1. Introduction

Many detectors for rare events in particle and astroparticle physics require large interaction volumes, ranging up to cubic kilometers, in order to achieve a reasonable detection rate. However, the larger the volume, the smaller the feasible density of instrumentation. A viable method for reading out detectors with transparent target media is the detection of optical photons emitted by incident particles (or their secondaries) in the form of Cherenkov emission or scintillation light. The prevailing sensor types that are capable of detecting

single photons are photomultiplier tubes (PMTs). They are, for example, deployed in neutrino telescopes, neutrino detectors, and dark matter experiments, such as IceCube [

1], Super-Kamiokande [

2], Borexino [

3], SNO [

4], JUNO [

5], XENON [

6], LUX [

7], DARWIN [

8], and many others. The photosensitive area of a PMT scales approximately linearly with the area of its photocathode, as does the dark current—the dominant source of noise. The peak quantum efficiency of conventional PMTs is around

, which is suboptimal for Cherenkov light, as well as for scintillation emissions from common liquid scintillators based on linear alkylbenzene (LAB) at approximately

[

9] or liquid noble gases, such as xenon or argon, at around

and

, respectively.

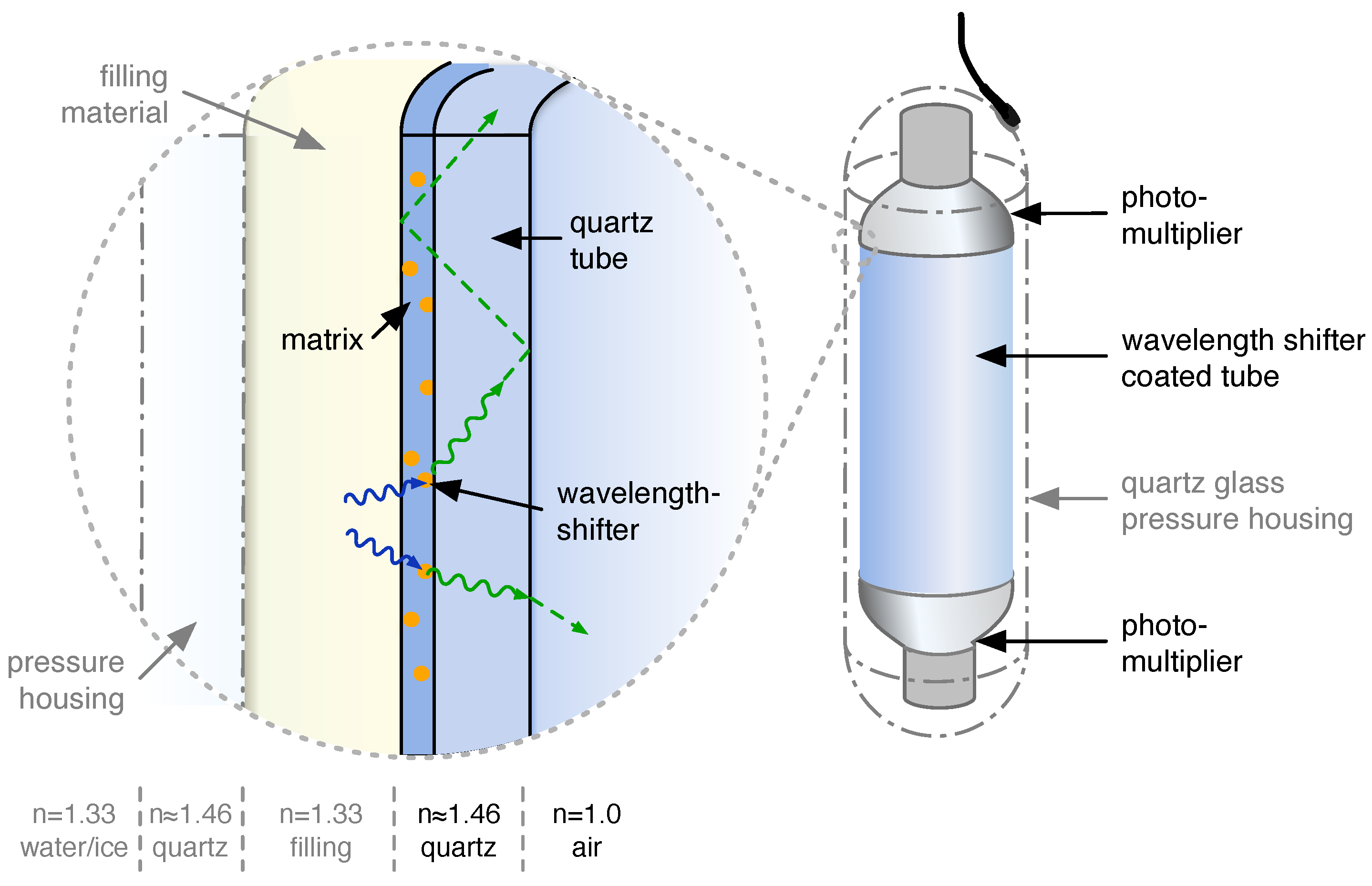

The wavelength-shifting optical module (WOM) has been developed as an alternative sensor for large volume detectors. The WOM, schematically shown in

Figure 1, consists of a transparent tube with photosensors attached to its ends. The tube is coated with a paint containing wavelength-shifting (WLS) organic luminophores and acts as a light collector. The delayed isotropic emission of the WLS molecules circumvents the conservation of phase space as required by Liouville’s theorem (etendue), which otherwise forbids the concentration of a homogeneous light distribution in a smaller area using refractive and reflective optics.

The performance of the WOM is determined by a number of efficiency factors, which are discussed throughout this work. The overall efficiency of the WOM

is defined as the number of detected photons

compared to the number of incident photons

as follows:

UV photons incident on the WLS tube are absorbed in the paint layer and re-emitted isotropically as optical photons with the light yield

. This efficiency depends on the wavelength of the incident photons

, as well as the thickness of the paint layer

d and the concentration of wavelength-shifting molecules

. Values close to unity can be achieved over a large part of the absorption spectrum. A fraction

of the re-emitted photons have an angle with the tube wall smaller than the critical angle for total internal reflection (TIR). The radial symmetry of the configuration ensures that the photon incidence angle on the surface remains constant for each interaction. Therefore, subsequent surface interactions also fulfill the TIR criterion, such that the photons are trapped and guided towards the ends of the tube; see

Figure 2. The TIR fraction

depends on the fraction of the tube’s radius

at which the photons are emitted, as well as on the refractive indices of the tube

and the environment

, which define the critical angle.

While the captured photons are propagating towards the ends of the tube, they can be absorbed or scattered out of the material. This attenuation effect, denoted as , depends on the distance z between the emission point and the end of the tube, as well as the scattering and absorption length (merged into the attenuation length ). Attached to the tube are PMTs that are characterized by their wavelength-dependent quantum efficiency , which depends on the wavelength of the re-emitted photons . A small fraction of photons are lost at the tube–PMT interface, which is denoted as .

In some environments, it is necessary to encapsulate the WOM with a housing, e.g., in deep water or ice, to protect the WOM from pressure. The probability for transmission into the housing through an optional filling into the WOM depends on the wavelength of the incident photons and the refractive indices of the materials enclosing the WLS tube.

All of the efficiencies described above are used to characterize the WOM in this paper. As a baseline in this paper, the following

prototype design is discussed: The tube, coated on the inside surface with wavelength-shifting paint, is 700 mm long, made of quartz [

10] with an outer diameter of 60 mm and a wall thickness of

mm. Two 3.5 inch PMTs [

11] are attached to the ends with optical gel [

12]. An optional quartz pressure vessel (the dimensions of this pressure vessel are given by availability in the laboratory; the dimensions of the WOM tube and the PMT diameters are derived from these) is added around the WOM with 1200 mm length, 110 mm outer diameter, and 10 mm wall thickness. The dimensions and materials of any setup discussed in this text correspond to this prototype design—apart from a few exceptions, which are described accordingly.

In this paper, the different optical processes required to describe and optimize the efficiency of the WOM are discussed in

Section 2. The optimized production of the main component of the WOM, the coating of the wavelength-shifting tube, is described in

Section 3. Finally, characterization and performance measurements of the WOM are presented in

Section 4.

3. Coating

In addition to the optimization of the WOM design based on theoretical considerations, as presented in the previous section, some components are optimized empirically.

The absorption probability for photons incident on a WLS paint layer is given by

Here, d denotes the distance of a photon traveling inside the WLS matrix—i.e., the thickness of the coating—and stands for the cross-section of the wavelength shifter with incident photons of wavelength . The number density of WLS particles along the incident photon path solely depends on the concentration of WLS in the matrix c. The effectiveness of the light absorption can be expressed either in the form of an optical thickness or in terms of an absorption length . The emission efficiency of the WLS paint is denoted as .

In this chapter, the steps taken along the development of the WLS coating are outlined, as are the considerations on the coupling of the tube and PMT. First, the test setup that was built to aid the optimization and to measure the WOM characteristics given in the next section is presented.

3.1. Test Stand

The scope of the test stand is to measure the local sensitivity of a WLS tube and its timing characteristics. The setup is schematically depicted in

Figure 6. In the test stand, a Xenon arc lamp [

15] serves as a light source for wavelengths between 250 nm to 700 nm. The lamp is coupled to a monochromator [

16] of which the slit width is set in such a way that the bandwidth of the selected wavelength is

nm.

The monochromatic beam is chopped to allow for a signal readout via a

lock-in amplifier [

17]. The chopper frequency is fed into two lock-in amplifiers, which demodulate a PMT signal. Subsequently, the light passes a diffusor, which shapes the beam to a homogeneous Gaussian profile. The beam is split up by a beam splitter. The reflected fraction of the beam illuminates a reference photodiode [

18] to correct for lamp intensity variations, while the transmitted fraction is guided into a dark box to illuminate a WLS tube using a liquid light guide [

19]. The end of the light guide in the dark box can be moved along the symmetry axis (the

position) and the azimuthal angle

(note that this is a different definition from that of the variable

in the flattened model in Equation (

5)). The size of the illumination spot is around 1 cm in diameter. Thereby, selected points in

and

on the tube surface can be illuminated to determine the local efficiency. The light is detected at both tube ends using PMTs [

11]. The PMT surface is described in polar coordinates with the radius

r and the angle

.

In this

lock-in setup, the efficiency of the WOM for a given light source position and incident wavelength is calculated as

Here, refers to the PMT output current corrected by the reference diode signal. For the reference measurement, the light source illuminates the PMT directly. The current is measured on the tube radius by varying in a total of steps around the circumference; in our case, . The mean of these measurements is calculated to take the PMT sensitivity variations on the photocathode into account. The resulting currents of signal and the reference measurement are corrected for the wavelength-dependent quantum efficiency of the PMT, as well as for the intensity variations of the light source.

An overview of systematic uncertainties in the efficiency determination in the test stand is given in Ref. [

20]. The largest uncertainty is the coupling of the WOM tube to the PMT using optical gel instead of a gel disc. An overall systematic error of approximately 4% in the efficiency determination for the prototype tube was obtained. This value was obtained by repeatedly coupling the tube and PMT with gel to measure the variance of the one-sided efficiency induced by the losses at the interface

. Additionally, the variation of the paint layer was taken into account (compare Figure 10). The values for the currents

and

are averaged over a time window of

at a chopping frequency of

, and the standard deviation is used as uncertainty.

The described setup can be adjusted for

single-photon readout by replacing the Xe-Lamp, monochromator, and chopper with a 375 nm pico-second pulser [

21]. The pulser is dimmed so that ∼6% of the waveforms recorded with a triggered fast ADC [

22] include one photon signal within the expected time window. For the

single-photon readout, the collection efficiency of the tube

is determined by the ratio:

where

denotes the number of photons detected when illuminating the point

with wavelength

. The number of photons detected when directly illuminating the PMT is denoted by

, and

is the number of photons falsely reconstructed from background light. The stability of the pulser was measured over a 12

cycle, and the light output variance was found to be smaller than 2%, and was thus a subdominant contribution to the overall systematic error. The statistical error was calculated based on the number of measured photons

n for each measurement. Since the same systematics as in the lock-in amplifier setup apply, the estimated systematic error for this setup amounts to approximately 4%.

3.2. Chemical Composition

Wavelength shifting is a special case of photofluorescence. The WLS molecules are excited when absorbing short-wavelength photons. After a decay time on the order of 1 ns to 2 ns [

23] depending on the specific wavelength shifter, the molecule returns to the ground state, and a photon of a larger wavelength is emitted. A fraction of the energy is dissipated non-radiatively.

The WLS paint for the WOM is selected from a large number of variants with regard to the following criteria, as treated in detail in Ref. [

24]:

maximal overlap of the emission spectrum and the sensitivity of the readout PMT;

large Stokes shift, i.e., minimal overlap of the absorption and emission spectra;

maximal transparency of the WLS paint for re-emitted photons;

similar refractive index of the coating and the WLS tube material;

good adhesiveness and mechanical properties;

optical thickness to enable reaching high concentration of WLS film to absorb 100% of the light for a broad spectrum.

The best results are obtained with a solution of toluene containing 213 g/L of the plastic polyethylmethylacrylate (PEMA) [

25], which provides the matrix for the wavelength-shifting molecules, and a wavelength-shifting dye mix of 1.3 g/L Bis-MSB and 2.6 g/L p-Terphenyl per liter (the proportions given apply to the mixing process of the paint; in the paint layer of a coated tube, the proportions differ as the toluene evaporates during drying). The absorption spectrum of p-Terphenyl lies well below the Bis-MSB absorption spectrum. Since the emission spectrum of p-Terphenyl lies within the absorption spectrum of Bis-MSB, adding p-Terphenyl yields a sensitivity enhancement in the lower UV region.

3.3. Coating Process

For the tube material, PMMA (polymethylmethacrylate) and quartz glass are considered due to their optical properties with attenuation lengths for photons of multiple meters [

14,

26]. PMMA and PEMA are both soluble in toluene, which yields a transit region in which the two materials are mixed. This guaranties a strong bond that is able to withstand shearing forces generated by the different coefficients of thermal expansion over a wide temperature range. Since quartz glass is not soluble in toluene, the paint is bonded by van der Waals forces only.

Since the bond between quartz glass and the paint is purely of van der Waals nature, any contamination on the tube surface affects the bonding strength of the paint. When the tube surface is treated with a sequence of citric acid, acetone, and isopropanol, we find good adhesion in the subsequent coating. An alternative method is the usage of caustic soda and cleaning agent [

27]. Both methods yield satisfying results. Current versions of coated quartz tubes have proven to be stable over time. We found no signs of delamination in several freezing cycles. Additionally, no significant deterioration of the paint layer when exposed to laboratory light was observed.

The coating can be applied to the inside or outside of the cylinder. It is also possible to coat both sides, but generally, high enough absorptivity for the incident UV light can be obtained with a single coating. Some major differences between in- and outside coating are summarized as follows:

Coating on the inside shifts the light emission point towards the center, resulting in a reduced capture efficiency, as discussed in

Section 2.1. The performance loss will increase with the thickness of the tube and the refractive index of the environment in which the coated tube is deployed.

While quartz glass has high transmission down to wavelengths of 180 nm, PMMA is generally opaque to light below 300 nm [

28], but in commercial products, it is often doped with additional UV absorbers to reduce aging in sunlight, thus limiting the UV light yield. Quartz glass can therefore be coated on either side, while PMMA performs best when coated outside.

Coating a tube on the inside allows for easier handling. Impurities such as fat or dirt act as scattering centers for photons traveling inside the tube. Under UV light illumination, contaminated areas are clearly visible, presumably because photons couple out of the tube at these sites. The WLS paint is hydrophilic and therefore delaminates as a whole when immersed in water, rendering the tube opaque to light.

In an assembly, an inside-coated tube will not interact chemically with the medium surrounding it, allowing for the surrounding medium to be chosen freely. While embedding the module in a housing can alleviate the problem in a similar way for outside-coated tubes, a filling material is generally required between the housing and the tube (see

Figure 5), transferring the problem to chemical compatibility with the filling material.

In order to apply coatings to tubes, two simple techniques were developed, which are both based on the industrially employed

dip-coating method [

29,

30]. For an external coating, the tube is vertically immersed in the paint and removed at a controlled speed to yield a homogeneous coating of adjustable thickness. Plugs are used to keep the inside of the tube paint free. In order to achieve an internal coating, the tube is filled completely with paint, which is then released at a constant flow rate using a valve. Due to the viscosity of the WLS solution, a higher velocity of extracting the paint in the coating process leads to a thicker paint layer (see Equation (

10)). Both coating procedures are performed at a temperature of (

) °C, and the tubes stay immersed in the paint for 90

before the paint or tube is extracted at a fixed velocity. Both processes are operated in the Landau–Levich–Derjaguin (LLD) regime [

31] where, for sufficiently high viscosity

and coating speed

, the wet-film thickness is given as [

29,

30]

Here,

denotes the density of the paint and

g is the gravitational acceleration. As the solvent evaporates, a dry film of constant thickness

, with

, is deployed on the surface. The relative factor

corrects for the paint densities before and after coating. Aside from its simplicity, it is found that this method yields excellent surface quality. Using profilometer measurements on microscope slides coated with this technique, a small-scale surface roughness of <

and a wavyness of 50–100

on scales of

was found; see

Figure 7.

In

Figure 8, the effects of the variation of coating velocity

and concentration of the wavelength shifter Bis-MBS

on the absorption of the paint layer as a function of the wavelength are shown. To verify that the absorption efficiency follows Equation (

7), we use the

dependency from the lowest absorption curve to estimate the optical depth for the other coating speeds and concentrations. The fit and data values are in good agreement. Comparing the different variations, it can be observed that high paint layer thicknesses lead to an overall broadening of the absorption spectrum up to a maximum where all incident photons are absorbed. In this way, the absorptive properties of the WLS paint can be optimized.

In

Figure 9, the relative light yield of PMTs at the end faces of quartz and PMMA tubes coated on the outside is shown as a function of the coating velocity. The incident light has a wavelength of 375 nm. For quartz, the same tube was coated and measured, and the coating was removed again. This procedure was repeated at different velocities and twice for the highest velocity. For PMMA tubes, the coating could not be removed, so a different individual PMMA tube was coated for each measurement. As soon as nearly complete absorption of the injected light is achieved, a further increase in the coating thickness yields no further increase in efficiency. For the highest velocity, the two efficiencies obtained in the two coatings of quartz glass differ by significantly less than the measurement error, indicating that the coating process is well reproducible. In comparison, the results achieved for PMMA tubes show a larger spread and significantly lower efficiency values (see

Figure 9), indicating a less reliable coating process. The larger value simultaneously obtained for the absorption length for incident light

possibly suggests that the tube surface is partly dissolved by the toluene in the coating process, thus locally diluting the wavelength-shifter concentration.

The obtained absorption length

for quartz can be transformed into an optical depth using Equation (

7) and the estimated paint thickness of 2

(paint layers on both sides of the tube contribute) to be

. This number lies well within the different optical thicknesses obtained in

Figure 8.

In

Figure 10, a measured relative efficiency over half the surface of a quartz tube is shown. The current

is measured in steps of

in azimuth angle

and 10 mm in a cylinder of height

z. The intensity value at a given position

z is divided by the corresponding value at

. In conclusion, an overall relative variation of the paint layer efficiency of ±5% was obtained.

3.4. Absorption and Emission

In order to measure the properties of the WLS coating, quartz microscope slides were coated with a thin film of WLS paint. The coated slides were then illuminated by a 365 nm UV LED focused on the paint layer. The angular distribution of the emission was measured in the UV band (

= 365 ± 10 nm) to test for complete absorption of the UV light, as well as in the optical range (

= 450 ± 40 nm) to investigate the re-emission. In

Figure 11, the measured absorption and emission spectra of the WLS paint are shown together with an absorption measurement of a fully coated quartz tube.

Between 280 and 400 nm, the paint is around 92.7% absorptive for a sufficiently thick paint layer. The overlap between the absorption and emission spectra is a small band between 400 nm to 420 nm. Therefore, by calculating the overlap, a re-emission and consecutive capture probability of 99.61% is expected in air. The emission spectrum peaks around 440 nm, which is the high-quantum-efficiency region for standard PMTs that have a borosilicate window and a bialkali photocathode.

3.5. Deterioration

The setup described in

Section 3.4 was further used to explore possible deterioration of the paint layer due to high UV exposure. It was found that focusing the light output of the diode with 100 mW on a spot size of 1 mm

over several hours led to a deterioration of the paint layer. A diffuse illumination of the entire slide with 1250 mm

using the same light intensity showed no damaging effects on a time scale of days. In conclusion, with a damage threshold on the order of mW/mm

2×h deterioration of the paint due to illumination is not a limiting factor. The UV light intensity in detector experiments in which the WOM is a suitable light sensor will be orders of magnitude lower.

Degradation of efficiency was not found either with time or after exposing the tubes to cold temperatures.

3.6. Optical Coupling

In order to minimize photon losses at the interface between the end face of the WOM tube and PMT glass, different methods of optically coupling the two components were used. For repeatability of different experiments, an optical coupling gel [

12] was used in most experiments. However, for a deployable WOM, where a disassembly of the module is not desired, optical glue [

33] is the preferred choice. The refractive index of the cured glue was chosen to lie between quartz glass (

) and borosilicate glass (

, used for the PMT surface) to minimize Fresnel losses at the interface. It should be noted that flat-surface PMTs are preferable when using optical glue, since spherical PMTs require chamfered ends of the WLS tubes to fit the curvature of the PMT perfectly. If this is not the case, cracks in the glue layer are observed, which likely reduce bond strength and transmission efficiency of the glue. Given the transmission from the datasheet and the Fresnel losses at the interface (calculated using the angular distribution of the light output of the WOM from simulation), a transmission probability of

> 90% is expected when using optical glue for the coupling.

It would be desirable to concentrate the light emission of the WOM from the tube cross-section onto a compact area, allowing one to further reduce the photocathode area of the readout PMT. While conservation of etendue does not prohibit this if the cross-sectional area is preserved, a viable solution was not found. Starting from theoretical calculations [

34], several approaches have been investigated in simulations [

13,

35] and experiments [

36]. It was found that all lead to severe efficiency losses (in simulation, this is mostly due to photons being reflected back into the tube) and are therefore not suitable for the WOM design.

4. Characterization

In order to compare the WOM with other light sensors, measurements of its characteristics were conducted, i.e., the one-sided efficiency

(see Equation (

5)), the transit time spread, and the dark noise. The effective area and the signal-to-noise ratio (SNR) were derived from these values, as well as the efficiencies discussed in the previous sections.

4.1. Efficiency

In the absence of light reflected from the other end of the tube, the efficiency measured with the test stand described in

Section 3.1 can be be identified with the one-sided efficiency in Equation (

5). The efficiency of the WOM as a function of the

z-position is determined using the

lock-in setup (Equation (

8)) and the

single-photon setup (Equation (

9)) independently for the same WLS tube. The results of both measurements overlap within their respective uncertainties. In

Figure 12, the measured efficiency is shown as a function of the cylinder height

z obtained for the 700 mm long, 60 mm outer diameter prototype quartz tube described in

Section 1. The tube was coated on the inside at a speed of 25 mm s

−1. Using the obtained efficiency as a function of the distance

z, the

flattened model (see

Section 2.2) was used as a fit function in conjunction with a normalization constant

N as an additional fit parameter. The constant

N accounts for light losses independently of the position along the tube

z.

The respective fits lead to attenuation lengths of () mm and () mm and normalization constants of ()% and ()%. The mean and standard deviation obtained for each PMT measurement result in an attenuation length of and a normalization constant of . Several factors contribute to the deviation of N from unity:

Overlap between absorption and emission spectra of the WLS paint leads to re-absorption of emitted photons with an estimated 0.39% relative efficiency loss.

Some efficiency is lost due to the inside coating of the tube (see Equation (

4) and

Figure 4). For the prototype, a reduction in capture efficiency

compared to the outside coating of 4.2% is obtained.

Interface losses are calculated using the difference in refractive indices between the tube () and glass of the PMT () together with the angular distribution on the end faces from the simulation. Averaging between s- and p-polarized transmission yields a relative loss of .

Concluding, aside from the aspects discussed here, only minor additional efficiency losses may occur, and in air, of photons can reach the end of the prototype tube.

4.2. Transit Time Spread of Photons

Using the

single-photon setup described in

Section 3.1, the transit time spread of photon coupling into the WLS tube is measured as a function of the distance to the PMT

z. Here, the arrival time of each individual photon is calculated as the first bin in which the recorded waveform amplitude reaches half of the peak amplitude in the photon event (

constant fraction discriminator). The transit time spread is the distribution of the individual arrival times. Measurements were taken on a 900 mm long outside-coated PMMA tube in increasing distance between the PMT and light entry point. The light pulser [

21] had a full width at half maximum (FWHM) of

ns, and the sampling time step of the ADC digitizing the PMT output was 1 ns. The time resolution of the WOM is a convolution of three effects [

37]:

Time resolution of the PMT, which is measured to be a Gaussian profile with ns.

Absorption and re-emission of the WLS paint measured to be an exponential decay with

ns (in accordance with Ref. [

23]). For the lower UV

, where the light needs to be absorbed and shifted by p-Terphenyl first (as mentioned in

Section 3), an additional exponential decay with a time constant of around 1 ns is expected.

Photon trajectory path length distribution inside the tube depending on the absorption length of the material.

The final result, together with the FWHM of the distribution, is shown in

Figure 13. The transit time spread of the full module has an FWHM of approximately

ns (a fit with a symmetric Gaussian gives

ns). The dominant contribution is caused by the photon propagation in the tube. A trend towards larger time delays for increasing distances

z between PMT and the light entry point for the baseline response time can be observed.

4.3. Noise

The background noise of the WOM comprises the dark noise of the PMT and the scintillation noise caused by radioactive decays in the tube glass and, optionally, the glass of the housing. A climate chamber was used to measure the PMTs’ dark noise rate at different temperatures. The PMTs were wrapped in black cloth and enclosed in a metal box to prevent impact from background light and radio frequency interference (RFI). To estimate the noise rate of the PMTs, a single photo-electron (SPE) spectrum was obtained from a measurement over time. An exponential together with a Gaussian was fitted to the data, and the number of photons under the Gaussian distribution was taken. The noise rate was then estimated by dividing the number of photons by the dead-time-corrected measurement length in seconds. The chosen PMTs had dark noise rates at °C of .

For the choice of the pressure vessel, quartz glass samples from different companies were tested. For the quartz glass of the prototype [

10], a dark noise rate of 6 Hz kg

−1 was measured at room temperature; thus,

for the

tube and

for the

housing in the prototype design.

4.4. Effective Area

The mean projected effective area is defined here by

where

photons are emitted from a plane that is uniformly rotated around the detection device, and of these,

will be recorded by the device.

The effective area of a single PMT with a diameter of 3.5 inch (see Ref. [

11]) is obtained by deriving the sensitive projected area for isotropic illumination using the MC simulation described in

Section 2.3. Using a quantum efficiency of 18% averaged over the WLS emission wavelengths (

to

) and cathode area, the effective area is approximately

in water, ice, or air as environment.

For a WOM in the prototype geometry (see

Section 1), all losses from optical propagation into and in the WOM tube, as summarized in Equation (

1), are multiplied by the projected sensitive area. The WLS efficiency is taken from the slide measurement in

Figure 11. The fraction of captured photons

is derived using Equation (

3). The attenuation during propagation in the tube

in dependence on the distance to the tube end is taken from the data shown in

Figure 12, where the TIR effect is factored out. The PMT efficiency is chosen as above, and the loss at the tube to glue or at the gel to PMT interfaces is chosen to be

(compare with

Section 3.6). Then, the effective area of the WOM is approximately

in water or ice and

in air, averaged over the wavelength range of

to

.

In the evaluated design, the effective area of the WOM exceeds the effective area of the single PMT by a factor of approximately

in ice and

in air. The wavelength-dependent effective area of the WOM and a single PMT is shown in

Figure 14. The Cherenkov spectrum (without attenuation in medium) is shown in parallel to illustrate the advantage of an enhanced sensitivity at a lower wavelength. The ratio of the average effective area improves to a factor of approximately

in ice and

when weighted with the Cherenkov spectrum.

The effective area scales linearly with the diameter of the tube. The scaling of the effective area in dependence on the WOM length saturates due to the attenuation of photons during propagation in the tube, as shown in

Figure 15. In reality, the dimensions are further restricted by several limitations: The dip-coating station would need to be scaled; glass tubes of appropriate quality are limited in diameter due to manufacturability; the high weight and bulkiness of the device complicate handling in the laboratory and during deployment.

4.5. Signal-to-Noise Ratio

In order to calculate the signal-to-noise ratio (SNR) of the WOM in comparison to a single PMT, the averaged effective area from

Section 4.4 is used as signal strength, and the sum of the noise measurement in

Section 4.3 of all components is used for the denominator. In practice, the noise of the WOM components would not sum up, at least not for bright signals, because one would add a coincidence requirement for photons hitting both PMTs, which should reduce the noise significantly. Here, noise rates are summed up conservatively.

For the WOM SNR, this calculation yields improvement factors of approximately or compared to a single PMT embedded in ice or air. Weighting the effective area with a Cherenkov spectrum (without photon attenuation in medium) would improve the SNR even further. The corresponding improvement factors are approximately in ice and in air.

5. Conclusions, Applications, and Outlook

In this work, a novel photosensor concept is described in which PMTs are complemented with a tube with wavelength-shifting coating in order to enhance the signal-to-noise ratio. It is demonstrated that consistent coatings can be applied in a simple procedure to glass tubes, which allows one to effectively convert the UV fraction of the incident spectrum. Theoretical studies and experimental work were conducted to understand all features of this concept and its performance in detail. In particular, it is shown that, in air, % of the converted photons can be detected at the end of the prototype tube. This simple concept can thus be applied to significantly enhance the light collection area of any light sensors. As the WLS tube does not add significantly to the dark noise, for the prototype design, this leads to improvement factors in the Cherenkov weighted signal-to-noise ratio of in ice and in air. As a side effect, the sensitivity of the WOMs is improved in the UV, which is particularly beneficial for the detection of Cherenkov or scintillation light by matching the emission spectrum of the WLS paint with the PMT wavelength sensitivity. Aside from the PMT, the cost of the module is dominated by the coated glass tube, while expenses of the paint and glue are insignificant due to the small amounts required for each module. The transit time spread of detected photons is wider than for bare PMTs because it is smeared predominantly by the propagation time in the tube. While the photosensors at the tube ends can be read out independently, only a single photon is generated in the wavelength-shifting process, so in single-photon detection mode, no information about the incidence position along the tube can be obtained.

The prototype design does not reach the maximal sensitivity possible in an optimized geometry due to practical considerations. A wider and longer tube, if manageable, would improve the SNR. Silicone photomultipliers (SiPMs) could be chosen for the tube readout in bright conditions, e.g., when deploying in liquid scintillator as a detector medium. Light guides were evaluated to couple smaller PMTs to wider tubes. However, this has stringent theoretical limitations and proved complicated in practice.

One prototype module enclosed with a vessel was built using simple

off-the-shelf electronics as

proof of concept following the prototype design described in this work; see

Figure 16. Hydrogel [

38] was used as a filling material to improve the optical properties of the module. The module was deployed in the Canadian sea at a depth of

within the Ocean Network Canada [

39]. It operated stably at the given conditions and provided data on the local bio-luminescence.

Another application for which prototypes are already at hand is the envisioned SHiP experiment [

40,

41]. SiPMs are coupled to the WLS tubes, which are to be deployed in the veto chamber of the experiment.

For the upcoming IceCube Upgrade, which extends the low-energy infill of IceCube, a WOM with an improved design that has been adjusted to the environmental needs has been designed. Twelve modules with

long pressure vessels, 5-inch PMTs, and customized electronics have been developed and will be deployed [

42].