Innovative Bidirectional Isolated High-Power Density On-Board Charge for Vehicle-to-Grid

Abstract

:1. Introduction

- A description of the implementation of the first prototype and its problems related to the circuit topology and parasitic properties of the elements encountered and their solutions not reported in the literature;

- Describe the elimination of voltage spikes using passive disconnectors (RCDs) proved inappropriate due to the significant power losses;

- The introduction of an innovative approach that eliminates voltage spikes based on the use of an applied active clamp in this situation;

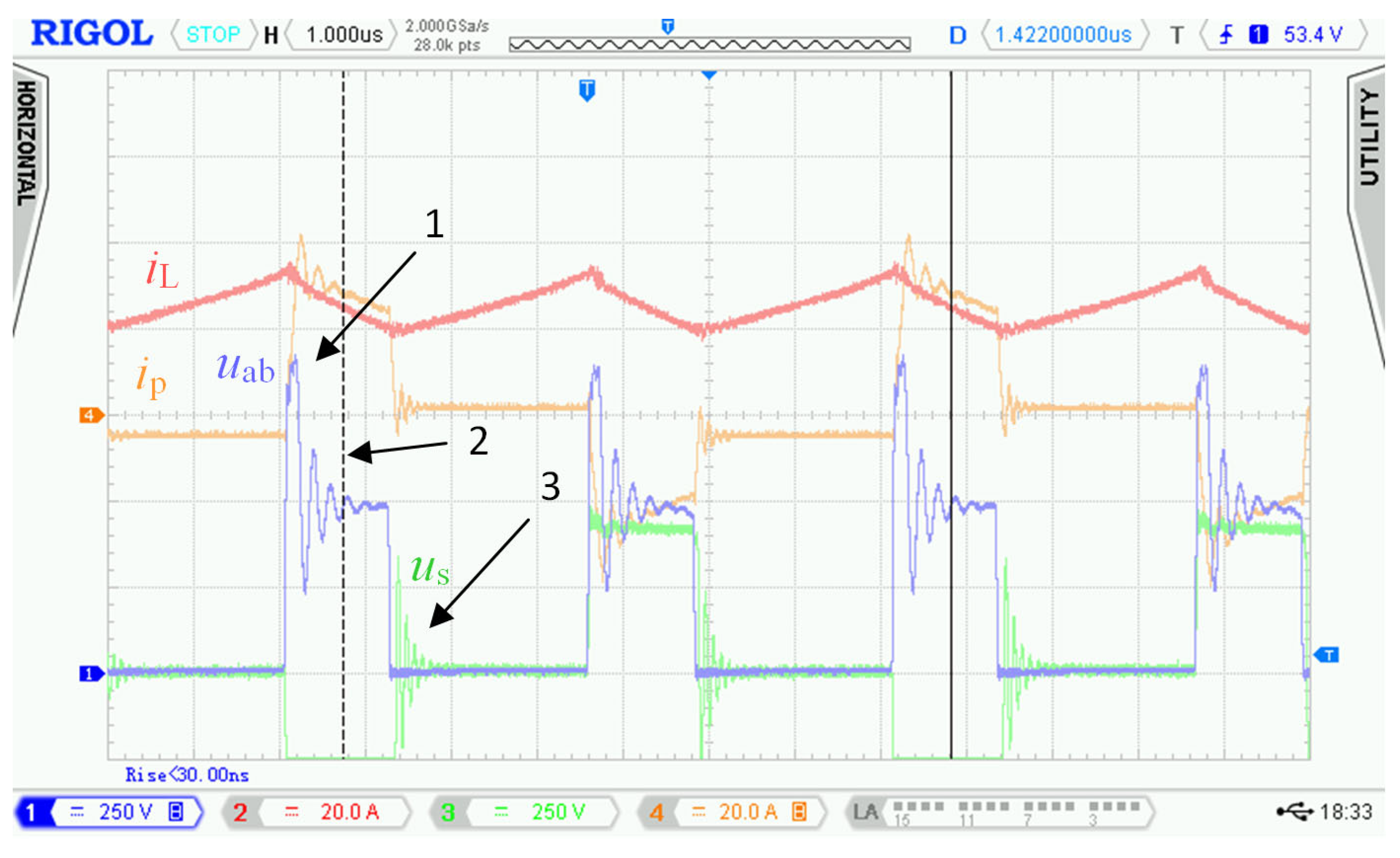

- Proposed and described a switching control method that eliminates unwanted HF oscillations on both the primary and secondary sides of the transformer in the on-board charger;

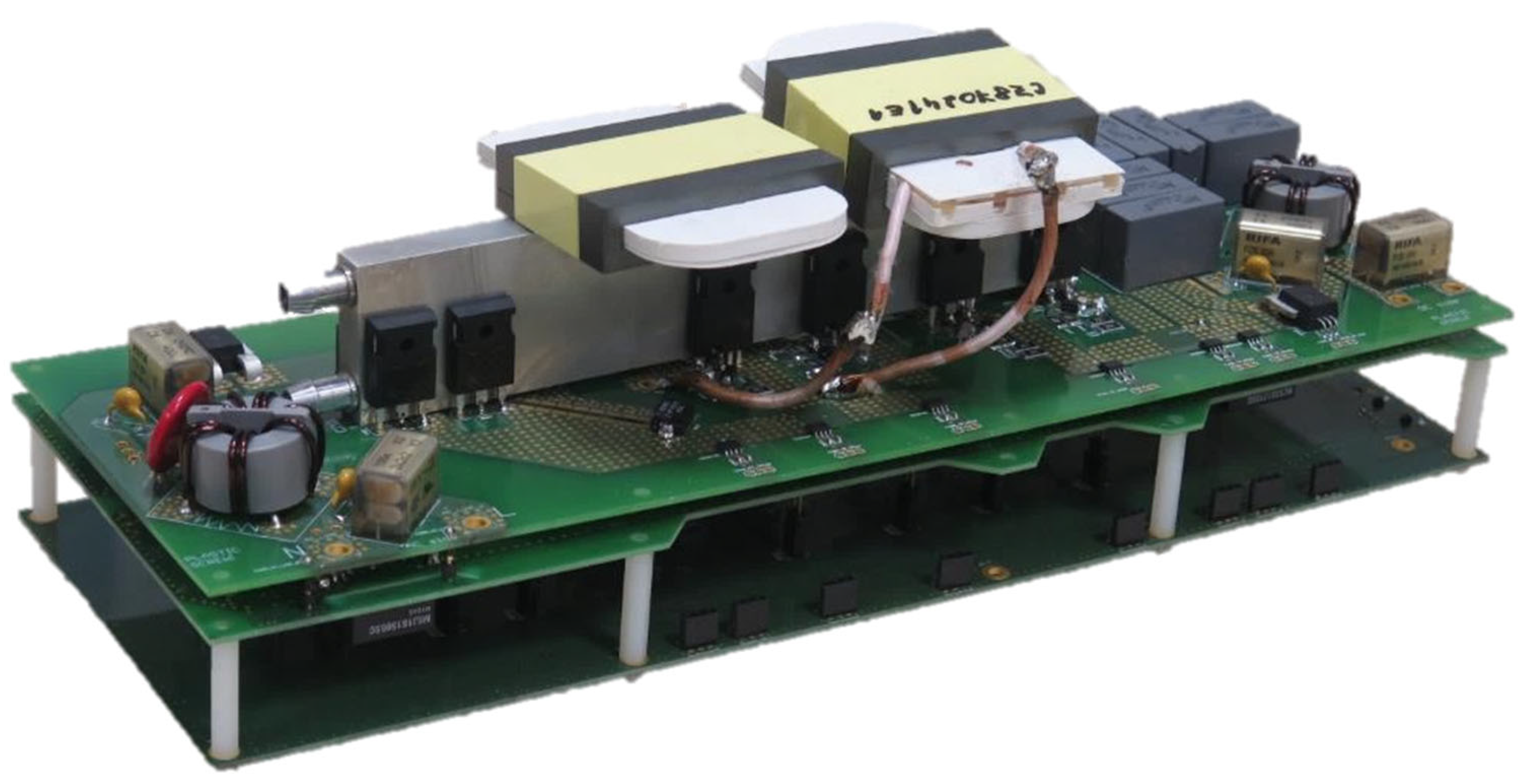

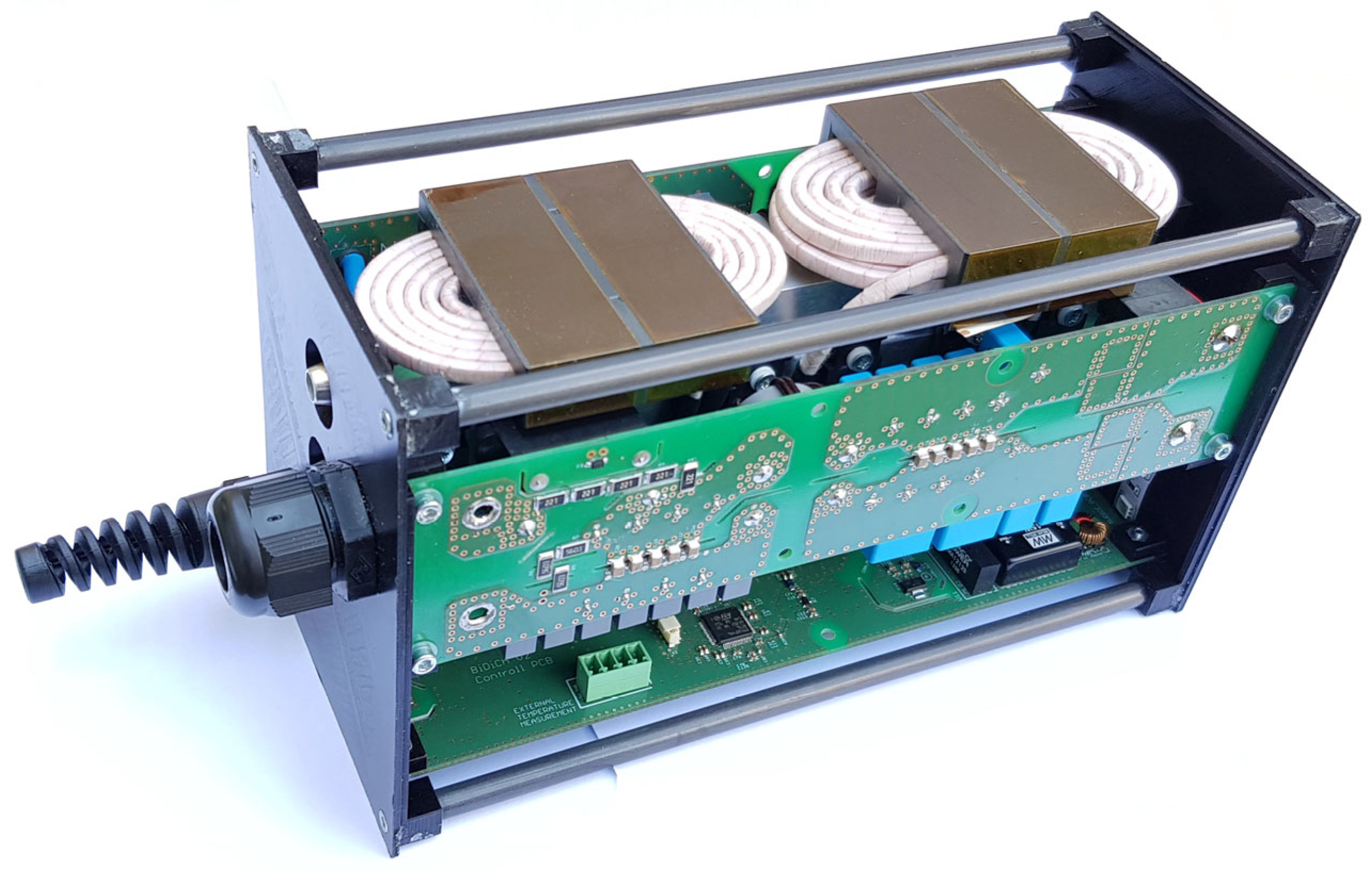

- Description of the development, implementation and testing of a bidirectional charger with galvanic isolation, whose parameters were 4 kW/kg and 2.46 kW/dm3 and the maximum power of the charger is 7.2 kW, which uses a switching frequency of 150 kHz.

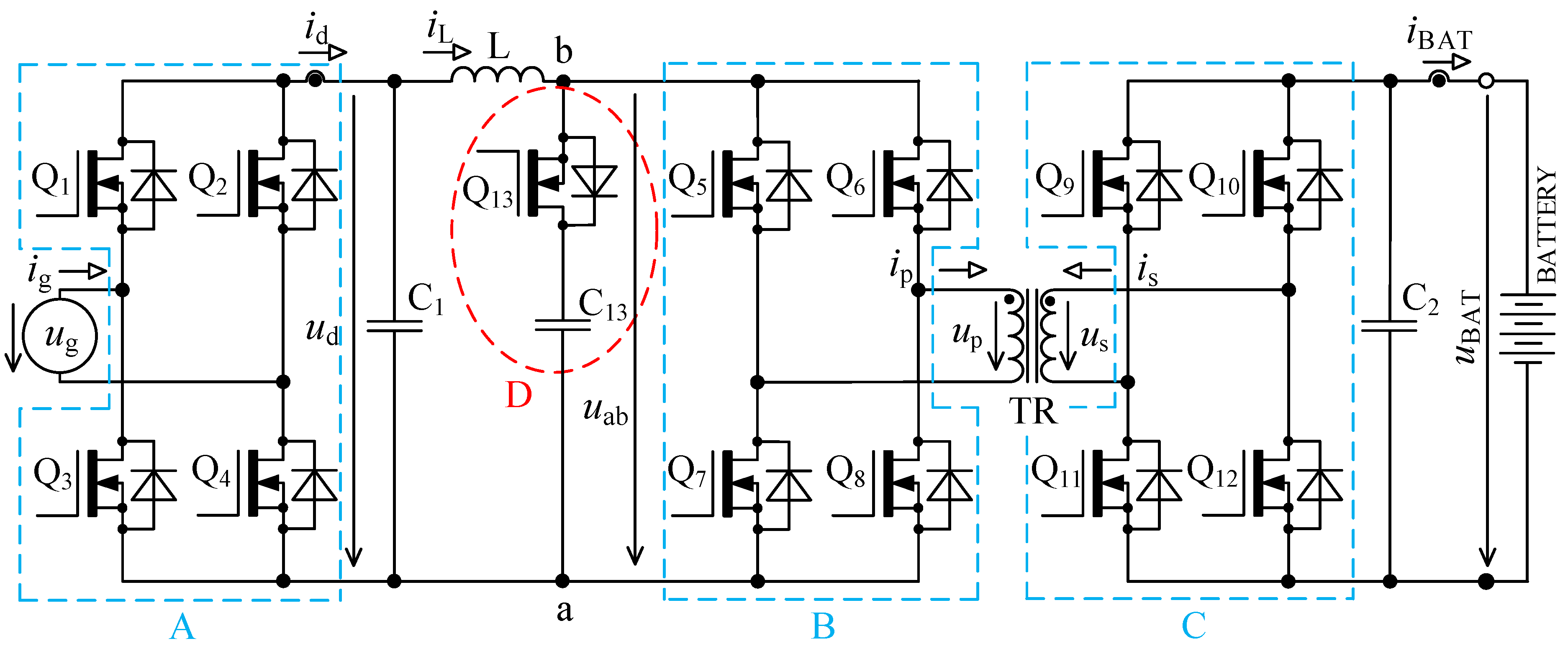

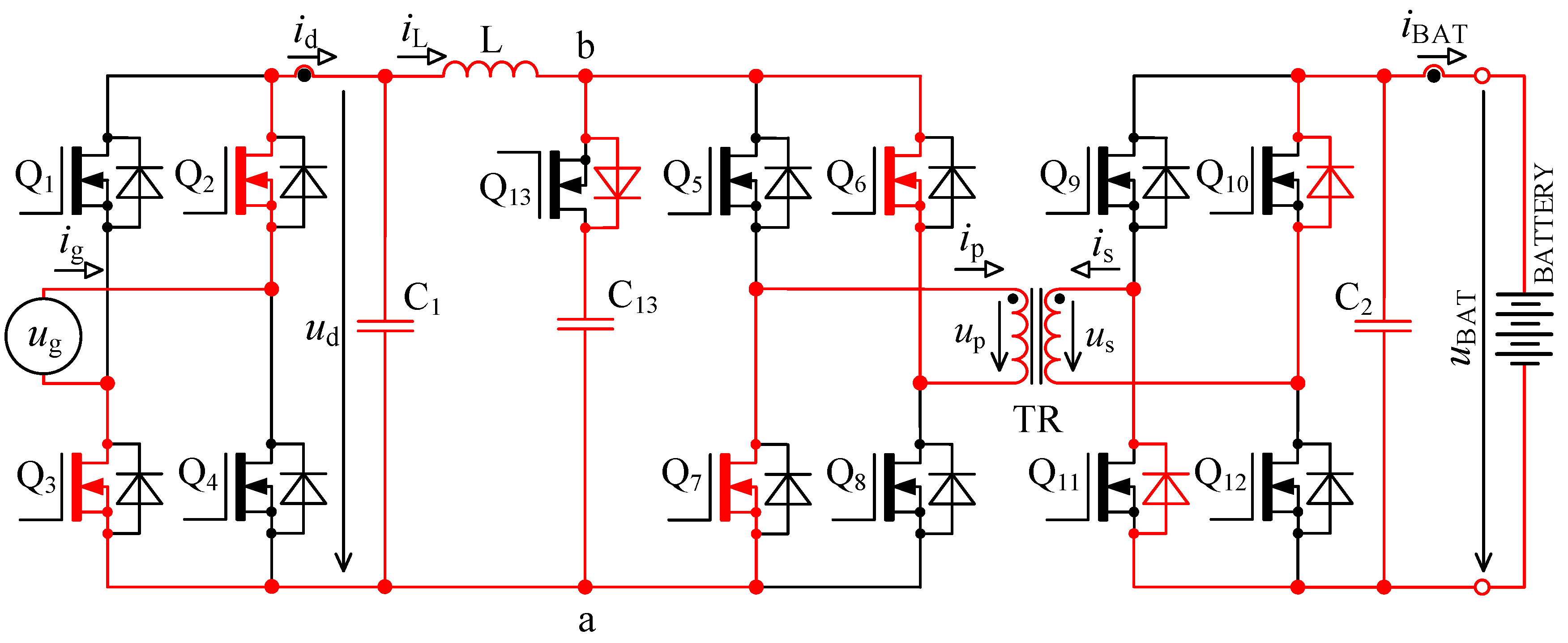

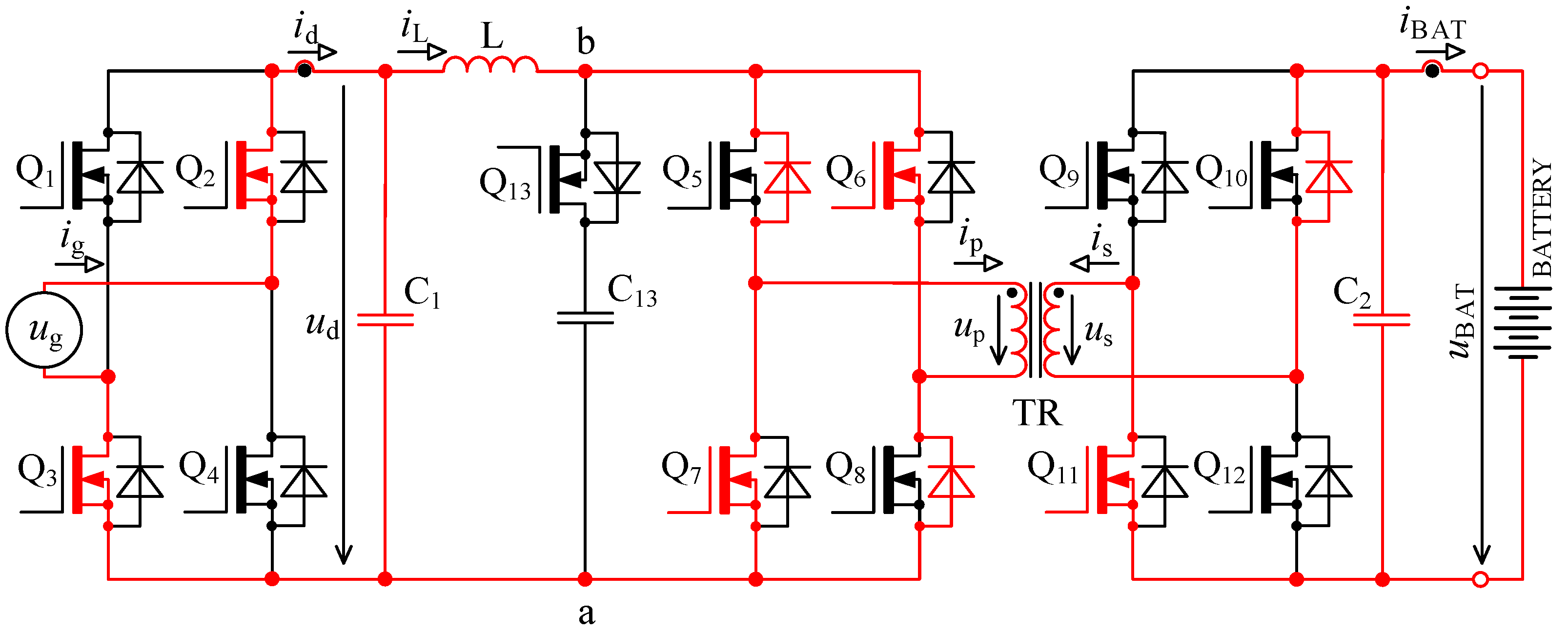

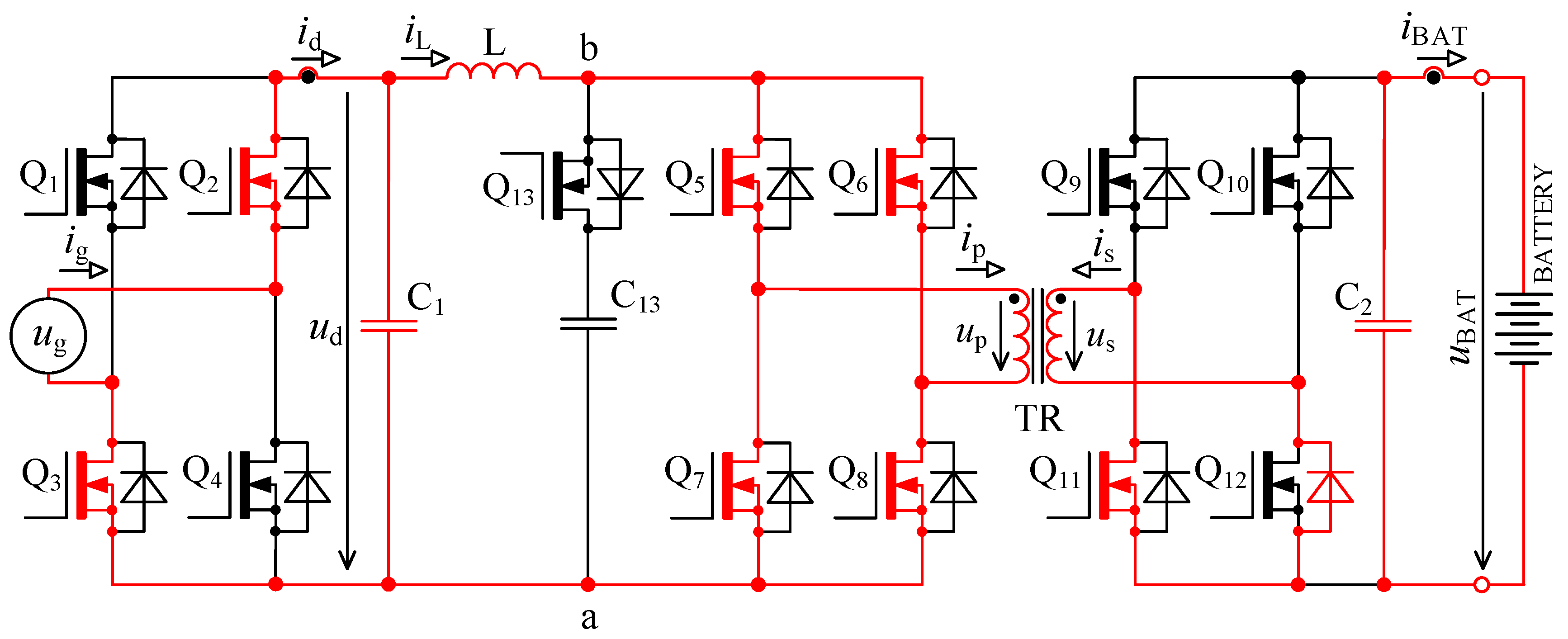

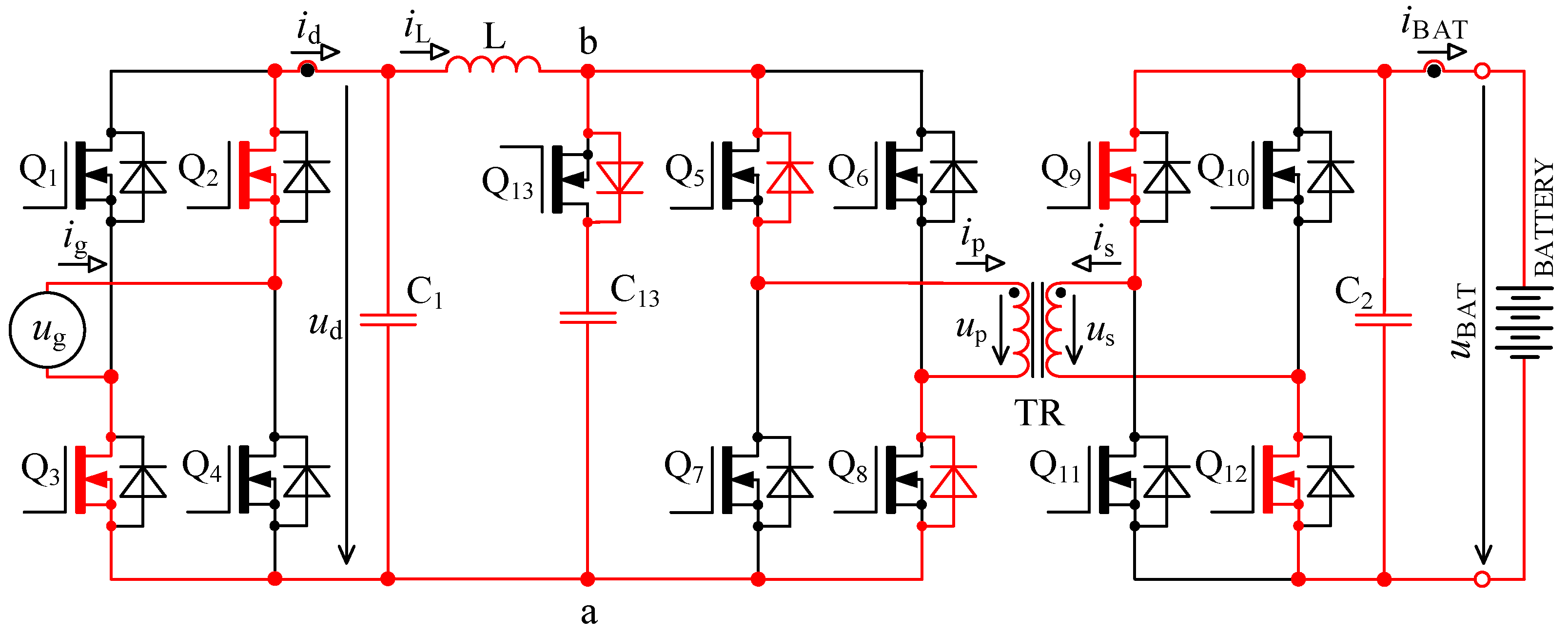

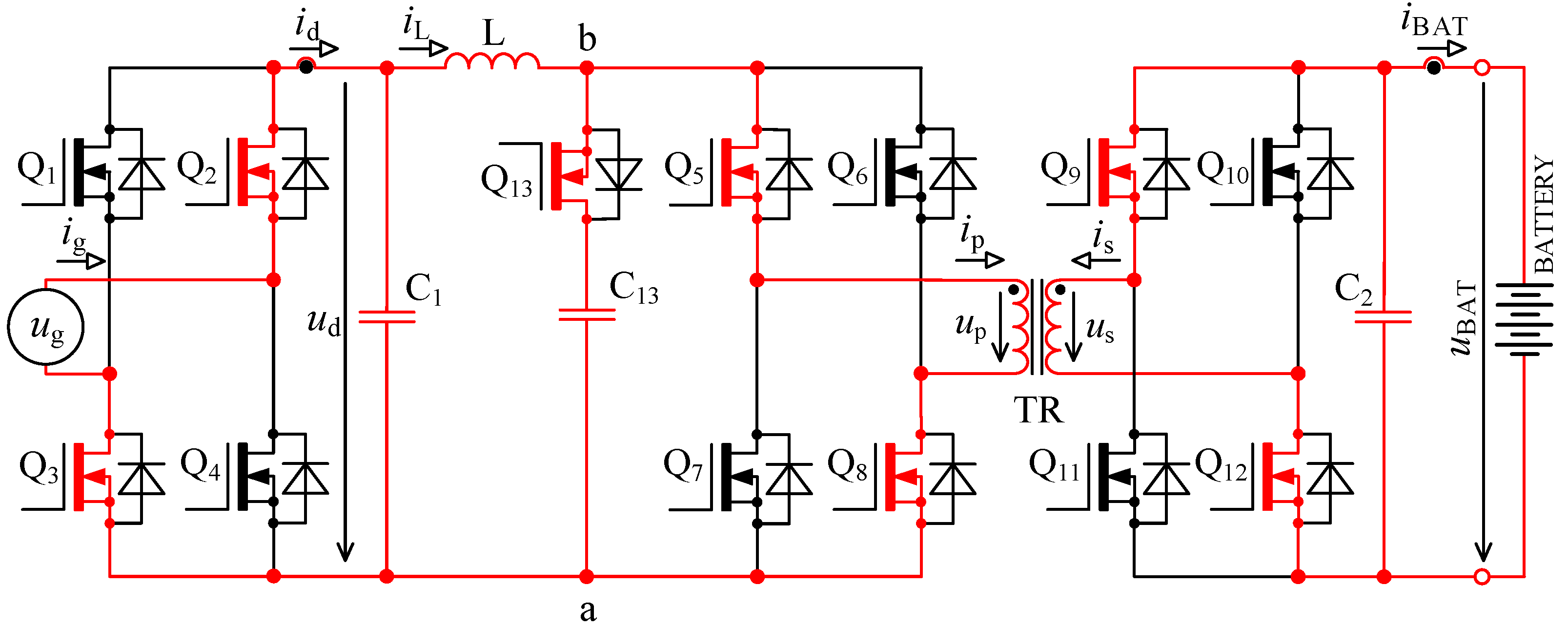

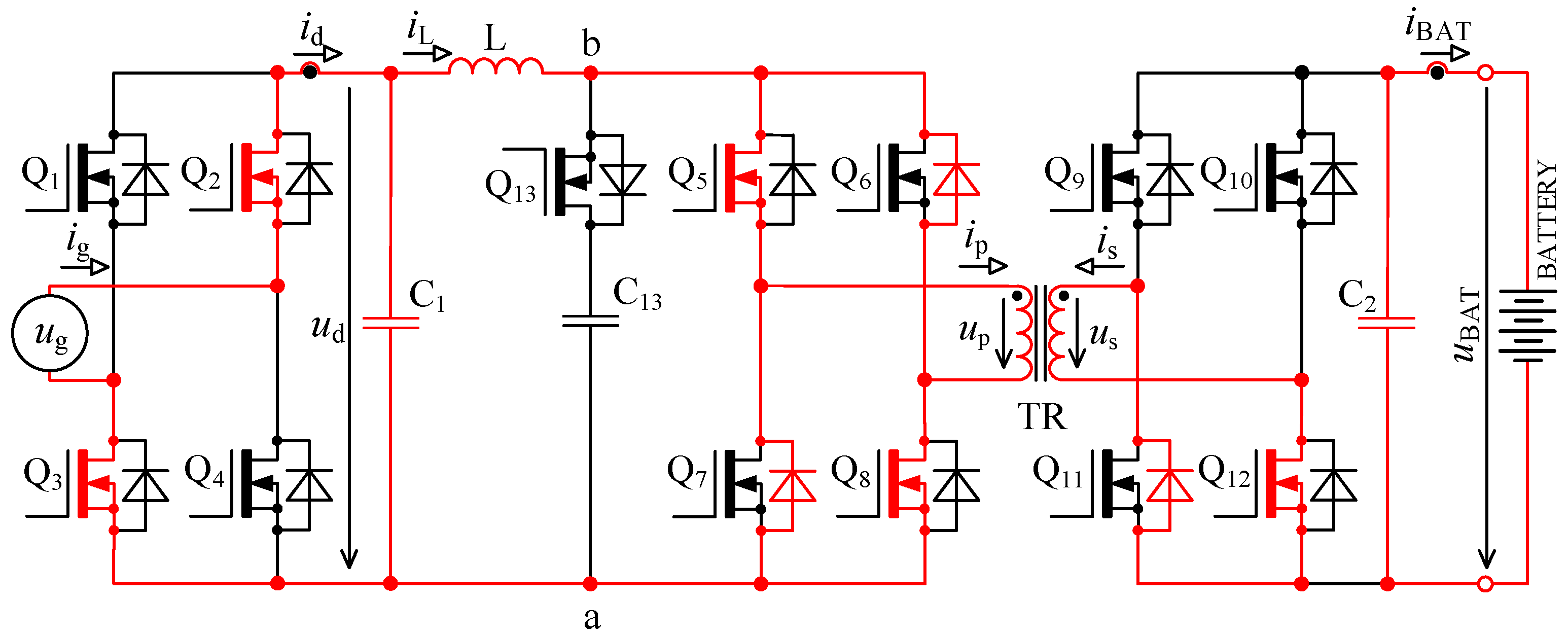

2. Verification of Selected Topology of Bidirectional Charger

2.1. Calculation of Accumulating Inductor Inductance

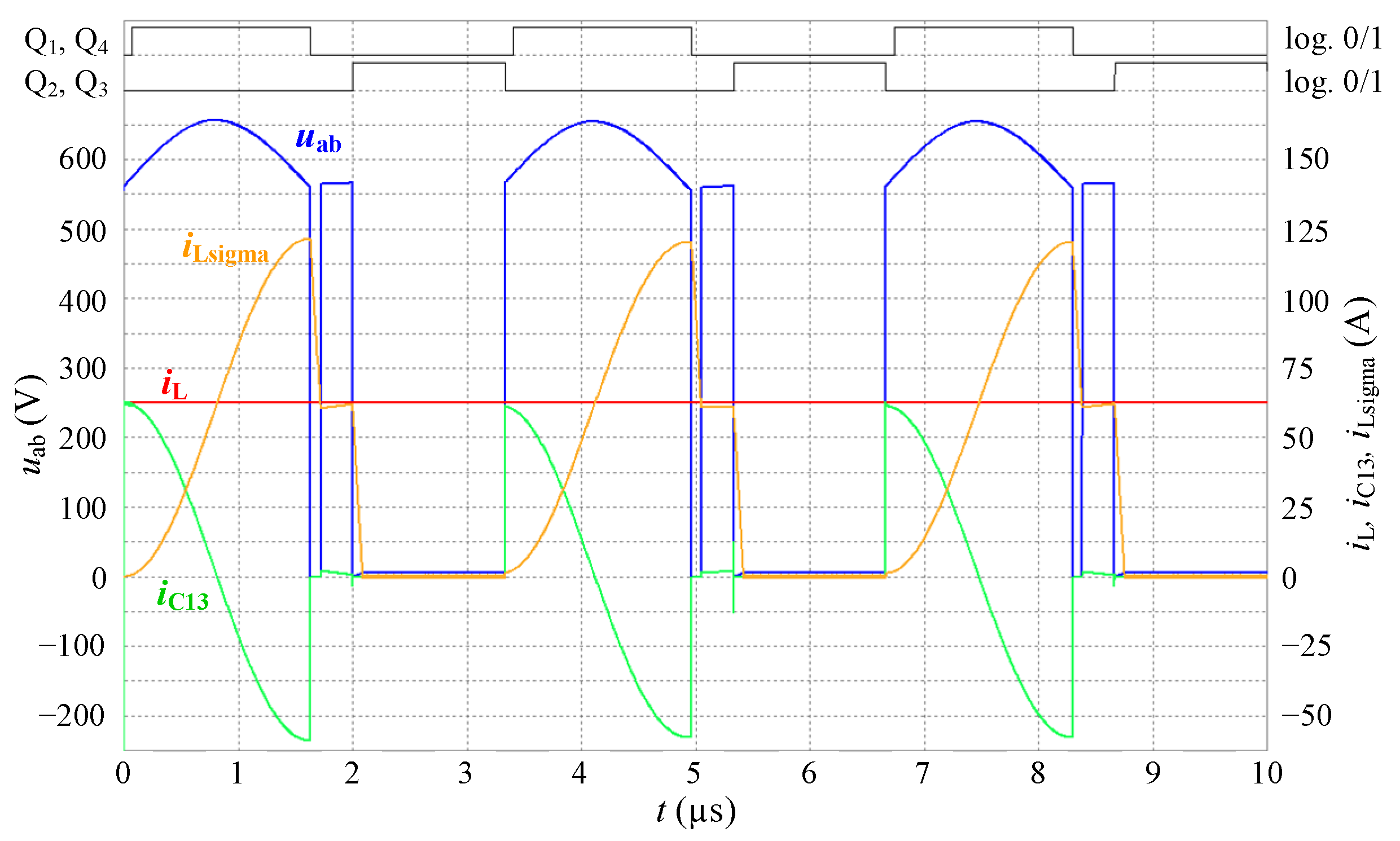

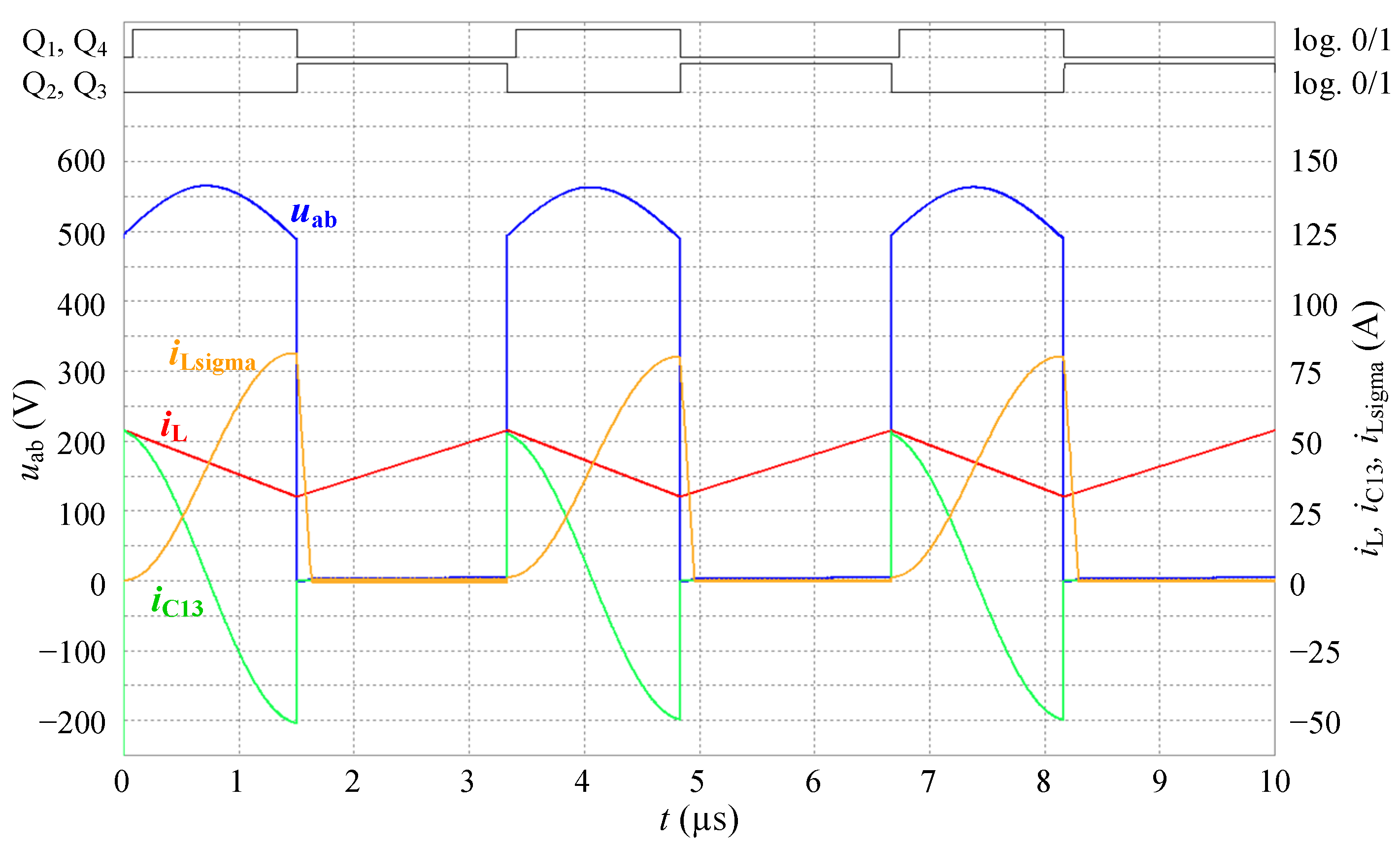

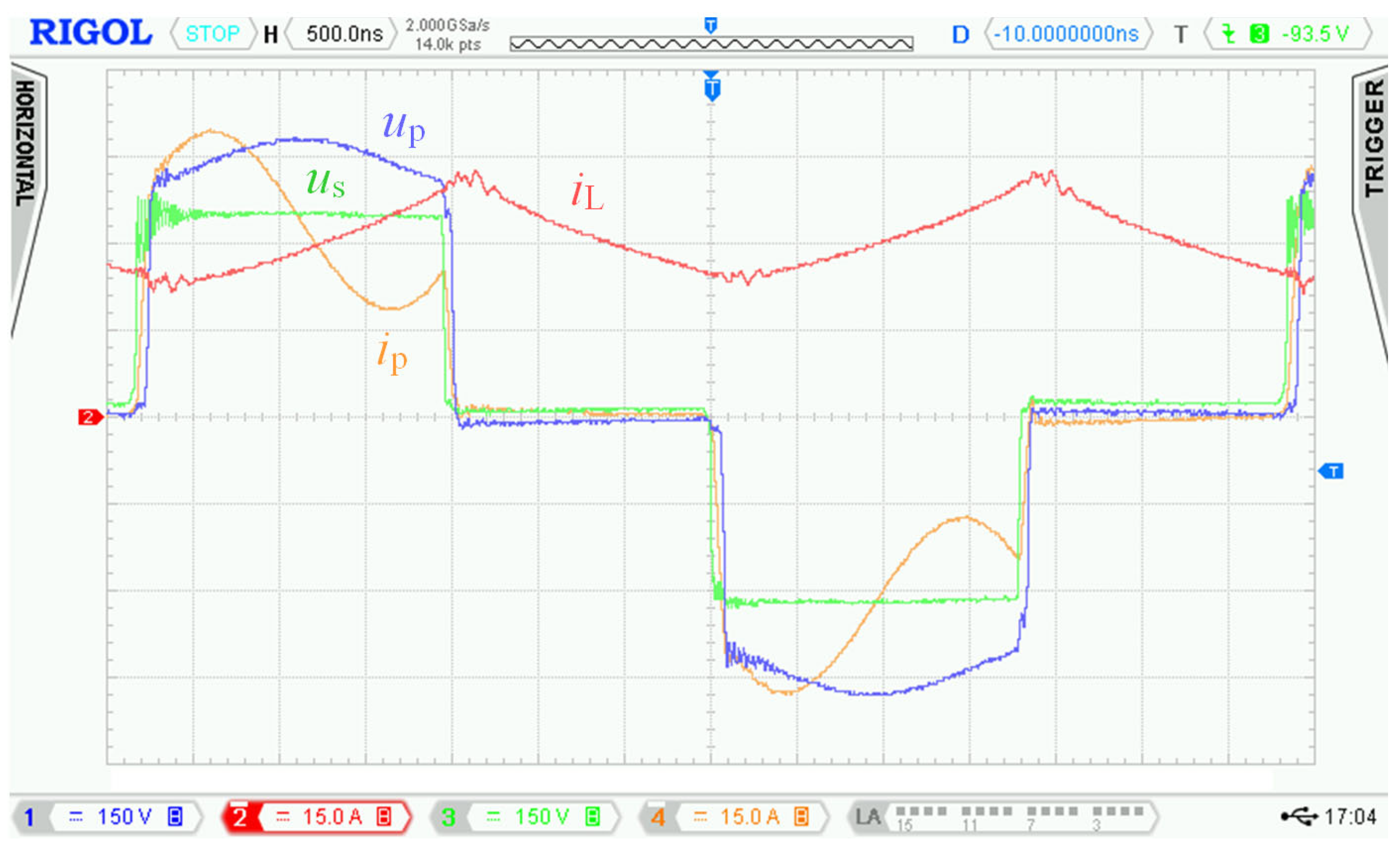

2.2. Experimental Results Measured on the First Prototype of Bidirectional Charger

- Microcontroller EFM8LB12F64E-QFP32 from Silicon Labs.

- Supporting circuits for logic of control pulses and elimination of various switching failure modes.

- Regulated power supplies with various output voltages.

- Power transistors, capacitors, planar transformer and inductor. With respect to the required dimensions and overall weight of the device cores, E64/10/50-3F36 and PLT64/50/5-3F36 were used. A detailed list of the used components is given in Section 4.

3. Selected Topology Troubleshooting

3.1. Root Cause Description of Overvoltage on the Primary Side of Transformer and Solution

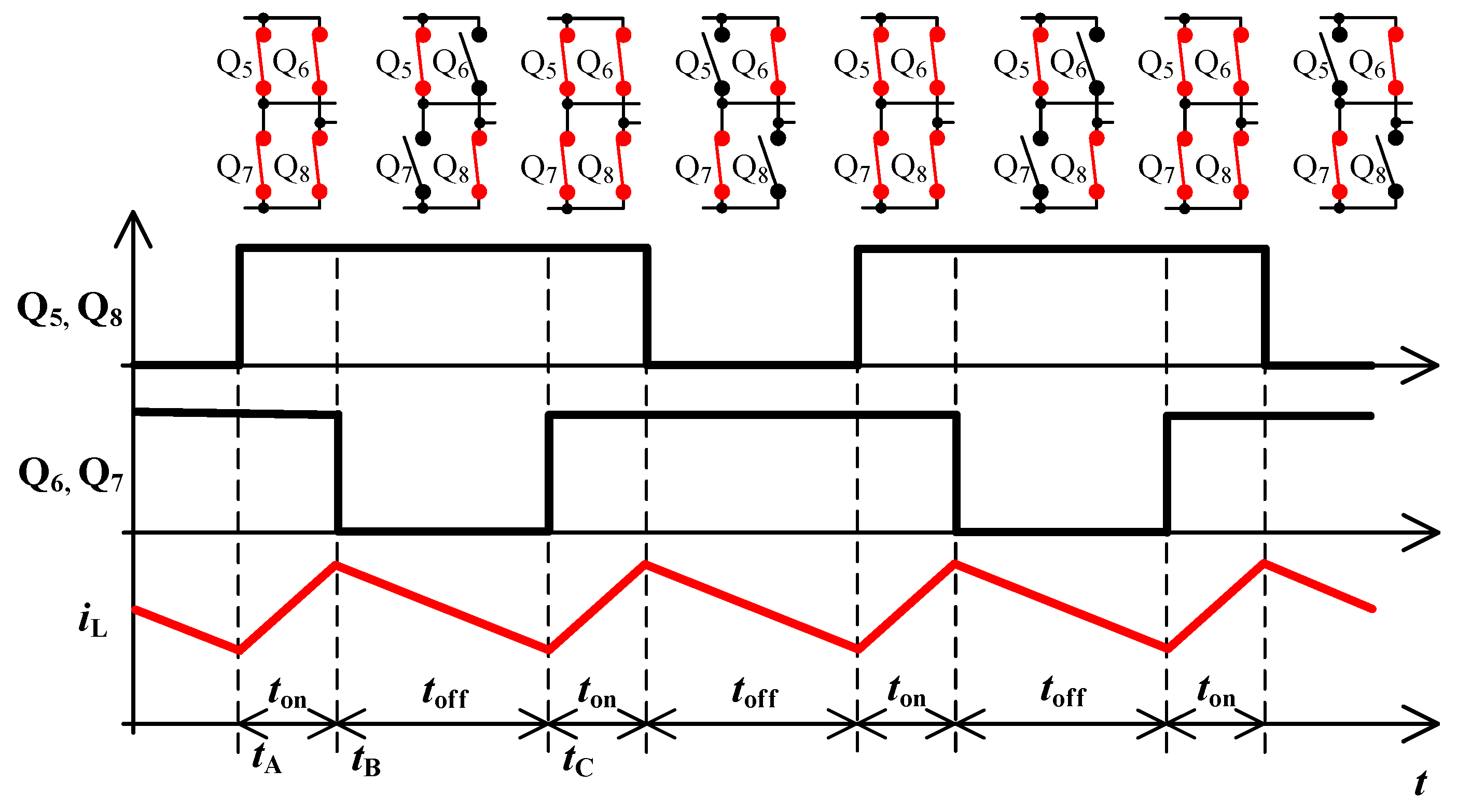

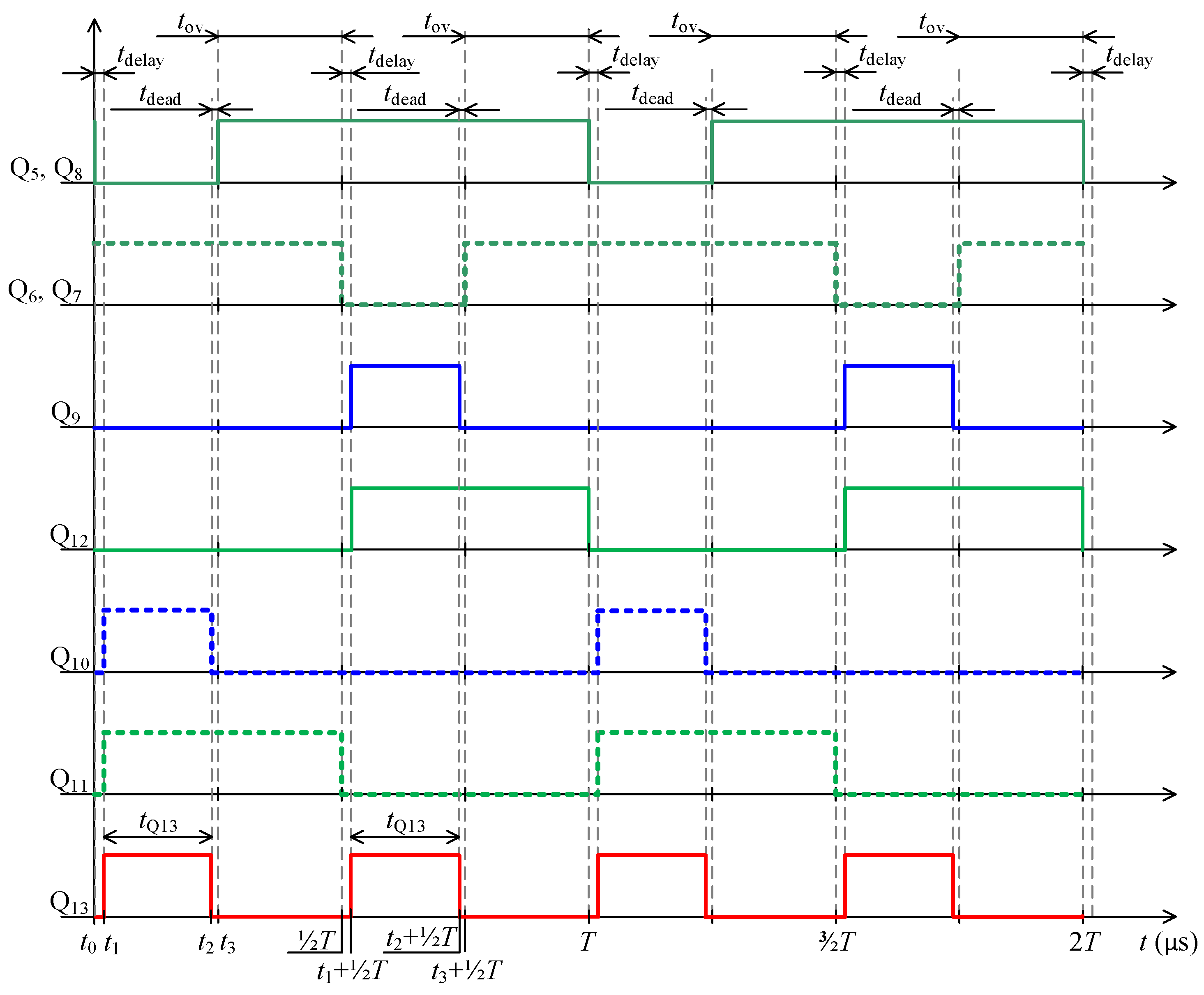

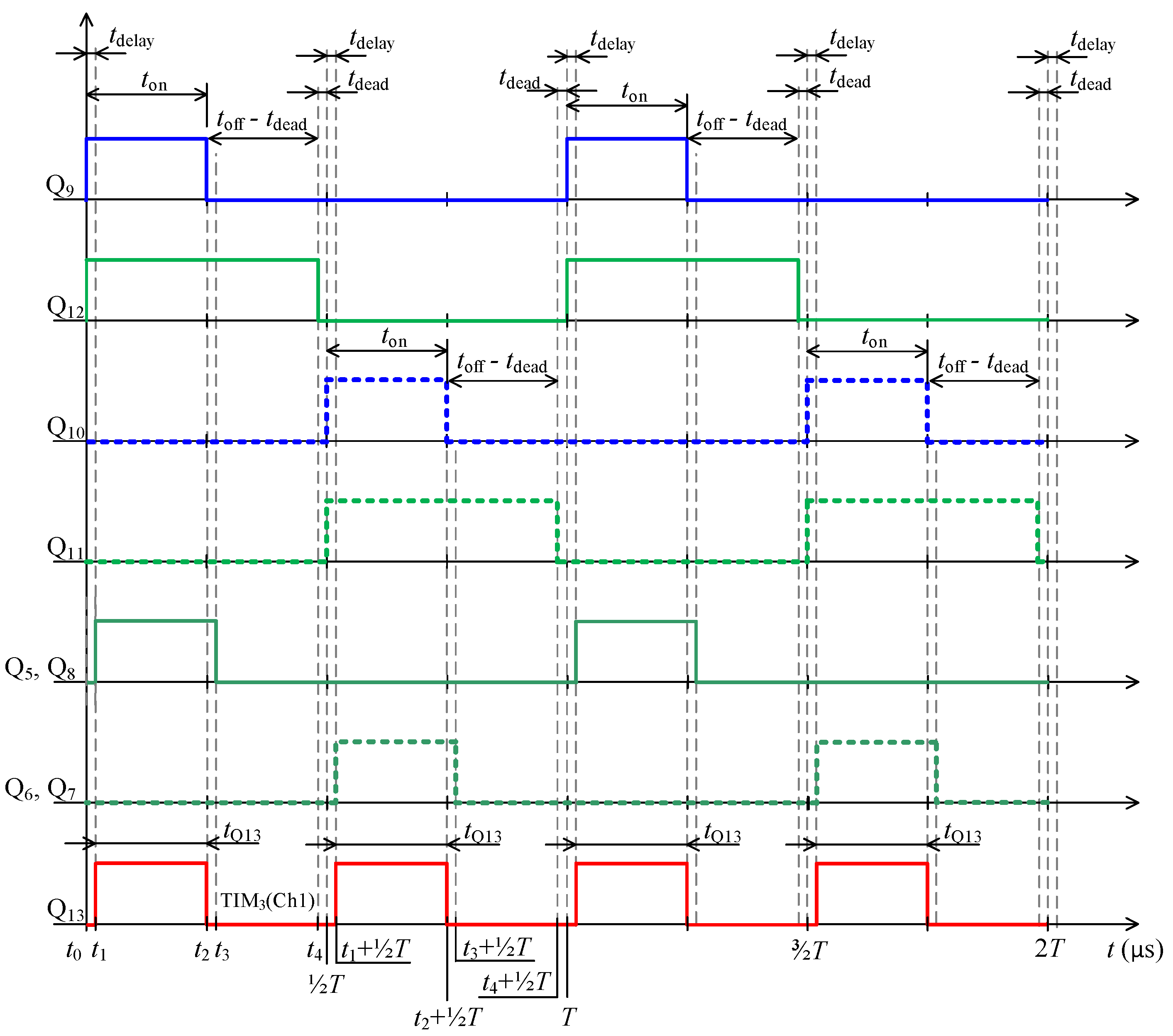

3.2. Principle of the New Strategy of Bidirectional Charger Control in the Charging Mode

3.2.1. Time Interval t0 ≤ t < t1

3.2.2. Time Interval t1 ≤ t < t2

- Between switching off transistor pair Q5, Q8 and switching on Q3, while transistors Q6, Q7 remain switched off. Simultaneous switching on of all transistors in bridge “B” would mean short circuit of capacitor C13.

- Guarantees that voltage generated across the secondary winding of the transformer is greater than battery voltage uBAT.

3.2.3. Time Interval t2 ≤ t < t3

3.2.4. Time Interval t3 ≤ t < ½T

3.2.5. Time Interval ½T ≤ t < (t1 + ½T)

3.2.6. Time Interval (t1 + ½T) ≤ t < (t2 + ½T)

3.2.7. Time Interval (t2 + ½T) ≤ t < (t3 + ½T)

3.2.8. Time Interval (t3 + ½T) ≤ t < T

3.3. Principle of the New Strategy of Bidirectional Charger Control in the Discharging Mode

3.3.1. Time Interval t0 ≤ t < t1

3.3.2. Time Interval t1 ≤ t < t2

3.3.3. Time Interval t2 ≤ t < t3

3.3.4. Time Interval t3 ≤ t < t4

3.3.5. Time Interval t4 ≤ t < ½T

3.3.6. Time Interval ½T ≤ t < (t1 + ½T)

3.3.7. Time Interval (t1 + ½T) ≤ t < (t2 + ½T)

3.3.8. Time Interval (t2 + ½T) ≤ t < (t3 + ½T)

3.3.9. Time Interval (t3 + ½T) ≤ t < (t4 + ½T)

3.3.10. Time Interval (t4 + ½T) ≤ t < T

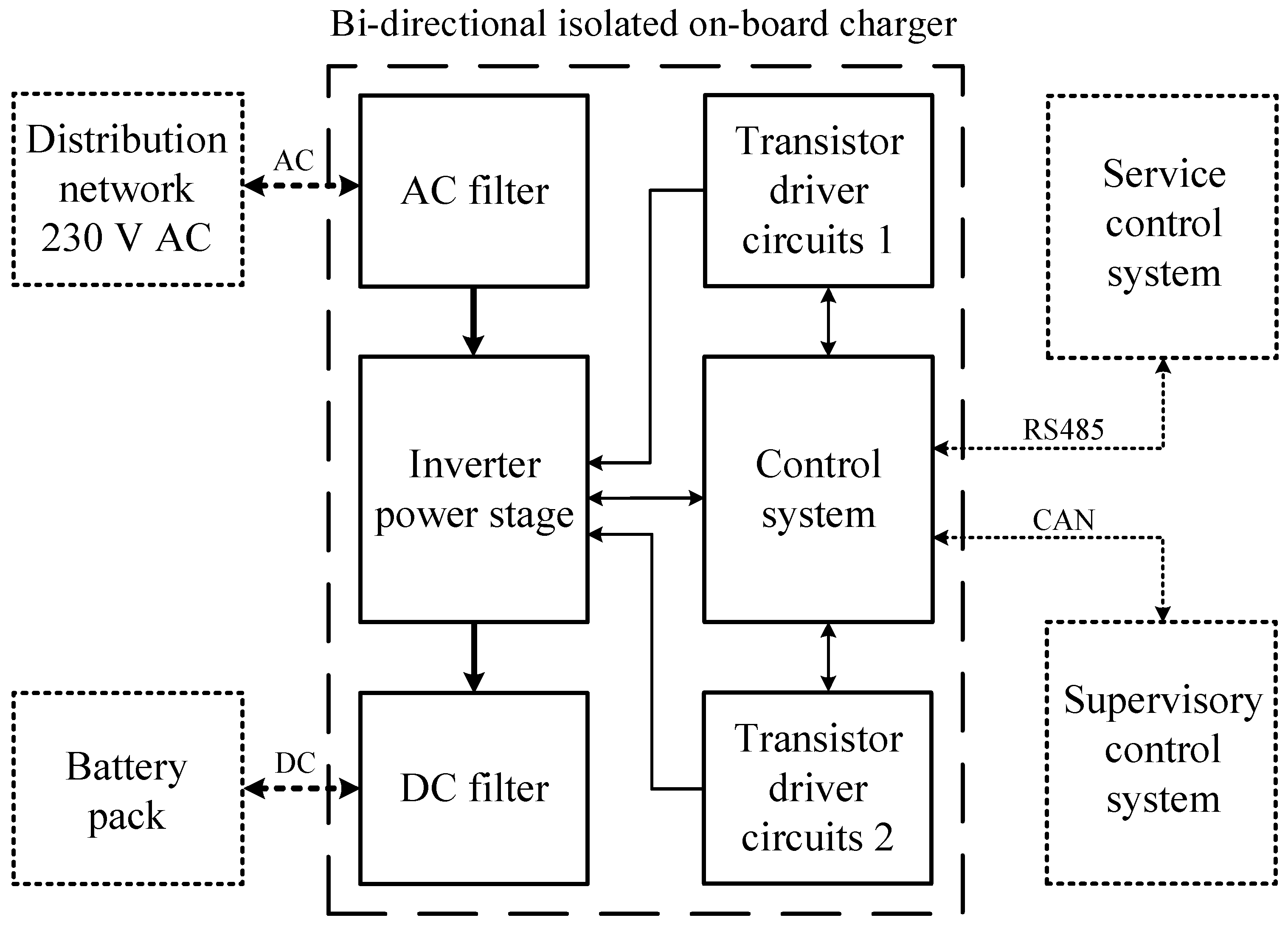

4. New Prototype of a Bidirectional Charger Enhanced with Active Element “D”

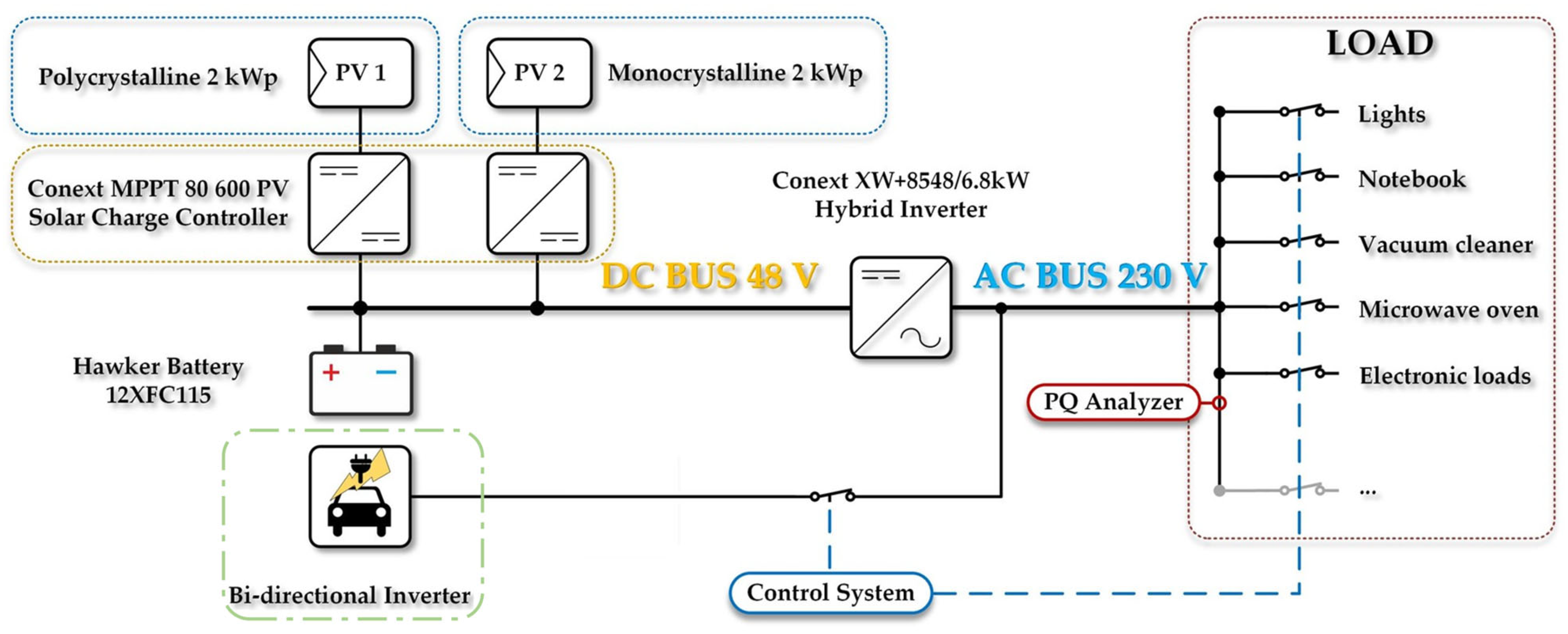

5. The Experimental Microgrid Platform

6. Results and Discussion

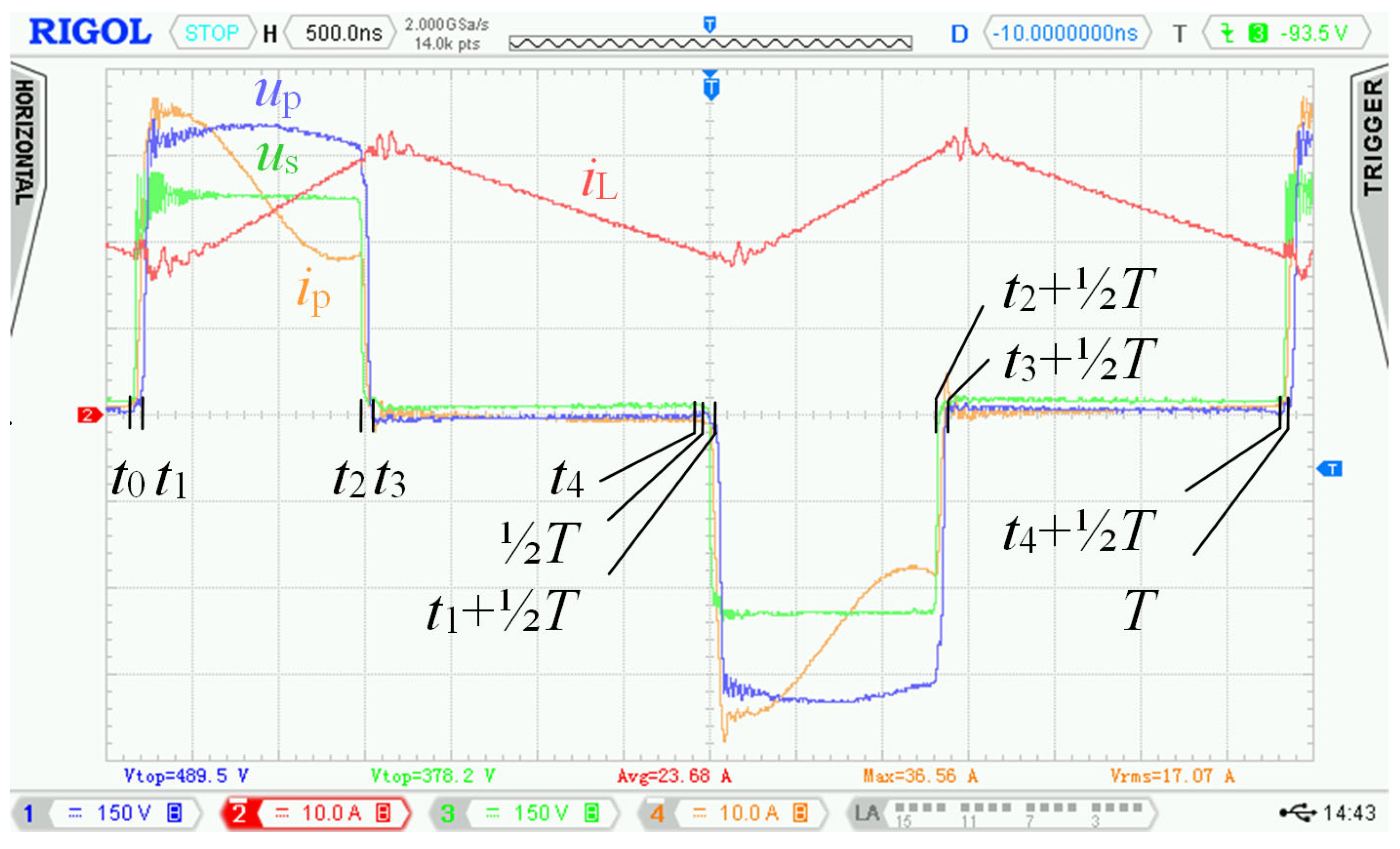

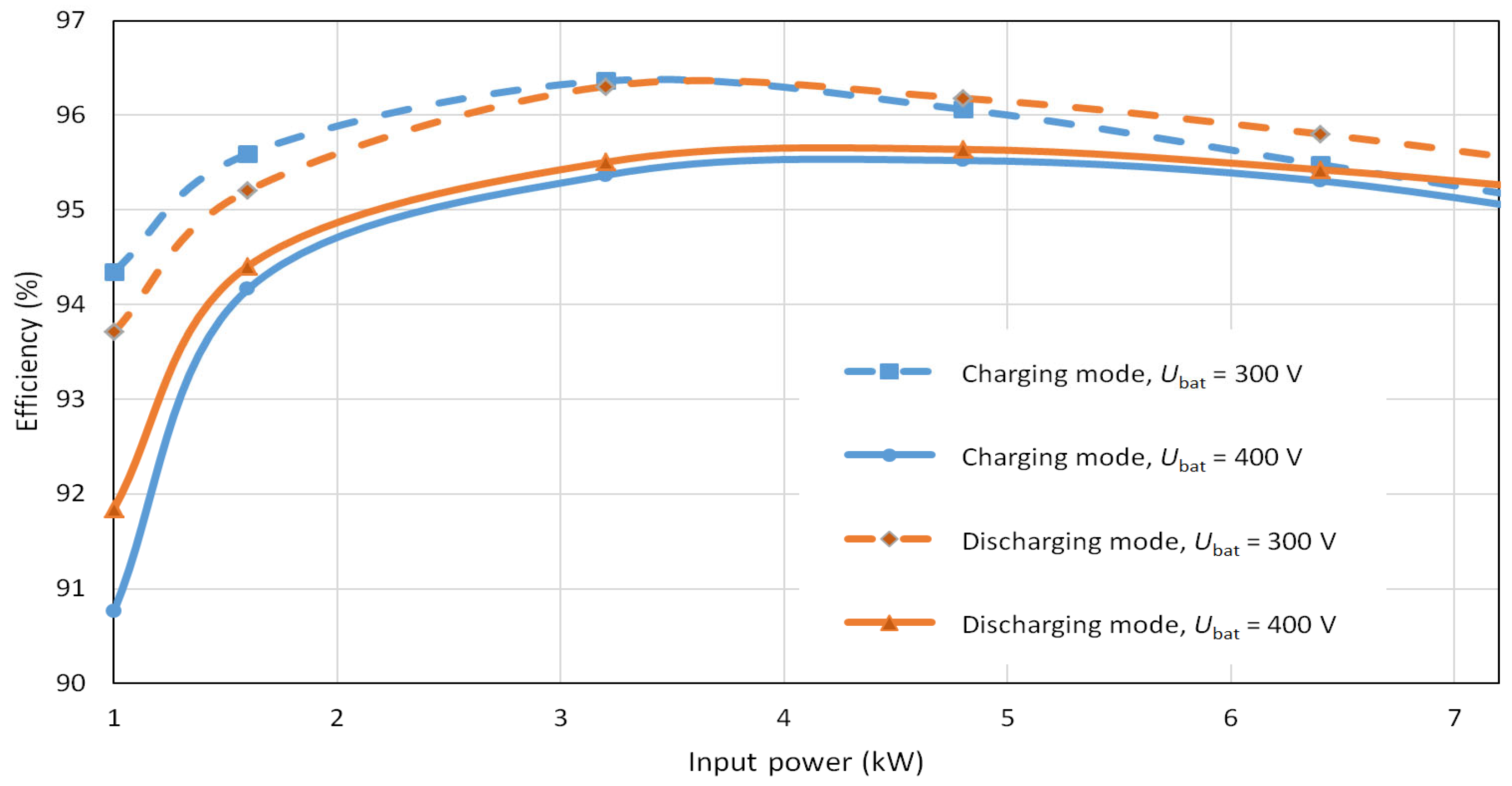

6.1. Experimental Measurement Results Acquired in Charging Mode

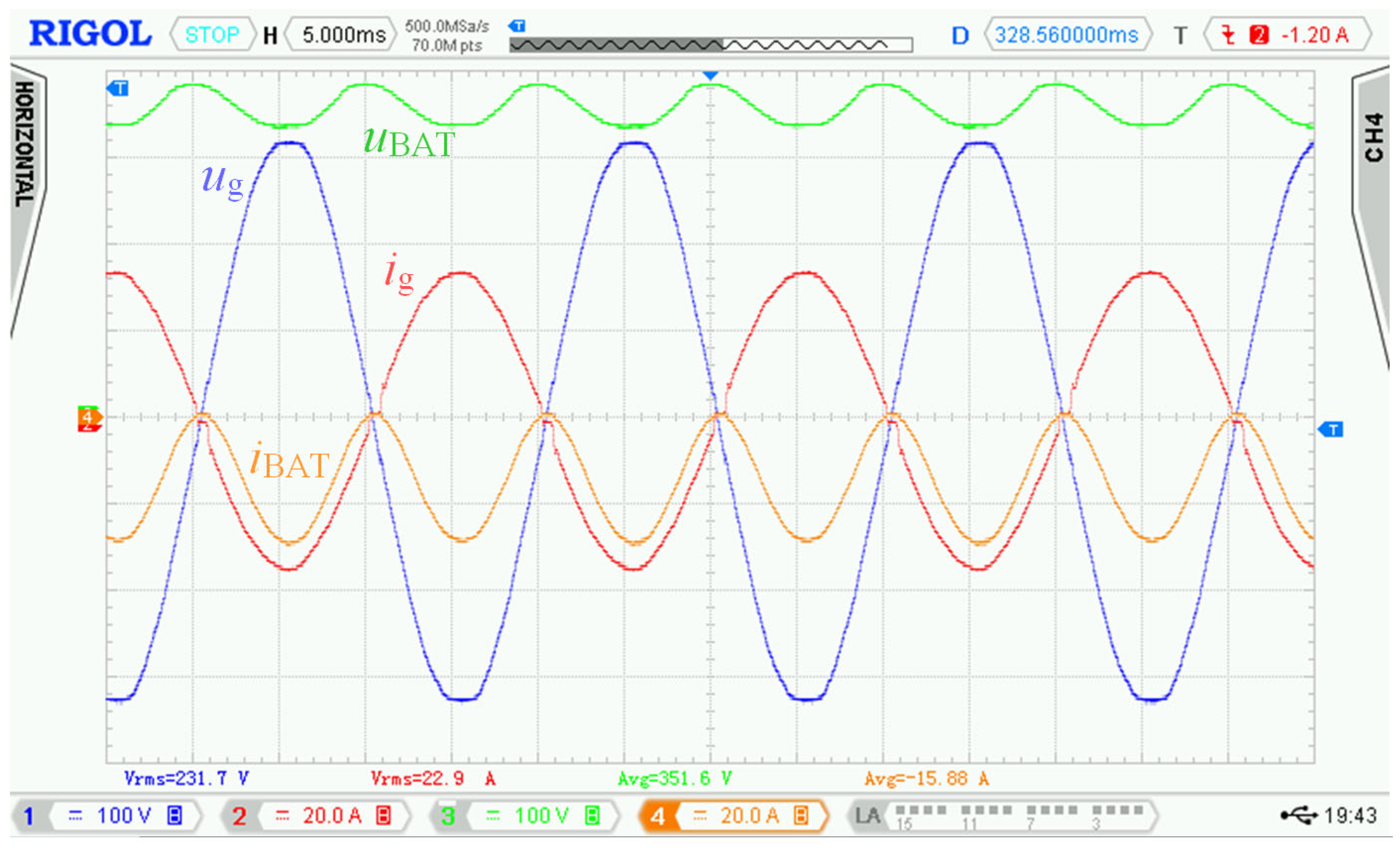

6.2. Experimental Measurement Results Acquired in Discharging Mode

- CE02—Conducted Emission, Voltage method (IEC CISPR 25)

- RE01, Radiated Emission, ALSE method (IEC CISPR 25)

- ESD02, Unpowered test (ISO 10605)

- TP01, Immunity to transient pulse 1 and 1b (ISO 7637-2)

- TP02, Immunity to transient pulse 2 (ISO 7637-2)

- TP03, Immunity to transient pulse 3a and 3b (ISO 7637-2)

- TP04, Immunity to transient pulse 4 (ISO 7637-2)

- TP05, Immunity to transient pulse 5 (ISO 7637-2)

7. Conclusions

- The single-stage inverter topology was modified to eliminate undesirable phenomena.

- Bidirectional power control and galvanic insulation from the power grid.

- Owing to the novel switching strategy of Q9 to Q12 transistors’ control, the charger does not need RCD snubbers in order to limit the voltage spikes caused by leakage inductance of the transformer. This has the effect of reducing losses, increasing efficiency and also reducing weight and volume.

- The proposed transistor switching control method eliminates unwanted HF oscillations on both the primary and secondary sides of the transformer in the on-board charger.

- In order to reduce the size and weight of the inductor and transformer, high switching frequency of 150 kHz was used.

- The charger allows V2G technology.

- The power density of the new charger was 4 kW/kg and 2.46 kW/dm3, and the maximum efficiency was 96.4% at 3.4 kW.

- The new charger has an output of either 7.2 kW if it uses only single-phase, or 21.6 kW if it uses three-phases.

8. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Patent Annotation

References

- Globisch, J.; Plötz, P.; Dütschke, E.; Wietschel, M. Consumer Evaluation of Public Charging Infrastructure for Electric Vehicles; Working Paper Sustainability and Innovation; No. S13/2018; Fraunhofer-Institut für System- und Innovationsforschung ISI: Karlsruhe, Germany, 2018. [Google Scholar]

- Miller, I.; Arbabzadeh, M.; Gençer, E. Hourly Power Grid Variations, Electric Vehicle Charging Patterns, and Operating Emissions. Environ. Sci. Technol. 2020, 54, 16071–16085. [Google Scholar] [CrossRef]

- Elghitani, F.; El-Saadany, E.F. Efficient Assignment of Electric Vehicles to Charging Stations. IEEE Trans. Smart Grid 2021, 12, 761–773. [Google Scholar] [CrossRef]

- Mohammed, S.A.Q.; Jung, J.-W. A Comprehensive State-of-the-Art Review of Wired/Wireless Charging Technologies for Battery Electric Vehicles: Classification/Common Topologies/Future Research Issues. IEEE Access 2021, 9, 19572–19585. [Google Scholar] [CrossRef]

- Hee, C.S. An Electric Vehichle Charger Having Load Smoothing Function. Korean Patent KR20120086388A, 3 August 2012. [Google Scholar]

- Nezamuddin, O.N.; Nicholas, C.L.; Santos, E.C. dos The Problem of Electric Vehicle Charging: State-of-the-Art and an Innovative Solution. IEEE Trans. Intell. Transp. Syst. 2022, 23, 4663–4673. [Google Scholar] [CrossRef]

- Jafari, M.; Kavousi-Fard, A.; Niknam, T.; Avatefipour, O. Stochastic Synergies of Urban Transportation System and Smart Grid in Smart Cities Considering V2G and V2S Concepts. Energy 2021, 215, 119054. [Google Scholar] [CrossRef]

- CEN-CENELEC-ETSI Smart Grid Coordination Group CEN-CENELEC-ETSI Smart Grid Coordination Group Smart Grid Reference Architecture. CENELEC. 2012. Available online: https://www.cencenelec.eu/media/CEN-CENELEC/AreasOfWork/CEN-CENELEC_Topics/Smart%20Grids%20and%20Meters/Smart%20Grids/reference_architecture_smartgrids.pdf (accessed on 26 October 2022).

- Shabanzadeh, M.; Moghaddam, M. What Is the Smart Grid? Definitions, Perspectives, and Ultimate Goals. In Proceedings of the Power System Conference, September 28th International Power System Conference (PSC), Tehran, Iran, 13 November 2013. [Google Scholar]

- Fernandez-Jimenez, L.A.; Muñoz-Jimenez, A.; Falces, A.; Mendoza-Villena, M.; Garcia-Garrido, E.; Lara-Santillan, P.M.; Zorzano-Alba, E.; Zorzano-Santamaria, P.J. Short-Term Power Forecasting System for Photovoltaic Plants. Renew. Energy 2012, 44, 311–317. [Google Scholar] [CrossRef]

- Shaqsi, A.Z.A.L.; Sopian, K.; Al-Hinai, A. Review of Energy Storage Services, Applications, Limitations, and Benefits. Energy Rep. 2020, 6, 288–306. [Google Scholar] [CrossRef]

- Verma, A.; Singh, B.; Chandra, A.; Al-Haddad, K. An Implementation of Solar PV Array Based Multifunctional EV Charger. In Proceedings of the 2018 IEEE Transportation Electrification Conference and Expo (ITEC), Long Beach, CA, USA, 13–15 June 2018; pp. 531–536. [Google Scholar]

- Berthold, F.; Ravey, A.; Blunier, B.; Bouquain, D.; Williamson, S.; Miraoui, A. Design and Development of a Smart Control Strategy for Plug-In Hybrid Vehicles Including Vehicle-to-Home Functionality. IEEE Trans. Transp. Electrif. 2015, 1, 168–177. [Google Scholar] [CrossRef]

- Çelik, D.; Meral, M.E. A Coordinated Virtual Impedance Control Scheme for Three Phase Four Leg Inverters of Electric Vehicle to Grid (V2G). Energy 2022, 246, 123354. [Google Scholar] [CrossRef]

- Wickramasinghe Abeywardana, D.B.; Acuna, P.; Hredzak, B.; Aguilera, R.P.; Agelidis, V.G. Single-Phase Boost Inverter-Based Electric Vehicle Charger with Integrated Vehicle to Grid Reactive Power Compensation. IEEE Trans. Power Electron. 2018, 33, 3462–3471. [Google Scholar] [CrossRef]

- Zhang, H.; Hu, Z.; Xu, Z.; Song, Y. Evaluation of Achievable Vehicle-to-Grid Capacity Using Aggregate PEV Model. IEEE Trans. Power Syst. 2017, 32, 784–794. [Google Scholar] [CrossRef]

- Jawad, M.; Qureshi, M.B.; Ali, S.M.; Shabbir, N.; Khan, M.U.S.; Aloraini, A.; Nawaz, R. A Cost-Effective Electric Vehicle Intelligent Charge Scheduling Method for Commercial Smart Parking Lots Using a Simplified Convex Relaxation Technique. Sensors 2020, 20, 4842. [Google Scholar] [CrossRef]

- Schlüter, J.; Weyer, J. Car Sharing as a Means to Raise Acceptance of Electric Vehicles: An Empirical Study on Regime Change in Automobility. Transp. Res. Part F Traffic Psychol. Behav. 2019, 60, 185–201. [Google Scholar] [CrossRef]

- Jung, J.; Koo, Y. Analyzing the Effects of Car Sharing Services on the Reduction of Greenhouse Gas (GHG) Emissions. Sustainability 2018, 10, 539. [Google Scholar] [CrossRef] [Green Version]

- Sam, C.A.; Jegathesan, V. Bidirectional Integrated On-Board Chargers for Electric Vehicles—A Review. Sādhanā 2021, 46, 26. [Google Scholar] [CrossRef]

- Whitaker, B.; Barkley, A.; Cole, Z.; Passmore, B.; Martin, D.; McNutt, T.R.; Lostetter, A.B.; Lee, J.S.; Shiozaki, K. A High-Density, High-Efficiency, Isolated On-Board Vehicle Battery Charger Utilizing Silicon Carbide Power Devices. IEEE Trans. Power Electron. 2014, 29, 2606–2617. [Google Scholar] [CrossRef]

- Beniak, R.; Górecki, K.; Paduch, P.; Rogowski, K. Reduced Switch Count in Space Vector PWM for Three-Level NPC Inverter. Energies 2020, 13, 5945. [Google Scholar] [CrossRef]

- Neborak, I.; Sladecek, V.; Kuchar, M. Modelling and Simulation of Induction Machine and Frequency Converter Considering Power Losses. In Proceedings of the 2015 16th International Scientific Conference on Electric Power Engineering (EPE), Ostrava, Czech Republic, 20–22 May 2015; pp. 251–255. [Google Scholar]

- Gowda, C.K.; Khedekar, V.G.; Anandh, N.; Paragond, L.R.S.; Kulkarni, P. Bidirectional On-Board EV Battery Charger with V2H Application. In Proceedings of the 2019 Innovations in Power and Advanced Computing Technologies (i-PACT), Vellore, India, 22–23 March 2019; pp. 1–5. [Google Scholar]

- Nassary, M.; Orabi, M.; Ghoneima, M.; El-Nemr, M.K. Single-Phase Isolated Bidirectional AC-DC Battery Charger for Electric Vehicle—Review. In Proceedings of the 2019 International Conference on Innovative Trends in Computer Engineering (ITCE), Aswan, Egypt, 2–4 February 2019; pp. 581–586. [Google Scholar]

- Karthikeyan, V.; Gupta, R. Light-Load Efficiency Improvement by Extending ZVS Range in DAB-Bidirectional DC-DC Converter for Energy Storage Applications. Energy 2017, 130, 15–21. [Google Scholar] [CrossRef]

- De Doncker, R.W.A.A.; Divan, D.M.; Kheraluwala, M.H. A Three-Phase Soft-Switched High-Power-Density DC/DC Converter for High-Power Applications. IEEE Trans. Ind. Appl. 1991, 27, 63–73. [Google Scholar] [CrossRef]

- Jauch, F.; Biela, J. Single-Phase Single-Stage Bidirectional Isolated ZVS AC-DC Converter with PFC. In Proceedings of the 2012 15th International Power Electronics and Motion Control Conference (EPE/PEMC), Novi Sad, Serbia, 4–6 September 2012; pp. LS5d.1-1–LS5d.1-8. [Google Scholar]

- Ramli, M.Z.; Salam, Z.; Toh, L.S.; Nge, C.L. A Bidirectional High-Frequency Link Inverter Using Center-Tapped Transformer. In Proceedings of the 2004 IEEE 35th Annual Power Electronics Specialists Conference (IEEE Cat. No.04CH37551), Aachen, Germany, 20–25 June 2004; pp. 3883–3888. [Google Scholar]

- Everts, J.; Krismer, F.; van den Keybus, J.; Driesen, J.; Kolar, J.W. Optimal ZVS Modulation of Single-Phase Single-Stage Bidirectional DAB AC–DC Converters. IEEE Trans. Power Electron. 2014, 29, 3954–3970. [Google Scholar] [CrossRef]

- Ostlund, S. Reduction of Transformer Rated Power and Line Current Harmonics in a Primary Switched Converter System for Traction Applications. In Proceedings of the 1993 Fifth European Conference on Power Electronics and Applications, Brighton, UK, 13–16 September 1993; Volume 7, pp. 112–119. [Google Scholar]

- Norrga, S. A Soft-Switched Bi-Directional Isolated AC/DC Converter for AC-Fed Railway Propulsion Applications. In Proceedings of the International Conference on Power Electronics Machines and Drives, Bath, UK, 16–18 April 2002; pp. 433–438. [Google Scholar]

- Jiang, J.; Bao, Y.; Wang, L. Topology of a Bidirectional Converter for Energy Interaction between Electric Vehicles and the Grid. Energies 2014, 7, 4858–4894. [Google Scholar] [CrossRef] [Green Version]

- Kjaer, S.B.; Pedersen, J.K.; Blaabjerg, F. Power Inverter Topologies for Photovoltaic Modules-a Review. In Proceedings of the Conference Record of the 2002 IEEE Industry Applications Conference, 37th IAS Annual Meeting (Cat. No.02CH37344), Pittsburgh, PA, USA, 13–18 October 2002; pp. 782–788. [Google Scholar]

- Shi, F.; Li, R.; Yang, J.; Yu, W. High Efficiency Bidirectional DC-DC Converter with Wide Gain Range for Photovoltaic Energy Storage System Utilization. In Proceedings of the 2018 IEEE International Power Electronics and Application Conference and Exposition (PEAC) 2018, Shenzhen, China, 4–7 November 2018; pp. 1–6. [Google Scholar]

- Liu, Y.-C.; Huang, B.-S.; Lin, C.-H.; Kim, K.A.; Chiu, H.-J. Design and Implementation of a High Power Density Active-Clamped Flyback Converter. In Proceedings of the 2018 International Power Electronics Conference (IPEC-Niigata 2018-ECCE Asia), Niigata, Japan, 20–24 May 2018; pp. 2092–2096. [Google Scholar]

- Ahmed, M.R.; Li, Y. A Low-Cost, High-Power-Density DC-DC Converter for Hybrid and Electric Vehicle Applications. In Proceedings of the 2019 21st European Conference on Power Electronics and Applications (EPE’19 ECCE Europe), Genova, Italy, 3–5 September 2019; pp. P.1–P.8. [Google Scholar]

- Zhu, M.; Shao, C.; Wang, S.; Hang, L.; He, Y.; Fan, S. System Design of Dual Active Bridge (DAB) Converter Based on GaN HEMT Device. In Proceedings of the 2019 22nd International Conference on Electrical Machines and Systems (ICEMS), Harbin, China, 11–14 August 2019; pp. 1–6. [Google Scholar]

- Pittini, R.; Mira, M.C.; Zhang, Z.; Knott, A.; Andersen, M.A.E. Analysis and Comparison Based on Component Stress Factor of Dual Active Bridge and Isolated Full Bridge Boost Converters for Bidirectional Fuel Cells Systems. In Proceedings of the 2014 International Power Electronics and Application Conference and Exposition, Shanghai, China, 5–8 November 2014; pp. 1026–1031. [Google Scholar]

- Blazek, V.; Slanina, Z.; Petruzela, M.; Hrbáč, R.; Vysocký, J.; Prokop, L.; Misak, S.; Walendziuk, W. Error Analysis of Narrowband Power-Line Communication in the Off-Grid Electrical System. Sensors 2022, 22, 2265. [Google Scholar] [CrossRef] [PubMed]

| Parameter | Value |

|---|---|

| Grid AC Voltage | 230 V + 10% |

| Battery DC Voltage | 300 to 420 V |

| Maximum grid current | 32 A RMS |

| Maximum battery current | 20 A |

| Nominal input power | 7.2 kW |

| AC grid frequency | 50 Hz |

| Switching frequency | 150 kHz |

| Inductance L | 25 μH |

| Capacity C1 | 3.01 μF |

| Capacity C2 | 12.1 μF |

| Capacity C13 | 270 nF |

| Transformer windings | 4 primary turns, 3 secondary turns |

| Weight | 1.8 kg |

| Volume | 2.92 dm3 |

| Q1–Q4, CoolMOS PowerTransistor IPW60R017C7XKSA1 | (600 V, 129 A, RDS(on) = 17 mΩ, USD = 0.9 V 1 @ IF = 58.2 A) |

| Q5–Q8, Q13, Silicon Carbide Power MOSFET C3M0032120K | (1200 V, 63 A, RDS(on) = 32 mΩ, USD = 4.6 V 1 @ IF = 20 A) |

| Q9–Q12, Silicon Carbide Power MOSFET C3M0030090K | (900 V, 63 A, RDS(on) = 30 mΩ, USD = 4.8 V 1 @ IF = 17.5 A) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hrbac, R.; Hrdina, L.; Kolar, V.; Slanina, Z.; Blazek, V.; Vantuch, T.; Bartłomiejczyk, M.; Misak, S. Innovative Bidirectional Isolated High-Power Density On-Board Charge for Vehicle-to-Grid. Sensors 2022, 22, 8473. https://doi.org/10.3390/s22218473

Hrbac R, Hrdina L, Kolar V, Slanina Z, Blazek V, Vantuch T, Bartłomiejczyk M, Misak S. Innovative Bidirectional Isolated High-Power Density On-Board Charge for Vehicle-to-Grid. Sensors. 2022; 22(21):8473. https://doi.org/10.3390/s22218473

Chicago/Turabian StyleHrbac, Roman, Libor Hrdina, Vaclav Kolar, Zdenek Slanina, Vojtech Blazek, Tomas Vantuch, Mikołaj Bartłomiejczyk, and Stanislav Misak. 2022. "Innovative Bidirectional Isolated High-Power Density On-Board Charge for Vehicle-to-Grid" Sensors 22, no. 21: 8473. https://doi.org/10.3390/s22218473

APA StyleHrbac, R., Hrdina, L., Kolar, V., Slanina, Z., Blazek, V., Vantuch, T., Bartłomiejczyk, M., & Misak, S. (2022). Innovative Bidirectional Isolated High-Power Density On-Board Charge for Vehicle-to-Grid. Sensors, 22(21), 8473. https://doi.org/10.3390/s22218473