Validation of an Automatic Inertial Sensor-Based Methodology for Detailed Barbell Velocity Monitoring during Maximal Paralympic Bench Press

Abstract

:1. Introduction

2. Materials and Methods

2.1. Participants

2.2. Data Collection

2.3. Data Analysis

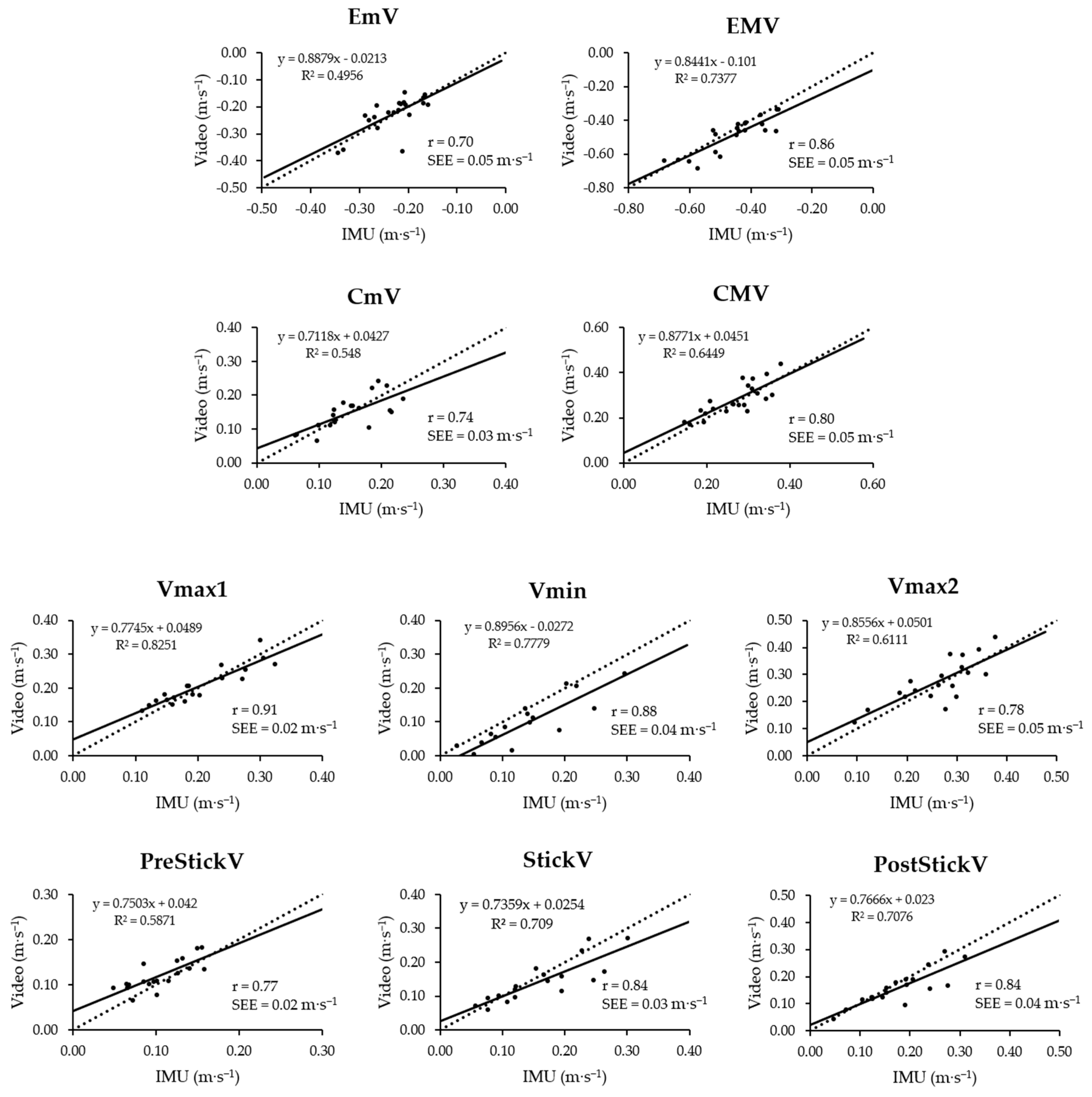

- Between Start and Stop (eccentric mean/maximum velocity: EmV/EMV);

- Between Stop and End (concentric mean/maximum velocity: CmV/CMV);

- Between Stop and Vmax1 (pre-sticking region mean velocity: PreStickV);

- Between Vmax1 and Vmin (sticking region mean velocity: StickV);

- Between Vmin and Vmax2 (post-sticking region mean velocity: PostStickV).

2.4. Statistical Analysis

2.4.1. Discrete Velocity Parameters

2.4.2. Curve Similarity Analysis

3. Results

3.1. Discrete Velocity Parameters

3.2. Curve Similarity Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Romagnoli, R.; Piacentini, M.F. Perception of Velocity during Free-Weight Exercises: Difference between Back Squat and Bench Press. J. Funct. Morphol. Kinesiol. 2022, 7, 34. [Google Scholar] [CrossRef]

- Guerriero, A.; Varalda, C.; Piacentini, M. The Role of Velocity Based Training in the Strength Periodization for Modern Athletes. J. Funct. Morphol. Kinesiol. 2018, 3, 55. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Banyard, H.G.; Tufano, J.J.; Delgado, J.; Thompson, S.W.; Nosaka, K. Comparison of the Effects of Velocity-Based Training Methods and Traditional 1RM-Percent-Based Training Prescription on Acute Kinetic and Kinematic Variables. Int. J. Sports Physiol. Perform. 2019, 14, 246–255. [Google Scholar] [CrossRef] [Green Version]

- Abbott, J.C.; Wagle, J.P.; Sato, K.; Painter, K.; Light, T.J.; Stone, M.H. Validation of Inertial Sensor to Measure Barbell Kinematics across a Spectrum of Loading Conditions. Sports 2020, 8, 93. [Google Scholar] [CrossRef] [PubMed]

- Comstock, B.A.; Solomon-Hill, G.; Flanagan, S.D.; Earp, J.E.; Luk, H.-Y.; Dobbins, K.A.; Dunn-Lewis, C.; Fragala, M.S.; Ho, J.-Y.; Hatfield, D.L.; et al. Validity of the Myotest® in Measuring Force and Power Production in the Squat and Bench Press. J. Strength Cond. Res. 2011, 25, 2293–2297. [Google Scholar] [CrossRef] [PubMed]

- Courel-Ibáñez, J.; Martínez-Cava, A.; Morán-Navarro, R.; Escribano-Peñas, P.; Chavarren-Cabrero, J.; González-Badillo, J.J.; Pallarés, J.G. Reproducibility and Repeatability of Five Different Technologies for Bar Velocity Measurement in Resistance Training. Ann. Biomed. Eng. 2019, 47, 1523–1538. [Google Scholar] [CrossRef]

- Held, S.; Rappelt, L.; Deutsch, J.-P.; Donath, L. Valid and Reliable Barbell Velocity Estimation Using an Inertial Measurement Unit. Int. J. Environ. Res. Public Health 2021, 18, 9170. [Google Scholar] [CrossRef]

- Lake, J.; Augustus, S.; Austin, K.; Comfort, P.; McMahon, J.; Mundy, P.; Haff, G.G. The Reliability and Validity of the Bar-Mounted PUSH Band TM 2.0 during Bench Press with Moderate and Heavy Loads. J. Sports Sci. 2019, 37, 2685–2690. [Google Scholar] [CrossRef]

- Thompson, S.W.; Rogerson, D.; Dorrell, H.F.; Ruddock, A.; Barnes, A. The Reliability and Validity of Current Technologies for Measuring Barbell Velocity in the Free-Weight Back Squat and Power Clean. Sports 2020, 8, 94. [Google Scholar] [CrossRef]

- Clemente, F.M.; Akyildiz, Z.; Pino-Ortega, J.; Rico-González, M. Validity and Reliability of the Inertial Measurement Unit for Barbell Velocity Assessments: A Systematic Review. Sensors 2021, 21, 2511. [Google Scholar] [CrossRef]

- van den Hoek, D.; Garrett, J.; Howells, R.; Latella, C. Paralympians Are Stronger Than You Know: A Comparison of Para and Nondisabled Powerlifting Bench Press World Records. J. Strength Cond. Res. 2022. publish ahead of print. [Google Scholar] [CrossRef] [PubMed]

- Willick, S.E.; Cushman, D.M.; Blauwet, C.A.; Emery, C.; Webborn, N.; Derman, W.; Schwellnus, M.; Stomphorst, J.; Van de Vliet, P. The Epidemiology of Injuries in Powerlifting at the London 2012 Paralympic Games: An Analysis of 1411 Athlete-Days. Scand. J. Med. Sci. Sports 2016, 26, 1233–1238. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- World Para Powerlifting about the Sport. Available online: https://www.paralympic.org/powerlifting/about (accessed on 11 October 2022).

- World Para Powerlifting. Technical Rules and Regulations; World Para Powerlifting: Bonn, Germany, 2022. [Google Scholar]

- Aidar, F.J.; Clemente, F.M.; de Matos, D.G.; Marçal, A.C.; de Souza, R.F.; Moreira, O.C.; de Almeida-Neto, P.F.; Vilaça-Alves, J.; Garrido, N.D.; Dos Santos, J.L.; et al. Evaluation of Strength and Muscle Activation Indicators in Sticking Point Region of National-Level Paralympic Powerlifting Athletes. J. Funct. Morphol. Kinesiol. 2021, 6, 43. [Google Scholar] [CrossRef] [PubMed]

- Loturco, I.; Pereira, L.A.; Winckler, C.; Santos, W.L.; Kobal, R.; McGuigan, M. Load-Velocity Relationship in National Paralympic Powerlifters: A Case Study. Int. J. Sports Physiol. Perform. 2019, 14, 531–535. [Google Scholar] [CrossRef]

- Mendonça, T.P.; Aidar, F.J.; Matos, D.G.; Souza, R.F.; Marçal, A.C.; Almeida-Neto, P.F.; Cabral, B.G.; Garrido, N.D.; Neiva, H.P.; Marinho, D.A.; et al. Force Production and Muscle Activation during Partial vs. Full Range of Motion in Paralympic Powerlifting. PLoS ONE 2021, 16, e0257810. [Google Scholar] [CrossRef]

- Teles, L.J.L.; Aidar, F.J.; de Matos, D.G.; Marçal, A.C.; de Almeida-Neto, P.F.; Neves, E.B.; Moreira, O.C.; Ribeiro Neto, F.; Garrido, N.D.; Vilaça-Alves, J.; et al. Static and Dynamic Strength Indicators in Paralympic Power-Lifters with and without Spinal Cord Injury. Int. J. Environ. Res. Public Health 2021, 18, 5907. [Google Scholar] [CrossRef] [PubMed]

- Aidar, F.J.; Cataldi, S.; Badicu, G.; Silva, A.F.; Clemente, F.M.; Latino, F.; Greco, G.; Fischetti, F. Paralympic Powerlifting as a Sustainable Way to Improve Strength in Athletes with Spinal Cord Injury and Other Disabilities. Sustainability 2022, 14, 2017. [Google Scholar] [CrossRef]

- Ribeiro Neto, F.; Dorneles, J.R.; Luna, R.M.; Spina, M.A.; Gonçalves, C.W.; Gomes Costa, R.R. Performance Differences Between the Arched and Flat Bench Press in Beginner and Experienced Paralympic Powerlifters. J. Strength Cond. Res. 2022, 36, 1936–1943. [Google Scholar] [CrossRef]

- Ramos Dalla Bernardina, G.; Danillo Matos dos Santos, M.; Alves Resende, R.; Túlio de Mello, M.; Rodrigues Albuquerque, M.; Augusto Paolucci, L.P.; Carpes, F.; Silva, A.; Gustavo Pereira de Andrade, A. Asymmetric Velocity Profiles in Paralympic Powerlifters Performing at Different Exercise Intensities Are Detected by Functional Data Analysis. J. Biomech. 2021, 123, 110523. [Google Scholar] [CrossRef]

- Orange, S.T.; Metcalfe, J.W.; Marshall, P.; Vince, R.V.; Madden, L.A.; Liefeith, A. Test-Retest Reliability of a Commercial Linear Position Transducer (GymAware PowerTool) to Measure Velocity and Power in the Back Squat and Bench Press. J. Strength Cond. Res. 2020, 34, 728–737. [Google Scholar] [CrossRef]

- Grgic, J.; Scapec, B.; Pedisic, Z.; Mikulic, P. Test-Retest Reliability of Velocity and Power in the Deadlift and Squat Exercises Assessed by the GymAware PowerTool System. Front. Physiol. 2020, 11, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Romagnoli, R.; Civitella, S.; Minganti, C.; Piacentini, M. Concurrent and Predictive Validity of an Exercise-Specific Scale for the Perception of Velocity in the Back Squat. Int. J. Environ. Res. Public Health 2022, 19, 11440. [Google Scholar] [CrossRef] [PubMed]

- Rum, L.; Lazich, A.; Sciarra, T.; Balletti, N.; Bergamini, E. Automatic Event Identification of Para Powerlifting Bench Press with a Single Inertial Measurement Unit. In Proceedings of the 2022 IEEE International Workshop on Sport, Technology and Research (STAR), Trento-Cavalese, Italy, 6–8 July 2022; IEEE; pp. 164–168. [Google Scholar]

- World Para Powerlifting. Classification Rules and Regulations; World Para Powerlifting: Bonn, Germany, 2018. [Google Scholar]

- Bernardina, G.R.D.; Monnet, T.; Pinto, H.T.; de Barros, R.M.L.; Cerveri, P.; Silvatti, A.P. Are Action Sport Cameras Accurate Enough for 3D Motion Analysis? A Comparison With a Commercial Motion Capture System. J. Appl. Biomech. 2019, 35, 80–86. [Google Scholar] [CrossRef] [PubMed]

- Shin, E.-H.; El-Sheimy, N. A New Calibration Method for Strapdown Inertial Navigation Systems. Z. Vermess 2002, 127, 1–10. [Google Scholar]

- Reya, M.; Škarabot, J.; Cvetičanin, B.; Šarabon, N. Factors Underlying Bench Press Performance in Elite Competitive Powerlifters. J. Strength Cond. Res. 2021, 35, 2179–2186. [Google Scholar] [CrossRef] [Green Version]

- Kenttä, G.; Hassmén, P. Overtraining and Recovery. A Conceptual Model. Sports Med. 1998, 26, 1–16. [Google Scholar] [CrossRef]

- Bland, J.M.; Altman, D.G. Statistical Methods for Assessing Agreement between Two Methods of Clinical Measurement. Lancet 1986, 1, 307–310. [Google Scholar] [CrossRef]

- Hopkins, W.G.; Marshall, S.W.; Batterham, A.M.; Hanin, J. Progressive Statistics for Studies in Sports Medicine and Exercise Science. Med. Sci. Sports Exerc. 2009, 41, 3–13. [Google Scholar] [CrossRef] [Green Version]

- Koo, T.K.; Li, M.Y. A Guideline of Selecting and Reporting Intraclass Correlation Coefficients for Reliability Research. J. Chiropr. Med. 2016, 15, 155–163. [Google Scholar] [CrossRef] [Green Version]

- Atkinson, G.; Nevill, A.M. Statistical Methods for Assessing Measurement Error (Reliability) in Variables Relevant to Sports Medicine. Sports Med. 1998, 26, 217–238. [Google Scholar] [CrossRef]

- Nelson-Wong, E.; Howarth, S.; Winter, D.A.; Callaghan, J.P. Application of Autocorrelation and Cross-Correlation Analyses in Human Movement and Rehabilitation Research. J. Orthop. Sports Phys. Ther. 2009, 39, 287–295. [Google Scholar] [CrossRef] [PubMed]

- Pataky, T.C.; Robinson, M.A.; Vanrenterghem, J. Vector Field Statistical Analysis of Kinematic and Force Trajectories. J. Biomech. 2013, 46, 2394–2401. [Google Scholar] [CrossRef] [Green Version]

- Arede, J.; Figueira, B.; Gonzalo-Skok, O.; Leite, N. Validity and Reliability of Gyko Sport for the Measurement of Barbell Velocity on the Bench-Press Exercise. J. Sports Med. Phys. Fit. 2019, 59, 1651–1658. [Google Scholar] [CrossRef]

- Pérez-Castilla, A.; Piepoli, A.; Delgado-García, G.; Garrido-Blanca, G.; García-Ramos, A. Reliability and Concurrent Validity of Seven Commercially Available Devices for the Assessment of Movement Velocity at Different Intensities during the Bench Press. J. Strength Cond. Res. 2019, 33, 1258–1265. [Google Scholar] [CrossRef] [PubMed]

- Elliott, B.C.; Wilson, G.J.; Kerr, G.K. A Biomechanical Analysis of the Sticking Region in the Bench Press. Med. Sci. Sports Exerc. 1989, 21, 450–462. [Google Scholar] [CrossRef] [PubMed]

- van den Tillaar, R.; Ettema, G. The “Sticking Period” in a Maximum Bench Press. J. Sports Sci. 2010, 28, 529–535. [Google Scholar] [CrossRef] [PubMed]

- Nagahara, R. Kinetic and Kinematic Synchronization between Blind and Guide Sprinters. J. Sports Sci. 2021, 39, 1661–1668. [Google Scholar] [CrossRef]

- Gao, Z.; Fekete, G.; Baker, J.S.; Liang, M.; Xuan, R.; Gu, Y. Effects of Running Fatigue on Lower Extremity Symmetry among Amateur Runners: From a Biomechanical Perspective. Front. Physiol. 2022, 13, 899818. [Google Scholar] [CrossRef]

- Rum, L.; Laudani, L.; Vannozzi, G.; Macaluso, A. Age-Related Changes in Upper Body Contribution to Braking Forward Locomotion in Women. Gait Posture 2019, 68, 81–87. [Google Scholar] [CrossRef]

- Elliott, D.; Zuberec, S.; Milgram, P. A Statistical Approach to Sensorimotor Strategies: Conjugate Cross-Correlations. J. Mot. Behav. 1994, 26, 113–122. [Google Scholar] [CrossRef]

- Mcgrath, G.; Flanagan, E.P.; O’donovan, P.; Collins, D.; Kenny, C. Velocity Based Training: Validity of Monitoring Devices to Assess Mean Concentric Velocity in the Bench Press Exercise. J. Aust. Strength Cond. 2018, 26, 23–30. [Google Scholar]

- Orange, S.T.; Metcalfe, J.W.; Liefeith, A.; Marshall, P.; Madden, L.A.; Fewster, C.R.; Vince, R.V. Validity and Reliability of a Wearable Inertial Sensor to Measure Velocity and Power in the Back Squat and Bench Press. J. Strength Cond. Res. 2019, 33, 2398–2408. [Google Scholar] [CrossRef] [PubMed]

| Age (Years) | 30.5 ± 4.3 |

| Sitting height (cm) | 71.6 ± 6.8 |

| Mass (kg) | 72.5 ± 16.4 |

| Impairment type (n. athlete) |

|

| 1RM | 148.4 ± 38.6 |

| Strength training experience (years) | 12.8 ± 7.4 |

| Powerlifting training experience (years) | 5.4 ± 4.1 |

| Powerlifting competition experience (years) | 4.6 ± 4.0 |

| Mean ± SD Video-IMU Difference (m·s−1) | 95% LoA (m·s−1) | Cronbach’s Alpha | ICC [95% CI] | SEM (m·s−1) | SDC (m·s−1) | |

|---|---|---|---|---|---|---|

| EmV | 0.00 ± 0.05 | [−0.09, 0.10] | 0.81 | 0.69 [0.38–0.86] * | 0.03 | 0.07 |

| EMV | −0.03 ± 0.06 | [−0.14, 0.08] | 0.92 | 0.83 [0.59–0.93] * | 0.02 | 0.06 |

| CmV | 0.00 ± 0.04 | [−0.07, 0.07] | 0.85 | 0.75 [0.47–0.89] * | 0.02 | 0.05 |

| CMV | 0.01 ± 0.04 | [−0.08, −0.10] | 0.89 | 0.80 [0.57–0.91] * | 0.02 | 0.06 |

| Vmax1 | 0.00 ± 0.03 | [−0.05, 0.06] | 0.95 | 0.90 [0.76–0.96] * | 0.01 | 0.02 |

| Vmin | −0.04 ± 0.04 | [−0.12, 0.03] | 0.94 | 0.78 [0.12–0.93] * | 0.02 | 0.05 |

| Vmax2 | 0.01 ± 0.05 | [−0.09, 0.12] | 0.88 | 0.78 [0.52–0.91] * | 0.02 | 0.07 |

| PreStickV | 0.02 ± 0.02 | [−0.03, 0.06] | 0.87 | 0.69 [0.25–0.88] * | 0.01 | 0.03 |

| StickV | −0.02 ± 0.04 | [−0.09, 0.06] | 0.91 | 0.81 [0.56–0.93] * | 0.02 | 0.05 |

| PostStickV | −0.02 ± 0.04 | [−0.09, 0.06] | 0.91 | 0.82 [0.55–0.93] * | 0.02 | 0.05 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rum, L.; Sciarra, T.; Balletti, N.; Lazich, A.; Bergamini, E. Validation of an Automatic Inertial Sensor-Based Methodology for Detailed Barbell Velocity Monitoring during Maximal Paralympic Bench Press. Sensors 2022, 22, 9904. https://doi.org/10.3390/s22249904

Rum L, Sciarra T, Balletti N, Lazich A, Bergamini E. Validation of an Automatic Inertial Sensor-Based Methodology for Detailed Barbell Velocity Monitoring during Maximal Paralympic Bench Press. Sensors. 2022; 22(24):9904. https://doi.org/10.3390/s22249904

Chicago/Turabian StyleRum, Lorenzo, Tommaso Sciarra, Nicoletta Balletti, Aldo Lazich, and Elena Bergamini. 2022. "Validation of an Automatic Inertial Sensor-Based Methodology for Detailed Barbell Velocity Monitoring during Maximal Paralympic Bench Press" Sensors 22, no. 24: 9904. https://doi.org/10.3390/s22249904

APA StyleRum, L., Sciarra, T., Balletti, N., Lazich, A., & Bergamini, E. (2022). Validation of an Automatic Inertial Sensor-Based Methodology for Detailed Barbell Velocity Monitoring during Maximal Paralympic Bench Press. Sensors, 22(24), 9904. https://doi.org/10.3390/s22249904