Development of an Innovative Mechatronic Binder Machine

Abstract

:1. Introduction

1.1. Related Work

1.2. Equipment Use Description

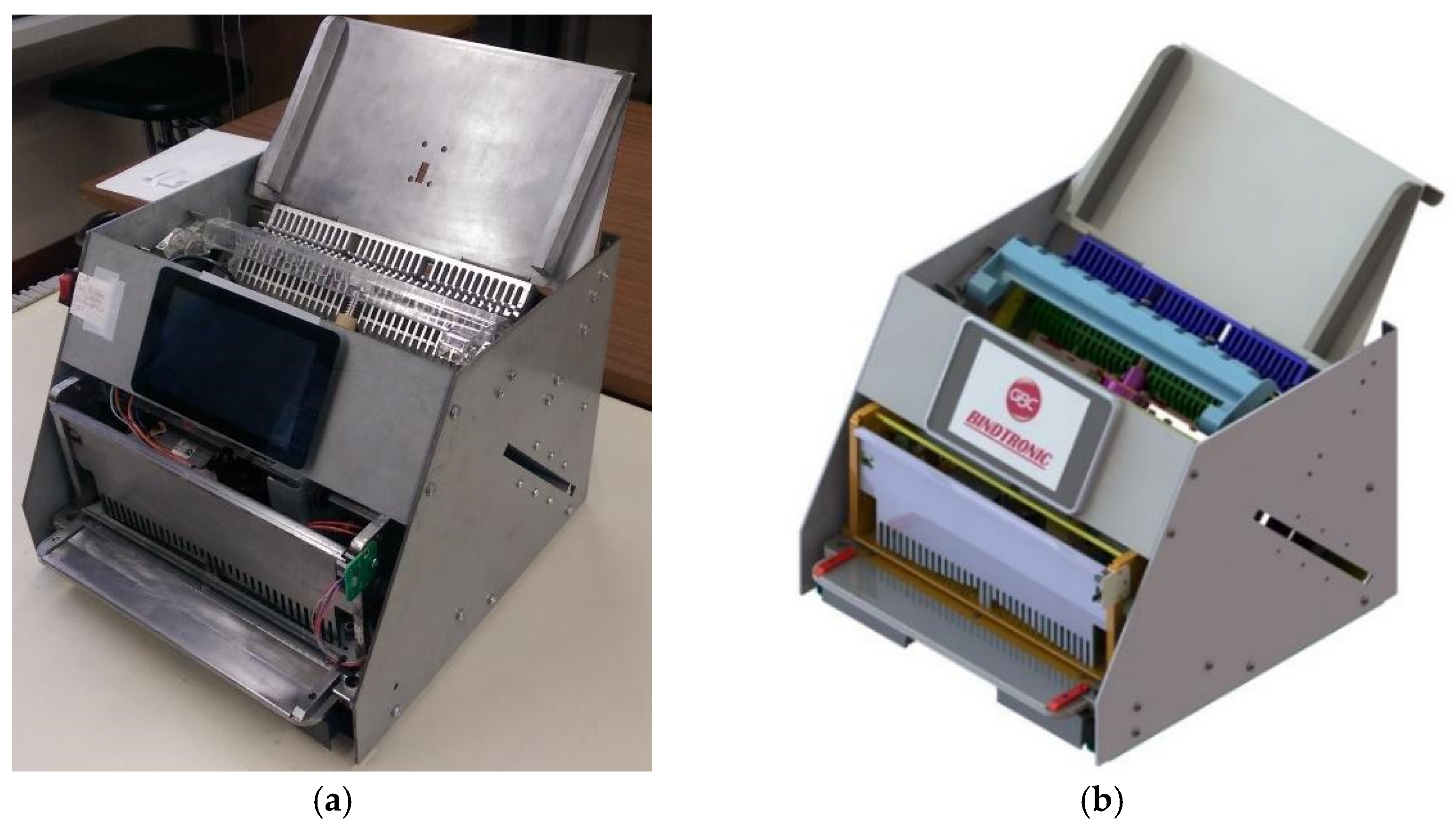

2. BindTronic Prototype

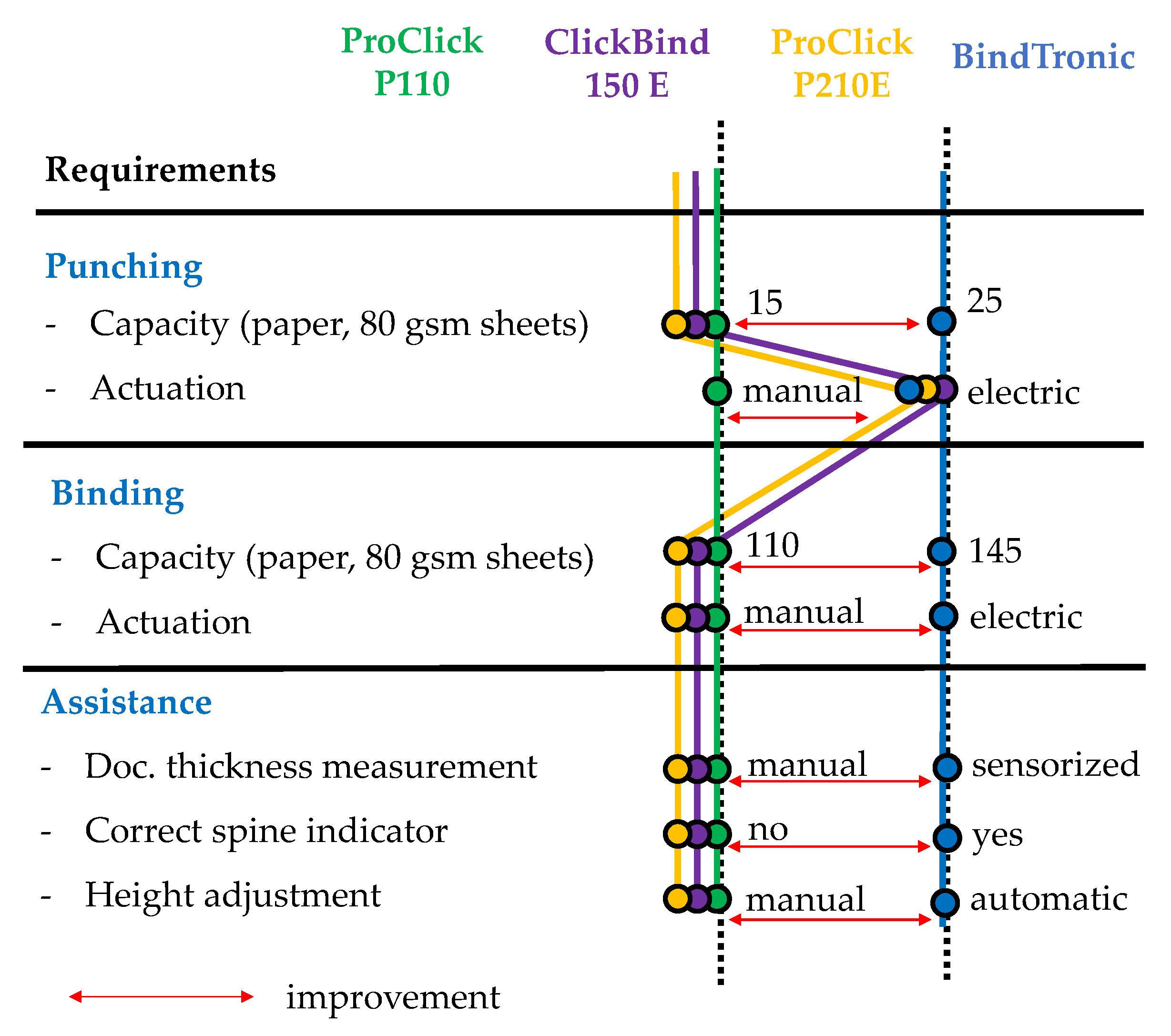

2.1. Prototype Requirements

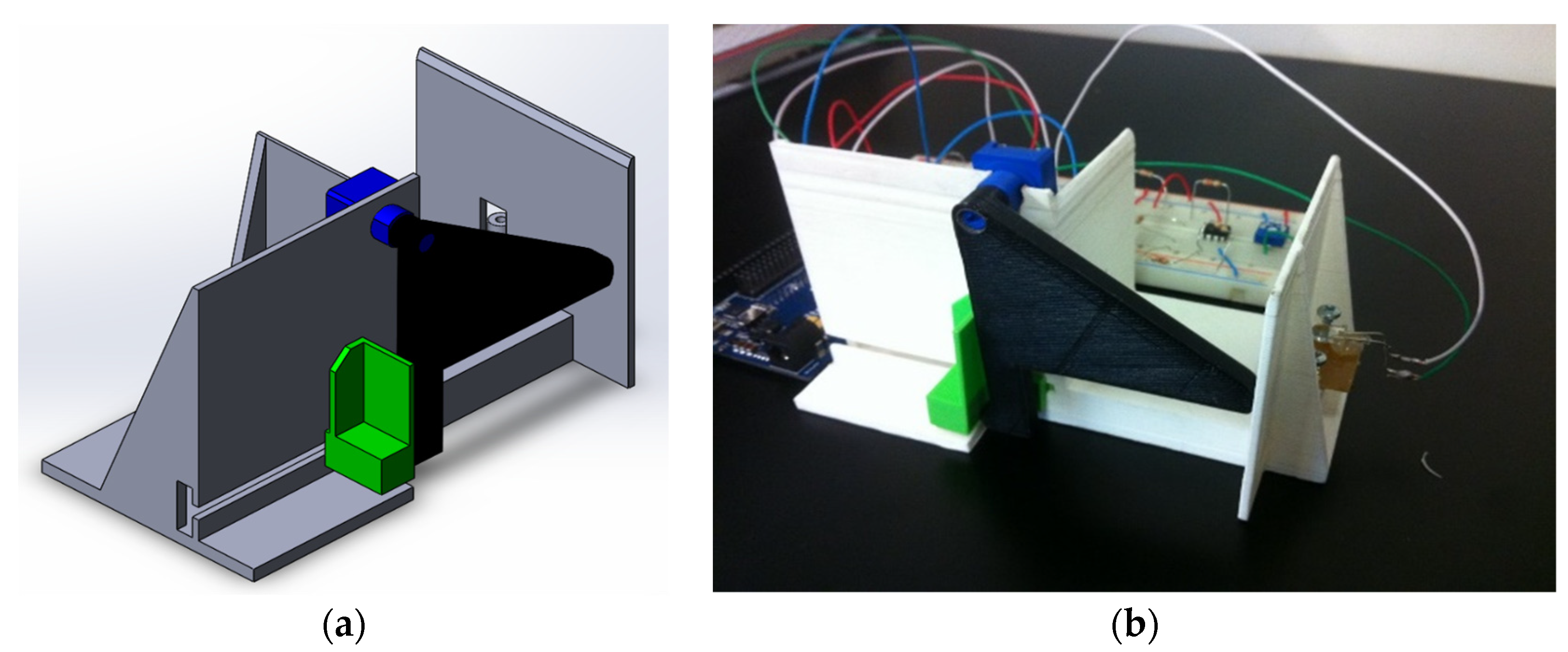

2.2. Document Thickness Measurement System

2.3. Binding System

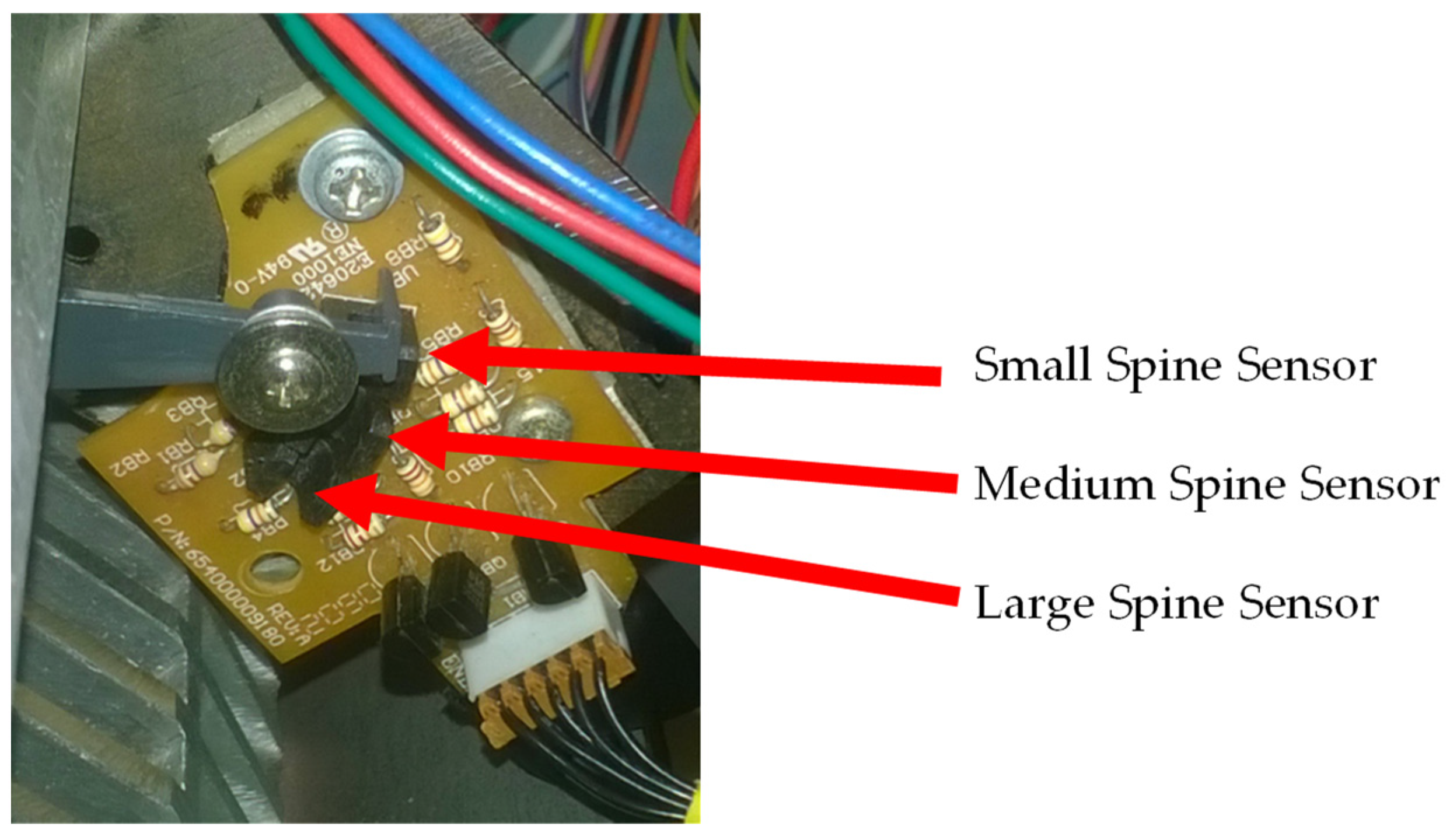

2.3.1. The Inserted Spine Measurement Mechanism

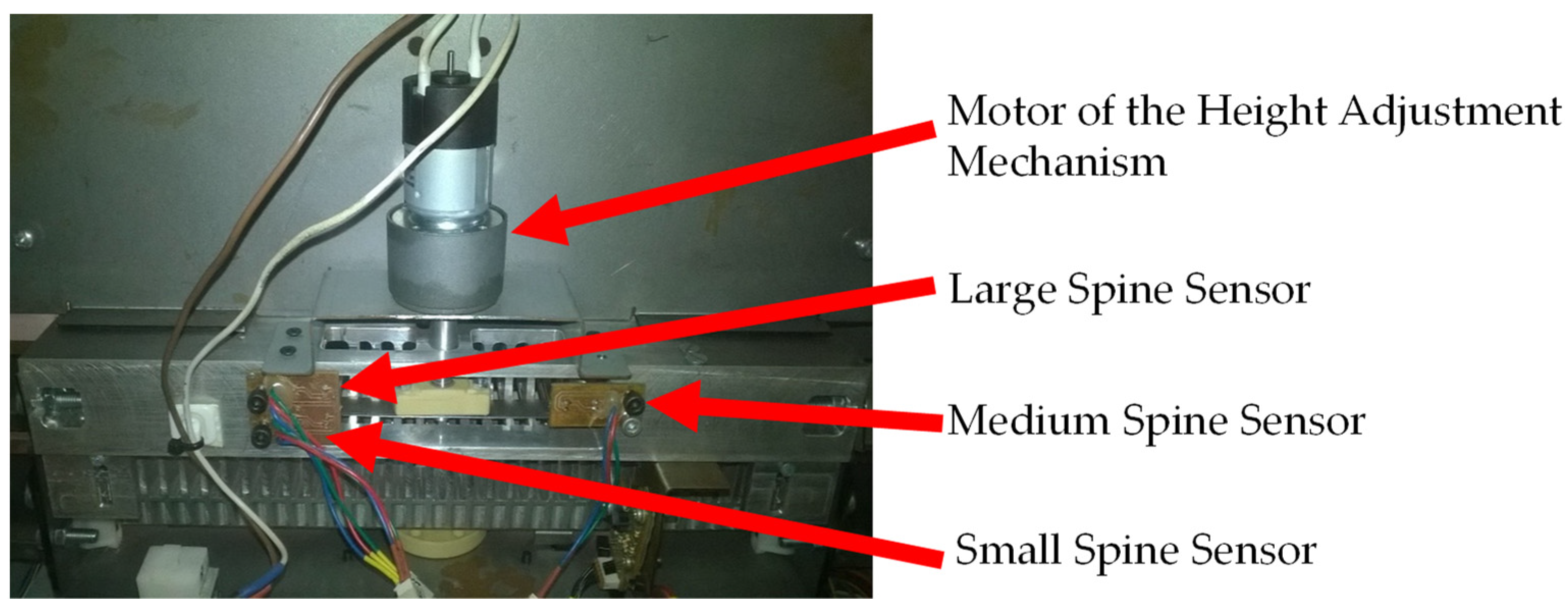

2.3.2. Document Height Adjustment Mechanism

2.3.3. Spine Closing Mechanism

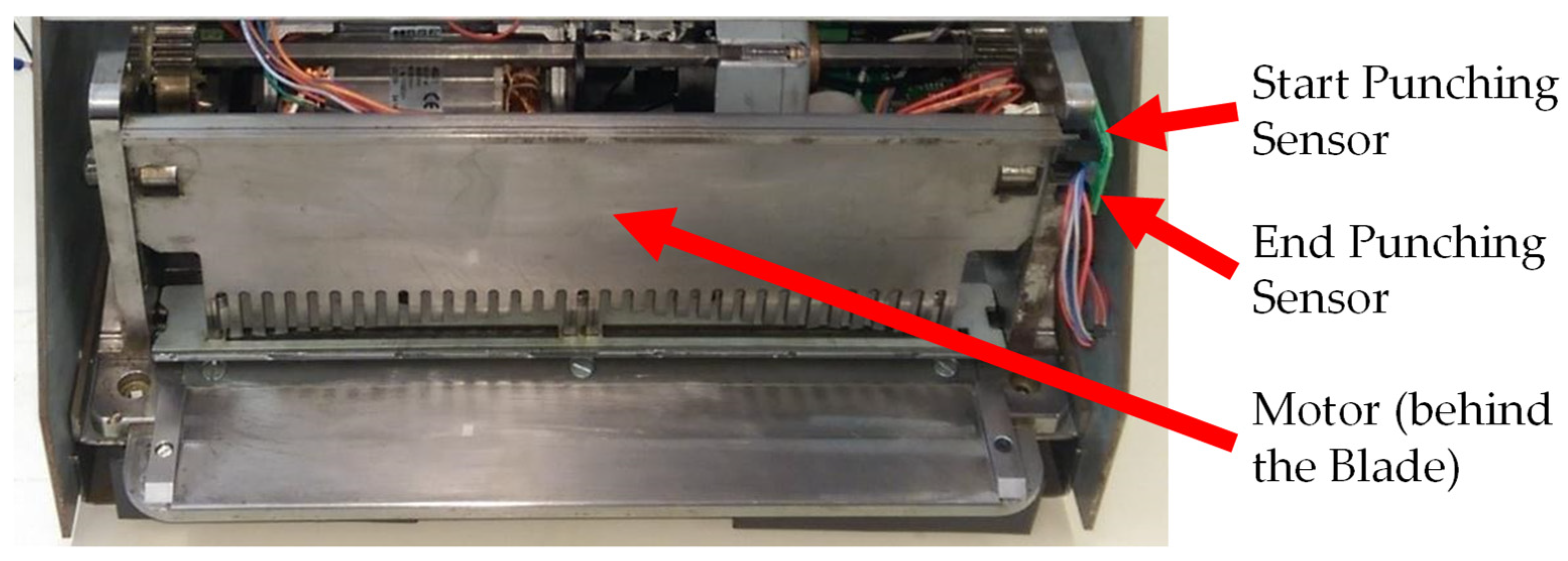

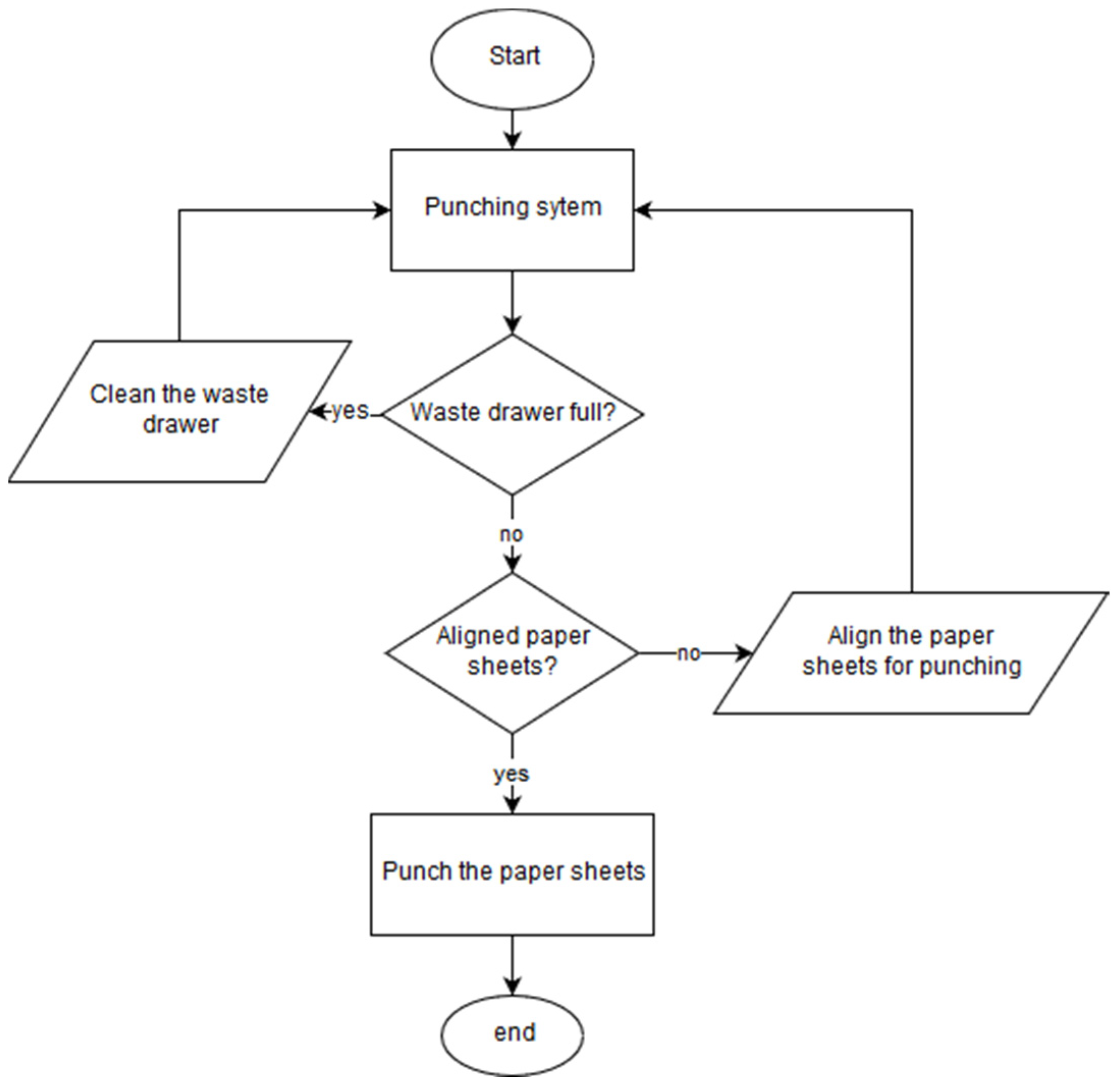

2.4. Punching System

2.5. Control System

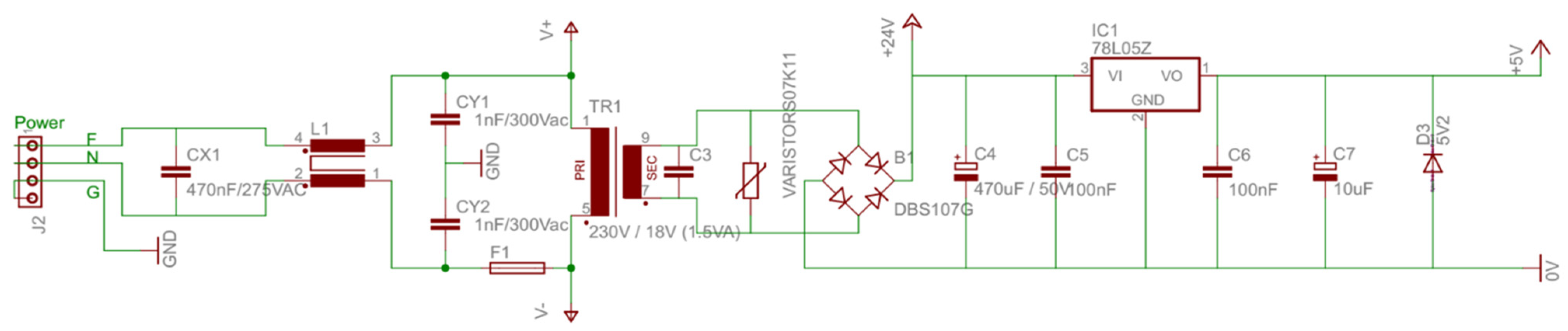

3. Electric Connections Scheme

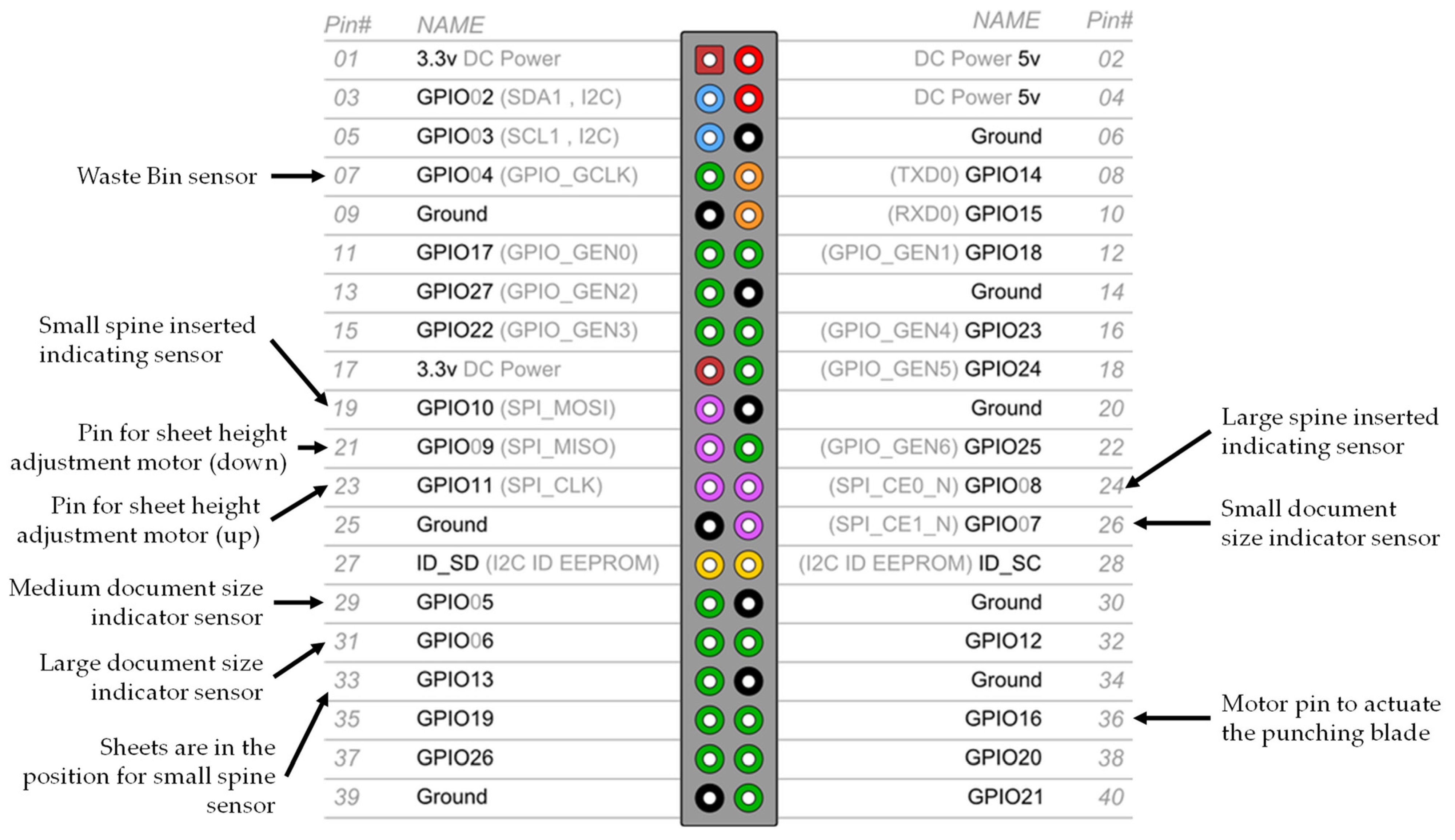

3.1. Raspberry PI GPIO Connections

3.2. Definitions and Electrical Schematics for the Sensors

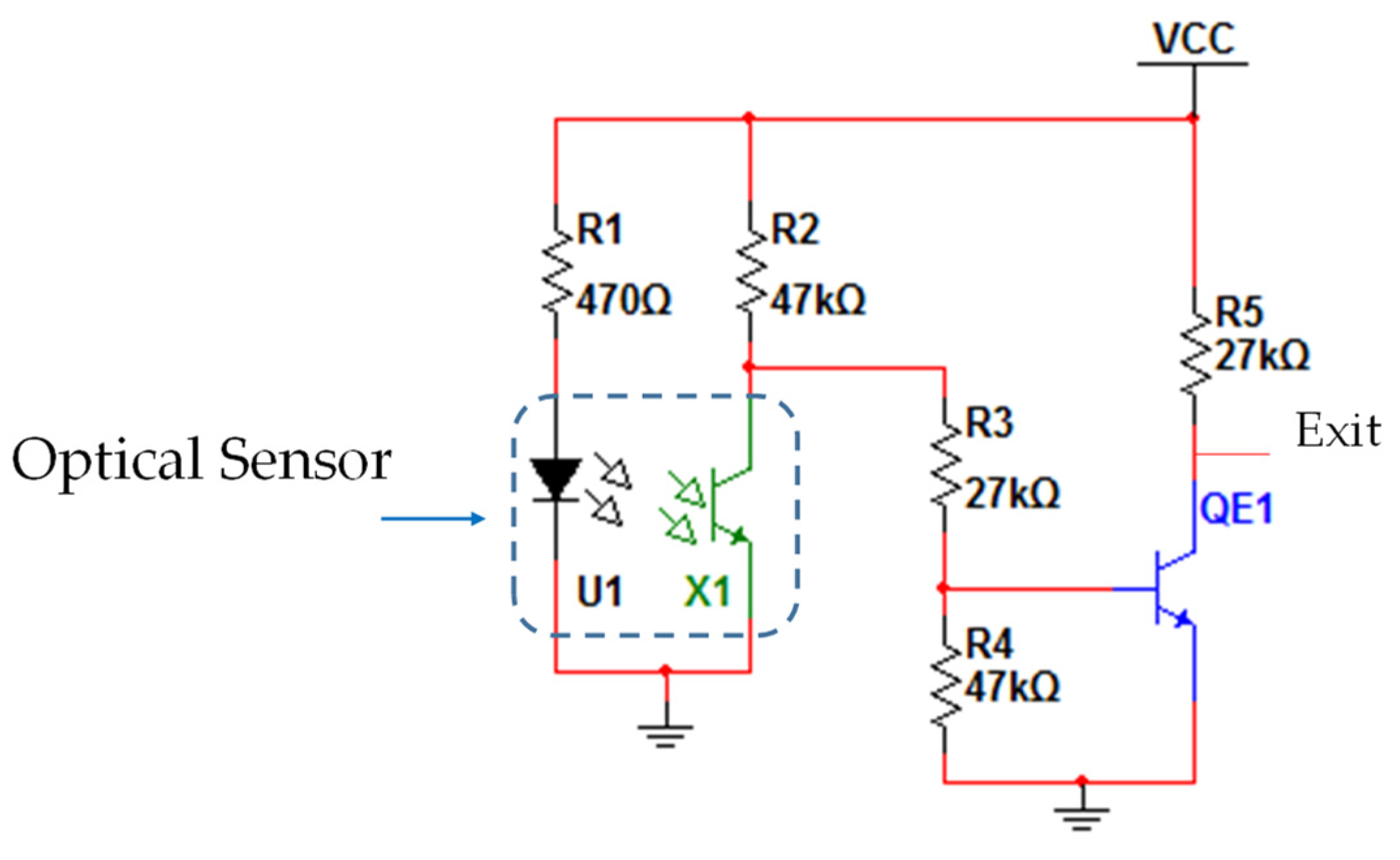

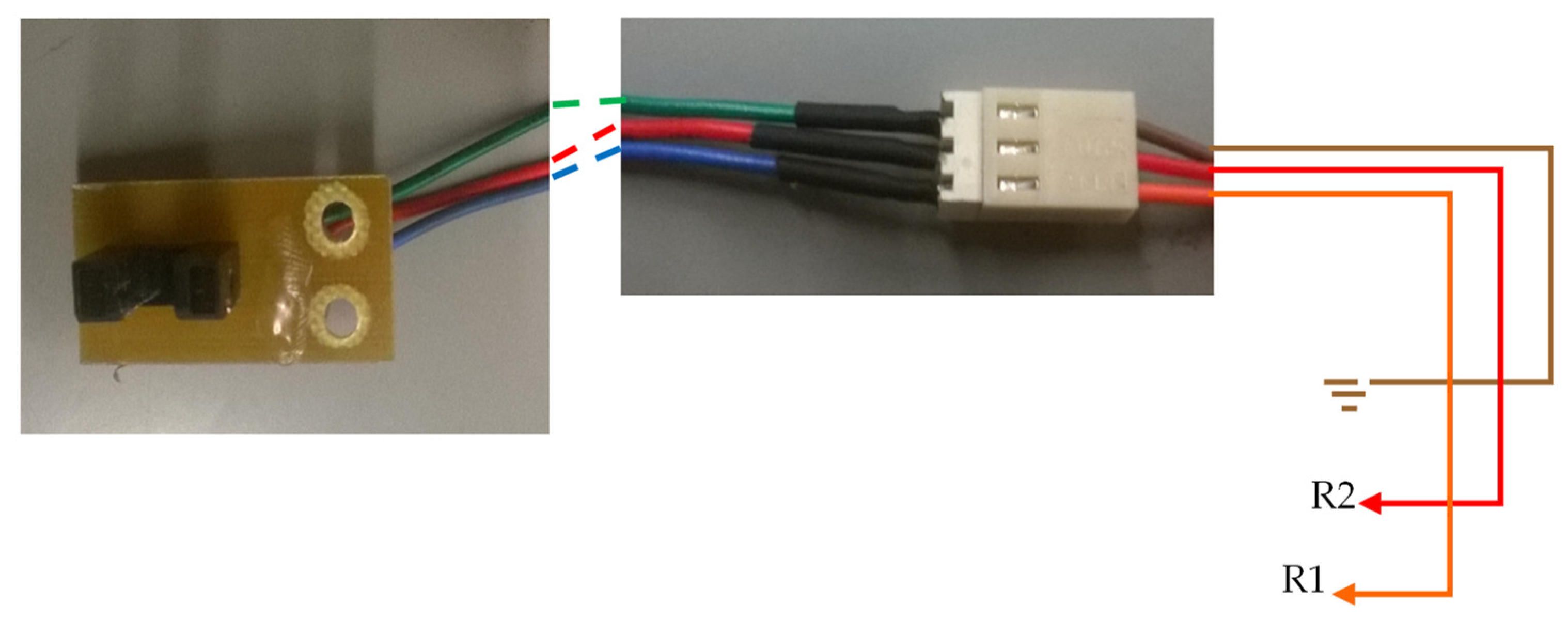

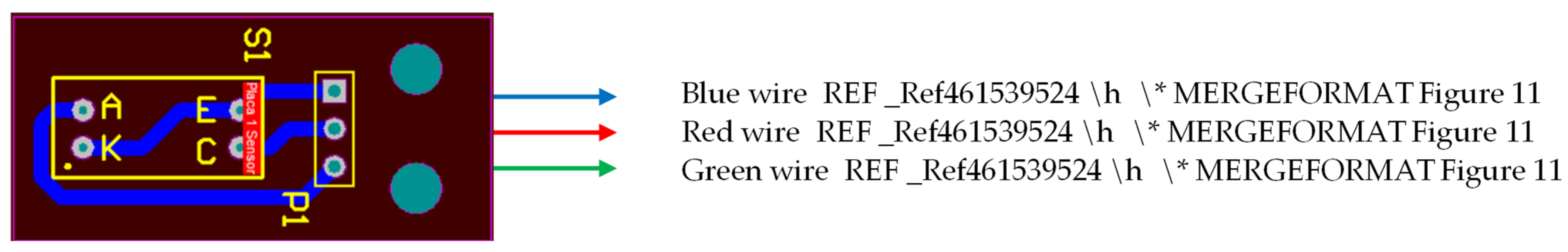

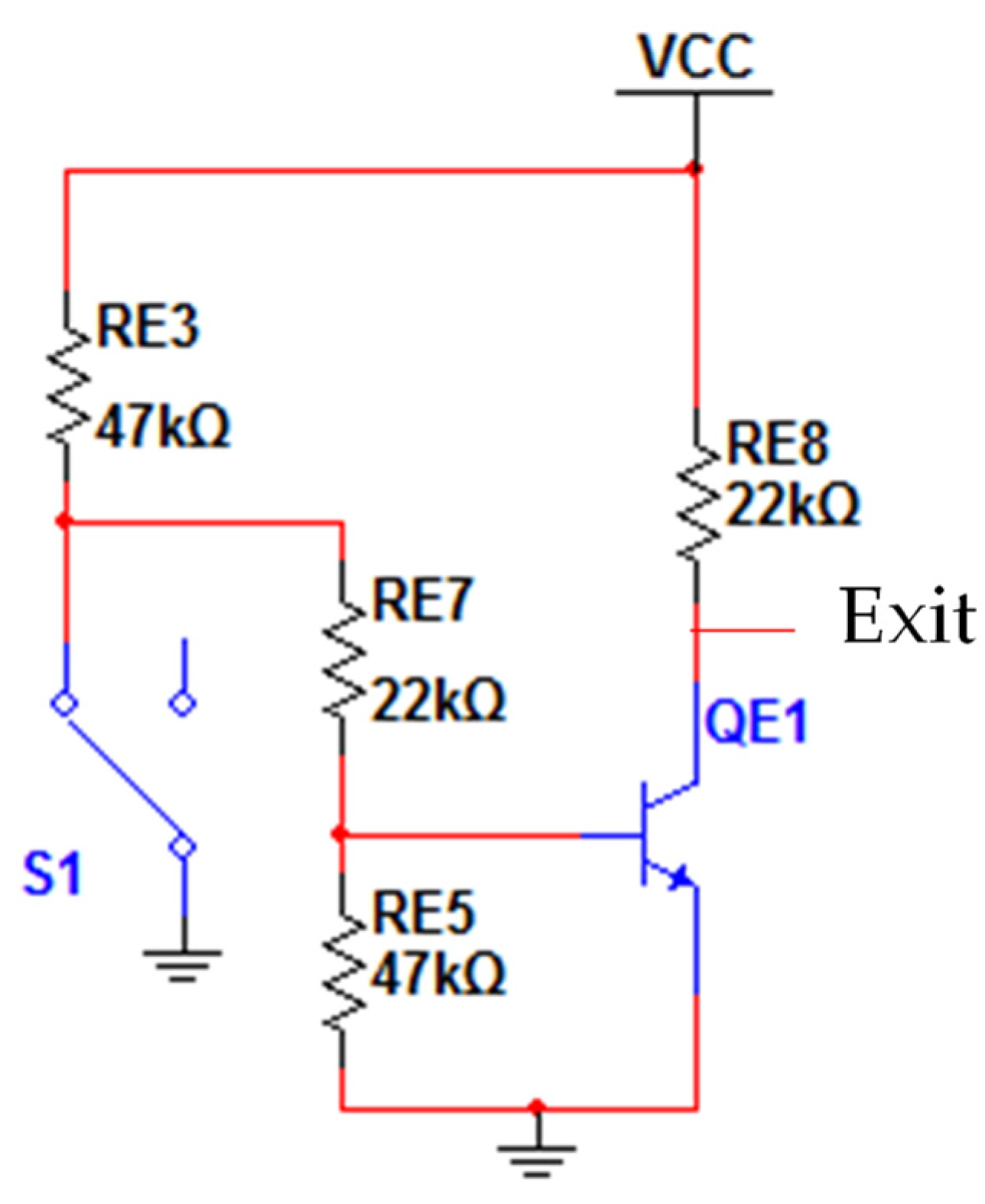

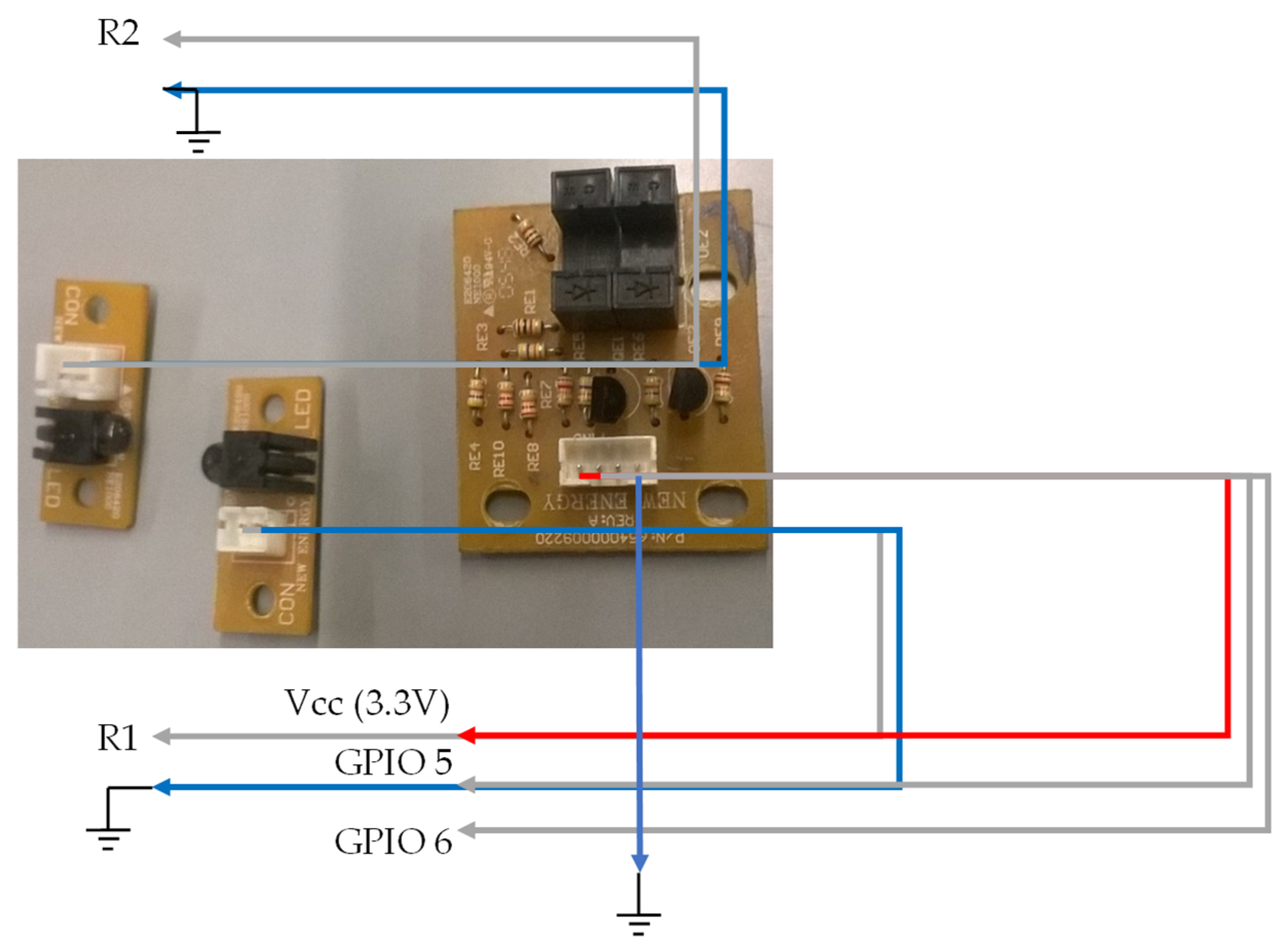

3.2.1. Optical Sensors

3.2.2. Mechanical Sensors (Waste Bin Drawer)

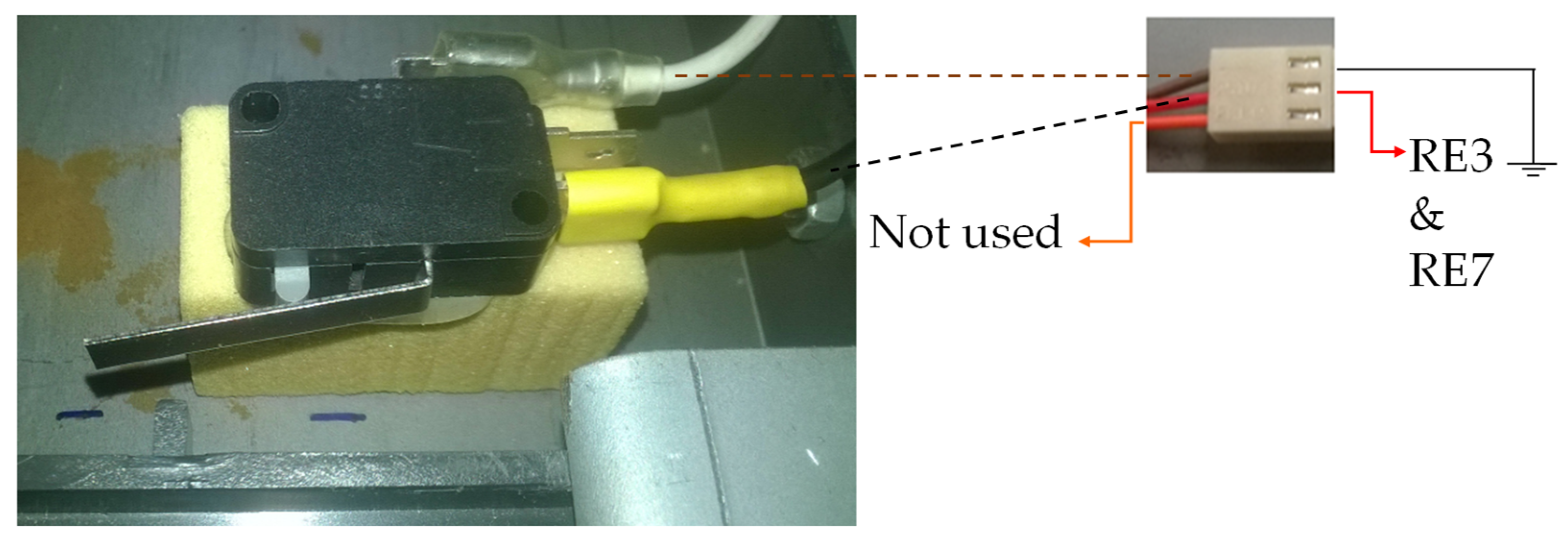

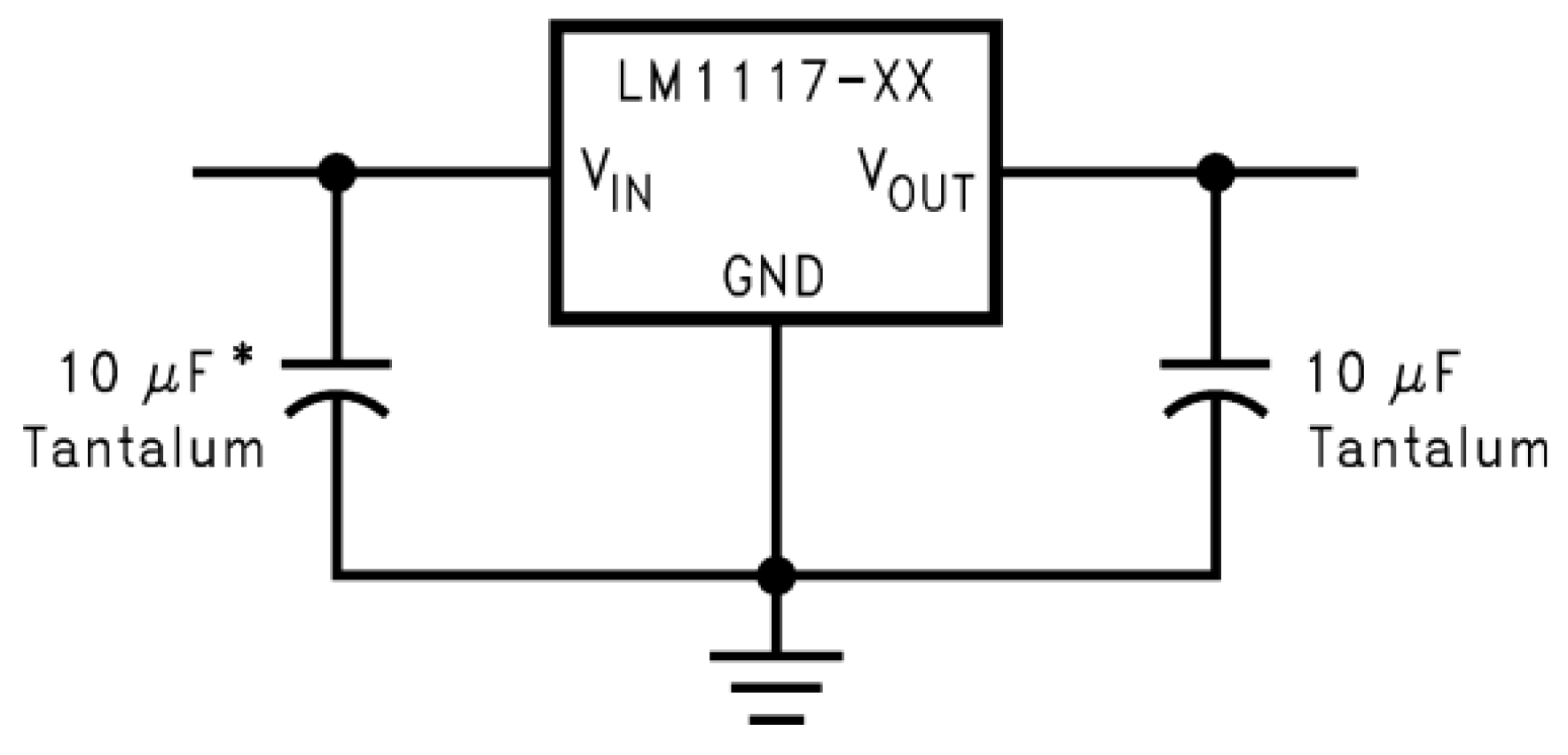

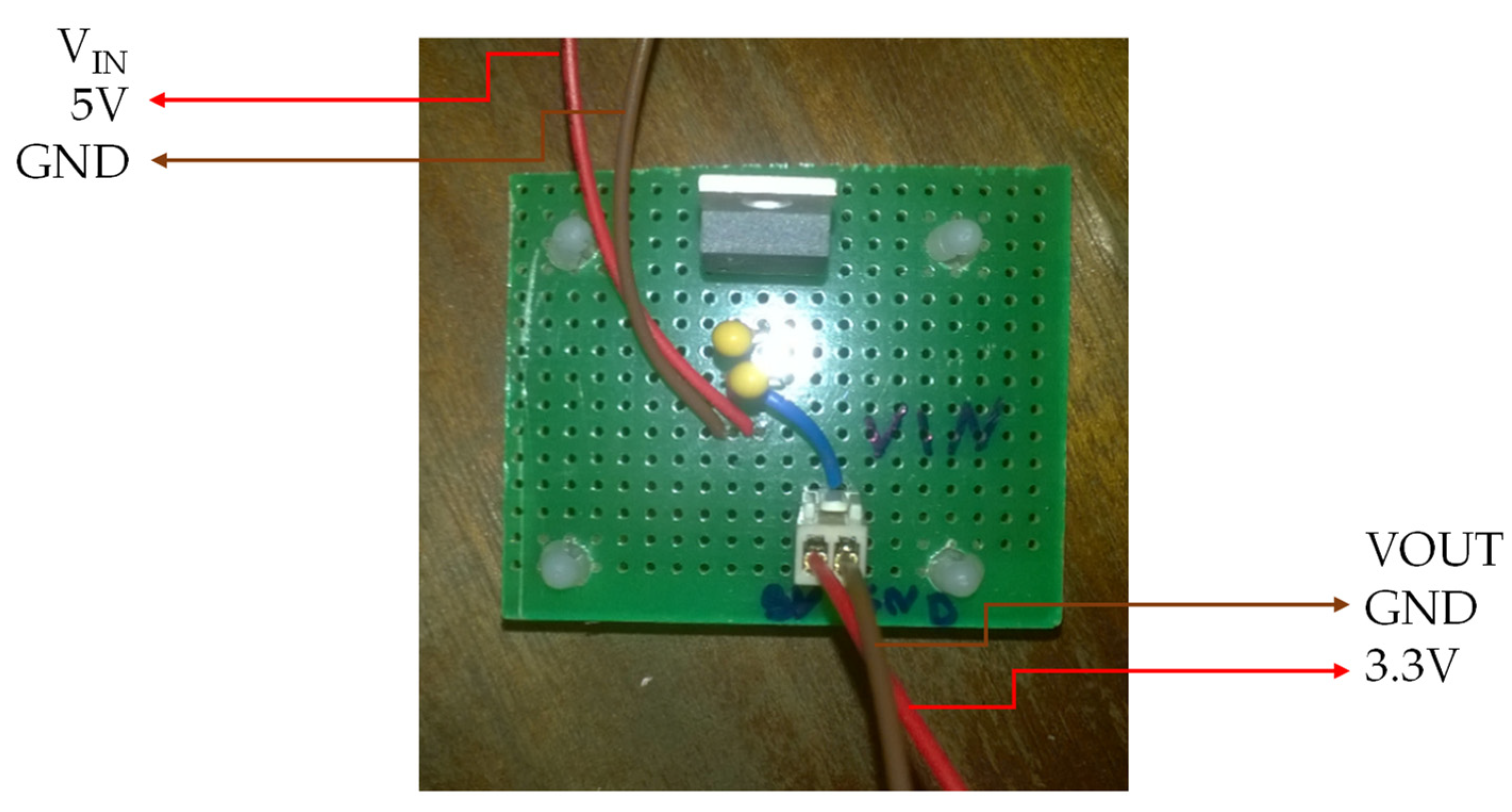

3.2.3. Electrical Power Scheme for Optical Sensors and Mechanical Sensors

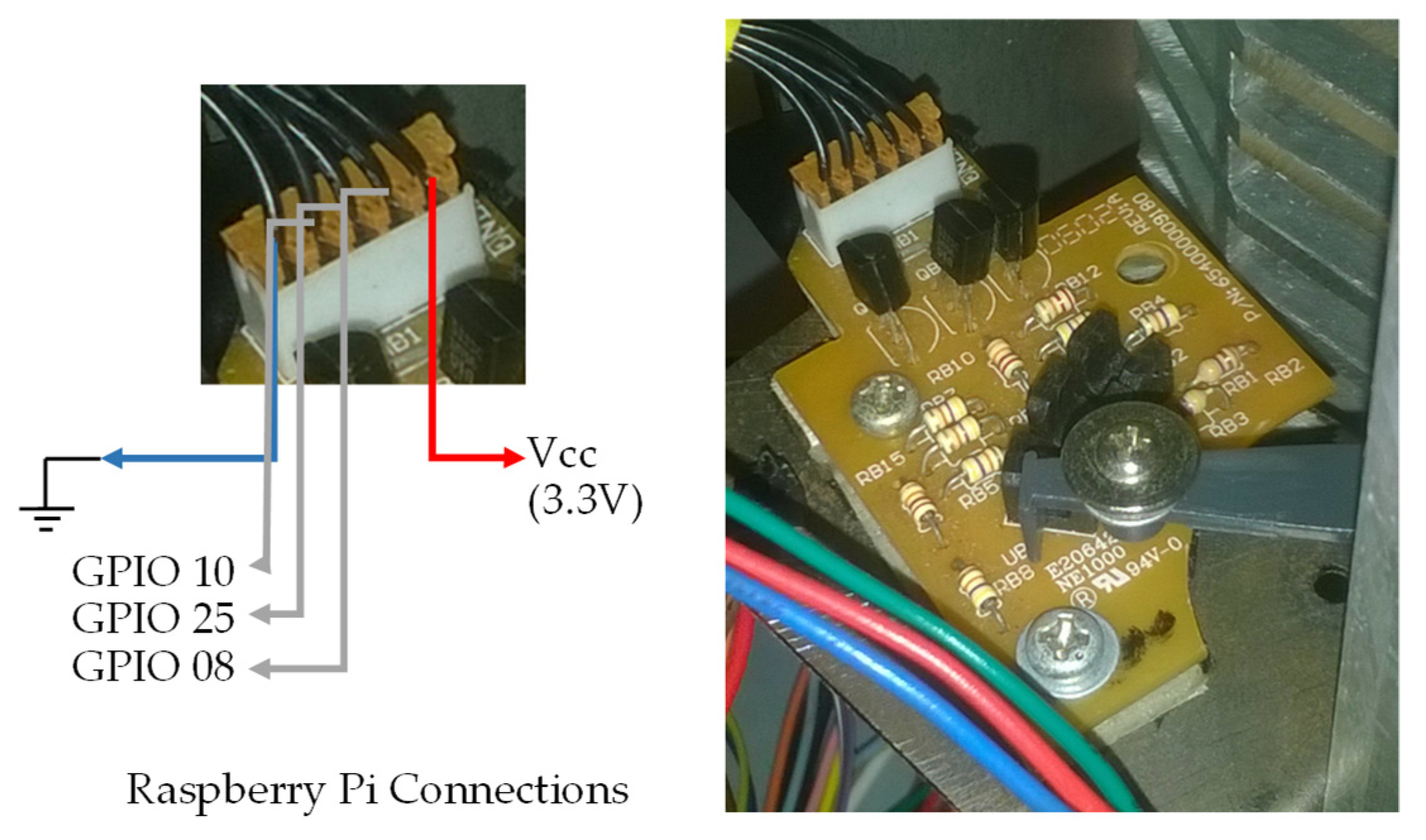

3.3. Engine Definitions and Schematics

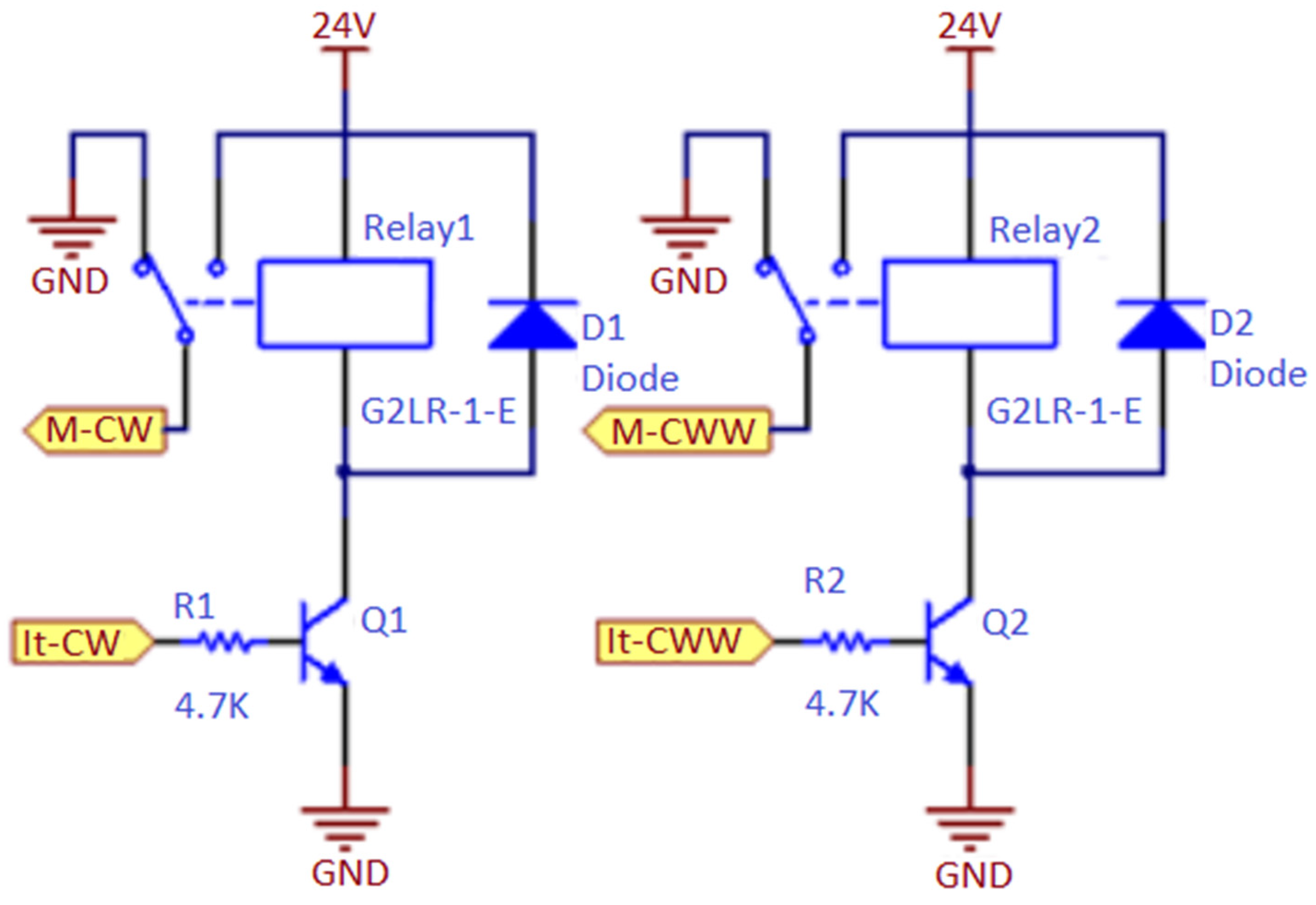

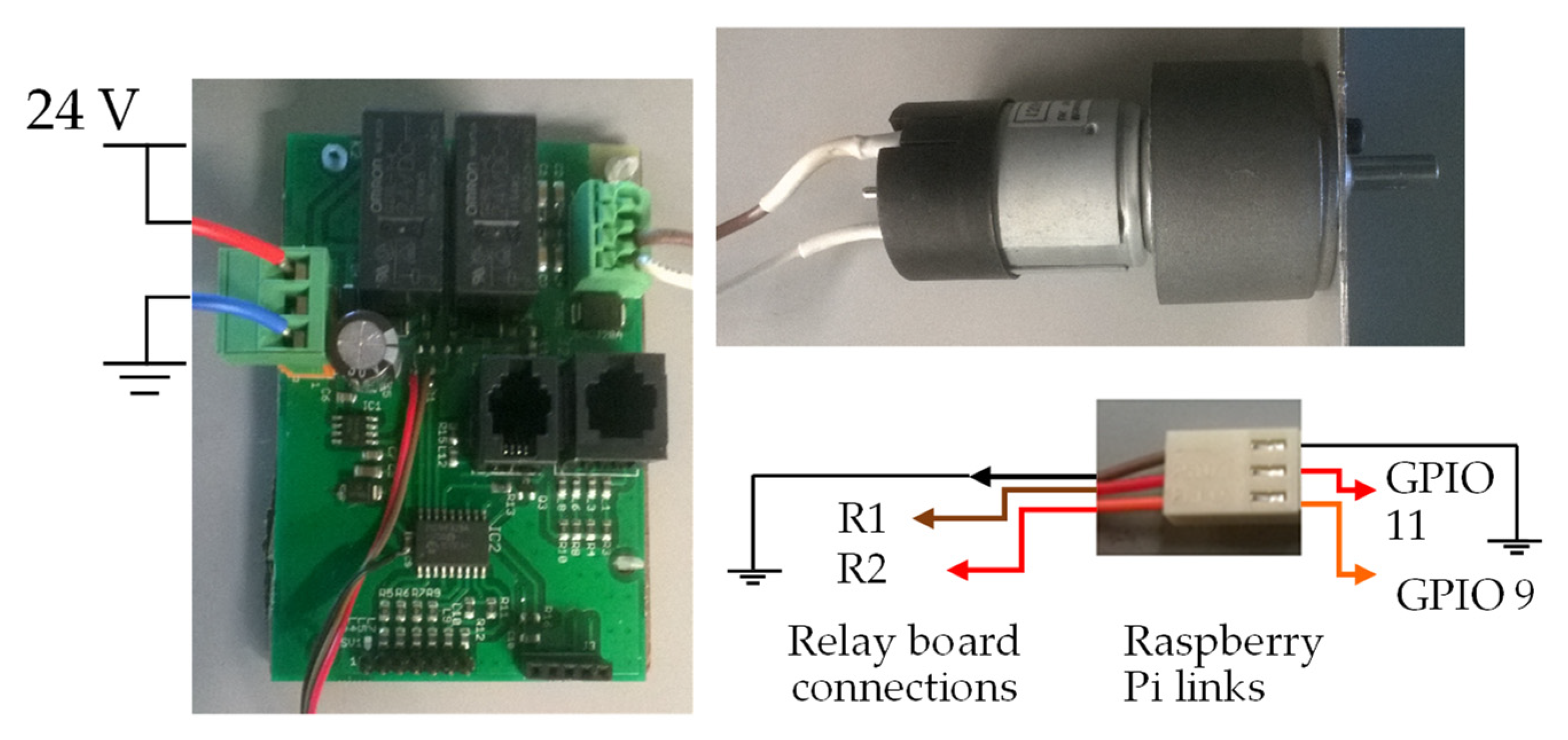

3.3.1. Spine Closing Motor

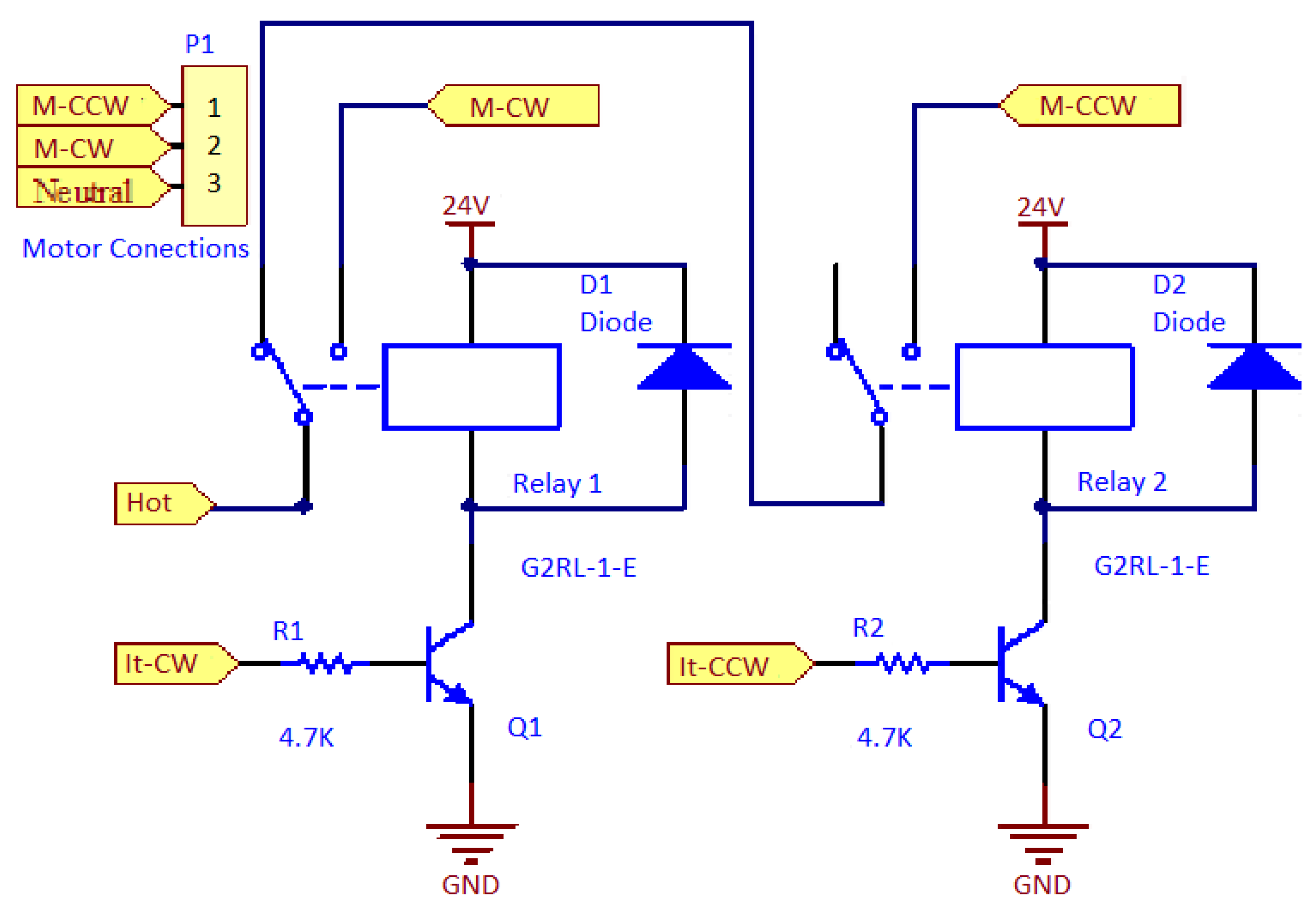

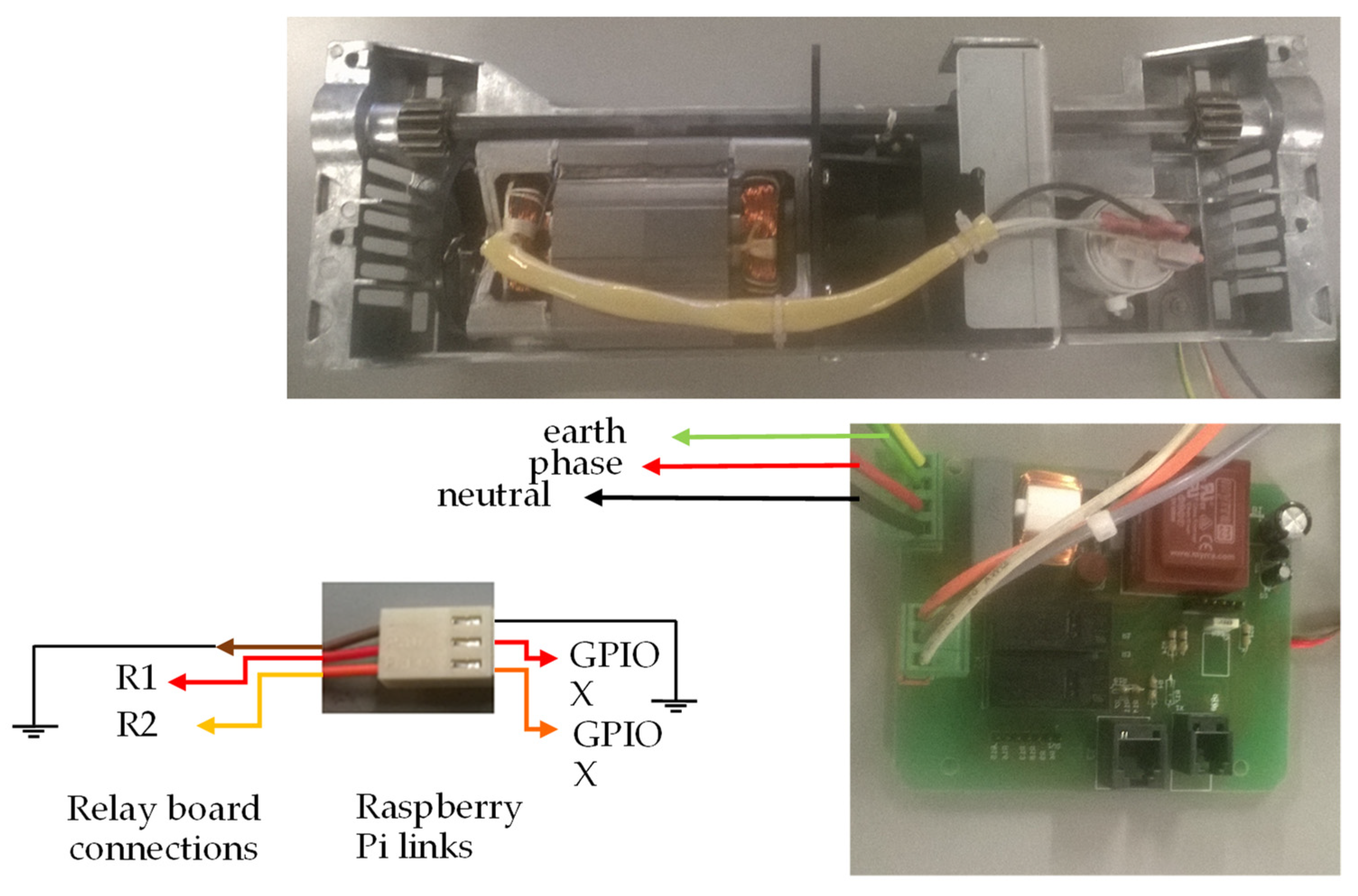

3.3.2. Document Height Adjustment Motor

3.3.3. Document Punching Motor

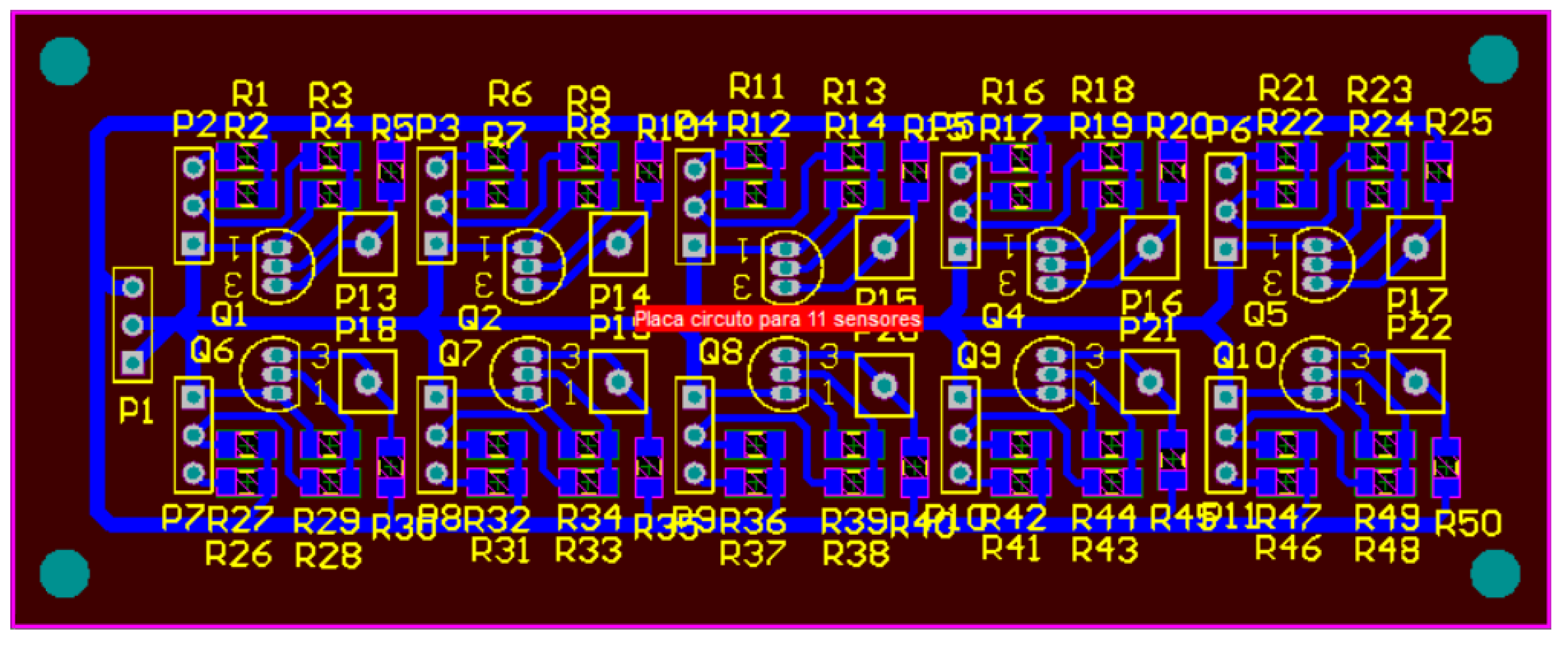

3.4. Wiring Diagram of the Document Thickness Measuring Plate

3.5. Wiring Diagram of the Inserted Spine Plate for Binding

3.6. Document Thickness Measurement System with the Operating Principle of a Potentiometer

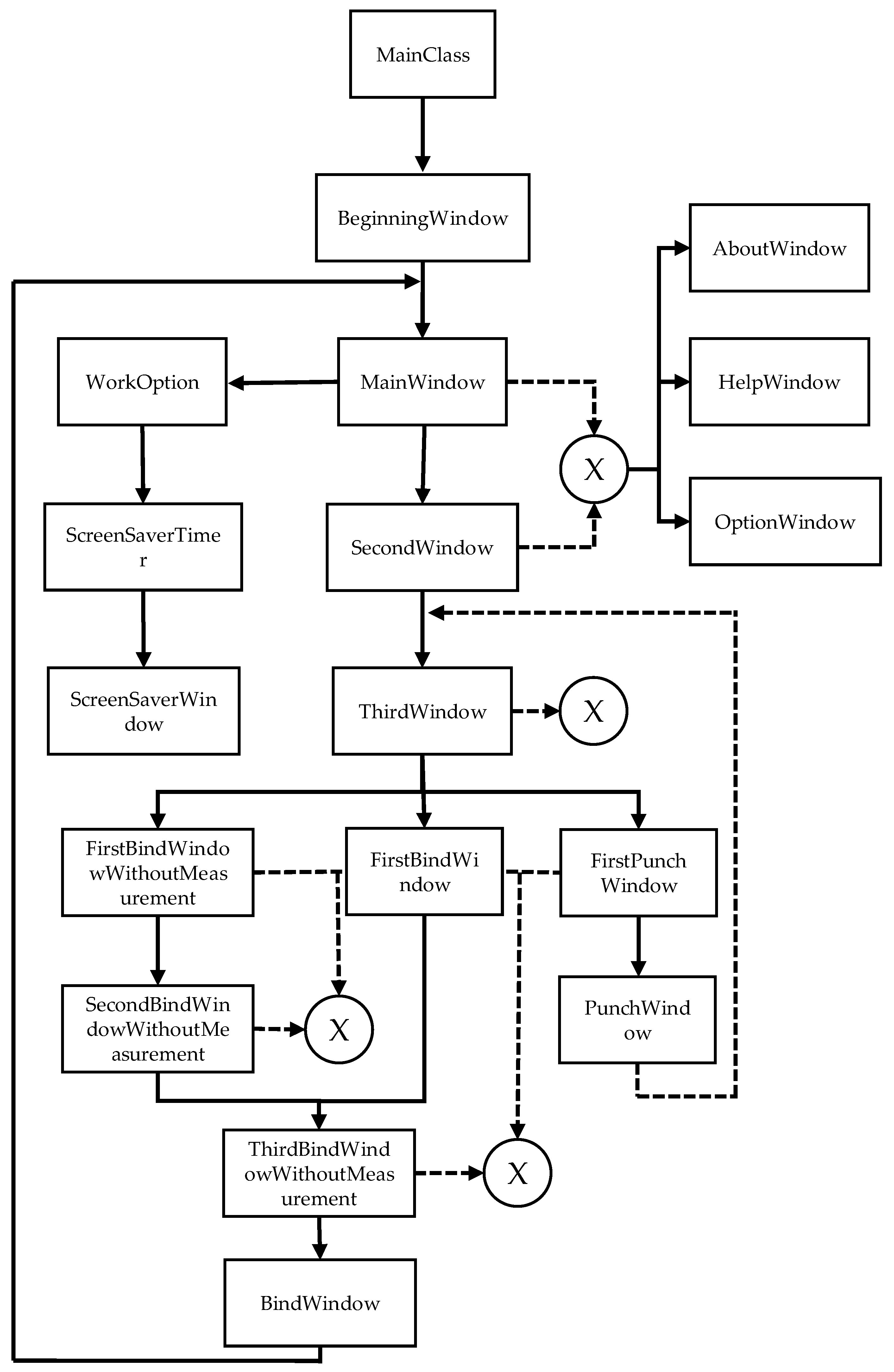

4. BindTronic Control Software

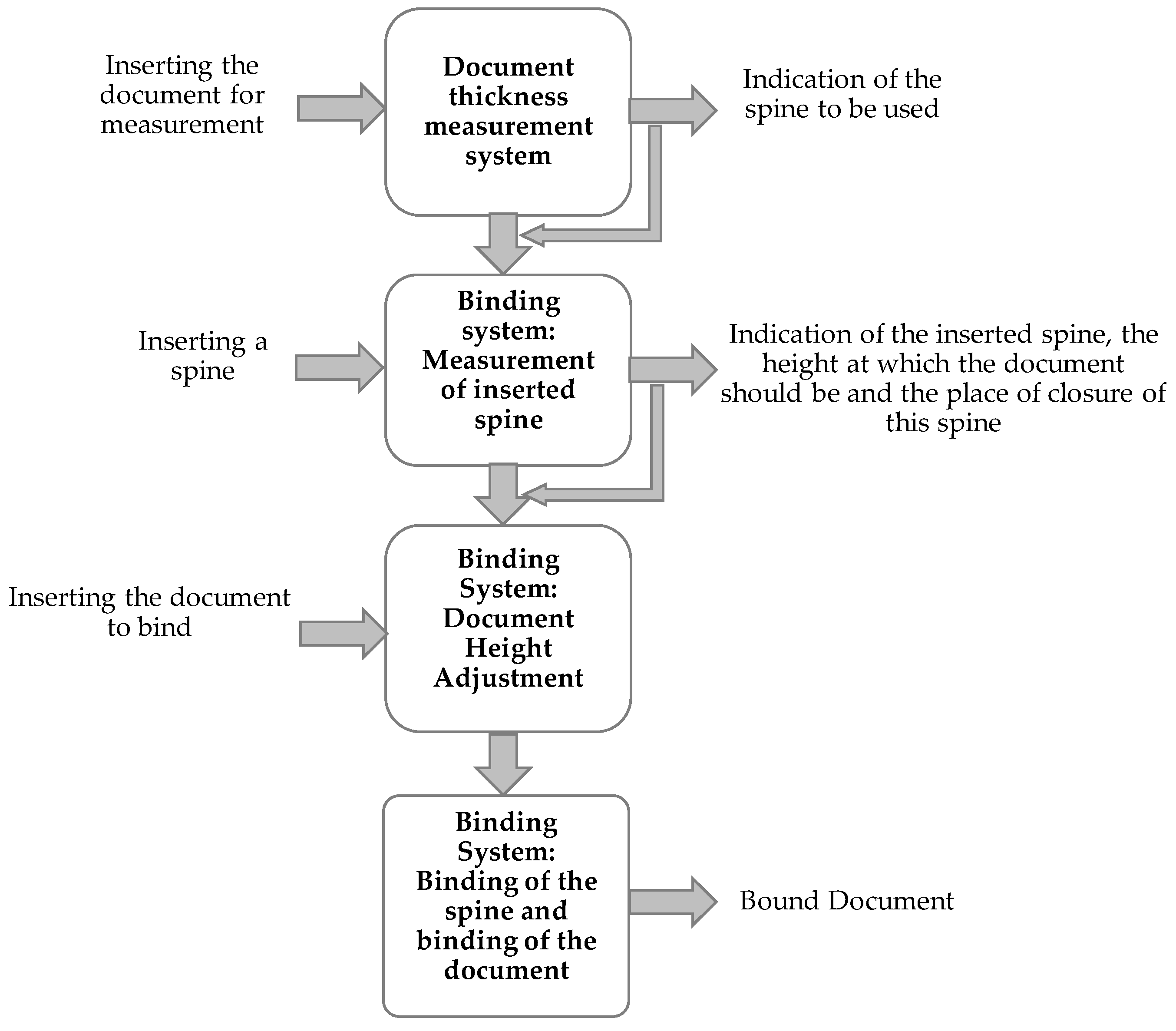

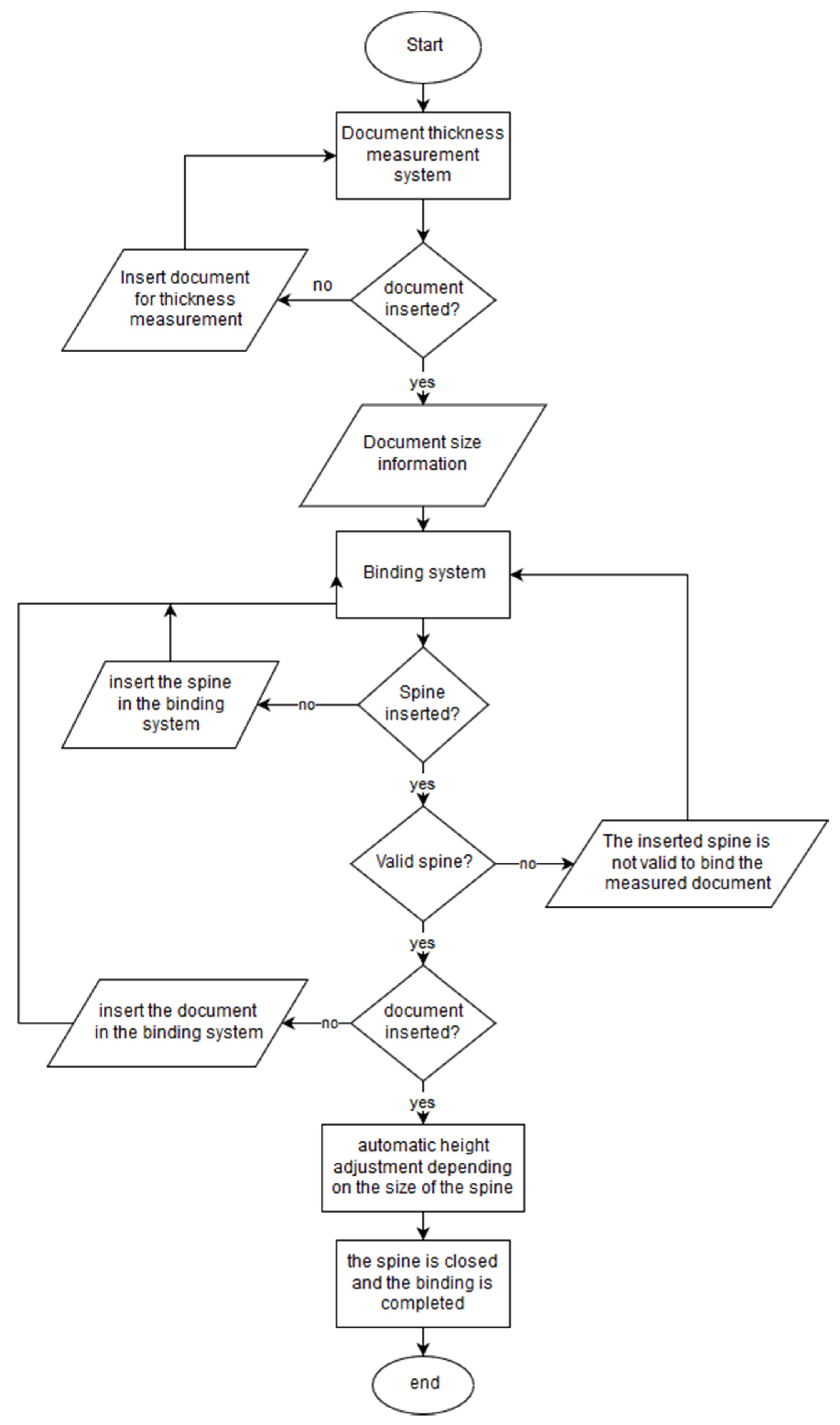

4.1. Working Block Diagram of the Prototype

4.2. Software Features Implemented in the Prototype

- Several languages available;

- Easy addition of more languages;

- Counting of perforations and bindings (totals and chains);

- Reset of current counts;

- Possibility of using or not using the waste tray;

- Reset the capacity of the waste tray automatically when you remove it (5 s);

- Possibility of using or not using the alignment of the sheets (graphical component only);

- Using a screensaver;

- Possibility of changing the time for the screensaver’s performance;

- Automatic document measurement;

- Automatic and autonomous measurement of the spine inserted in the binding equipment;

- Automatic closing of spines;

- Automatic and autonomous adjustment of the height of the document to be bound according to the inserted spine;

- Verification of whether the spine allows binding, warning the user if it does not;

- Return to the initial position of the binding system in the case of failure and the loss of its location (at the beginning of the program, or when binding, if there is a spine inserted and to be measured);

- Possibility of using the equipment without measuring the document (choosing the size of the spine to be used);

- Automatic sheet perforation;

- Return the initial position of the punching system in case of failure and the loss of its location (it is necessary to re-bind, but the system only returns the initial position this time);

- Stopping the punching system, if the blade descends more than 1 s or the blade rises for more than 1 s (fault protection); and

- Class associations.

5. Conclusions

6. Patents

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Figueiredo, L.; Sousa, J.; Machado, J.; Mendonça, J.P. Optimized punches geometry for paper punching systems: An industrial approach. In Proceedings of the 2017 4th International Conference on Control, Decision and Information Technologies (CoDIT), Barcelona, Spain, 5–7 April 2017; pp. 866–871. [Google Scholar] [CrossRef]

- Sousa, J.; Figueiredo, L.; Machado, J.; Mendonca, J.P. Measuring the Punching Profile of a Punch And Bind Machine. In Proceedings of the Advances in Manufacturing; Hamrol, A., Ciszak, O., Legutko, S., Jurczyk, M., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 727–732. [Google Scholar] [CrossRef]

- Sousa, J.; Pinho, T.; Figueiredo, L.; Mendonça, J.; Machado, J. Development and Optimization of a Paper Punching System. In Proceedings of the International Mechanical Engineering Congress and Exposition, Houston, TX, USA, 13–19 November 2015; American Society of Mechanical Engineers: Houston, TX, USA, 2015. Paper No: IMECE2015-52371, V02BT02A028. [Google Scholar] [CrossRef]

- Figueiredo, L.; Sousa, J.; Monteiro, L.; Mendonça, J.; Machado, J. Innovative Mechatronic Approach to Redesign a Punch and Bind Machine. In Advanced Manufacturing; American Society of Mechanical Engineers: Phoenix, AZ, USA, 2016; Volume 2, V002T02A043. [Google Scholar]

- Cox, S. Binding Machines. Patent EP0647186B1, 15 October 1997. Available online: https://patents.google.com/patent/EP0647186B1/de (accessed on 29 November 2021).

- Badham, G.; Morgan, G.O. Binding Machine for Closing Wire Comb Binding Elements. Patent GB2427850A, 10 January 2007. Available online: https://patents.google.com/patent/GB2427850A/en (accessed on 29 November 2021).

- GBC ClickBind Binding Spines|GBC. Available online: https://www.gbceurope.com/en-ax/products/gbc-clickbind-binding-spines_387302e (accessed on 29 November 2021).

- Sakata, T.; Yoshie, T. Binder and Binding Device. Patent EP1512549A1, 9 March 2005. Available online: https://patents.google.com/patent/EP1512549A1/en (accessed on 29 November 2021).

- Knight, C. Binding Machine and Method. Patent WO2004108425A1, 16 December 2004. Available online: https://patents.google.com/patent/WO2004108425A1/en (accessed on 29 November 2021).

- Jervis, R.; James, M.; Hadden, R. A Document Binding Machine. Patent EP2062739A1, 27 May 2009. Available online: https://patents.google.com/patent/EP2062739A1/en (accessed on 29 November 2021).

- Finishers│GBC—GBC Connect. Available online: https://www.gbcconnect.com/us/us/2448/finishers (accessed on 29 November 2021).

- Vogel-Heuser, B.; Hess, D. Guest Editorial Industry 4.0–Prerequisites and Visions. IEEE Trans. Autom. Sci. Eng. 2016, 13, 411–413. [Google Scholar] [CrossRef]

| Manufacturer | Reference | Type |

|---|---|---|

| OMRON | EE-SX1081 | Transmission |

| Reference | Type | Contact Format |

|---|---|---|

| D3V | Reliable Basic Switch with External Lever | SPDT |

| Reference | Power Voltage [V] | rpm |

|---|---|---|

| SG37RS35ZY40 | DC—24 V | 50 |

| Manufacture | Reference | Supply Voltage [V] | Rated Speed [rpm] |

|---|---|---|---|

| Mclennan | 1308-24-250 | DC—24 | 8 |

| Reference | Power Supply [V] | Rpm for 60 Hz | Rpm for 50 Hz |

|---|---|---|---|

| ACC8055Ea-70JB150G10 | 230 V AC | 23 ± 2 | 20 ± 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sousa, J.; Figueiredo, L.; Ventura, C.; Mendonça, J.P.; Machado, J. Development of an Innovative Mechatronic Binder Machine. Sensors 2022, 22, 741. https://doi.org/10.3390/s22030741

Sousa J, Figueiredo L, Ventura C, Mendonça JP, Machado J. Development of an Innovative Mechatronic Binder Machine. Sensors. 2022; 22(3):741. https://doi.org/10.3390/s22030741

Chicago/Turabian StyleSousa, João, Luis Figueiredo, Carlos Ventura, João Pedro Mendonça, and José Machado. 2022. "Development of an Innovative Mechatronic Binder Machine" Sensors 22, no. 3: 741. https://doi.org/10.3390/s22030741

APA StyleSousa, J., Figueiredo, L., Ventura, C., Mendonça, J. P., & Machado, J. (2022). Development of an Innovative Mechatronic Binder Machine. Sensors, 22(3), 741. https://doi.org/10.3390/s22030741