A Low Temperature Coefficient Time-to-Digital Converter with 1.3 ps Resolution Implemented in a 28 nm FPGA

Abstract

:1. Introduction

2. Methodology

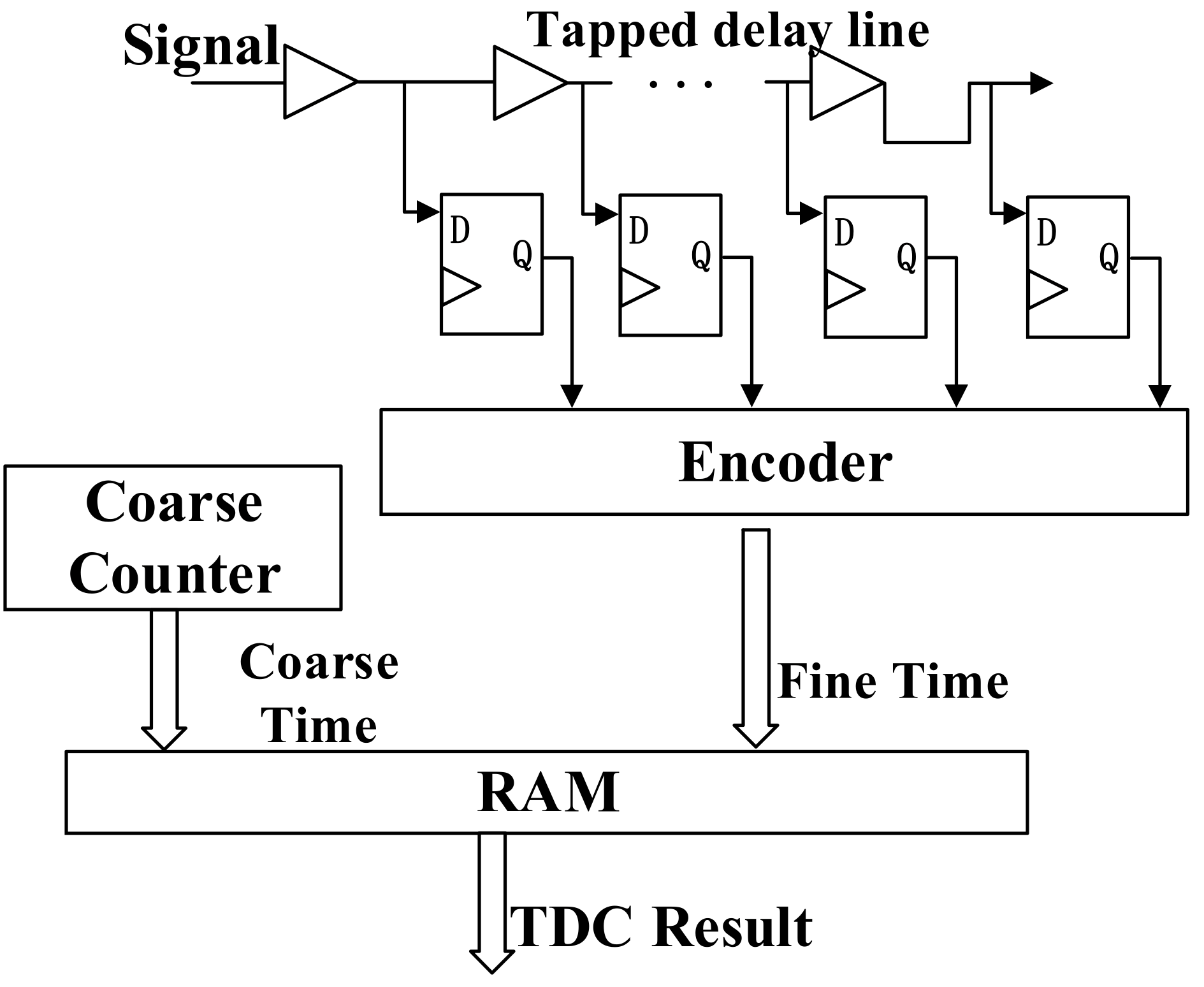

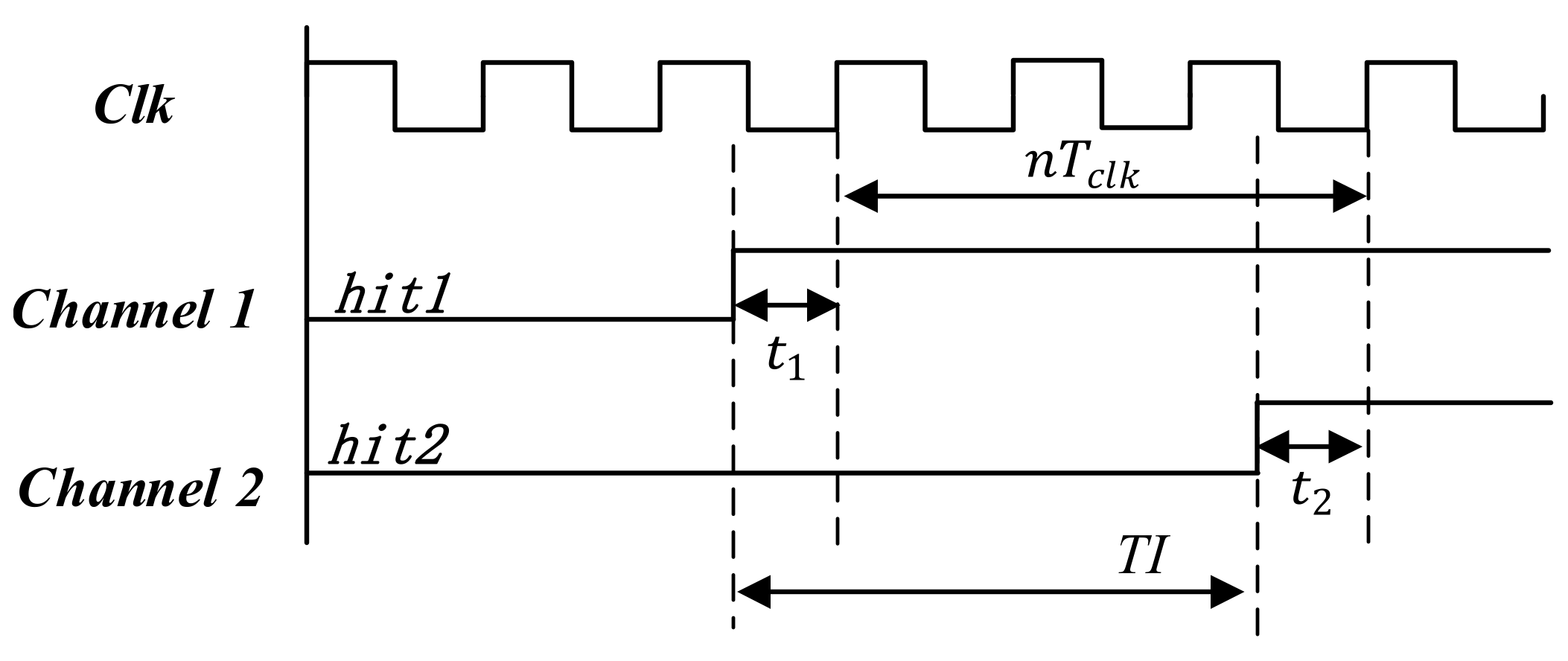

2.1. Bin-by-Bin Calibration

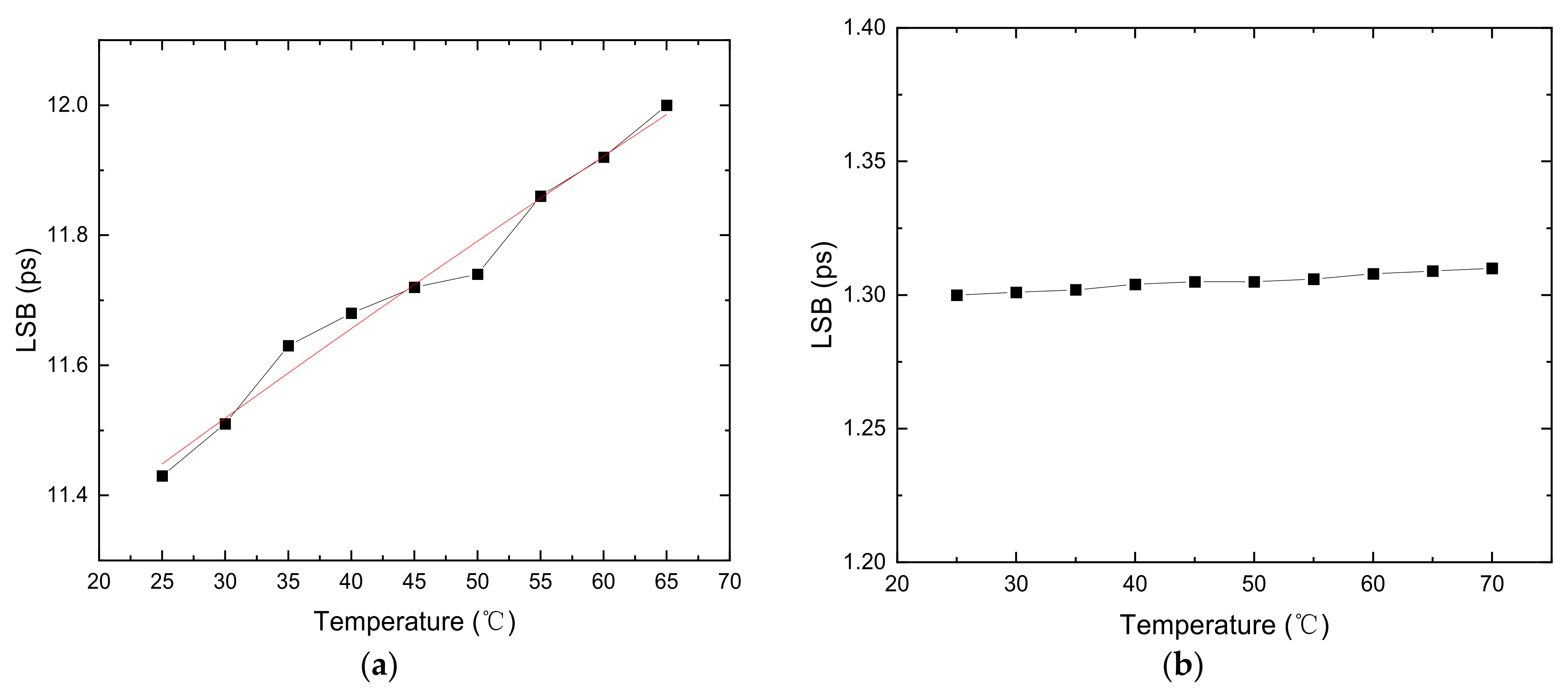

2.2. Effects of Temperature and Thermally Induced Electronic Noise

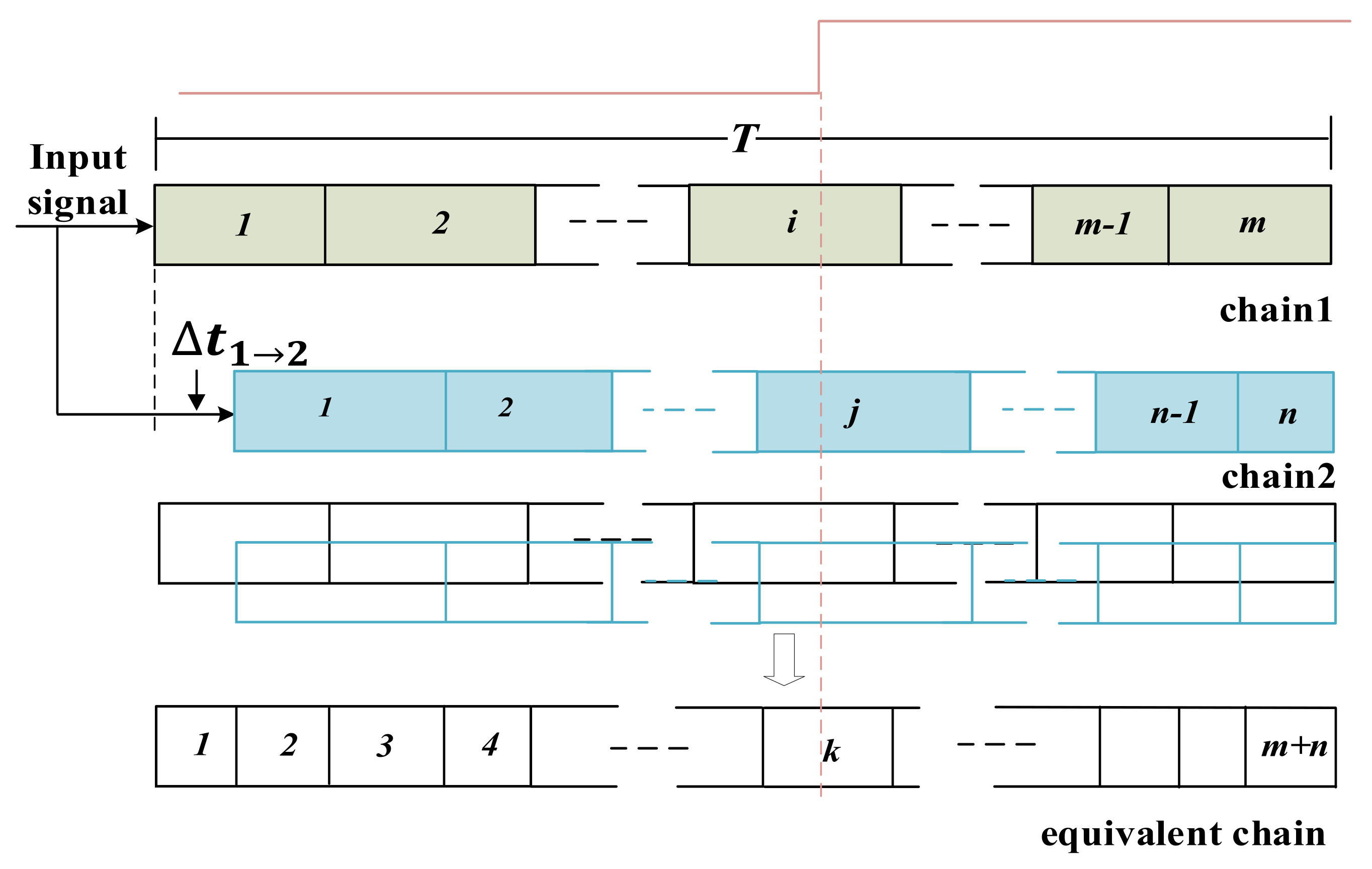

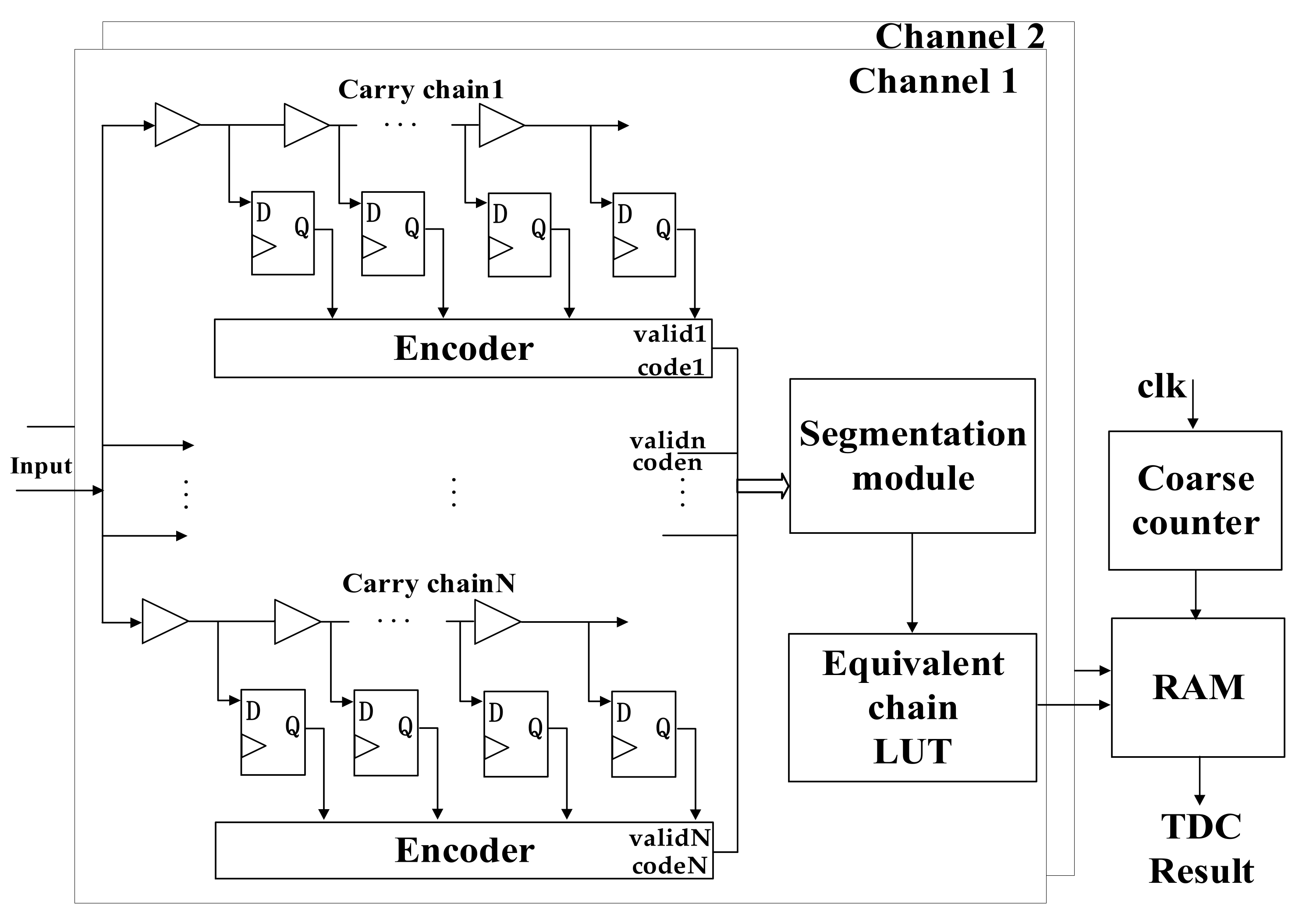

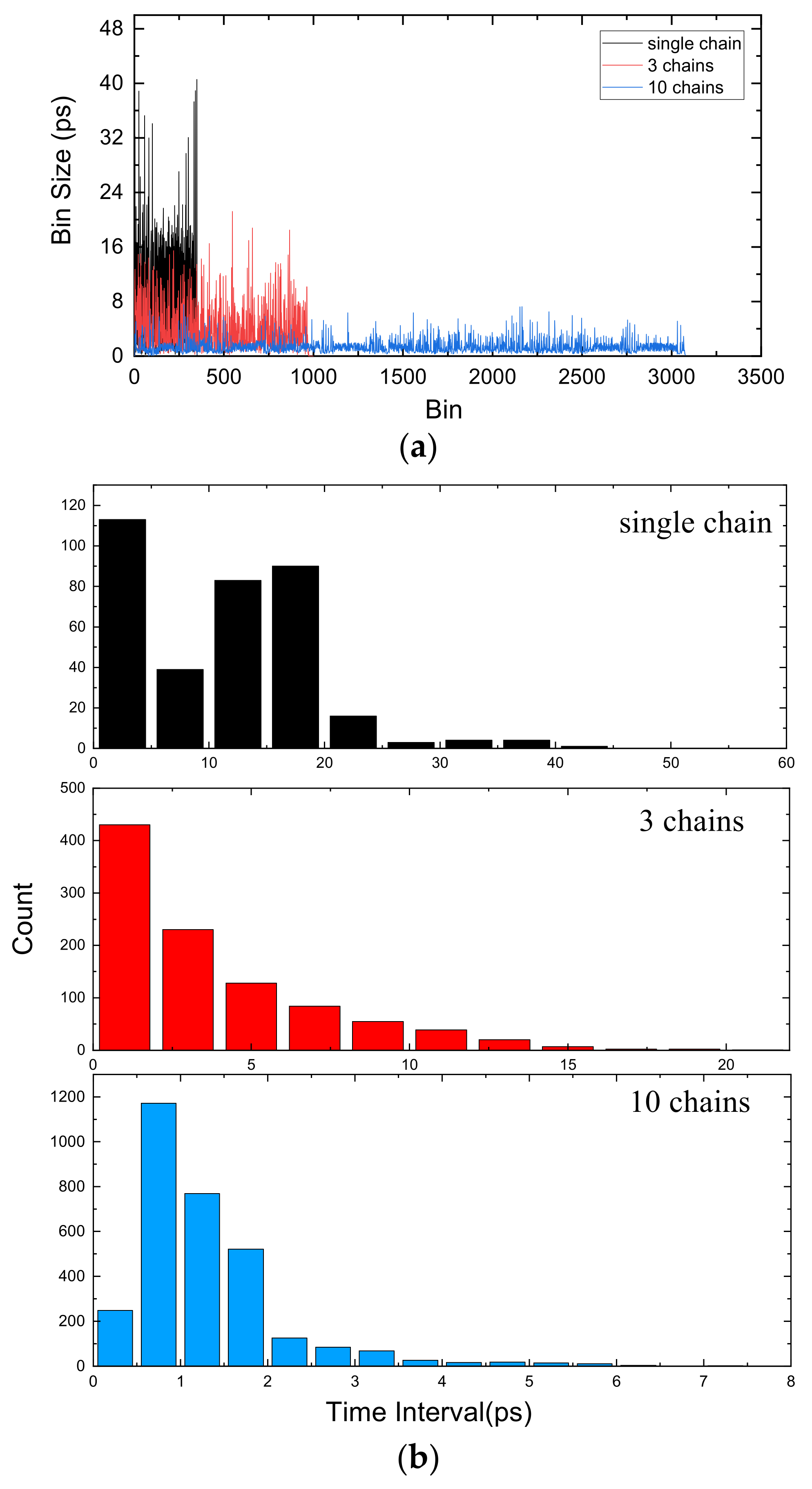

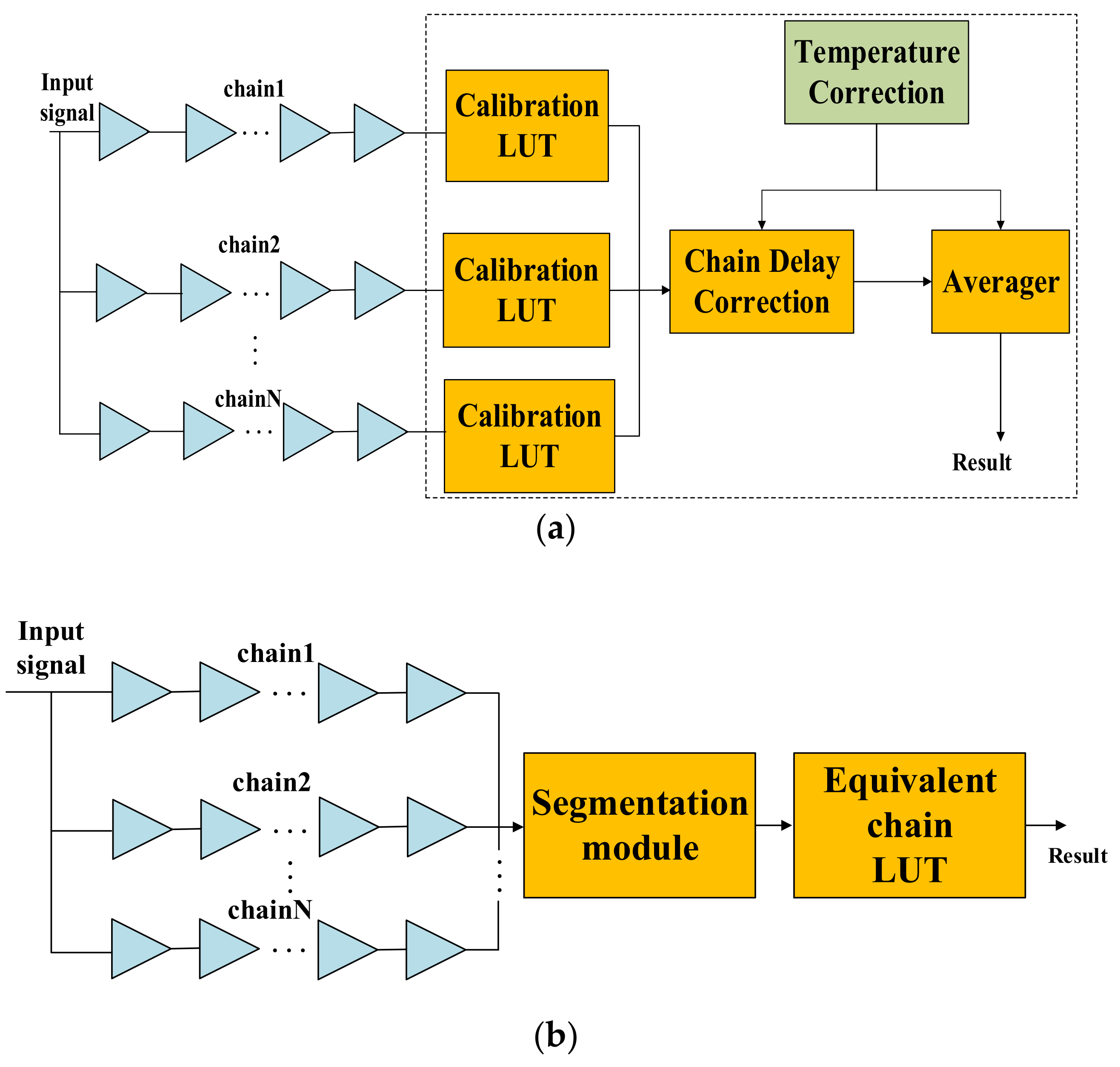

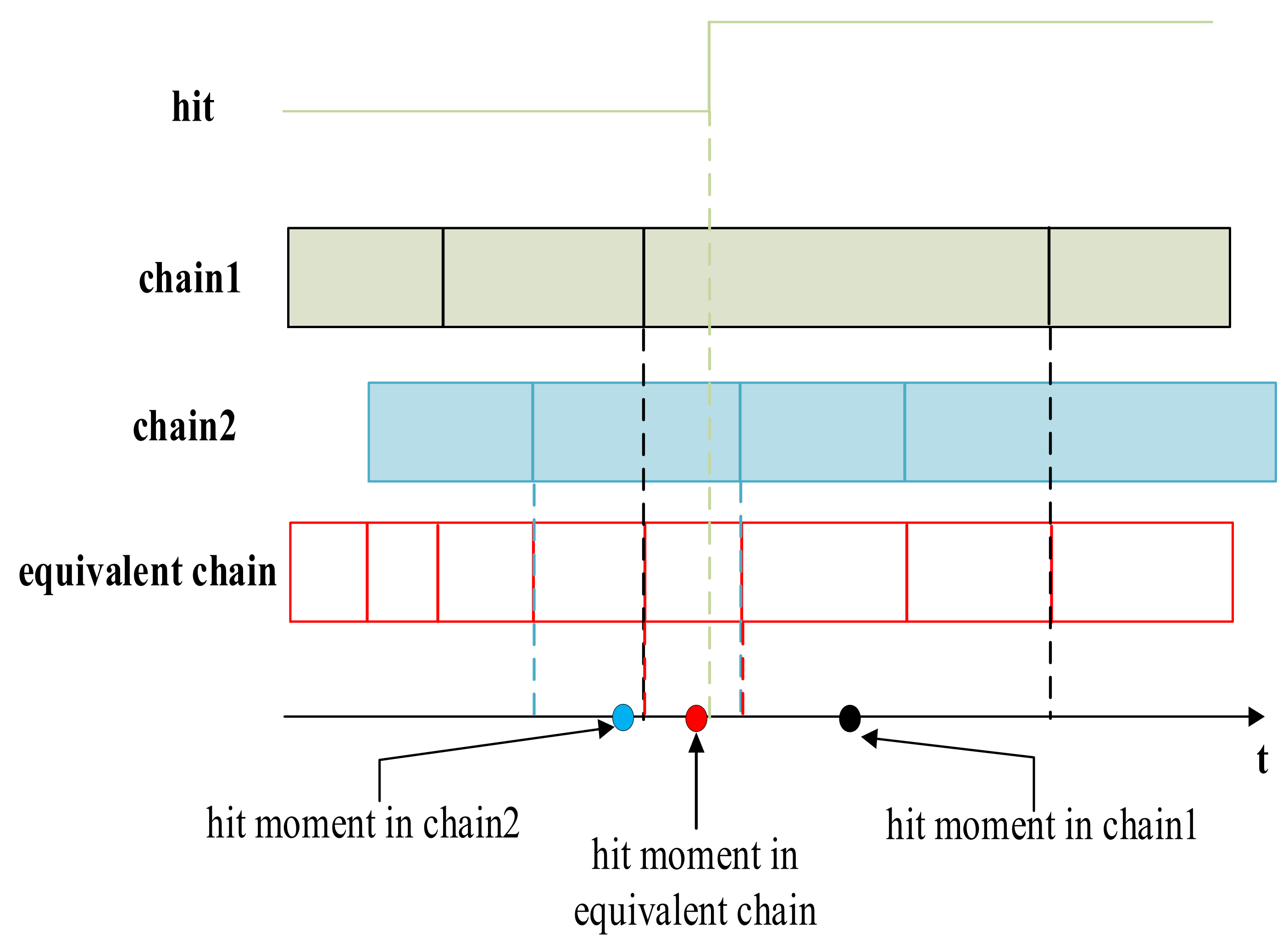

2.3. Multichain Cross Segmentation Method

3. Results

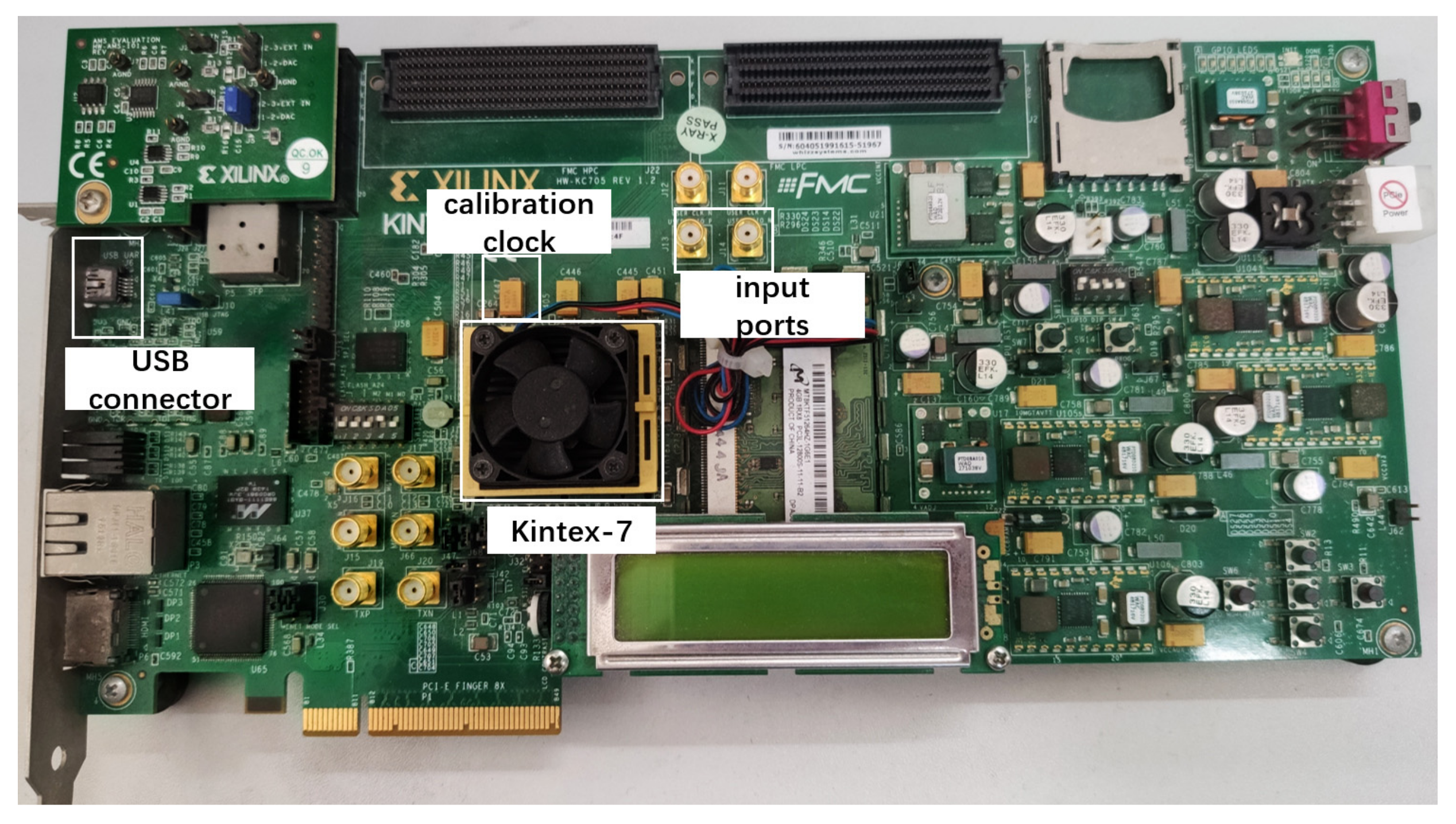

3.1. Implementation of the Multichain TDC

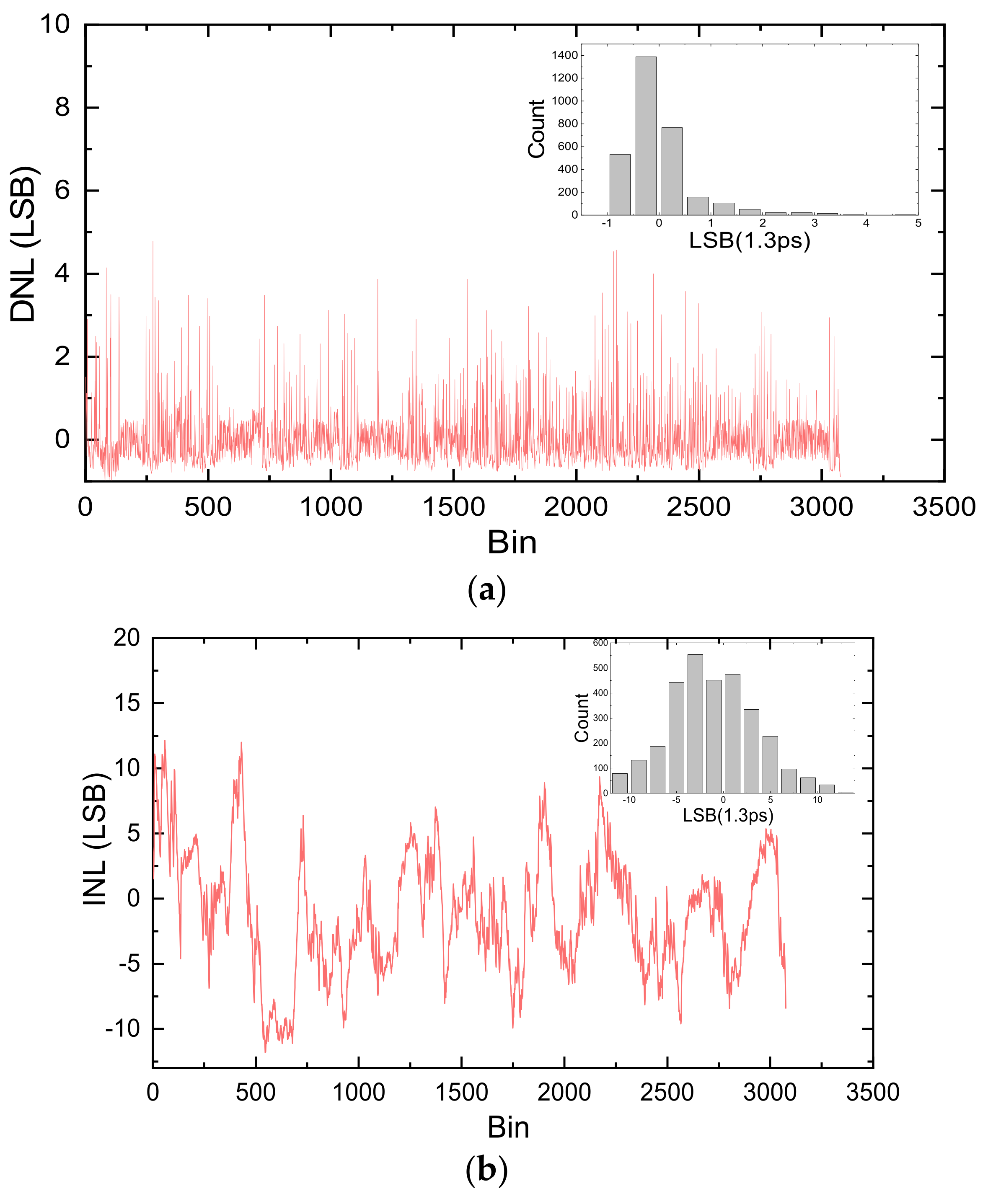

3.2. Averaged Resolution and Nonlinearity

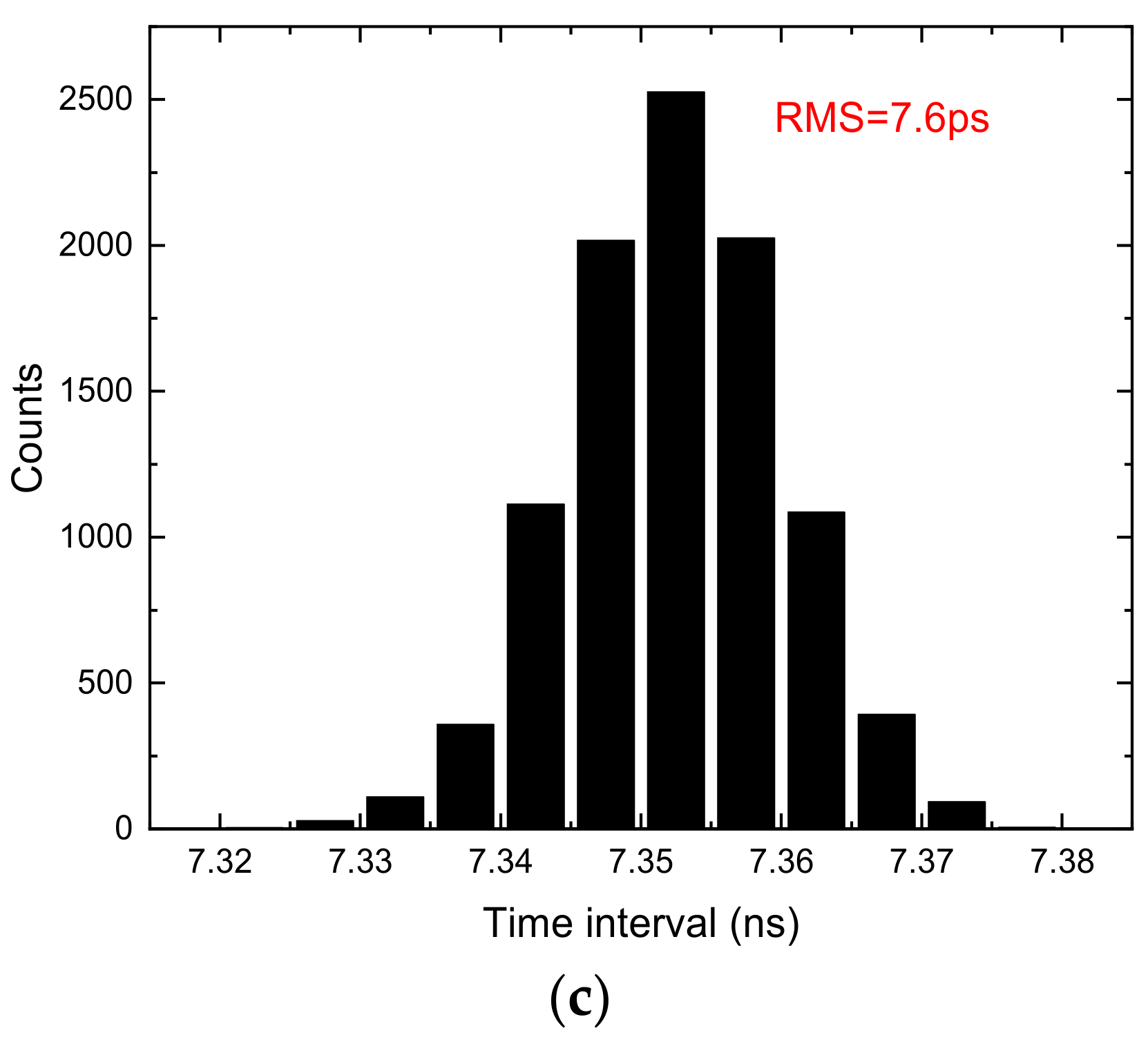

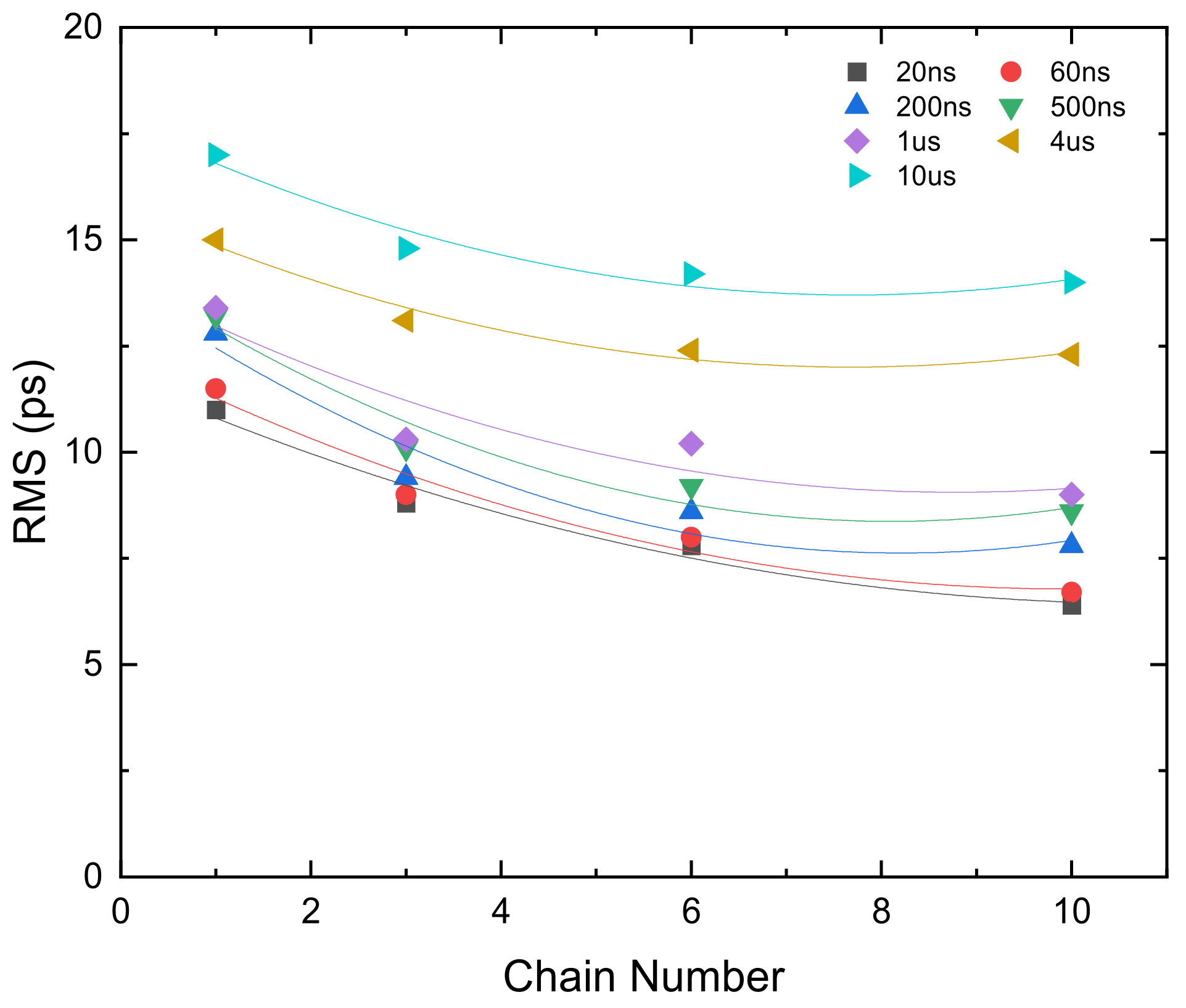

3.3. RMS Precision

3.4. Temperature Variation

3.5. Resource Usage and Power Consumption

4. Discussion

4.1. Features of the Multichain Cross Segmentation Method

4.2. Resolution and Precision

4.3. Accuracy

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kodet, J.; Pánek, P.; Procházka, I. Two-way time transfer via optical fiber providing subpicosecond precision and high temperature stability. Metrologia 2016, 53, 18–26. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Yue, C.; Xi, Y. Fiber-optic joint time and frequency transfer with the same wavelength. Opt. Lett. 2020, 45, 208–211. [Google Scholar] [CrossRef] [Green Version]

- Lau, K.Y.; Lutes, G.F.; Tjoelker, R.L. Ultra-Stable RF-Over-Fiber Transport in NASA Antennas, Phased Arrays and Radars. J. Lightwave Technol. 2014, 32, 3440–3451. [Google Scholar] [CrossRef]

- Godun, R.M.; Nisbet-Jones, P.B.R.; Jones, J.M. Frequency Ratio of Two Optical Clock Transitions in Yb-171(+) and Constraints on the Time Variation of Fundamental Constants. Phys. Rev. Lett. 2014, 113, 210801. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Y.; Yu, H.; Liu, S.; Huang, X.; Jiang, L. A CMOS Time-to-Digital Converter for Real-Time Optical Time-of-Flight Sensing System. IEEE Commun. Mag. 2018, 56, 113–119. [Google Scholar] [CrossRef]

- Haase, J.F.; Grollius, S.; Grosse, S.; Buchner, A.; Ligges, M. A 32×24 pixel SPAD detector system for LiDAR and quantum imaging. In Proceedings of the Photonic Instrumentation Engineering VIII, Online, 5 March 2021; Volume 11693, p. 116930M. [Google Scholar]

- SR620 Universal Time Interval Counter Manual, Revision 2.8; SRS Inc.: Greensboro, NC, USA, 2019.

- TDC-GPX2 Datasheet, V1.3; Ams Inc.: American Falls, ID, USA, 2017.

- Perktold, L.; Christiansen, J. A multichannel time-to-digital converter ASIC with better than 3 ps RMS time resolution. J. Instrum. 2014, 9, C01060. [Google Scholar] [CrossRef]

- Huang, H.; Chou, W. Hysteresis Switch Adaptive Velocity Evaluation and High-Resolution Position Subdivision Detection Based on FPGA. IEEE Trans. Instrum. Meas. 2015, 64, 3387–3395. [Google Scholar] [CrossRef]

- Sui, T.; Zhao, Z.; Xie, S.; Xie, Y.; Zhao, Y.; Huang, Q.; Xu, J.; Peng, Q. A 2.3-ps RMS Resolution Time-to-Digital Converter Implemented in a Low-Cost Cyclone V FPGA. IEEE Trans. Instrum. Meas. 2018, 68, 3647–3660. [Google Scholar] [CrossRef]

- Bengtsson, L. Embedded Vernier TDC with sub-nano second resolution using fractional-N PLL. Measurement 2017, 108, 48–54. [Google Scholar] [CrossRef]

- Won, J.Y.; Lee, J.S. Time-to-Digital Converter Using a Tuned-Delay Line Evaluated in 28-, 40-, and 45-nm FPGAs. IEEE Trans. Instrum. Meas. 2016, 65, 1678–1689. [Google Scholar] [CrossRef]

- Jachna, Z.; Szplet, R.; Kwiatkowski, P.; Różyc, K. Permanently calibrated interpolating time counter. Meas. Sci. Technol. 2015, 26, 015006. [Google Scholar] [CrossRef]

- Song, Z.; Wang, Y.; Kuang, J. A 256-channel, high throughput and precision time-to-digital converter with a decomposition encoding scheme in a Kintex-7 FPGA. J. Instrum. 2018, 13, P05012. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, Y.; Li, D.D.-U. A Low Nonlinearity, Missing-Code Free Time-to-Digital Converter Based on 28-nm FPGAs with Embedded Bin-Width Calibrations. IEEE Trans. Instrum. Meas. 2017, 66, 1912. [Google Scholar] [CrossRef] [Green Version]

- Cao, G.; Xia, H.; Dong, N. An 18-ps TDC using timing adjustment and bin realignment methods in a Cyclone-IV FPGA. Rev. Sci. Instrum. 2018, 89, 054707. [Google Scholar] [CrossRef]

- Wang, J.; Liu, S.; Shen, Q.; Li, H.; An, Q. A Fully Fledged TDC Implemented in Field-Programmable Gate Arrays. In IEEE Transactions on Nuclear Science; IEEE: Manhattan, NY, USA, 2010; Volume 57, pp. 446–450. [Google Scholar]

- Wu, J.; Shi, Z. The 10ps wave union TDC: Improving FPGA TDC resolution beyond its cell delay. In Proceedings of the IEEE International Symposium Circuits and Systems, Como, Italy, 5–9 October 2008; pp. 3440–3446. [Google Scholar]

- Wu, J. On-Chip processing for the wave union TDC implemented in FPGA. In Proceedings of the 2009 16th IEEE-NPSS Real Time Conference, Beijing, China, 10–15 May 2009; pp. 279–282. [Google Scholar]

- Bayer, E.; Zipf, P.; Traxler, M. A multichannel high-resolution (<5 ps RMS between two channels) Time-to-Digital Converter (TDC) implemented in a field programmable gate array (FPGA). In Proceedings of the 2011 IEEE Nuclear Science Symposium Conference Record, Valencia, Spain, 23–29 October 2011; pp. 876–879. [Google Scholar]

- Qin, X.; Wang, L.; Liu, D.; Zhao, Y.; Rong, X.; Du, J. A 1.15-ps Bin Size and 3.5-ps Single-Shot Precision Time-to-Digital Converter With On-Board Offset Correction in an FPGA. IEEE Trans. Nucl. Sci. 2017, 64, 2951–2957. [Google Scholar] [CrossRef]

- Hu, X.; Zhao, L.; Liu, S.; Wang, J.; An, Q. A stepped-up tree encoder for the10-ps Wave Union TDC. IEEE Trans. Nucl. Sci. 2013, 60, 3544–3549. [Google Scholar] [CrossRef]

- Wang, J.; Liu, S.; Shen, Q.; Li, H.; An, Q. A fully fledged TDC implemented in field-programmable-gate-arrays. In Proceedings of the 2009 16th IEEE-NPSS Real Time Conference, Beijing, China, 10–15 May 2009; pp. 290–294. [Google Scholar]

- Pan, W.; Gong, G.; Li, J. A 20-ps Time-to-Digital Converter (TDC) Implemented in Field-Programmable Gate Array (FPGA) with Automatic Temperature Correction. IEEE Trans. Nucl. Sci. 2014, 61, 1468–1473. [Google Scholar] [CrossRef]

- Song, Z.; Zhao, Z.; Yu, H.; Yang, J.; Zhang, X.; Sui, T.; Xu, J.; Xie, S.; Huang, Q.; Peng, Q. An 8.8 ps RMS Resolution Time-To-Digital Converter Implemented in a 60 nm FPGA with Real-Time Temperature Correction. Sensors 2020, 20, 2172. [Google Scholar] [CrossRef] [Green Version]

- Tang, Y.; Townsend, T.; Deng, H.; Liu, Y.; Zhang, R.; Chen, J. A Highly Linear FPGA-Based TDC and a Low-Power Multichannel Readout ASIC With a Shared SAR ADC for SiPM Detectors. IEEE Trans. Nucl. Sci. 2021, 68, 2286–2293. [Google Scholar] [CrossRef]

- Liu, C.; Wang, Y. A 128-Channel, 710 M Samples/Second, and Less Than 10 ps RMS Resolution Time-to-Digital Converter Implemented in a Kintex-7 FPGA. IEEE Trans. Nucl. Sci. 2015, 62, 773–783. [Google Scholar] [CrossRef]

- Kuang, J.; Wang, Y.; Cao, Q.; Liu, C. Implementation of a high precision multi-measurement time-to-digital convertor on a Kintex-7 FPGA. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2018, 891, 37–41. [Google Scholar] [CrossRef]

- Machado, R.; Cabral, J.; Alves, F.S. Recent Developments and Challenges in FPGA-Based Time-to-Digital Converters. IEEE Trans. Instrum. Meas. 2019, 68, 4205–4221. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Y.; Song, Z. A ring-oscillator based multi-mode time-to-digital converter on Xilinx Kintex-7 FPGA. Nucl. Instrum. Methods Phys. Res. 2021, 1011, 165578. [Google Scholar] [CrossRef]

- Deng, J.; Yin, P.; Lei, X.; Shu, Z.; Tang, M.; Tang, F. A Tunable Parameter, High Linearity Time-to-Digital Converter Implemented in 28-nm FPGA. IEEE Trans. Instrum. Meas. 2021, 70, 1–12. [Google Scholar] [CrossRef]

- Zhang, M.; Yang, K.; Chai, Z.; Wang, H.; Ding, Z.; Bao, W. High-Resolution Time-to-Digital Converters Implemented on 40-, 28-, and 20-nm FPGAs. IEEE Trans. Instrum. Meas. 2020, 70, 2002310. [Google Scholar] [CrossRef]

- Dong, X.; Ma, C.; Zhao, X.; Li, X.; Huang, Z. A high resolution multi-phase clock Time-Digital Convertor implemented on Kintex-7 FPGA. J. Instrum. 2020, 15, T11005. [Google Scholar] [CrossRef]

| Resource | Available | 1-Chain | 10-Chain | ||

|---|---|---|---|---|---|

| Use | Use % | Use | Use % | ||

| LUT | 203,400 | 826 | 0.4 | 6299 | 3.1 |

| FF | 406,800 | 1727 | 0.42 | 14,334 | 3.5 |

| BRAM | 445 | 1 | 0.22 | 3 | 0.67 |

| Power | 0.482 w | 0.563 w | |||

| Ref. | Method | Device | LSB [ps] | Precision [ps] | DNL [LSB] | INL [LSB] | Dead Time [ns] | Temperature Correction | Resources | Power [w] |

|---|---|---|---|---|---|---|---|---|---|---|

| [31] | Vernier-type | Kintex-7 | 43 | 34 | −0.98, +0.08 | −1, +0.97 | 50 | NA | NA | NA |

| [27] | Multi-chain averaging | Kintex-7 | 11 | 15 | −1, +1.4 | −1.75, +3.5 | NA | NA | NA | NA |

| [32] | NUMMP (1) | Kintex-7 | 1.87 | 2.79 | −0.54, +1.3 | −2.21, +3.51 | 8 | Re-TSM (6) | 1103FFs+ 1679LUTs | 0.740 |

| [33] | LSPM (2) | Kintex-7 | 1.29 | 3.54 | −1.2, +1.4 | −3.28, +3.78 | NA | NA | 3900FFs+ 1002LUTs | 0.453 |

| [28] | Wave union +Bin Realignment | Kintex-7 | NA | 8.7 | 0, +4.6 | NA | 1.47 | Calibration table updating | NA | NA |

| [29] | Multi-measurement | Kintex-7 | 3 | 5.76 | −1, +3.3 | −8, +9 | 22 | Calibration table updating | NA | NA |

| [34] | Multi-phase | Kintex-7 | 78.13 | 35 | −0.28, +0.53 | −0.56, +0.38 | <50 | NA | 347FFs+ 199LUTs | NA |

| [26] | NUMP (3) | Cyclone-V | 2.3 | 8.8 | −0.81, +1.20 | NA | NA | LUT auto-updating | 11433LCs+ 7127FFs | NA |

| [22] | Multi-chain averaging | Virtex-7 | 1.15 | 3.5 | −0.98, +3.5 | −5.9, +3.1 | 8 | Curve fitting | 19666LUTs | NA |

| [25] | Wave union | Cyclone II | 22 | 30 | −0.99, +2.18 | NA | NA | Dedicated correction channel | 23494LCs+ 28085FFs | NA |

| [24] | TDL (4) | Virtex-4 | ~50 | 25 | −0.4, +0.6 | −1.3, +1.7 | 10 | Coefficient compensation | NA | NA |

| This work | MCS (5) | Kintex-7 | 1.3 | 4.6 | −0.99, +4.79 | −14.18, +13.16 | 8 | Self-adaption | 14334FFs+ 6299 LUTs | 0.563 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, X.; Yang, F.; Wei, F.; Shi, J.; Cai, J.; Cai, H. A Low Temperature Coefficient Time-to-Digital Converter with 1.3 ps Resolution Implemented in a 28 nm FPGA. Sensors 2022, 22, 2306. https://doi.org/10.3390/s22062306

Mao X, Yang F, Wei F, Shi J, Cai J, Cai H. A Low Temperature Coefficient Time-to-Digital Converter with 1.3 ps Resolution Implemented in a 28 nm FPGA. Sensors. 2022; 22(6):2306. https://doi.org/10.3390/s22062306

Chicago/Turabian StyleMao, Xiangyu, Fei Yang, Fang Wei, Jiawen Shi, Jian Cai, and Haiwen Cai. 2022. "A Low Temperature Coefficient Time-to-Digital Converter with 1.3 ps Resolution Implemented in a 28 nm FPGA" Sensors 22, no. 6: 2306. https://doi.org/10.3390/s22062306

APA StyleMao, X., Yang, F., Wei, F., Shi, J., Cai, J., & Cai, H. (2022). A Low Temperature Coefficient Time-to-Digital Converter with 1.3 ps Resolution Implemented in a 28 nm FPGA. Sensors, 22(6), 2306. https://doi.org/10.3390/s22062306