Measuring System for Determining the Quality of LED Light Sources and an Overview of LED Light Bulbs for Household Use

Abstract

1. Introduction

- measurement and plot for observing fluctuations in the emitted luminous flux,

- measurement and plot for observing the AC current flowing into the switching converter (LED bulb),

- the illuminance measurement and polar diagram of the angular distribution of luminous intensity,

- plotting the frequency spectrum and spectrogram of the luminous flux signal,

- measurement of the luminous flux emitted by the light source.

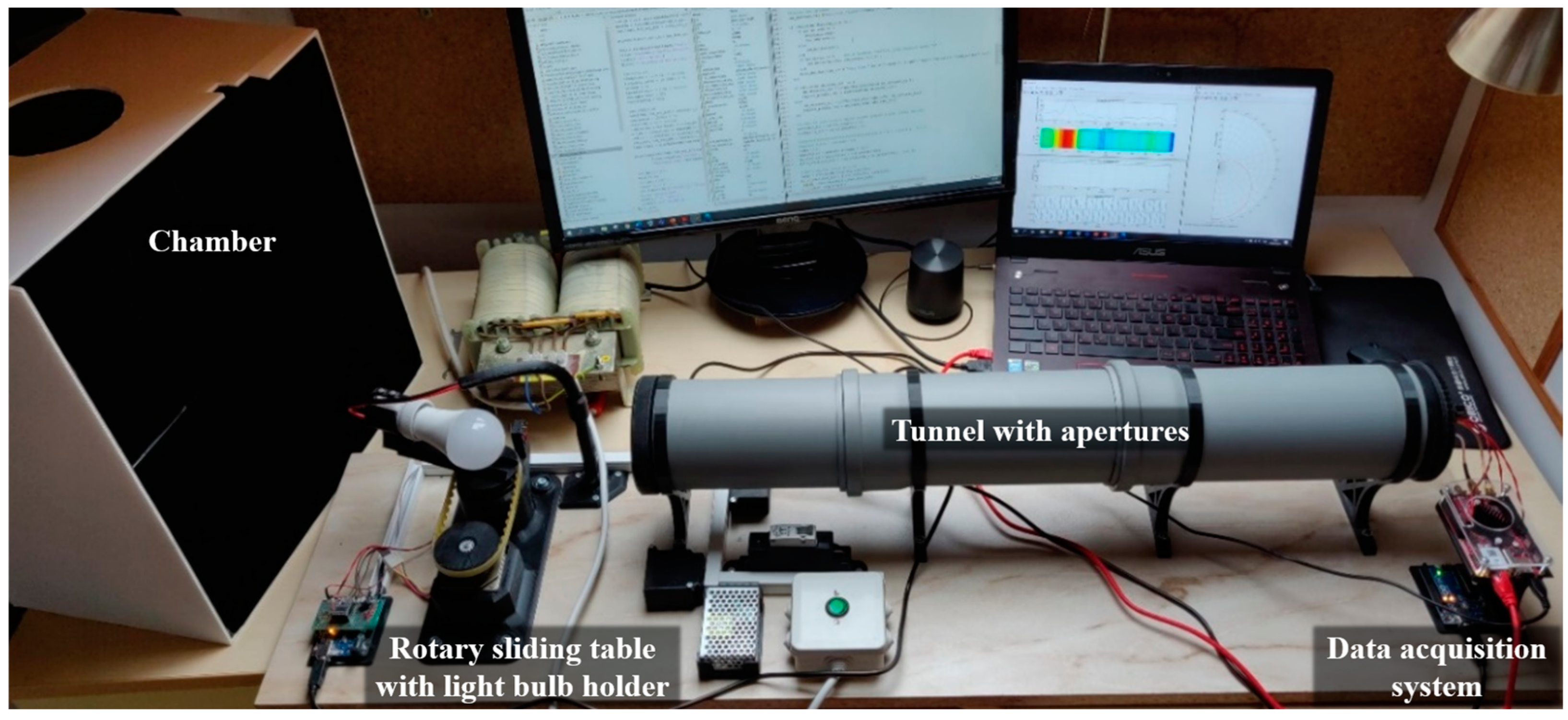

2. Measuring System [7]

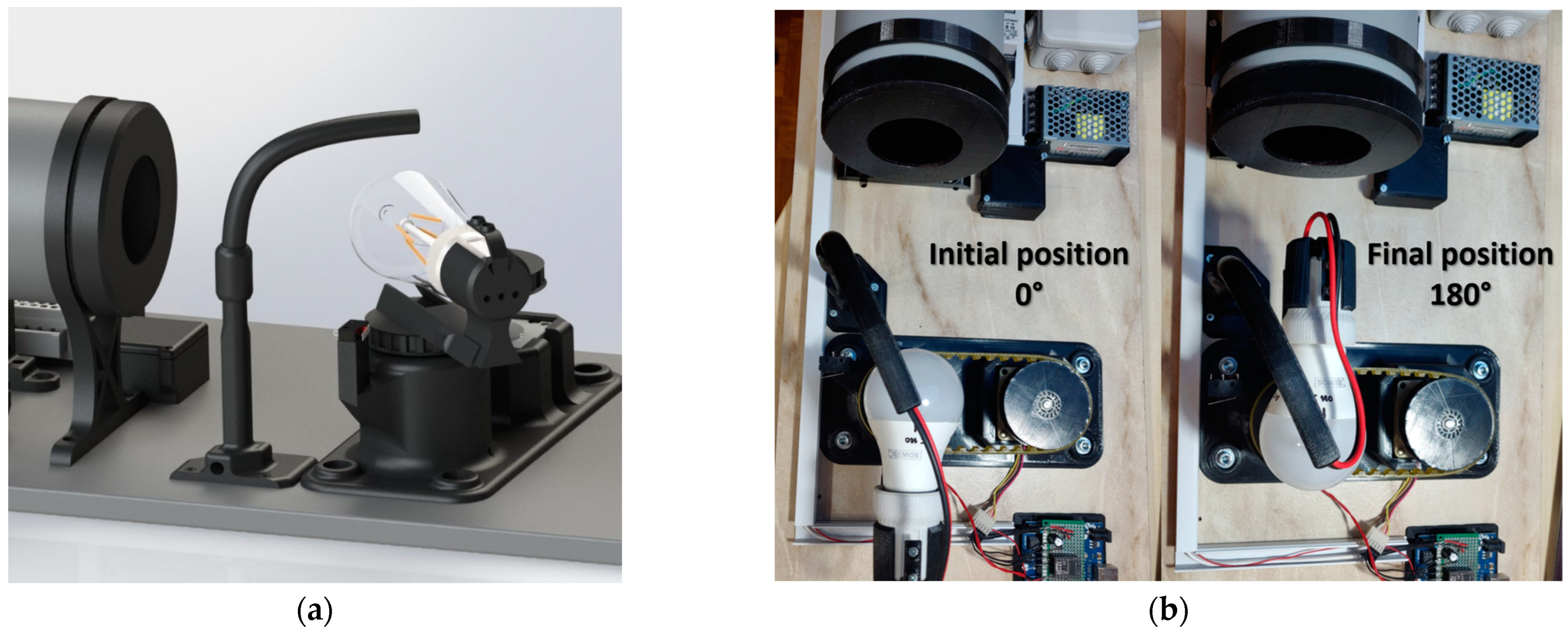

2.1. Rotary Sliding Table with Light Bulb Holder

2.2. Tunnel with Apertures

2.3. Light Bulb Power Cable Stand

2.4. Chamber for Preventing the Influence of Ambient Light on Measurements

2.5. Microcontroller and Multifunctional Measurement Device Red Pitaya Holder

2.6. Electronic Assembly for Stepper Motor Control

2.7. Electronic Assembly for Illuminance Measurement

2.8. System for High-Frequency Data Acquisition

- sampling frequency: 300 kHz,

- save measured samples in audio file format (WAV),

- save samples from both analog inputs,

- resolution of input channels: 16 bits,

- data transmission protocol: TCP,

- number of acquired samples: 150,000 (duration of the acquisition: 0.5 s),

- IP address of the measurement device Red Pitaya.

2.9. Electronic Circuit for Observing Fluctuations in the Luminous Flux

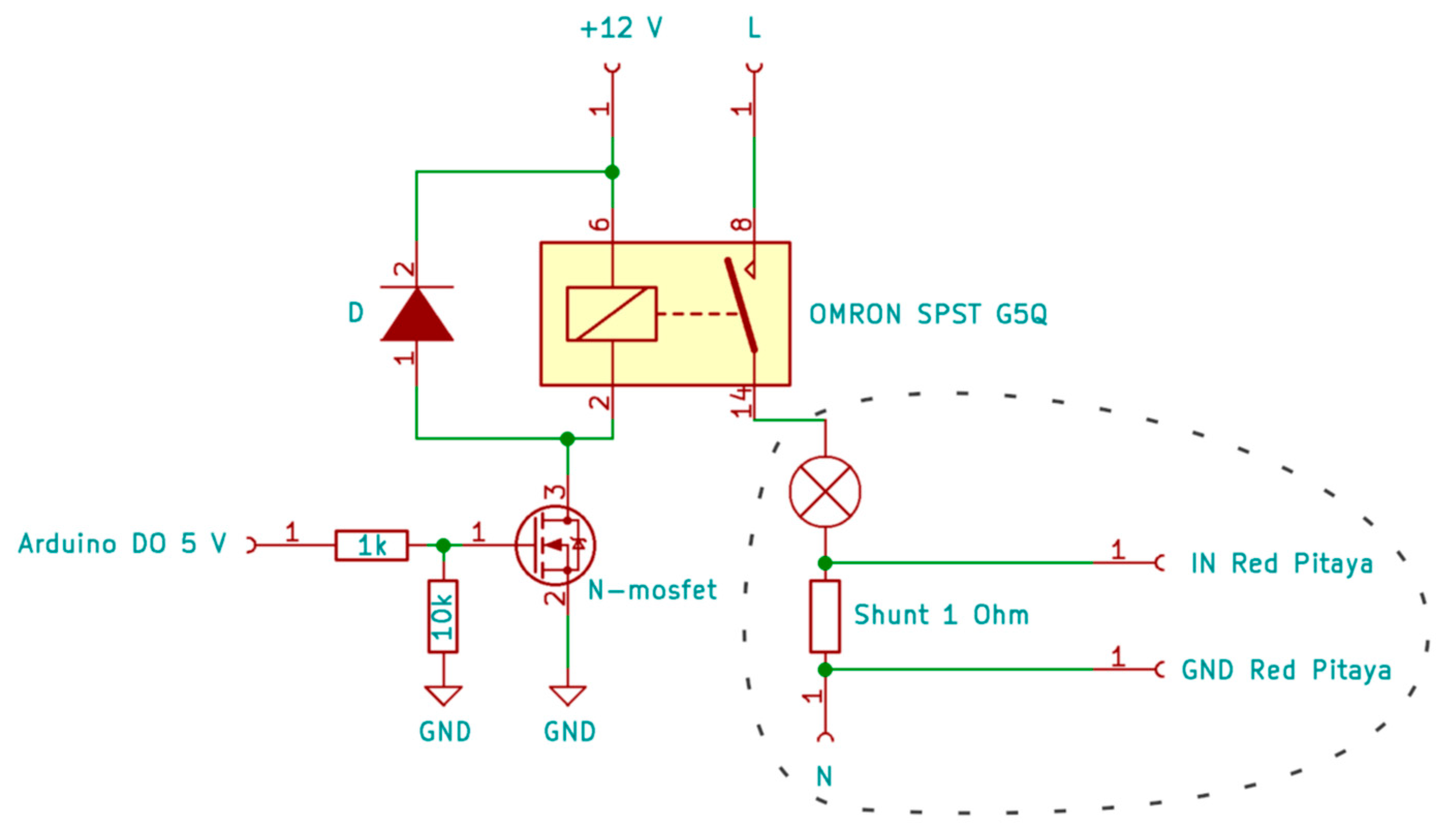

2.10. Electric Circuit for Measuring the Electric Current through a Light Bulb

3. Results and Discussion

3.1. List of Measured LED Light Bulbs

3.2. Classification of LED Light Bulbs Based on the Percentage of Fluctuations in the Luminous Flux

3.3. Classification of LED Light Bulbs Based on the Percentage of Deviation of the Measured Luminous Flux Value from the Luminous Flux Value Stated on the Packaging

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Udovychenko, K.O. The Advantages and Disadvantages of Using Led Light Bulbs; Tavria State Agrotechnological University: Melitopol, Ukraine, 2019; pp. 115–116. Available online: https://core.ac.uk/download/pdf/287032067.pdf (accessed on 5 May 2021).

- Wang, Q.; Xu, H.; Gong, R.; Cai, J. Investigation of visual fatigue under LED lighting based on reading task. Optik 2015, 126, 1433–1438. [Google Scholar] [CrossRef]

- Serikov, Y.A.; Nazarenko, L.A.; Serikova, K.S. Non-Visual Exposure to Light as a Production Factor of the Influence of Lighting of the Working Area on Labor Productivity and Safety of Workers. Metrol. Instrum. 2020, 39, 35–39. [Google Scholar] [CrossRef]

- Berzina, K.; Zicmane, I.; Podgornovs, A.; Zhiravecka, A.; Kuckovskis, J.; Berzina, N.N. The impact of lighting fluctuations on anthropological aspects. In Proceedings of the 2018 IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Palermo, Italy, 12–15 June 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Inger, R.; Bennie, J.; Davies, T.W.; Gaston, K.J. Potential Biological and Ecological Effects of Flickering Artificial Light. PLoS ONE 2014, 9, e98631. [Google Scholar] [CrossRef] [PubMed]

- Sametoglu, F. Construction of Two-Axis Goniophotometer for Measurement of Spatial Distribution of a Light Source and Calculation of Luminous Flux. Acta Phys. Pol. 2011, 119, 783–791. [Google Scholar] [CrossRef]

- Markovič, M. Measuring System for Determining the Quality of LED Substitutes for Conventional Light bulbs. Bachelor’s Thesis, University of Maribor, Maribor, Slovenia, 9 September 2021. [Google Scholar]

- Pololu, Stepper Motor Driver Carrier, High Current. Available online: https://www.pololu.com/product/2133 (accessed on 16 June 2021).

- Lock-in+PID, the Red Pitaya Board. Available online: https://marceluda.github.io/rp_lock-in_pid/TheApp/RedPitaya_board/ (accessed on 25 June 2021).

- Lorencon, R. Elektronski Elementi in vezja; Narodna in Univerzitetna Knižnjica; Studio Maya: Ljubljana, Slovenia, 1996; pp. 159–183. Available online: http://212.235.190.162/literatura/vt/Elektronska%20vezja%20in%20elementi.pdf (accessed on 24 June 2021).

- Bizjak, G.; Kobav, M.B.; Prelovšek, M. Razsvetljava, 1st ed.; Tomažič, S., Ed.; UL Fakuleta za Elektrotehniko: Ljubljana, Slovenia, 2014; Volume 390, pp. 63–65. Available online: http://lrf.fe.uni-lj.si/razsvetljava.pdf (accessed on 19 August 2021).

- Keitz, H.A.E. Light Calculations and Measurements: An Introduction to the System of Quantities and Units in Light-Technology and to Photometry, 2nd ed.; Macmillan International Higher Education: London, UK, 1971; Available online: https://books.google.si/books?hl=sl&lr=&id=PVJdDwAAQBAJ&oi=fnd&pg=PR4&dq=Light+calculations+and+measurements:+An+introduction+to+the+system+od+quantities+and+units+in+light-technology+and+to+photometry&ots=14a7ze3h02&sig=eEMUmqn2fglgMWs7LLMdqGIk2kI&redir_esc=y-v=onepage&q=Light%20calculations%20and%20measurements%3A%20An%20introduction%20to%20the%20system%20od%20quantities%20and%20units%20in%20light-technology%20and%20to%20photometry&f=false (accessed on 2 August 2021).

| Code nr. | Manufacturer | Wattage [W] | Luminous Flux [lm] | Color Temperature [K] |

|---|---|---|---|---|

| 1 | SYLVANIA (ToLEDo Retro GLS) | 7 | 806 | 2700 |

| 2 | SYLVANIA (ToLEDo GLS) | 8.5 | 806 | 2700 |

| 3 | LIGHTWAY | 11 | 806 | 2700 |

| 4 | XAVAX | 9 | 806 | 2700 |

| 5 | BELLALUX | 7 | 806 | 2700 |

| 6 | EMOS (LED filament) | 8 | 1060 | 2700 |

| 7 | EMOS (LED A60, step dimmable) | 10 | 880 | 2700 |

| 8 | EMOS (LED Classic) | 10 | 806 | 2700 |

| 9 | OSRAM (LED value classic A60) | 8.5 | 806 | 2700 |

| 10 | OSRAM (LED star classic A60, retrofit) | 7 | 806 | 2700 |

| 11 | OPTONICA | 10 | 820 | 4500 |

| 12 | WELL LIGHT (Basic) | 10 | 750 | 3000 |

| 13 | PHILIPS (CorePro LEDbulb) | 9 | 806 | 2700 |

| 14 | AVIDE | 8 | 640 | 3000 |

| 15 | OSRAM (LED superstar P25 advanced) | 4 | 250 | 2700 |

| 16 | OSRAM (Parathom classic A100) | 11 | 1521 | 2700 |

| 17 | BOXXX | 5.5 | 470 | 3000 |

| 18 | HOMEWARE (LED filament) | 6 | 550 | 2700 |

| 19 | HOMEWARE | 6 | 470 | 3000 |

| 20 | V-TAC (LED A60 bulb) | 9 | 806 | 4000 |

| 21 | V-TAC (Pro Samsung LED chip) | 9 | 806 | 4000 |

| 22 | V-TAC (Dimmable filament A67 bulb) | 8 | 700 | 2700 |

| 23 | V-TAC (LED R80 bulb) | 10 | 800 | 4000 |

| 24 | ETA | 7 | 640 | 2700 |

| 25 | ETA (LED filament) | 8 | 1055 | 2700 |

| 26 | TESLA (LED filament) | 4 | 470 | 2700 |

| 27 | TESLA (reflektorska) | 7 | 560 | 3000 |

| 28 | TESLA | 7 | 640 | 3000 |

| 29 | TUNGSRAM (LED filament) | 4.5 | 470 | 2700 |

| 30 | TUNGSRAM | 9 | 810 | 2700 |

| 31 | BLAUPUNKT (G45 LED) | 4 | 470 | 2700 |

| 32 | BLAUPUNKT (A60 LED) | 8.5 | 806 | 3000 |

| 33 | GOOBAY | 9 | 810 | 2700 |

| 34 | GOOBAY (LED filament) | 4 | 450 | 2700 |

| 35 | FEROTEHNA | 5 | 400 | 3000 |

| 36 | VOLTOLUX (LED filament) | 4 | 470 | 2700 |

| 37 | VOLTOLUX | 8.5 | 806 | 2700 |

| 38 | SIMPEX (LED filament, dimmable) | 8.3 | 806 | 2700 |

| 39 | SIMPEX | 9.4 | 806 | 2700 |

| 40 | S-BUDGET | 7 | 806 | 2700 |

| 41 | S-BUDGET (LED filament) | 7 | 806 | 2700 |

| 42 | COMMEL | 9 | 806 | 3000 |

| 43 | TORE | 9 | 806 | 2700 |

| 44 | KOBI-LIGHT | 10 | 800 | 3000 |

| 45 | KOBI-LIGHT (LED filament, retro) | 7 | 800 | 2700 |

| 46 | VP-EL | 12 | 1200 | 2700 |

| 47 | GLOBO | 6 | 650 | 2700 |

| 48 | GLOBO (LED filament) | 7 | 806 | 2700 |

| 49 | HOROZ | 8 | 850 | 4200 |

| 50 | ISKRA | 5 | 470 | 3000 |

| 51 | ISKRA (LED filament) | 4 | 400 | 2700 |

| 52 | EGLO (LED filament, dimmable) | 6 | 806 | 2700 |

| 53 | GE LIGHTING (LED filament) | 5 | 590 | 2700 |

| 54 | GE LIGHTING | 7 | 470 | 2700 |

| 55 | BRILAGI (ECO line A60) | 10 | 900 | 3000 |

| 56 | FARO (milky LED) | 7 | 800 | 2700 |

| 57 | EMITHOR | 5 | 400 | 3000 |

| 58 | EGLO (dimmable) | 10 | 806 | 3000 |

| 59 | PAULMANN (LED filament, dimmable) | 4.5 | 470 | 2700 |

| Ranking | Code nr. | Manufacturer | Percentage of Fluctuations [%] |

|---|---|---|---|

| 1. | 8 | EMOS (LED Classic) | 0 |

| 2. | 27 | TESLA (reflektorska) | 4.1 |

| 3. | 23 | V-TAC (LED R80 bulb) | 5.0 |

| 4. | 46 | VP-EL | 5.5 |

| 5. | 16 | OSRAM (Parathom classic A100) | 7.6 |

| 6. | 37 | VOLTOLUX | 7.8 |

| 7. | 13 | PHILIPS (CorePro LEDbulb) | 7.8 |

| 8. | 32 | BLAUPUNKT (A60 LED) | 8.3 |

| 9. | 2 | SYLVANIA (ToLEDo GLS) | 8.4 |

| 10. | 43 | TORE | 8.6 |

| 11. | 7 | EMOS (LED A60, step dimmable) | 8.9 |

| 12. | 42 | COMMEL | 10.1 |

| 13. | 58 | EGLO (dimmable) | 10.8 |

| 14. | 44 | KOBI-LIGHT | 10.8 |

| 15. | 55 | BRILAGI (ECO line A60) | 11.2 |

| 16. | 33 | GOOBAY | 11.5 |

| 17. | 4 | XAVAX | 11.5 |

| 18. | 24 | ETA | 12.2 |

| 19. | 9 | OSRAM (LED value classic A60) | 12.8 |

| 20. | / | / | 13.0 |

| 21. | / | / | 13.1 |

| 22. | / | / | 13.2 |

| 23. | / | / | 13.2 |

| 24. | / | / | 13.3 |

| 25. | / | / | 13.8 |

| 26. | / | / | 14.0 |

| 27. | / | / | 14.1 |

| 28. | / | / | 14.4 |

| 29. | / | / | 16.7 |

| 30. | / | / | 17.7 |

| 31. | / | / | 17.8 |

| 32. | / | / | 17.9 |

| 33. | / | / | 19.3 |

| 34. | / | / | 20.3 |

| 35. | / | / | 20.5 |

| 36. | / | / | 20.8 |

| 37. | / | / | 21.3 |

| 38. | / | / | 23.2 |

| 39. | / | / | 23.5 |

| 40. | / | / | 23.6 |

| 41. | / | / | 24.1 |

| 42. | / | / | 24.5 |

| 43. | / | / | 24.7 |

| 44. | / | / | 26.2 |

| 45. | / | / | 26.7 |

| 46. | / | / | 28.1 |

| 47. | / | / | 28.8 |

| 48. | / | / | 29.3 |

| 49. | / | / | 29.9 |

| 50. | / | / | 32.7 |

| 51. | / | / | 34.6 |

| 52. | / | / | 35.5 |

| 53. | / | / | 36.6 |

| 54. | / | / | 53.6 |

| 55. | / | / | 63.6 |

| 56. | / | / | 64.6 |

| 57. | / | / | 65.4 |

| 58. | / | / | 74.0 |

| 59. | / | / | 82.4 |

| Ranking | Code nr. | Manufacturer | Deviation [%] |

|---|---|---|---|

| 1. | 16 | OSRAM (Parathom classic A100) | −0.3 |

| 2. | 43 | TORE | 0.6 |

| 3. | 54 | GE LIGHTING | −0.9 |

| 4. | 38 | SIMPEX (LED filament, dimmable) | −1.0 |

| 5. | 50 | ISKRA | 1.6 |

| 6. | 34 | GOOBAY (LED filament) | 2.3 |

| 7. | 5 | BELLALUX | −3.1 |

| 8. | 48 | GLOBO (LED filament) | −3.3 |

| 9. | 21 | V-TAC (Pro Samsung LED chip) | −3.3 |

| 10. | 11 | OPTONICA | 3.5 |

| 11. | 2 | SYLVANIA (ToLEDo GLS) | −4.5 |

| 12. | 3 | LIGHTWAY | 4.8 |

| 13. | 32 | BLAUPUNKT (A60 LED) | −5.1 |

| 14. | 42 | COMMEL | −5.7 |

| 15. | 47 | GLOBO | −5.7 |

| 16. | 23 | V-TAC (LED R80 bulb) | −6.3 |

| 17. | 37 | VOLTOLUX | −6.3 |

| 18. | 19 | HOMEWARE | 6.5 |

| 19. | 56 | FARO (milky LED) | −7.2 |

| 20. | / | / | 7.2 |

| 21. | / | / | −7.8 |

| 22. | / | / | 8.0 |

| 23. | / | / | 8.7 |

| 24. | / | / | 9.1 |

| 25. | / | / | −9.3 |

| 26. | / | / | −9.6 |

| 27. | / | / | −10.1 |

| 28. | / | / | 10.1 |

| 29. | / | / | −10.6 |

| 30. | / | / | −11.2 |

| 31. | / | / | −11.5 |

| 32. | / | / | 11.5 |

| 33. | / | / | −12.5 |

| 34. | / | / | −13.4 |

| 35. | / | / | −13.9 |

| 36. | / | / | −14.0 |

| 37. | / | / | 14.5 |

| 38. | / | / | −15.6 |

| 39. | / | / | −16.8 |

| 40. | / | / | −17.9 |

| 41. | / | / | −18.2 |

| 42. | / | / | −18.5 |

| 43. | / | / | −19.0 |

| 44. | / | / | −19.4 |

| 45. | / | / | −19.5 |

| 46. | / | / | −20.4 |

| 47. | / | / | −20.4 |

| 48. | / | / | −20.5 |

| 49. | / | / | −21.1 |

| 50. | / | / | −21.2 |

| 51. | / | / | −22.4 |

| 52. | / | / | 24.7 |

| 53. | / | / | −25.8 |

| 54. | / | / | −25.9 |

| 55. | / | / | 30.4 |

| 56. | / | / | −30.9 |

| 57. | / | / | −41.5 |

| 58. | / | / | −42.2 |

| 59. | / | / | −47.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Markovič, M.; Orgulan, A.; Sukič, P. Measuring System for Determining the Quality of LED Light Sources and an Overview of LED Light Bulbs for Household Use. Sensors 2022, 22, 8351. https://doi.org/10.3390/s22218351

Markovič M, Orgulan A, Sukič P. Measuring System for Determining the Quality of LED Light Sources and an Overview of LED Light Bulbs for Household Use. Sensors. 2022; 22(21):8351. https://doi.org/10.3390/s22218351

Chicago/Turabian StyleMarkovič, Matic, Andrej Orgulan, and Primož Sukič. 2022. "Measuring System for Determining the Quality of LED Light Sources and an Overview of LED Light Bulbs for Household Use" Sensors 22, no. 21: 8351. https://doi.org/10.3390/s22218351

APA StyleMarkovič, M., Orgulan, A., & Sukič, P. (2022). Measuring System for Determining the Quality of LED Light Sources and an Overview of LED Light Bulbs for Household Use. Sensors, 22(21), 8351. https://doi.org/10.3390/s22218351