1. Introduction

The prototype of aquaponics came from fish farming in rice paddies which happened in ancient China [

1]. Modern aquaponics systems integrate aquaculture, soilless cultivation, and modern agricultural information technology [

2]. Ibtissame E. et al. [

3] compared aquaponics with the hydroponic and the traditional method, pointing out the advantages of aquaponics systems in agricultural production. Aquaponics provides high-quality agricultural products while reducing the ecological impact. With the rapid development of science and technology, agricultural informatization has moved from traditional agriculture to smart agriculture mainly supported by Internet of Things technology [

4]. The smart factory of aquaponics was proposed in recent years, which uses smart sensing, information control, and other Internet of Things (IoT) technology to achieve a low-cost, green cycle production model.

While aquaponic farming is an alternative agricultural method [

5], the varying adaptability of species to the environment poses significant challenges for research in both academic and commercial sectors. To improve production efficiency as much as possible, it becomes indispensable to monitor and regulate the growth environment of fish and vegetables by using IoT technology. This technology when used alongside innovative agricultural techniques such as aquaponics can lead to new dimensions of food production [

6]. Numerous technological studies have been undertaken in an effort to better handle this type of agricultural technology. Studies have shown that it is efficient in aquaponics systems to use intelligent analysis and processing [

7].

Nhan Chi Nguyen et al. [

8] introduced an aquaponics monitoring and control system based on IoT technology, which allows users to monitor the potential of hydrogen (pH) value, Dissolved Oxygen (DO), temperature, and humidity through an application on their smartphones, and to set thresholds to control water and air pumps. This method eliminates manual intervention and simplifies production costs compared with manual monitoring methods, but the monitoring parameters cannot yet be comprehended. Sun Jian et al. [

9] conducted a study on an aquaponics environmental monitoring system based on IoT technology and described its role in promoting aquaponics technology. Ma Zichao et al. [

10] designed a low-power monitoring device with ZigBee for an aquaponics system to collect temperature and pH values online. The device can be used to remotely control fish feeding, and save water resources effectively. FL Valiente et al. [

11] monitored and controlled pH and temperature in a Nile tilapia-lettuce aquaponics system through IoT. The growth of plants and fish in the automated aquaponics system was significantly better than in the traditional aquaponics system. Siyao An et al. [

12] designed a data collection device for aquaponics systems to realize real-time monitoring of various environmental data. Then, an aquaponics data service platform was developed to make the best decisions by monitoring the status of the system online. Mohanad Odema et al. [

13] proposed a system with Modbus Transmission Control Protocol (TCP) as the primary communication protocol, allowing it to benefit from the advantages of Modbus and TCP technologies simultaneously. Murad et al. [

14] have developed a low-cost system for monitoring and controlling water parameters using Arduino as a Microcontroller Unit (MCU). Mandap et al. [

15] equipped Arduino with a web application to design an automated aquaponics system that allows the system to control actuators in response to pH level, temperature, and DO parameter changes. However, the systems mentioned above are mainly designed for the monitoring of pH, temperature, and DO, which belongs to water quality monitoring. Some of them have added remote control functions. The data monitoring is not comprehensive enough for aquaponics scenarios.

Further, Haryanto et al. [

16] designed a smart aquaponics system that could control and monitor the degree of acidity, water level, water temperature, and fish feed that were integrated with an internet-based mobile application. Mohammad Alselek et al. [

17] developed a complete 5G-enabled IoT system for fully monitoring the performance of fishery farms, which improves the state-of-the-art in terms of aquaponics life cycle monitoring metrics and communication technologies. Mehra et al. [

18] introduced deep neural networks to the analysis of tomato hydroponic growth parameters and compared them with traditional soil culture. These studies extend the parameters monitored by the system but still did not overcome the problem of automatic acquisition of plant growth condition data.

In conclusion, up to now, the research on aquaponics systems was mostly focused on system integration, water-quality, environmental parameters monitoring, and fish behavior detection, but many disadvantages have not considered, such as poor mobility, long development cycle, complicated operation, and high power-consumption. Additionally, there is a relative lack of attention to research on plant growth monitoring in aquaponics systems. The image processing technology is a low-cost solution for vegetable growth monitoring. However, for cloud-storage IoT systems, image data upload and cloud computing are limited by bandwidth and transmission delay.

According to the characteristics of aquaponics systems and urban agriculture scenarios, a miniaturized intelligent aquaponics monitoring system is proposed in this paper. This system can realize real-time monitoring of key indicators, such as water quality, planting environment, and plant growth conditions based on intelligent embedded technology and edge-computing. To overcome the impact of uploading speed and delay during processing a large amount of image data, an image edge-computing unit is introduced to the aquaponics system for monitoring growth conditions, such as plant height, plant stem, etc., which can improve the data transmission efficiency rapidly.

The contributions of our work are three-fold:

We propose a modularized IoT monitoring system with edge-computing for aquaponics, which overcomes many problems of traditional handheld aquaponics systems, such as high latency, labor-intensive, low efficiency, and poor scalability.

We build an end-edge-cloud system architecture. Using Raspberry PI as an edge sensor, an edge image processing module is implemented, which enables the system to monitor plant growth conditions by deep learning without destruction.

We develop a WeChat Mini Program for the monitoring system, improving system management efficiency, and reducing cost. With the software platform, users can easily realize remote monitoring and control of the aquaponics system by smart cell phone.

This paper has the following structure and organization: First, in this section, cases and work related to traditional and modern aquaponics systems are discussed.

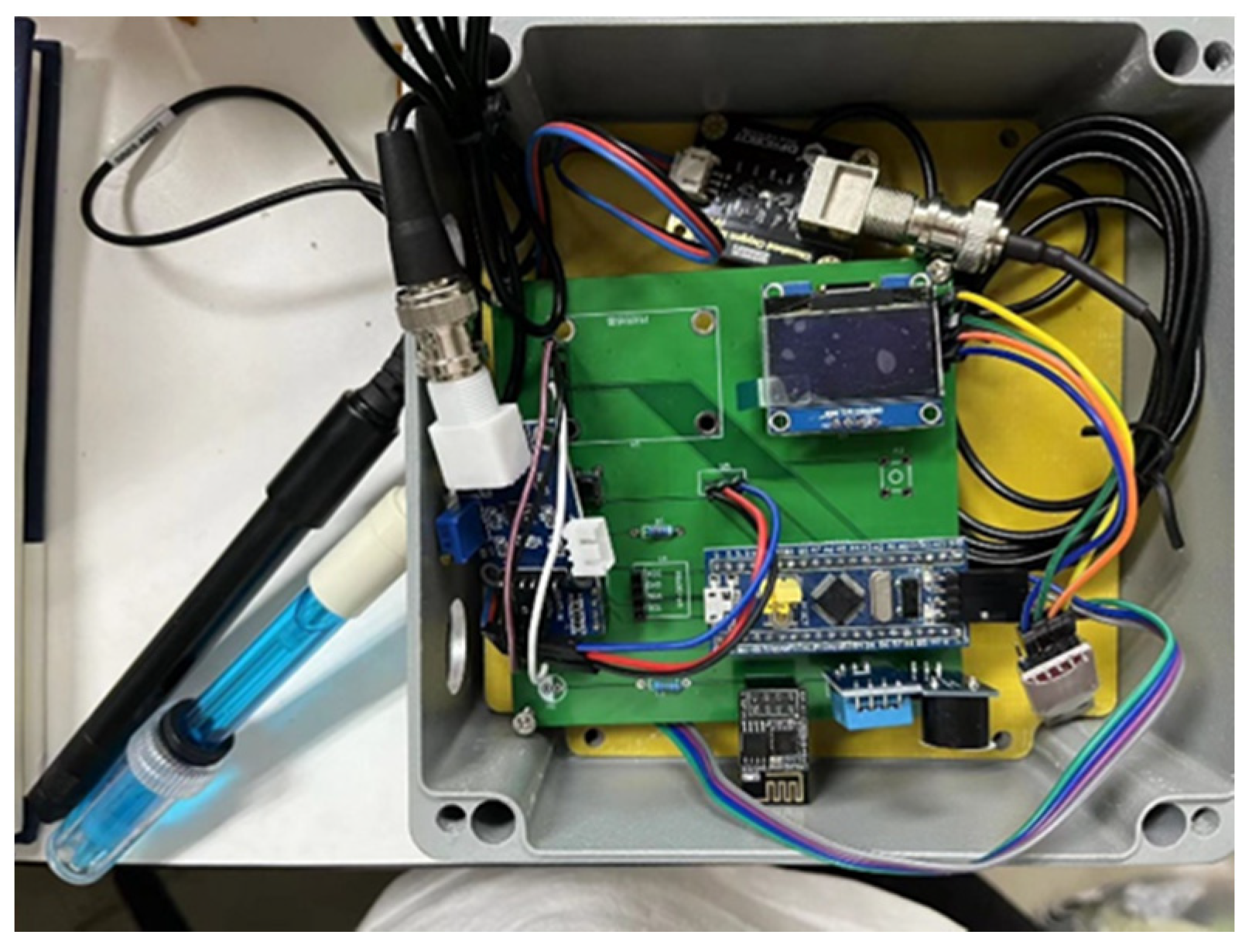

Section 2 describes the overall architecture and functions of the monitoring system that we designed. The main hardware modules include intelligent sensing unit design, edge image processing module design, and so on are shown in

Section 3.

Section 4 presents the system software design. The tests and results are listed in

Section 5. In

Section 6, we summarize our research results, clarify the significance of the work, and analyze the prospects for future work.

2. System Architecture

When it involves high yields and quality, designing and managing a system for aquaponic is a difficult task. Due to a combination of a greenhouse and a symbiotic environment, the parameters and factors that must be controlled are diverse. [

19]. Therefore, in light of the investigation and analysis of current research related to the aquaponics system, the aquaponics monitoring system is built based on embedded edge-computing and IoT technology to reach the full supervision and abnormal monitoring of water quality (temperature, pH, DO, etc.), planting environment (temperature, humidity, light intensity, etc.), and plant growth conditions (plant height, plant stem, leaf area, etc.). The general framework of the system was presented in

Figure 1.

The IoT can empower systems and machines to communicate with each other and make decisions based on data without human intervention. In general, the architecture of IoT consists of three layers: Perception Layer (sensing), Network Layer (data transmission), and Application Layer (data storage and manipulation) [

20]. In this paper, the perception layer mainly contains three parts: the environment sensing unit, the plant growth conditions sensing unit, and the intelligent control unit. The environment sensing unit used Wireless Sensor Network (WSN) technology to realize the collection of water quality and planting environment in the aquaponics system. The edge-computing module with image processing algorithms is introduced to the plant growth sensing unit, which can quickly obtain and upload the indicator data of plant growth and alleviate the network transmission load. Intelligent control unit enables remote control of equipment in aquaponics systems. The network layer uses Wireless Fidelity technology (Wi-Fi) to transmit the processed data to the server for storage via TCP-based Message Queuing Telemetry Transport (MQTT) protocol. The application layer includes the Ali-cloud server and WeChat Mini Program. MySQL database is deployed in the server for cloud storage, sending, and receiving of IoT data. The Mini Program can realize the functions of real-time monitoring, history data display, abnormal alarm, and remote control with the collected data.

6. Conclusions

As this study has demonstrated, we focused on the integrity of monitoring parameters in the aquaponics system and realized the possibility of simultaneous remote monitoring and intelligent control of the environment, water quality, and plant growth conditions. The proposed system ensures the quality operation of aquaponics system and lays a foundation for the research of cultivation-breeding ratio to a certain extent.

As for the environment and water-quality parameters, the system overcomes many problems of the traditional handheld aquaponics system, such as high latency, labor-intensive, low efficiency, and poor scalability. Furthermore, in order to monitor the growth conditions of plants in the aquaponics system and improve the intelligence of the system, edge computing was introduced to build an end-edge-cloud system architecture. Thus, deep learning algorithms can be used for image processing. In this way, the computing tasks of the traditional system are transferred from the data center to the edge sensor, realizing the diversion of high energy-consuming image data and low energy-consuming sensing data. It proves that the edge sensor can improve the timeliness of data calculation, reduce the flow pressure, improve the efficiency of data transmission and enhance the scalability of the system. Using the WeChat Mini Program as the software platform, users can easily access remote monitoring and control of the aquaponics system by using a smart cell phone. The test results show that the system can provide stable local data collection and remote transmission, trend curve plotting, and database storage services for aquaponics systems effectively. The packet loss rate of the wireless transmission network is 0% within 90 m and 3.2% at 110 m. The system measurement data is proven to reflect the system condition well.

Due to the limited site, the research object of this paper is set in the miniaturized aquaponics system. In theory, a larger site can be covered by more monitoring nodes. This paper provides a good basis for further discussion and study. In the future, further research can make the system more efficient and intelligent by strengthening the computing power at the edge, such as further pruning and compression of the model or connecting the accelerator for deep learning in the periphery of the microcontroller.