Wedged Fiber Optic Surface Plasmon Resonance Sensor for High-Sensitivity Refractive Index and Temperature Measurements

Abstract

:1. Introduction

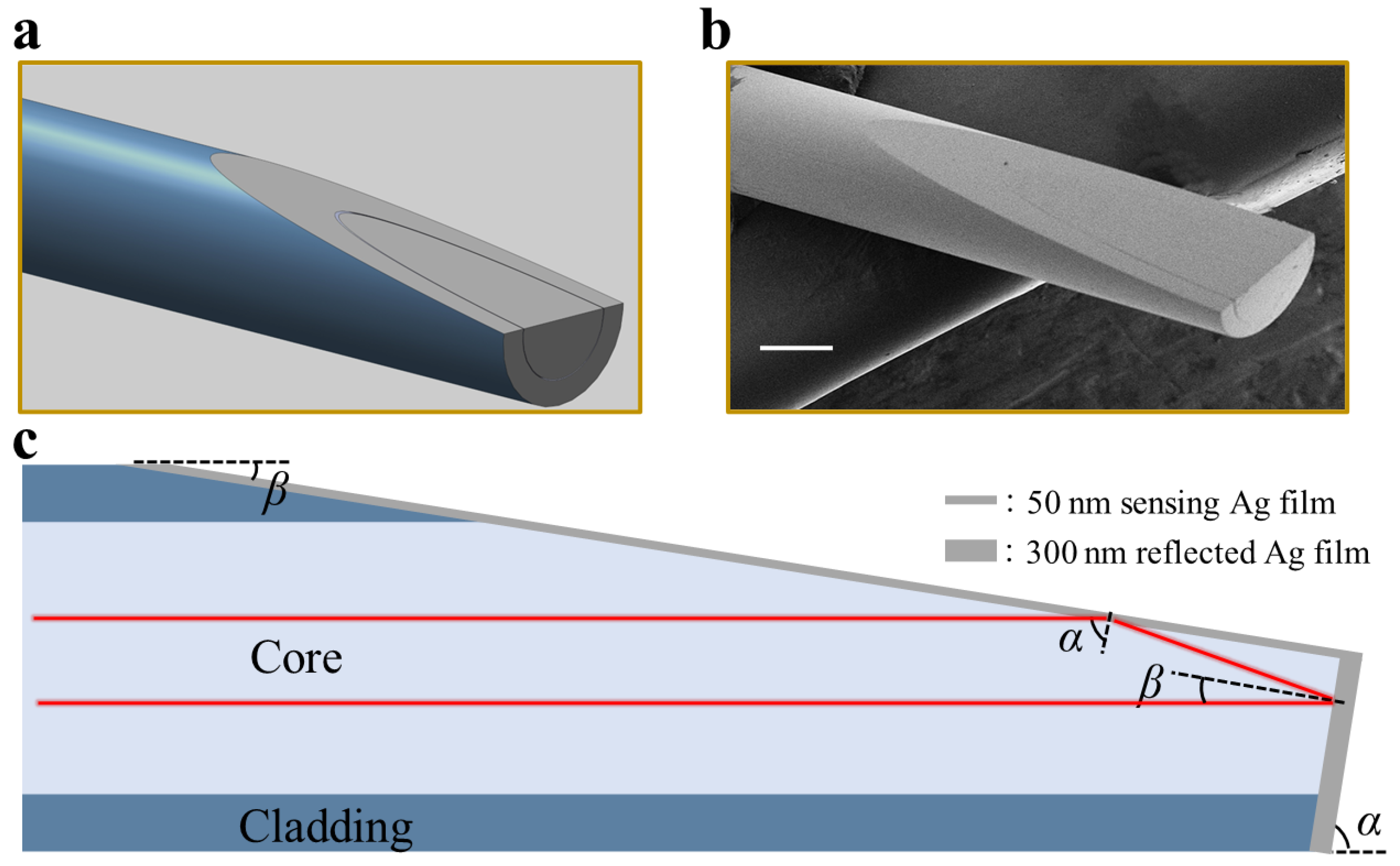

2. Methods

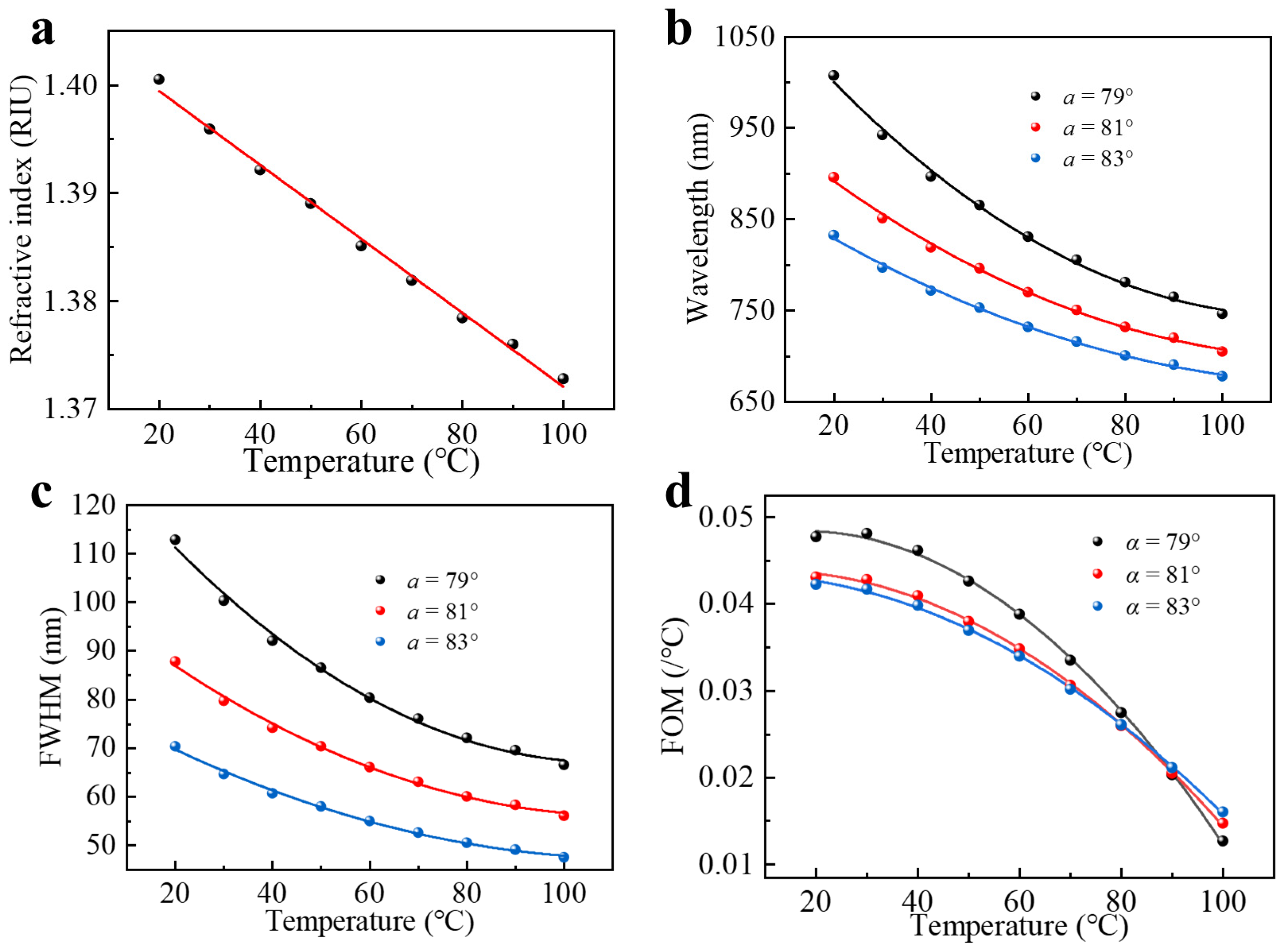

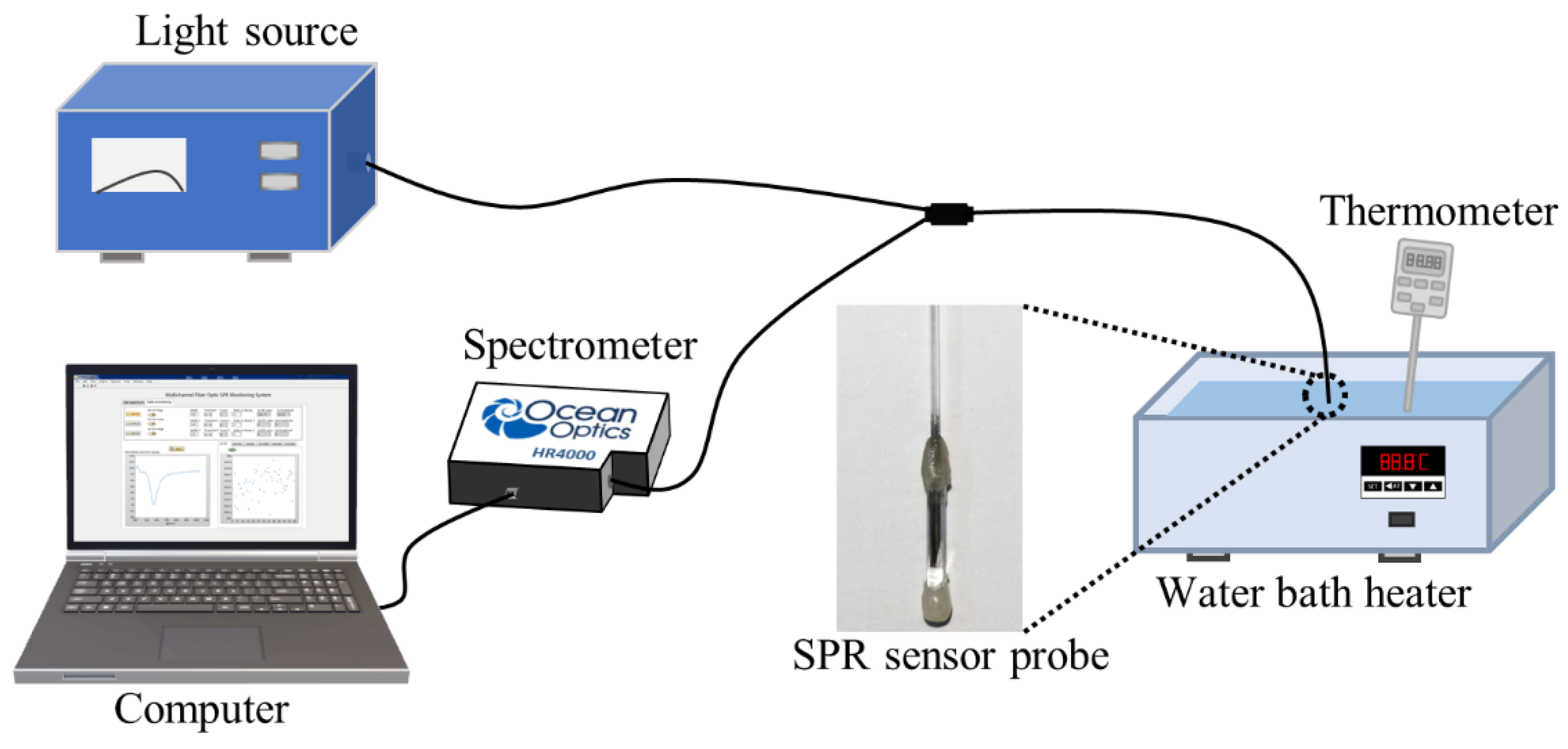

3. Experiments and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Duan, Q.; Liu, Y.; Chang, S.; Chen, H.; Chen, J.H. Surface Plasmonic Sensors: Sensing Mechanism and Recent Applications. Sensors 2021, 21, 5262. [Google Scholar] [CrossRef] [PubMed]

- Zuppella, P.; Tosatto, S.; Corso, A.J.; Zuccon, S.; Pelizzo, M.G. Graphene–noble metal bilayers for inverted surface plasmon resonance biosensors. J. Opt. 2013, 15, 055010. [Google Scholar] [CrossRef]

- Tabassum, R.; Gupta, B.D. Fiber optic hydrogen gas sensor utilizing surface plasmon resonance and native defects of zinc oxide by palladium. J. Opt. 2016, 18, 015004. [Google Scholar] [CrossRef]

- Zhou, J.; Qi, Q.; Wang, C.; Qian, Y.; Liu, G.; Wang, Y.; Fu, L. Surface plasmon resonance (SPR) biosensors for food allergen detection in food matrices. Biosens. Bioelectron. 2019, 142, 111449. [Google Scholar] [CrossRef] [PubMed]

- Bagi, A.; Soelberg, S.D.; Furlong, C.E.; Baussant, T. Implementing morpholino-based nucleic acid sensing on a portable surface plasmon resonance instrument for future application in environmental monitoring. Sensors 2018, 18, 3529. [Google Scholar] [CrossRef] [Green Version]

- Wei, Y.; Li, L.; Liu, C.; Hu, J.; Su, Y.; Wu, P.; Zhao, X. Cascaded dual-channel fiber SPR temperature sensor based on liquid and solid encapsulations. Chin. Phys. B 2021, 30, 100701. [Google Scholar] [CrossRef]

- Michel, D.; Xiao, F.; Alameh, K. A compact, flexible fiber-optic surface plasmon resonance sensor with changeable sensor chips. Sens. Actuators B Chem. 2017, 246, 258–261. [Google Scholar] [CrossRef]

- Li, J.; Han, D.; Zeng, J.; Deng, J.; Hu, N.; Yang, J. Multi-channel surface plasmon resonance biosensor using prism-based wavelength interrogation. Opt. Express 2020, 28, 14007–14017. [Google Scholar] [CrossRef]

- Liu, Y.; Peng, W. Fiber-Optic Surface Plasmon Resonance Sensors and Biochemical Applications: A Review. J. Lightwave Technol. 2021, 39, 3781–3791. [Google Scholar] [CrossRef]

- Wang, Q.; Sun, B.; Hu, E.; Wei, W. Cu/ITO-Coated Uncladded Fiber-Optic Biosensor Based on Surface Plasmon Resonance. IEEE Photonics Technol. Lett. 2019, 31, 1159–1162. [Google Scholar] [CrossRef]

- Navarrete, M.-C.; Díaz-Herrera, N.; González-Cano, A.; Esteban, Ó. A Polarization-Independent SPR Fiber Sensor. Plasmonics 2009, 5, 7–12. [Google Scholar] [CrossRef]

- Gasior, K.; Martynkien, T.; Napiorkowski, M.; Zolnacz, K.; Mergo, P.; Urbanczyk, W. A surface plasmon resonance sensor based on a single mode D-shape polymer optical fiber. J. Opt. 2017, 19, 025001. [Google Scholar] [CrossRef]

- Hao, Z.; Pu, S.; Wang, J.; Liu, W.; Zhang, C.; Fan, Y.; Lahoubi, M. Dual-channel temperature-compensated vector magnetic field sensor based on lab-on-a-fiber-tip. Opt. Express 2022, 30, 25208–25218. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Li, S.; Li, X.; Yan, X.; Zhang, X.; Wang, F.; Cheng, T. High-sensitivity SPR temperature sensor based on hollow-core fiber. IEEE Trans. Instrum. Meas. 2020, 69, 8494–8499. [Google Scholar] [CrossRef]

- Liu, S.; Cao, S.; Zhang, Z.; Wang, Y.; Liao, C.; Wang, Y. Temperature Sensor Based on Side-Polished Fiber SPR Device Coated with Polymer. Sensors 2019, 19, 4063. [Google Scholar] [CrossRef] [Green Version]

- Lu, L.; Jiang, Z.; Hu, Y.; Zhou, H.; Liu, G.; Chen, Y.; Luo, Y.; Chen, Z. A portable optical fiber SPR temperature sensor based on a smart-phone. Opt. Express 2019, 27, 25420–25427. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Liu, Z.; Zhang, Y.; Liu, S. Side-polished D-type fiber SPR sensor for RI sensing with temperature compensation. IEEE Sens. J. 2021, 21, 16621–16628. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, H.; Wang, M.; Liu, Y.; Fan, X.; Chen, Q.; Wu, B. Simultaneous measurement of refractive index and temperature of seawater based on surface plasmon resonance in a dual D-type photonic crystal fiber. Mater. Res. Express 2021, 8, 085201. [Google Scholar] [CrossRef]

- Lu, M.; Zhang, X.; Liang, Y.; Li, L.; Masson, J.F.; Peng, W. Liquid crystal filled surface plasmon resonance thermometer. Opt. Express 2016, 24, 10904–10911. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, Q.; Zhu, W.; Yang, M.; Lewis, E. Novel optical fiber SPR temperature sensor based on MMF-PCF-MMF structure and gold-PDMS film. Opt. Express 2018, 26, 1910–1917. [Google Scholar] [CrossRef]

- Liu, L.; Liu, Z.H.; Zhang, Y.; Liu, S.T. V-shaped micro-structure optical fiber surface plasmon resonance sensor for the simultaneous measurement of the refractive index and temperature. Opt. Lett. 2019, 44, 5093–5096. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Z.; Liu, L.; Liu, Z.; Zhang, Y.; Zhang, Y. Surface-plasmon-resonance-based optical-fiber temperature sensor with high sensitivity and high figure of merit. Opt. Lett. 2017, 42, 2948–2951. [Google Scholar] [CrossRef] [PubMed]

- Shan, B.-H.; Kong, L.-X.; Wu, K.-J.; Ou, S.-F.; He, P.-F.; Jin, G.; Li, Z.; Zhang, Y.-S. High sensitivity and ultra compact fiber-optic microtip SPR thermometer coated with Ag/PDMS bilayer film. Opt. Fiber Technol. 2021, 65, 102619. [Google Scholar] [CrossRef]

- Liu, Z.; Wei, Y.; Zhang, Y.; Zhang, Y.; Zhao, E.; Yang, J.; Yuan, L. Twin-core fiber SPR sensor. Opt. Lett. 2015, 40, 2826–2829. [Google Scholar] [CrossRef]

- Alonso-Murias, M.d.C.; Velazquez-Gonzalez, J.S.; Monzon-Hernandez, D. SPR Fiber Tip Sensor for the Simultaneous Measurement of Refractive Index, Temperature, and Level of a Liquid. J. Lightwave Technol. 2019, 37, 4808–4814. [Google Scholar] [CrossRef]

- Rodrigo, S.G.; García-Vidal, F.J.; Martín-Moreno, L. Influence of material properties on extraordinary optical transmission through hole arrays. Phys. Rev. B 2008, 77, 075401. [Google Scholar] [CrossRef]

| Sensor Type | SRI (nm/RIU) | RI Range (RIU) | ST (nm/°C) | T Range (°C) | FWHM (nm) | FOM (/°C) | Sensitization Method |

|---|---|---|---|---|---|---|---|

| Unclad MMF [10] | 4358.4 | 1.36–1.41 | Cu/ITO | ||||

| Tapered fiber SMF [11] | 4166.7 | 1.358–1.410 | — | — | — | — | Al/TiO2 |

| D-shaped SMF [12] | 2765 | 1.410 | Au | ||||

| U-shaped MMF [14] | — | — | −0.978 | 25–100 | 79–83 | 0.012 | Au/UV-curable |

| Internally filled hollow fiber [17] | — | — | −1.16 | 35.5–70.1 | 75–123 | 0.009–0.033 | Ag/alcohol |

| Spliced MMF-PCF-MMF [20] | — | — | −1.551 | 35–100 | — | — | Au/PDMS |

| Circular truncated cone-shaped twin-core fiber [22] | — | — | −2.07–4.13 | 20–70 | 70–121 | 0.029–0.035 | Au/PDMS |

| Pencil-shaped MMF [23] | — | — | −1.985 | 20–70 | 98–142 | 0.014–0.02 | Ag/PDMS |

| This Paper | 1284–8161 | 1.333–1.404 | −1.184–3.35 | 20–100 | 125–182 | 0.01–0.018 | Ag/n-butanol |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Li, Y.; Zong, X.; Zhao, L.; Li, P.; Yu, K.; Liu, Y. Wedged Fiber Optic Surface Plasmon Resonance Sensor for High-Sensitivity Refractive Index and Temperature Measurements. Sensors 2022, 22, 9099. https://doi.org/10.3390/s22239099

Li L, Li Y, Zong X, Zhao L, Li P, Yu K, Liu Y. Wedged Fiber Optic Surface Plasmon Resonance Sensor for High-Sensitivity Refractive Index and Temperature Measurements. Sensors. 2022; 22(23):9099. https://doi.org/10.3390/s22239099

Chicago/Turabian StyleLi, Lixia, Yuli Li, Xueyang Zong, Linlin Zhao, Penglei Li, Kun Yu, and Yufang Liu. 2022. "Wedged Fiber Optic Surface Plasmon Resonance Sensor for High-Sensitivity Refractive Index and Temperature Measurements" Sensors 22, no. 23: 9099. https://doi.org/10.3390/s22239099

APA StyleLi, L., Li, Y., Zong, X., Zhao, L., Li, P., Yu, K., & Liu, Y. (2022). Wedged Fiber Optic Surface Plasmon Resonance Sensor for High-Sensitivity Refractive Index and Temperature Measurements. Sensors, 22(23), 9099. https://doi.org/10.3390/s22239099