Detecting the Presence of Intrusive Drilling in Secure Transport Containers Using Non-Contact Millimeter-Wave Radar

Abstract

:1. Introduction

2. Background Information

2.1. Container Vibrational Model

2.2. Millimeter-Wave Radar Operating Principle

3. Signal-Processing Pipeline

- does not contain drilling ;

- : contains drilling

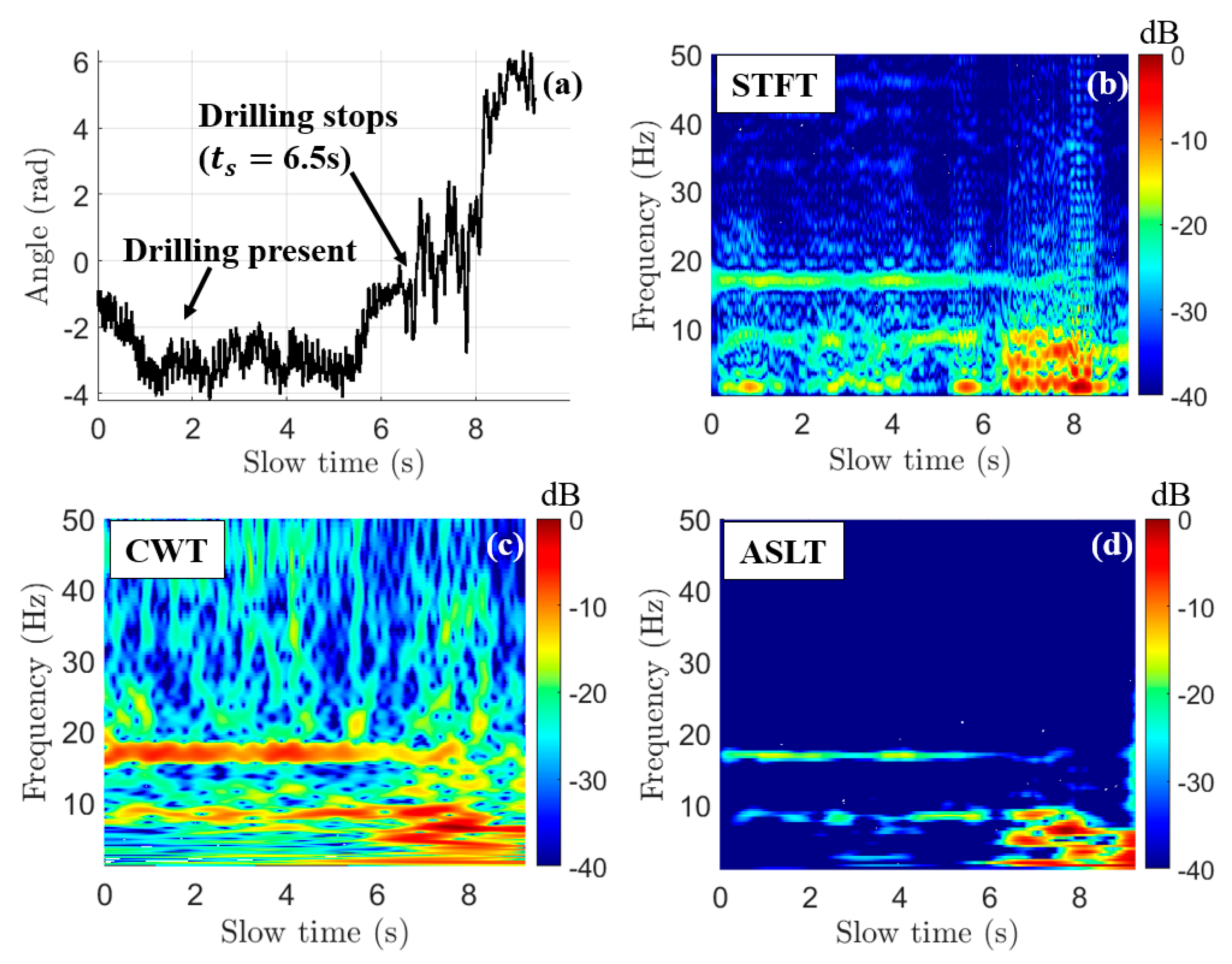

3.1. Time–Frequency Conversion

3.2. De-Cluttering

3.3. Search for Horizontal Harmonics

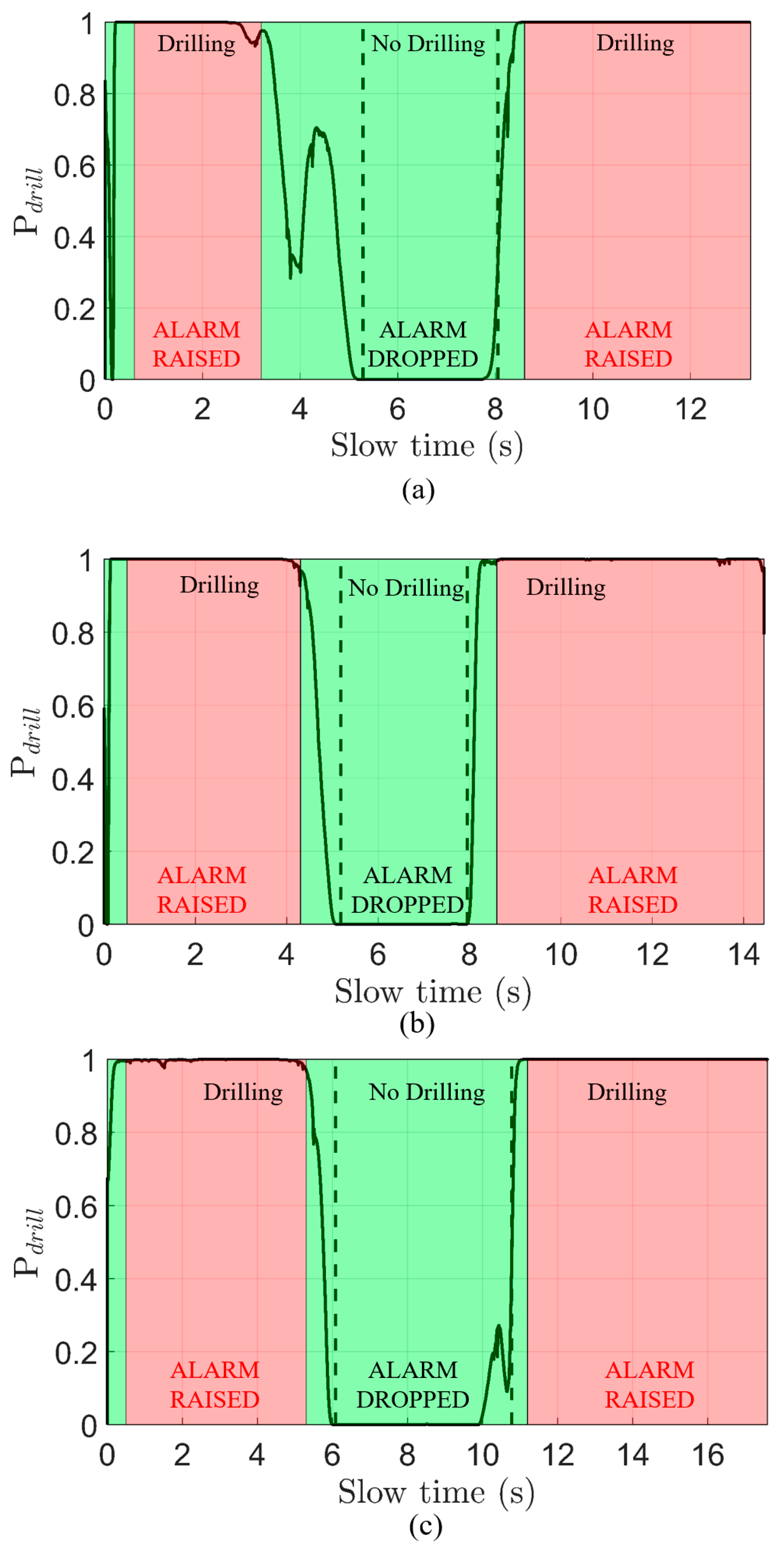

3.4. Detection and Probability-Versus-Time

4. Experimental Setup

5. Results

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Firsov, V.; Markowsky, G.; Kutovoy, S.; Pozdnyakov, D.; Litvinova, O.; Lyzikova, N. Detection of Unauthorized Intrusion into Cargo Containers that are under Custom Seals. In Proceedings of the 2005 IEEE Intelligent Data Acquisition and Advanced Computing Systems: Technology and Applications, Sofia, Bulgaria, 5–7 September 2005; pp. 366–368. [Google Scholar]

- Becker, K.; Sayhan, I.; Kluge, M.; Neubauer, F.; Gerum, B.; Enderle, S. Intrusion detection system for container security. In Proceedings of the SENSORS, 2008 IEEE, Lecce, Italy, 26–29 October 2008; pp. 1623–1625. [Google Scholar]

- Whiffen, J.; Naylor, M. Acoustic signal processing techniques for container security. In Proceedings of the IEE Seminar on Signal Processing Solutions for Homeland Security, Ref. No. 2005/11108, London, UK, 11 October 2005. [Google Scholar]

- Wang, G.; Muñoz-Ferreras, J.; Gu, C.; Li, C.; Gómez-García, R. Application of Linear-Frequency-Modulated Continuous-Wave (LFMCW) Radars for Tracking of Vital Signs. IEEE Trans. Microw. Theory Tech. 2014, 62, 1387–1399. [Google Scholar] [CrossRef]

- Butler, M.; Poitevin, P.; Bjomholt, J. Benefits of Wide Area Intrusion Detection Systems using FMCW Radar. In Proceedings of the 2007 41st Annual IEEE International Carnahan Conference on Security Technology, Ottawa, ON, Canada, 8–11 October 2007; pp. 176–182. [Google Scholar]

- Tian, W.; Li, Y.; Hu, C.; Li, Y.; Wang, J.; Zeng, T. Vibration Measurement Method for Artificial Structure Based on MIMO Imaging Radar. IEEE Trans. Aerosp. Electron. Syst. 2020, 56, 748–760. [Google Scholar] [CrossRef]

- Wagner, S.; Pham, A.V. Standoff Non-Line-of-Sight Vibration Sensing Using Millimeter- Wave Radar. In Proceedings of the 2020 17th European Radar Conference (EuRAD), Utrecht, The Netherlands, 10–15 January 2021; pp. 82–85. [Google Scholar]

- AWR1642 Single-Chip 76-GHz to 81-GHz Automotive Radar Sensor Evaluation Module. Available online: http://www.ti.com/tool/AWR1642BOOST (accessed on 2 February 2022).

- Li, C.; Chen, W.; Liu, G.; Yan, R.; Xu, H.; Qi, Y. A Noncontact FMCW Radar Sensor for Displacement Measurement in Structural Health Monitoring. Sensors 2015, 15, 7412–7433. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rai, P.K.; Idsøe, H.; Yakkati, R.R.; Kumar, A.; Ali Khan, M.Z.; Yalavarthy, P.K.; Cenkeramaddi, L.R. Localization and Activity Classification of Unmanned Aerial Vehicle Using mmWave FMCW Radars. IEEE Sens. J. 2021, 21, 16043–16053. [Google Scholar] [CrossRef]

- Griffin, D.; Lim, J. Signal estimation from modified short-time Fourier transform. IEEE Trans. Acoust. Speech Signal Process. 1984, 32, 236–243. [Google Scholar] [CrossRef]

- Dai, T.K.V.; Yu, Y.; Theilmann, P.; Fathy, A.E.; Kilic, O. Remote Vital Sign Monitoring with Reduced Random Body Swaying Motion Using Heartbeat Template and Wavelet Transform Based on Constellation Diagrams. IEEE J. Electromagn. RF Microw. Med. Biol. 2022, 1–8. [Google Scholar] [CrossRef]

- Selesnick, I.W.; Baraniuk, R.G.; Kingsbury, N.C. The dual-tree complex wavelet transform. IEEE Signal Process. Mag. 2005, 22, 22–123. [Google Scholar] [CrossRef] [Green Version]

- Unser, M.; Aldroubi, A. A review of wavelets in biomedical applications. Proc. IEEE 1996, 84, 626–638. [Google Scholar] [CrossRef]

- Continuous 1-D wavelet transform—MATLAB. Available online: https://www.mathworks.com/help/wavelet/ref/cwt.html (accessed on 2 February 2022).

- Moca, V.V.; Bârzan, H.; Nagy-Dăbâcan, A. Time-frequency super-resolution with superlets. Nat. Commun. 2021, 12, 337. [Google Scholar] [CrossRef] [PubMed]

- Crnojevic, V.; Senk, V.; Trpovski, Z. Advanced impulse Detection Based on pixel-wise MAD. IEEE Signal Process. Lett. 2004, 11, 589–592. [Google Scholar] [CrossRef]

- Xiong, B.; Yin, Z. A Universal Denoising Framework with a New Impulse Detector and Nonlocal Means. IEEE Trans. Image Process. 2012, 21, 1663–1675. [Google Scholar] [CrossRef] [PubMed]

- Lefevre, S.; Dixon, C.; Jeusse, C.; Vincent, N. A local approach for fast line detection. In Proceedings of the 2002 14th International Conference on Digital Signal Processing Proceedings, DSP 2002 (Cat. No.02TH8628), Santorini, Greece, 1–3 July 2002. [Google Scholar] [CrossRef] [Green Version]

- Gonzalez, G.; Woods, R. Digital Image Processing; Addison Wesley: Reading, MA, USA, 1992; pp. 187–190. [Google Scholar]

- Keshava, N.; Mustard, J.F. Spectral unmixing. IEEE Signal Process. Mag. 2002, 19, 44–57. [Google Scholar] [CrossRef]

- Karlsen, B.; Larsen, J.; Sorensen, H.B.D.; Jakobsen, K.B. Comparison of PCA and ICA based clutter reduction in GPR systems for anti-personal landmine detection. In Proceedings of the 11th IEEE Signal Processing Workshop on Statistical Signal Processing (Cat. No.01TH8563), Singapore, 8 August 2001. [Google Scholar] [CrossRef] [Green Version]

- Pantoja, M.F.; Rodríguez, J.B.; Bretones, A.R.; de Jong, C.M.; García, S.G.; Martín, R.G.; Vieira, D.A.G. Application of neural network and principal component analysis to GPR data. In Proceedings of the 2011 6th International Workshop on Advanced Ground Penetrating Radar (IWAGPR), Aachen, Germany, 22–24 June 2011. [Google Scholar] [CrossRef]

| Parameter | Significance | 112 km/h Experimental Estimate | Method of Determination |

|---|---|---|---|

| Magnitude of radar vibration due to transport (mm) | Monitor impulsive peaks from experimental data | ||

| Base vibration impulse waveform | Hz | Fit waveform shape and spectrum to experimental data | |

| Time of the i vibration impulse (s) | Monitor impulsive peaks from experimental data | ||

| Magnitude dampening from presence of drilling (0–1) | 0.377 | Monitor average PSD with and without drilling | |

| Magnitude coefficient of the kth drilling harmonic | Fit to experimental data | ||

| mmW-radar vibration estimation noise (mm) | Estimate from radar phase noise based on stationary target |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Chirp time (Tc) | 170 μs | Center frequency (fc) | 78.6 GHz |

| Idle time | 100 μs | Number of fast-time samples Ntf | 256 |

| Bandwidth (B) | 3.23 GHz | Number of receivers | 4 |

| Chirp slope (S) | 19 MHz/μs | Number of transmitters | 1 |

| ADC sampling rate | 6.25 MS/s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wagner, S.; Alkasimi, A.; Pham, A.-V. Detecting the Presence of Intrusive Drilling in Secure Transport Containers Using Non-Contact Millimeter-Wave Radar. Sensors 2022, 22, 2718. https://doi.org/10.3390/s22072718

Wagner S, Alkasimi A, Pham A-V. Detecting the Presence of Intrusive Drilling in Secure Transport Containers Using Non-Contact Millimeter-Wave Radar. Sensors. 2022; 22(7):2718. https://doi.org/10.3390/s22072718

Chicago/Turabian StyleWagner, Samuel, Ahmad Alkasimi, and Anh-Vu Pham. 2022. "Detecting the Presence of Intrusive Drilling in Secure Transport Containers Using Non-Contact Millimeter-Wave Radar" Sensors 22, no. 7: 2718. https://doi.org/10.3390/s22072718

APA StyleWagner, S., Alkasimi, A., & Pham, A.-V. (2022). Detecting the Presence of Intrusive Drilling in Secure Transport Containers Using Non-Contact Millimeter-Wave Radar. Sensors, 22(7), 2718. https://doi.org/10.3390/s22072718