Similarity Simulation on the Movement Characteristics of Surrounding Rock and Floor Stress Distribution for Large-Dip Coal Seam

Abstract

:1. Introduction

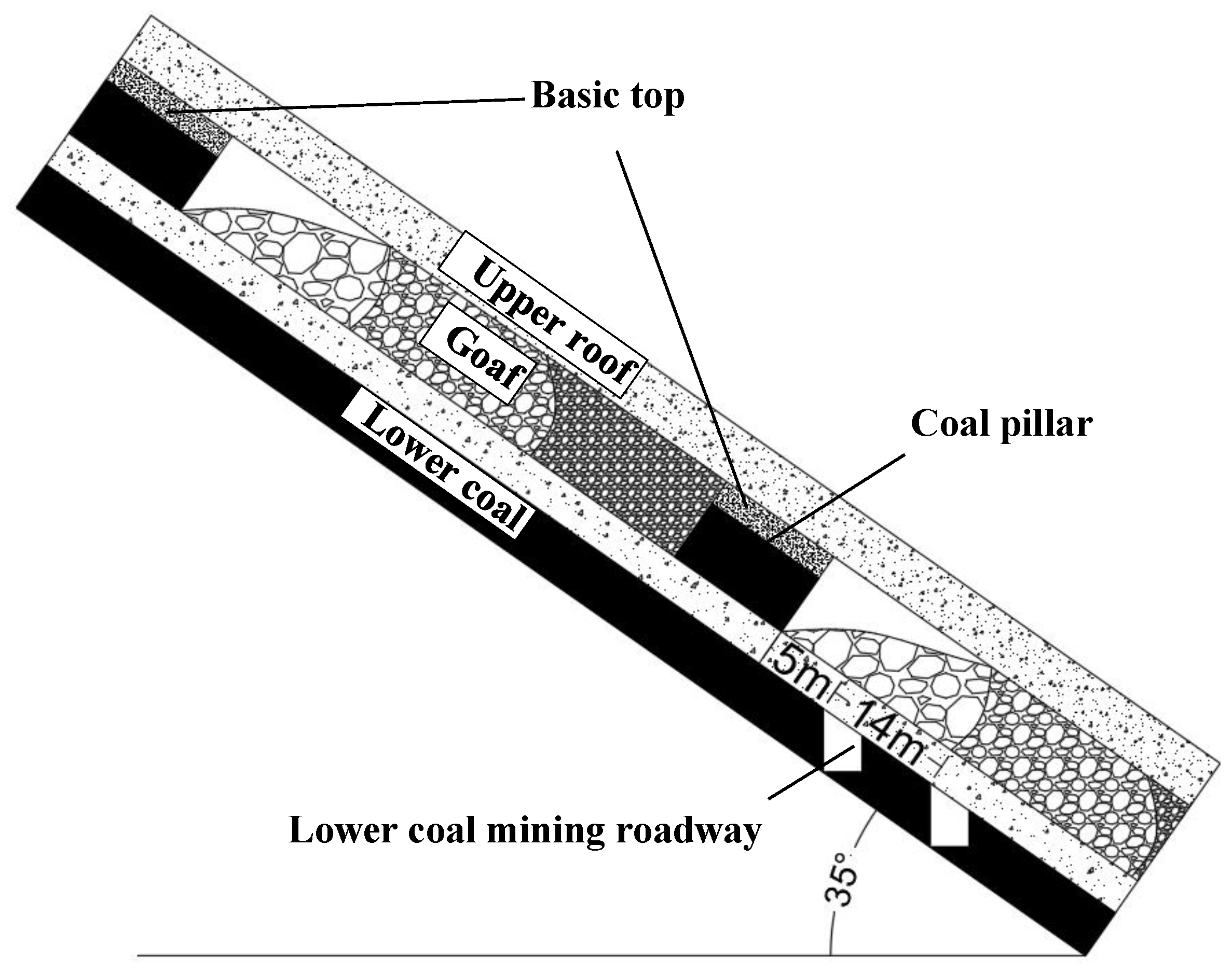

2. Mining Geological Condition

3. Experimental Program

3.1. Experimental Equipment

3.2. Mix Design of Similarity Material

3.3. Set-Up of the Similarity Model

4. Fracture Characteristics of Mining-Induced Overburden

5. Distribution Law of Mining-Induced Floor Stress

5.1. Distribution Law of Floor Stress in Inverted Mining Face

5.2. Distribution Rule of Floor Stress in Underhand Working Face

5.3. Distribution Characteristics of Floor Stress

6. Results

- (1)

- The collapse and breakage of the basic roof of the upper coal seam with a large dip resulted in a triangular goaf. The overburden fracture area was perpendicular to the working face and presented “M“ distribution with the excavation of the lower coal seam, whereas the vertical displacement of the lower coal overburden presented “W” distribution with double pressure relief;

- (2)

- The vertical displacement of overburden in the top mining face was generally greater than that in the upward mining face. With the advance of the working face, the maximum displacement shifted to the deep seam along the dip angle;

- (3)

- With the increase in the mining advance distance, floor stress concentration occurred about 24 m (upward mining) and 27 m (top mining) from the coal pillar in the upward mining and top mining working faces, respectively. The distance from the top mining stress reduction area to the coal pillar was generally greater than that in the upward mining working face;

- (4)

- Affected by the stratum dip angle, the displacement of deep overburden was greater than that of shallow overburden. The floor stress under the coal pillar was asymmetrically distributed. The pressure relief degree of the floor stress of the deep working face was higher than that of the shallow working face. The asymmetric movement of overburden led to the differential distribution of floor stress;

- (5)

- In order to facilitate roadway support and save costs, a lower coal roadway is recommended to be arranged below the goaf 5–19 m away from the coal pillar in the deep working face.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qian, M.G.; Xu, J.L.; Wang, J.C. Further on the sustainable mining of coal. J. China Coal Soc. 2018, 43, 1–13. [Google Scholar]

- Zhang, D.S.; Liu, H.L.; Fan, G.W.; Wang, X.F. Connotation and prospection on scientific mining of large Xinjiang coal base. J. Min. Saf. Eng. 2015, 32, 1–6. [Google Scholar]

- Wu, Y.P.; Liu, K.Z.; Yun, D.F.; Xie, P.S.; Wang, H.W. Research progress on the safe and efficient mining technology of steeply dipping seam. J. China Coal Soc. 2014, 39, 1611–1618. [Google Scholar]

- Hu, S.X.; Ma, L.Q.; Guo, J.S.; Yang, P.J. Support-surrounding rock relationship and top-coal movement laws in large dip angle fully-mechanized caving face. Int. J. Min. Sci. Technol. 2017, 28, 533–539. [Google Scholar]

- Liu, H.L.; Xu, C.; Wang, H.Z.; Li, G.D.; Fan, S.Y. Investigation on Surrounding Rock Stability Control Technology of High Stress Roadway in Steeply Dipping Coal Seam. Adv. Civ. Eng. 2021, 2021, 5269716. [Google Scholar] [CrossRef]

- Yang, K.; Wei, Z.; Chi, X.; Gao, A.S.; Fu, Q. Fracture criterion of basic roof deformation in fully mechanized mining with large dip angle. Energy Explor. Exploit. 2021, 39, 886–902. [Google Scholar] [CrossRef]

- Wang, X. Similar Simulation Test of Overlying Rock Failure and Crack Evolution in Fully Mechanized Caving Face with Compound Roof. Geotechnol. Geol. Eng. 2022, 40, 73–82. [Google Scholar]

- Xie, P.S.; Luo, Y.; Wu, Y.P.; Gao, X.C.; Luo, S.H.; Zeng, Y.F. Roof Deformation Associated with Mining of Two Panels in Steeply Dipping Coal Seam Using Subsurface Subsidence Prediction Model and Physical Simulation Experiment. Min. Metall. Explor. 2019, 37, 581–591. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, Y.D.; Ji, M.; Guo, H.J.; Li, H.Z. Research on Physical Similarity Simulation of Mining Uphill and Downhill at the Large-Angle Working Face. Adv. Civ. Eng. 2019, 2019, 7696752. [Google Scholar] [CrossRef] [Green Version]

- Kong, D.Z.; Han, C.H.; Lou, Y.H.; Zheng, S.S.; Pu, S.J.; Wang, Z.J. Study on Ground Pressure Behavior Law of a Large-Cutting-Height Panel with Large Dip Angle. Geotechnol. Geol. Eng. 2019, 37, 3805–3815. [Google Scholar] [CrossRef]

- Cui, Z.M.; Emmanuel, C.; Zhao, J.L.; Wang, Z.H. Stress distribution characteristics in the vicinity of coal seam floor. IOP Conf. Ser. Earth Environ. Sci. 2018, 108, 032056. [Google Scholar] [CrossRef]

- Xie, P.S.; Zhang, Y.Y.; Luo, S.H.; Duan, J.J. Instability Mechanism of a Multi-Layer Gangue Roof and Determination of Support Resistance Under Inclination and Gravity. Min. Metall. Explor. 2020, 37, 1487–1498. [Google Scholar] [CrossRef]

- Luo, S.H.; Wang, T.; Wu, Y.P.; Huangfu, J.Y.; Zhao, H.T. Internal mechanism of asymmetric deformation and failure characteristics of the roof for longwall mining of a steeply dipping coal seam. Arch. Min. Sci. 2021, 1, 101–124. [Google Scholar]

- Kang, X.; Yang, S.L.; Zhan, P.; Li, L.H.; Yao, H. Simulation Study of the Roof Fracture Pattern of a Horizontal Sublevel Caving in a Steeply Inclined Thick Coal Seam. Adv. Civ. Eng. 2020, 2020, 8370634. [Google Scholar] [CrossRef]

- Lang, D.; Wu, X.B.; Wu, Y.P.; Lin, H.F.; Luo, S.H. Boundary distribution of top-coal limit-equilibrium zone in fully mechanized caving in steeply dipping coal seams. Geomat. Nat. Hazards Risk. 2021, 12, 2561–2589. [Google Scholar] [CrossRef]

- Shi, J.J.; Feng, J.C.; Ma, L.J.; Li, H. Analysis on the Regular of Underground Pressure in Large Dip Angle Coal Seam with Soft Roof and Floor. Geotechnol. Geol. Eng. 2021, 39, 5375–5380. [Google Scholar] [CrossRef]

- Qi, X.Y.; Wang, R.J.; Mi, W.T.; Wen, Z.J. Failure Characteristics and Control Technology of Surrounding Rock in Deep Coal Seam Roadway with Large Dip Angle under the Influence of Weak Structural Plane. Adv. Civ. Eng. 2020, 2020, 6623159. [Google Scholar] [CrossRef]

- Wang, Y.L.; Tang, J.X.; Dai, Z.Y.; Yi, T.; Li, X.Y. Flexible roadway protection technology in medium-thickness coal seam with large dip angle. Energy Sour. Part A Recover. Util. Environ. Eff. 2019, 41, 3085–3102. [Google Scholar] [CrossRef]

- Wu, Y.P.; Huangfu, J.Y.; Xie, P.S.; Hu, B.S.; Liu, K.Z. Mechanism of instability of section coal pillar in steeply dipping seam based on large-scale strata control technology. J. China Coal Soc. 2018, 43, 3062–3071. [Google Scholar] [CrossRef]

- Wu, Y.P.; Yuan, D.F.; Zhang, M.F. Research on basic problems of fully mechanized mining of large dipping Seam. J. China Coal Soc. 2000, 25, 465–468. [Google Scholar]

- Xie, P.S.; Wu, Y.P.; Luo, S.H.; Wang, H.W.; Lang, D. Evolution and stability analysis of dip step structure with large dip Angle and large mining height. J. Min. Saf. Eng. 2018, 35, 953–959. (In Chinese) [Google Scholar]

- Liu, H.L.; Cao, W.X.; Shan, C.F.; Qian, J.; Wu, C.; Xu, H.; Zhou, W.L. Similar simulation experimental study on fracture characteristics of overburden strata under mining with large dip angle. J. Xinjiang Univ. Nat. Sci. Ed. Chin. Engl. 2020, 37, 301–308. [Google Scholar]

- Ma, L.Q.; Zhang, Y.; Zhang, D.S.; Cao, X.Q.; Li, Q.Q.; Zhang, Y.B. Support stability mechanism in a coal face with large angles in both strike and dip. J. S. Afr. Inst. Min. Metall. 2015, 115, 599–606. [Google Scholar] [CrossRef]

- Song, W.H.; Liu, C.Y.; Zhao, J.; Han, Y.L.; Li, Y.Z. Simulation experiment of overburden movement in protective layer mining at short distance. Chin. J. Geol. Hazard Control 2016, 27, 147–152. (In Chinese) [Google Scholar]

- Xiao, P.; Li, S.G.; Lin, H.F.; Zhao, P.X. Evolution of mining-induced fractures in overburden based on physical similarity simulation experiment. J. Saf. Sci. Technol. 2014, 10, 18–23. [Google Scholar]

- Luo, J.A.; Wang, L.G. Stress distribution law of floor under coal pillar in short distance coal seam. Saf. Coal Min. 2014, 45, 29–31. [Google Scholar]

- Ye, Q.; Wang, G.; Jia, Z.Z.; Zheng, C.S.; Wang, W.J. Similarity simulation of mining-crack-evolution characteristics of overburden strata in deep coal mining with large dip. J. Pet. Sci. Eng. 2018, 165, 477–487. [Google Scholar] [CrossRef] [Green Version]

- Zhao, H.C. State-of-the-art of standing supports for gob-side entry retaining technology in China. J. S. Afr. Inst. Min. Metall. 2019, 119, 891–906. [Google Scholar] [CrossRef]

- Zhao, H.C.; Ren, T.; Remennikov, A. A hybrid tubular standing support for underground mines: Compressive behaviour. Int. J. Min. Sci. Technol. 2021, 31, 215–224. [Google Scholar] [CrossRef]

- Das, A.J.; Mandal, P.K.; Paul, P.S.; Sinha, R.K.; Tewari, S. Assessment of the Strength of Inclined Coal Pillars through Numerical Modelling based on the Ubiquitous Joint Model. Rock Mech. Rock Eng. 2019, 52, 3691–3717. [Google Scholar] [CrossRef]

- Das, A.J.; Mandal, P.K.; Paul, P.S.; Sinha, R.K. Generalised Analytical Models for the Strength of the Inclined as well as the Flat Coal Pillars using Rock Mass Failure Criterion. Rock Mech. Rock Eng. 2019, 52, 3921–3946. [Google Scholar] [CrossRef]

- Kulakov, V.N. Geomechanical conditions of mining steep coal beds. J. Min. Sci. 1995, 31, 136–143. [Google Scholar] [CrossRef]

- Kulakov, V.N. Stress state in the face region of a steep coal bed. J. Min. Sci. 1995, 31, 161–168. [Google Scholar] [CrossRef]

- Das, A.J.; Paul, P.S.; Mandal, P.K.; Kumar, R.; Tewari, S. Investigation of Failure Mechanism of Inclined Coal Pillars: Numerical Modelling and Tensorial Statistical Analysis with Field Validations. Rock Mech. Rock Eng. 2021, 54, 3263–3289. [Google Scholar] [CrossRef]

- Garza-Cruz, T.; Pierce, M.; Board, M. Effect of Shear Stresses on Pillar Stability: A Back Analysis of the Troy Mine Experience to Predict Pillar Performance at Montanore Mine. Rock Mech. Rock Eng. 2019, 52, 4979–4996. [Google Scholar] [CrossRef]

- Li, H.Z.; Guo, G.L.; Zha, J.F. Study on time-varying characteristics of similar material model strength and the regulation measures. Environ. Earth Sci. 2017, 76, 518. [Google Scholar] [CrossRef]

- Chen, S.J.; Wang, H.L.; Zhang, J.W.; Xing, H.L.; Wang, H.Y. Experimental Study on Low-Strength Similar-Material Proportioning and Properties for Coal Mining. Adv. Mater. Sci. Eng. 2015, 2015, 696501. [Google Scholar] [CrossRef] [Green Version]

- Yanli, H.; Jixiong, Z.; Baifu, A.; Qiang, Z. Overlying strata movement law in fully mechanized coal mining and backfilling longwall face by similar physical simulation. J. Min. Sci. 2011, 47, 618–627. [Google Scholar] [CrossRef]

| Name of Top and Bottom Plate | Rock Category | Thickness (m) | Lithology Description |

|---|---|---|---|

| Overlying strata | Coarse-grained sandstone | 21.60 | Medium-thick, layered sandy conglomerate, gravelly coarse sandstone and quartz coarse sandstone |

| Basic top | Fine-grained sandstone | 10.10 | Layered, fine coarse sandstone |

| Pseudo top | Carbonaceous mudstone | 0.57 | Thin-layer carbonaceous mudstone |

| Direct bottom | Carbonaceous mudstone and fine sandstone | 10.95 | Mainly carbonaceous mudstone and fine sandstone, locally sandy mudstone, with small cross bedding |

| Basic base | Siltstone, fine–medium–coarse sandstone | 24.90 | Siltstone, fine–medium–coarse sandstone, locally carbonaceous argillaceous siltstone |

| Rock Name | Compressive Strength (MPa) | Tensile Strength (MPa) | 45° Shear Strength (MPa) | Elastic Modulus (GPa) |

|---|---|---|---|---|

| Coarse sandstone | 57.82 | 2.86 | 30.74 | 11.30 |

| Fine sandstone | 64.15 | 3.09 | 34.15 | 12.74 |

| Carbonaceous mudstone | 18.03 | 2.05 | 9.33 | 4.16 |

| Coal | 6.35 | 0.39 | 1.20 | 0.52 |

| Sandy mudstone | 27.37 | 2.65 | 13.27 | 4.10 |

| Fine sandstone | 72.38 | 3.57 | 38.62 | 14.35 |

| Serial Number | Lithology | Actual Thickness (m) | Model Thickness (cm) | Matching Number | River Sand (Kg) | Calcium Carbonate (Kg) | Plaster (Kg) | Water (Kg) | Remarks |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Overlying strata | 62.83 | 64.00 | 673 | 42.27 | 4.93 | 2.11 | 7.05 | |

| 2 | Sandy mudstone | 25.00 | 25.00 | 673 | 224.61 | 26.20 | 18.23 | 37.44 | |

| 3 | Siltstone | 42.87 | 43.00 | 673 | 457.02 | 53.32 | 22.85 | 76.17 | |

| 4 | Coarse sandstone | 21.60 | 21.00 | 646 | 187.48 | 12.50 | 18.75 | 31.25 | |

| 5 | Fine sandstone | 10.10 | 10.00 | 737 | 120.74 | 5.17 | 12.07 | 19.71 | Basic top |

| 6 | VI13a coal seam | 1.70~2.70 | 2.50 | 837 | 34.74 | 1.3 | 3.04 | 5.58 | |

| 7 | Sandy mudstone | 0.85~4.20 | 5.00 | 673 | 53.79 | 6.28 | 2.69 | 8.79 | |

| 8 | VI13b coal seam | 2.50~3.20 | 3.00 | 837 | 32.20 | 1.21 | 2.82 | 5.18 | |

| 9 | Carbonaceous mudstone | 4.10 | 4.00 | 673 | 96.90 | 11.30 | 4.84 | 16.15 | Direct bottom |

| 10 | Fine sandstone | 6.85 | 7.00 | 737 | 84.52 | 3.62 | 8.45 | 13.80 | |

| 11 | Basic base | 90.20 | 90.00 | 346 | 362.26 | 48.30 | 72.45 | 48.30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, W.; Liu, H.; Hang, Y.; Wang, H.; Li, G. Similarity Simulation on the Movement Characteristics of Surrounding Rock and Floor Stress Distribution for Large-Dip Coal Seam. Sensors 2022, 22, 2761. https://doi.org/10.3390/s22072761

Cao W, Liu H, Hang Y, Wang H, Li G. Similarity Simulation on the Movement Characteristics of Surrounding Rock and Floor Stress Distribution for Large-Dip Coal Seam. Sensors. 2022; 22(7):2761. https://doi.org/10.3390/s22072761

Chicago/Turabian StyleCao, Wenxiang, Honglin Liu, Yinjian Hang, Hongzhi Wang, and Guodong Li. 2022. "Similarity Simulation on the Movement Characteristics of Surrounding Rock and Floor Stress Distribution for Large-Dip Coal Seam" Sensors 22, no. 7: 2761. https://doi.org/10.3390/s22072761