Low-Cost Microplate Reader with 3D Printed Parts for under 500 USD

Abstract

:1. Introduction

2. Materials and Methods

2.1. Construction of Plate Reader

2.1.1. Overview of Plate Reader Light Detection Electronics

2.1.2. 3D Printing

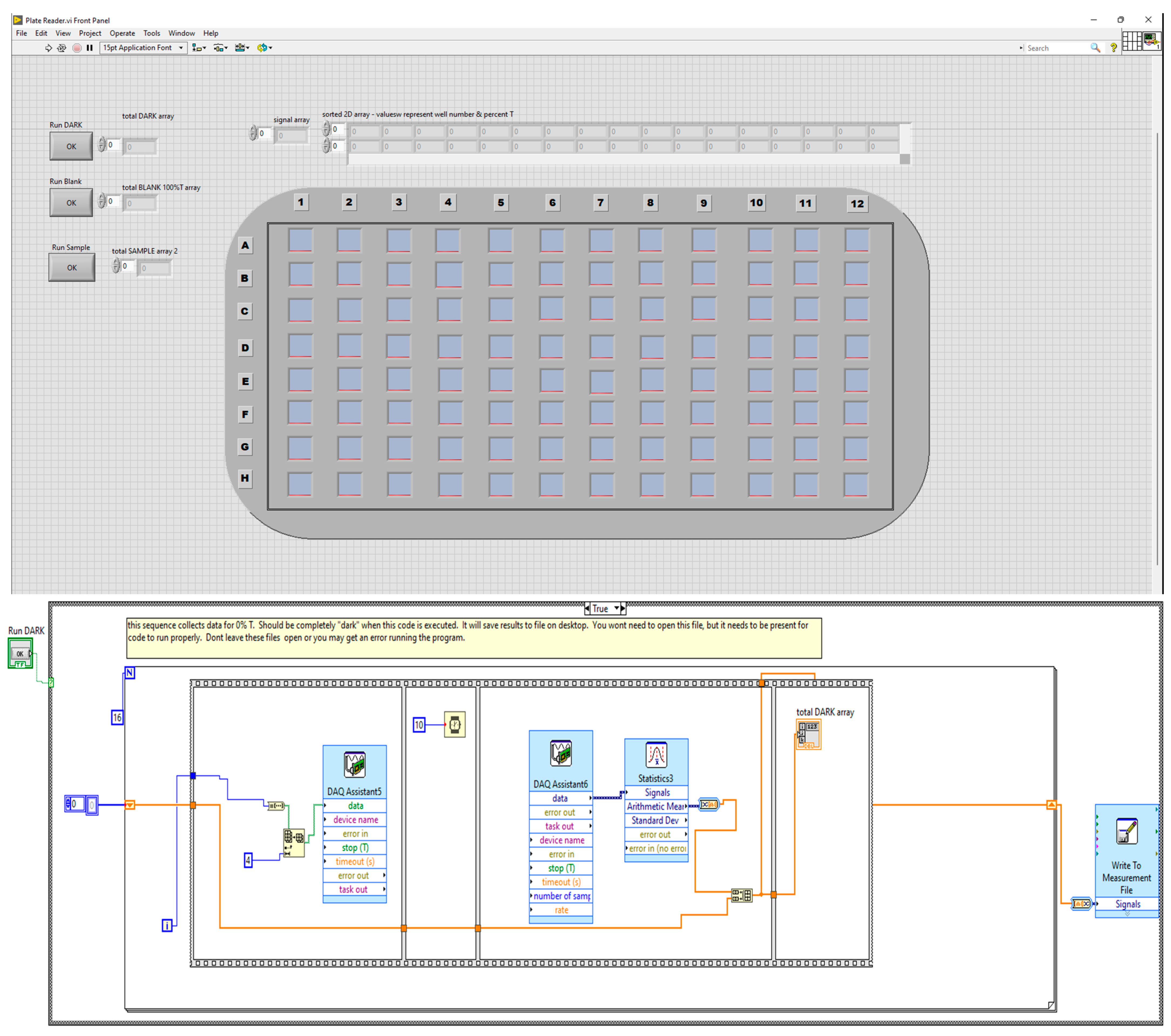

2.1.3. Description of Software

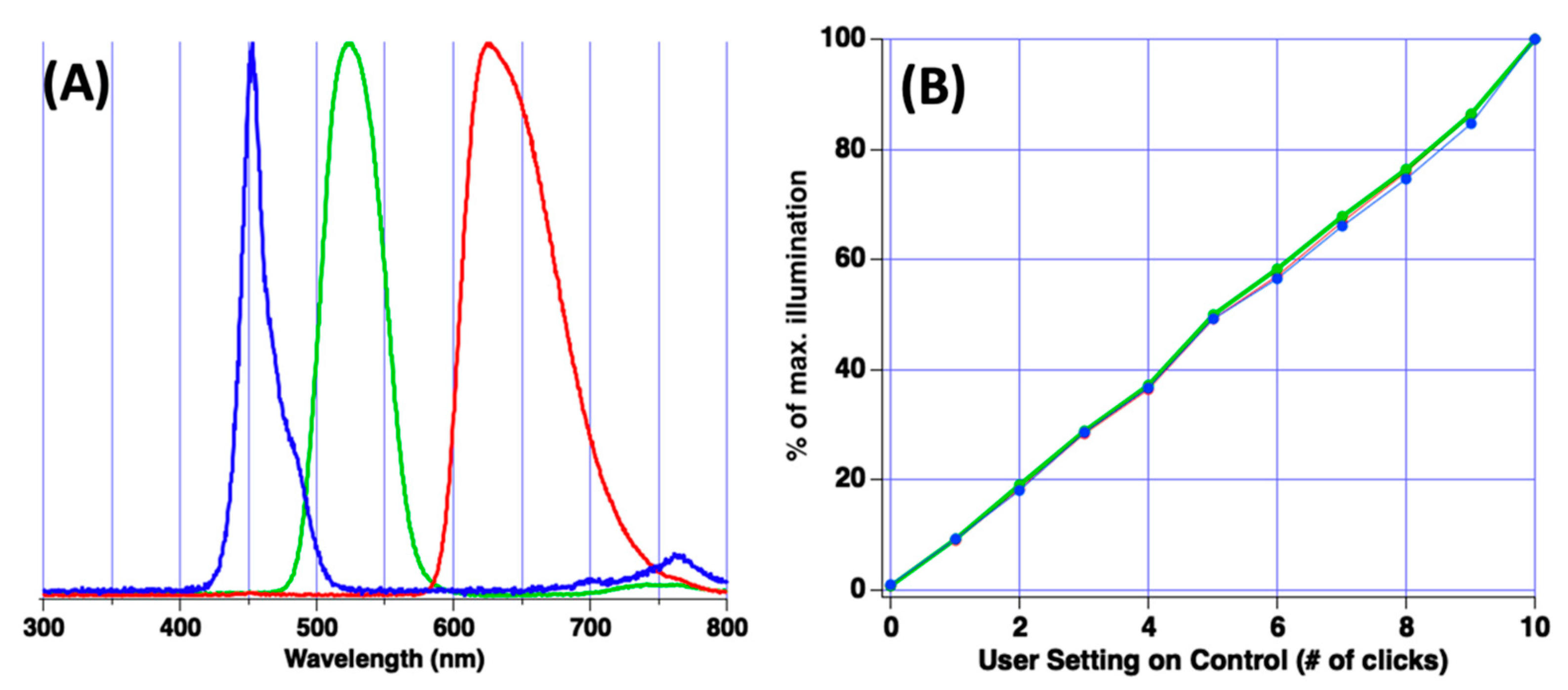

2.1.4. Light Source

3. Results

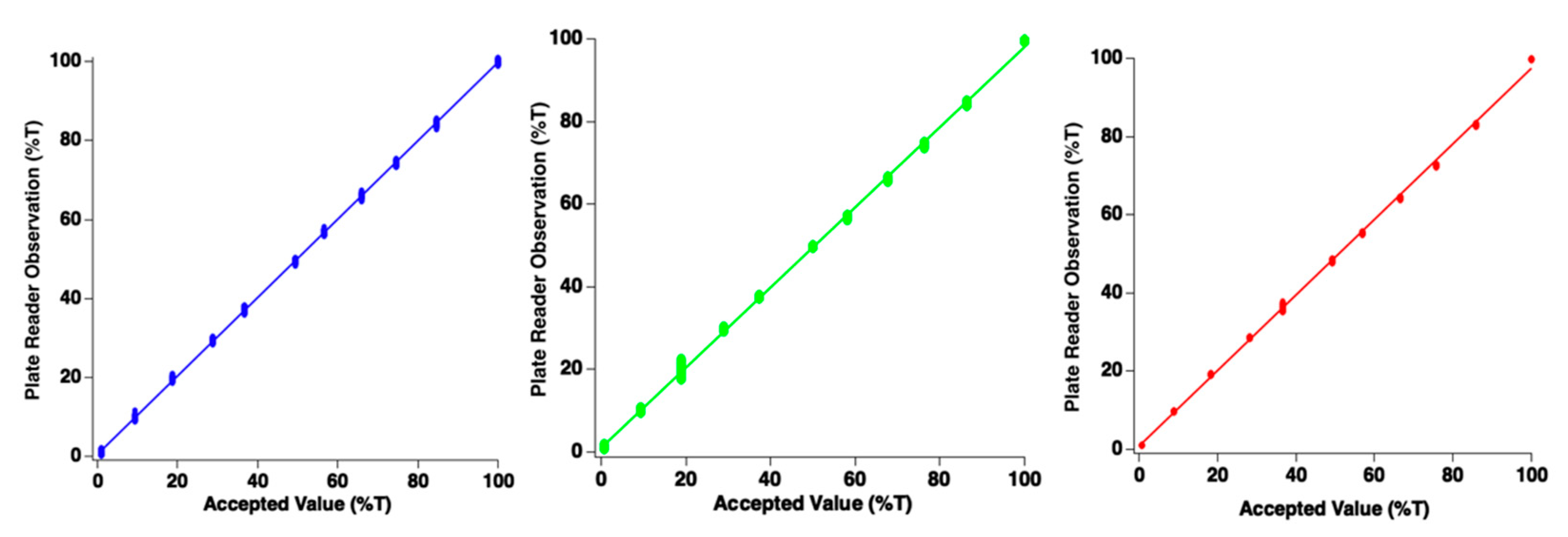

3.1. Detector Linearity

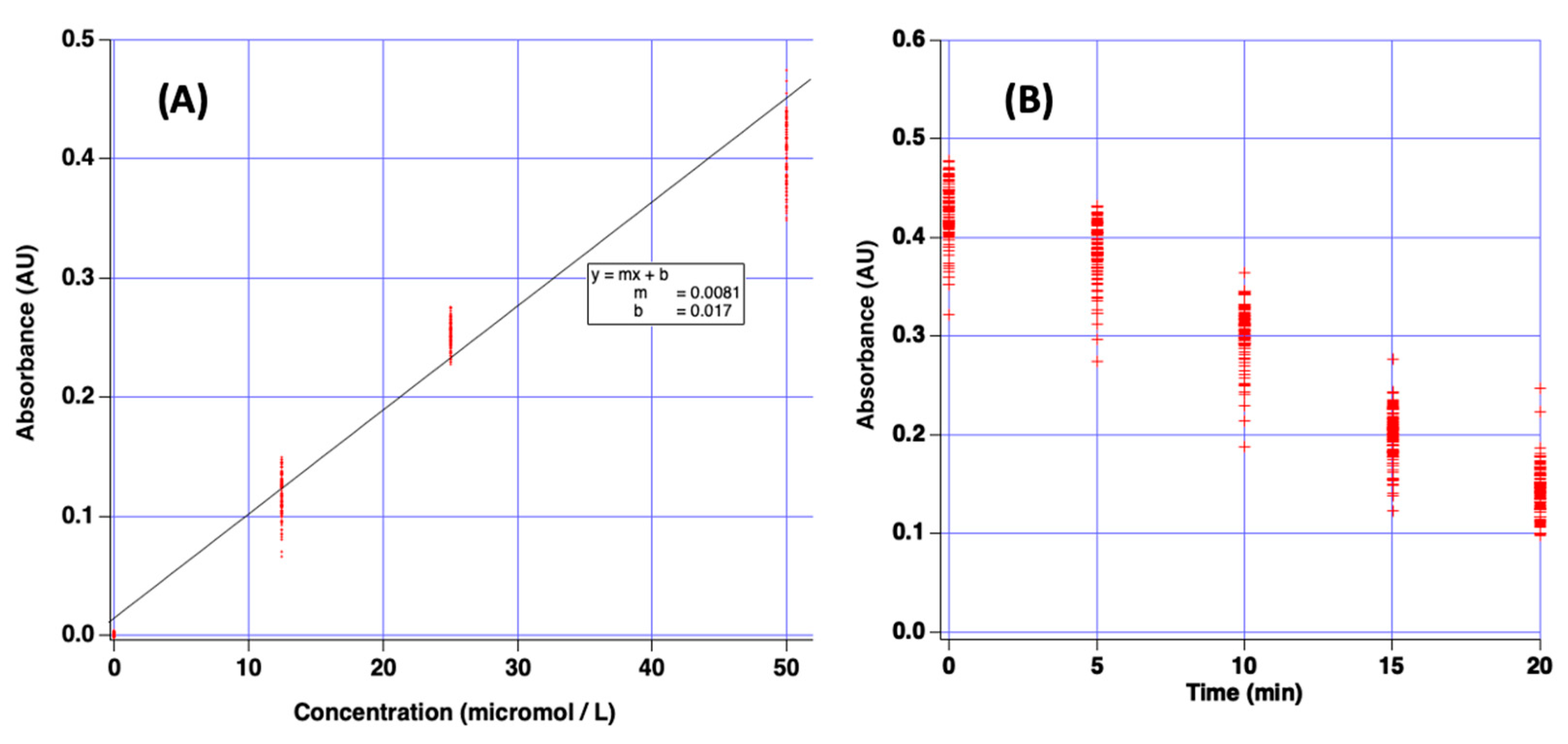

3.2. Demonstration of Device Utility

4. Discussion

5. Conclusions

Supplementary Materials

Funding

Data Availability Statement

Conflicts of Interest

References

- Gibney, E. “Open-Hardware” Pioneers Push for Low-Cost Lab Kit. Nature 2016, 531, 147–148. [Google Scholar] [CrossRef] [PubMed]

- Baden, T.; Chagas, A.M.; Gage, G.; Marzullo, T.; Prieto-Godino, L.L.; Euler, T. Open Labware: 3-D Printing Your Own Lab Equipment. PLoS Biol. 2015, 13, e1002086. [Google Scholar] [CrossRef] [PubMed]

- Pearce, J.M. Building Research Equipment with Free, Open-Source Hardware. Science 2012, 337, 1303–1304. [Google Scholar] [CrossRef] [PubMed]

- Silver, A. Five Innovative Ways to Use 3D Printing in the Laboratory. Nature 2019, 565, 123–124. [Google Scholar] [CrossRef] [PubMed]

- Kalsoom, U.; Nesterenko, P.N.; Paull, B. Current and Future Impact of 3D Printing on the Separation Sciences. TrAC—Trends Anal. Chem. 2018, 105, 492–502. [Google Scholar] [CrossRef]

- Brewin, R.J.W.; Brewin, T.G.; Phillips, J.; Rose, S.; Abdulaziz, A.; Wimmer, W.; Sathyendranath, S.; Platt, T. A Printable Device for Measuring Clarity and Colour in Lake and Nearshore Waters. Sensors 2019, 19, 936. [Google Scholar] [CrossRef] [Green Version]

- Fonda, C.; Canessa, E.; Zennaro, M. Low-Cost 3D Printing for Science, Education and Sustainable Development; The Abdus Salam International Centre for Theoretical Physics (ICTP): Trieste, Italy, 2013. [Google Scholar]

- Agrawaal, H.; Thompson, J.E. Additive Manufacturing (3D Printing) for Analytical Chemistry. Talanta Open. 2021, 3, 100036. [Google Scholar] [CrossRef]

- Ambrosi, A.; Pumera, M. 3D-Printing Technologies for Electrochemical Applications. Chem. Soc. Rev. 2 2016, 45, 2740–2755. [Google Scholar] [CrossRef] [Green Version]

- Grajewski, M.; Hermann, M.; Oleschuk, R.D.; Verpoorte, E.; Salentijn, G.I. Leveraging 3D Printing to Enhance Mass Spectrometry: A Review. Anal. Chimica Acta. 2021, 1166, 338332. [Google Scholar] [CrossRef]

- Agrawaal, H.; Jones, C.; Thompson, J.E. Personal Exposure Estimates via Portable and Wireless Sensing and Reporting of Particulate Pollution. Int. J. Environ. Res. Public Health 2020, 17, 843. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.; Brode, L.; Cao, T.; Thompson, J.E. Learning Laboratory Chemistry through Electronic Sensors, a Microprocessor, and Student Enabling Software: A Preliminary Demonstration. J. Chem. Educ. 2017, 94, 1562–1566. [Google Scholar] [CrossRef]

- Cao, T.; Thompson, J.E. Portable, Ambient PM2.5 Sensor for Human and/or Animal Exposure Studies. Anal. Lett. 2017, 50, 712–723. [Google Scholar] [CrossRef]

- Cao, T.; Thompson, J.E. Personal Monitoring of Ozone Exposure: A Fully Portable Device for under $150 USD Cost. Sens. Actuators B Chem. 2016, 224, 936–943. [Google Scholar] [CrossRef]

- Gordeev, E.G.; Ananikov, V.P. Widely Accessible 3D Printing Technologies in Chemistry, Biochemistry and Pharmaceutics: Applications, Materials and Prospects. Russ. Chem. Rev. 2020, 89, 1507–1561. [Google Scholar] [CrossRef]

- Gross, B.C.; Erkal, J.L.; Lockwood, S.Y.; Chen, C.; Spence, D.M. Evaluation of 3D Printing and Its Potential Impact on Biotechnology and the Chemical Sciences. Anal. Chem. 2014, 86, 3240–3253. [Google Scholar] [CrossRef] [PubMed]

- Cao, T.; Thompson, J.E. Remote Sensing of Atmospheric Optical Depth Using a Smartphone Sun Photometer. PLoS ONE 2014, 9, e84119. [Google Scholar] [CrossRef] [PubMed]

- Nuñez, I.; Matute, T.; Herrera, R.; Keymer, J.; Marzullo, T.; Rudge, T.; Federici, F. Low Cost and Open Source Multi-Fluorescence Imaging System for Teaching and Research in Biology and Bioengineering. PLoS ONE 2017, 12, e0187163. [Google Scholar] [CrossRef] [Green Version]

- Castillo-Hair, S.M.; Sexton, J.T.; Landry, B.P.; Olson, E.J.; Igoshin, O.A.; Tabor, J.J. FlowCal: A User-Friendly, Open Source Software Tool for Automatically Converting Flow Cytometry Data from Arbitrary to Calibrated Units. ACS Synth. Biol. 2016, 5, 774–780. [Google Scholar] [CrossRef] [Green Version]

- Albert, D.R.; Todt, M.A.; Davis, H.F. A Low-Cost Quantitative Absorption Spectrophotometer. J. Chem. Educ. 2012, 89, 1432–1435. [Google Scholar] [CrossRef]

- Takahashi, C.N.; Miller, A.W.; Ekness, F.; Dunham, M.J.; Klavins, E. A Low Cost, Customizable Turbidostat for Use in Synthetic Circuit Characterization. ACS Synth. Biol. 2015, 4, 32–38. [Google Scholar] [CrossRef] [Green Version]

- Steffens, S.; Nüßer, L.; Seiler, T.B.; Ruchter, N.; Schumann, M.; Döring, R.; Cofalla, C.; Ostfeld, A.; Salomons, E.; Schüttrumpf, H.; et al. A Versatile and Low-Cost Open Source Pipetting Robot for Automation of Toxicological and Ecotoxicological Bioassays. PLoS ONE 2017, 12, e0179636. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wijnen, B.; Hunt, E.J.; Anzalone, G.C.; Pearce, J.M. Open-Source Syringe Pump Library. PLoS ONE 2014, 9, e107216. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fu, Q.; Wu, Z.; Li, X.; Yao, C.; Yu, S.; Xiao, W.; Tang, Y. Novel Versatile Smart Phone Based Microplate Readers for On-Site Diagnoses. Biosens. Bioelectron. 2016, 81, 524–531. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, Y.; Fu, Q.; Li, D.; Xie, J.; Ke, D.; Song, Q.; Tang, Y.; Wang, H. A Smartphone Colorimetric Reader Integrated with an Ambient Light Sensor and a 3D Printed Attachment for On-Site Detection of Zearalenone. Anal. Bioanal. Chem. 2017, 409, 6567–6574. [Google Scholar] [CrossRef] [PubMed]

- Berg, B.; Cortazar, B.; Tseng, D.; Ozkan, H.; Feng, S.; Wei, Q.; Chan, R.Y.L.; Burbano, J.; Farooqui, Q.; Lewinski, M.; et al. Cellphone-Based Hand-Held Microplate Reader for Point-of-Care Testing of Enzyme-Linked Immunosorbent Assays. ACS Nano 2015, 9, 7857–7866. [Google Scholar] [CrossRef]

- Szymula, K.P.; Magaraci, M.S.; Patterson, M.; Clark, A.; Mannickarottu, S.G.; Chow, B.Y. An Open-Source Plate Reader. Biochemistry 2019, 58, 468–473. [Google Scholar] [CrossRef] [Green Version]

- Thompson, J.E. Parts-per-Billion Limits of Detection via Absorbance Spectroscopy: An Ultraviolet (254 Nm) Absorbance Detector for Liquid Chromatography Using a Light Emitting Diode (LED). Eurasian J. Anal. Chem. 2017, 12, 901–911. [Google Scholar] [CrossRef]

- Thompson, J.E.; Ting, J. A Simple, Inexpensive Water-Jacketed Cuvette for the Spectronic 20. J. Chem. Educ. 2004, 81, 81. [Google Scholar] [CrossRef]

| Item | Source | Cost (USD) |

|---|---|---|

| Photodiode Mount | 3D printing | $2.04 1 |

| Top for Plate Reader | 3D Printing | $37.47 1 |

| Collimation Screen | 3D Printing | $2.04 1 |

| Base for Plate Reader | 3D Printing | $40.25 1 |

| Data Acquisition Card | National Instruments USB-6009 | $239.99 2 |

| Misc. Wire and Solder | various | $10 |

| Light Source | Neewar Dimmable 5600K USB LED | $32.39 3 |

| Colored Filters | Lee Filters | $43.30 4 |

| Qty 6 16-Channel Multiplexer | Sparkfun CD74HC4067 | $33 |

| 96 Photodiodes | Digikey 1830-INL-5ANPD80-ND | $17.29 |

| TOTAL HARDWARE COST | - | $457.77 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thompson, J.E. Low-Cost Microplate Reader with 3D Printed Parts for under 500 USD. Sensors 2022, 22, 3242. https://doi.org/10.3390/s22093242

Thompson JE. Low-Cost Microplate Reader with 3D Printed Parts for under 500 USD. Sensors. 2022; 22(9):3242. https://doi.org/10.3390/s22093242

Chicago/Turabian StyleThompson, Jonathan E. 2022. "Low-Cost Microplate Reader with 3D Printed Parts for under 500 USD" Sensors 22, no. 9: 3242. https://doi.org/10.3390/s22093242

APA StyleThompson, J. E. (2022). Low-Cost Microplate Reader with 3D Printed Parts for under 500 USD. Sensors, 22(9), 3242. https://doi.org/10.3390/s22093242