Evaluation of Corrosion Damage in Sulfate-Attacked Concrete by CT, Ultrasonic Pulse Velocity Testing and AHP Methods

Abstract

:1. Introduction

2. Materials and Methods

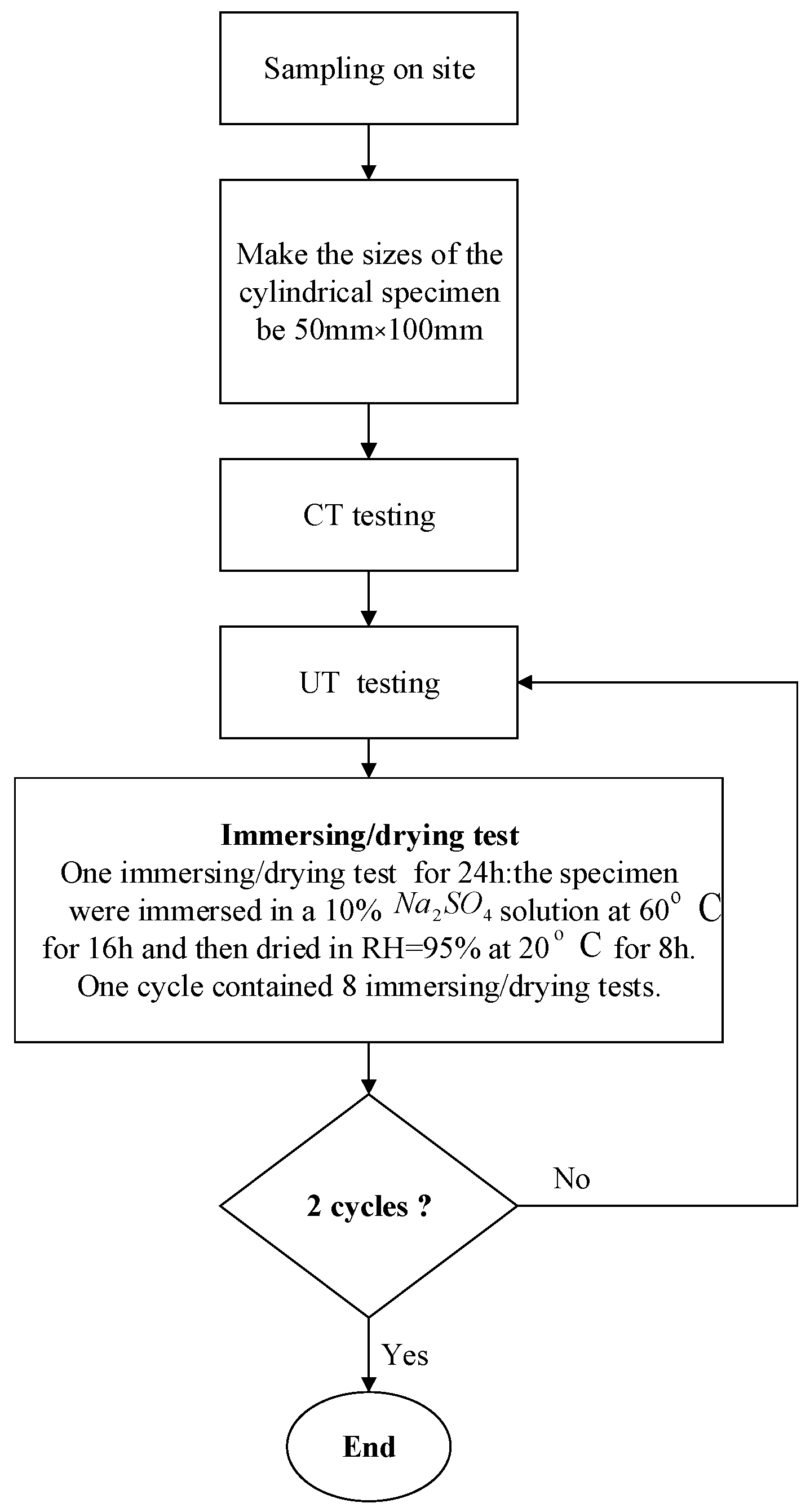

2.1. Specimen Preparation and Experimental Design

2.2. Testing Devices and Methods

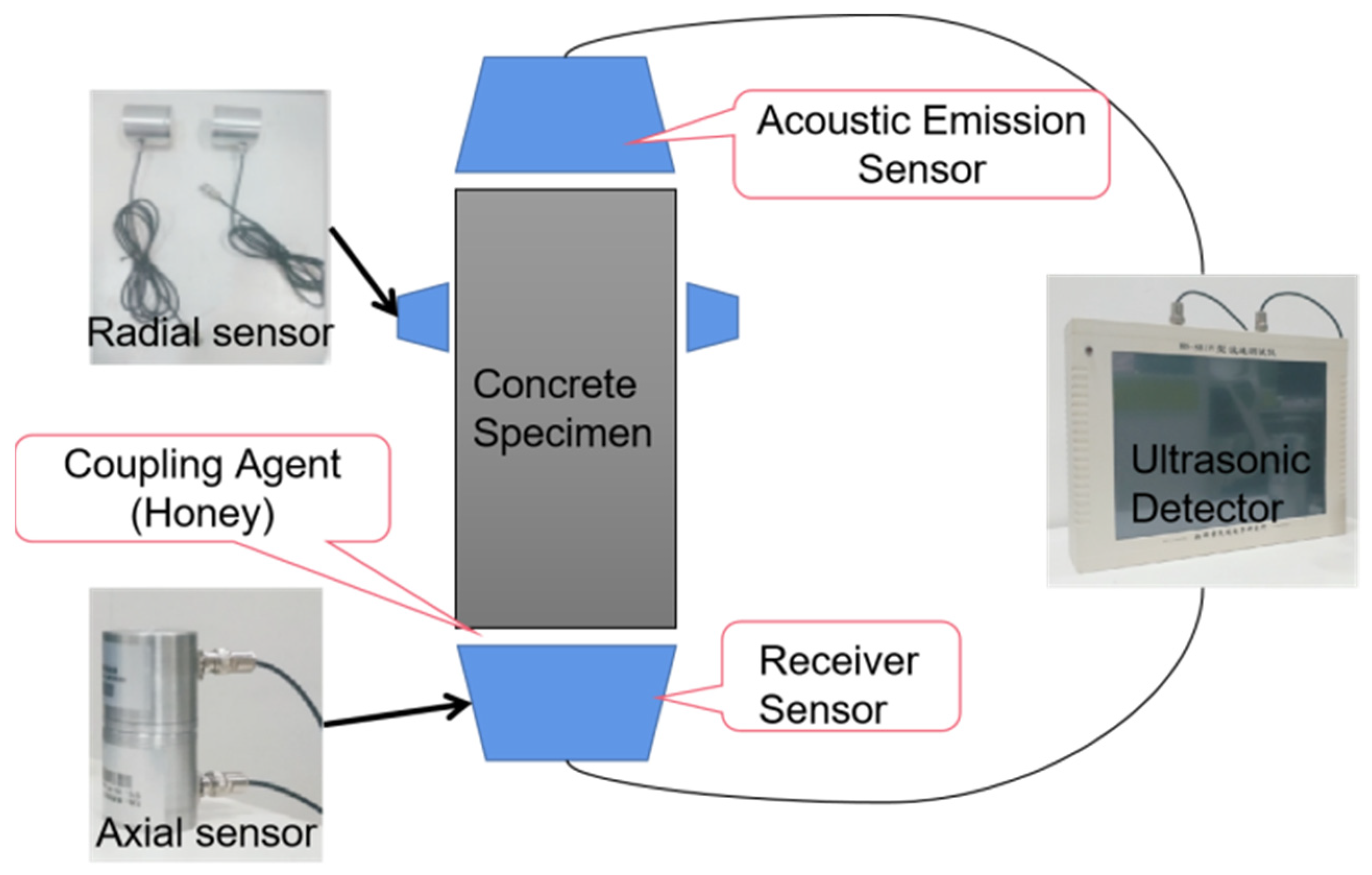

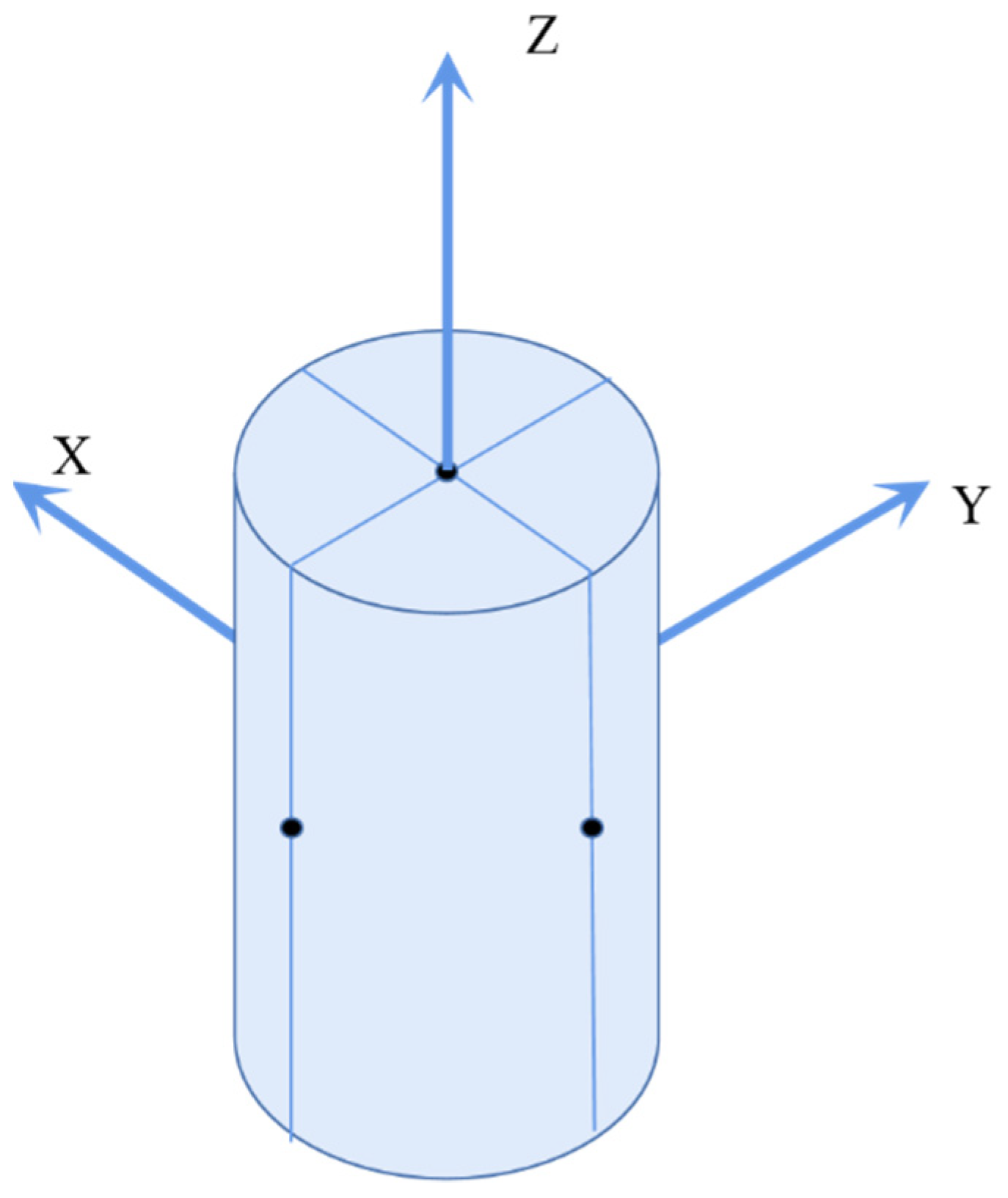

2.2.1. Ultrasonic Pulse Velocity Testing (UPV)

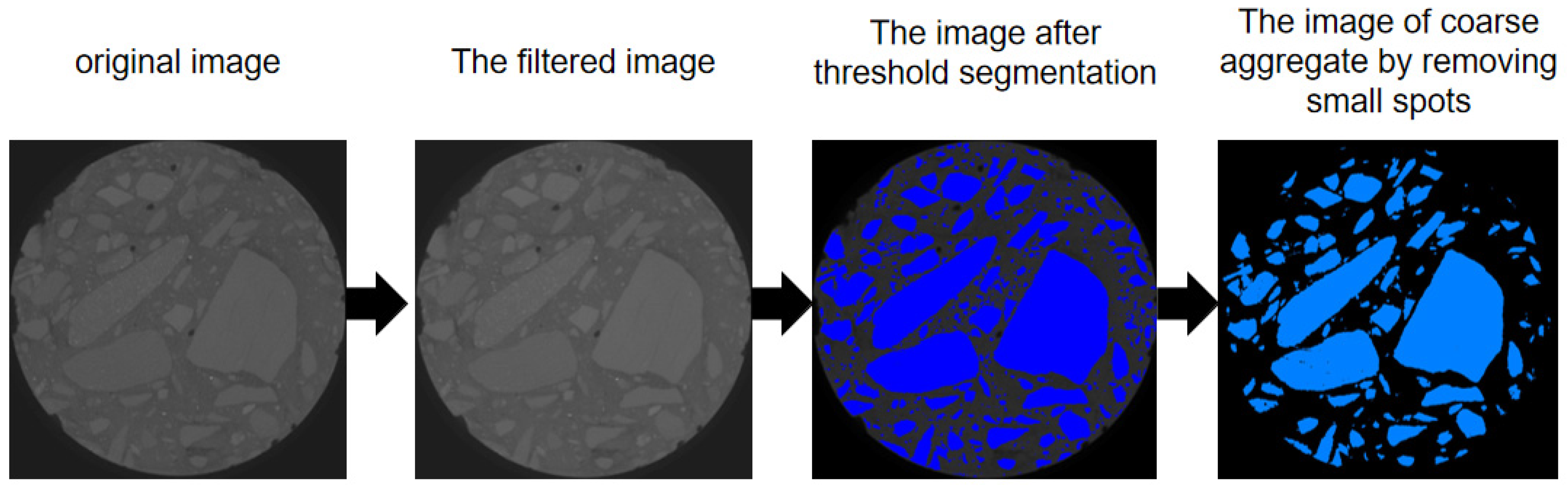

2.2.2. X-ray CT Technique

2.3. Sulfate Corrosion Assessment Based on AHP

2.3.1. Overview of the Method

2.3.2. Establishment of the Comprehensive Evaluation Model Based on AHP

2.3.3. Analysis of the Concrete Corrosion Classes

3. Result and Discussion

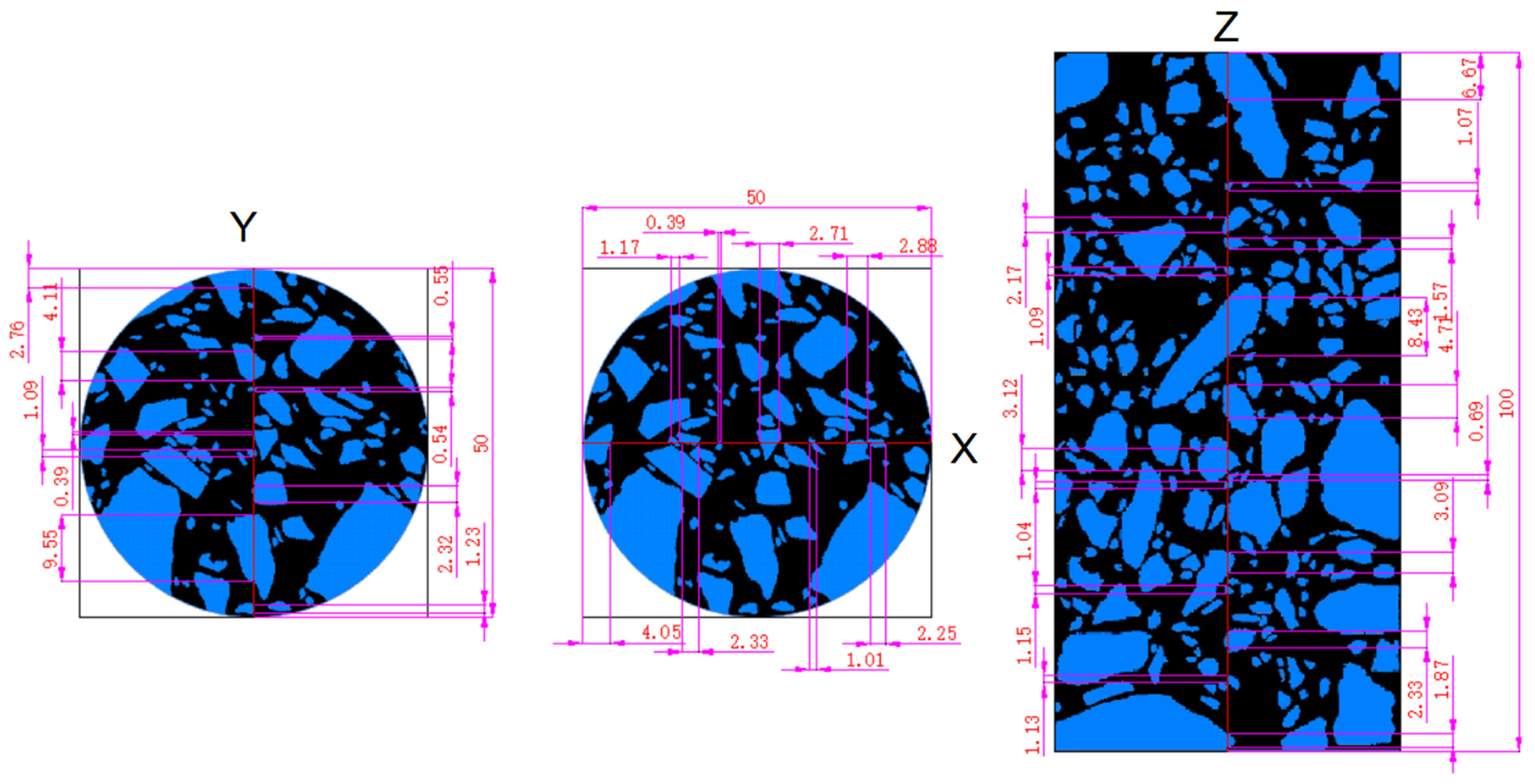

3.1. Analysis of Concrete Coarse Aggregate Based on CT

3.2. Correction Calculation of the UPV of the Concrete Structure

3.3. The Results of the Corrosion Assessment of Sulfate-Attacked Concrete Based on AHP

3.4. Evaluation Result Verification

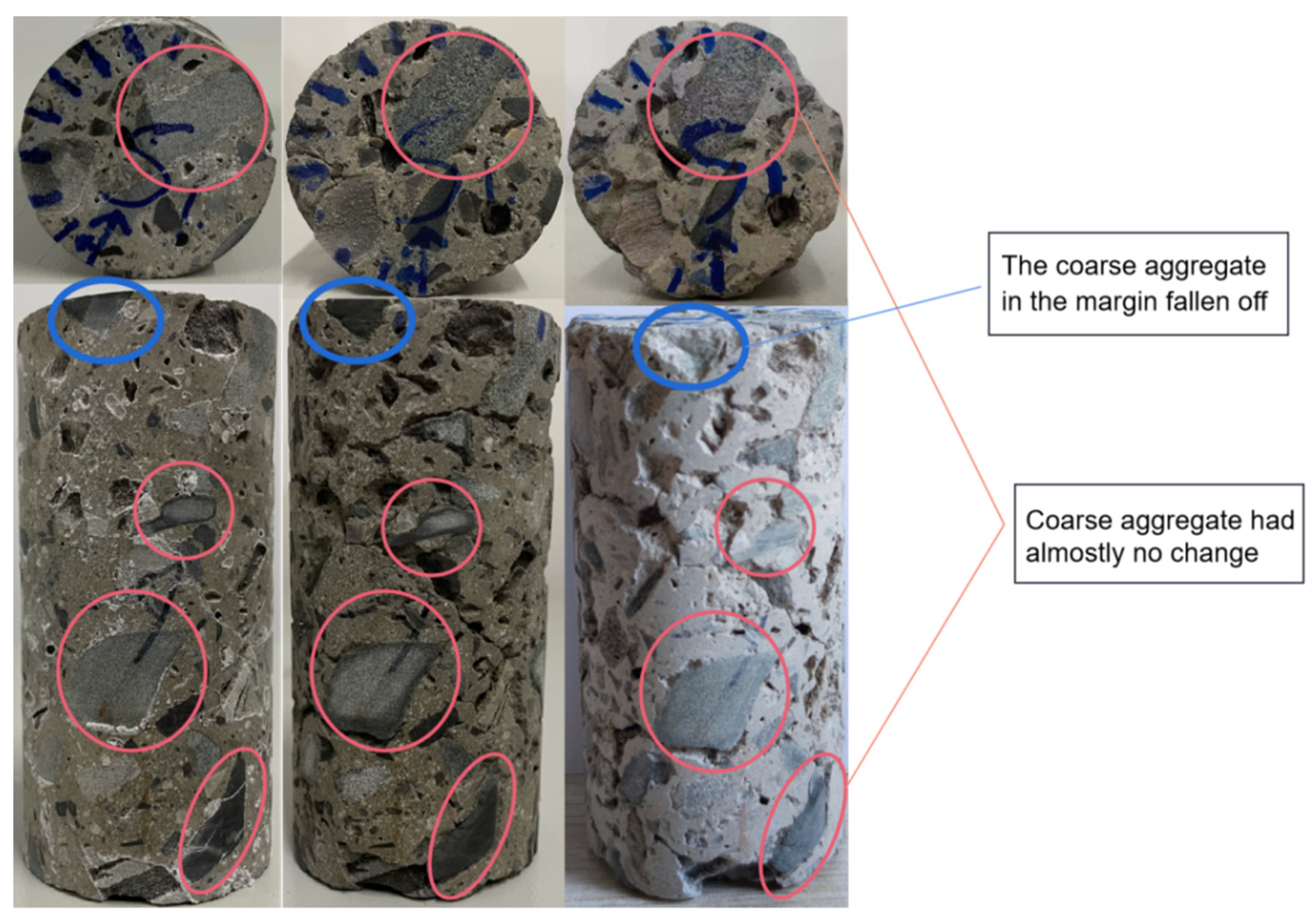

3.4.1. Change in Appearance of Concrete Specimen

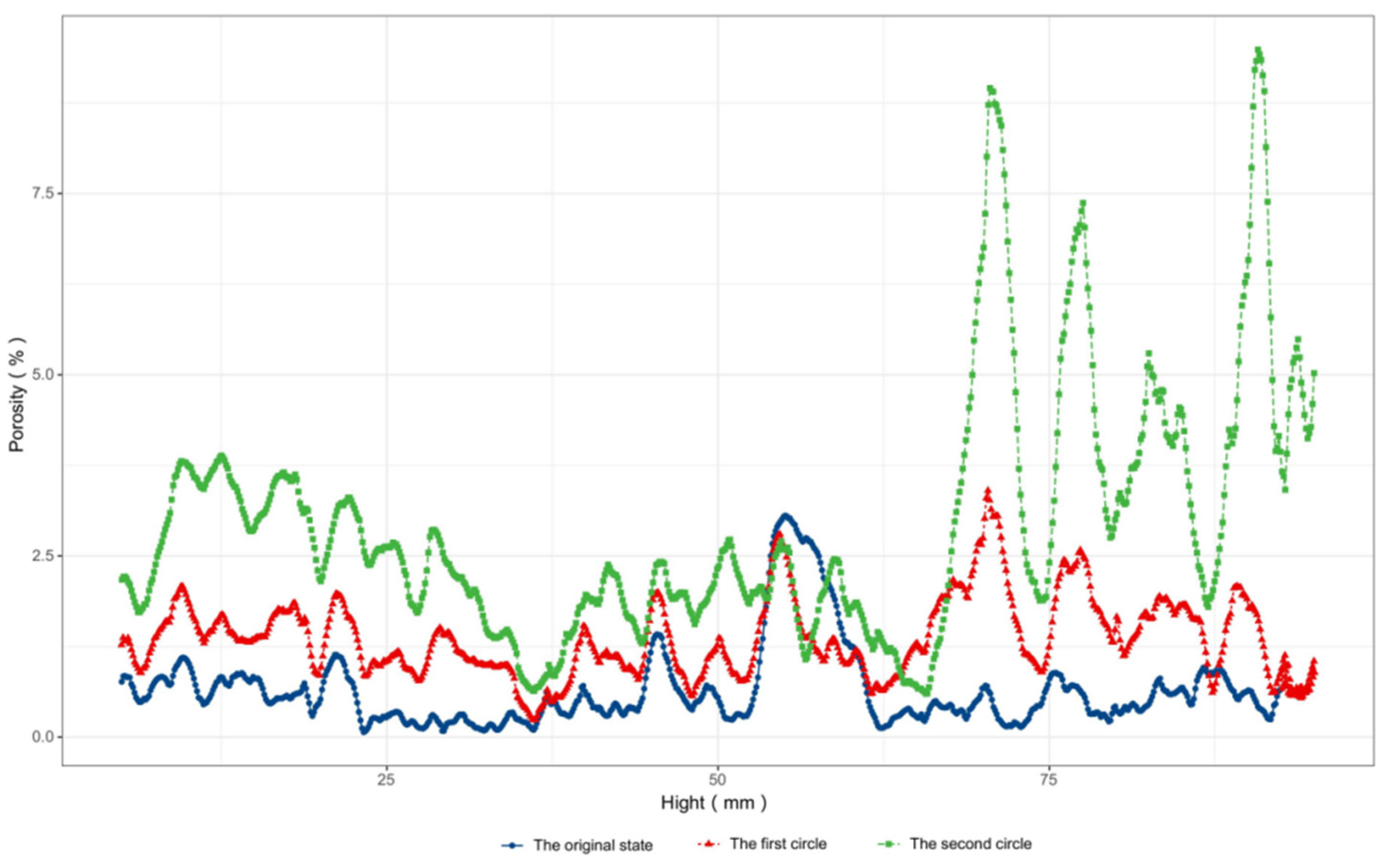

3.4.2. Change in the Porosity of the Concrete Specimen

4. Conclusions

- (1)

- A CT-based analysis method for the proportion of the length of the coarse aggregate in concrete along an ultrasonic survey line was proposed. The internal structural characteristics of concrete can be accurately extracted using CT scanning, and the distribution and size of the coarse aggregate in the concrete specimen were obtained using Avizo image processing software and determined the proportion of coarse aggregate length on a certain ultrasonic test line;

- (2)

- A method for analyzing the influence of removing coarse aggregates in concrete structures on UPV was proposed. In general, the proportion of coarse aggregate in concrete structure is relatively large (up to approximately 40%), and its ultrasonic speed was large (up to approximately 6000 m/s). The coarse aggregate in the concrete was basically free from sulfate corrosion. If the influence of the coarse aggregate in the concrete is not eliminated, the change amount of the concrete ultrasonic pulse velocity value was directly used to evaluate the damage degree of sulfate corrosion in the concrete, and the results are often inaccurate. By calculating the proportion of coarse aggregate on a certain ultrasonic test line, the correction value of ultrasonic pulse velocity (UPV) of concrete structure was obtained. The effect of coarse aggregate on the concrete structure on the value of the UPV of the concrete specimen was eliminated, reflecting small changes in the value of the UPV of the concrete specimen caused by the cement matrix and pores so that the corrected change amount of the value of the UPV of the concrete could more correctly reflect the degree of corrosion damage in sulfate-attacked concrete;

- (3)

- A method for evaluating the sulfate corrosion degree of concrete specimens based on AHP was constructed. By testing and correcting the UPV in multiple directions of the concrete sample and using the AHP method to calculate the weight and the overall relative corrosion degree makes the use of ultrasonic testing to judge changes in concrete structures under sulfate attack more in line with reality. The results of experimental and porosity changes showed that the overall relative corrosion evaluation results of concrete structures calculated by corrected UPV were more accurate.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Han, T.; Wang, X.; Li, D.; Li, D.; Han, N.; Xing, F. Damage and degradation mechanism for single intermittent cracked mortar specimens under a combination of chemical solutions and dry-wet cycles. Constr. Build. Mater. 2019, 213, 567–581. [Google Scholar] [CrossRef]

- He, R.; Zheng, S.; Gan, V.J.L.; Wang, Z.; Fang, J.; Shao, Y. Damage mechanism and interfacial transition zone characteristics of concrete under sulfate erosion and Dry-Wet cycles. Constr. Build. Mater. 2020, 255, 119340. [Google Scholar] [CrossRef]

- Ikumi, T.; Cavalaro, S.H.P.; Segura, I.; Aguado, A. Alternative methodology to consider damage and expansions in external sulfate attack modeling. Cem. Concr. Res. 2014, 63, 105–116. [Google Scholar] [CrossRef] [Green Version]

- Sarkar, S.; Mahadevan, S.; Meeussen, J.C.L.; van der Sloot, H.; Kosson, D.S. Numerical simulation of cementitious materials degradation under external sulfate attack. Cem. Concr. Comp. 2010, 32, 241–252. [Google Scholar] [CrossRef] [Green Version]

- Idiart, A.E.; López, C.M.; Carol, I. Chemo-mechanical analysis of concrete cracking and degradation due to external sulfate attack: A meso-scale model. Cem. Concr. Comp. 2011, 33, 411–423. [Google Scholar] [CrossRef]

- Neville, A. The confused world of sulfate attack on concrete. Cem. Concr. Res. 2004, 34, 1275–1296. [Google Scholar] [CrossRef]

- Xie, F.; Li, J.; Zhao, G.; Wang, C.; Wang, Y.; Zhou, P. Experimental investigations on the durability and degradation mechanism of cast-in-situ recycled aggregate concrete under chemical sulfate attack. Constr. Build. Mater. 2021, 297, 123771. [Google Scholar] [CrossRef]

- Li, T.; Huang, H. Probabilistic quantitative analysis on the contents of sulfate corrosion products in concrete. Constr. Build. Mater. 2021, 275, 122134. [Google Scholar] [CrossRef]

- Liu, Y.; Dai, K.; Li, D.; Luo, M.; Liu, Y.; Shi, Y.; Xu, J.; Huang, Z. Structural performance assessment of concrete components based on fractal information of cracks. J. Build. Eng. 2021, 43, 103177. [Google Scholar] [CrossRef]

- Liu, Y.; Yeoh, J.K.W. Automated crack pattern recognition from images for condition assessment of concrete structures. Automat. Constr. 2021, 128, 103765. [Google Scholar] [CrossRef]

- Kerr, T.; Vetter, M.; Gonzalez-Rodriguez, J. Evaluating residual compressive strength of post-fire concrete using Raman Spectroscopy. Forensic Sci. Int. 2021, 325, 110874. [Google Scholar] [CrossRef] [PubMed]

- Cheng, H.; Liu, T.; Zou, D.; Zhou, A. Compressive strength assessment of sulfate-attacked concrete by using sulfate ions distributions. Constr. Build. Mater. 2021, 293, 123550. [Google Scholar] [CrossRef]

- Liao, K.; Zhang, Y.; Zhang, W.; Wang, Y.; Zhang, R. Modeling constitutive relationship of sulfate-attacked concrete. Constr. Build. Mater. 2020, 260, 119902. [Google Scholar] [CrossRef]

- Zhao, G.; Guo, M.; Cui, J.; Li, J.; Xu, L. Partially-exposed cast-in-situ concrete degradation induced by internal-external sulfate and magnesium multiple coupled attack. Constr. Build. Mater. 2021, 294, 123560. [Google Scholar] [CrossRef]

- Elahi, M.M.A.; Shearer, C.R.; Reza, A.N.R.; Saha, A.K.; Khan, M.N.N.; Hossain, M.M.; Sarker, P.K. Improving the sulfate attack resistance of concrete by using supplementary cementitious materials (SCMs): A review. Constr. Build. Mater. 2021, 281, 122628. [Google Scholar] [CrossRef]

- Jiang, L.; Niu, D. Study of deterioration of concrete exposed to different types of sulfate solutions under drying-wetting cycles. Constr. Build. Mater. 2016, 117, 88–98. [Google Scholar] [CrossRef]

- Yan, W.; Wu, Z.; Niu, F.; Wan, T.; Zheng, H. Study on the service life prediction of freeze–thaw damaged concrete with high permeability and inorganic crystal waterproof agent additions based on ultrasonic velocity. Constr. Build. Mater. 2020, 259, 120405. [Google Scholar] [CrossRef]

- Rodríguez-Mariscal, J.D.; Canivell, J.; Solís, M. Evaluating the performance of sonic and ultrasonic tests for the inspection of rammed earth constructions. Constr. Build. Mater. 2021, 299, 123854. [Google Scholar] [CrossRef]

- Katunin, A.; Wronkowicz-Katunin, A.; Dragan, K. Impact Damage Evaluation in Composite Structures Based on Fusion of Results of Ultrasonic Testing and X-ray Computed Tomography. Sensors 2020, 20, 1867. [Google Scholar] [CrossRef] [Green Version]

- Breysse, D.; Romão, X.; Alwash, M.; Sbartaï, Z.M.; Luprano, V.A.M. Risk evaluation on concrete strength assessment with NDT technique and conditional coring approach. J. Build. Eng. 2020, 32, 101541. [Google Scholar] [CrossRef]

- Wiciak, P.; Cascante, G.; Polak, M.A. Sensor and Dimensions Effects in Ultrasonic Pulse Velocity Measurements in Mortar Specimens. Procedia Eng. 2017, 193, 409–416. [Google Scholar] [CrossRef]

- Ghosh, R.; Sagar, S.P.; Kumar, A.; Gupta, S.K.; Kumar, S. Estimation of geopolymer concrete strength from ultrasonic pulse velocity (UPV) using high power pulser. J. Build. Eng. 2018, 16, 39–44. [Google Scholar] [CrossRef]

- Lin, Y.; Kuo, S.; Hsiao, C.; Lai, C. Investigation of Pulse Velocity-Strength Relationship of Hardened Concrete. ACI Mater. J. 2007, 104, 344–350. [Google Scholar] [CrossRef]

- Trtnik, G.; Kavčič, F.; Turk, G. Prediction of concrete strength using ultrasonic pulse velocity and artificial neural networks. Ultrasonics 2009, 49, 53–60. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, T.; Lee, J. Setting time and compressive strength prediction model of concrete by nondestructive ultrasonic pulse velocity testing at early age. Constr. Build. Mater. 2020, 252, 119027. [Google Scholar] [CrossRef]

- Solís-Carcaño, R.; Moreno, E.I. Evaluation of concrete made with crushed limestone aggregate based on ultrasonic pulse velocity. Constr. Build. Mater. 2008, 22, 1225–1231. [Google Scholar] [CrossRef]

- Prassianakis, I.N.; Prassianakis, N.I. Ultrasonic testing of non-metallic materials: Concrete and marble. Theor. Appl. Fract. Mech. 2004, 42, 191–198. [Google Scholar] [CrossRef]

- Chen, S.; Ren, J.; Song, Y.; Li, Q.; Sun, J.; Che, Y.; Chen, J. Salt Freeze-Thaw Damage Characteristics of Concrete based on Computed Tomography. Teh. Vjesn. 2019, 26, 1753–1763. [Google Scholar] [CrossRef]

- Sun, H.; Gao, Y.; Zheng, X.; Chen, Y.; Jiang, Z.; Zhang, Z. Meso-Scale Simulation of Concrete Uniaxial Behavior Based on Numerical Modeling of CT Images. Materials 2019, 12, 3403. [Google Scholar] [CrossRef] [Green Version]

- Yang, W. Finite element model of concrete material based on CT image processing technology. J. Vis. Commun. Image Represent. 2019, 64, 102631. [Google Scholar] [CrossRef]

- Zhang, L.; Dang, F.; Ding, W.; Zhu, L. Quantitative study of meso-damage process on concrete by CT technology and improved differential box counting method. Meas. J. Int. Meas. Confed. 2020, 160, 107832. [Google Scholar] [CrossRef]

- Tekin, I.; Birgul, R.; Yaman, I.O.; Gencel, O.; Aruntas, H.Y. Monitoring macro voids in mortars by computerized tomography method. Measurement 2015, 63, 299–308. [Google Scholar] [CrossRef]

- Ren, W.; Yang, Z.; Sharma, R.; Zhang, C.; Withers, P.J. Two-dimensional X-ray CT image based meso-scale fracture modelling of concrete. Eng. Fract. Mech. 2015, 133, 24–39. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, H.; Li, B.; Yang, Z.; Wu, J.; Withers, P.J. Generation of high-fidelity random fields from micro CT images and phase field-based mesoscale fracture modelling of concrete. Eng. Fract. Mech. 2021, 249, 107762. [Google Scholar] [CrossRef]

- Saaty, T.L. The Analytical Hierrarchy Process; McGraw Hill: New York, NY, USA, 1980. [Google Scholar]

- Akinlalu, A.A.; Olayanju, G.M.; Adiat, K.A.N.; Omosuyi, G.O. Mineralisation potential assessment using analytical hierarchy process (AHP) modeling technique: A case study of Ilesha schist belt, southwestern Nigeria. Results Geophys. Sci. 2021, 7, 100026. [Google Scholar] [CrossRef]

- Rao, S.K.; Sravana, P.; Rao, T.C. Experimental studies in Ultrasonic Pulse Velocity of roller compacted concrete pavement containing fly ash and M-sand. Int. J. Pavement Res. Technol. 2016, 9, 289–301. [Google Scholar] [CrossRef] [Green Version]

- Perlin, L.P.; Pinto, R.C.D.A. Use of network theory to improve the ultrasonic tomography in concrete. Ultrasonics 2019, 96, 185–195. [Google Scholar] [CrossRef]

- Karahalios, H. The application of the AHP-TOPSIS for evaluating ballast water treatment systems by ship operators, Transportation research. Part D. Transp. Environ. 2017, 52, 172–184. [Google Scholar] [CrossRef]

- Erdogmus, E.; Garcia, E.; Amiri, A.S.; Schuller, M. A Novel Structural Health Monitoring Method for Reinforced Concrete Bridge Decks Using Ultrasonic Guided Waves. Infrastructures 2020, 5, 49. [Google Scholar] [CrossRef]

- Lee, J.; Kim, I.; Kim, H.; Kang, J. SWOT-AHP analysis of the Korean satellite and space industry: Strategy recommendations for development. Technol. Forecast. Soc. Chang. 2021, 164, 120515. [Google Scholar] [CrossRef]

| Meaning | ||

|---|---|---|

| >0.99 | 1 | The degree of corrosion in both directions is basically the same |

| 0.95–0.99 | 2, 3 | The degree of corrosion in one direction is a little bit more serious than the other |

| 0.90–0.95 | 4, 5 | The degree of corrosion in one direction is more serious than the other |

| 0.75–0.90 | 6, 7 | The degree of corrosion in one direction is quite a bit more serious than the other |

| ≤0.75 | 8, 9 | The degree of corrosion in one direction is extremely more serious than the other |

| Target Layer | |||

|---|---|---|---|

| n | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RI | 0.00 | 0.00 | 0.52 | 0.89 | 1.12 | 1.26 | 1.36 | 1.41 | 1.46 | 1.49 | 1.52 | 1.54 | 1.56 | 1.58 | 1.59 |

| ADI | Relative Corrosion Coefficient | Classification |

|---|---|---|

| Extremely corrosion | ||

| No corrosion | ||

| Mild corrosion | ||

| Medium corrosion | ||

| High corrosion | ||

| Extremely corrosion |

| Samples of Limestone | z-Direction | x-Direction | y-Direction | Average Value |

|---|---|---|---|---|

| 1 | 5978.00 | 5960.00 | 6012.00 | 5983.33 |

| 2 | 5972.00 | 6065.00 | 5980.00 | 6005.67 |

| Average value | 5975.00 | 6012.50 | 5996.00 | 5994.50 |

| Direction | The Length of Coarse Aggregate (mm) | The Proportion of Coarse Aggregate () |

|---|---|---|

| x | 16.79 | 33.58% |

| y | 22.54 | 45.08% |

| z | 40.13 | 40.13% |

| Direction | The Original State () | The First Circle () | The Second Circle () | |||

|---|---|---|---|---|---|---|

| Corrected Value | Measuring Value | Corrected Value | Measuring Value | Corrected Value | Measuring Value | |

| x | 3068.8981 | 3670.4321 | 2963.2226 | 3569.3141 | 2908.3193 | 3516.2073 |

| y | 3159.5703 | 4015.6873 | 2956.5488 | 3832.0138 | 2832.7579 | 3716.4092 |

| z | 3085.3554 | 3831.5583 | 3009.0237 | 3760.6300 | 2924.8742 | 3681.3800 |

| The Original State | The First Circle | The Second Circle | ||||

|---|---|---|---|---|---|---|

| Corrected Value | Measuring Value | Corrected Value | Measuring Value | Corrected Value | Measuring Value | |

| UPV | 3088.6018 | 3747.8150 | 2969.7133 | 3637.8654 | 2866.0668 | 3582.9285 |

| The Original State | The First Circle | The Second Circle | ||||

|---|---|---|---|---|---|---|

| Corrected Value | Measuring Value | Corrected Value | Measuring Value | Corrected Value | Measuring Value | |

| Relative corrosion coefficient | 1 | 1 | 0.9615 | 0.9707 | 0.9279 | 0.9560 |

| Assessment Result | Mild corrosion | Mild corrosion | Medium corrosion | Mild corrosion | ||

| The Original State | The First Circle | The Second Circle | |

|---|---|---|---|

| Porosity (%) | 0.65 | 1.50 | 2.82 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, D.; Gong, C.; Tang, Y.; Jian, Y.; Cao, K.; Chen, H. Evaluation of Corrosion Damage in Sulfate-Attacked Concrete by CT, Ultrasonic Pulse Velocity Testing and AHP Methods. Sensors 2022, 22, 3037. https://doi.org/10.3390/s22083037

Liu D, Gong C, Tang Y, Jian Y, Cao K, Chen H. Evaluation of Corrosion Damage in Sulfate-Attacked Concrete by CT, Ultrasonic Pulse Velocity Testing and AHP Methods. Sensors. 2022; 22(8):3037. https://doi.org/10.3390/s22083037

Chicago/Turabian StyleLiu, Dunwen, Chun Gong, Yu Tang, Yinghua Jian, Kunpeng Cao, and Haofei Chen. 2022. "Evaluation of Corrosion Damage in Sulfate-Attacked Concrete by CT, Ultrasonic Pulse Velocity Testing and AHP Methods" Sensors 22, no. 8: 3037. https://doi.org/10.3390/s22083037

APA StyleLiu, D., Gong, C., Tang, Y., Jian, Y., Cao, K., & Chen, H. (2022). Evaluation of Corrosion Damage in Sulfate-Attacked Concrete by CT, Ultrasonic Pulse Velocity Testing and AHP Methods. Sensors, 22(8), 3037. https://doi.org/10.3390/s22083037