Strain Virtual Sensing for Structural Health Monitoring under Variable Loads

Abstract

:1. Introduction

2. Materials and Methods

2.1. System Modeling

2.1.1. Finite Element Model

2.1.2. Model Reduction

2.1.3. State-Space Model

2.2. Virtual Sensing Algorithms

2.2.1. Kalman Filter

2.2.2. Augmented Kalman Filter

2.2.3. Least-Squares Strain Estimation (LSSE)

2.3. Virtual Sensing Implementation

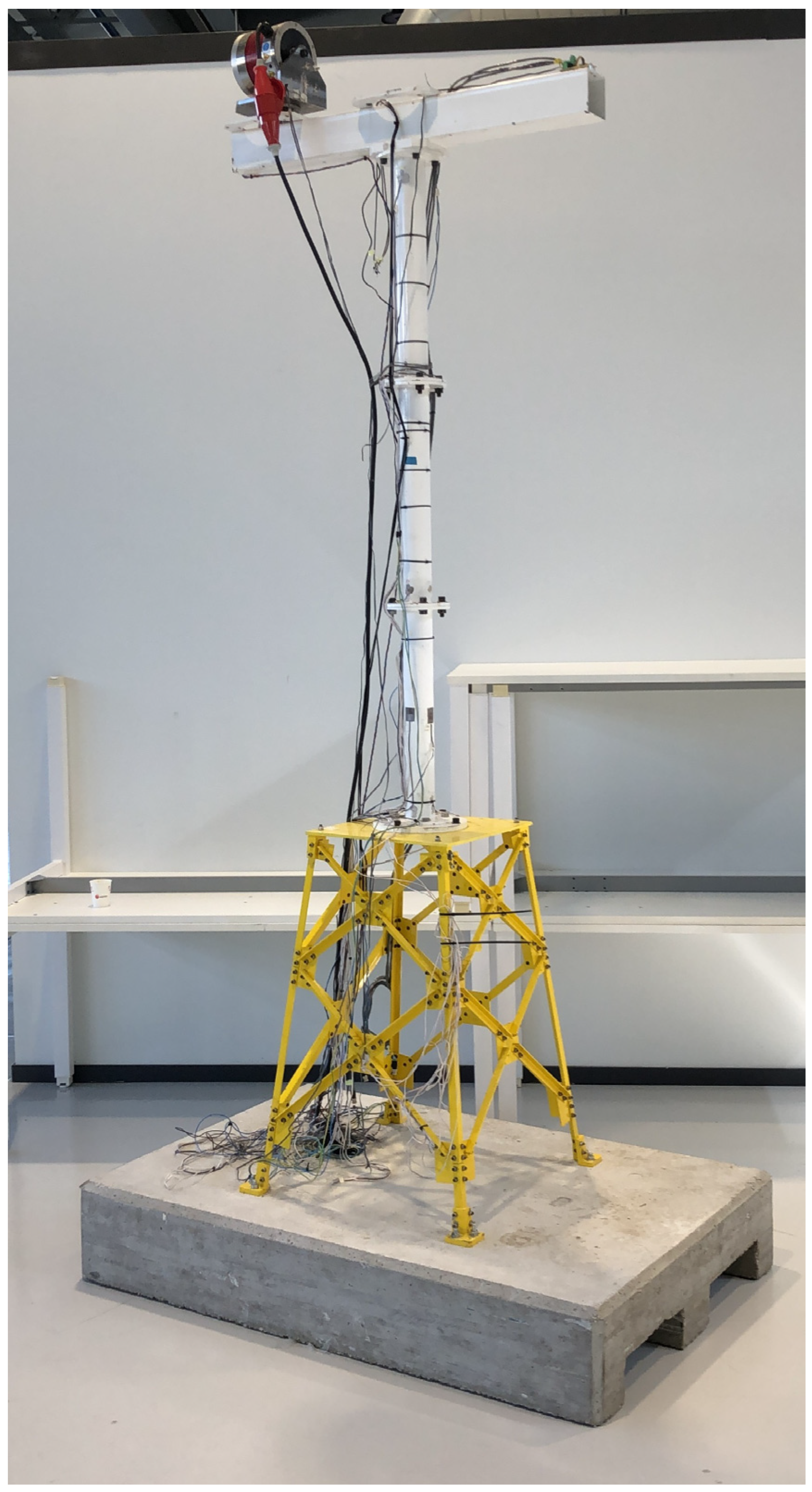

2.4. Use Case

2.4.1. Prototype Description

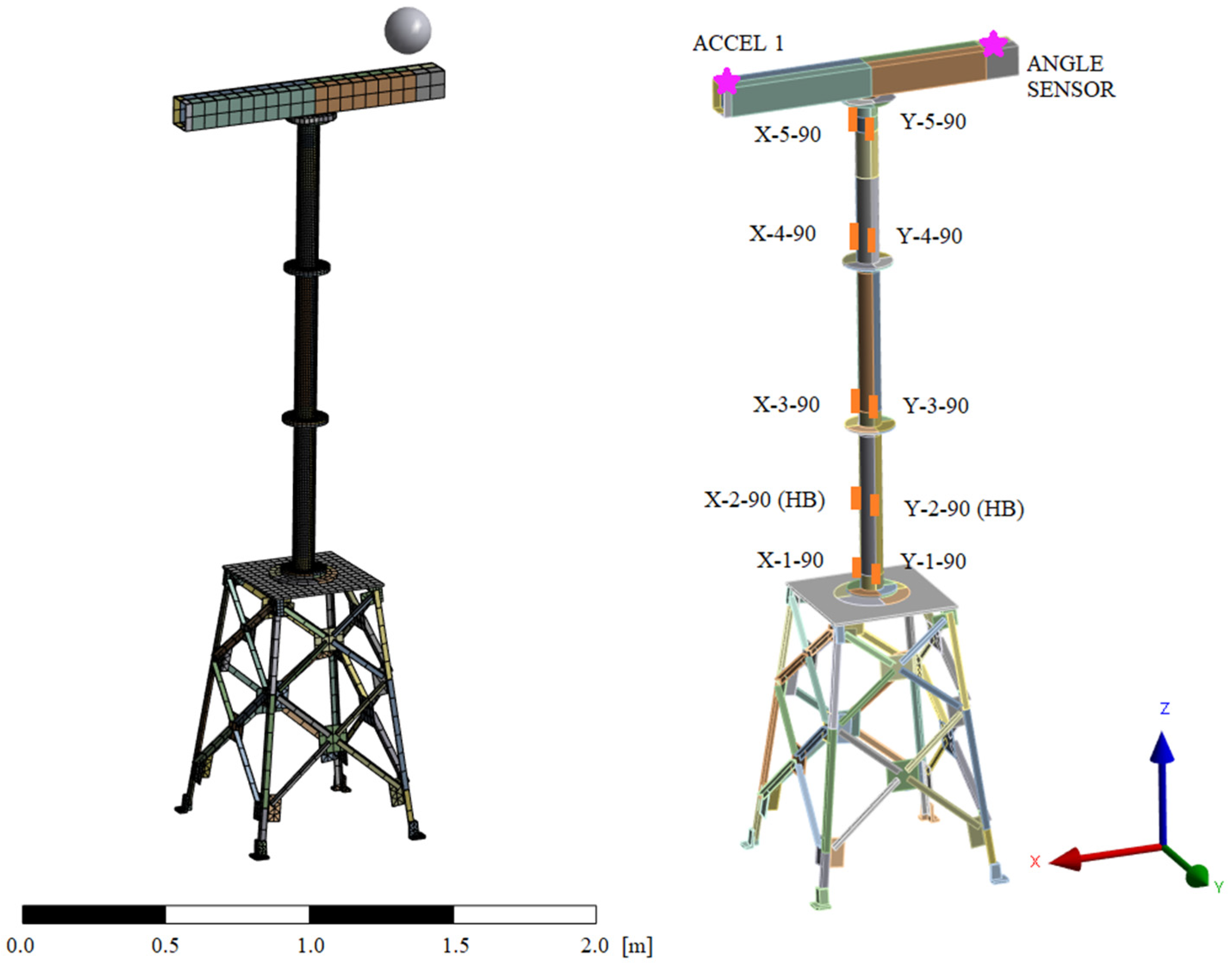

2.4.2. FE Model and Model Reduction

2.4.3. Model Validation

2.4.4. Sensors

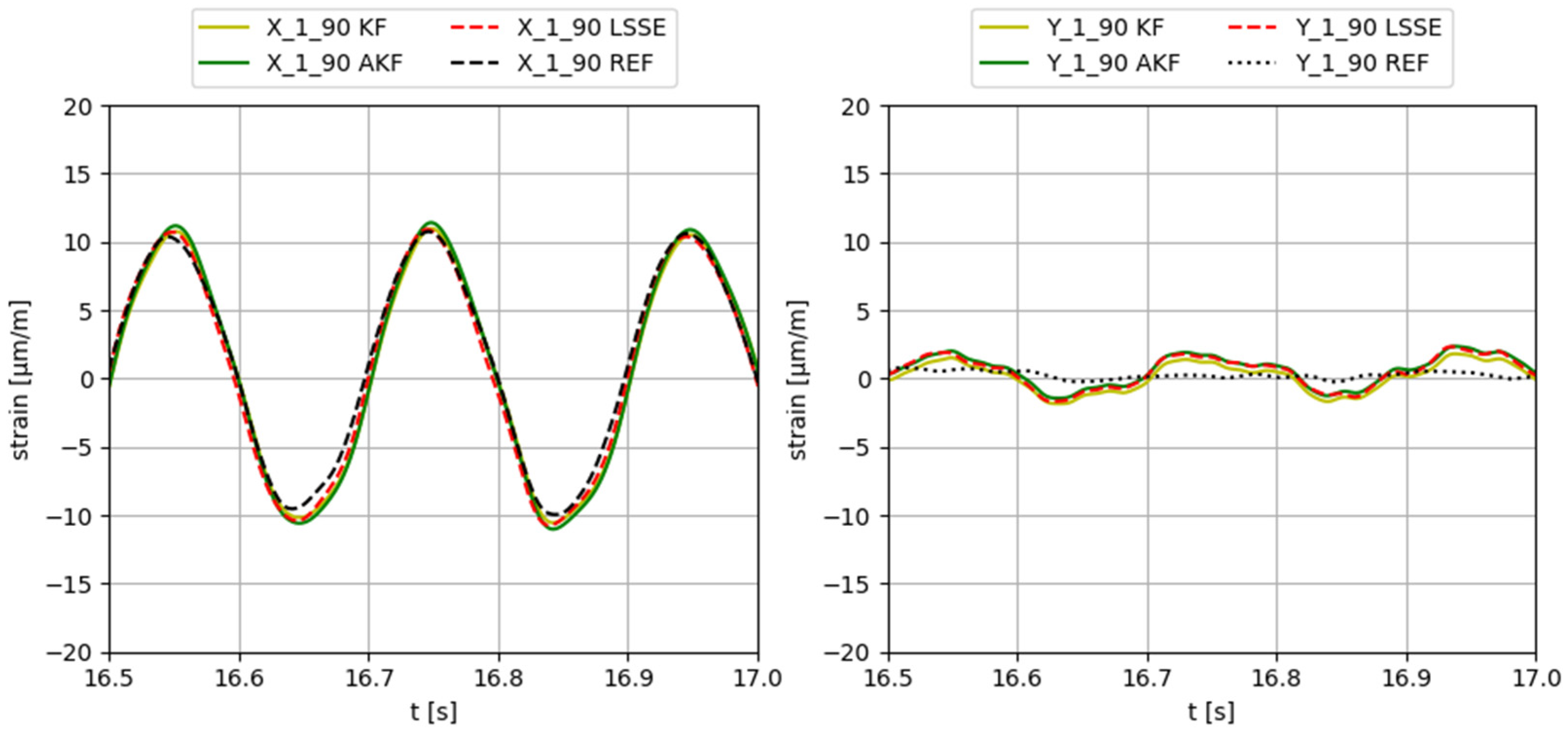

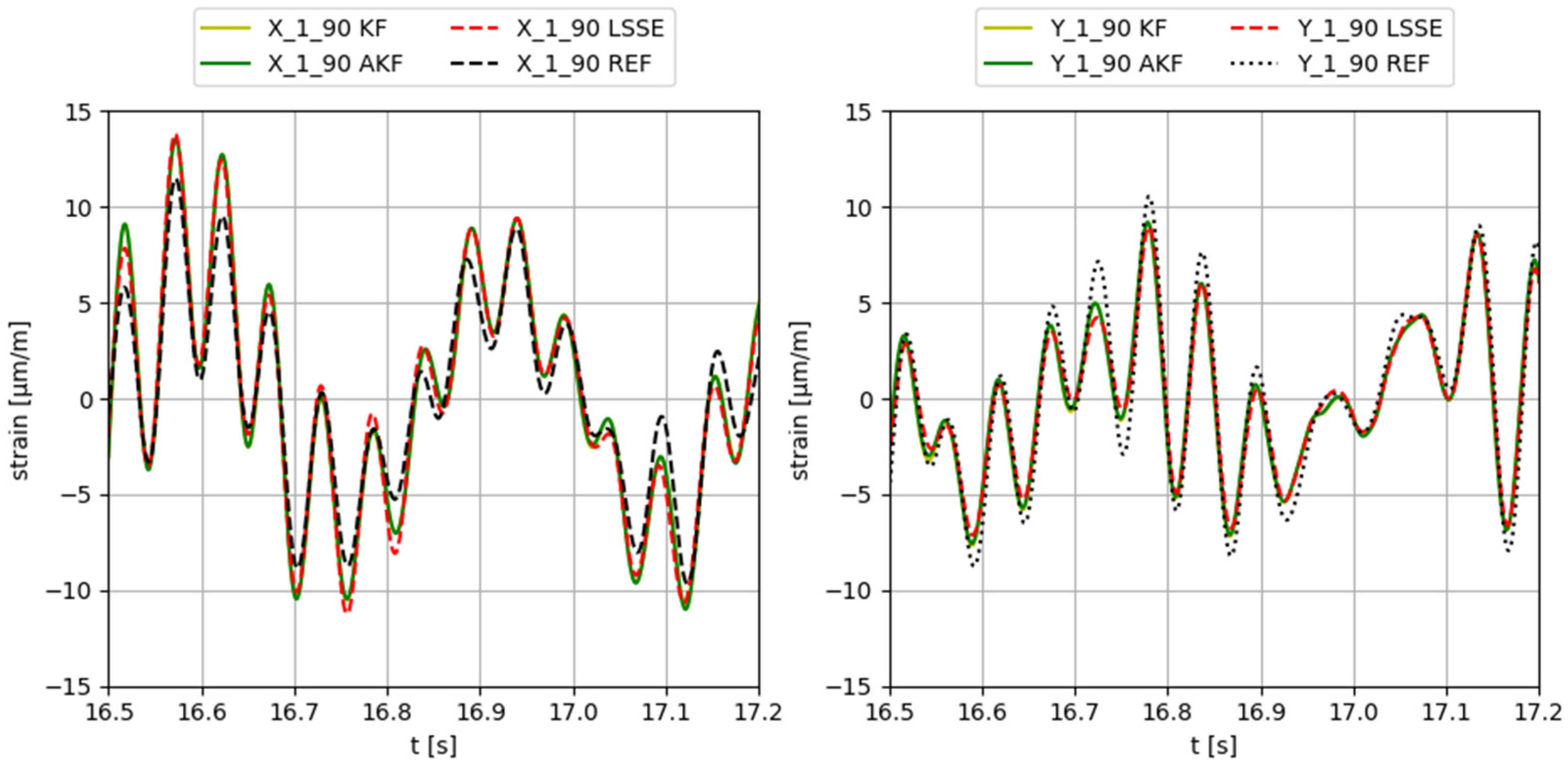

3. Results

3.1. Evaluation Methods

3.2. Tests Performed

3.3. Obtained Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rih-Teng, W.; Mohammad Reza, J. Data Fusion Approaches for Structural Health Monitoring and System Identification: Past, Present, and Future. SAGE Struct. Health Monit. 2018, 19, 552–586. [Google Scholar] [CrossRef]

- Liu, L.; Kuo, S.M.; Zhou, M.C. Virtual Sensing Techniques and Their Applications. In Proceedings of the IEEE International Conference on Networking, Sensing and Control, Okayama, Japan, 26–29 March 2009; pp. 31–36. [Google Scholar]

- Maes, K.; Iliopoulos, A.; Weijtjens, W.; Devriendt, C.; Lombaert, G. Dynamic Strain Estimation for Fatigue Assessment of an Offshore Monopile Wind Turbine Using Filtering and Modal Expansion Algorithms. Mech. Syst. Signal. Process. 2016, 76–77, 592–611. [Google Scholar] [CrossRef]

- Ilyas, E.B.; Fischer, M.; Iggena, T.; Tonjes, R. Virtual Sensor Creation to Replace Faulty Sensors Using Automated Machine Learning Techniques. In Proceedings of the GIoTS 2020—Global Internet of Things Summit, Online, 3 June 2020; pp. 3–8. [Google Scholar]

- Woodbury, T.; Srivastava, A.N. Analysis of Virtual Sensors for Predicting Aircraft Fuel Consumption. In Proceedings of the AIAA Infotech at Aerospace Conference and Exhibit, Pasadena, CA, USA, 11–13 September 2012; pp. 1–15. [Google Scholar]

- Renard, P.; Alcolea, A.; Ginsbourger, D. Stochastic versus Deterministic Approaches. In Environmental Modelling: Finding Simplicity in Complexity, 2nd ed.; Wiley: Hoboken, NJ, USA, 2013; pp. 133–149. ISBN 9780470749111. [Google Scholar]

- Azzam, B.; Schelenz, R.; Roscher, B.; Baseer, A.; Jacobs, G. Development of a Wind Turbine Gearbox Virtual Load Sensor Using Multibody Simulation and Artificial Neural Networks. Forsch. Ing. Eng. Res. 2021, 85, 241–250. [Google Scholar] [CrossRef]

- Sun, S.; He, Y.; Zhou, S.; Yue, Z. A Data-Driven Response Virtual Sensor Technique with Partial Vibration Measurements Using Convolutional Neural Network. Sensors 2017, 17, 2888. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kalman, R. A New Approach to Linear Filtering and Prediction Problems. Trans. ASME J. Basic Eng. 1960, 82, 35–45. [Google Scholar] [CrossRef] [Green Version]

- Chen, Z. Bayesian Filtering: From Kalman Filters to Particle Filters, and Beyond. Stat. J. Theor. Appl. Stat. 2003, 182, 1–69. [Google Scholar] [CrossRef]

- Maes, K.; De Roeck, G.; Iliopoulos, A.; Weijtjens, W.; Devriendt, C.; Lombaert, G. Kalman Filter Based Strain Estimation for Fatigue Assessment of an Offshore Monopile Wind Turbine. In Proceedings of the ISMA 2016, Leuven, Belgium, 19–21 September 2016; pp. 1649–1661. [Google Scholar]

- Palanisamy, R.P.; Cho, S.; Kim, H.; Sim, S.H. Experimental Validation of Kalman Filter-Based Strain Estimation in Structures Subjected to Non-Zero Mean Input. Smart Struct. Syst. 2015, 15, 489–503. [Google Scholar] [CrossRef] [Green Version]

- Friedland, B. Treatment of Bias in Recursive Filtering. IEEE Trans. Automat. Contr. 1969, 14, 359–367. [Google Scholar] [CrossRef]

- Lourens, E.; Reynders, E.; De Roeck, G.; Degrande, G.; Lombaert, G. An Augmented Kalman Filter for Force Identification in Structural Dynamics. Mech. Syst. Signal. Process. 2011, 27, 446–460. [Google Scholar] [CrossRef]

- Julier, S.J.; Uhlmann, J.K. Unscented Filtering and Nonlinear Estimation. Proc. IEEE 2004, 92, 401–422. [Google Scholar] [CrossRef] [Green Version]

- Borges, G.A.; Vargas, A.N.; Ishihara, J.Y.; Menegaz, H.M.T. A Systematization of the Unscented Kalman Filter Theory. IEEE-TAC 2015, 60, 2583–2598. [Google Scholar] [CrossRef] [Green Version]

- Jouin, M.; Gouriveau, R.; Hissel, D.; Péra, M.C.; Zerhouni, N. Particle Filter-Based Prognostics: Review, Discussion and Perspectives. Mech. Syst. Signal. Process. 2016, 72–73, 2–31. [Google Scholar] [CrossRef]

- Henkel, M.; Weijtjens, W.; Devriendt, C. Fatigue Stress Estimation for Submerged and Sub-Soil Welds of Offshore Wind Turbines on Monopiles Using Modal Expansion. Energies 2021, 14, 7576. [Google Scholar] [CrossRef]

- Avitabile, P.; Pingle, P. Prediction of Full Field Dynamic Strain from Limited Sets of Measured Data. Shock Vib. 2012, 19, 765–785. [Google Scholar] [CrossRef]

- Penrose, R. A Generalized Inverse for Matrices. In Proceedings of the Mathematical Proceedings of the Cambridge Philosophical Society; Cambridge University Press: Cambridge, UK, 1955; Volume 51, pp. 406–413. [Google Scholar]

- Elfving, T. A Stationary Iterative Pseudoinverse Algorithm. BIT Numer. Math. 1998, 38, 275–282. [Google Scholar] [CrossRef]

- Branlard, E.; Giardina, D.; Brown, C.S.D. Augmented Kalman Filter with a Reduced Mechanical Model to Estimate Tower Loads on a Land-Based Wind Turbine: A Step towards Digital-Twin Simulations. Wind Energy Sci. 2020, 5, 1155–1167. [Google Scholar] [CrossRef]

- Yan, A.; De Boe, P.; Golinval, J. Structural Damage Diagnosis by Kalman Model Based on Stochastic Subspace Identification. SAGE Struct. Health Monit. 2004, 3, 103–119. [Google Scholar] [CrossRef]

- Tarpø, M.; Nabuco, B.; Georgakis, C.; Brincker, R. Expansion of Experimental Mode Shape from Operational Modal Analysis and Virtual Sensing for Fatigue Analysis Using the Modal Expansion Method. Int. J. Fatigue 2020, 130, 105280. [Google Scholar] [CrossRef]

- Moghadam, F.K.; Nejad, A.R. Online Condition Monitoring of Floating Wind Turbines Drivetrain by Means of Digital Twin. Mech. Syst. Signal. Process. 2022, 162, 108087. [Google Scholar] [CrossRef]

- Baqersad, J.; Bharadwaj, K.; Poozesh, P. Modal Expansion Using Strain Mode Shapes. In Shock & Vibration, Aircraft/Aerospace, Energy Harvesting, Acoustics & Optics, Volume 9: Proceedings of the 35th IMAC, A Conference and Exposition on Structural Dynamics 2017; Springer: Berlin/Heidelberg, Germany, 2017; Volume 9, pp. 219–226. [Google Scholar]

- Dorosti, M.; Fey, R.; Heertjes, M.; Van De Wal, M.; Nijmeijer, H. Finite Element Model Reduction and Model Updating of Structures for Control. IFAC Proc. Vol. 2014, 47, 4517–4522. [Google Scholar] [CrossRef] [Green Version]

- Guyan, R. Reduction of Stiffness and Mass Matrices. AIAA J. 1965, 3, 380. [Google Scholar] [CrossRef]

- Friswell, M.I.; Garvey, S.D.; Penny, J.E.T. Model Reduction Using Dynamic and Iterated IRS Techniques. J. Sound Vib. 1995, 186, 311–323. [Google Scholar] [CrossRef]

- Craig, R.; Bampton, M. Coupling of Substructures for Dynamic Analyses. AIAA J. 1968, 6, 1313–1319. [Google Scholar] [CrossRef] [Green Version]

- Tolani, S.K. Modal Truncation of Substructures Used in Vibration Analysis; University of Missouri-Rolla: Rolla, MO, USA, 1972. [Google Scholar]

- Tarpø, M.; Vigsø, M. Modal Truncation in Experimental Modal Analysis. In Topics in Modal Analysis & Testing; Springer: Berlin/Heidelberg, Germany, 2019; Volume 9, pp. 143–152. ISBN 9783319747002. [Google Scholar]

- Li, D.S.; Li, H.N.; Fritzen, C.P. The Connection between Effective Independence and Modal Kinetic Energy Methods for Sensor Placement. J. Sound Vib. 2007, 305, 945–955. [Google Scholar] [CrossRef]

| Feature | Value |

|---|---|

| Tower + nacelle weight | 42 kg |

| Jacket weight | 13.5 kg |

| Shaker + support weight | 27 kg |

| Total weight | 82.5 kg |

| Tower height | 1790 mm |

| Jacket height | 1300 mm |

| Total height | 3090 mm |

| Material | Steel |

| Supports | Fixed to a concrete base |

| Shaker model | Data Physics IV47 |

| Inertial mass | 14.5 kg |

| Max sinus force (peak) | 250 N |

| Total shaker mass | 21 kg |

| Shaker main mode freq. | 20 Hz |

| Feature | Description |

|---|---|

| Number of elements | 11,387 |

| Element type | Shell and solid |

| Element order | Quadratic |

| Young modulus | 2.2 × 1011 Pa |

| Boundary conditions | 4 fixed supports |

| Model weight | 82.5 kg |

| FE Model | OMA | ||||

|---|---|---|---|---|---|

| Mode | Mode Description | freq. [Hz] | freq. [Hz] | Damping Ratio [%] | MAC [%] |

| 1 | 1st in X. Bending | 3.1 | 3.1 | 0.5 | 85 |

| 2 | 1st in Y. Bending | 3.1 | 3.1 | 0.7 | 93 |

| 3 | 2nd in X. Bending | 17.0 | 16.2 | 4.1 | 86 |

| 4 | 1st in Z. Torsion | 19.2 | 17.4 | 2.7 | 99 |

| Sensor | Number | Description |

|---|---|---|

| Strain gauges: quarter bridge | 8 | 120 Ω, gauge factor = 2 |

| Strain gauges: half bridge | 2 | 120 Ω, gauge factor = 2 * |

| Accelerometer | 1 (3 channels) | MEMS type (ADXL335) |

| Angle sensor | 1 | Potentiometer |

| Input Force Type | Frequency [Hz] | Directions |

|---|---|---|

| 0 mean sinusoidal | 2 | X, Y and XY |

| 0 mean sinusoidal | 5 | X, Y and XY |

| 0 mean sinusoidal | 10 | X, Y and XY |

| 0 mean sinusoidal | 15 | X, Y and XY |

| 0 mean white noise | 5 to 25 | X, Y and XY |

| Algorithms | Config. | AcX | AcY | Ac Z | G2 | G3 | G4 | G5 |

|---|---|---|---|---|---|---|---|---|

| KF, AKF, LSSE | 1 | x | x | x | x | |||

| KF, AKF, LSSE | 2 | x | x | x | ||||

| KF, AKF, LSSE | 3 | x | x | x | ||||

| KF, AKF, LSSE | 4 | x | x | |||||

| KF, AKF, LSSE | 5 | x | x | |||||

| KF, AKF | 6 | x | x | x | x | x | x | x |

| KF, AKF | 7 | x | x | x | x | x | x | |

| KF, AKF | 8 | x | x | x | x | x | x | |

| KF, AKF | 9 | x | x | x | x | x | ||

| KF, AKF | 10 | x | x | x | x | x | ||

| KF, AKF | 11 | x | x | x | x | |||

| KF, AKF | 12 | x | x | x | x |

| R | Value |

|---|---|

| gauges | 1 × 108 |

| accelerometers | 1 × 103 |

| Configuration | KF | AKF | LSSE | |||

|---|---|---|---|---|---|---|

| Modes | Q | Modes | Q | QF | Modes | |

| 1 | 4 | 1 × 10−1 | 4 | 1 × 10−1 | 1 × 103 | 4 |

| 2 | 4 | 1 × 10−1 | 4 | 1 × 10−1 | 1 × 103 | 4 |

| 3 | 4 | 1 × 10−1 | 4 | 1 × 10−1 | 1 × 103 | 4 |

| 4 | 4 | 1 × 10−1 | 4 | 1 × 10−1 | 1 × 103 | 4 |

| 5 | 4 | 1 × 10−2 | 4 | 1 × 10−2 | 1 × 103 | 4 |

| 6 | 4 | 1 × 10−9 | 4 | 1 × 10−1 | 1 × 103 | - |

| 7 | 4 | 1 × 10−9 | 4 | 1 × 10−1 | 1 × 103 | - |

| 8 | 4 | 1 × 10−9 | 4 | 1 × 10−1 | 1 × 103 | - |

| 9 | 4 | 1 × 10−9 | 4 | 1 × 10−1 | 1 × 103 | - |

| 10 | 4 | 1 × 10−9 | 4 | 1 × 10−1 | 1 × 103 | - |

| 11 | 4 | 1 × 10−9 | 4 | 1 × 10−1 | 1 × 103 | - |

| 12 | 4 | 1 × 10−9 | 4 | 1 × 10−3 | 1 × 103 | - |

| Configuration | Number Gauges | Number Accelerometers | Error %/PCC X Direction | Error %/PCC Y Direction | Error %/PCC XY 45° Direction |

|---|---|---|---|---|---|

| 1 | 8 | 0 | 11.0/99.3 | 19.2/99.9 | 16.9/99.5 |

| 2 | 6 | 0 | 10.4/99.2 | 19.4/99.8 | 19.3/99.3 |

| 3 | 6 | 0 | 8.8/97.8 | 5.6/99.7 | 19.4/99.4 |

| 4 | 4 | 0 | 13.4/99.3 | 23.7/99.8 | 21.8/99.1 |

| 5 | 4 | 0 | 30.3/84.6 | 22.0/96.4 | 28.1/97.2 |

| 6 | 8 | 1 | 751.5/86.4 | 55.9/73.5 | 368.8/81.2 |

| 7 | 6 | 1 | 751.5/86.4 | 55.9/73.5 | 368.8/81.2 |

| 8 | 6 | 1 | 751.5/86.4 | 55.9/73.5 | 368.8/81.2 |

| 9 | 4 | 1 | 751.5/86.4 | 55.9/73.5 | 368.8/81.2 |

| 10 | 4 | 1 | 751.5/86.4 | 55.9/73.5 | 368.8/81.2 |

| 11 | 2 | 1 | 54.3/91.5 | 56.3/73.2 | 50.8/90.4 |

| 12 | 2 | 1 | 54.3/91.5 | 56.3/73.2 | 50.8/90.4 |

| Configuration | Number Gauges | Number Accelerometers | Error %/PCC X Direction | Error %/PCC Y Direction | Error %/PCC XY 45° Direction |

|---|---|---|---|---|---|

| 1 | 8 | 0 | 10.6/99.4 | 19.2/99.9 | 17.3/99.7 |

| 2 | 6 | 0 | 9.9/99.2 | 19.4/99.8 | 19.6/99.3 |

| 3 | 6 | 0 | 7.3/97.9 | 4.6/99.8 | 19.2/98.4 |

| 4 | 4 | 0 | 13.3/99.3 | 24.2/99.8 | 22.0/99.1 |

| 5 | 4 | 0 | 32.4/87.0 | 16.6/97.9 | 26.7/97.1 |

| 6 | 8 | 1 | 10.3/99.0 | 26.3/99.5 | 22.6/98.7 |

| 7 | 6 | 1 | 15.1/99.0 | 24.2/99.6 | 21.8/98.5 |

| 8 | 6 | 1 | 4.5/97.1 | 18.4/98.4 | 19.3/97.5 |

| 9 | 4 | 1 | 13.6/99.4 | 63.0/74.3 | 35.4/94.3 |

| 10 | 4 | 1 | 35.1/81.3 | 65.2/65.2 | 47.1/76.6 |

| 11 | 2 | 1 | 56.6/82.7 | 66.6/77.7 | 53.9/91.2 |

| 12 | 2 | 1 | 70.2/46.3 | 87.1/49.3 | 76.6/70.3 |

| Configuration | Number Gauges | Error %/PCC X Direction | Error %/PCC Y Direction | Error %/PCC XY 45° Direction |

|---|---|---|---|---|

| 1 | 8 | 11.1/99.5 | 20.1/99.9 | 17.5/99.7 |

| 2 | 6 | 10.9/99.3 | 21.5/99.9 | 20.9/99.4 |

| 3 | 6 | 8.2/99.6 | 5.5/99.8 | 18.8/98.9 |

| 4 | 4 | 15.7/99.2 | 30.5/99.7 | 25.7/98.9 |

| 5 | 4 | 36.4/84.1 | 26.0/97.3 | 45.2/90.0 |

| F X 5 Hz | X-1-90 | Y-1-90 |

|---|---|---|

| KF | 3.6/99.4 | 178.6/61.6 |

| AKF | 7.7/99.4 | 187.3/60.2 |

| LSSE | 4.1/99.8 | 197.1/58.3 |

| F Y 15 Hz | X-1-90 | Y-1-90 |

|---|---|---|

| KF | 195.6/95.4 | 7.3/99.9 |

| AKF | 209.3/95.2 | 7.0/99.9 |

| LSSE | 217.3/98.5 | 6.9/99.9 |

| F XY Noise | X-1-90 | Y-1-90 |

|---|---|---|

| KF | 19.8/97.4 | 13.7/99.1 |

| AKF | 20.0/97.4 | 13.9/99.0 |

| LSSE | 18.2/97.3 | 15.9/98.9 |

| F VAR 5 Hz | X-1-90 | Y-1-90 |

|---|---|---|

| KF | 12.3/92.8 | 8.6/99.0 |

| AKF | 19.5/99.0 | 4.9/98.9 |

| LSSE | 16.8/99.3 | 4.1/98.7 |

| F X HIT | X-1-90 | Y-1-90 |

|---|---|---|

| KF | 11.6/99.5 | 2.1/93.7 |

| AKF | 11.3/99.5 | 1.8/93.3 |

| LSSE | 11.6/99.6 | 3.2/92.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mora, B.; Basurko, J.; Sabahi, I.; Leturiondo, U.; Albizuri, J. Strain Virtual Sensing for Structural Health Monitoring under Variable Loads. Sensors 2023, 23, 4706. https://doi.org/10.3390/s23104706

Mora B, Basurko J, Sabahi I, Leturiondo U, Albizuri J. Strain Virtual Sensing for Structural Health Monitoring under Variable Loads. Sensors. 2023; 23(10):4706. https://doi.org/10.3390/s23104706

Chicago/Turabian StyleMora, Bartomeu, Jon Basurko, Iman Sabahi, Urko Leturiondo, and Joseba Albizuri. 2023. "Strain Virtual Sensing for Structural Health Monitoring under Variable Loads" Sensors 23, no. 10: 4706. https://doi.org/10.3390/s23104706