Application of Biosensors, Sensors, and Tags in Intelligent Packaging Used for Food Products—A Review

Abstract

:1. Introduction

- sensors, mainly including:

- gas sensors—devices monitoring changes in the composition of gases inside the package;

- fluorescence oxygen sensors—detecting spoilage of the product, determining freshness of the product,

- biosensors;

- indicators—interactive indicators located outside or inside the package, which change their color and color intensity or expose dye dispersion under the influence of changes in the conditions prevailing in the package. In this way, they provide the consumer with qualitative or semi-quantitative information regarding the quality, freshness, and other parameters of the packaged product [16,17]:

- time-temperature indicators—devices in the form of various types of stickers/labels attached to the outside of collective or individual packaging, recording even short-term thermal changes in the environment (an increase or a decrease in temperature beyond the limit acceptable for a given product) during the storage, transport, and distribution of food. TTIs can be based either on controlling physical changes or chemical reactions (e.g., melting, polymerization) or on changes in biological activity (microbes, spores, enzymes). These types of indicators are used primarily in the case of frozen products and chilled food, as well as in the packaging of semi-finished products intended for preparation in microwave ovens or ovens [16,18],

- gas leakage/concentration indicators—devices used to control the tightness of packaging by detecting carbon dioxide without violating the integrity of the packaging material—a gas leak in the packaging may cause favorable conditions for the development of microorganisms,

- microbial growth indicators reacting with microbial metabolites, which helps to observe the possible growth of microorganisms in the packed product,

- freshness indicators—determining freshness by showing different colors or color changes. They provide direct information on product quality resulting from microbial growth or chemical changes in the food product. The microbiological quality can be determined by the reactions between the indicators contained inside the package and the metabolites of microbial growth, e.g., organic acids, ethanol, volatile nitrogen, biogenic amines, carbon dioxide, glucose, and sulfur compounds [19,20];

- barcodes and radio-frequency identification (RFID) devices—devices that detect and identify a product in the supply chain by radio signal modulation.

- external indicators—attached to the outside of the package; they mainly include time-temperature indices and physical shock indices;

- internal indicators—placed inside the package (in the upper part of the package or attached to the lid), e.g., oxygen leakage rates, carbon dioxide, microbial and pathogen indicators;

- indicators facilitating a more effective process of information flow and communication of the packaged product with its consumer—special barcodes (storing information about food products, such as the use and expiry date, and enabling product traceability) and anti-theft, anti-counterfeiting, and anti-tampering devices.

2. The Genesis and Essence of Intelligent Packaging

3. Intelligent Packaging Based on Sensors

3.1. Sensors Based on Oxygen and Carbon Dioxide

3.2. Sensors Based on pH Changes and Specific Chemicals

3.3. Sensors Based on Humidity

3.4. Sensors Based on Time and Temperature (TTI)

3.5. Characteristics of Optical Sensors and Others

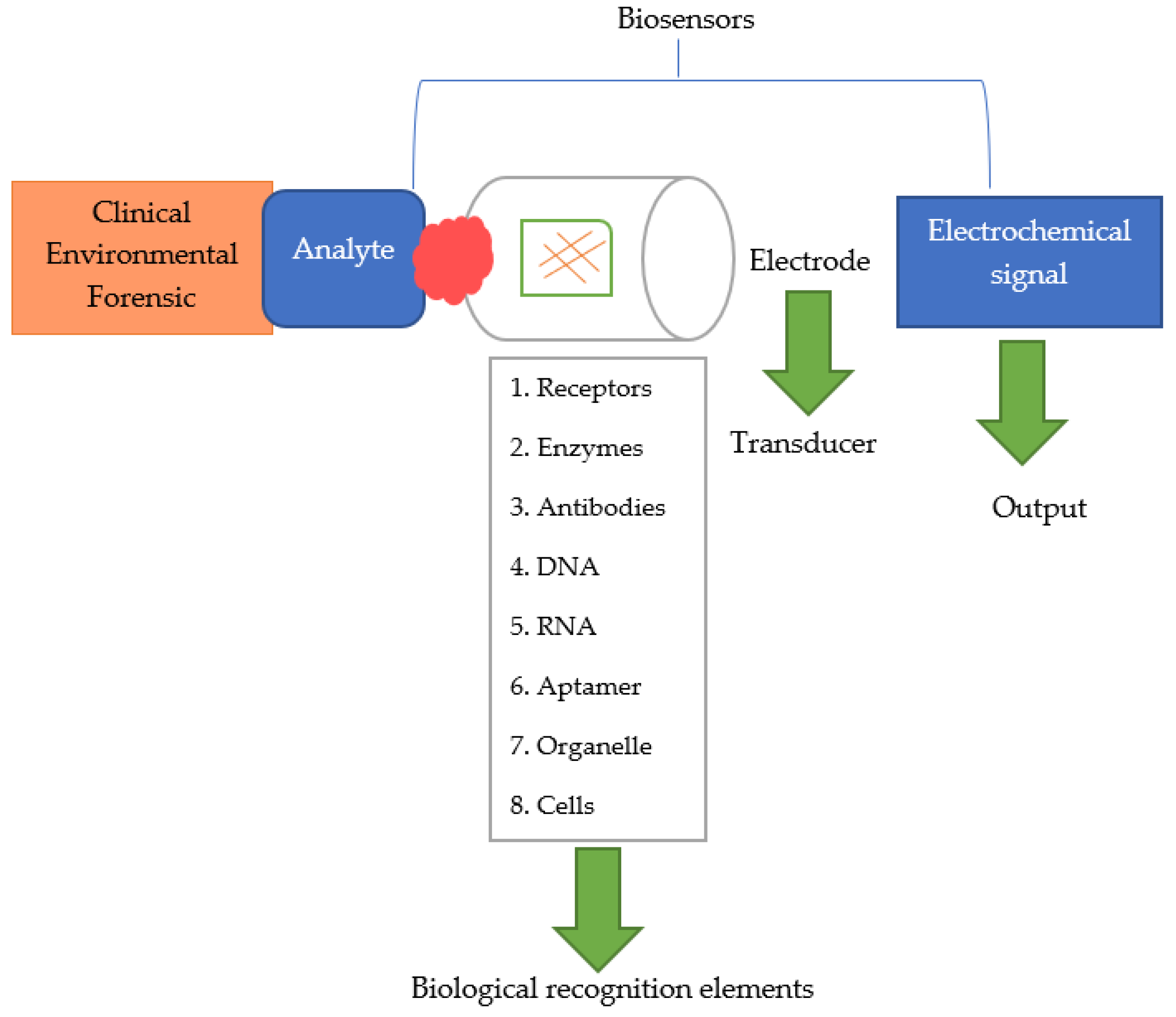

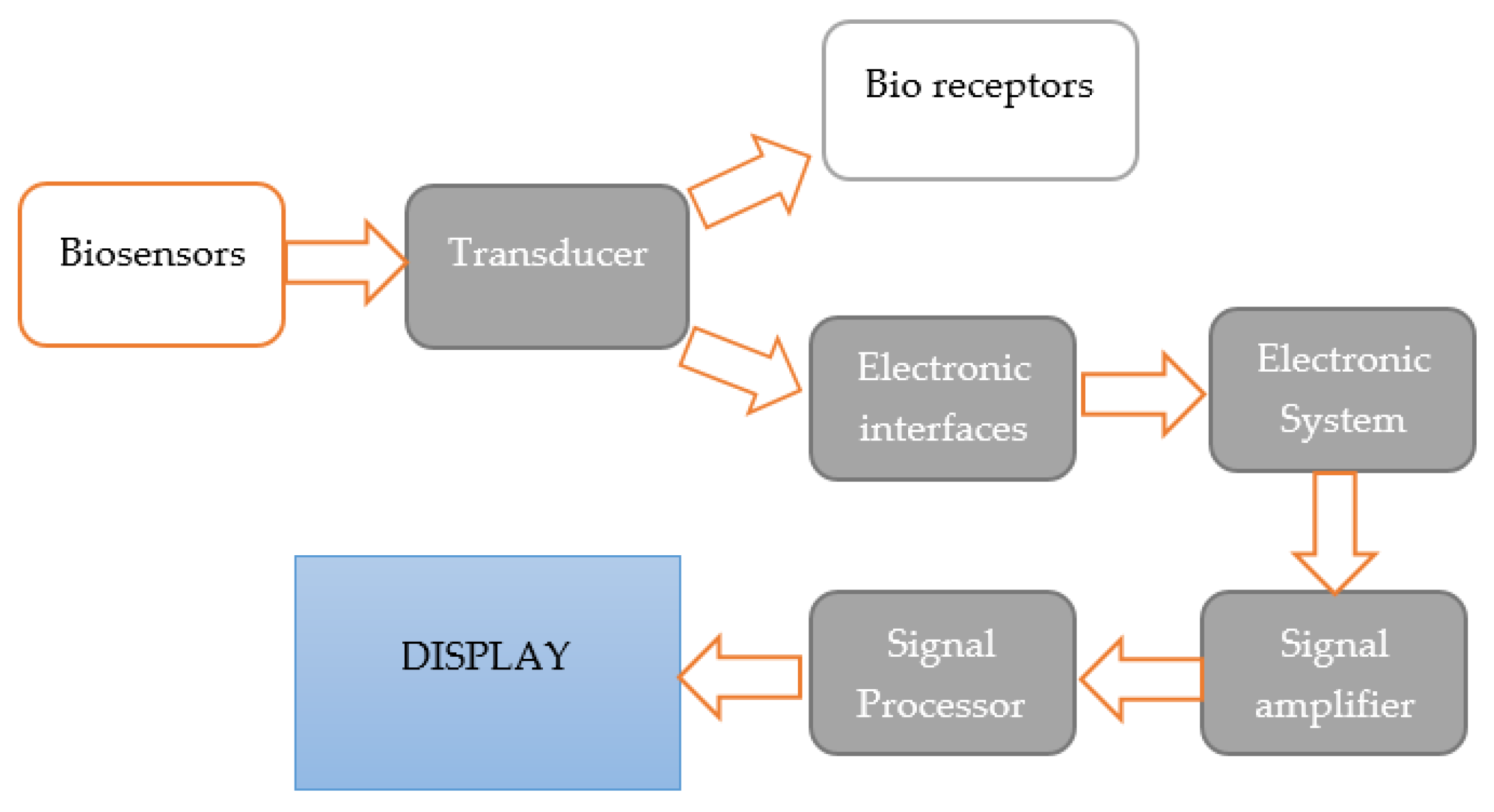

4. Intelligent Packaging Based on Biosensors

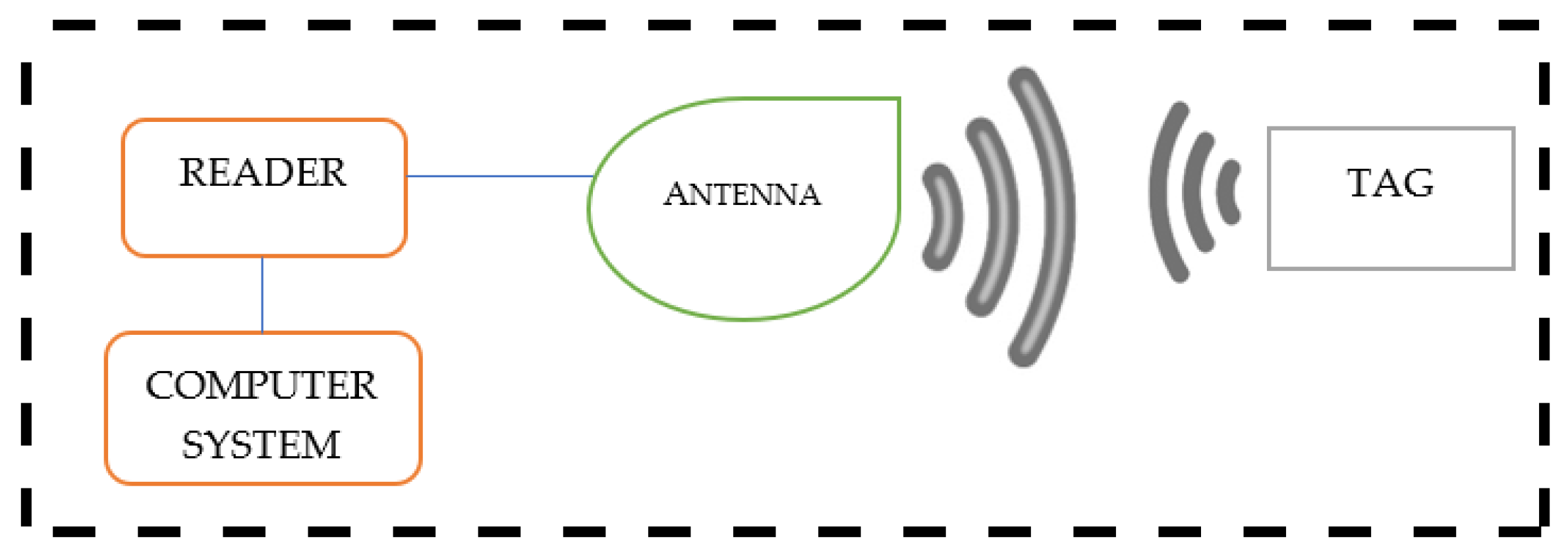

5. RFID—Radio-Frequency Identification Systems

6. Hybrid Intelligent Packaging Systems

7. Application of Nanotechnology in Intelligent Packaging Systems

8. Challenges and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wikström, F.; Verghese, K.; Auras, R.; Olsson, A.; Williams, H.; Wever, R.; Grönman, K.; Kvalvåg Pettersen, M.; Møller, H.; Soukka, R. Packaging Strategies That Save Food: A Research Agenda for 2030. J. Ind. Ecol. 2019, 23, 532–540. [Google Scholar] [CrossRef]

- Fuertes, G.; Soto, I.; Carrasco, R.; Vargas, M.; Sabattin, J.; Lagos, C. Intelligent Packaging Systems: Sensors and Nanosensors to Monitor Food Quality and Safety. J. Sens. 2016, 2016, 4046061. [Google Scholar] [CrossRef] [Green Version]

- Fung, F.; Wang, H.-S.; Menon, S. Food Safety in the 21st Century. Biomed. J. 2018, 41, 88–95. [Google Scholar] [CrossRef] [PubMed]

- Lorite, G.S.; Selkälä, T.; Sipola, T.; Palenzuela, J.; Jubete, E.; Viñuales, A.; Cabañero, G.; Grande, H.J.; Tuominen, J.; Uusitalo, S. Novel, Smart and RFID Assisted Critical Temperature Indicator for Supply Chain Monitoring. J. Food Eng. 2017, 193, 20–28. [Google Scholar] [CrossRef] [Green Version]

- Tichoniuk, M.; Biegańska, M.; Cierpiszewski, R. Intelligent Packaging: Sustainable Food Processing and Engineering Challenges. In Sustainable Food Processing and Engineering Challenges; Academic Press: Cambridge, MA, USA, 2021; pp. 279–313. [Google Scholar]

- Molina-Besch, K.; Olsson, A. Innovations in Food Packaging—Sustainability Challenges and Future Scenarios. In Future Foods; Academic Press: Cambridge, MA, USA, 2022; pp. 375–392. [Google Scholar]

- Bagchi, A.; He, T. Intelligent Sensing and Packaging of Foods for Enhancement of Shelf Life: Concepts and Applications. Int. J. Sci. Eng. Res. 2012, 3, 1–13. [Google Scholar]

- Tu, Y.; Yang, Z.; Ma, C. Touching Tastes: The Haptic Perception Transfer of Liquid Food Packaging Materials. Food Qual. Prefer. 2015, 39, 124–130. [Google Scholar] [CrossRef]

- Sohail, M.; Sun, D.-W.; Zhu, Z. Recent Developments in Intelligent Packaging for Enhancing Food Quality and Safety. Crit. Rev. Food Sci. Nutr. 2018, 58, 2650–2662. [Google Scholar] [CrossRef]

- Müller, P.; Schmid, M. Intelligent Packaging in the Food Sector: A Brief Overview. Foods 2019, 8, 16. [Google Scholar] [CrossRef] [Green Version]

- Kalpana, S.; Priyadarshini, S.R.; Leena, M.M.; Moses, J.A.; Anandharamakrishnan, C. Intelligent Packaging: Trends and Applications in Food Systems. Trends Food Sci. Technol. 2019, 93, 145–157. [Google Scholar] [CrossRef]

- Domínguez, R.; Barba, F.J.; Gómez, B.; Putnik, P.; Kovačević, D.B.; Pateiro, M.; Santos, E.M.; Lorenzo, J.M. Active Packaging Films with Natural Antioxidants to Be Used in Meat Industry: A Review. Food Res. Int. 2018, 113, 93–101. [Google Scholar] [CrossRef]

- Khaneghah, A.M.; Hashemi, S.M.B.; Limbo, S. Antimicrobial Agents and Packaging Systems in Antimicrobial Active Food Packaging: An Overview of Approaches and Interactions. Food Bioprod. Process. 2018, 111, 1–19. [Google Scholar] [CrossRef]

- Chen, S.; Brahma, S.; Mackay, J.; Cao, C.; Aliakbarian, B. The Role of Smart Packaging System in Food Supply Chain. J. Food Sci. 2020, 85, 517–525. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mustafa, F.; Andreescu, S. Chemical and Biological Sensors for Food-Quality Monitoring and Smart Packaging. Foods 2018, 7, 168. [Google Scholar] [CrossRef] [Green Version]

- Mohebi, E.; Marquez, L. Intelligent Packaging in Meat Industry: An Overview of Existing Solutions. J. Food Sci. Technol. 2015, 52, 3947–3964. [Google Scholar] [CrossRef] [PubMed]

- Kuswandi, B.; Wicaksono, Y.; Abdullah, A.; Heng, L.Y.; Ahmad, M. Smart Packaging: Sensors for Monitoring of Food Quality and Safety. Sens. Instrum. Food Qual. Saf. 2011, 5, 137–146. [Google Scholar] [CrossRef]

- Fang, Z.; Zhao, Y.; Warner, R.D.; Johnson, S.K. Active and Intelligent Packaging in Meat Industry. Trends Food Sci. Technol. 2017, 61, 60–71. [Google Scholar] [CrossRef]

- Chowdhury, E.U.; Morey, A. Intelligent Packaging for Poultry Industry. J. Appl. Poult. Res. 2019, 28, 791–800. [Google Scholar] [CrossRef]

- Ghaani, M.; Cozzolino, C.A.; Castelli, G.; Farris, S. An Overview of the Intelligent Packaging Technologies in the Food Sector. Trends Food Sci. Technol. 2016, 51, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Han, J.H.; Ho, C.H.; Rodrigues, E.T. Intelligent Packaging. In Innovations in Food Packaging; Academic Press: Cambridge, MA, USA, 2005; pp. 138–155. [Google Scholar]

- Ahvenainen, R. Novel Food Packaging Techniques; Elsevier: Amsterdam, The Netherlands, 2003. [Google Scholar]

- Coles, R.; McDowell, D.; Kirwan, M.J. Food Packaging Technology; CRC Press: Boca Raton, FL, USA, 2003; Volume 5. [Google Scholar]

- Vanderroost, M.; Ragaert, P.; Devlieghere, F.; De Meulenaer, B. Intelligent Food Packaging: The next Generation. Trends Food Sci. Technol. 2014, 39, 47–62. [Google Scholar] [CrossRef]

- Beshai, H.; Sarabha, G.K.; Rathi, P.; Alam, A.U.; Deen, M.J. Freshness Monitoring of Packaged Vegetables. Appl. Sci. 2020, 10, 7937. [Google Scholar] [CrossRef]

- Chelliah, R.; Wei, S.; Daliri, E.B.-M.; Rubab, M.; Elahi, F.; Yeon, S.-J.; Jo, K.H.; Yan, P.; Liu, S.; Oh, D.H. Development of Nanosensors Based Intelligent Packaging Systems: Food Quality and Medicine. Nanomaterials 2021, 11, 1515. [Google Scholar] [CrossRef] [PubMed]

- Kerry, J.P.; O’grady, M.N.; Hogan, S.A. Past, Current and Potential Utilisation of Active and Intelligent Packaging Systems for Meat and Muscle-Based Products: A Review. Meat Sci. 2006, 74, 113–130. [Google Scholar] [CrossRef] [PubMed]

- Zhai, X.; Li, Z.; Shi, J.; Huang, X.; Sun, Z.; Zhang, D.; Zou, X.; Sun, Y.; Zhang, J.; Holmes, M. A Colorimetric Hydrogen Sulfide Sensor Based on Gellan Gum-Silver Nanoparticles Bionanocomposite for Monitoring of Meat Spoilage in Intelligent Packaging. Food Chem. 2019, 290, 135–143. [Google Scholar] [CrossRef]

- Miller, K.; Reichert, C.L.; Schmid, M. Biogenic Amine Detection Systems for Intelligent Packaging Concepts: Meat and Meat Products. In Food Reviews International; Taylor & Francis: Oxford, UK, 2021; pp. 1–25. [Google Scholar]

- Rukchon, C.; Nopwinyuwong, A.; Trevanich, S.; Jinkarn, T.; Suppakul, P. Development of a Food Spoilage Indicator for Monitoring Freshness of Skinless Chicken Breast. Talanta 2014, 130, 547–554. [Google Scholar] [CrossRef] [PubMed]

- Realini, C.E.; Marcos, B. Active and Intelligent Packaging Systems for a Modern Society. Meat Sci. 2014, 98, 404–419. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Zou, X.; Zhai, X.; Huang, X.; Jiang, C.; Holmes, M. Preparation of an Intelligent PH Film Based on Biodegradable Polymers and Roselle Anthocyanins for Monitoring Pork Freshness. Food Chem. 2019, 272, 306–312. [Google Scholar] [CrossRef]

- Yousefi, H.; Ali, M.M.; Su, H.-M.; Filipe, C.D.; Didar, T.F. Sentinel Wraps: Real-Time Monitoring of Food Contamination by Printing DNAzyme Probes on Food Packaging. ACS Nano 2018, 12, 3287–3294. [Google Scholar] [CrossRef]

- Wu, D.; Zhang, M.; Chen, H.; Bhandari, B. Freshness Monitoring Technology of Fish Products in Intelligent Packaging. Crit. Rev. Food Sci. Nutr. 2021, 61, 1279–1292. [Google Scholar] [CrossRef]

- Naghdi, S.; Rezaei, M.; Abdollahi, M. A Starch-Based PH-Sensing and Ammonia Detector Film Containing Betacyanin of Paperflower for Application in Intelligent Packaging of Fish. Int. J. Biol. Macromol. 2021, 191, 161–170. [Google Scholar] [CrossRef]

- Ezati, P.; Rhim, J.-W. PH-Responsive Chitosan-Based Film Incorporated with Alizarin for Intelligent Packaging Applications. Food Hydrocoll. 2020, 102, 105629. [Google Scholar] [CrossRef]

- Apriliyanti, M.W.; Wahyono, A.; Fatoni, M.; Poerwanto, B.; Suryaningsih, W. The Potency of Betacyanins Extract from a Peel of Dragon Fruits as a Source of Colourimetric Indicator to Develop Intelligent Packaging for Fish Freshness Monitoring. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Banda Aceh, Indonesia, 26–27 September 2018; IOP Publishing: Bristol, UK, 2018; Volume 207, p. 012038. [Google Scholar]

- Ibrahim, S.; Fahmy, H.; Salah, S. Application of Interactive and Intelligent Packaging for Fresh Fish Shelf-Life Monitoring. Front. Nutr. 2021, 8, 333. [Google Scholar] [CrossRef] [PubMed]

- Zeng, P.; Chen, X.; Qin, Y.-R.; Zhang, Y.-H.; Wang, X.-P.; Wang, J.-Y.; Ning, Z.-X.; Ruan, Q.-J.; Zhang, Y.-S. Preparation and Characterization of a Novel Colorimetric Indicator Film Based on Gelatin/Polyvinyl Alcohol Incorporating Mulberry Anthocyanin Extracts for Monitoring Fish Freshness. Food Res. Int. 2019, 126, 108604. [Google Scholar] [CrossRef] [PubMed]

- Bhadra, S.; Narvaez, C.; Thomson, D.J.; Bridges, G.E. Non-Destructive Detection of Fish Spoilage Using a Wireless Basic Volatile Sensor. Talanta 2015, 134, 718–723. [Google Scholar] [CrossRef] [PubMed]

- Heising, J.K.; Dekker, M.; Bartels, P.V.; Van Boekel, M. Monitoring the Quality of Perishable Foods: Opportunities for Intelligent Packaging. Crit. Rev. Food Sci. Nutr. 2014, 54, 645–654. [Google Scholar] [CrossRef] [PubMed]

- Mirza Alizadeh, A.; Masoomian, M.; Shakooie, M.; Zabihzadeh Khajavi, M.; Farhoodi, M. Trends and Applications of Intelligent Packaging in Dairy Products: A Review. Crit. Rev. Food Sci. Nutr. 2021, 62, 383–397. [Google Scholar] [CrossRef] [PubMed]

- Romero, A.; Sharp, J.L.; Dawson, P.L.; Darby, D.; Cooksey, K. Evaluation of Two Intelligent Packaging Prototypes with a PH Indicator to Determine Spoilage of Cow Milk. Food Packag. Shelf Life 2021, 30, 100720. [Google Scholar] [CrossRef]

- Soares, N.; Silva, C.; Santiago-Silva, P.; Espitia, P.; Gonçalves, M.; Lopez, M.; Miltz, J.; Cerqueira, M.A.; Vicente, A.A.; Teixeira, J.A. Active and Intelligent Packaging for Milk and Milk Products; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Magnaghi, L.R.; Zanoni, C.; Alberti, G.; Quadrelli, P.; Biesuz, R. Towards Intelligent Packaging: BCP-EVOH@ Optode for Milk Freshness Measurement. Talanta 2022, 241, 123230. [Google Scholar] [CrossRef]

- Pereira, V.A., Jr.; de Arruda, I.N.Q.; Stefani, R. Active Chitosan/PVA Films with Anthocyanins from Brassica Oleraceae (Red Cabbage) as Time–Temperature Indicators for Application in Intelligent Food Packaging. Food Hydrocoll. 2015, 43, 180–188. [Google Scholar] [CrossRef]

- Shinde, R.; Rodov, V.; Krishnakumar, S.; Subramanian, J. Active and Intelligent Packaging for Reducing Postharvest Losses of Fruits and Vegetables. In Post Harvest Biology Nanotechnol; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2018; pp. 171–190. [Google Scholar]

- Occhiuzzi, C.; D’Uva, N.; Nappi, S.; Amendola, S.; Giallucca, C.; Chiabrando, V.; Garavaglia, L.; Giacalone, G.; Marrocco, G. Radio-Frequency-Identification-Based Intelligent Packaging: Electromagnetic Classification of Tropical Fruit Ripening. IEEE Antennas Propag. Mag. 2020, 62, 64–75. [Google Scholar] [CrossRef]

- Eom, K.H.; Kim, M.C.; Lee, S.J.; won Lee, C. The Vegetable Freshness Monitoring System Using RFID with Oxygen and Carbon Dioxide Sensor. Int. J. Distrib. Sens. Netw. 2012, 8, 472986. [Google Scholar] [CrossRef] [Green Version]

- Borchert, N.B.; Kerry, J.P.; Papkovsky, D.B. A CO2 Sensor Based on Pt-Porphyrin Dye and FRET Scheme for Food Packaging Applications. Sens. Actuators B Chem. 2013, 176, 157–165. [Google Scholar] [CrossRef]

- Abdolsattari, P.; Rezazadeh-Bari, M.; Pirsa, S. Smart Film Based on Polylactic Acid, Modified with Polyaniline/ZnO/CuO: Investigation of Physicochemical Properties and Its Use of Intelligent Packaging of Orange Juice. Food Bioprocess Technol. 2022, 15, 2803–2825. [Google Scholar] [CrossRef]

- Kim, J.U.; Ghafoor, K.; Ahn, J.; Shin, S.; Lee, S.H.; Shahbaz, H.M.; Shin, H.-H.; Kim, S.; Park, J. Kinetic Modeling and Characterization of a Diffusion-Based Time-Temperature Indicator (TTI) for Monitoring Microbial Quality of Non-Pasteurized Angelica Juice. LWT-Food Sci. Technol. 2016, 67, 143–150. [Google Scholar] [CrossRef]

- Papetti, P.; Costa, C.; Antonucci, F.; Figorilli, S.; Solaini, S.; Menesatti, P. A RFID Web-Based Infotracing System for the Artisanal Italian Cheese Quality Traceability. Food Control 2012, 27, 234–241. [Google Scholar] [CrossRef]

- Lee, S.Y.; Lee, S.J.; Choi, D.S.; Hur, S.J. Current Topics in Active and Intelligent Food Packaging for Preservation of Fresh Foods. J. Sci. Food Agric. 2015, 95, 2799–2810. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Liu, L.; Mu, W.; Moga, L.M.; Zhang, X. Development of Temperature-Managed Traceability System for Frozen and Chilled Food during Storage and Transportation. J. Food Agric. Environ. 2009, 7, 28–31. [Google Scholar]

- Regulation (EC) No. 1935/2004 of the European Parliament and of the Council of 27 October 2004 on Materials and Articles Intended to Come into Contact with Food and Repealing Directives 80/590/EEC and 89/109/EEC. J. Eur. Union L 2004, 338, 4–16.

- Dainelli, D.; Gontard, N.; Spyropoulos, D.; Zondervan-van den Beuken, E.; Tobback, P. Active and Intelligent Food Packaging: Legal Aspects and Safety Concerns. Trends Food Sci. Technol. 2008, 19, S103–S112. [Google Scholar] [CrossRef]

- Janjarasskul, T.; Suppakul, P. Active and Intelligent Packaging: The Indication of Quality and Safety. Crit. Rev. Food Sci. Nutr. 2018, 58, 808–831. [Google Scholar] [CrossRef]

- Restuccia, D.; Spizzirri, U.G.; Parisi, O.I.; Cirillo, G.; Curcio, M.; Iemma, F.; Puoci, F.; Vinci, G.; Picci, N. New EU Regulation Aspects and Global Market of Active and Intelligent Packaging for Food Industry Applications. Food Control 2010, 21, 1425–1435. [Google Scholar] [CrossRef]

- Summers, L. Intelligent Packaging; Centre for Exploitation of Science and Technology: London, UK, 1992. [Google Scholar]

- Karel, M. Tasks of Food Technology in the 21st Century. Food Technol. Chic. 2000, 54, 56–64. [Google Scholar]

- Ohlsson, T.; Bengtsson, N. Minimal Processing Technologies in the Food Industry; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Commission Regulation (EC) No. 450/2009 of 29 May 2009 on Active and Intelligent Materials and Articles Intended to Come into Contact with Food. J. Eur. Union 2009, 135, 3–11.

- European Food Safety Authority (EFSA) Guidelines on Submission of a Dossier for Safety Evaluation by the EFSA of Active or Intelligent Substances Present in Active and Intelligent Materials and Articles Intended to Come into Contact with Food. EFSA J. 2009, 7, 1208.

- Mendes, A.C.; Pedersen, G.A. Perspectives on Sustainable Food Packaging:–Is Bio-Based Plastics a Solution? Trends Food Sci. Technol. 2021, 112, 839–846. [Google Scholar] [CrossRef]

- Beneventi, E.; Tietz, T.; Merkel, S. Risk Assessment of Food Contact Materials. EFSA J. 2020, 18, e181109. [Google Scholar] [PubMed]

- EFSA Panel on Contaminants in the Food Chain (EFSA CONTAM Panel); Schrenk, D.; Bignami, M.; Bodin, L.; Chipman, J.K.; del Mazo, J.; Grasl-Kraupp, B.; Hogstrand, C.; Hoogenboom, L.; Leblanc, J.-C. Risk to Human Health Related to the Presence of Perfluoroalkyl Substances in Food. EFSA J. 2020, 18, e06223. [Google Scholar] [PubMed]

- Panel, E.B. Update of the List of QPS-Recommended Biological Agents Intentionally Added to Food or Feed as Notified to EFSA 14: Suitability of Taxonomic Units Notified to EFSA until March 2021. EFSA J. 2021, 19, e06689. [Google Scholar]

- Allende, A.; Alvarez-Ordóñez, A.; Bolton, D.; Bover-Cid, S.; Chemaly, M.; Davies, R.; De Cesare, A.; Hilbert, F. Update of the List of QPS-Recommended Biological Agents Intentionally Added to Food or Feed as Notified to EFSA 10: Suitability of Taxonomic Units Notified to EFSA until March 2019. EFSA J. 2019, 17, e05753. [Google Scholar]

- Yam, K.L.; Takhistov, P.T.; Miltz, J. Intelligent Packaging: Concepts and Applications. J. Food Sci. 2005, 70, R1–R10. [Google Scholar] [CrossRef]

- Biji, K.; Ravishankar, C.; Mohan, C.; Srinivasa Gopal, T. Smart Packaging Systems for Food Applications: A Review. J. Food Sci. Technol. 2015, 52, 6125–6135. [Google Scholar] [CrossRef]

- Poyatos-Racionero, E.; Ros-Lis, J.V.; Vivancos, J.-L.; Martinez-Manez, R. Recent Advances on Intelligent Packaging as Tools to Reduce Food Waste. J. Clean. Prod. 2018, 172, 3398–3409. [Google Scholar] [CrossRef]

- Mlalila, N.; Kadam, D.M.; Swai, H.; Hilonga, A. Transformation of Food Packaging from Passive to Innovative via Nanotechnology: Concepts and Critiques. J. Food Sci. Technol. 2016, 53, 3395–3407. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yamasaki, H. What Are the Intelligent Sensors. In Handbook of Sensors and Actuators; Elsevier: Amsterdam, The Netherlands, 1996; Volume 3, pp. 1–17. [Google Scholar]

- Cattrall, R.W. Chemical Sensors; Oxford University Press: Oxford, UK, 1997. [Google Scholar]

- Hanrahan, G.; Patil, D.G.; Wang, J. Electrochemical Sensors for Environmental Monitoring: Design, Development and Applications. J. Environ. Monit. 2004, 6, 657–664. [Google Scholar] [CrossRef] [PubMed]

- Yousefi, H.; Su, H.-M.; Imani, S.M.; Alkhaldi, K.; Filipe, M.C.D.; Didar, T.F. Intelligent Food Packaging: A Review of Smart Sensing Technologies for Monitoring Food Quality. ACS Sens. 2019, 4, 808–821. [Google Scholar] [CrossRef]

- Pavelková, A. Time Temperature Indicators as Devices Intelligent Packaging. Acta Univ. Agric. Silvic. Mendel. Brun. 2013, 61, 245–251. [Google Scholar] [CrossRef] [Green Version]

- Drago, E.; Campardelli, R.; Pettinato, M.; Perego, P. Innovations in Smart Packaging Concepts for Food: An Extensive Review. Foods 2020, 9, 1628. [Google Scholar] [CrossRef]

- Han, J.-W.; Ruiz-Garcia, L.; Qian, J.-P.; Yang, X.-T. Food Packaging: A Comprehensive Review and Future Trends. Compr. Rev. Food Sci. Food Saf. 2018, 17, 860–877. [Google Scholar] [CrossRef] [Green Version]

- Pandey, S.K.; Kim, K.-H. The Relative Performance of NDIR-Based Sensors in the near Real-Time Analysis of CO2 in Air. Sensors 2007, 7, 1683–1696. [Google Scholar] [CrossRef]

- Park, Y.W.; Kim, S.M.; Lee, J.Y.; Jang, W. Application of Biosensors in Smart Packaging. Mol. Cell. Toxicol. 2015, 11, 277–285. [Google Scholar] [CrossRef]

- Putra, B.T.W.; Kuswandi, B. Smart Food Sensing and IoT Technologies. In Bio-and Nano-Sensing Technologies for Food Processing and Packaging; Royal Society of Chemistry: London, UK, 2022; pp. 129–150. [Google Scholar]

- Won, S.; Won, K. Self-Powered Flexible Oxygen Sensors for Intelligent Food Packaging. Food Packag. Shelf Life 2021, 29, 100713. [Google Scholar] [CrossRef]

- Kuswandi, B.; Jayus; Restyana, A.; Abdullah, A.; Heng, L.Y.; Ahmad, M. A Novel Colorimetric Food Package Label for Fish Spoilage Based on Polyaniline Film. Food Control 2012, 25, 184. [Google Scholar] [CrossRef]

- Pereira, P.F.; Picciani, P.H.; Calado, V.; Tonon, R.V. Gelatin-Based Nanobiocomposite Films as Sensitive Layers for Monitoring Relative Humidity in Food Packaging. Food Bioprocess Technol. 2020, 13, 1063–1073. [Google Scholar] [CrossRef]

- Gaikwad, K.K.; Singh, S.; Ajji, A. Moisture Absorbers for Food Packaging Applications. Environ. Chem. Lett. 2019, 17, 609–628. [Google Scholar] [CrossRef]

- Das, R.; Bej, S.; Hirani, H.; Banerjee, P. Trace-Level Humidity Sensing from Commercial Organic Solvents and Food Products by an AIE/ESIPT-Triggered Piezochromic Luminogen and Ppb-Level “OFF–ON–OFF” Sensing of Cu2+: A Combined Experimental and Theoretical Outcome. ACS Omega 2021, 6, 14104–14121. [Google Scholar] [CrossRef]

- Tan, E.L.; Ng, W.N.; Shao, R.; Pereles, B.D.; Ong, K.G. A Wireless, Passive Sensor for Quantifying Packaged Food Quality. Sensors 2007, 7, 1747–1756. [Google Scholar] [CrossRef]

- Bibi, F.; Guillaume, C.; Vena, A.; Gontard, N.; Sorli, B. Wheat Gluten, a Bio-Polymer Layer to Monitor Relative Humidity in Food Packaging: Electric and Dielectric Characterization. Sens. Actuators Phys. 2016, 247, 355–367. [Google Scholar] [CrossRef] [Green Version]

- Wawrzynek, E.; Baumbauer, C.; Arias, A.C. Characterization and Comparison of Biodegradable Printed Capacitive Humidity Sensors. Sensors 2021, 21, 6557. [Google Scholar] [CrossRef] [PubMed]

- Raju, R.; Bridges, G.E. Radar Cross Section-Based Chipless Tag with Built-in Reference for Relative Humidity Monitoring of Packaged Food Commodities. IEEE Sens. J. 2021, 21, 18773–18780. [Google Scholar] [CrossRef]

- Cheng, H.; Xu, H.; McClements, D.J.; Chen, L.; Jiao, A.; Tian, Y.; Miao, M.; Jin, Z. Recent Advances in Intelligent Food Packaging Materials: Principles, Preparation and Applications. Food Chem. 2022, 375, 131738. [Google Scholar] [CrossRef]

- Wang, S.; Liu, X.; Yang, M.; Zhang, Y.; Xiang, K.; Tang, R. Review of Time Temperature Indicators as Quality Monitors in Food Packaging. Packag. Technol. Sci. 2015, 28, 839–867. [Google Scholar] [CrossRef]

- Firouz, M.S.; Mohi-Alden, K.; Omid, M. A Critical Review on Intelligent and Active Packaging in the Food Industry: Research and Development. Food Res. Int. 2021, 141, 110113. [Google Scholar] [CrossRef] [PubMed]

- Lim, S.; Gunasekaran, S.; Imm, J.-Y. Gelatin-Templated Gold Nanoparticles as Novel Time–Temperature Indicator. J. Food Sci. 2012, 77, N45–N49. [Google Scholar] [CrossRef] [PubMed]

- Siddiqui, J.; Taheri, M.; Alam, A.U.; Deen, M.J. Nanomaterials in Smart Packaging Applications: A Review. Small 2022, 18, 2101171. [Google Scholar] [CrossRef] [PubMed]

- Choi, S.; Eom, Y.; Kim, S.-M.; Jeong, D.-W.; Han, J.; Koo, J.M.; Hwang, S.Y.; Park, J.; Oh, D.X. A Self-Healing Nanofiber-Based Self-Responsive Time-Temperature Indicator for Securing a Cold-Supply Chain. Adv. Mater. 2020, 32, 1907064. [Google Scholar] [CrossRef]

- Dodero, A.; Escher, A.; Bertucci, S.; Castellano, M.; Lova, P. Intelligent Packaging for Real-Time Monitoring of Food-Quality: Current and Future Developments. Appl. Sci. 2021, 11, 3532. [Google Scholar] [CrossRef]

- Baleizao, C.; Nagl, S.; Schäferling, M.; Berberan-Santos, M.N.; Wolfbeis, O.S. Dual Fluorescence Sensor for Trace Oxygen and Temperature with Unmatched Range and Sensitivity. Anal. Chem. 2008, 80, 6449–6457. [Google Scholar] [CrossRef]

- Ibañez, G.A.; Escandar, G.M. Luminescence Sensors Applied to Water Analysis of Organic Pollutants—An Update. Sensors 2011, 11, 11081–11102. [Google Scholar] [CrossRef] [Green Version]

- Dalmoro, V.; dos Santos, J.H.Z.; Pires, M.; Simanke, A.; Baldino, G.B.; Oliveira, L. Encapsulation of Sensors for Intelligent Packaging. In Food Packaging; Elsevier: Amsterdam, The Netherlands, 2017; pp. 111–145. [Google Scholar]

- Wang, X.; Wolfbeis, O.S. Fiber-Optic Chemical Sensors and Biosensors (2015–2019). Anal. Chem. 2019, 92, 397–430. [Google Scholar] [CrossRef]

- Alocilja, E.C.; Radke, S.M. Market Analysis of Biosensors for Food Safety. Biosens. Bioelectron. 2003, 18, 841–846. [Google Scholar] [CrossRef]

- Han, J.H. A Review of Food Packaging Technologies and Innovations. In Innovations in Food Packaging; Academic Press: Cambridge, MA, USA, 2014; pp. 3–12. [Google Scholar]

- Ma, Q.; Du, L.; Wang, L. Tara Gum/Polyvinyl Alcohol-Based Colorimetric NH3 Indicator Films Incorporating Curcumin for Intelligent Packaging. Sens. Actuators B Chem. 2017, 244, 759–766. [Google Scholar] [CrossRef]

- Fu, N.; Cheng, T.C.E.; Tian, Z. RFID Investment Strategy for Fresh Food Supply Chains. J. Oper. Res. Soc. 2019, 70, 1475–1489. [Google Scholar] [CrossRef]

- Kumar, P.; Reinitz, H.W.; Simunovic, J.; Sandeep, K.P.; Franzon, P.D. Overview of RFID Technology and Its Applications in the Food Industry. J. Food Sci. 2009, 74, R101–R106. [Google Scholar] [CrossRef] [PubMed]

- Costa, C.; Antonucci, F.; Pallottino, F.; Aguzzi, J.; Sarriá, D.; Menesatti, P. A Review on Agri-Food Supply Chain Traceability by Means of RFID Technology. Food Bioprocess Technol. 2013, 6, 353–366. [Google Scholar] [CrossRef]

- Bibi, F.; Guillaume, C.; Gontard, N.; Sorli, B. A Review: RFID Technology Having Sensing Aptitudes for Food Industry and Their Contribution to Tracking and Monitoring of Food Products. Trends Food Sci. Technol. 2017, 62, 91–103. [Google Scholar] [CrossRef]

- Chen, R.-S.; Chen, C.C.; Yeh, K.C.; Chen, Y.-C.; Kuo, C.W. Using RFID Technology in Food Produce Traceability. WSEAS Trans. Inf. Sci. Appl. 2008, 5, 1551–1560. [Google Scholar]

- Neumann, T. Koncepcja Zastosowania Technologii RFID w Transporcie Drogowym. Zesz. Nauk. Akad. Morskiej W Gdyni 2017, 102, 44–60. [Google Scholar]

- Zhou, H. Application of RFID Information Technology in Fresh Food Cold Chain Logistics Management. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2021; Volume 1881, p. 032002. [Google Scholar]

- Mosadegh Sedghy, B. Evolution of Radio Frequency Identification (RFID) in Agricultural Cold Chain Monitoring: A Literature Review. J. Agric. Sci. 2018, 11, 43–58. [Google Scholar]

- Olsen, P.; Borit, M. How to Define Traceability. Trends Food Sci. Technol. 2013, 29, 142–150. [Google Scholar] [CrossRef]

- Vivaldi, F.; Melai, B.; Bonini, A.; Poma, N.; Salvo, P.; Kirchhain, A.; Tintori, S.; Bigongiari, A.; Bertuccelli, F.; Isola, G. A Temperature-Sensitive RFID Tag for the Identification of Cold Chain Failures. Sens. Actuators Phys. 2020, 313, 112182. [Google Scholar] [CrossRef]

- Głowienka, W.; Jarosz, M.; Stoma, M. Technologia RFID–Koncepcja i Zastosowanie. In Problemy Wspólczesnej Inżynierii; Wyd. Politechniki Lubelskiej: Lublin, Poland, 2020; pp. 72–83. [Google Scholar]

- Rahman, M.A. RFID-Based Tracing for Wine Supply Chain. Int. J. Commun. Netw. Distrib. Syst. 2016, 16, 48–70. [Google Scholar] [CrossRef] [Green Version]

- Potyrailo, R.A.; Nagraj, N.; Tang, Z.; Mondello, F.J.; Surman, C.; Morris, W. Battery-Free Radio Frequency Identification (RFID) Sensors for Food Quality and Safety. J. Agric. Food Chem. 2012, 60, 8535–8543. [Google Scholar] [CrossRef] [PubMed]

- Amin, E.M.; Karmakar, N.C.; Jensen, B.W. Fully Printable Chipless RFID Multi-Parameter Sensor. Sens. Actuators Phys. 2016, 248, 223–232. [Google Scholar] [CrossRef]

- Huang, W.-D.; Cao, H.; Deb, S.; Chiao, M.; Chiao, J.-C. A Flexible PH Sensor Based on the Iridium Oxide Sensing Film. Sens. Actuators Phys. 2011, 169, 1–11. [Google Scholar] [CrossRef]

- Smits, E.; Schram, J.; Nagelkerke, M.; Kusters, R.; van Heck, G.; van Acht, V.; Koetse, M.; van den Brand, J.; Gerlinck, G. Development of Printed RFID Sensor Tags for Smart Food Packaging. In Proceedings of the 14th International Meeting on Chemical Sensors, Nuremberg, Germany, 20–23 May 2012; pp. 403–406. [Google Scholar]

- Sen, L.; Hyun, K.H.; Kim, J.W.; Shin, J.W.; Eom, K.H. The Design of Smart RFID System with Gas Sensor for Meat Freshness Monitoring. Adv. Sci. Technol. Lett. 2013, 41, 17–20. [Google Scholar]

- Martínez-Olmos, A.; Fernández-Salmerón, J.; Lopez-Ruiz, N.; Rivadeneyra Torres, A.; Capitan-Vallvey, L.F.; Palma, A.J. Screen Printed Flexible Radiofrequency Identification Tag for Oxygen Monitoring. Anal. Chem. 2013, 85, 11098–11105. [Google Scholar] [CrossRef]

- Alfian, G.; Rhee, J.; Ahn, H.; Lee, J.; Farooq, U.; Ijaz, M.F.; Syaekhoni, M.A. Integration of RFID, Wireless Sensor Networks, and Data Mining in an e-Pedigree Food Traceability System. J. Food Eng. 2017, 212, 65–75. [Google Scholar] [CrossRef]

- Feynman, R.P. Plenty of Room at the Bottom. In Proceedings of the APS Annual Meeting, Pasadena, CA, USA, 29 December 1959. [Google Scholar]

- Hulla, J.E.; Sahu, S.C.; Hayes, A.W. Nanotechnology: History and Future. Hum. Exp. Toxicol. 2015, 34, 1318–1321. [Google Scholar] [CrossRef] [Green Version]

- Taniguchi, N. On the Basic Concept of ‘nano-Technology’. In Proceedings of the International Conference of Production Engineering Japan Society of Precision Engineering, Tokyo, Japan; 1974. [Google Scholar]

- NNI. The National Nanotechnology Initiative Strategic Plan. December 2004. Available online: https://www.nano.gov/2004-Strategic-Plan (accessed on 20 November 2022).

- Commission, E.U. Recommendation on the Definition of Nanomaterial (2011/696/EU). Off. J. Eur. Com. Online 2011, 275, 38–40. [Google Scholar]

- Singh, N.A. Nanotechnology Definitions, Research, Industry and Property Rights. In Nanoscience in Food and Agriculture 1; Springer: Berlin, Germany, 2016; pp. 43–64. [Google Scholar]

- Sahani, S.; Sharma, Y.C. Advancements in Applications of Nanotechnology in Global Food Industry. Food Chem. 2021, 342, 128318. [Google Scholar] [CrossRef]

- Sanchez, F.; Sobolev, K. Nanotechnology in Concrete—A Review. Constr. Build. Mater. 2010, 24, 2060–2071. [Google Scholar] [CrossRef]

- Salata, O.V. Applications of nanoparticles in biology and medicine. J. Nano Biotechnol. 2004, 2, 1–6. [Google Scholar]

- Wyrwa, J.; Barska, A. Innovations in the Food Packaging Market: Active Packaging. Eur. Food Res. Technol. 2017, 243, 1681–1692. [Google Scholar] [CrossRef]

- Park, B. Nanotechnology and the Packaging of Food and Other Fast-Moving Consumer Goods. In Trends in Packaging of Food, Beverages and Other Fast-Moving Consumer Goods (FMCG); Woodhead Publishing: Swaston, UK, 2013; pp. 241–260. [Google Scholar]

- Cushen, M.; Kerry, J.; Morris, M.; Cruz-Romero, M.; Cummins, E. Nanotechnologies in the Food Industry–Recent Developments, Risks and Regulation. Trends Food Sci. Technol. 2012, 24, 30–46. [Google Scholar] [CrossRef]

- Chausali, N.; Saxena, J.; Prasad, R. Recent Trends in Nanotechnology Applications of Bio-Based Packaging. J. Agric. Food Res. 2022, 7, 100257. [Google Scholar] [CrossRef]

- Tang, S.; Wang, Z.; Li, W.; Li, M.; Deng, Q.; Wang, Y.; Li, C.; Chu, P.K. Ecofriendly and Biodegradable Soybean Protein Isolate Films Incorporated with Zno Nanoparticles for Food Packaging. ACS Appl. Bio Mater. 2019, 2, 2202–2207. [Google Scholar] [CrossRef] [PubMed]

- Mohammadzadeh-Vazifeh, M.; Hosseini, S.M.; Mohammadi, A.; Jahanfar, M.; Maleki, H. Investigation of the Antimicrobial Properties of Nanoclay and Chitosan Based Nanocomposite on the Microbial Characteristics of Gouda Cheese. Iran. J. Microbiol. 2020, 12, 121. [Google Scholar] [CrossRef]

- Wang, H.; Qian, J.; Ding, F. Emerging Chitosan-Based Films for Food Packaging Applications. J. Agric. Food Chem. 2018, 66, 395–413. [Google Scholar] [CrossRef]

- Costa, S.M.; Ferreira, D.P.; Teixeira, P.; Ballesteros, L.F.; Teixeira, J.A.; Fangueiro, R. Active Natural-Based Films for Food Packaging Applications: The Combined Effect of Chitosan and Nanocellulose. Int. J. Biol. Macromol. 2021, 177, 241–251. [Google Scholar] [CrossRef]

- Nouri, A.; Yaraki, M.T.; Ghorbanpour, M.; Agarwal, S.; Gupta, V.K. Enhanced Antibacterial Effect of Chitosan Film Using Montmorillonite/CuO Nanocomposite. Int. J. Biol. Macromol. 2018, 109, 1219–1231. [Google Scholar] [CrossRef]

- Rodrigues, C.; de Mello, J.M.M.; Dalcanton, F.; Macuvele, D.L.P.; Padoin, N.; Fiori, M.A.; Soares, C.; Riella, H.G. Mechanical, Thermal and Antimicrobial Properties of Chitosan-Based-Nanocomposite with Potential Applications for Food Packaging. J. Polym. Environ. 2020, 28, 1216–1236. [Google Scholar] [CrossRef]

- Lara, B.R.B.; de Andrade, P.S.; Guimaraes Junior, M.; Dias, M.V.; Alcântara, L.A.P. Novel Whey Protein Isolate/Polyvinyl Biocomposite for Packaging: Improvement of Mechanical and Water Barrier Properties by Incorporation of Nano-Silica. J. Polym. Environ. 2021, 29, 2397–2408. [Google Scholar] [CrossRef]

- Corrado, I.; Abdalrazeq, M.; Pezzella, C.; Di Girolamo, R.; Porta, R.; Sannia, G.; Giosafatto, C.V.L. Design and Characterization of Poly(3-Hydroxybutyrate-Co-Hydroxyhexanoate) Nanoparticles and Their Grafting in Whey Protein-Based Nanocomposites. Food Hydrocoll. 2021, 110, 106167. [Google Scholar] [CrossRef]

- Bastante, C.C.; Silva, N.H.; Cardoso, L.C.; Serrano, C.M.; de la Ossa, E.J.M.; Freire, C.S.; Vilela, C. Biobased Films of Nanocellulose and Mango Leaf Extract for Active Food Packaging: Supercritical Impregnation versus Solvent Casting. Food Hydrocoll. 2021, 117, 106709. [Google Scholar] [CrossRef]

- Wu, Z.; Deng, W.; Luo, J.; Deng, D. Multifunctional Nano-Cellulose Composite Films with Grape Seed Extracts and Immobilized Silver Nanoparticles. Carbohydr. Polym. 2019, 205, 447–455. [Google Scholar] [CrossRef]

- Goudarzi, V.; Shahabi-Ghahfarrokhi, I.; Babaei-Ghazvini, A. Preparation of Ecofriendly UV-Protective Food Packaging Material by Starch/TiO2 Bio-Nanocomposite: Characterization. Int. J. Biol. Macromol. 2017, 95, 306–313. [Google Scholar] [CrossRef] [PubMed]

- Jayakumar, A.; Heera, K.V.; Sumi, T.S.; Joseph, M.; Mathew, S.; Praveen, G.; Nair, I.C.; Radhakrishnan, E.K. Starch-PVA Composite Films with Zinc-Oxide Nanoparticles and Phytochemicals as Intelligent PH Sensing Wraps for Food Packaging Application. Int. J. Biol. Macromol. 2019, 136, 395–403. [Google Scholar] [CrossRef]

- Souza, A.G.; Ferreira, R.R.; Paula, L.C.; Mitra, S.K.; Rosa, D.S. Starch-Based Films Enriched with Nanocellulose-Stabilized Pickering Emulsions Containing Different Essential Oils for Possible Applications in Food Packaging. Food Packag. Shelf Life 2021, 27, 100615. [Google Scholar] [CrossRef]

- Primožič, M.; Knez, Ž.; Leitgeb, M. (Bio)Nanotechnology in Food Science—Food Packaging. Nanomaterials 2021, 11, 292. [Google Scholar] [CrossRef]

- Cerqueira, M.A.; Vicente, A.A.; Pastrana, L.M. Nanotechnology in Food Packaging: Opportunities and Challenges. In Nanomaterials for Food Packaging; Elsevier: Amsterdam, The Netherlands, 2018; pp. 1–11. [Google Scholar]

- Caon, T.; Martelli, S.M.; Fakhouri, F.M. New Trends in the Food Industry: Application of Nanosensors in Food Packaging. In Nanobiosensors; Elsevier: Amsterdam, The Netherlands, 2017; pp. 773–804. [Google Scholar]

- Mills, A. Oxygen Indicators and Intelligent Inks for Packaging Food. Chem. Soc. Rev. 2005, 34, 1003–1011. [Google Scholar] [CrossRef]

- Mohammadi, Z.; Jafari, S.M. Detection of Food Spoilage and Adulteration by Novel Nanomaterial-Based Sensors. Adv. Colloid Interface Sci. 2020, 286, 102297. [Google Scholar] [CrossRef]

- Ojeda, G.A.; Gorman, A.M.A.; Sgroppo, S.C. Nanotechnology and the Application in the Food Industry. Charact. Appl. Nanomater. 2022, 5, 1–8. [Google Scholar] [CrossRef]

- Das, J.; Mishra, H.N. Recent Advances in Sensors for Detecting Food Pathogens, Contaminants, and Toxins: A Review. Eur. Food Res. Technol. 2022, 248, 1125–1148. [Google Scholar] [CrossRef]

- Girigoswami, A.; Ghosh, M.M.; Pallavi, P.; Ramesh, S.; Girigoswami, K. Nanotechnology in Detection of Food Toxins–Focus on the Dairy Products. Biointerface Res Appl Chem 2021, 11, 14155–14172. [Google Scholar]

- Ngafwan, N.; Rasyid, H.; Abood, E.S.; Abdelbasset, W.K.; Al-Shawi, S.G.; Bokov, D.; Jalil, A.T. Study on Novel Fluorescent Carbon Nanomaterials in Food Analysis. Food Sci. Technol. 2021, 42, e37821. [Google Scholar] [CrossRef]

- Lotfi, S.; Ahari, H.; Sahraeyan, R. The Effect of Silver Nanocomposite Packaging Based on Melt Mixing and Sol–Gel Methods on Shelf Life Extension of Fresh Chicken Stored at 4 C. J. Food Saf. 2019, 39, e12625. [Google Scholar] [CrossRef]

- Zhong, M.; Yang, L.; Yang, H.; Cheng, C.; Deng, W.; Tan, Y.; Xie, Q.; Yao, S. An Electrochemical Immunobiosensor for Ultrasensitive Detection of Escherichia Coli O157: H7 Using CdS Quantum Dots-Encapsulated Metal-Organic Frameworks as Signal-Amplifying Tags. Biosens. Bioelectron. 2019, 126, 493–500. [Google Scholar] [CrossRef]

- Hasan, M.R.; Pulingam, T.; Appaturi, J.N.; Zifruddin, A.N.; Teh, S.J.; Lim, T.W.; Ibrahim, F.; Leo, B.F.; Thong, K.L. Carbon Nanotube-Based Aptasensor for Sensitive Electrochemical Detection of Whole-Cell Salmonella. Anal. Biochem. 2018, 554, 34–43. [Google Scholar] [CrossRef]

- Borah, N.; Gogoi, D.; Ghosh, N.N.; Tamuly, C. GA-AuNP@ Tollens’ Complex as a Highly Sensitive Plasmonic Nanosensor for Detection of Formaldehyde and Benzaldehyde in Preserved Food Products. Food Chem. 2023, 399, 133975. [Google Scholar] [CrossRef]

- Sundramoorthy, A.K.; Kumar, T.H.V.; Gunasekaran, S. Graphene-Based Nanosensors and Smart Food Packaging Systems for Food Safety and Quality Monitoring. In Graphene Bioelectronics; Elsevier: Amsterdam, The Netherlands, 2018; pp. 267–306. [Google Scholar]

- Verdian, A. Apta-Nanosensors for Detection and Quantitative Determination of Acetamiprid—A Pesticide Residue in Food and Environment. Talanta 2018, 176, 456–464. [Google Scholar] [CrossRef]

- Zhao, S.; Huang, J.; Lei, J.; Huo, D.; Huang, Q.; Tan, J.; Li, Y.; Hou, C.; Tian, F. A Portable and Automatic Dual-Readout Detector Integrated with 3D-Printed Microfluidic Nanosensors for Rapid Carbamate Pesticides Detection. Sens. Actuators B Chem. 2021, 346, 130454. [Google Scholar] [CrossRef]

- Khaledian, S.; Noroozi-Aghideh, A.; Kahrizi, D.; Moradi, S.; Abdoli, M.; Ghasemalian, A.H.; Heidari, M.F. Rapid Detection of Diazinon as an Organophosphorus Poison in Real Samples Using Fluorescence Carbon Dots. Inorg. Chem. Commun. 2021, 130, 108676. [Google Scholar] [CrossRef]

- Mustafa, F.; Andreescu, S. Nanotechnology-Based Approaches for Food Sensing and Packaging Applications. RSC Adv. 2020, 10, 19309–19336. [Google Scholar] [CrossRef] [PubMed]

- Oh, S.Y.; Lee, M.J.; Heo, N.S.; Kim, S.; Oh, J.S.; Lee, Y.; Jeon, E.J.; Moon, H.; Kim, H.S.; Park, T.J. Cuvette-Type LSPR Sensor for Highly Sensitive Detection of Melamine in Infant Formulas. Sensors 2019, 19, 3839. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jiang, Y.; Sun, D.-W.; Pu, H.; Wei, Q. Ultrasensitive Analysis of Kanamycin Residue in Milk by SERS-Based Aptasensor. Talanta 2019, 197, 151–158. [Google Scholar] [CrossRef]

- He, L.; Wang, F.; Chen, Y.; Liu, Y. Rapid and Sensitive Colorimetric Detection of Ascorbic Acid in Food Based on the Intrinsic Oxidase-like Activity of MnO2 Nanosheets. Luminescence 2018, 33, 145–152. [Google Scholar] [CrossRef]

- Fathima, A.; Chiome, T.J.; Catherine, A.A.; Egbuna, C.; Achar, R.R.; Srinivasan, A. Smart Use of Nanomaterials as Sensors for Detection and Monitoring of Food Spoilage. In Application of Nanotechnology in Food Science, Processing and Packaging; Springer: Berlin, Germany, 2022; pp. 169–188. [Google Scholar]

- Bhusare, S.; Kadam, S. Applications of Nanotechnology in Fruits and Vegetables. Food Agric. Spectr. J. 2021, 2, 231–236. [Google Scholar]

- Thirugnanasambandan, T. Smart and Intelligent Packaging Based on Biodegradable Composites. In Biodegradable Composites for Packaging Applications; CRC Press: Boca Raton, FL, USA, 2022; pp. 169–191. [Google Scholar]

- Abraham, J. Future of Food Packaging. In Nanotechnology in Intelligent Food Packaging; Wiley: Hoboke, NJ, USA, 2022; pp. 383–417. [Google Scholar]

- Zuo, J.; Feng, J.; Gameiro, M.G.; Tian, Y.; Liang, J.; Wang, Y.; Ding, J.; He, Q. RFID-Based Sensing in Smart Packaging for Food Applications: A Review. Future Foods 2022, 6, 100198. [Google Scholar] [CrossRef]

| Intelligent Packaging | ||

|---|---|---|

| Component | Base | |

| Sensors |

|

|

| ||

| Indicators |

|

|

| ||

| Tags/Barcodes |

|

|

|

| |

| Holograms | ||

| Thermochromic inks | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Osmólska, E.; Stoma, M.; Starek-Wójcicka, A. Application of Biosensors, Sensors, and Tags in Intelligent Packaging Used for Food Products—A Review. Sensors 2022, 22, 9956. https://doi.org/10.3390/s22249956

Osmólska E, Stoma M, Starek-Wójcicka A. Application of Biosensors, Sensors, and Tags in Intelligent Packaging Used for Food Products—A Review. Sensors. 2022; 22(24):9956. https://doi.org/10.3390/s22249956

Chicago/Turabian StyleOsmólska, Emilia, Monika Stoma, and Agnieszka Starek-Wójcicka. 2022. "Application of Biosensors, Sensors, and Tags in Intelligent Packaging Used for Food Products—A Review" Sensors 22, no. 24: 9956. https://doi.org/10.3390/s22249956

APA StyleOsmólska, E., Stoma, M., & Starek-Wójcicka, A. (2022). Application of Biosensors, Sensors, and Tags in Intelligent Packaging Used for Food Products—A Review. Sensors, 22(24), 9956. https://doi.org/10.3390/s22249956