Fiber/Yarn-Based Triboelectric Nanogenerators (TENGs): Fabrication Strategy, Structure, and Application

Abstract

1. Introduction

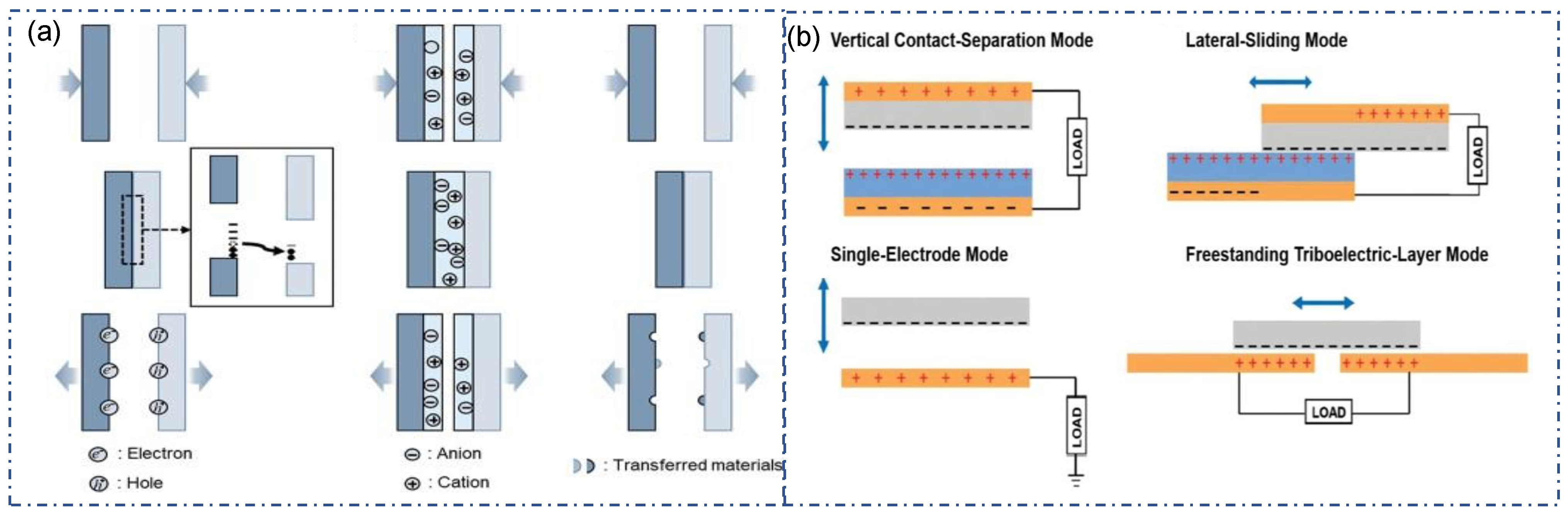

1.1. Fundamentals of TENGs

1.2. Textile-TENG

2. Material Used in Fiber/Yarn Based Triboelectric Nanogenerator

3. Fabrication Strategy and Structure Design

3.1. SE Mode of Fiber/Yarn-TENG

3.2. Stretchable Fiber/Yarn-TENG

3.3. Self-Trigger Fiber/Yarn-TENG

3.4. CS Mode Fiber/Yarn-TENG

3.5. Scalable Production of Fiber/Yarn-TENG

4. Fabrication of Fiber/Yarn TENG

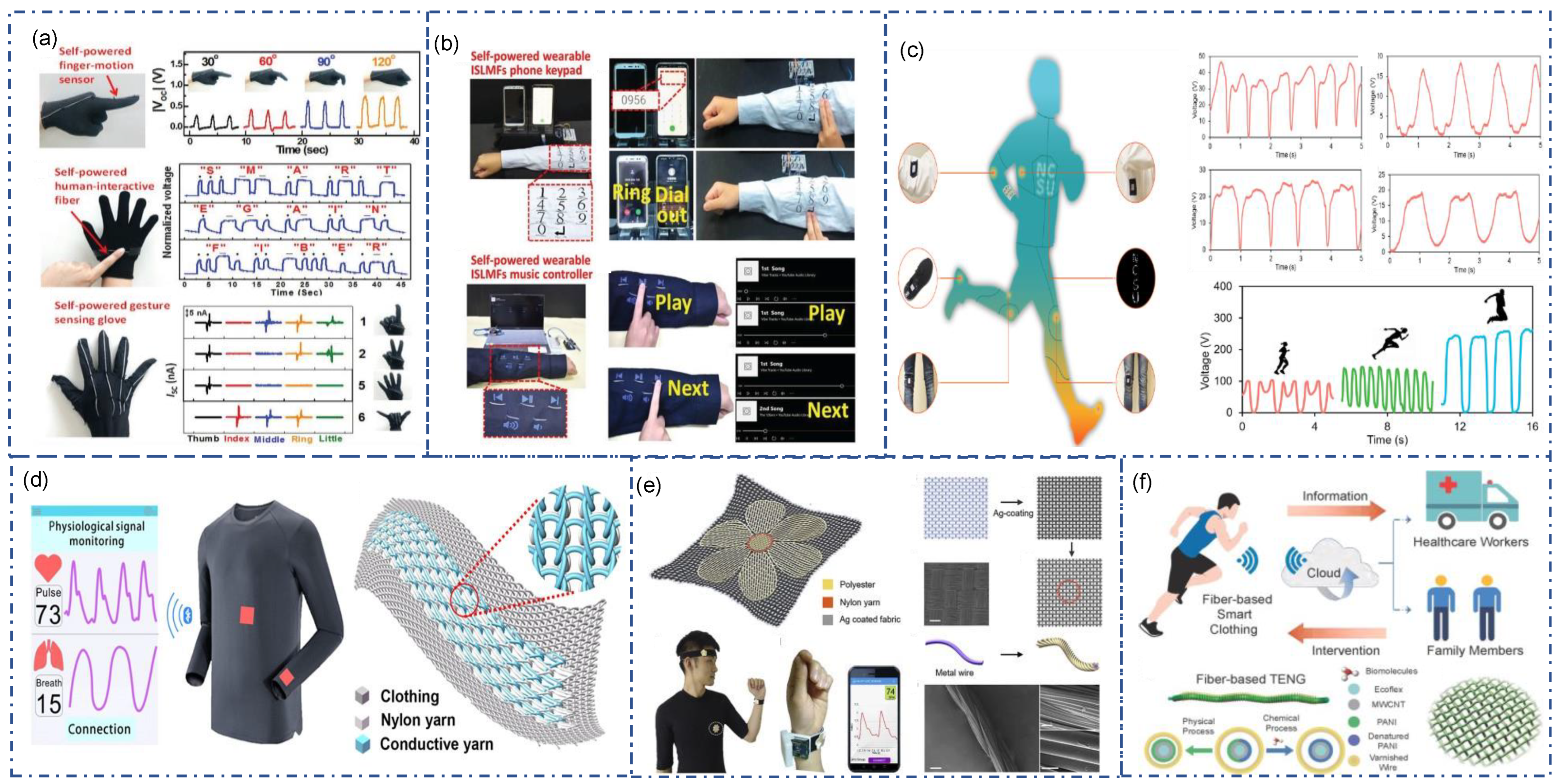

5. Application

5.1. Energy Harvesting

5.2. Sensors

6. Challenges and Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Viola, F.A.; Spanu, A.; Ricci, P.C.; Bonfiglio, A.; Cosseddu, P. Ultrathin, flexible and multimodal tactile sensors based on organic field-effect transistors. Sci. Rep. 2018, 8, 8073–8078. [Google Scholar] [CrossRef] [PubMed]

- Li, E.; Pan, Y.; Wang, C.; Liu, C.; Shen, C.; Pan, C.; Liu, X. Multifunctional and superhydrophobic cellulose composite paper for electromagnetic shielding, hydraulic triboelectric nanogenerator and Joule heating applications. Chem. Eng. J. 2021, 420, 129864. [Google Scholar] [CrossRef]

- Pei, J.; Deng, L.; Song, S.; Zhao, M.; Zhang, Y.; Wu, S.; Wang, G.; Zou, Z.; Wu, Z.; He, W.; et al. Towards artificial general intelligence with hybrid Tianjic chip architecture. Nature 2019, 572, 106–111. [Google Scholar] [CrossRef] [PubMed]

- Xiong, J.; Lee, P.S. Progress on wearable triboelectric nanogenerators in shapes of fiber, yarn, and textile. Sci. Technol. Adv. Mater. 2019, 20, 837–857. [Google Scholar] [CrossRef]

- Zhou, Q.; Pan, J.; Deng, S.; Xia, F.; Kim, T. Triboelectric Nanogenerator-Based Sensor Systems for Chemical or Biological Detection. Adv. Mater. 2021, 33, e2008276. [Google Scholar] [CrossRef]

- Bu, C.; Li, F.; Yin, K.; Pang, J.; Wang, L.; Wang, K. Research Progress and Prospect of Triboelectric Nanogenerators as Self-Powered Human Body Sensors. ACS Appl. Electron. Mater. 2020, 2, 863–878. [Google Scholar] [CrossRef]

- Kim, C.S.; Yang, H.M.; Lee, J.; Lee, G.S.; Choi, H.; Kim, Y.J.; Lim, S.H.; Cho, S.H.; Cho, B.J. Self-Powered Wearable Electrocardiography Using a Wearable Thermoelectric Power Generator. ACS Energy Lett. 2018, 3, 501–507. [Google Scholar] [CrossRef]

- Gao, W.; Emaminejad, S.; Nyein, H.Y.Y.; Challa, S.; Chen, K.; Peck, A.; Fahad, H.M.; Ota, H.; Shiraki, H.; Kiriya, D.; et al. Fully integrated wearable sensor arrays for multiplexed in situ perspiration analysis. Nature 2016, 529, 509–514. [Google Scholar] [CrossRef]

- Kim, J.; Gutruf, P.; Chiarelli, A.M.; Heo, S.Y.; Cho, K.; Xie, Z.; Banks, A.; Han, S.; Jang, K.; Lee, J.W.; et al. Miniaturized Battery-Free Wireless Systems for Wearable Pulse Oximetry. Adv. Funct. Mater. 2017, 27, 1604373. [Google Scholar] [CrossRef]

- Mo, X.; Zhou, H.; Li, W.; Xu, Z.; Duan, J.; Huang, L.; Hu, B.; Zhou, J. Piezoelectrets for wearable energy harvesters and sensors. Nano Energy 2019, 65, 104033. [Google Scholar] [CrossRef]

- Park, J.; Bhat, G.; Nk, A.; Geyik, C.S.; Ogras, U.Y.; Lee, H.G. Energy per Operation Optimization for Energy-Harvesting Wearable IoT Devices. Sensors 2020, 20, 764. [Google Scholar] [CrossRef] [PubMed]

- Gao, Q.; Cheng, T.; Wang, Z.L. Triboelectric mechanical sensors—Progress and prospects. Extrem. Mech. Lett. 2021, 42, 101100. [Google Scholar] [CrossRef]

- Xiang, H.; Zeng, Y.; Huang, X.; Wang, N.; Cao, X.; Wang, Z.L. From Triboelectric Nanogenerator to Multifunctional Triboelectric Sensors: A Chemical Perspective toward the Interface Optimization and Device Integration. Small 2022, 18, e2107222. [Google Scholar] [CrossRef] [PubMed]

- Dong, K.; Peng, X.; Wang, Z.L. Fiber/Fabric-Based Piezoelectric and Triboelectric Nanogenerators for Flexible/Stretchable and Wearable Electronics and Artificial Intelligence. Adv. Mater. 2020, 32, e1902549. [Google Scholar] [CrossRef] [PubMed]

- Tehrani, F.; Teymourian, H.; Wuerstle, B.; Kavner, J.; Patel, R.; Furmidge, A.; Aghavali, R.; Hosseini-Toudeshki, H.; Brown, C.; Zhang, F.; et al. An integrated wearable microneedle array for the continuous monitoring of multiple biomarkers in interstitial fluid. Nat. Biomed. Eng. 2022, 6, 1214–1224. [Google Scholar] [CrossRef]

- Fan, F.; Tian, Z.; Lin Wang, Z. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Shi, Q.; Zhang, Z.; Chen, T.; Lee, C. Minimalist and multi-functional human machine interface (HMI) using a flexible wearable triboelectric patch. Nano Energy 2019, 62, 355–366. [Google Scholar] [CrossRef]

- Khandelwal, G.; Dahiya, R. Self-Powered Active Sensing Based on Triboelectric Generators. Adv. Mater. 2022, 34, e2200724. [Google Scholar] [CrossRef]

- Song, E.; Li, J.; Won, S.M.; Bai, W.; Rogers, J.A. Materials for flexible bioelectronic systems as chronic neural interfaces. Nat. Mater. 2020, 19, 590–603. [Google Scholar] [CrossRef]

- Zamarayeva, A.M.; Ostfeld, A.E.; Wang, M.; Duey, J.K.; Deckman, I.; Lechêne, B.P.; Davies, G.; Steingart, D.A.; Arias, A.C. Flexible and stretchable power sources for wearable electronics. Sci. Adv. 2017, 3, e1602051. [Google Scholar] [CrossRef]

- Lee, M.H.; Wu, W. 2D Materials for Wearable Energy Harvesting. Adv. Mater. Technol. 2022, 7, 2101623. [Google Scholar] [CrossRef]

- Chen, B.; Yang, Y.; Wang, Z.L. Scavenging Wind Energy by Triboelectric Nanogenerators. Adv. Energy Mater. 2018, 8, 1702649. [Google Scholar] [CrossRef]

- Liu, Z.; Li, H.; Shi, B.; Fan, Y.; Wang, Z.L.; Li, Z. Wearable and Implantable Triboelectric Nanogenerators. Adv. Funct. Mater. 2019, 29, 1808820. [Google Scholar] [CrossRef]

- Cui, X.; Wu, H.; Wang, R. Fibrous triboelectric nanogenerators: Fabrication, integration, and application. J. Mater. Chemistry. A Mater. Energy Sustain. 2022, 1, 15881–15905. [Google Scholar] [CrossRef]

- Gunawardhana, K.R.S.D.; Wanasekara, N.D.; Dharmasena, R.D.I.G. Towards Truly Wearable Systems: Optimizing and Scaling Up Wearable Triboelectric Nanogenerators. iScience 2020, 23, 101360. [Google Scholar] [CrossRef] [PubMed]

- Dolez, P.I. Energy Harvesting Materials and Structures for Smart Textile Applications: Recent Progress and Path Forward. Sensors 2021, 21, 6297. [Google Scholar] [CrossRef]

- Kim, W.; Kim, D.; Tcho, I.; Kim, J.; Kim, M.; Choi, Y. Triboelectric Nanogenerator: Structure, Mechanism, and Applications. ACS Nano 2021, 15, 258–287. [Google Scholar] [CrossRef]

- Pan, S.; Zhang, Z. Fundamental theories and basic principles of triboelectric effect: A review. Friction 2019, 7, 2–17. [Google Scholar] [CrossRef]

- Vasandani, P.; Mao, Z.; Jia, W.; Sun, M. Relationship between triboelectric charge and contact force for two triboelectric layers. J. Electrost. 2017, 90, 147–152. [Google Scholar] [CrossRef]

- Baytekin, H.T.; Patashinski, A.Z.; Branicki, M.; Baytekin, B.; Soh, S.; Grzybowski, B.A. The Mosaic of Surface Charge in Contact Electrification. Science 2011, 333, 308–312. [Google Scholar] [CrossRef]

- Shin, S.; Bae, Y.E.; Moon, H.K.; Kim, J.; Choi, S.; Kim, Y.; Yoon, H.J.; Lee, M.H.; Nah, J. Formation of Triboelectric Series via Atomic-Level Surface Functionalization for Triboelectric Energy Harvesting. ACS Nano 2017, 11, 6131–6138. [Google Scholar] [CrossRef] [PubMed]

- Niu, S.; Wang, S.; Lin, L.; Liu, Y.; Zhou, Y.; Hu, Y.; Wang, Z. Theoretical study of contact-mode triboelectric nanogenerators as an effective power source. Energy Environ. Sci. 2013, 6, 3576–3583. [Google Scholar] [CrossRef]

- Wu, C.; Wang, A.C.; Ding, W.; Guo, H.; Wang, Z.L. Triboelectric Nanogenerator: A Foundation of the Energy for the New Era. Adv. Energy Mater. 2019, 9, 1802906. [Google Scholar] [CrossRef]

- Wu, J.; Wang, X.; Li, H.; Wang, F.; Yang, W.; Hu, Y. Insights into the mechanism of metal-polymer contact electrification for triboelectric nanogenerator via first-principles investigations. Nano Energy 2018, 48, 607–616. [Google Scholar] [CrossRef]

- Diaz, A.F.; Felix-Navarro, R.M. A semi-quantitative tribo-electric series for polymeric materials: The influence of chemical structure and properties. J. Electrost. 2004, 62, 277–290. [Google Scholar] [CrossRef]

- Lacks, D.J.; Mohan Sankaran, R. Contact electrification of insulating materials. J. Physics. D Appl. Phys. 2011, 44, 453001. [Google Scholar] [CrossRef]

- Chen, A.; Zhang, C.; Zhu, G.; Wang, Z.L. Polymer Materials for High-Performance Triboelectric Nanogenerators. Adv. Sci. 2020, 7, 2000186. [Google Scholar] [CrossRef]

- McCarty, L.S.; Whitesides, G.M. Electrostatic Charging Due to Separation of Ions at Interfaces: Contact Electrification of Ionic Electrets. Angew. Chem. 2008, 47, 2188–2207. [Google Scholar] [CrossRef]

- Weng, W.; Chen, P.; He, S.; Sun, X.; Peng, H. Smart Electronic Textiles. Angew. Chem. 2016, 55, 6140–6169. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, X.; Ying, B. On textile biomedical engineering. Sci. China Technol. Sci. 2019, 62, 945–957. [Google Scholar] [CrossRef]

- Massella, D.; Giraud, S.; Guan, J.; Ferri, A.; Salaün, F. Textiles for health: A review of textile fabrics treated with chitosan microcapsules. Environ. Chem. Lett. 2019, 17, 1787–1800. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, Y.; Li, M.; Chen, E.; Mu, W.; Fisher, R.; Yin, R. Wearable Actuators: An Overview. Textiles 2021, 1, 283–321. [Google Scholar] [CrossRef]

- Stoppa, M.; Chiolerio, A. Wearable Electronics and Smart Textiles: A Critical Review. Sensors 2014, 14, 11957–11992. [Google Scholar] [CrossRef] [PubMed]

- Stylios, G.K. Novel Smart Textiles. Materials 2020, 13, 950. [Google Scholar] [CrossRef]

- Grancarić, A.M.; Jerković, I.; Koncar, V.; Cochrane, C.; Kelly, F.M.; Soulat, D.; Legrand, X. Conductive polymers for smart textile applications. J. Ind. Text. 2018, 48, 612–642. [Google Scholar] [CrossRef]

- Li, X.; Lin, Z.; Cheng, G.; Wen, X.; Liu, Y.; Niu, S.; Wang, Z.L. 3D Fiber-Based Hybrid Nanogenerator for Energy Harvesting and as a Self-Powered Pressure Sensor. ACS Nano 2014, 8, 10674–10681. [Google Scholar] [CrossRef] [PubMed]

- Xu, B.; Eike, R.J.; Cliett, A.; Ni, L.; Cloud, R.; Li, Y. Durability testing of electronic textile surface resistivity and textile antenna performance. Text. Res. J. 2019, 89, 3708–3721. [Google Scholar] [CrossRef]

- Jost, K.; Dion, G.; Gogotsi, Y. Textile energy storage in perspective. J. Mater. Chemistry. A Mater. Energy Sustain. 2014, 2, 10776–10787. [Google Scholar] [CrossRef]

- Wang, J.; Li, X.; Zi, Y.; Wang, S.; Li, Z.; Zheng, L.; Yi, F.; Li, S.; Wang, Z.L. A Flexible Fiber-Based Supercapacitor-Triboelectric-Nanogenerator Power System for Wearable Electronics. Adv. Mater. 2015, 27, 4830–4836. [Google Scholar] [CrossRef]

- Zhao, Z.; Yan, C.; Liu, Z.; Fu, X.; Peng, L.; Hu, Y.; Zheng, Z. Machine-Washable Textile Triboelectric Nanogenerators for Effective Human Respiratory Monitoring through Loom Weaving of Metallic Yarns. Adv. Mater. 2016, 28, 10267–10274. [Google Scholar] [CrossRef]

- Panda, P.K. Review: Environmental friendly lead-free piezoelectric materials. J. Mater. Sci. 2009, 44, 5049–5062. [Google Scholar] [CrossRef]

- Zhao, Z.; Huang, Q.; Yan, C.; Liu, Y.; Zeng, X.; Wei, X.; Hu, Y.; Zheng, Z. Machine-washable and breathable pressure sensors based on triboelectric nanogenerators enabled by textile technologies. Nano Energy 2020, 70, 104528. [Google Scholar] [CrossRef]

- Wang, S.; Lin, L.; Wang, Z.L. Triboelectric nanogenerators as self-powered active sensors. Nano Energy 2015, 11, 436–462. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, Y.; Su, Y.; Chen, J.; Adams, K.; Lee, S.; Hu, C.; Wang, Z.L. Triboelectric Nanogenerator for Harvesting Vibration Energy in Full Space and as Self-Powered Acceleration Sensor. Adv. Funct. Mater. 2014, 24, 1401–1407. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Z.L. Air/Liquid-Pressure and Heartbeat-Driven Flexible Fiber Nanogenerators as a Micro/Nano-Power Source or Diagnostic Sensor. Adv. Mater. 2011, 23, 84–89. [Google Scholar] [CrossRef]

- Sim, H.J.; Choi, C.; Kim, S.H.; Kim, K.M.; Lee, C.J.; Kim, Y.T.; Lepró, X.; Baughman, R.H.; Kim, S.J. Stretchable Triboelectric Fiber for Self-powered Kinematic Sensing Textile. Sci. Rep. 2016, 6, 35153. [Google Scholar] [CrossRef]

- Wei, L.; Qin, X. Nanofiber bundles and nanofiber yarn device and their mechanical properties: A review. Text. Res. J. 2016, 86, 1885–1898. [Google Scholar] [CrossRef]

- Zhong, J.; Zhang, Y.; Zhong, Q.; Hu, Q.; Hu, B.; Wang, Z.L.; Zhou, J. Fiber-Based Generator for Wearable Electronics and Mobile Medication. ACS Nano 2014, 8, 6273–6280. [Google Scholar] [CrossRef]

- Lee, M.; Chen, C.; Wang, S.; Cha, S.N.; Park, Y.J.; Kim, J.M.; Chou, L.; Wang, Z.L. A Hybrid Piezoelectric Structure for Wearable Nanogenerators. Adv. Mater. 2012, 24, 1759–1764. [Google Scholar] [CrossRef]

- Kim, S.; We, J.; Cho, B. A wearable thermoelectric generator fabricated on a glass fabric. Energy Environ. Sci. 2014, 7, 1959–1965. [Google Scholar] [CrossRef]

- Liu, M.; Pu, X.; Jiang, C.; Liu, T.; Huang, X.; Chen, L.; Du, C.; Sun, J.; Hu, W.; Wang, Z.L. Large-Area All-Textile Pressure Sensors for Monitoring Human Motion and Physiological Signals. Adv. Mater. 2017, 29, 1703700. [Google Scholar] [CrossRef] [PubMed]

- Yetisen, A.K.; Qu, H.; Manbachi, A.; Butt, H.; Dokmeci, M.R.; Hinestroza, J.P.; Skorobogatiy, M.; Khademhosseini, A.; Yun, S.H. Nanotechnology in Textiles. ACS Nano 2016, 10, 3042–3068. [Google Scholar] [CrossRef] [PubMed]

- Chatterjee, K.; Tabor, J.; Ghosh, T.K. Electrically Conductive Coatings for Fiber-Based E-Textiles. Fibers 2019, 7, 51. [Google Scholar] [CrossRef]

- Tseghai, G.B.; Malengier, B.; Fante, K.A.; Nigusse, A.B.; Van Langenhove, L. Integration of Conductive Materials with Textile Structures, an Overview. Sensors 2020, 20, 6910. [Google Scholar] [CrossRef]

- Castrillon, R.; Pnrez, J.J.; Andrade-Caicedo, H. Electrical performance of PEDOT:PSS-based textile electrodes for wearable ECG monitoring: A comparative study. BioMedical Eng. OnLine 2018, 17, 38. [Google Scholar] [CrossRef]

- Zhu, J.; Zhu, P.; Yang, Q.; Chen, T.; Wang, J.; Li, J. A fully stretchable textile-based triboelectric nanogenerator for human motion monitoring. Mater. Lett. 2020, 280, 128568. [Google Scholar] [CrossRef]

- Tao, X.; Zhou, Y.; Qi, K.; Guo, C.; Dai, Y.; He, J.; Dai, Z. Wearable textile triboelectric generator based on nanofiber core-spun yarn coupled with electret effect. J. Colloid Interface Sci. 2022, 608, 2339–2346. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Zheng, Z. Progress in textile-based triboelectric nanogenerators for smart fabrics. Nano Energy 2019, 56, 16–24. [Google Scholar] [CrossRef]

- Jeong, J.; Kwon, J.; Lim, K.; Biswas, S.; Tibaldi, A.; Lee, S.; Oh, H.J.; Kim, J.; Ko, J.; Lee, D.; et al. Comparative Study of Triboelectric Nanogenerators with Differently Woven Cotton Textiles for Wearable Electronics. Polymers 2019, 11, 1443. [Google Scholar] [CrossRef]

- Zhong, W.; Xu, L.; Wang, H.; An, J.; Wang, Z.L. Tilting-Sensitive Triboelectric Nanogenerators for Energy Harvesting from Unstable/Fluctuating Surfaces. Adv. Funct. Mater. 2019, 29, 1905319. [Google Scholar] [CrossRef]

- Liang, X.; Zhao, T.; Jiang, W.; Yu, X.; Hu, Y.; Zhu, P.; Zheng, H.; Sun, R.; Wong, C. Highly transparent triboelectric nanogenerator utilizing in-situ chemically welded silver nanowire network as electrode for mechanical energy harvesting and body motion monitoring. Nano Energy 2019, 59, 508–516. [Google Scholar] [CrossRef]

- Bai, P.; Zhu, G.; Zhou, Y.S.; Wang, S.; Ma, J.; Zhang, G.; Wang, Z.L. Dipole-moment-induced effect on contact electrification for triboelectric nanogenerators. Nano Res. 2014, 7, 990–997. [Google Scholar] [CrossRef]

- Yu, A.; Zhu, Y.; Wang, W.; Zhai, J. Progress in Triboelectric Materials: Toward High Performance and Widespread Applications. Adv. Funct. Mater. 2019, 29, 1900098. [Google Scholar] [CrossRef]

- Su, Y.; Yang, Y.; Zhong, X.; Zhang, H.; Wu, Z.; Jiang, Y.; Wang, Z.L. Fully Enclosed Cylindrical Single-Electrode-Based Triboelectric Nanogenerator. ACS Appl. Mater. Interfaces 2014, 6, 553–559. [Google Scholar] [CrossRef]

- Niu, S.; Liu, Y.; Wang, S.; Lin, L.; Zhou, Y.S.; Hu, Y.; Wang, Z.L. Theoretical Investigation and Structural Optimization of Single-Electrode Triboelectric Nanogenerators. Adv. Funct. Mater. 2014, 24, 3332–3340. [Google Scholar] [CrossRef]

- Shi, Q.; Qiu, C.; He, T.; Wu, F.; Zhu, M.; Dziuban, J.A.; Walczak, R.; Yuce, M.R.; Lee, C. Triboelectric single-electrode-output control interface using patterned grid electrode. Nano Energy 2019, 60, 545–556. [Google Scholar] [CrossRef]

- Lai, Y.; Deng, J.; Zhang, S.L.; Niu, S.; Guo, H.; Wang, Z.L. Single-Thread-Based Wearable and Highly Stretchable Triboelectric Nanogenerators and Their Applications in Cloth-Based Self-Powered Human-Interactive and Biomedical Sensing. Adv. Funct. Mater. 2017, 27, 1604462. [Google Scholar] [CrossRef]

- Dong, K.; Peng, X.; An, J.; Wang, A.C.; Luo, J.; Sun, B.; Wang, J.; Wang, Z.L. Shape adaptable and highly resilient 3D braided triboelectric nanogenerators as e-textiles for power and sensing. Nat. Commun. 2020, 11, 2868. [Google Scholar] [CrossRef]

- Busolo, T.; Szewczyk, P.K.; Nair, M.; Stachewicz, U.; Kar-Narayan, S. Triboelectric Yarns with Electrospun Functional Polymer Coatings for Highly Durable and Washable Smart Textile Applications. ACS Appl. Mater. Interfaces 2021, 13, 16876–16886. [Google Scholar] [CrossRef]

- Ma, L.; Zhou, M.; Wu, R.; Patil, A.; Gong, H.; Zhu, S.; Wang, T.; Zhang, Y.; Shen, S.; Dong, K.; et al. Continuous and Scalable Manufacture of Hybridized Nano-Micro Triboelectric Yarns for Energy Harvesting and Signal Sensing. ACS Nano 2020, 14, 4716–4726. [Google Scholar] [CrossRef]

- Yu, A.; Pu, X.; Wen, R.; Liu, M.; Zhou, T.; Zhang, K.; Zhang, Y.; Zhai, J.; Hu, W.; Wang, Z.L. Core–Shell-Yarn-Based Triboelectric Nanogenerator Textiles as Power Cloths. ACS Nano 2017, 11, 12764–12771. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.F.; Fang, S.; Moura, F.A.; Ding, J.N.; Jiang, N.; Di, J.; Zhang, M.; Lepro, X.; Galvao, D.S.; Haines, C.S.; et al. Hierarchically buckled sheath-core fibers for superelastic electronics, sensors, and muscles. Science 2015, 349, 400–404. [Google Scholar] [CrossRef] [PubMed]

- Ning, C.; Dong, K.; Cheng, R.; Yi, J.; Ye, C.; Peng, X.; Sheng, F.; Jiang, Y.; Wang, Z.L. Flexible and Stretchable Fiber-Shaped Triboelectric Nanogenerators for Biomechanical Monitoring and Human-Interactive Sensing. Adv. Funct. Mater. 2021, 31, 2006679. [Google Scholar] [CrossRef]

- Yang, Y.; Sun, N.; Wen, Z.; Cheng, P.; Zheng, H.; Shao, H.; Xia, Y.; Chen, C.; Lan, H.; Xie, X.; et al. Liquid-Metal-Based Super-Stretchable and Structure-Designable Triboelectric Nanogenerator for Wearable Electronics. ACS Nano 2018, 12, 2027–2034. [Google Scholar] [CrossRef] [PubMed]

- Jing, T.; Xu, B.; Xin, J.H.; Guan, X.; Yang, Y. Series to parallel structure of electrode fiber: An effective method to remarkably reduce inner resistance of triboelectric nanogenerator textiles. J. Mater. Chemistry. A Mater. Energy Sustain. 2021, 9, 12331–12339. [Google Scholar] [CrossRef]

- Dong, L.; Wang, M.; Wu, J.; Zhu, C.; Shi, J.; Morikawa, H. Deformable Textile-Structured Triboelectric Nanogenerator Knitted with Multifunctional Sensing Fibers for Biomechanical Energy Harvesting. Adv. Fiber Mater. 2022. [Google Scholar] [CrossRef]

- Park, J.; Choi, A.Y.; Lee, C.J.; Kim, D.; Kim, Y.T. Highly stretchable fiber-based single-electrode triboelectric nanogenerator for wearable devices. RSC Adv. 2017, 7, 54829–54834. [Google Scholar] [CrossRef]

- Gong, W.; Hou, C.; Zhou, J.; Guo, Y.; Zhang, W.; Li, Y.; Zhang, Q.; Wang, H. Continuous and scalable manufacture of amphibious energy yarns and textiles. Nat. Commun. 2019, 10, 868. [Google Scholar] [CrossRef]

- Gao, Y.; Li, Z.; Xu, B.; Li, M.; Jiang, C.; Guan, X.; Yang, Y. Scalable core–spun coating yarn-based triboelectric nanogenerators with hierarchical structure for wearable energy harvesting and sensing via continuous manufacturing. Nano Energy 2022, 91, 106672. [Google Scholar] [CrossRef]

- Zhang, D.; Yang, W.; Gong, W.; Ma, W.; Hou, C.; Li, Y.; Zhang, Q.; Wang, H. Abrasion Resistant/Waterproof Stretchable Triboelectric Yarns Based on Fermat Spirals. Adv. Mater. 2021, 33, 2100782. [Google Scholar] [CrossRef]

- Ye, C.; Dong, S.; Ren, J.; Ling, S. Ultrastable and High-Performance Silk Energy Harvesting Textiles. Nano-Micro Lett. 2020, 12, 12. [Google Scholar] [CrossRef] [PubMed]

- Guan, X.; Xu, B.; Wu, M.; Jing, T.; Yang, Y.; Gao, Y. Breathable, washable and wearable woven-structured triboelectric nanogenerators utilizing electrospun nanofibers for biomechanical energy harvesting and self-powered sensing. Nano Energy 2021, 80, 105549. [Google Scholar] [CrossRef]

- Yu, X.; Pan, J.; Zhang, J.; Sun, H.; He, S.; Qiu, L.; Lou, H.; Sun, X.; Peng, H. A coaxial triboelectric nanogenerator fiber for energy harvesting and sensing under deformation. J. Mater. Chemistry. A Mater. Energy Sustain. 2017, 5, 6032–6037. [Google Scholar] [CrossRef]

- Dai, Z.; Wang, N.; Yu, Y.; Lu, Y.; Jiang, L.; Zhang, D.; Wang, X.; Yan, X.; Long, Y. One-Step Preparation of a Core-Spun Cu/P(VDF-TrFE) Nanofibrous Yarn for Wearable Smart Textile to Monitor Human Movement. ACS Appl. Mater. Interfaces 2021, 13, 44234–44242. [Google Scholar] [CrossRef]

- Chen, C.; Chen, L.; Wu, Z.; Guo, H.; Yu, W.; Du, Z.; Wang, Z.L. 3D double-faced interlock fabric triboelectric nanogenerator for bio-motion energy harvesting and as self-powered stretching and 3D tactile sensors. Mater. Today 2020, 32, 84–93. [Google Scholar] [CrossRef]

- Niu, L.; Peng, X.; Chen, L.; Liu, Q.; Wang, T.; Dong, K.; Pan, H.; Cong, H.; Liu, G.; Jiang, G.; et al. Industrial production of bionic scales knitting fabric-based triboelectric nanogenerator for outdoor rescue and human protection. Nano Energy 2022, 97, 107168. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, E.; Wang, Z.; Ling, Y.; Fisher, R.; Li, M.; Hart, J.; Mu, W.; Gao, W.; Tao, X.; et al. Flexible, durable, and washable triboelectric yarn and embroidery for self-powered sensing and human-machine interaction. Nano Energy 2022, 104, 107929. [Google Scholar] [CrossRef]

- Zhou, T.; Zhang, C.; Han, C.B.; Fan, F.R.; Tang, W.; Wang, Z.L. Woven Structured Triboelectric Nanogenerator for Wearable Devices. ACS Appl. Mater. Interfaces 2014, 6, 14695–14701. [Google Scholar] [CrossRef]

- Dong, K.; Wang, Y.; Deng, J.; Dai, Y.; Zhang, S.L.; Zou, H.; Gu, B.; Sun, B.; Wang, Z.L. A Highly Stretchable and Washable All-Yarn-Based Self-Charging Knitting Power Textile Composed of Fiber Triboelectric Nanogenerators and Supercapacitors. ACS Nano 2017, 11, 9490–9499. [Google Scholar] [CrossRef]

- Lai, Y.; Lu, H.; Wu, H.; Zhang, D.; Yang, J.; Ma, J.; Shamsi, M.; Vallem, V.; Dickey, M.D. Elastic Multifunctional Liquid–Metal Fibers for Harvesting Mechanical and Electromagnetic Energy and as Self-Powered Sensors. Adv. Energy Mater. 2021, 11, 2100411. [Google Scholar] [CrossRef]

- Zhao, T.; Fu, Y.; Sun, C.; Zhao, X.; Jiao, C.; Du, A.; Wang, Q.; Mao, Y.; Liu, B. Wearable biosensors for real-time sweat analysis and body motion capture based on stretchable fiber-based triboelectric nanogenerators. Biosens. Bioelectron. 2022, 205, 114115. [Google Scholar] [CrossRef] [PubMed]

- Meng, K.; Zhao, S.; Zhou, Y.; Wu, Y.; Zhang, S.; He, Q.; Wang, X.; Zhou, Z.; Fan, W.; Tan, X.; et al. A Wireless Textile-Based Sensor System for Self-Powered Personalized Health Care. Matter 2020, 2, 896–907. [Google Scholar] [CrossRef]

- Fan, W.; He, Q.; Meng, K.; Tan, X.; Zhou, Z.; Zhang, G.; Yang, J.; Wang, Z.L. Machine-knitted washable sensor array textile for precise epidermal physiological signal monitoring. Sci. Adv. 2020, 6, eaay2840. [Google Scholar] [CrossRef] [PubMed]

| Refs | Work Mode | Power Density | Triboelectric Material |

|---|---|---|---|

| [78] | CS | 26 W m−3 | PDMS/Ag-coated yarn |

| [80] | SE | 336.2 μW/m | PAN/PVDF nanofibers/Acrylic |

| [81] | SE | 60 mW m–2 | Spandex/Polyester |

| [84] | SE | 8.43 mW/m2 | Skin/PDMS |

| [88] | CS | 12.5 μW/m | Polyacrylonitrile/PDMS |

| [90] | SE | 1.25 W/m2 | Nylon/PVDF |

| [91] | CS | 3.5 μW/m2 | Silk/PTFE |

| [92] | CS | 93 mW/m2 | PA66/PVDF-TrFE/Rubber |

| [97] | SE | 245 μW/m | PU/PTFE |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Ling, Y.; Yin, R. Fiber/Yarn-Based Triboelectric Nanogenerators (TENGs): Fabrication Strategy, Structure, and Application. Sensors 2022, 22, 9716. https://doi.org/10.3390/s22249716

Chen Y, Ling Y, Yin R. Fiber/Yarn-Based Triboelectric Nanogenerators (TENGs): Fabrication Strategy, Structure, and Application. Sensors. 2022; 22(24):9716. https://doi.org/10.3390/s22249716

Chicago/Turabian StyleChen, Yu, Yali Ling, and Rong Yin. 2022. "Fiber/Yarn-Based Triboelectric Nanogenerators (TENGs): Fabrication Strategy, Structure, and Application" Sensors 22, no. 24: 9716. https://doi.org/10.3390/s22249716

APA StyleChen, Y., Ling, Y., & Yin, R. (2022). Fiber/Yarn-Based Triboelectric Nanogenerators (TENGs): Fabrication Strategy, Structure, and Application. Sensors, 22(24), 9716. https://doi.org/10.3390/s22249716