Design and Test of an Integrated Measurement System for Multi-Hole Probe Calibration and Vortex Measurement

Abstract

:1. Introduction

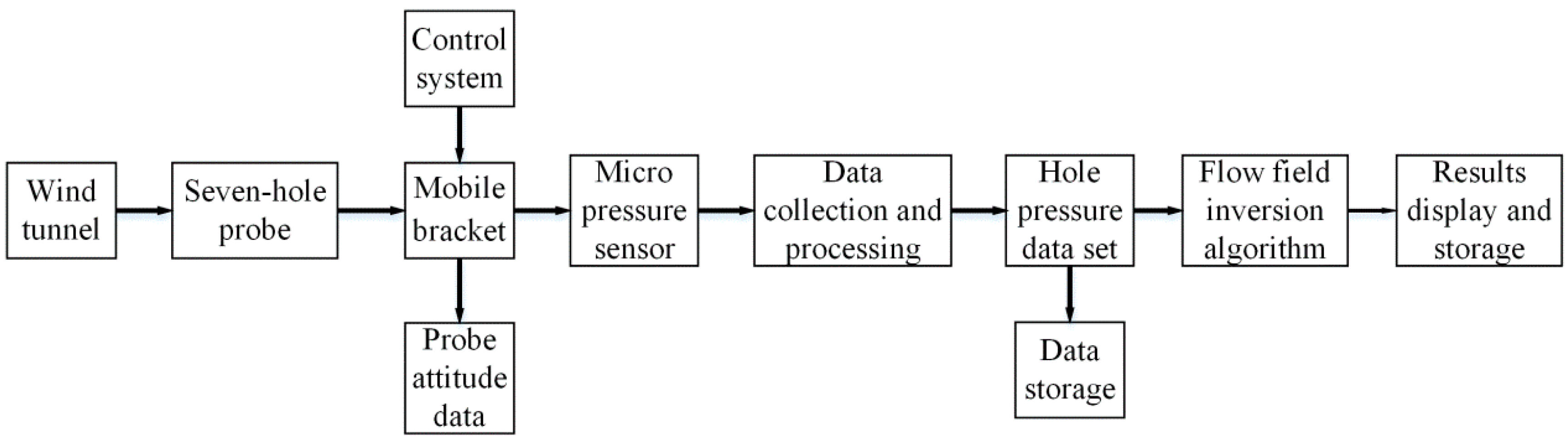

2. Design of the Test System

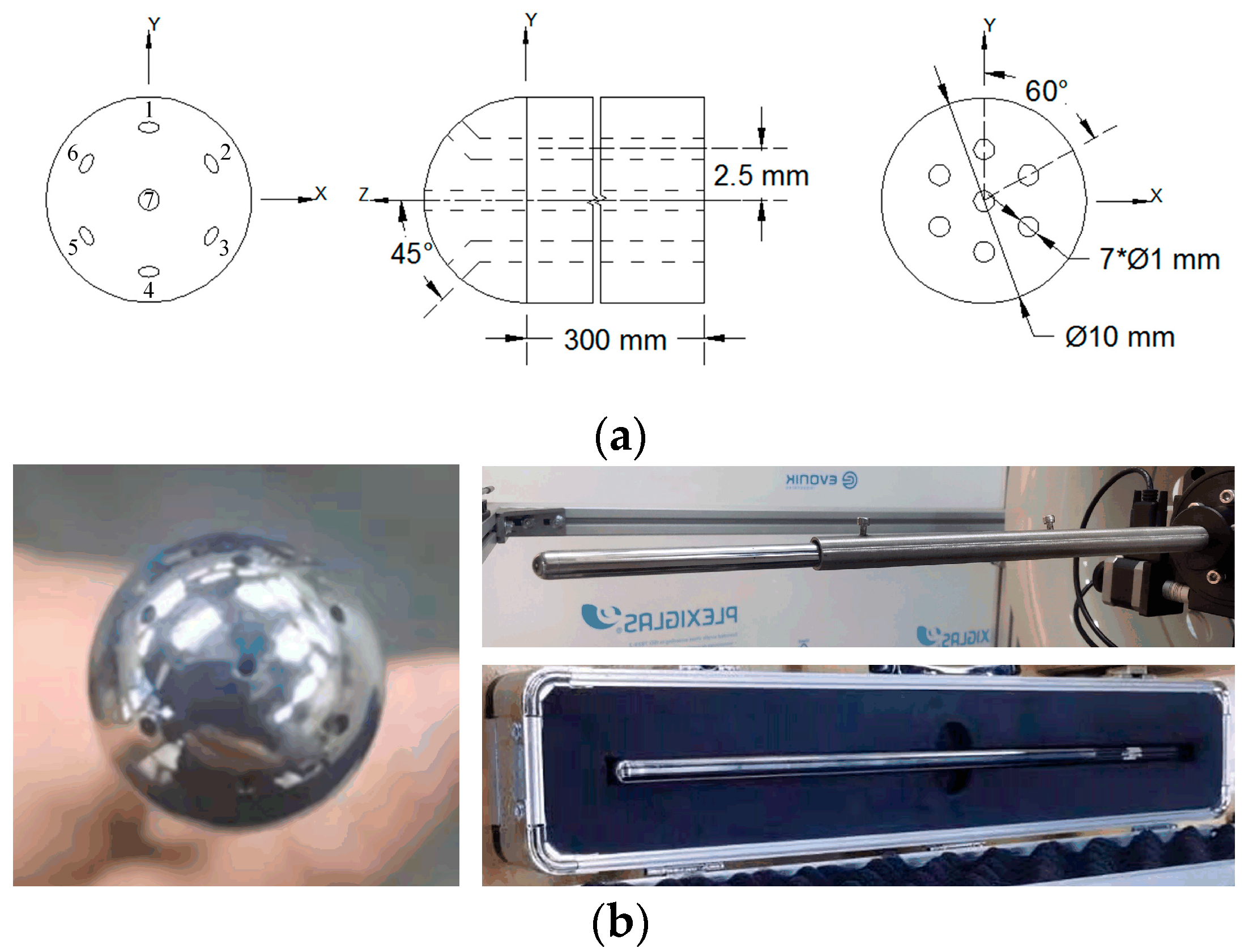

2.1. Structural Parameters of the Hemispherical Seven-Hole Probe

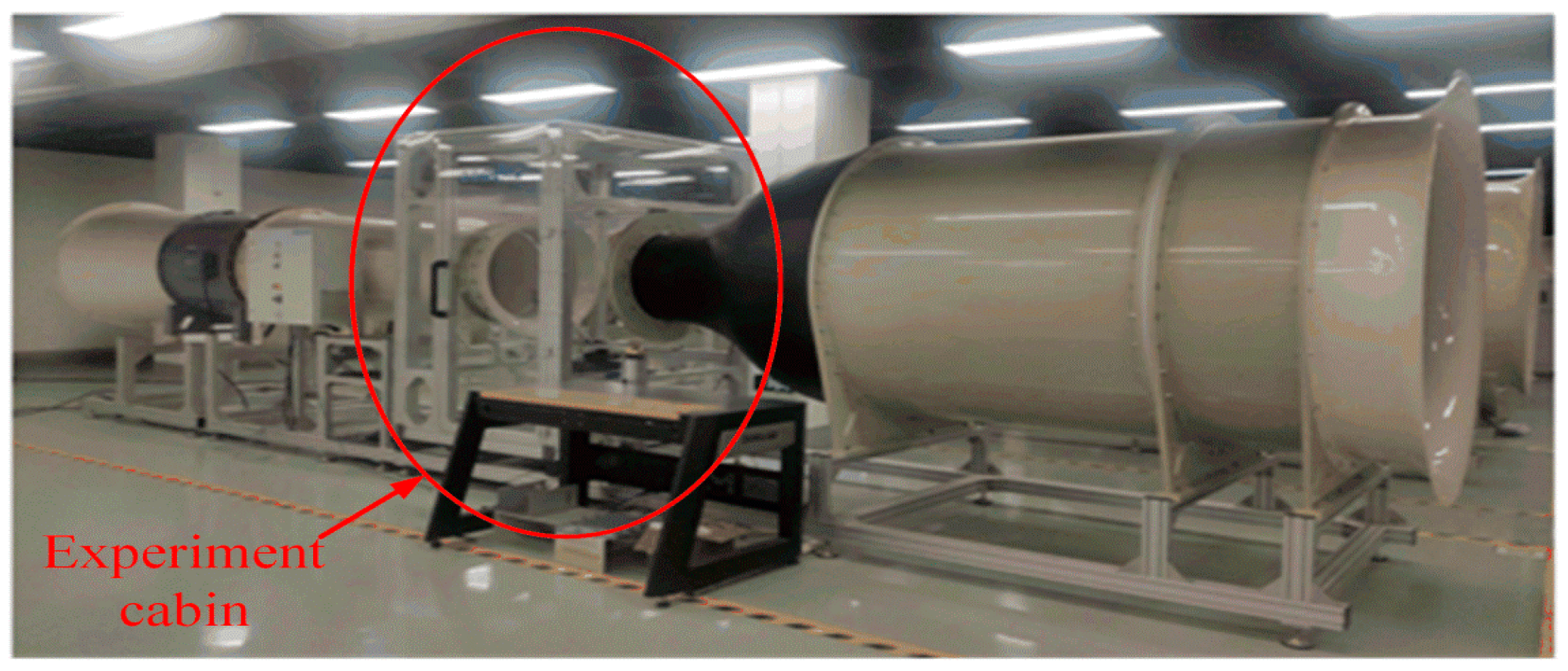

2.2. Straight Open Wind Tunnel Parameters

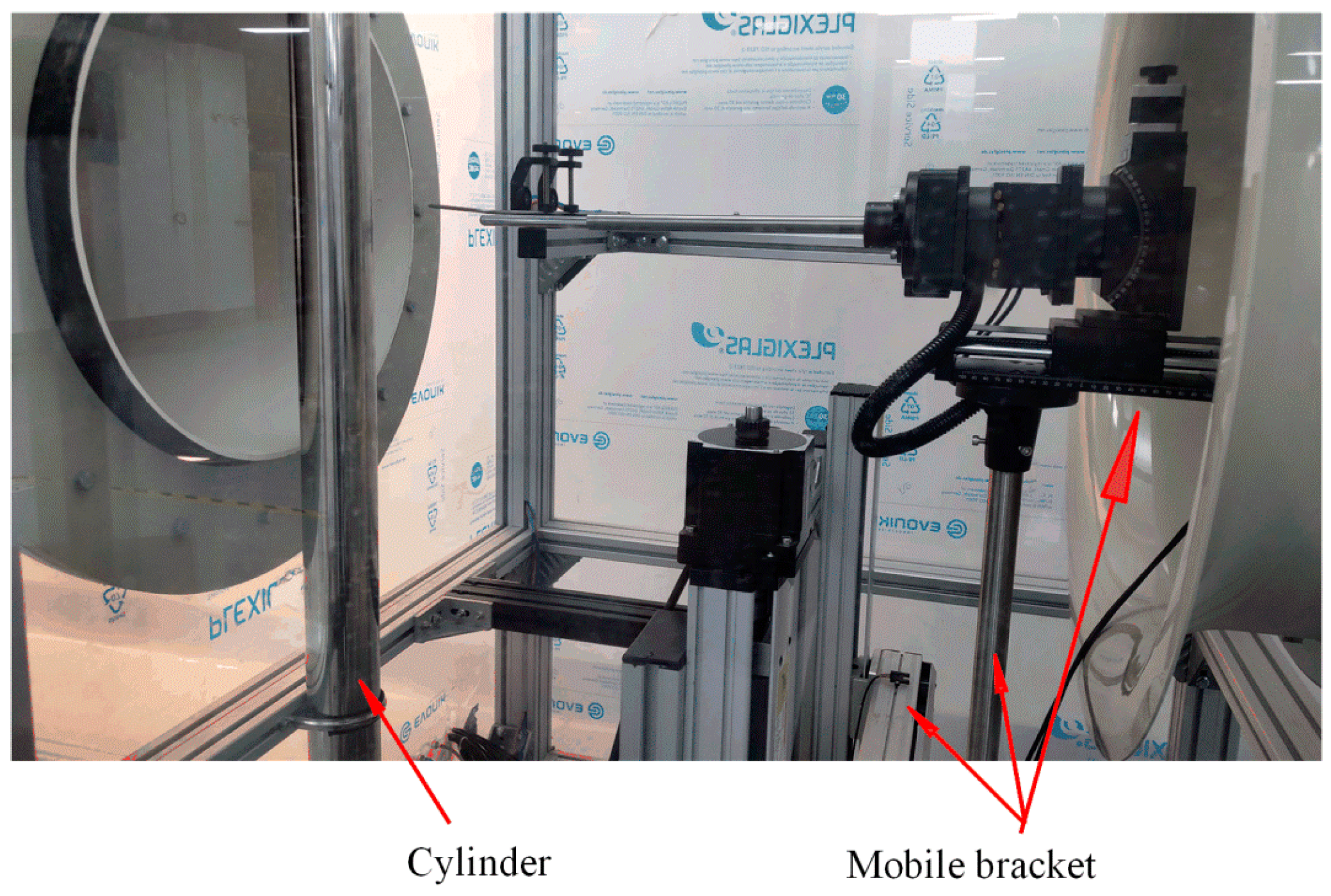

2.3. Three-Coordinate Mobile Bracket

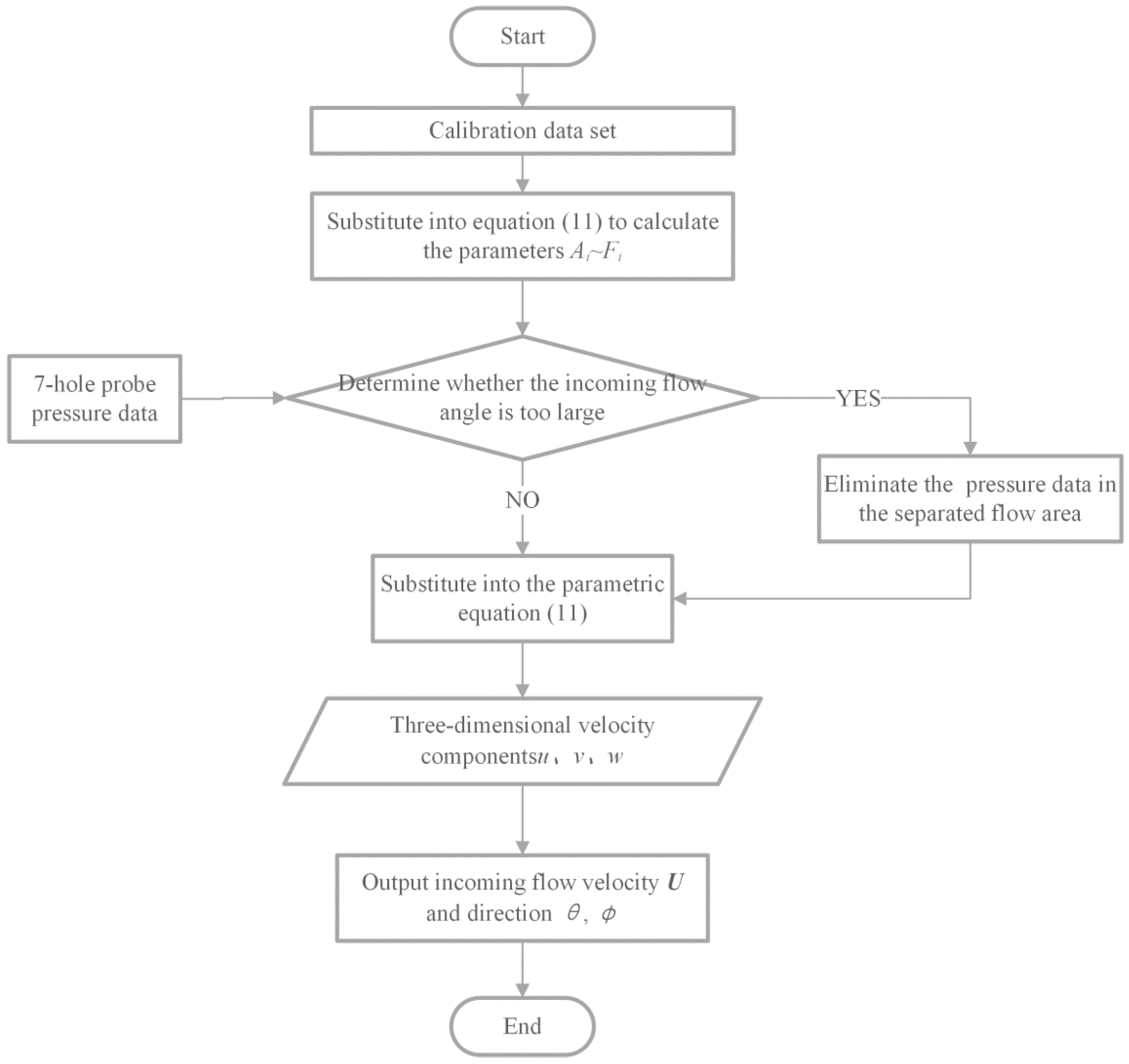

3. Multi-Hole Probe Calibration and Measurement

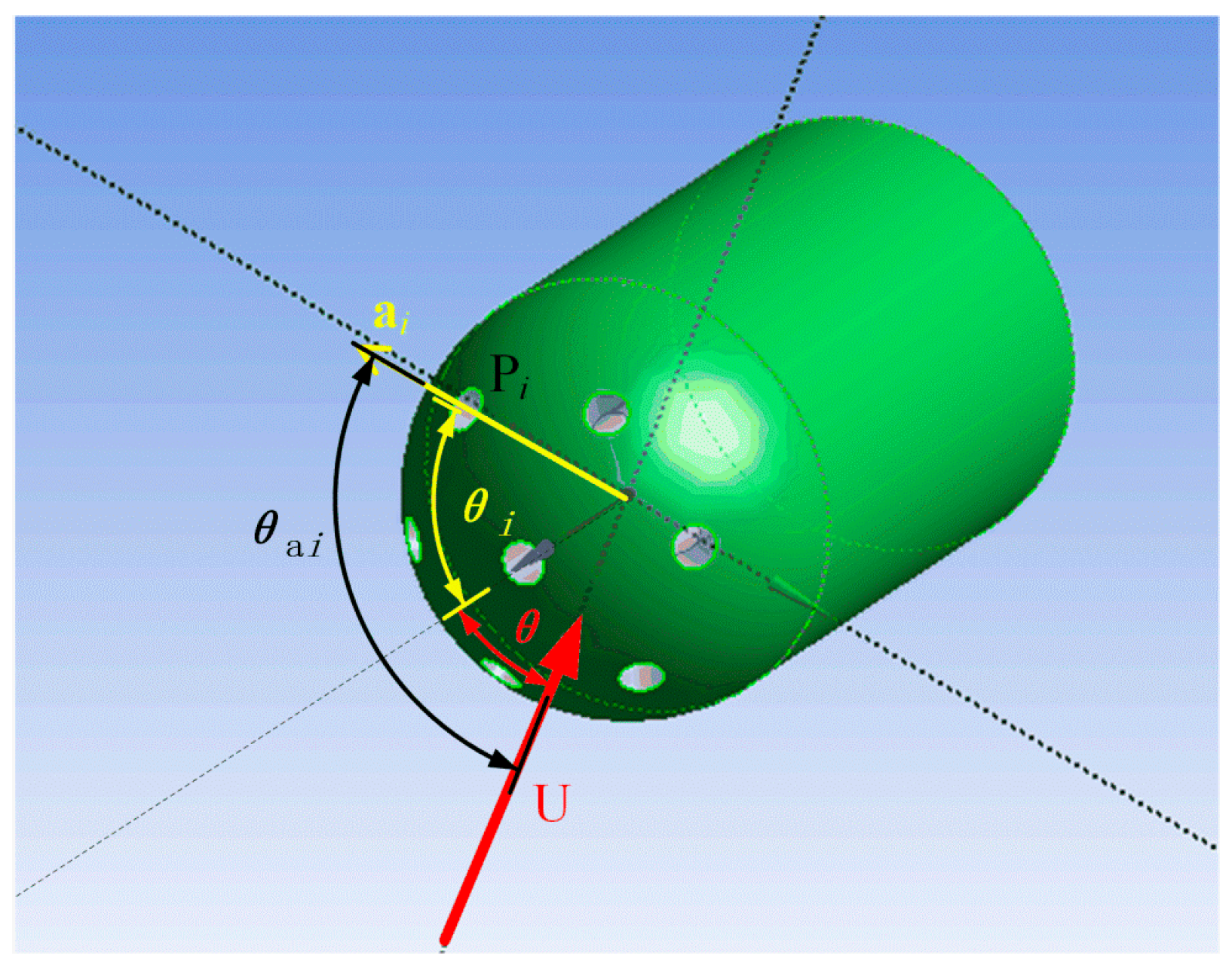

3.1. Calibration Method

3.2. Calibration and Measurement Steps

- Adjust the initial position of the probe, by changing the pitch and yaw angle to make the pressure of the outer six holes equal when the flow field is stable.

- Change the velocity of the flow field and the angle of the probe and record the pressure of seven holes under the flow conditions of known velocity and direction to obtain a calibration data set.

- According to the calibration pressure data set, select six groups of pressure data measured at different angles of attack and azimuth and substitute them into the calculation parameters using Equation (11).

- Substitute the obtained parameter group back into Equation (11) to obtain the pressure-velocity parameterized equation.

- Check whether the pressure data of seven holes are out of range during measurement.

- Substitute the pressure data of the seven holes into Equation (11), and calculate the three-dimensional velocity components u, v, and w at this time.

- Calculate the speed and direction of the incoming flow according to the angle relationship.

3.3. Calibration Results

4. Vortex Measurement

4.1. Measurement of the Flow Field around a Cylinder

- Calibrate the multi-hole probe and adjust the initial position.

- Divide the test points, as shown in Figure 9, for cylinders of different diameters, and move the multi-hole probe to the initial point.

- Install a cylinder with a diameter of 3 cm and measure sequentially from the initial point in the y direction and then in the x direction. Each test point should be kept constant for 5 s after being positioned, and the pressure data of the hole are to be collected after the flow field is stable. After all points are measured, a dataset is formed.

- Change the velocity of the flow field and set the velocity of the flow field to 5, 10, and 15 m/s, respectively. The test process is time consuming, and the environmental parameters need to be recorded at the beginning and end of the measurement to avoid long-term environmental changes that may affect the measurement.

- Steps 3 and steps 4 are repeated with cylinders of different diameters.

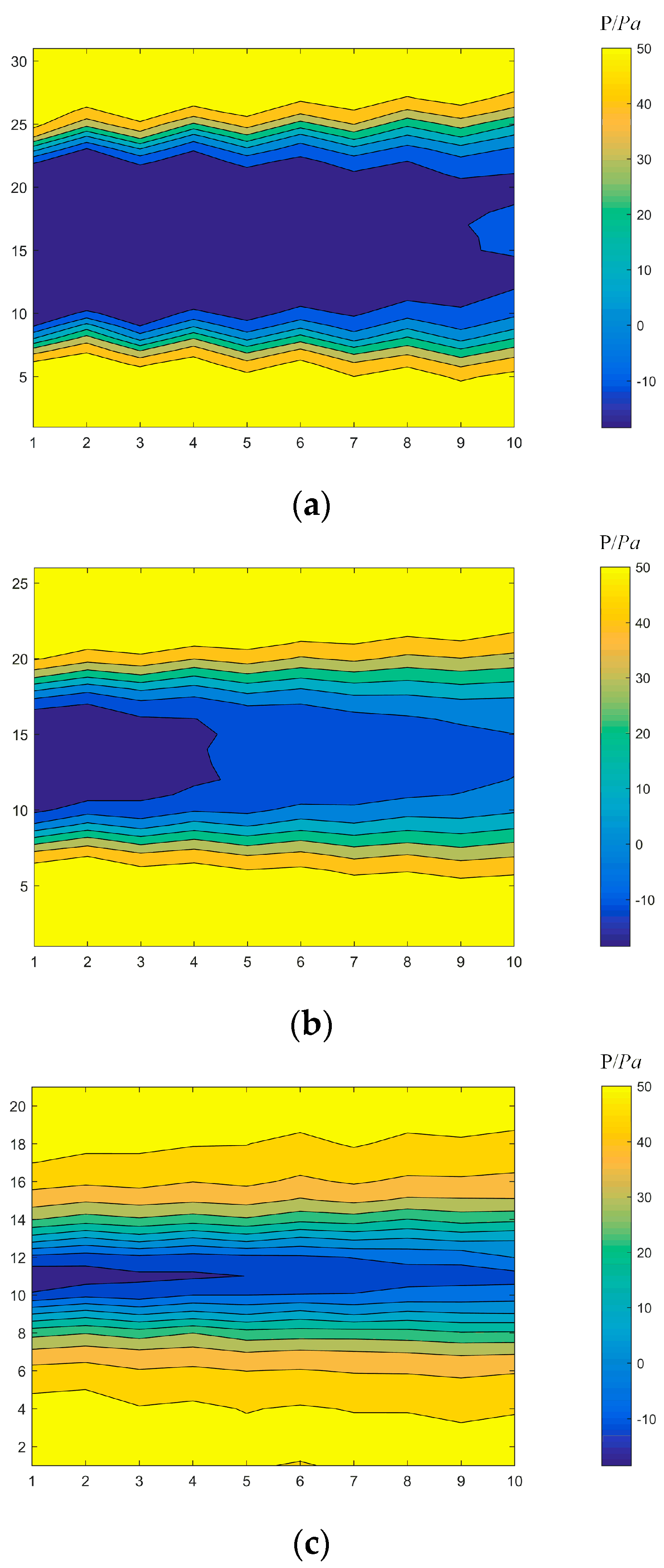

4.2. Pressure Distribution after Flow around a Cylinder

4.3. Analysis of the Frequency of Vortex Shedding in the Flow Field around a Cylinder

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Díaz, K.M.A.; Oro, J.M.F.; Marigorta, E.B. Cylindrical three-hole pressure probe calibration for large angular range. Flow Meas. Instrum. 2009, 20, 57–68. [Google Scholar] [CrossRef]

- Santiago, J.G.; Wereley, S.T.; Meinhart, C.D.; Beebe, D.J.; Adrian, R.J. A particle image velocimetry system for microfluidics. Exp. Fluids 1998, 25, 316–319. [Google Scholar] [CrossRef]

- Adrian, R.J. Twenty years of particle image velocimetry. Exp. Fluids 2005, 39, 159–169. [Google Scholar] [CrossRef]

- Zhang, H.; Huang, Y.; Sun, Z. A study of mass flow rate measurement based on the vortex shedding principle. Flow Meas. Instrum. 2006, 17, 29–38. [Google Scholar] [CrossRef]

- Rediniotis, O.; Edu, R.T. Recent Developments in Multi-Hole Probe (MHP) Technology. In Proceedings of the COBEM—International Congress of Mechanical Engineering, Gramado, RS, Brazil, 15–20 November 2009; Available online: http://abcm.org.br/anais/cobem/2009/pdf/COB09-3415.pdf (accessed on 29 January 2022).

- Hall, B.F.; Povey, T. The Oxford Probe: An open access five-hole probe for aerodynamic measurements. Meas. Sci. Technol. 2017, 28, 035004. [Google Scholar] [CrossRef]

- Pisasale, A.J.; Ahmed, N.A. Theoretical calibration for highly three-dimensionallow-speed flows of a five-hole probe. Meas. Sci. Technol. 2002, 13, 1100. [Google Scholar] [CrossRef]

- Zilliac, G.G. Calibration of Seven-Hole Probes for Use in Fluid Flows with Large Angularity. NASA TM 102200, 1989. Available online: https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19900006083.pdf (accessed on 29 January 2022).

- Crawford, J.; Birk, M.A. Influence of Tip Shape on Reynolds Number Sensitivity for a Seven Hole Pressure Probe. J. Eng. Gas Turbines Power 2013, 135, 1–8. [Google Scholar] [CrossRef]

- Wu, G.; Guo, X.; Yang, K.; Yang, H. A robust calibration method for seven-hole pressure probes. Exp. Fluids 2019, 60, 120. [Google Scholar] [CrossRef]

- Georgiou, D.P.; Milidonis, K.F. Fabrication and calibration of a sub-miniature 5-hole probe with embedded pressure sensors for use in extremely confined and complex flow areas in turbomachinery research facilities. Flow Meas. Instrum. 2014, 39, 54–63. [Google Scholar] [CrossRef]

- Shaw-Ward, S.; Titchmarsh, A.; Birch, D.M. Calibration and Use of n-Hole Velocity Probes. AIAA J. 2014, 53, 336–346. [Google Scholar] [CrossRef] [Green Version]

- Shaw-Ward, S.; McParlin, S.C.; Nathan, P.; Birch, D.M. Optimal Calibration of Directional Velocity Probes. AIAA J. 2018, 56, 2594–2603. [Google Scholar] [CrossRef] [Green Version]

- Yao, T.; Zhou, S.-D.; Wang, M.; Zhang, Y.-C.; Ye, S. Calibration model and numerical simulation of a 7-hole probe based on pressure–velocity parameterization equation. Meas. Sci. Technol. 2022, 33, 025902. [Google Scholar] [CrossRef]

- Yao, T.; Zhou, S.D.; Wang, M.; Ye, S.; Zhang, Y.-C. Optimal design of hemispherical 7-hole probe tip with perpendicular holes. IEEE Access 2021, 9, 85101–85108. [Google Scholar] [CrossRef]

- Batchelor, G.K. An Introduction to Fluid Dynamics; Cambridge University Press: Cambridge, UK, 1967. [Google Scholar]

- Gerner, A.A.; Maurer, C.L.; Gallington, R.W. Non-nulling seven-hole probes for high angle flow measurement. Exp. Fluids 1984, 2, 95–103. [Google Scholar] [CrossRef]

| Technical Indicators | Value |

|---|---|

| Diameter of the experimental section | 600 mm |

| Length of the experimental section | 1000 mm |

| Shrinkage ratio | 1:6 |

| Wind speed range | 0.2–40 m/s |

| Uniformity of the flow field | ≤1% |

| Turbulence | <0.5% |

| Wind tunnel size | 10,023 × 1970 × 2500 mm |

| U (m/s) | u (m/s) | v (m/s) | w (m/s) | ΔU | Δθ (deg) | Δϕ (deg) |

|---|---|---|---|---|---|---|

| 10.1223 | 9.7632 | 2.3353 | 1.2986 | 1.2236% | 0.31 | 0.92 |

| 18.7771 | 17.8729 | 5.0146 | 2.8273 | 6.1144% | 2.85 | 0.59 |

| 29.2892 | 28.5301 | 5.6511 | 3.4578 | 2.3693% | 1.93 | 1.46 |

| 40.0302 | 38.6928 | 9.3067 | 4.3205 | 0.0754% | 0.15 | 5.10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, T.; Zhou, S.; Ye, S. Design and Test of an Integrated Measurement System for Multi-Hole Probe Calibration and Vortex Measurement. Sensors 2022, 22, 2376. https://doi.org/10.3390/s22062376

Yao T, Zhou S, Ye S. Design and Test of an Integrated Measurement System for Multi-Hole Probe Calibration and Vortex Measurement. Sensors. 2022; 22(6):2376. https://doi.org/10.3390/s22062376

Chicago/Turabian StyleYao, Tao, Shudao Zhou, and Song Ye. 2022. "Design and Test of an Integrated Measurement System for Multi-Hole Probe Calibration and Vortex Measurement" Sensors 22, no. 6: 2376. https://doi.org/10.3390/s22062376

APA StyleYao, T., Zhou, S., & Ye, S. (2022). Design and Test of an Integrated Measurement System for Multi-Hole Probe Calibration and Vortex Measurement. Sensors, 22(6), 2376. https://doi.org/10.3390/s22062376