A Wireless Indoor Environmental Quality Logger Processing the Indoor Global Comfort Index

Abstract

:1. Introduction

2. IEQ Logger Hardware and Software

- High response time (which leads to problems when numerous measurements are performed);

- Overestimating radiant contributions due to horizontal surfaces (ceiling and floor), due to its (perfectly) spherical shape;

- Not allowing the radiant temperature asymmetry calculation in moderate environments;

- Complex interfacing to the embedded systems (such as Raspberry Pi [56]);

- The required instrumentation would not be suitable for the environment in question (a classroom full of students) but rather for a “controlled” environment or a laboratory.

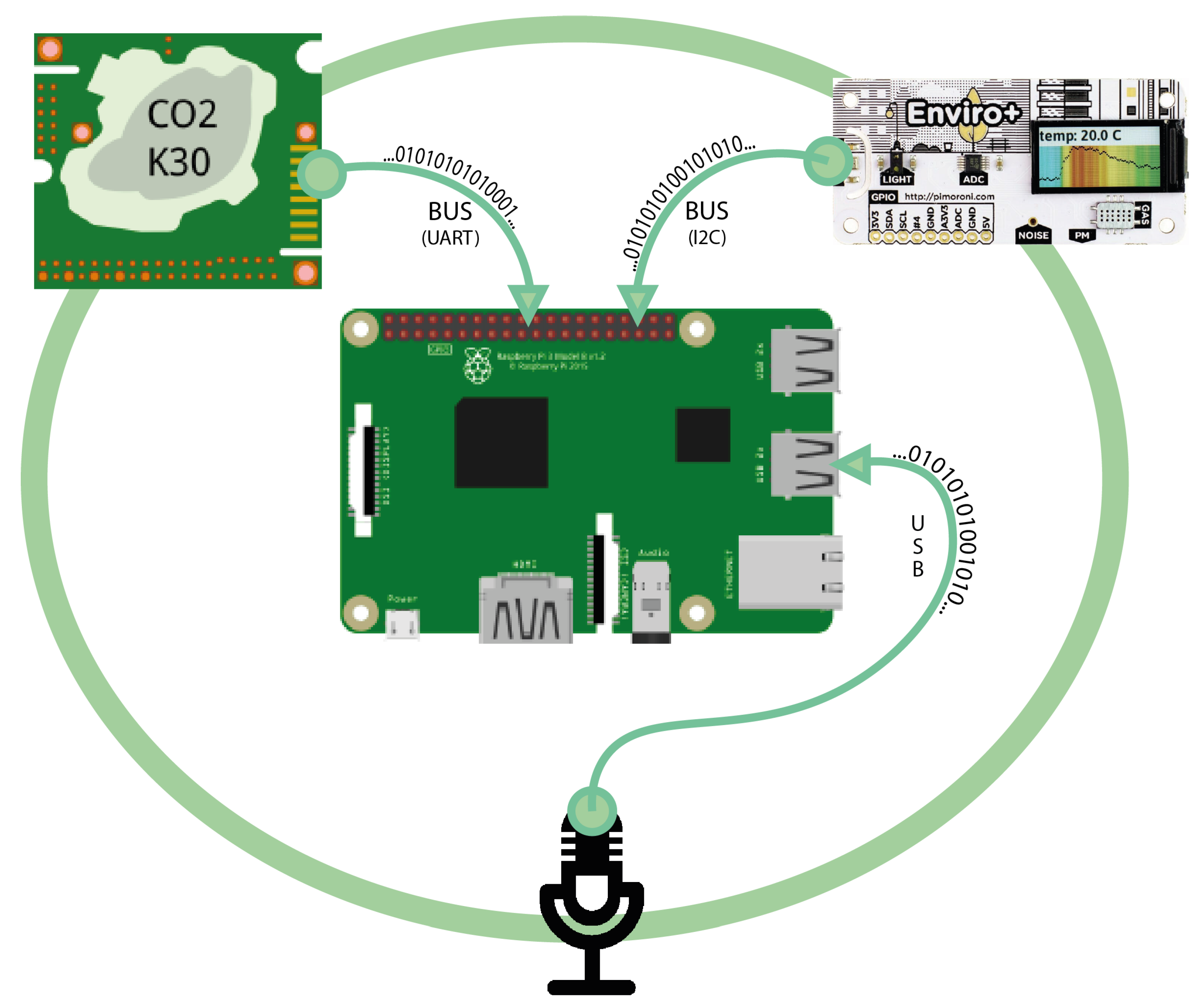

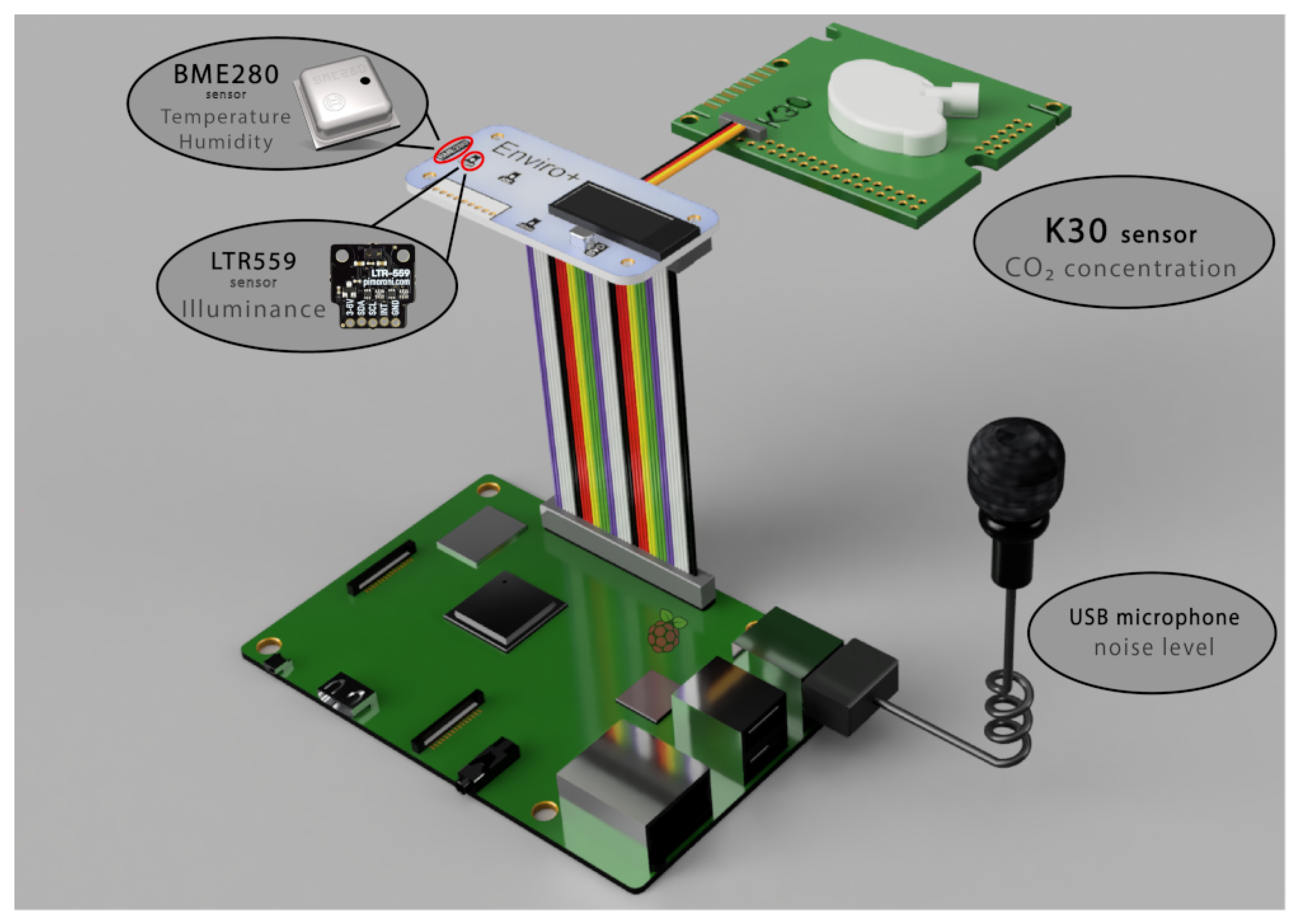

2.1. Hardware Implementation

2.2. Software Implementation

3. Case Study and Methods

3.1. Deployment

- It was sufficiently far from radiators or windows, allowing for correct temperature and humidity measurement;

- It was at a medium height, in order to correctly measure the CO2 concentration (corresponding approximately to the height of the air inhaled by people);

- It was in the middle of the side, because it was optimal for the perceived noise level (not too close to the teacher’s voice) and to detect both the artificial light (from neon) and natural light (from the windows at the bottom of the classroom);

- It was not too far from the wireless repeater (to ensure a good wireless signal).

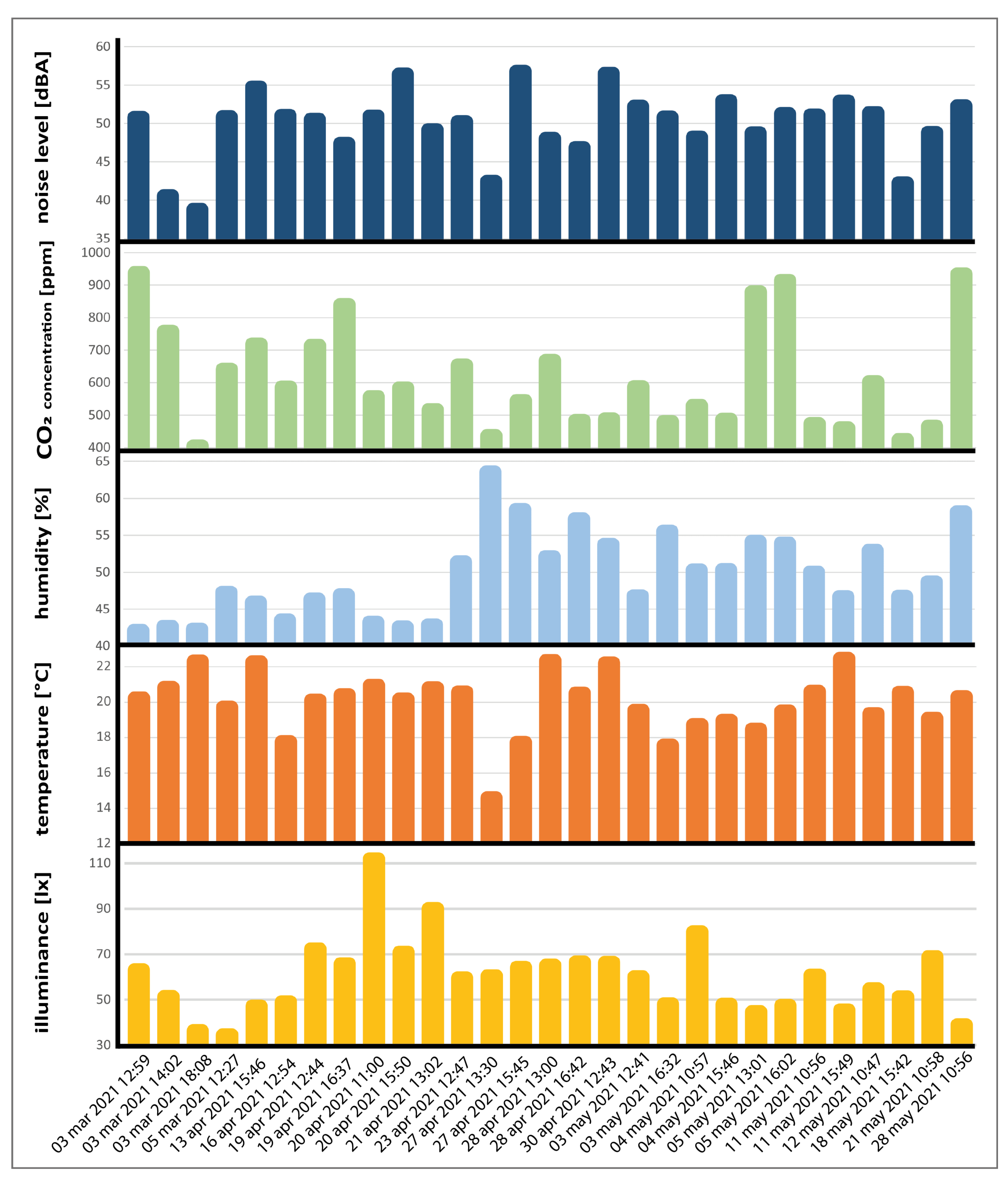

3.2. Data Collection

3.3. Methods

4. Results and Discussion

4.1. Data Analysis

- Thermal comfort: 37%;

- IAQ: 30%;

- Visual comfort: 16%;

- Acoustic comfort: 17%.

4.2. Model Building and Characterization

- In the worst case, will hardly go to 3 or 5 ();

- On average, will return 4.38 or 3.62;

- In the best case, will coincide with 4.00.

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pasini, D.; Ventura, S.M.; Rinaldi, S.; Bellagente, P.; Flammini, A.; Ciribini, A.L.C. Exploiting Internet of Things and building information modeling framework for management of cognitive buildings. In Proceedings of the 2016 IEEE International Smart Cities Conference (ISC2), Trento, Italy, 12–15 September 2016; pp. 1–6. [Google Scholar]

- Sarigiannis, D.A. Combined or Multiple Exposure to Health Stressors in Indoor Built Environments; Technical Report; WHO: Bonn, Germany, 2013. [Google Scholar]

- Vischer, J.C. The concept of workplace performance and its value to managers. Calif. Manag. Rev. 2007, 49, 62–79. [Google Scholar] [CrossRef] [Green Version]

- Vischer, J.C. Towards an environmental psychology of workspace: How people are affected by environments for work. Archit. Sci. Rev. 2008, 51, 97–108. [Google Scholar] [CrossRef]

- Woo, J.H. Towards Sustainable Workplaces: Effects of Indoor Environmental Quality on Occupant Comfort and Work Performance. Ph.D. Thesis, Faculty of Built Environment, The University of New South Wales, Sydney, Australia, 2010. [Google Scholar]

- Olesen, B.W. Indoor Environmental Input Parameters for Design and Assessment of Energy Performance of Buildings. REHVA J. 2015, 17–23. Available online: https://backend.orbit.dtu.dk/ws/portalfiles/portal/106970879/Indoor_Environmental_input_parameters_for_the_design_and_assessment_of_energy_performance_of_buildings.pdf (accessed on 20 September 2021).

- EN 16798-1:2019; Energy Performance of Buildings—Ventilation for Buildings—Part 1: Indoor Environmental Input Parameters for Design and Assessment of Energy Performance of Buildings Addressing Indoor Air Quality, Thermal Environment, Lighting and Acoustics—Module M1-6. European Committee for Standardization: Bruxelles, Belgium, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/b4f68755-2204-4796-854a-56643dfcfe89/en-16798-1-2019 (accessed on 20 September 2021).

- Persiani, S.G.; Kobas, B.; Koth, S.C.; Auer, T. Biometric data as real-time measure of physiological reactions to environmental stimuli in the built environment. Energies 2021, 14, 232. [Google Scholar] [CrossRef]

- ISO 7730:2005; Ergonomics of the Thermal Environment—Analytical Determination and Interpretation of Thermal Comfort Using Calculation of The PMV and PPD Indices and Local Thermal Comfort Criteria. ISO—International Organization for Standardization: Geneva, Switzerland, 2005. Available online: https://www.iso.org/standard/39155.html (accessed on 20 September 2021).

- Teodoreanu, E. Thermal Comfort Index. Present Environ. Sustain. Dev. 2016, 10, 105–118. [Google Scholar] [CrossRef] [Green Version]

- Wolkoff, P. The mystery of dry indoor air—An overview. Environ. Int. 2018, 121, 1058–1065. [Google Scholar] [CrossRef] [PubMed]

- ASHRAE Standard 55:2020; Thermal Environmental Conditions for Human Occupancy. ASHRAE—American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2020. Available online: https://www.ashrae.org/technical-resources/bookstore/standard-55-thermal-environmental-conditions-for-human-occupancy (accessed on 20 September 2021).

- Wolkoff, P.; Azuma, K.; Carrer, P. Health, work performance, and risk of infection in office-like environments: The role of indoor temperature, air humidity, and ventilation. Int. J. Hyg. Environ. Health 2021, 233, 113709. [Google Scholar] [CrossRef]

- ASHRAE. Ventilation and Infiltration chapter. In Fundamentals Volume of the ASHRAE Handbook; American Society of Heating Refrigerating and Air-Conditionin: Atlanta, GA, USA, 2005. [Google Scholar]

- The National Institute for Occupational Safety and Health (NIOSH). Indoor Environmental Quality; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Kilpatrick, K. Sick Classrooms Caused by Rising CO2 Levels. 2014. Available online: https://energyalliancegroup.org/sick-classrooms-require-energy-efficient-solutions-2/ (accessed on 20 September 2021).

- Richter, M.; Horn, W.; Juritsch, E.; Klinge, A.; Radeljic, L.; Jann, O. Natural building materials for interior fitting and refurbishment—What about indoor emissions? Materials 2021, 14, 23. [Google Scholar] [CrossRef]

- Bettarello, F.; Caniato, M.; Scavuzzo, G.; Gasparella, A. Indoor acoustic requirements for autism-friendly spaces. Appl. Sci. 2021, 11, 3942. [Google Scholar] [CrossRef]

- Artan, D.; Ergen, E.; Tekce, I. Acoustical comfort in office buildings. In Proceedings of the Annual International Conference on Architecture and Civil Engineering; Global Science and Technology Forum: Singapore, 2019; pp. 145–149. [Google Scholar] [CrossRef]

- Caniato, M.; Bettarello, F.; Gasparella, A. Indoor and outdoor noise changes due to the COVID-19 lockdown and their effects on individuals’ expectations and preferences. Sci. Rep. 2021, 11, 16533. [Google Scholar] [CrossRef]

- IESNA. Lighting Handbook; IESNA: New York, NY, USA, 2000. [Google Scholar]

- Kim, W.; Kim, J. The Scope of the Glare Light Source of the Window with Non-uniform Luminance Distribution. Indoor Built Environ. 2011, 20, 54–64. [Google Scholar] [CrossRef]

- Cantin, F.; Dubois, M.C. Daylighting metrics based on illuminance, distribution, glare and directivity. Light. Res. Technol. 2011, 43, 291–307. [Google Scholar] [CrossRef]

- Sapia, C. Daylighting in buildings: Developments of sunlight addressing by optical fiber. Sol. Energy 2013, 89, 113–121. [Google Scholar] [CrossRef]

- Carlucci, S.; Causone, F.; De Rosa, F.; Pagliano, L. A review of indices for assessing visual comfort with a view to their use in optimization processes to support building integrated design. Renew. Sustain. Energy Rev. 2015, 47, 1016–1033. [Google Scholar] [CrossRef] [Green Version]

- EN 12665:2018; Light and Lighting—Basic Terms and Criteria for Specifying Lighting Requirements. European Committee for Standardization: Bruxelles, Belgium, 2018. Available online: https://standards.iteh.ai/catalog/standards/cen/43e4dbbf-7710-4b60-9872-ad27a25a4661/en-12665-2018 (accessed on 20 September 2021).

- Skov, P.; Valbjørn, O. The “sick” building syndrome in the office environment: The Danish Town Hall Study. Environ. Int. 1987, 13, 339–349. [Google Scholar] [CrossRef]

- Burge, S.; Hedge, A.; Wilson, S.; Bass, J.H.; Robertson, A. Sick building syndrome: A study of 4373 office workers. Ann. Occup. Hyg. 1987, 31, 493–504. [Google Scholar] [PubMed]

- Norbäck, D.; Michel, I.; Widström, J. Indoor air quality and personal factors related to the sick building syndrome. Scand. J. Work. Environ. Health 1990, 16, 121–128. [Google Scholar] [CrossRef]

- Chirico, F. The «Indoor Environmental Quality» as an ergonomic risk factor at workplace: Proposal for a risk assessment strategy. SSRN Electron. J. 2021. [Google Scholar] [CrossRef]

- Reffat, R.M.; Harkness, E.L. Environmental comfort criteria: Weighting and integration. J. Perform. Constr. Facil. 2001, 15, 104–108. [Google Scholar] [CrossRef]

- Reffat, R.M.; Harkness, E.L. Expert System for Environmental Quality Evaluation. J. Perform. Constr. Facil. 2001, 15, 109–114. [Google Scholar] [CrossRef]

- Chiang, C.M.; Lai, C.M. A study on the comprehensive indicator of indoor environment assessment for occupants’ health in Taiwan. Build. Environ. 2002, 37, 387–392. [Google Scholar] [CrossRef]

- Humphreys, M.A. Quantifying occupant comfort: Are combined indices of the indoor environment practicable? Build. Res. Inf. 2005, 33, 317–325. [Google Scholar] [CrossRef]

- Wong, L.T.; Mui, K.W.; Hui, P.S. A multivariate-logistic model for acceptance of indoor environmental quality (IEQ) in offices. Build. Environ. 2008, 43, 1–6. [Google Scholar] [CrossRef]

- Astolfi, A.; Pellerey, F. Subjective and objective assessment of acoustical and overall environmental quality in secondary school classrooms. J. Acoust. Soc. Am. 2008, 123, 163–173. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Choi, J.H.; Aziz, A.; Loftness, V. Decision support for improving occupant environmental satisfaction in office buildings: The relationship between sub-set of IEQ satisfaction and overall environmental satisfaction. In Proceedings of the 9th International Conference and Exhibition—Healthy Buildings 2009, Syracuse, NY, USA, 13–17 September 2009. [Google Scholar]

- Lai, A.C.; Mui, K.W.; Wong, L.T.; Law, L.Y. An evaluation model for indoor environmental quality (IEQ) acceptance in residential buildings. Energy Build. 2009, 41, 930–936. [Google Scholar] [CrossRef]

- Bluyssen, P.M.; Aries, M.; van Dommelen, P. Comfort of workers in office buildings: The European HOPE project. Build. Environ. 2011, 46, 280–288. [Google Scholar] [CrossRef]

- Marino, C.; Nucara, A.; Pietrafesa, M. Proposal of comfort classification indexes suitable for both single environments and whole buildings. Build. Environ. 2012, 57, 58–67. [Google Scholar] [CrossRef]

- Cao, B.; Ouyang, Q.; Zhu, Y.; Huang, L.; Hu, H.; Deng, G. Development of a multivariate regression model for overall satisfaction in public buildings based on field studies in Beijing and Shanghai. Build. Environ. 2012, 47, 394–399. [Google Scholar] [CrossRef]

- Ncube, M.; Riffat, S. Developing an indoor environment quality tool for assessment of mechanically ventilated office buildings in the UK—A preliminary study. Build. Environ. 2012, 53, 26–33. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.; Haberl, J.S. Field-test of the new ASHRAE/CIBSE/USGBC performance measurement protocols for commercial buildings: Basic level. ASHRAE Trans. 2012, 118, 135–142. [Google Scholar]

- Fassio, F.; Fanchiotti, A.; de Lieto Vollaro, R. Linear, non-linear and alternative algorithms in the correlation of IEQ factors with global comfort: A case study. Sustainability 2014, 6, 8113–8127. [Google Scholar] [CrossRef] [Green Version]

- Loreti, L.; Barbaresi, L.; De Cesaris, S.; Garai, M. Overall indoor quality of a non-renewed secondary-school building. Energy Procedia 2015, 78, 3126–3131. [Google Scholar] [CrossRef] [Green Version]

- Wei, W.; Wargocki, P.; Zirngibl, J.; Bendžalová, J.; Mandin, C. Review of parameters used to assess the quality of the indoor environment in Green Building certification schemes for offices and hotels. Energy Build. 2020, 209, 109683. [Google Scholar] [CrossRef]

- Silva, M.F.; Maas, S.; de Souza, H.A.; Gomes, A.P. Post-occupancy evaluation of residential buildings in Luxembourg with centralized and decentralized ventilation systems, focusing on indoor air quality (IAQ). Assessment by questionnaires and physical measurements. Energy Build. 2017, 148, 119–127. [Google Scholar] [CrossRef]

- Ricciardi, P.; Buratti, C. Environmental quality of university classrooms: Subjective and objective evaluation of the thermal, acoustic, and lighting comfort conditions. Build. Environ. 2018, 127, 23–36. [Google Scholar] [CrossRef]

- Day, J.K.; Futrell, B.; Cox, R.; Ruiz, S.N. Blinded by the light: Occupant perceptions and visual comfort assessments of three dynamic daylight control systems and shading strategies. Build. Environ. 2019, 154, 107–121. [Google Scholar] [CrossRef]

- Ryu, J.; Kim, J.; Hong, W.; de Dear, R. Defining the thermal sensitivity (Griffiths constant) of building occupants in the Korean residential context. Energy Build. 2020, 208, 109648. [Google Scholar] [CrossRef]

- Riffelli, S. Global Comfort Indices in Indoor Environments: A Survey. Sustainability 2021, 13, 2784. [Google Scholar] [CrossRef]

- Yang, W.; Moon, H.J. Combined effects of acoustic, thermal, and illumination conditions on the comfort of discrete senses and overall indoor environment. Build. Environ. 2019, 148, 623–633. [Google Scholar] [CrossRef]

- Kim, J.; de Dear, R. Nonlinear relationships between individual IEQ factors and overall workspace satisfaction. Build. Environ. 2012, 49, 33–40. [Google Scholar] [CrossRef] [Green Version]

- Frontczak, M.; Wargocki, P. Literature survey on how different factors influence human comfort in indoor environments. Build. Environ. 2011, 46, 922–937. [Google Scholar] [CrossRef]

- Chen, C.F.; Yilmaz, S.; Pisello, A.L.; De Simone, M.; Kim, A.; Hong, T.; Bandurski, K.; Bavaresco, M.V.; Liu, P.L.; Zhu, Y. The impacts of building characteristics, social psychological and cultural factors on indoor environment quality productivity belief. Build. Environ. 2020, 185, 107189. [Google Scholar] [CrossRef]

- Teach, Learn, and Make with Raspberry Pi. Available online: https://www.raspberrypi.org/ (accessed on 20 September 2021).

- Arduino—Home. Available online: https://www.arduino.cc/ (accessed on 20 September 2021).

- Indoor Environment Sensor|Metriful. Available online: https://www.metriful.com/ms430 (accessed on 20 September 2021).

- Okdo Air Quality Kit—OKdo. Available online: https://www.okdo.com/project/okdo-air-quality-kit/ (accessed on 20 September 2021).

- Enviro for Raspberry Pi—Pimoroni. Available online: https://shop.pimoroni.com/products/enviro (accessed on 20 September 2021).

- ISO 7726:1998; Ergonomics of the tHermal Environment—Instruments for Measuring Physical Quantities. ISO—International Organization for Standardization: Geneva, Switzerland, 1998. Available online: https://www.iso.org/standard/14562.html (accessed on 20 September 2021).

- D’Ambrosio Alfano, F.; Dell’Isola, M.; Palella, B.; Riccio, G.; Russi, A. La misura della temperatura media radiante. In 61° Congresso Nazionale ATI; ATI: Perugia, Italy, 2006; pp. 285–290. [Google Scholar]

- CBE Thermal Comfort Tool. Available online: https://comfort.cbe.berkeley.edu/ (accessed on 20 September 2021).

- The Engineering ToolBox: Decibel A, B and C. Available online: https://www.engineeringtoolbox.com/decibel-d_59.html (accessed on 20 September 2021).

- Raspberry Pi 3 Model B+—Raspberry Pi. Available online: https://www.raspberrypi.org/products/raspberry-pi-3-model-b-plus/ (accessed on 20 September 2021).

- K-30—CO2 Sensor, Datasheet. Available online: http://co2meters.com/Documentation/Datasheets/DS_SE_0118_CM_0024_Revised9%20(1).pdf (accessed on 20 September 2021).

- BME280, Datasheet. Available online: https://www.bosch-sensortec.com/media/boschsensortec/downloads/datasheets/bst-bme280-ds002.pdf (accessed on 20 September 2021).

- LTR-559, Datasheet. Available online: https://optoelectronics.liteon.com/upload/download/ds86-2013-0003/ltr-559als-01_ds_v1.pdf (accessed on 20 September 2021).

- Enviroplus at Raspberry Pi GPIO Pinout. Available online: https://pinout.xyz/pinout/1_wire (accessed on 20 September 2021).

- Pimoroni Enviro+. Available online: https://learn.pimoroni.com/article/getting-started-with-enviro-plus (accessed on 20 September 2021).

- MiCS-6814, Datasheet. Available online: https://www.sgxsensortech.com/content/uploads/2015/02/1143_Datasheet-MiCS-6814-rev-8.pdf (accessed on 20 September 2021).

- VLIKE 6708 LCD Digital Audio Decibel Sound Level Meter. Available online: https://www.amazon.com/VLIKE-Digital-Measurement-Measuring-Function/dp/B01N2RLJ32 (accessed on 20 September 2021).

- Specifications for Netatmo Weather Station. Available online: https://www.netatmo.com/en-gb/weather/weatherstation/specifications (accessed on 20 September 2021).

- ThermoPro TP-53, Manual. Available online: https://buythermopro.com/wp-content/uploads/2018/06/Thermopro-DE-EN-FR-IT-ES-TP-53-instruction-manual-20180424.pdf (accessed on 20 September 2021).

- Weather API—OpenWeatherMap. Available online: https://openweathermap.org/api (accessed on 20 September 2021).

- Mui, K.W.; Chan, W.T. A new indoor environmental quality equation for air-conditioned buildings. Archit. Sci. Rev. 2005, 48, 41–46. [Google Scholar] [CrossRef]

- Buratti, C.; Belloni, E.; Merli, F.; Ricciardi, P. A new index combining thermal, acoustic, and visual comfort of moderate environments in temperate climates. Build. Environ. 2018, 139, 27–37. [Google Scholar] [CrossRef]

- SPSS Software|IBM. Available online: https://www.ibm.com/analytics/spss-statistics-software (accessed on 20 September 2021).

- MATLAB|MathWorks. Available online: https://www.mathworks.com/products/matlab.html (accessed on 20 September 2021).

- Smart Indoor Air Quality Monitor|Netatmo. Available online: https://www.netatmo.com/en-eu/aircare/homecoach (accessed on 20 September 2021).

- Airthings Wave Plus|Smart Radon and Indoor Air Quality Monitor. Available online: https://www.airthings.com/en/wave-plus (accessed on 20 September 2021).

- Lai, J.H.K.; Yik, F.W.H. Perception of importance and performance of the indoor environmental quality of high-rise residential buildings. Build. Environ. 2009, 44, 352–360. [Google Scholar] [CrossRef]

- Marans, R.W.; Yan, X.Y. Lighting quality and environmental satisfaction in open and enclosed offices. J. Archit. Plan. Res. 1989, 6, 118–131. [Google Scholar]

- Klimaaktiv—Climate Protection in Austria, klimaaktiv EN. Available online: https://www.klimaaktiv.at/english/ (accessed on 20 September 2021).

- LiderA—Sustainable Assessment System. Available online: http://www.lidera.info/index.aspx?p=index&RegionId=3&Culture=en (accessed on 20 September 2021).

- NABERS International|NABERS. Available online: https://www.nabers.gov.au/about/nabers-international (accessed on 20 September 2021).

- Vilčeková, S.; Apostoloski, I.Z.; Mečiarová, Ľ.; Burdová, E.K.; Kiseľák, J. Investigation of indoor air quality in houses of Macedonia. Int. J. Environ. Res. Public Health 2017, 14, 37. [Google Scholar] [CrossRef] [Green Version]

- Fernández-Agüera, J.; Dominguez-Amarillo, S.; Fornaciari, M.; Orlandi, F. TVOCs and PM 2.5 in naturally ventilated homes: Three case studies in a mild climate. Sustainability 2019, 11, 6225. [Google Scholar] [CrossRef] [Green Version]

- Domínguez-amarillo, S.; Fernández-agüera, J.; Cesteros-garcía, S.; González-lezcano, R.A. Bad air can also kill: Residential indoor air quality and pollutant exposure risk during the COVID-19 crisis. Int. J. Environ. Res. Public Health 2020, 17, 7183. [Google Scholar] [CrossRef]

- Breen, M.S.; Isakov, V.; Prince, S.; McGuinness, K.; Egeghy, P.P.; Stephens, B.; Arunachalam, S.; Stout, D.; Walker, R.; Alston, L.; et al. Integrating personal air sensor and gps to determine microenvironment-specific exposures to volatile organic compounds. Sensors 2021, 21, 5659. [Google Scholar] [CrossRef]

| Comfort Category | Physical Parameter | Unit |

|---|---|---|

| Thermal comfort | Air temperature | °C |

| Relative humidity | % | |

| Indoor air quality (IAQ) | CO2 concentration | ppm |

| Visual comfort | Illuminance | lx |

| Acoustic comfort | Noise level | dBA |

| Physical Parameter | Sensor |

|---|---|

| Air temperature | BME280 sensor on Enviro+ board |

| Relative humidity | BME280 sensor on Enviro+ board |

| Illuminance | LTR-559 sensor on Enviro+ board |

| CO2 | K-30 sensor |

| Noise level | USB omnidirectional condenser microphone |

| Technical Features | BME280 | LTR-559 | K-30 | Microphone |

|---|---|---|---|---|

| Interface | I2C | USB 2.0 | ||

| (up to 3.4 MHz) | I2C (Fast Mode @ 400 kbit/s) | I2C | ||

| SPI | UART | |||

| (up to 10 MHz) | ||||

| Power supply | 1.71–3.6 V | 2.4–3.6 V | 5–9 V | 5 V |

| (preferred Operating range) | ||||

| Operating range | −40…+85 °C | 0–10,000 ppm | 84 dB (SNR) | |

| (temperature) | 0.01–64 k Lux | (total) | ||

| 0…100% | (6 dynamic range) | 0–5000 ppm | ||

| (rel. humidity) | (within specifications) | |||

| Accuracy | °C | - | ppm ± 3% | Sensitivity range: within −3 dB (at 1 V) |

| (temperature) | (of measured value within specifications) | |||

| (rel. humidity) | ||||

| Resolution | 0.01 °C (temperature) | 16-bit | 10 mV | - |

| 0.008% | (effective resolution) | (8.5 bits in the range 0–4 V) | ||

| (rel. humidity) | ||||

| Measurement/ Response Time | Response Time (): 1 s | Integration time: | Response Time (T1/e): | |

| 50 ms | 20 s (diffusion time) | Frequency | ||

| Measurement time: | Response Rate: | Response: | ||

| 100 ms | 2 s | 20 Hz–16 KHz | ||

| Dimensions | mm | mm | mm | mm |

| Other specifications | 3 power modes: sleep, normal, forced |

|

|

|

| Python Library File | Sensor |

|---|---|

| temperature.py | BME280 sensor on Enviro+ board |

| humidity.py | BME280 sensor on Enviro+ board |

| luminosity.py | LTR-559 sensor on Enviro+ board |

| co2_level.py | K-30 sensor |

| noise_level.py | USB omnidirectional condenser microphone |

| Model | Method | RMSE | MSE |

|---|---|---|---|

| Linear regression | Linear | 0.40 | 0.16 |

| Interactions linear | 0.40 | 0.16 | |

| Robust linear | 0.42 | 0.18 | |

| Stepwise Linear | 0.38 | 0.14 | |

| Regression trees | Fine tree | 0.58 | 0.34 |

| Medium tree | 0.51 | 0.26 | |

| Coarse tree | 0.51 | 0.26 | |

| Support vector machines | Linear SVM | 0.47 | 0.22 |

| Quadratic SVM | 0.47 | 0.22 | |

| Cubic SVM | 0.56 | 0.31 | |

| Fine Gaussian SVM | 0.51 | 0.26 | |

| Medium Gaussian SVM | 0.51 | 0.26 | |

| Coarse Gaussian SVM | 0.47 | 0.22 | |

| Gaussian process | Rational quadratic GPR | 0.55 | 0.30 |

| Regression | Squared exponential GPR | 0.53 | 0.28 |

| Matérn 5/2 GPR | 0.53 | 0.28 | |

| Exponential GPR | 0.52 | 0.27 | |

| Ensembles of trees | Boosted trees | 0.51 | 0.26 |

| Bagged trees | 0.48 | 0.23 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Riffelli, S. A Wireless Indoor Environmental Quality Logger Processing the Indoor Global Comfort Index. Sensors 2022, 22, 2558. https://doi.org/10.3390/s22072558

Riffelli S. A Wireless Indoor Environmental Quality Logger Processing the Indoor Global Comfort Index. Sensors. 2022; 22(7):2558. https://doi.org/10.3390/s22072558

Chicago/Turabian StyleRiffelli, Stefano. 2022. "A Wireless Indoor Environmental Quality Logger Processing the Indoor Global Comfort Index" Sensors 22, no. 7: 2558. https://doi.org/10.3390/s22072558