Rapid Demagnetization of New Hybrid Core for Energy Harvesting

Abstract

:1. Introduction

- Small size, portability;

- Capability of performing in difficult-to-access environments;

- Fewer cables and reduced usage of other materials, devices, and systems;

- Provision of real-time information;

- Decreased cost;

- Low maintenance needs;

- Reduction of batteries—green energy;

- Great market potential, and the absorptiveness of the market.

2. Materials and Methods

2.1. Suction Casting Alloy

2.2. Ferro Magnetic Generator (FMG)

3. Results

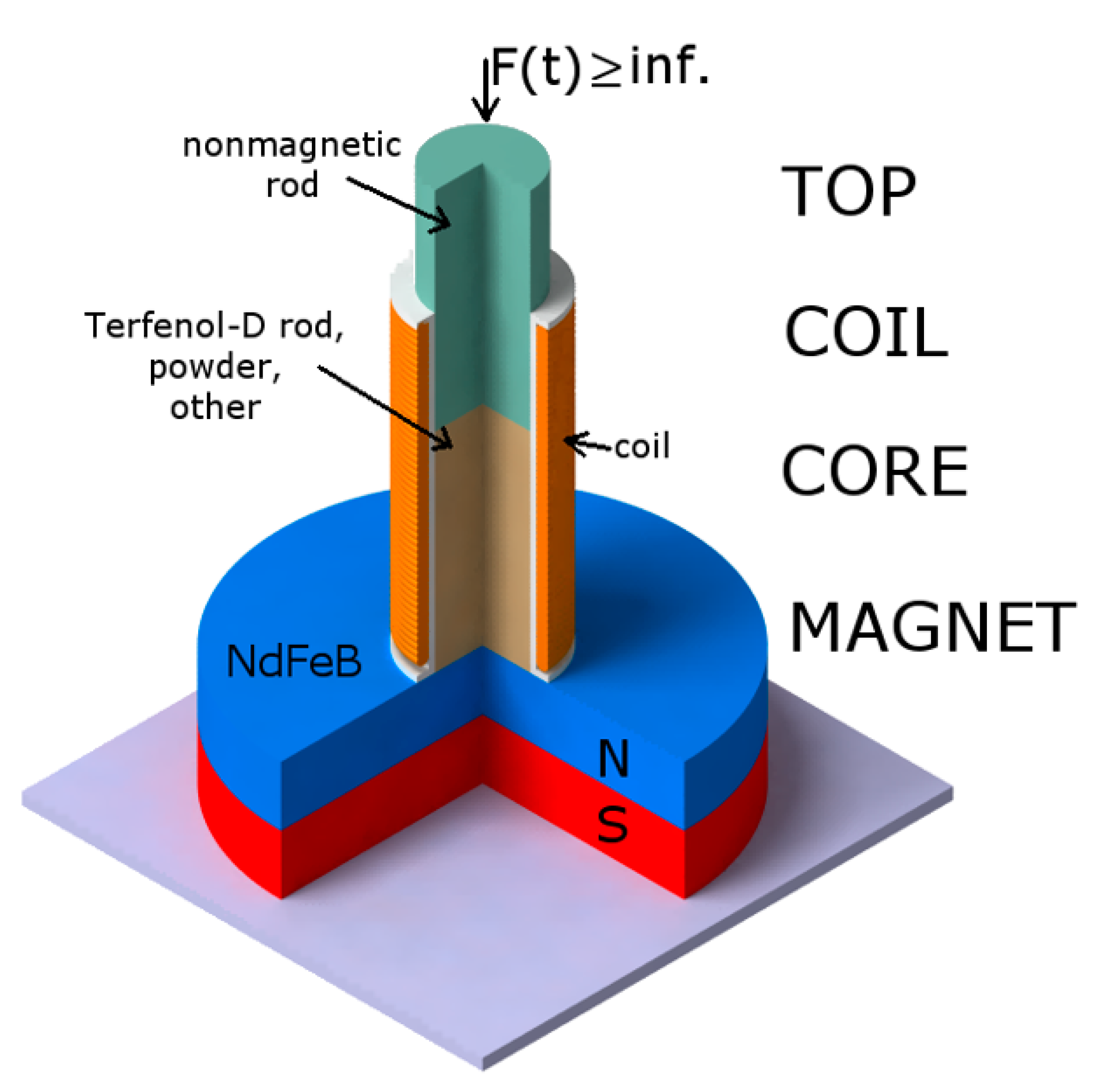

3.1. Harvesters

- A permanent NdFeB was used as a magnet.

- The material used for the core was important, because this is the part of the device responsible for the generation of current of sufficient value to operate as a pulse power supply. A few different core arrangements are proposed. The main material used was Terfenol-D and its powder. Additionally, pieces of the newly produced alloy were introduced to the core arrangement.

- The coil with a plastic body (the number of turns was 980, the resistance was 14Ohm, and the inductance was 1.1 mH) was fixed to the neodymium magnet.

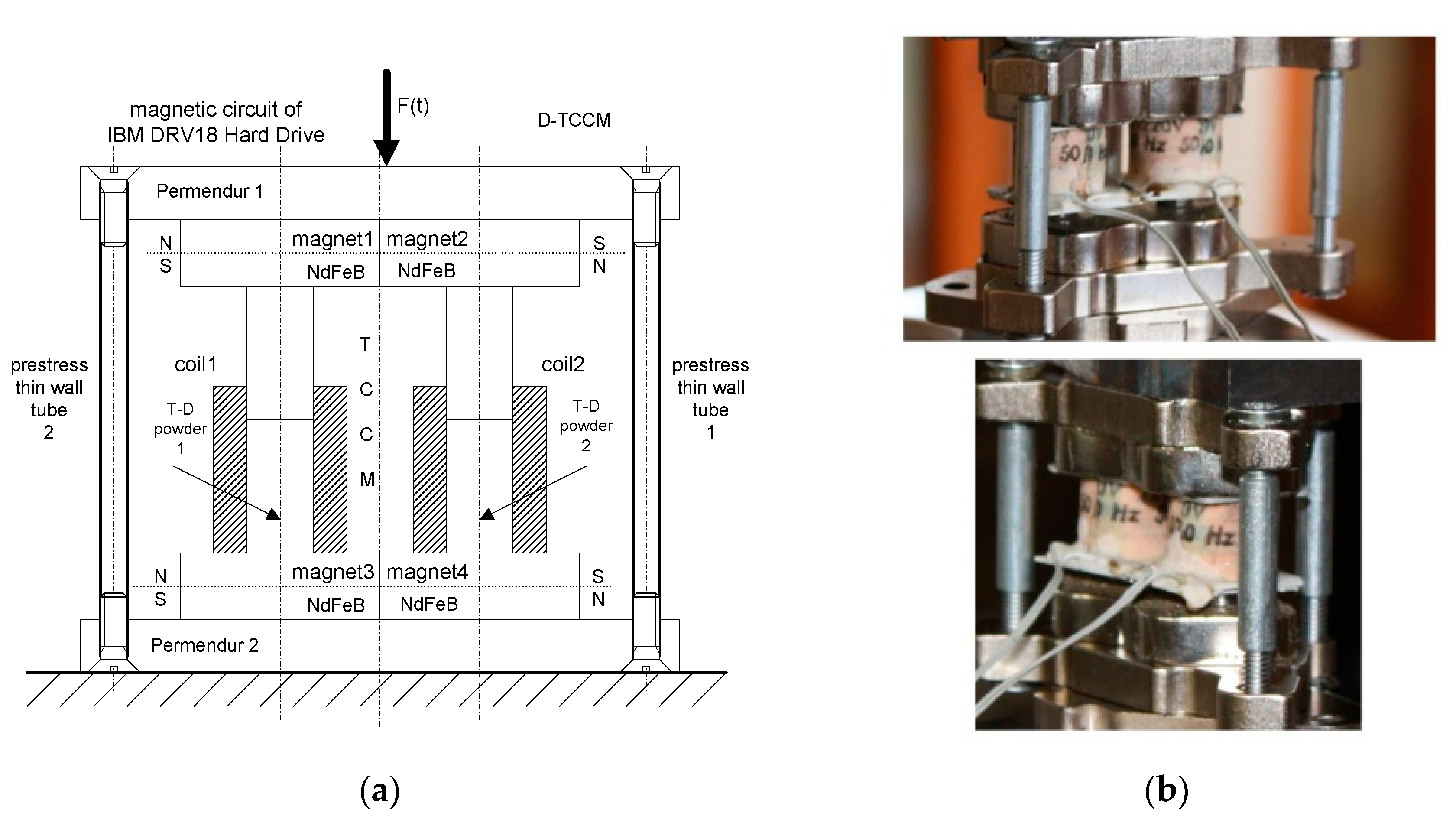

- Two coils used in the shown construction are the same, and have the same parameters, with static resistance Rc = 11 kΩ.

- In this type of harvester, it is possible to apply and control prestress. This is due to the thin-walled steel tubes, in which screw-bolts are placed, but the strength of both the screws and the tubes acts as a limitation.

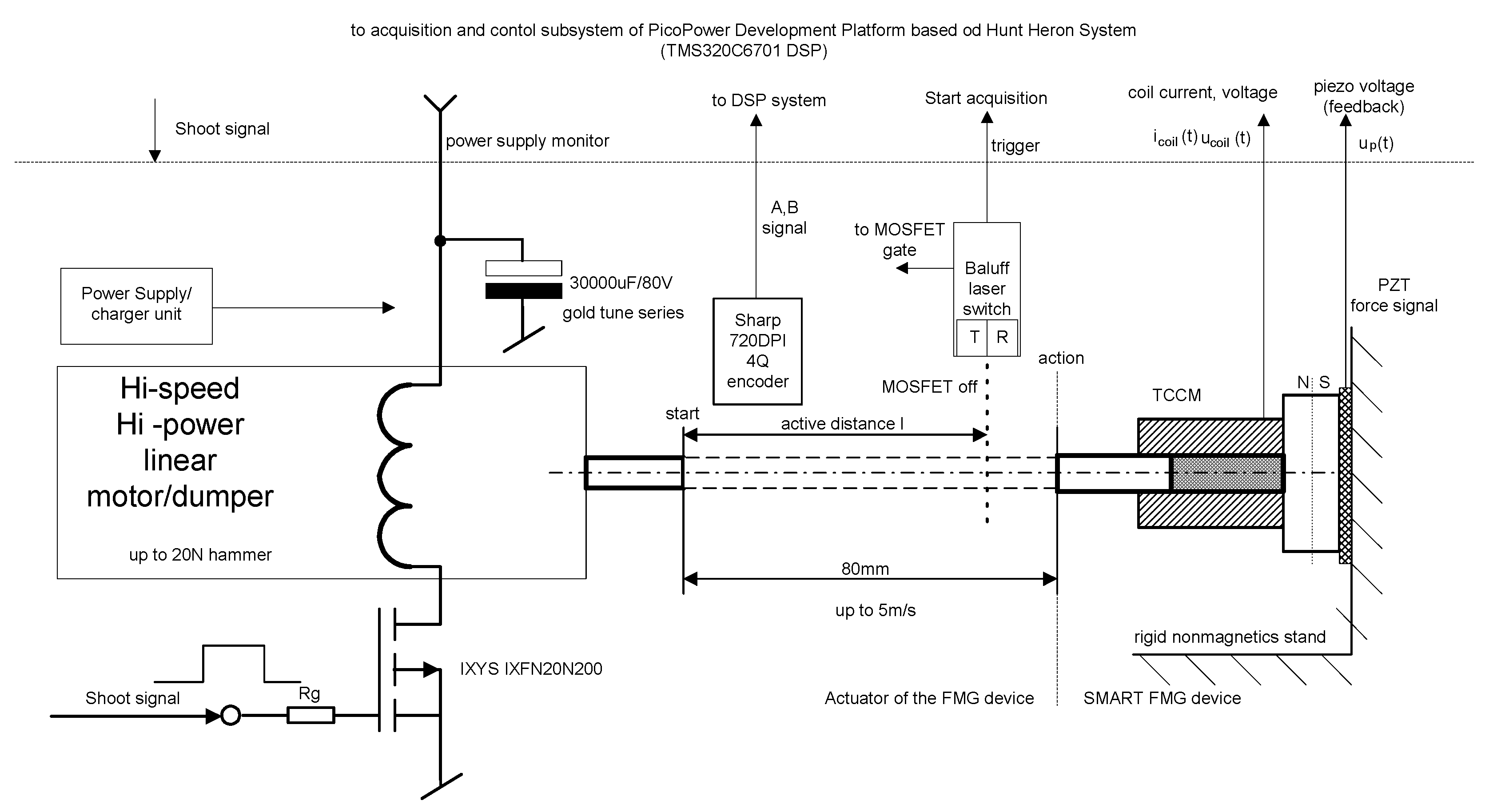

3.2. Test Stand and Measurements

- TotalLoad = 125 Ω is the resistive load on the coil, which is a source of generated energy due to an impact.

- Rc = 180 Ω is the static coil resistance (in this case quite a high value). In the case of harvesting energy from the reverse magnetostrictive effect, the coil parameters, i.e., how many Ohms and how many turns the coil has, are an important factor. In this paper, the aim was to generate the highest possible voltage increase so that the microprocessor power rectifier system was able to work under optimal conditions.

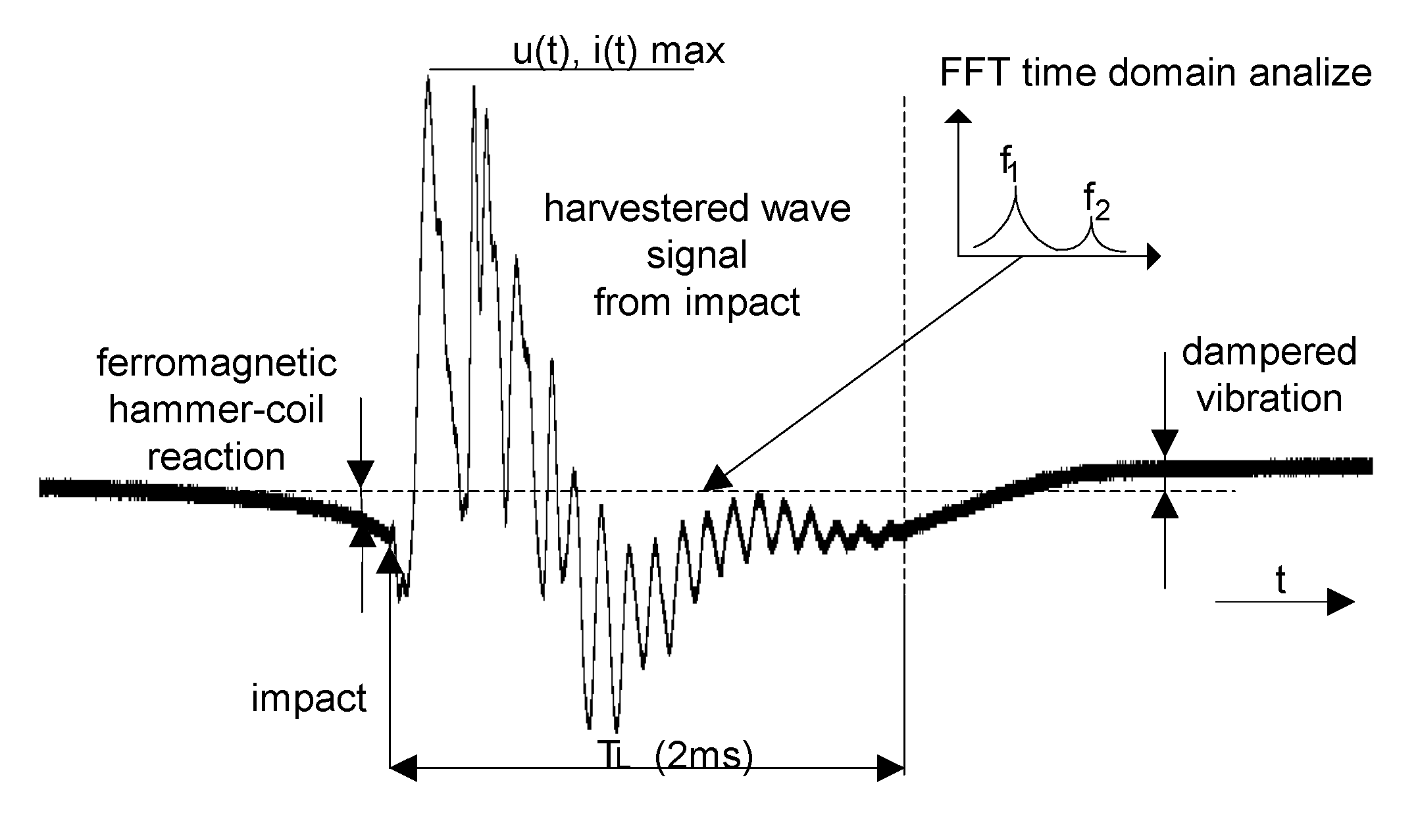

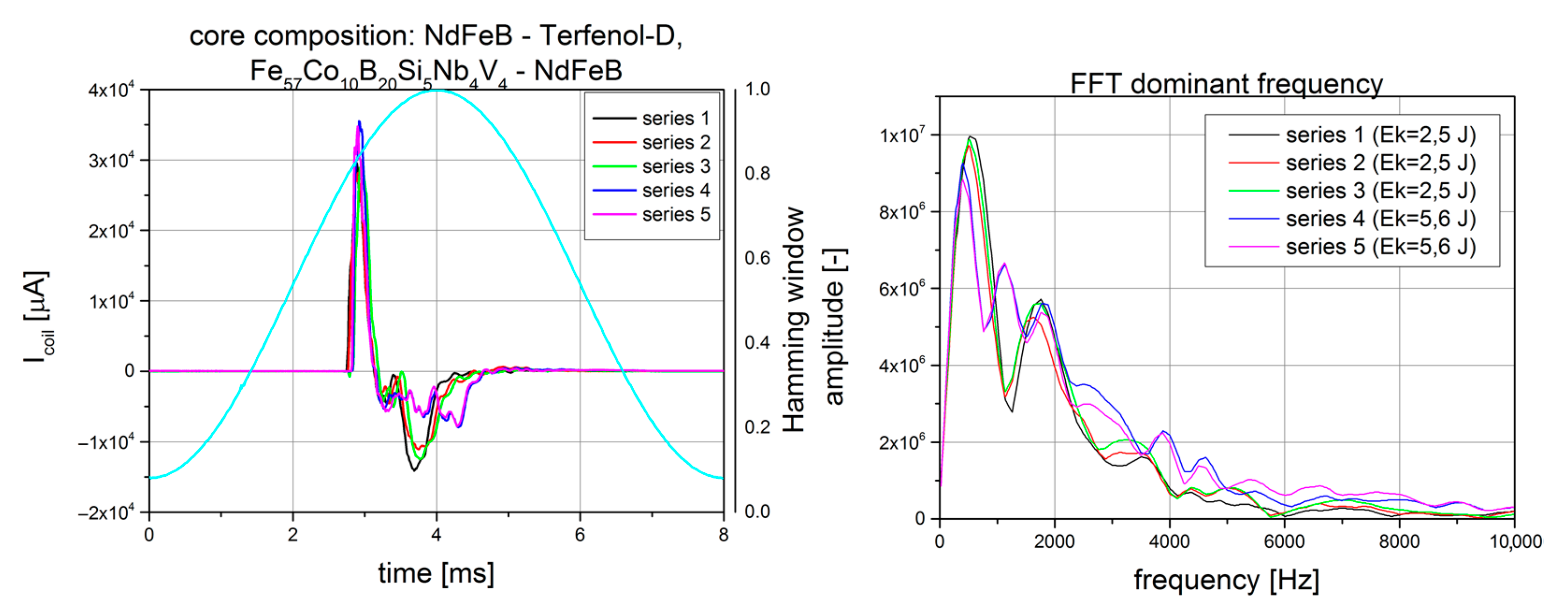

- Imax is the parameter that indicates the ability to power the microprocessor system from a single hit. This is the maximum current obtained during the impact phenomenon and the frequency response of the natural vibrations of the harvester’s core. In the case of using magnetostrictive cores, the Imax parameter is two orders higher than in the case of using other materials.

4. Conclusions

- The proper choice of the coil (the number of coils and its impedance) and the core material for the harvesting device is very important, and has a significant influence on the results.

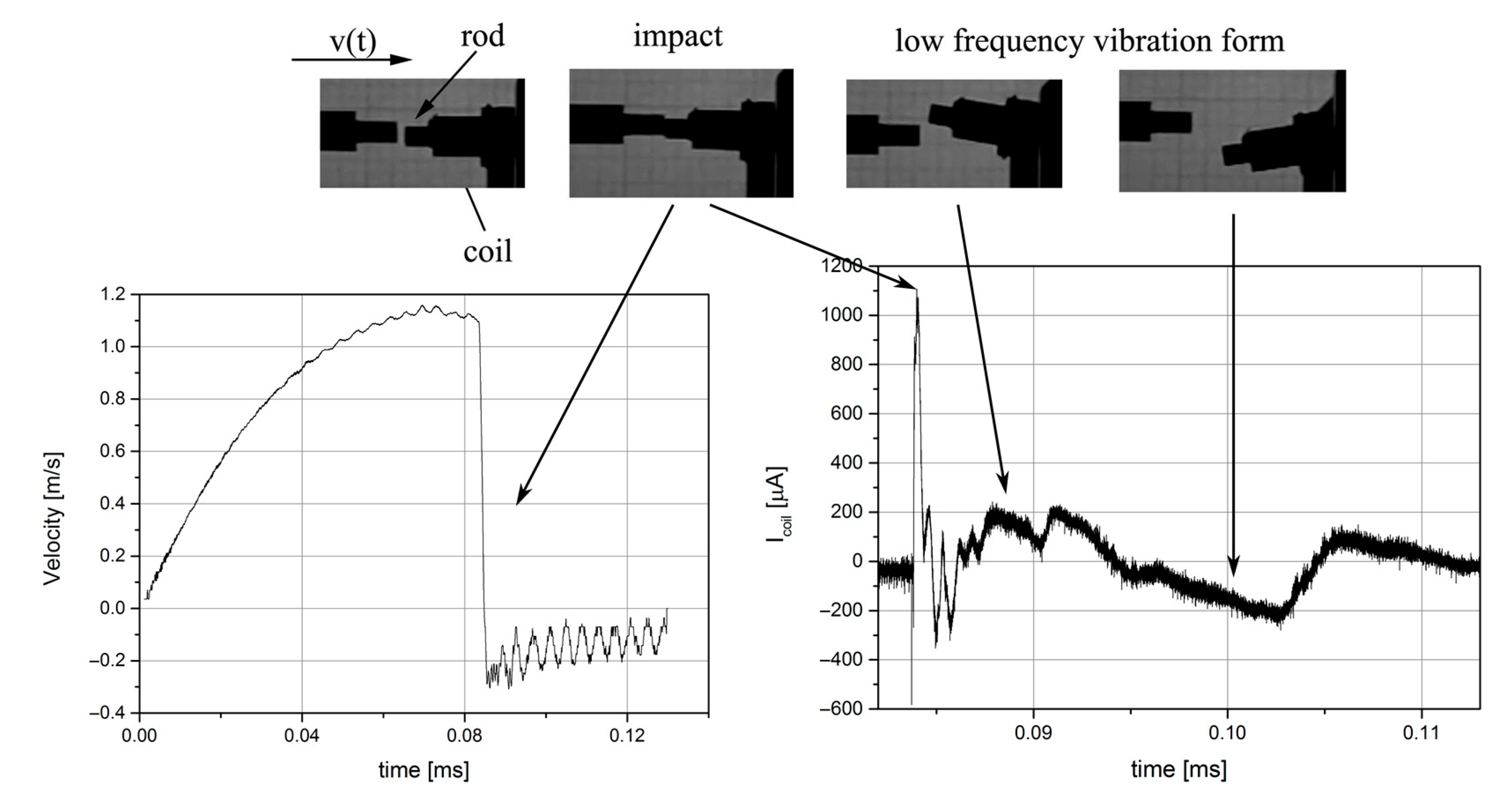

- Providing low-frequency vibration might have significant implications for the practical realization of energy harvesting, and application in industrial objects, as it could support the optimal operation (generation of current) of the harvester for a long time. However, it should be noted that the value of current generated as a result of impacts will be much higher than that generated from vibrations.

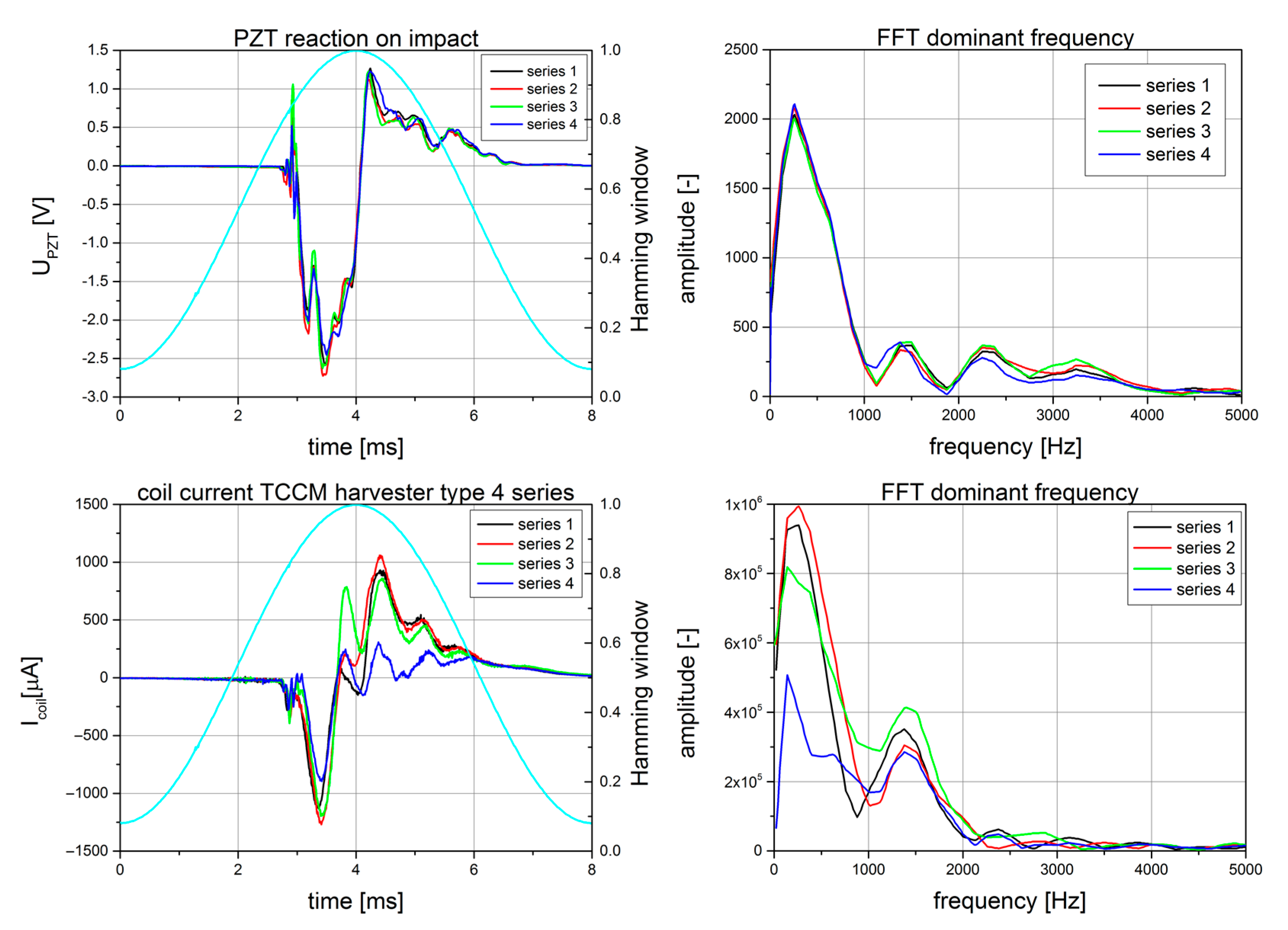

- In the coil and PZT sensor, the same frequencies were dominant, although the PZT spectrum had further harmonics that did not occur in the current signal of the coil. It was found that the two frequencies characterizing the material of the harvester core are sufficient.

- In the low-energy range of impulses, Ek ≤ 5.6 J, the application of Terfenol-D rod as the core results in the device to being able to supply about ten 8-bit RISC microelements in a time of about 1 ms.

- To ensure optimal prestress, while also increasing the resonance frequency and the lifetime of waves passing through the harvester device, the TCCM structure was modified. The developed DTCCM harvester structure made it possible to apply and tune the prestress value to the core of the device.

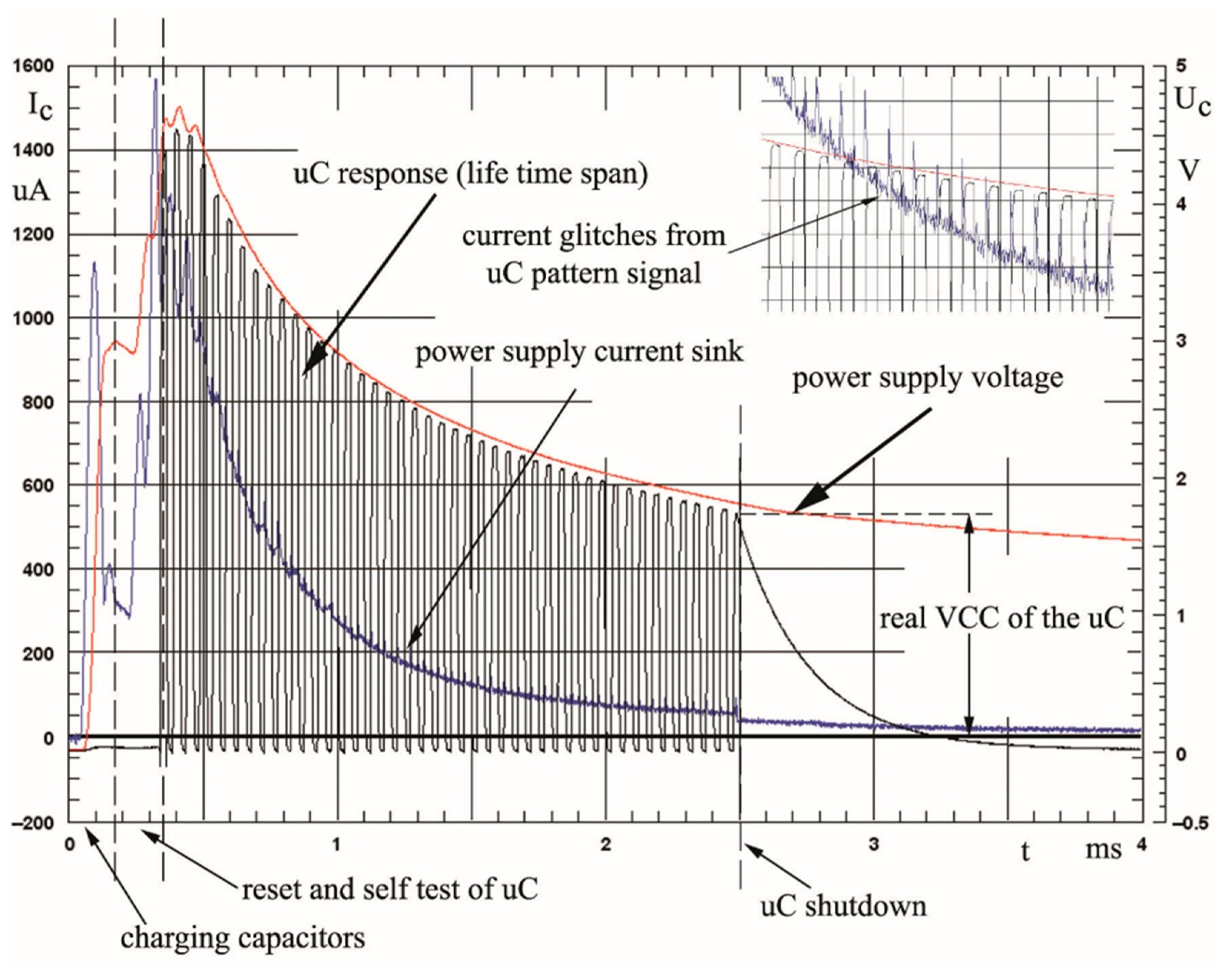

- Finally, an Energy Harvesting Device platform was developed that was able to supply a popular microcontroller that realizes its code within a timeframe of 3 ms with a low impact energy of Ek = 0.25 J.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Harrop, P. An Introduction to Energy Harvesting; IDTechEx Ltd.: Cambridge, UK, 2009. [Google Scholar]

- Narita, F.; Fox, M. A Review on Piezoelectric, Magnetostrictive, and Magnetoelectric Materials and Device Technologies for Energy Harvesting Applications. Adv. Eng. Mater. 2017, 20, 1700743. [Google Scholar] [CrossRef] [Green Version]

- Leung, C.M.; Li, J.-F.; Viehland, D.; Zhuang, X. A review on applications of magnetoelectric composites: From heterostructural uncooled magnetic sensors, energy harvesters to highly efficient power converters. J. Phys. D Appl. Phys. 2018, 51, 263002. [Google Scholar] [CrossRef]

- Zucca, M.; Mei, P.; Ferrara, E.; Fiorillo, F. Sensing Dynamic Forces by Fe–Ga in Compression. IEEE Trans. Magn. 2017, 53, 1–4. [Google Scholar] [CrossRef]

- Palumbo, S.; Rasilo, P.; Zucca, M. Experimental investi gation on a Fe-Ga close yoke vibrational harvester by matching magnetic and mechanical biases. J. Magn. Magn. Mater. 2019, 469, 354–363. [Google Scholar] [CrossRef]

- Narita, F.; Katabira, K. Stress-rate dependent output voltage for Fe29Co71 magnetostrictive fiber/polymer composites: Fabri-cation, experimental observation and theoretical prediction. Mater. Trans. 2017, 58, 302–304. [Google Scholar] [CrossRef] [Green Version]

- Yoffe, A.; Shilo, D. Themagneto-mechanical response of magnetostrictive composites for stress sensing applications. Smart Mater. Struct. 2017, 26, 065007. [Google Scholar] [CrossRef]

- Deng, Z. Explicit and efficient discrete energy-averaged model for Terfenol-D. J. Appl. Phys. 2017, 122, 043901. [Google Scholar] [CrossRef]

- Leon-Gil, J.A.; Cortes-Loredo, A.; Fabian-Mijangos, A.; Martinez-Flores, J.J.; Tovar-Padilla, M.; Cardona-Castro, M.A.; Morales-Sánchez, A.; Alvarez-Quintana, J. Medium and Short Wave RF Energy Harvester for Powering Wireless Sensor Networks. Sensors 2018, 18, 768. [Google Scholar] [CrossRef] [Green Version]

- Loreti, P.; Catini, A.; De Luca, M.; Bracciale, L.; Gentile, G.; Di Natale, C. The Design of an Energy Harvesting Wireless Sensor Node for Tracking Pink Iguanas. Sensors 2019, 19, 985. [Google Scholar] [CrossRef] [Green Version]

- Aoudia, F.A.; Gautier, M.; Magno, M.; Berder, O.; Benini, L. Leveraging Energy Harvesting and Wake-Up Receivers for Long-Term Wireless Sensor Networks. Sensors 2018, 18, 1578. [Google Scholar] [CrossRef] [Green Version]

- Lai, Y.C.; Hsiao, Y.C.; Wu, H.M.; Wang, Z.L. Waterproof fabric-based multifunctional triboelectric nanogenerator for uni-versally harvesting energy from raindrops, wind, and human motions and a self-powered sensors. Adv. Sci. 2019, 6, 1801883. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shi, S.; Yue, Q.; Zhang, Z.; Yuan, J.; Zhou, J.; Zhang, X.; Lu, S.; Luo, X.; Shi, C.; Yu, H. A Self-Powered Engine Health Monitoring System Based on L-Shaped Wideband Piezoelectric Energy Harvester. Micromachines 2018, 9, 629. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alrashdan, M.H.S.; Hamzah, A.A.; Majlis, B. Design and optimization of cantilever based piezoelectric micro power generator for cardiac pacemaker. Microsyst. Technol. Micro Nanosyst. Inf. Storage Process. Syst. 2014, 21, 1607–1617. [Google Scholar] [CrossRef]

- Deng, Z.; Dapino, M.J. Review of magnetostrictive vibration energy harvesters. Smart Mater. Struct. 2017, 26, 103001. [Google Scholar] [CrossRef]

- Backman, G.; Lawton, B.; Morley, N.A. Magnetostrictive Energy Harvesting: Materials and Design Study. IEEE Trans. Magn. 2019, 55, 1–6. [Google Scholar] [CrossRef]

- Deterre, M.; Lefeuvre, E.; Zhu, Y.; Woytasik, M.; Boutaud, B.; Molin, R.D. Microblood pressure energy harvester for intra cardi-acpacemaker. J. Microelectromechanical Syst. 2014, 23, 651–660. [Google Scholar] [CrossRef]

- Whelan, M.; Fuchs, M.P.; Gangone, M.V.; Janoyan, K.D. Development of a wireless bridge monitoring system for condition assessment using hybrid techniques. Proc. SPIE 2007, 6530, 65300H. [Google Scholar] [CrossRef]

- Song, Y. Finite-Element Implementation of Piezoelectric Energy Harvesting System from Vibrations of Railway Bridge. J. Energy Eng. 2019, 145, 04018076. [Google Scholar] [CrossRef]

- Harrop, P.R. Energy Harvesting and Storage for Electronic Devices 2009–2019; IDTechEx Report; IDTechEx Ltd.: Cambridge, UK, 2009. [Google Scholar]

- Herzer, G. Grain size dependence of coercivity and permeability in nanocrystalline ferromagnets. IEEE Trans. Magn. 1990, 26, 1397–1402. [Google Scholar] [CrossRef]

- Suzuki, K.; Cadogan, J.M. Random magnetocrystalline anisotropy in two-phase nanocrystalline systems. Phys. Rev. B 1998, 58, 2730–2739. [Google Scholar] [CrossRef]

- Shkuratov, S.I.; Talantsev, E.F.; Dickens, J.C.; Transverse, K.M. Shock wave demagnetization of NdFeB high-energy hard ferromagnetic. J. Appl. Phys. 2002, 92, 3007–3009. [Google Scholar] [CrossRef]

| Core Type | Imax [μA] | ABS Imax (1 ms) [μA] | FFT Dominate Frequency | |

|---|---|---|---|---|

| F1 [Hz] | F2 [Hz] | |||

| Cu | 1200 | 600 | 375 | 1500 |

| Fe | 1600 | 500 | 500 | 1750 |

| Ferrite | 500 | 200 | 375 | 1500 |

| NdFeB | 1200 | 400 | 875 | 1500 |

| Terfenol-D powder mixed with Fe57Co10B20Si5Nb4V4 | 2500 | 800 | 250 | 1625 |

| Terfenol-D rod with Fe57Co10B20Si5Nb4V4 pieces | 35,000 | 8300 | 500 | 1875 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mech, R.; Wiewiórski, P.; Wachtarczyk, K. Rapid Demagnetization of New Hybrid Core for Energy Harvesting. Sensors 2022, 22, 2102. https://doi.org/10.3390/s22062102

Mech R, Wiewiórski P, Wachtarczyk K. Rapid Demagnetization of New Hybrid Core for Energy Harvesting. Sensors. 2022; 22(6):2102. https://doi.org/10.3390/s22062102

Chicago/Turabian StyleMech, Rafał, Przemysław Wiewiórski, and Karol Wachtarczyk. 2022. "Rapid Demagnetization of New Hybrid Core for Energy Harvesting" Sensors 22, no. 6: 2102. https://doi.org/10.3390/s22062102

APA StyleMech, R., Wiewiórski, P., & Wachtarczyk, K. (2022). Rapid Demagnetization of New Hybrid Core for Energy Harvesting. Sensors, 22(6), 2102. https://doi.org/10.3390/s22062102