYZ | 2 |

| [19] | 19 μm × 120 μm × 1 μm | XYZ | 3 |

| [21] | 165.8 μm × 5.4 μm × 6.5 μm | XYZ | 3 |

| [23] | 112 μm × 112 μm × 112 μm | XYZ | 3 |

| [25] | 10.39 μm × 15.43 μm × 15.55 μm | XYZ | 3 |

| [26] | 141 μm × 141 μm × 141 μm | XYZ | 3 |

| [28] | 128.1 μm × 131.3 μm × 17.9 | XYZ | 3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dang, M.P.; Le, H.G.; Phan, T.T.D.; Chau, N.L.; Dao, T.-P. Design and Optimization for a New XYZ Micropositioner with Embedded Displacement Sensor for Biomaterial Sample Probing Application. Sensors 2022, 22, 8204. https://doi.org/10.3390/s22218204

Dang MP, Le HG, Phan TTD, Chau NL, Dao T-P. Design and Optimization for a New XYZ Micropositioner with Embedded Displacement Sensor for Biomaterial Sample Probing Application. Sensors. 2022; 22(21):8204. https://doi.org/10.3390/s22218204

Chicago/Turabian StyleDang, Minh Phung, Hieu Giang Le, Thu Thi Dang Phan, Ngoc Le Chau, and Thanh-Phong Dao. 2022. "Design and Optimization for a New XYZ Micropositioner with Embedded Displacement Sensor for Biomaterial Sample Probing Application" Sensors 22, no. 21: 8204. https://doi.org/10.3390/s22218204

APA StyleDang, M. P., Le, H. G., Phan, T. T. D., Chau, N. L., & Dao, T.-P. (2022). Design and Optimization for a New XYZ Micropositioner with Embedded Displacement Sensor for Biomaterial Sample Probing Application. Sensors, 22(21), 8204. https://doi.org/10.3390/s22218204