Comprehensive Understanding of Foot Development in Children Using Capacitive Textile Sensors

Abstract

:1. Introduction

2. Materials and Methods

- Prototype 1 explains the process of selecting suitable sensing materials, sensing configurations, and electrical components. The materials and sensing configuration are evaluated quantitatively and qualitatively.

- Prototype 2 is a design iteration of the previous prototype. It uses the selected materials from Prototype 1 and refined design configuration. The effectiveness, reliability, and feasibility of this prototype are tested and evaluated with children using a wireless electronics module.

2.1. Sensor Prototype 1

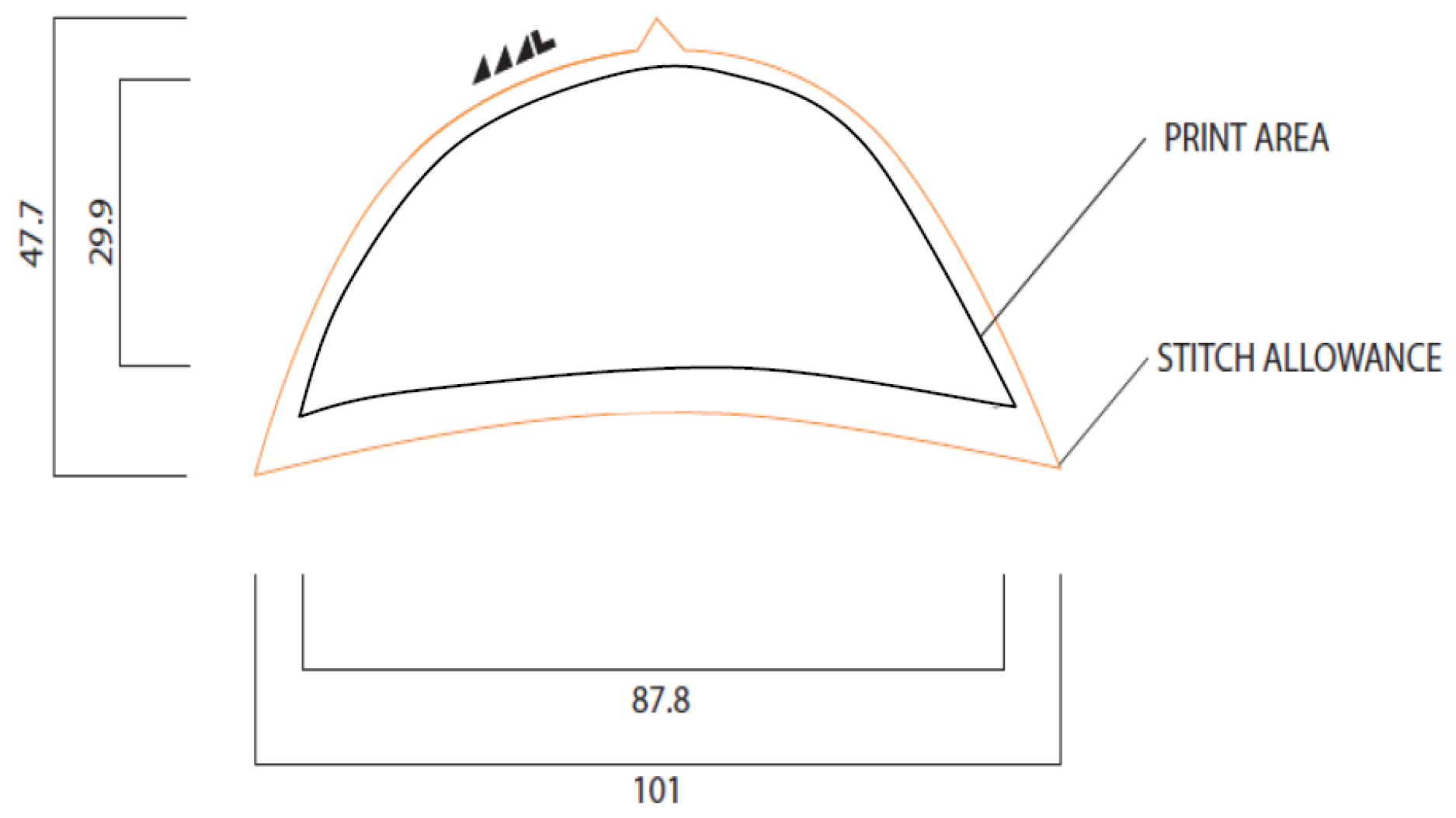

2.1.1. Sensor Placement, Size, and Layer Layout

2.1.2. Sensor Materials

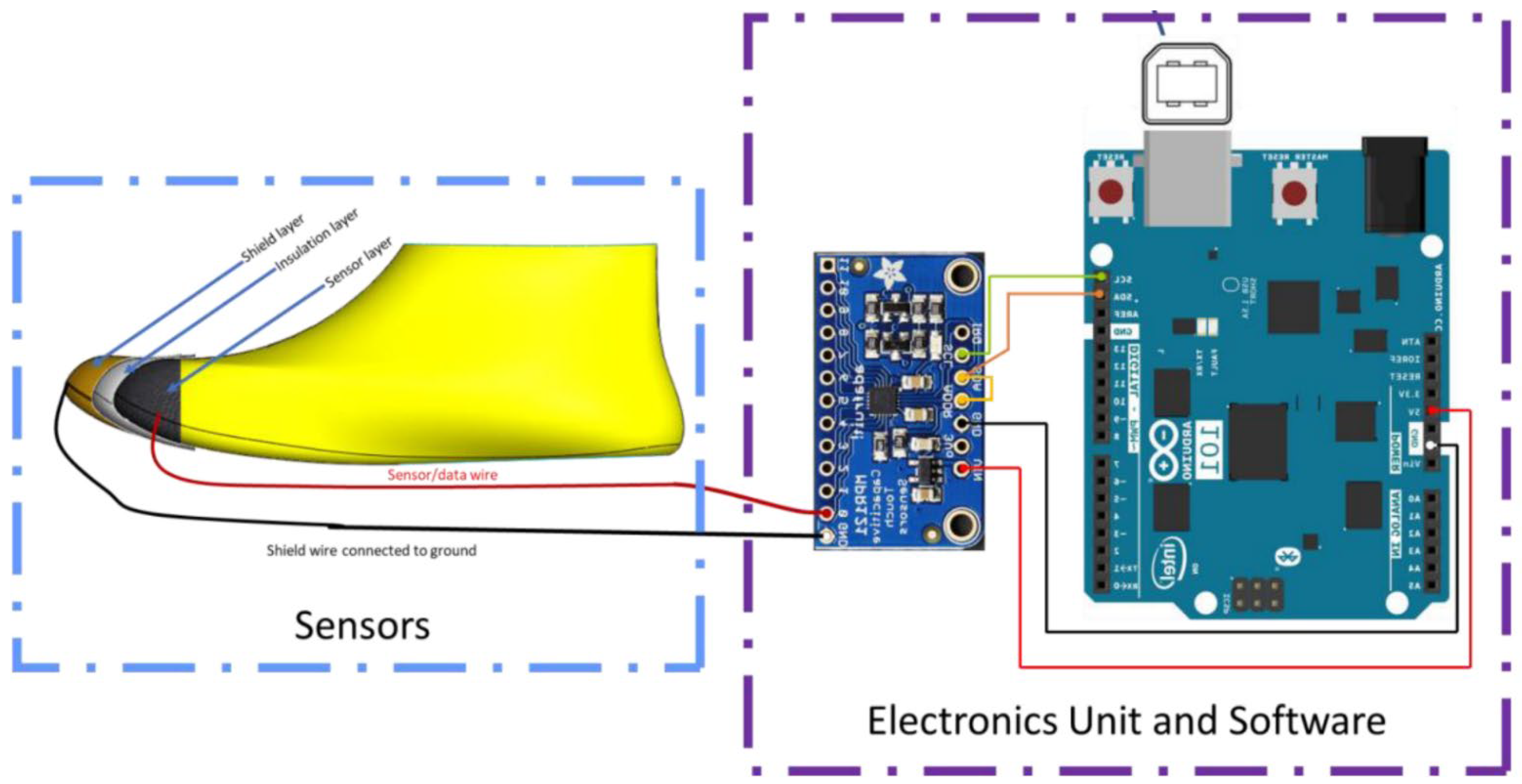

2.1.3. Electrical/Electronic Components and Software

Code Implementation

- Include header files and define device registers: As MPR121 is an external sensing chip, libraries and header files (i.e., #include “Adafruit_MPR121.h”) are included so that variables inside this file can be easily accessed. After introducing the header files, the device addresses must be defined so that Arduino knows which information to access.

- Define constant, reading, and configuration registers: Once the device is addressed and found, configuration registers are defined so that their values can be changed in the setup functions. There are corresponding values for these configuration registers and only some registers are selected, as not all the electrodes are being used. Some registers are not configured. However, they are introduced here as they will be read later, in the loop function. These registers change based on the changes made to the configuration register. The registers that need to be read are ELEC_Current, for reading the electrode’s current; ELEC_Time, the register for the electrode’s charge time; and ADC Registers, ADCLSB, and ADCMSB, for reading the electrode’s voltage.

- Setup function: the baud rate is defined to know how quickly the microcontroller samples and how often it obtains information from the serial port. It is set to read at the fastest rate, at 115,200 baud. The introduced configuration registers are changed to their corresponding values to perform as it needs. To set these registers to their new value, the device itself must be soft reset (SOFT RESET). This resets the registers into their default values. After this, the MPR121 is at stop mode (ELEC_CFG bit assignment is 0b10000000), so the remaining registers, such as the auto configuration registers (AUTOCONFIG0) and voltage operation limits (UPLIMIT, LO LIMIT, TARGETLIMIT), may be changed. Once registers are set, the MPR121 is changed to run mode so that these settings can be applied and used. To enable run mode, the electrode-configuration register-bit assignment changes to enable electrode detection and proximity sensing at electrode 0.

- Loop function: In this function, certain registers are read to enable the calculation of capacitance. As mentioned earlier, MPR121 operates using CTMU, which means that it needs current, voltage, and time to calculate capacitance. These can be read from reading registers defined earlier (ELEC_Current, ELEC_Time, ADCMSB, and ADCLSB). The current register can be read as is and does not need any other conversions. The time register contains two values, each corresponding to the charge time for that electrode. The electrode used for Sensor Prototype 1 is Electrode 0, the time for this register is accessed on the ELEC_Time register; however, this contains time values for electrodes 0 and 1.

2.1.4. Sensor-Material Evaluation and Code-Verification Testing

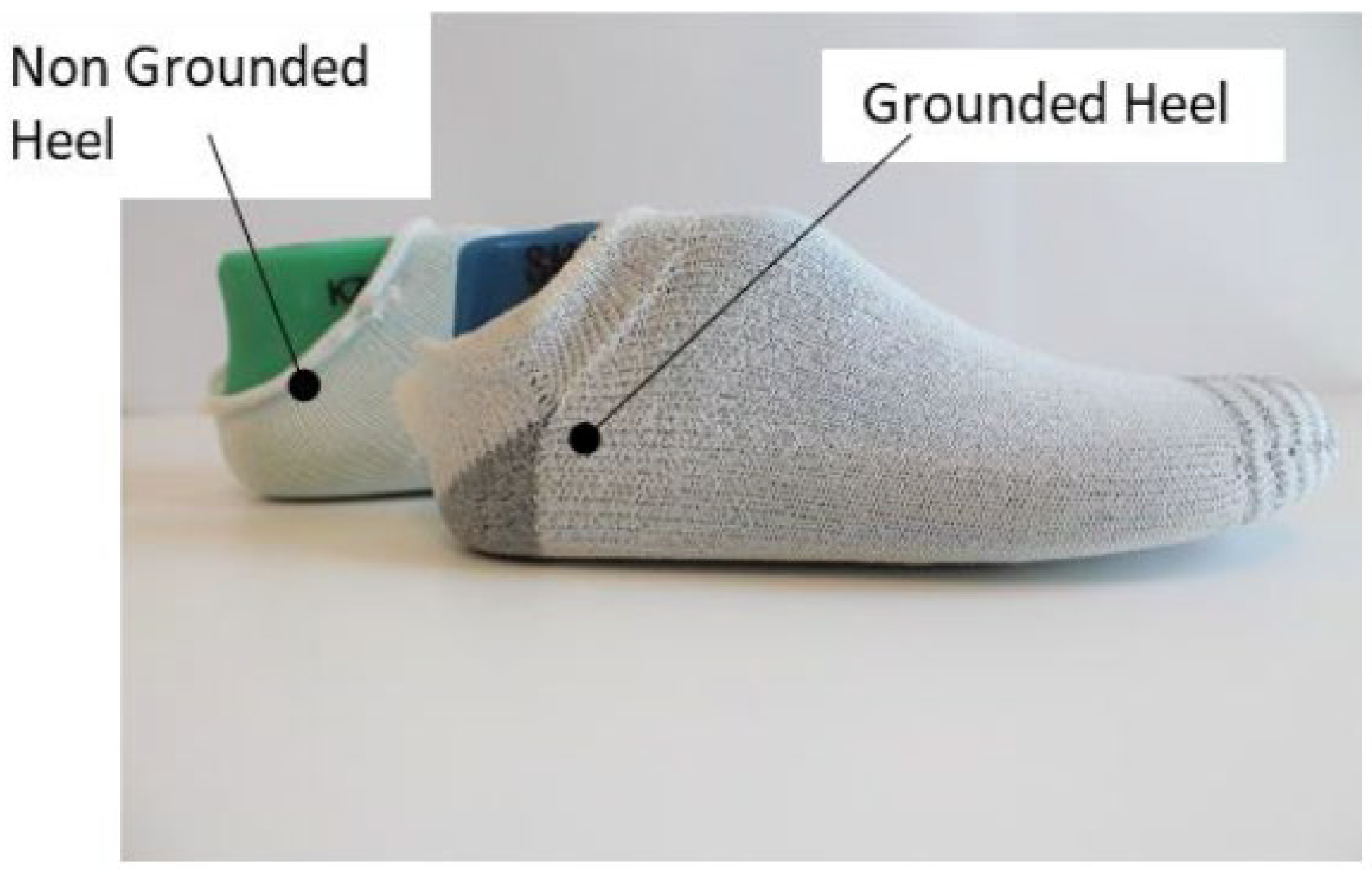

2.2. Sensor Prototype 2

2.3. Sensor Manufacturing—Sensor Fitment Iterations

2.4. Final Sensor Assemblies

2.5. Pycom Expansion Board and WiPy 2.0

2.5.1. Overall Connection and Assembly of Shoes and to Electronics Unit

2.5.2. Evaluation with Children

3. Results and Discussion

3.1. Sensor Prototype 1 Results and Evaluation

3.2. Sensor Prototype 2 Results and Evaluation

3.2.1. Foot-Length and Capacitance—Statistical Analysis

3.2.2. Foot-Length and Capacitance Relationship Results

3.2.3. Prototype 2 Evaluation

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

References

- Foot Growth in Children Age One to Five Years—PubMed. Available online: https://pubmed.ncbi.nlm.nih.gov/2307377/ (accessed on 21 September 2022).

- Gould, N.; Moreland, M.; Alvarez, R.; Trevino, S.; Fenwick, J. Development of the child’s arch. Foot Ankle 1989, 9, 241–245. [Google Scholar] [CrossRef]

- Big Issues for Small Feet: Developmental, Biomechanical and Clinical Narratives on Children’s Footwear | Journal of Foot and Ankle Research | Full Text. Available online: https://jfootankleres.biomedcentral.com/articles/10.1186/s13047-018-0281-2 (accessed on 21 September 2022).

- James, A.M.; Williams, C.M.; Haines, T.P. Heel raises versus prefabricated orthoses in the treatment of posterior heel pain associated with calcaneal apophysitis (Sever’s Disease): Study protocol for a randomised controlled trial. J. Foot Ankle Res. 2010, 3, 3. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Morrison, S.C.; Ferrari, J. Inter-rater reliability of the Foot Posture Index (FPI-6) in the assessment of the paediatric foot. J. Foot Ankle Res. 2009, 2, 26. [Google Scholar] [CrossRef] [Green Version]

- Evans, A.M.; Nicholson, H.; Zakarias, N. The paediatric flat foot proforma (p-FFP): Improved and abridged following a reproducibility study. J. Foot Ankle Res. 2009, 2, 25. [Google Scholar] [CrossRef] [Green Version]

- Evans, A.M. Growing pains: Contemporary knowledge and recommended practice. J. Foot Ankle Res. 2008, 1, 4. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Price, C.; Morrison, S.C.; Hashmi, F.; Phethean, J.; Nester, C. Biomechanics of the infant foot during the transition to independent walking: A narrative review. Gait Posture 2018, 59, 140–146. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Children Sport Shoes—Feelmax. Available online: https://feelmax.com/research/children-sport-shoes/ (accessed on 21 September 2022).

- Wegener, C.; Hunt, A.E.; Vanwanseele, B.; Burns, J.; Smith, R.M. Effect of children’s shoes on gait: A systematic review and meta-analysis. J. Foot Ankle Res. 2011, 4, 3. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Busscher, I.; Kingma, I.; Wapstra, F.H.; Bulstra, S.K.; Verkerke, G.J.; Veldhuizen, A.G. The value of shoe size for prediction of the timing of the pubertal growth spurt. Scoliosis 2011, 6, 1. [Google Scholar] [CrossRef]

- Textiles—An Introduction—Textile School. Available online: https://www.textileschool.com/119/textile-an-introduction/ (accessed on 21 September 2022).

- Harms, H.; Amft, O.; Troester, G. Does Loose Fitting Matter? Predicting Sensor Performance in Smart Garments. In Proceedings of the 7th International Conference on Body Area Networks, Oslo, Norway, 24–26 September 2012; Available online: https://eudl.eu/doi/10.4108/icst.bodynets.2012.249968 (accessed on 21 September 2022).

| Shoe Last Inserted | Distance of the Last to the Fabric Sensor (cm) | Capacitance Readings (pF) | |||

|---|---|---|---|---|---|

| Silver Samples | Stainless Steel Samples | ||||

| Arduino | LCR Meter | Arduino | LCR Meter | ||

| No last | 6 | 53.19 | 99.92 | 26.3 | 37 |

| Size 23 | 2 | 54 | 101.26 | 29 | 39 |

| Size 22 | 1.5 | 77 | 107.45 | 35.5 | 40 |

| Size 21 | 1 | 75.5 | 105.4 | 42.5 | 42 |

| Size 20 | 0 | 80.5 | 108 | 76 | 48 |

| Linear regression model: y = mx + cy = equation for both GH and NGH shoes; m = gradient of the equation; c = y intercept of the model | |||

| m (lower CI, upper CI, SE) | c (lower CI, upper CI, SE) | p | |

| yngh | 0.130 (−0.085, 0.346, 0.0991) | 10.57 (5.669, 15.48, 2.252) | 0.2135 |

| ygh | 0.238 (0.057, 0.418, 0.0829) | 8.158 (4.012, 12.2, 1.889) | 0.0141 |

| Linear regression model yv = foot volume regression equation = mx + cyv = equation for both GH and NGH shoes; m = gradient of the equation; c = y intercept of the model | |||

| m (lower CI, upper CI, SE) | c (lower CI, upper CI, SE) | p | |

| yvngh | 7.54 (−0.60, 15.68, 3.73) | 112.73 (−72.11, 297.6, 84.83) | 0.066 |

| yvgh | 10.06 (3.15, 16.97, 3.16) | 52.84 (−104.6, 210.3, 72.25) | 0.008 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Guzman, S.; Lowe, A.; Williams, C.; Kalra, A.; Anand, G. Comprehensive Understanding of Foot Development in Children Using Capacitive Textile Sensors. Sensors 2022, 22, 9499. https://doi.org/10.3390/s22239499

De Guzman S, Lowe A, Williams C, Kalra A, Anand G. Comprehensive Understanding of Foot Development in Children Using Capacitive Textile Sensors. Sensors. 2022; 22(23):9499. https://doi.org/10.3390/s22239499

Chicago/Turabian StyleDe Guzman, Sarah, Andrew Lowe, Cylie Williams, Anubha Kalra, and Gautam Anand. 2022. "Comprehensive Understanding of Foot Development in Children Using Capacitive Textile Sensors" Sensors 22, no. 23: 9499. https://doi.org/10.3390/s22239499

APA StyleDe Guzman, S., Lowe, A., Williams, C., Kalra, A., & Anand, G. (2022). Comprehensive Understanding of Foot Development in Children Using Capacitive Textile Sensors. Sensors, 22(23), 9499. https://doi.org/10.3390/s22239499