Selection of Surge Protection Module Components for Communication Lines Using a Genetic Algorithm

Abstract

:1. Introduction

2. Problem Description

3. Test Case

4. Protection Circuit Topology and Its Parameter Domain

- R4 is a CAN terminator of 120 Ω;

- C3 is the capacitance between the wayside device and a ground plate (its value is estimated based on experience, i.e., during similar tests at the laboratory);

- An inductor module is a specially designed circuit for reducing current emission;

4.1. Transils (D1, D2, D3, and D4)

4.2. Resistors (R5, R6, R9, and R10)

- —power dissipated on considered resistors, i.e., R5, R6, R9, and R10;

- —voltage on the considered resistor;

- —resistance of the considered elements.

4.3. Capacitor (C4)

4.4. Component Limitations

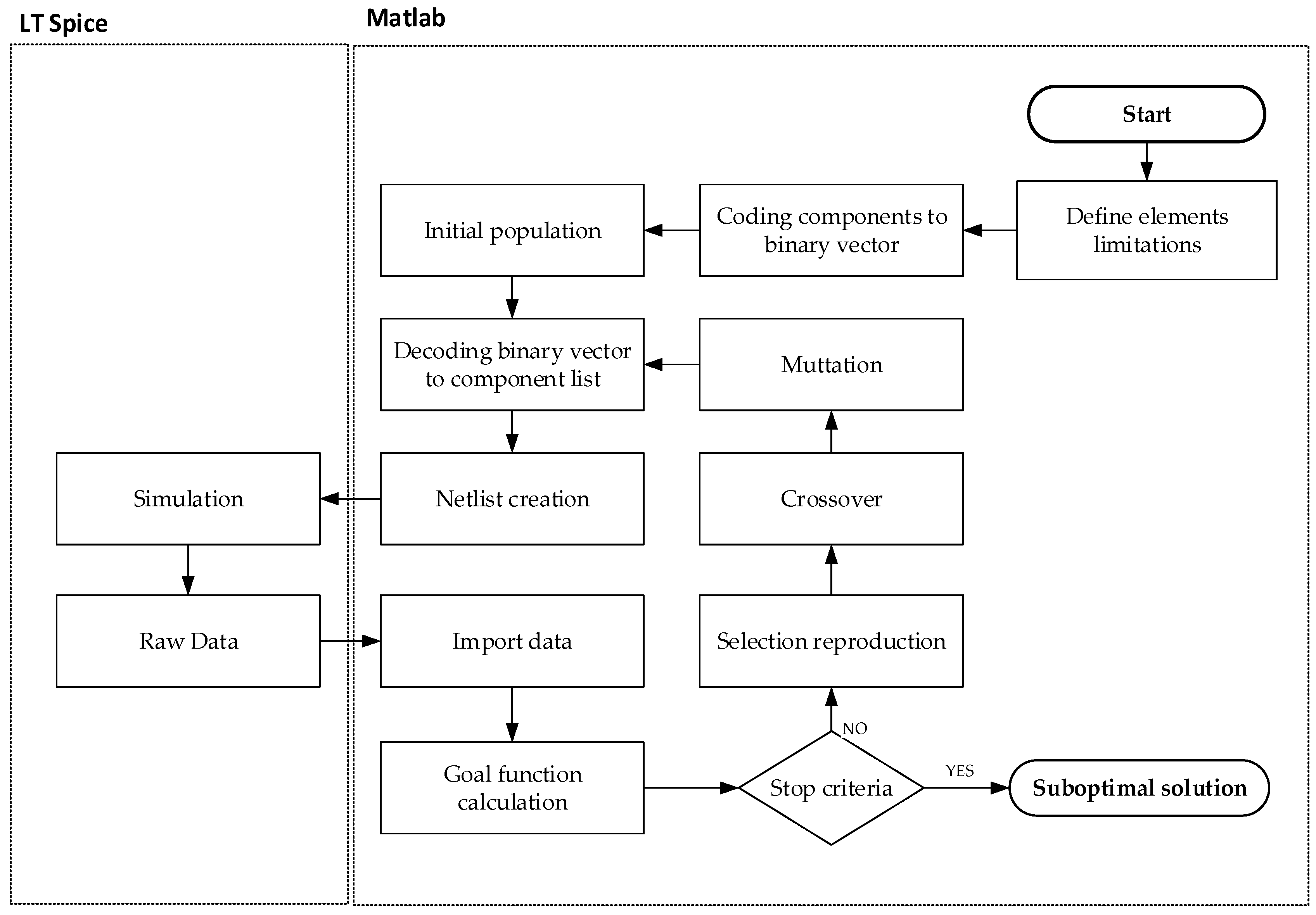

5. Algorithm Description

5.1. Binary Input Vector

- Bits 1:4—representing resistors R9 and R10 simultaneously. Each binary number corresponds to the following resistance in the predefined set (see Section 4.2);

- Bits 5:7—representing resistors R5 and R6 simultaneously. Each binary number corresponds to the following resistance in the predefined set (see Section 4.2);

- Bits 8:12—corresponding D4 to one of 32 diodes (see Section 4.1);

- Bits 13:17—corresponding D1 to one of 32 diodes (see Section 4.1);

- Bits 18:22—corresponding D2 and D3 simultaneously to one of 32 diodes (see Section 4.1);

- Bits 23:25—representing C4 possible configuration described in Section 4.3.

- Selection specifies how the genetic algorithm selects parents for the next iteration. The default option is set to “selectionstochunif”, i.e., parents are chosen randomly with uniform distribution;

- Reproduction describes how the genetic algorithm creates the next generation. “EliteCount” is corresponding to the number of the best parents, which will be used in the next generation. It was set to 5% of population size;

- Crossover options specify creating crossover child from parents, for the next generation. It was set to “crossoverscattered”, which uses a random binary vector to combine two individuals, to form a child for the next generation;

- Mutation is responsible for chromosome defects; it is set to “mutationgaussian”, which uses Gaussian distribution to make small changes to the parent vector.

5.2. Fitness Function Description

- —a calculated value of i-th parameter for component k, e.g., power peak for R9;

- —a maximum value of i-th parameter for component k, e.g., voltage, power, or current defined in the manufacturer documentation without margin;

- —a valuation parameter in respect of components in group A (Figure 3) it can be replaced with the maximum ratio factor (110% of maximum value [26]). In the case of the other one (group B), it was defined as 50% ([26]) of the value declared by the manufacturer. This factor represents the valuation parameter of component damage [26];

- —number of analyzed parameters per single component, e.g., for R9 = 3, namely average power, peak power, and voltage. = 1, …, , where is the following index of the simulated parameter;

- —number of analyzed components, in the diagram presented (Figure 3) Indicator = 1, 2, …9;

- —penalty factor can take values 1 or 26, i.e., if then , otherwise . The penalty factor (α) has been set to 26, so if the value of a parameter is above the limitation multiplied by ratio factor, the goal function will take 26 instead of the ratio of the calculated value to the limit to avoid a situation when one component is overloaded but there are no limitations for the others. Calculation is presented in Table 2.

- —stands for a circuit with infinitely large limitation, i.e., the result equaling zero is impossible;

- —stands for a circuit with all the components working with maximum limitation;

- indicates an unsuitable solution due to fact that a single parameter exceeds its critical margin.

| Group | Component | Factory Ratio | Voltage Limitation | Current Limitation | Average Power Limitation | Peak Power Limitation | Number of Critical Parameters |

|---|---|---|---|---|---|---|---|

| A | C4 | 110% | ✓ | 1 | |||

| GDT | 110% | ✓ | 1 | ||||

| R9 | 110% | ✓ | ✓ | ✓ | 3 | ||

| R10 | 110% | ✓ | ✓ | ✓ | 3 | ||

| D4 | 110% | ✓ | ✓ | 2 | |||

| B | R5 | 50% | ✓ | ✓ | ✓ | 3 | |

| R6 | 50% | ✓ | ✓ | ✓ | 3 | ||

| D1 | 50% | ✓ | ✓ | ✓ | 3 | ||

| D2 | 50% | ✓ | ✓ | ✓ | 3 | ||

| D3 | 50% | ✓ | ✓ | ✓ | 3 | ||

| Maximum sum of resistors in lines (R9 + R10 + R5 + R6) | 1 | ||||||

| Total Sum: | 26 | ||||||

6. Result Discussion

- D1: SMDJ6.0CA peak current is 3.505 A vs. 1456.5 A (limit value declared by the manufacturer);

- Peak power for D4 is 646.14 W (maximum 5 kW), and for D1 is 24.80 W (maximum 5 kW).

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Andrusca, M.; Adam, M.; Dragomir, A.; Lunca, E. Innovative Integrated Solution for Monitoring and Protection of Power Supply System from Railway Infrastructure. Sensors 2021, 14, 1891. [Google Scholar] [CrossRef] [PubMed]

- Perin, I.; Nussey, P.F.; Cella, U.M.; Tran, T.V.; Walker, G.R. Application of Power Electronics in Improving Power Quality and Supply Efficiency of AC Traction Networks. In Proceedings of the IEEE 11th International Conference on Power Electronics and Drive Systems, Sydney, Australis, 9–12 June 2015; pp. 1086–1094. [Google Scholar]

- Nakahata-Medrado, A.; Schanen, J.-L.; Guichon, J.-M.; Jeannin, P.-O.; Batista, E.; Desportes, G. Optimization of a Gate Distribution Layout to Compensate the Current Imbalance Generated by the 3D Geometry of a Railway Inverter. Energies 2021, 14, 1891. [Google Scholar] [CrossRef]

- Tian, Z.; Zhao, N.; Hillmansen, S.; Su, S.; Wen, C. Traction Power Substation Load Analysis with Various Train Operating Styles and Substation Fault Modes. Energies 2020, 13, 2788. [Google Scholar] [CrossRef]

- Steczek, M.; Chudzik, P.; Szeląg, A. Application of a Non-Carrier-Based Modulation for Current Harmonics Spectrum Control during Regenerative Braking of the Electric Vehicle. Energies 2020, 13, 6686. [Google Scholar] [CrossRef]

- Tao, H.; Hu, H.; Wang, X.; Blaabjerg, F.; He, Z. Impedance-Based Harmonic Instability Assessment in a Multiple Electric Trains and Traction Network Interaction System. IEEE Trans. Ind. Appl. 2018, 54, 5083–5096. [Google Scholar] [CrossRef]

- Mzulwini, M.; Awodele, K. Application of PSB, PSAT and ATP Tools in Traction Surge Arrester Selections. In Proceedings of the 2019 Southern African Universities Power Engineering Conference/Robotics and Mechatronics/Pattern Recognition Association of South Africa (SAUPEC/RobMech/PRASA), Bloemfontein, South Africa, 28–30 January 2019; pp. 719–725. [Google Scholar]

- Markowska, R.; Wróbel, Z. Selected Issues of Safe Operation of the Railway Traffic Control System in the Event of Exposition to Damage Caused by Lightning Discharges. Energies 2021, 14, 5808. [Google Scholar] [CrossRef]

- Morita, G.; Hirai, S.; Michishita, K. Lightning Protection of Control Board Equipped with Electronic Equipment. In Proceedings of the 34th International Conference on Lightning Protection (ICLP), Rzeszow, Poland, 2–7 September 2018; pp. 1–6. [Google Scholar]

- Morita, G.; Akagi, M.; Imamura, H.; Tanaka, H.; Kawahara, K.; Matsui, M.; Sakai, Y. Experimental Study on New Type Earth Mesh in Railway Substations Aimed at Lightning Protection. In Proceedings of the 33rd International Conference on Lightning Protection (ICLP), Estoril, Portugal, 25–30 September 2016; pp. 1–6. [Google Scholar]

- Arai, H.; Fujita, H.; Ono, Y. Effect Evaluation of Lightning Protection Measures on Train Detectors for Level Crossing System. In Proceedings of the 34th International Conference on Lightning Protection (ICLP), Rzeszow, Poland, 2–7 September 2018; pp. 1–7. [Google Scholar]

- Fukaya, D.; Matsumoto, S.; Hayashiya, H. Lightning Surge Simulation of Pole Transformers Used for Electrical Railway. In Proceedings of the 23rd International Conference on Electrical Machines and Systems (ICEMS), Hamamatsu, Japan, 24 November 2020; pp. 795–799. [Google Scholar]

- Kisielewicz, T.; Piparo, G.B.L.; Mazzetti, C. Probability of Surge Protective Device Systems to Reduce the Risk of Failure of Apparatus Due Direct Flashes to Overhead Low Voltage Lines. In Proceedings of the 33rd International Conference on Lightning Protection (ICLP), Estoril, Portugal, 25–30 September 2016; pp. 1–5. [Google Scholar]

- Acampora, G.; Landi, C.; Luiso, M.; Pasquino, N. Optimization of Energy Consumption in a Railway Traction System. In Proceedings of the International Symposium on Power Electronics, Electrical Drives, Automation and Motion, Taormina, Italy, 23–26 May 2006; pp. 1121–1126. [Google Scholar]

- Grzechca, D.; Zieliński, D.; Filipowski, W. What Is the Effect of Outer Jacket Degradation on the Communication Parameters? A Case Study of the Twisted Pair Cable Applied in the Railway Industry. Energies 2021, 14, 972. [Google Scholar] [CrossRef]

- Janu, P.; Jalovecky, R. Proposal of Power Supply Monitoring Unit with CANaerospace Protocol. In Proceedings of the Electrical Systems for Aircraft, Railway and Ship Propulsion, Bologna, Italy, 19–21 October 2010; pp. 1–5. [Google Scholar]

- Jin-Liang, H.; Wei-Han, W. Adopting Line Surge Arresters to Increase Lightning-Withstand Levels of Transmission-Lines. In Proceedings of the TENCON ’93. IEEE Region 10 International Conference on Computers, Communications and Automation, Beijing, China, 19–21 October 1993; pp. 450–453. [Google Scholar]

- Ahmad, N.I.; Ali, Z.; Ab. Kadir, M.Z.A.; Osman, M.; Zaini, N.H.; Roslan, M.H. Analysis of Lightning-Induced Voltages Effect with SPD Placement for Sustainable Operation in Hybrid Solar PV-Battery Energy Storage System. Sustainability 2021, 13, 6889. [Google Scholar] [CrossRef]

- Garmabaki, A.H.S.; Thaduri, A.; Famurewa, S.; Kumar, U. Adapting Railway Maintenance to Climate Change. Sustainability 2021, 13, 13856. [Google Scholar] [CrossRef]

- Wróbel, Z.; Jagiełło, A.S. The Risk of Lightning Losses in a Structure Equipped with RTC Devices According to the Standard EN 62305-2.2008. Energies 2021, 14, 1704. [Google Scholar] [CrossRef]

- Montanes Bellosta, L.C.; Garcia Garcia, M.A.; Llombart Estopinan, A.; Sanz Badia, M.; Garcia-Gracia, M. Simulation of Surges on Power Lines Using SPICE and EMTP: A Comparative Study. In Proceedings of the MELECON ’98, 9th Mediterranean Electrotechnical Conference, Tel-Aviv, Israel, 18–20 May 1998; Volume 1, pp. 202–206. [Google Scholar]

- Shi-ping, S.; Qi-feng, D. Study of Lightning Surge Over-Voltage at Substation. In Proceedings of the 4th International Conference on Electric Utility Deregulation and Restructuring and Power Technologies (DRPT), Weihai, China, 6–9 July 2011; pp. 1883–1886. [Google Scholar]

- PN-EN 50121-4:2017-04. Available online: https://sklep.pkn.pl/pn-en-50121-4-2017-04p.html (accessed on 16 August 2021).

- PN-EN 61000-4-5:2014-10/A1:2018-01. Available online: https://sklep.pkn.pl/pn-en-61000-4-5-2014-10-a1-2018-01e.html (accessed on 16 August 2021).

- Carobbi, C.F.M.; Bonci, A. Elementary and Ideal Equivalent Circuit Model of the 1, 2/50-8/20 Μs Combination Wave Generator. IEEE Electromagn. Compat. Mag. 2013, 2, 51–57. [Google Scholar] [CrossRef]

- Miller, D.; Kennel, R.; Reddig, M.; Schlenk, M. Surge Immunity Test Analysis for Modern Switching Mode Power Supplies. In Proceedings of the IEEE International Telecommunications Energy Conference (INTELEC), Austin, TX, USA, 23–27 October 2016; pp. 1–6. [Google Scholar]

- Littelfuse_GDT_SG_Datasheet_pdf-319337.Pdf. Available online: https://pl.mouser.com/datasheet/2/240/Littelfuse_GDT_SG_Datasheet_pdf-319337.pdf (accessed on 16 September 2021).

- Littelfuse_TVS_Diode_SMDJ_Datasheet_pdf-475081.Pdf. Available online: https://pl.mouser.com/datasheet/2/240/Littelfuse_TVS_Diode_SMDJ_Datasheet_pdf-475081.pdf (accessed on 8 September 2021).

- Rcaife3.Pdf. Available online: https://www.vishay.com/docs/20059/rcaife3.pdf (accessed on 8 September 2021).

- Geninfo-Cd-Rfi-Safcaps.Pdf. Available online: https://www.vishay.com/docs/28536/geninfo-cd-rfi-safcaps.pdf (accessed on 8 September 2021).

- PCA82C250 CAN Controller Interface. Available online: https://www.nxp.com/docs/en/data-sheet/PCA82C250.pdf (accessed on 12 October 2021).

- Odetayo, M.O. Optimal Population Size for Genetic Algorithms: An Investigation. In Proceedings of the IEEE Colloquium on Genetic Algorithms for Control Systems Engineering, London, UK, 28 May 1993. [Google Scholar]

| Component | Voltage [V] | Current [A] | Power Dissipation [W] | Peak Power [kW] | Possible Configuration |

|---|---|---|---|---|---|

| C4 | 3 kV × 1.5 [30] | Lack of data | Lack of data | Lack of data | Description in Section 4.3 |

| GDT | Lack of data | 2 k [27] | Lack of data | Lack of data | SG75 |

| R9 | 500 [29] | Related to peak power [Section 4.2] | 900 | 2.5 | Description in Section 4.2. |

| R10 | 500 [29] | Related to peak power [Section 4.2] | 900 | 2.5 | Description in Section 4.2. |

| D4 | Related to power | Depends on the type [28] | Lack of data | 5.0 (Figure 5) | Description in Section 4.1. |

| R5 | 500 [29] | Related to peak power [Section 4.2] | 900 W | 2.5 | Description in Section 4.2 |

| R6 | 500 [29] | Related to peak power [Section 4.2] | 900 W | 2.5 | Description in Section 4.2. |

| D1 | 18 [31] | Depends on the type [28] | Lack of data | 5.0 (Figure 5) | Description in Section 4.1. |

| D2 | 18 [31] | Depends on type [28] | Lack of data | 5.0 (Figure 5) | Description in Section 4.1. |

| D3 | 18 [31] | Depends on the type [28] | Lack of data | 5.0 (Figure 5) | Description in Section 4.1 |

| Option | Value | Description |

|---|---|---|

| Max Generations | 30 | Defines maximum number of generated population during algorithm execution. |

| Max Time | 24 × 3600 [s] | Maximum amount of time (in seconds) consumed by Matlab for internal data process (import data, goal function calculation, GA operation, create netlist for next simulation). |

| Function Tolerance | 0.001 | Difference between goal function calculation for following members of generations, below this factor the number of stall generations goes up. Value is set to 0.1%. |

| Max Stall Generations | 10 | Minimum number of stall generations which indicates stop to find a better solution. In this case 10 following goal function calculations with differences less than 0.1% (Function Tolerance = 0.001) will stop the execution of algorithm. |

| Component Designator | Proposed Value | Peak Voltage [V] | Peak Current [A] | Power Dissipation [W] | Power Peak [W] | Percent. of Max. Voltage | Percent of Max. Current | Percent. of Max. Diss. Power | Percent of Peak Power |

|---|---|---|---|---|---|---|---|---|---|

| C4 | 2.2n | 2083.09 | 10.73 | 2.27 | 5726.72 | 42.08% | 0.00% | 0.00% | 0.00% |

| GDT | SG75 | 98.75 | 1335.72 | 1303.29 | 15,974.54 | 0.00% | 60.71% | 0.00% | 0.00% |

| R9 | 1.8R | 19.72 | 10.96 | 3.11 | 216.03 | 1.99% | 0.00% | 0.31% | 7.86% |

| R10 | 1.8R | 19.58 | 10.88 | 3.11 | 216.03 | 1.98% | 0.00% | 0.31% | 7.86% |

| D4 | SMDJ48CA | 59.45 | 10.87 | 6.23 | 646.14 | 0.00% | 5.09% | 0.00% | 11.75% |

| R5 | 1R | 3.51 | 3.51 | 1.11 | 12.32 | 0.78% | 0.00% | 0.25% | 0.99% |

| R6 | 1R | 3.51 | 3.51 | 1.11 | 12.32 | 0.78% | 0.00% | 0.25% | 0.99% |

| D1 | SMDJ6.0CA | 7.08 | 3.51 | 3.49 | 24.80 | 78.63% | 0.48% | 0.00% | 0.99% |

| D2 | SMDJ6.0CA | 6.78 | 0.06 | 0.01 | 0.38 | 75.32% | 0.01% | 0.00% | 0.02% |

| D3 | SMDJ6.0CA | 6.80 | 0.08 | 0.01 | 0.56 | 75.60% | 0.01% | 0.00% | 0.02% |

| Total resistance | 5.6 Ω |

| Configuration | Population Size | Function Tolerance | Time of Processing | Fitness Function | Percentage Change of Fitness Function Related to Conf. 1 |

|---|---|---|---|---|---|

| 1 | 50 | 0.001 | 10 h 51 min | 4.061 | 0.00% |

| 2 | 20 | 0.001 | 8 h 51 min | 4.193 | +3.25% |

| 3 | 80 | 0.001 | 24 h 34 min | 4.080 | +0.47% |

| 4 | 120 | 0.001 | 26 h 10 min | 4.166 | +2.59% |

| 5 | 200 | 0.001 | 25 h 50 min | 4.055 | −0.15% |

| 6 | 50 | 0.01 | 9 h 40 min | 4.097 | +0.89% |

| 7 | 50 | 0.0001 | 24 h 10 min | 3.982 | −1.95% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zieliński, D.; Grzechca, D. Selection of Surge Protection Module Components for Communication Lines Using a Genetic Algorithm. Sensors 2022, 22, 2075. https://doi.org/10.3390/s22062075

Zieliński D, Grzechca D. Selection of Surge Protection Module Components for Communication Lines Using a Genetic Algorithm. Sensors. 2022; 22(6):2075. https://doi.org/10.3390/s22062075

Chicago/Turabian StyleZieliński, Dariusz, and Damian Grzechca. 2022. "Selection of Surge Protection Module Components for Communication Lines Using a Genetic Algorithm" Sensors 22, no. 6: 2075. https://doi.org/10.3390/s22062075