Investigation and Improvement of Test Methods for Capacitance and DCESR of EDLC Cells

Abstract

:1. Introduction

2. Experimental

2.1. EDLC Cells

2.2. Test Equipment and Procedure

2.2.1. LBT 20144 Test Equipment

2.2.2. Test Procedure

3. Results and Discussion

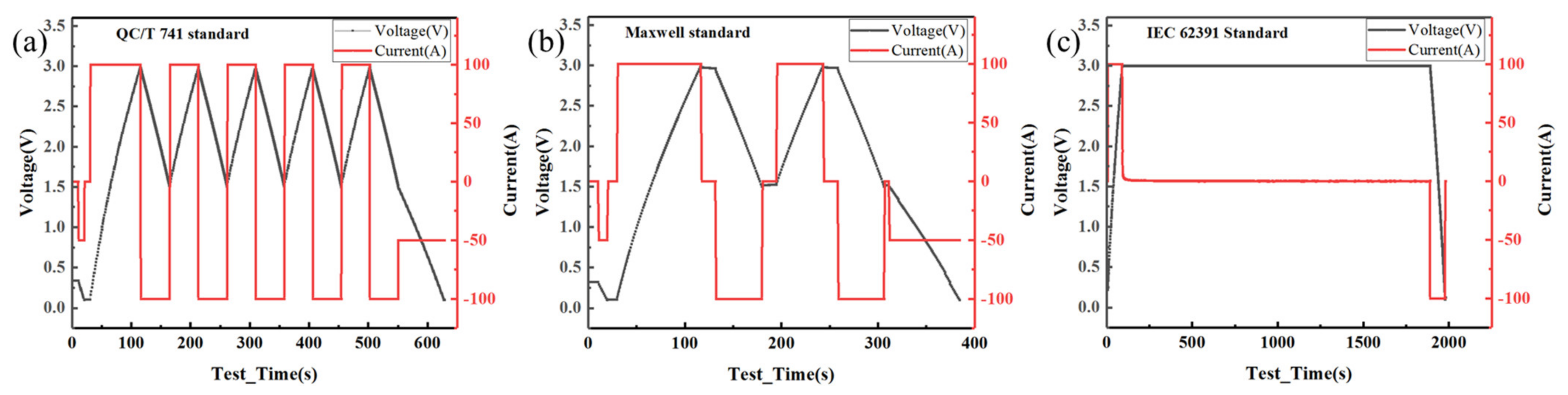

3.1. Comparative Analysis of the Three Test Standards

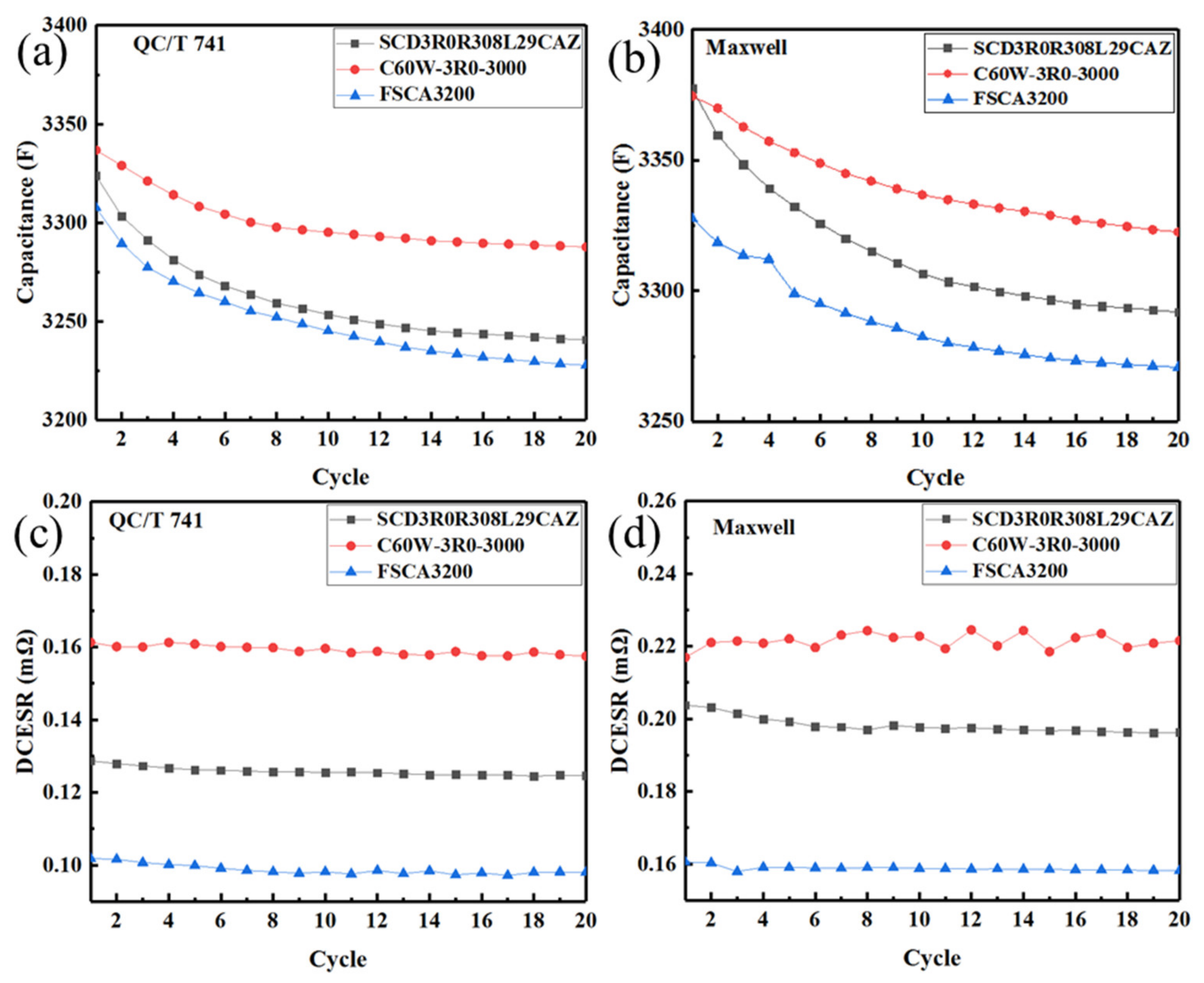

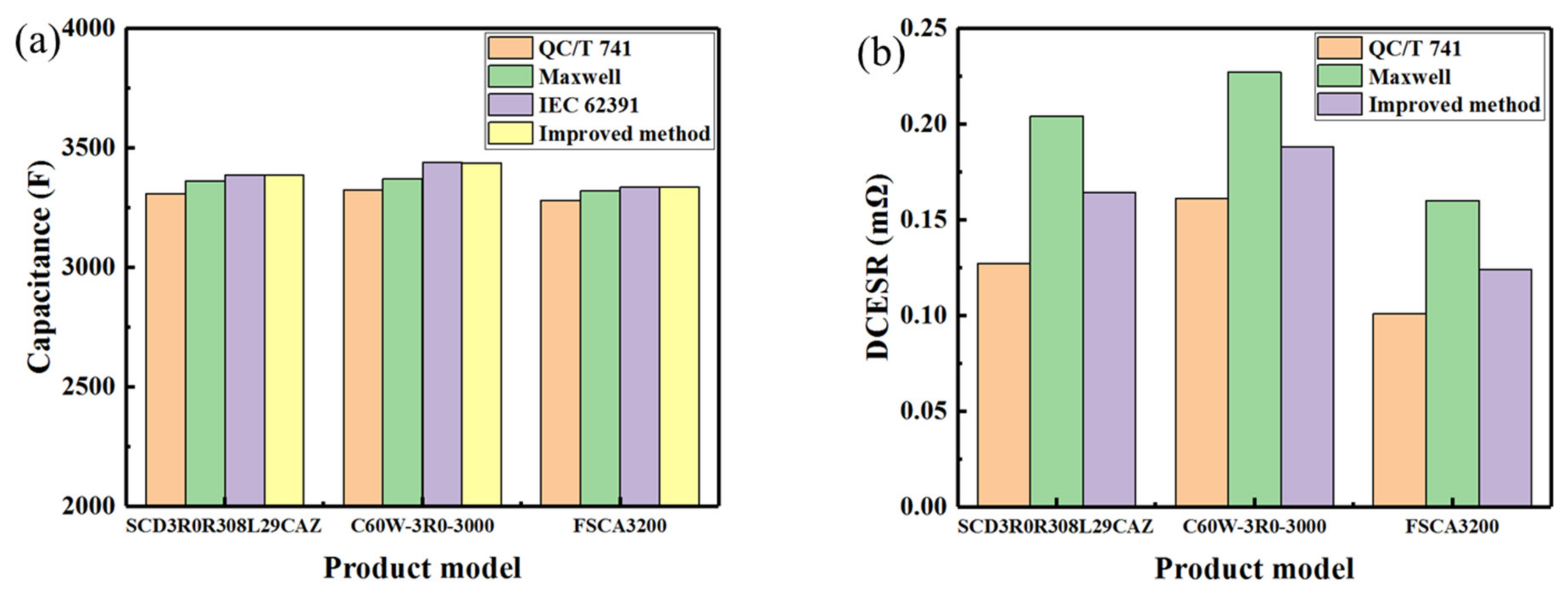

3.2. Comparison of Test Results

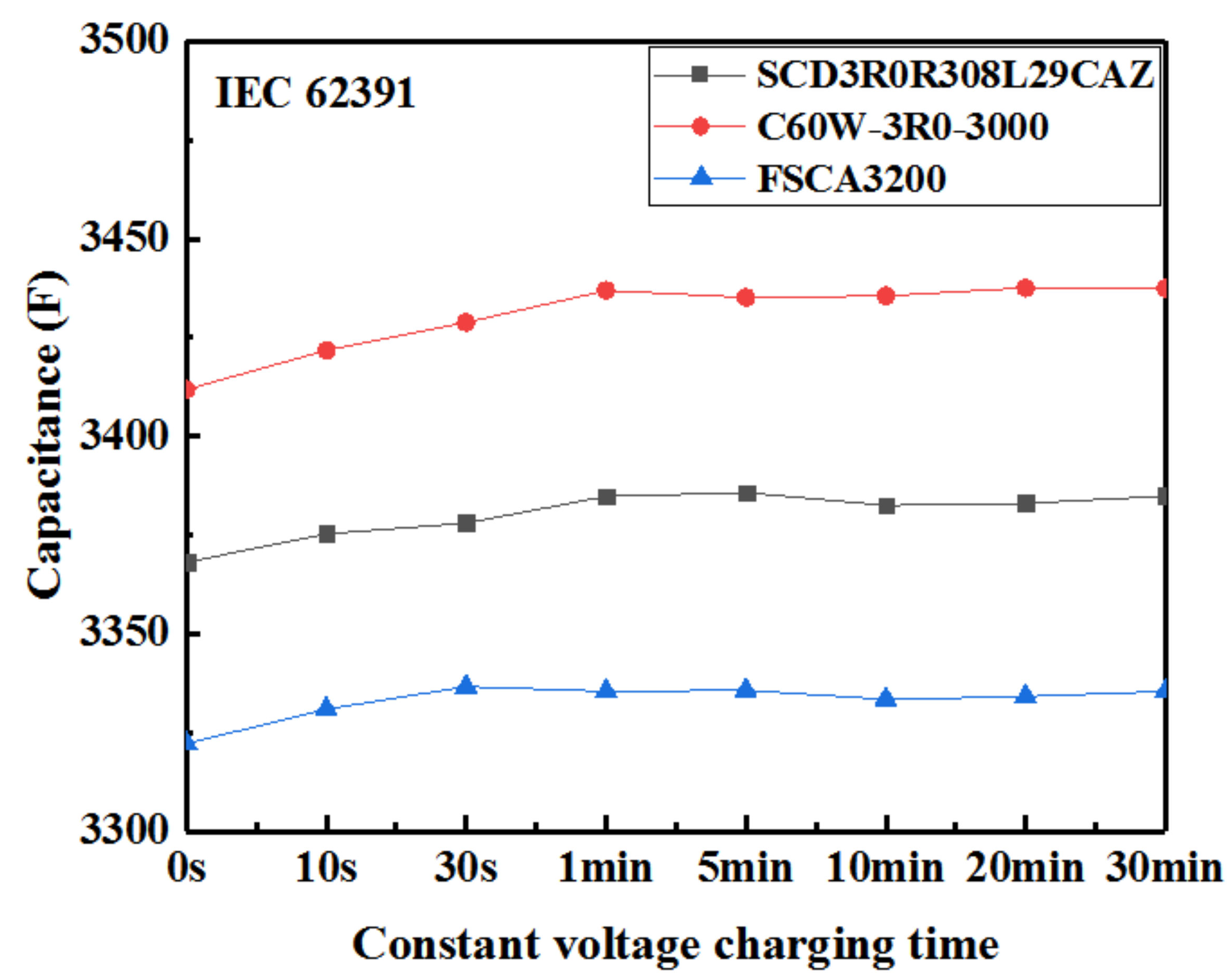

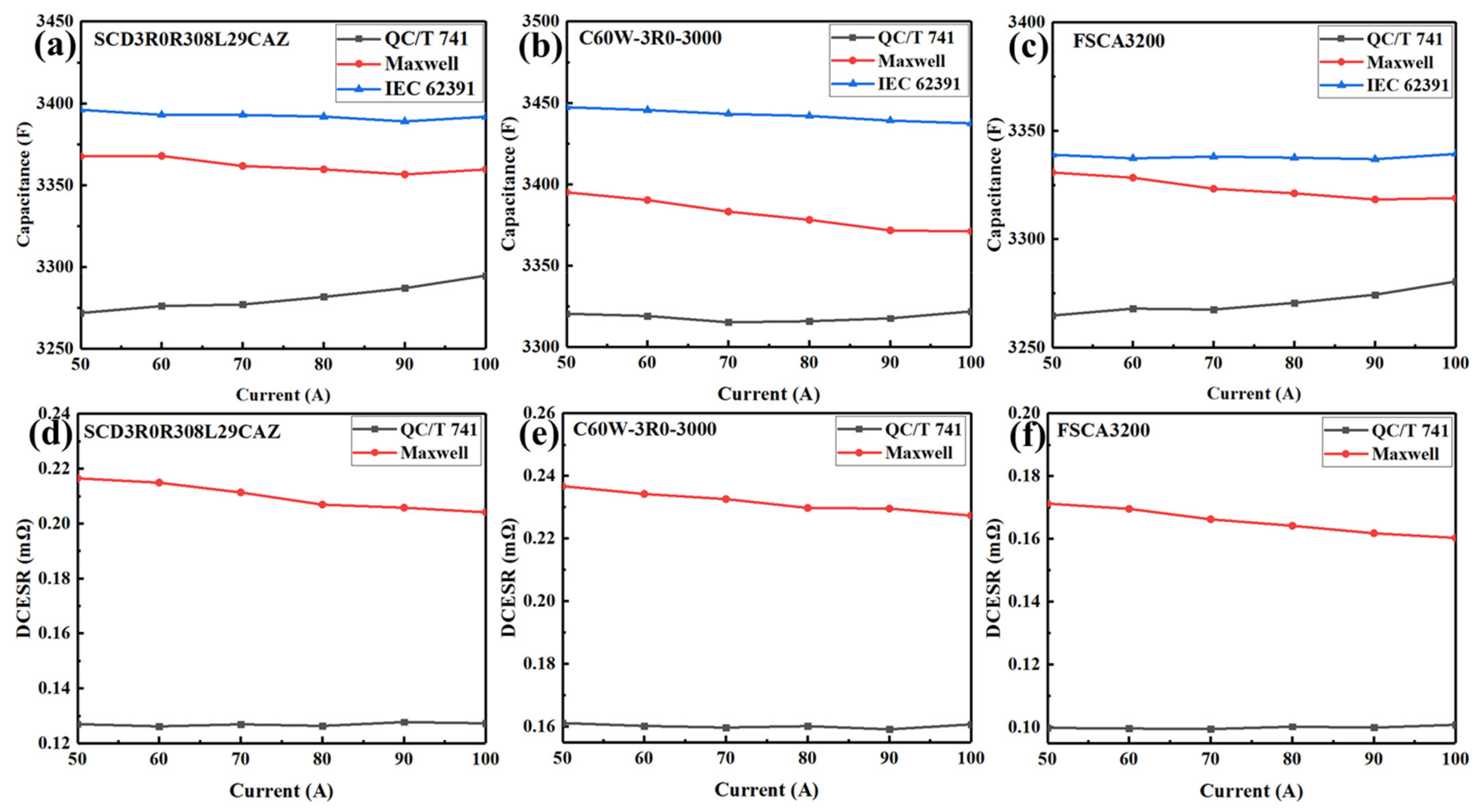

3.3. Improvement of the Test Method

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Conway, B.E. Electrochemical Supercapacitors: Scientific Fundamentals and Technological Applications; Kluwer Academic/Plenum Publishers: Dordrecht, The Netherlands, 1999; pp. 11–31. [Google Scholar]

- Miñambres-Marcos, V.M.; Guerrero-Martínez, M.Á.; Barrero-González, F.; Milanés-Montero, M.I. A grid connected photovoltaic inverter with battery-supercapacitor hybrid energy storage. Sensors 2017, 17, 1856. [Google Scholar] [CrossRef] [PubMed]

- Alhumade, H.; Rezk, H.; Louzazni, M.; Moujdin, I.A.; Al-Shahrani, S. Advanced Energy Management Strategy of Photovoltaic/PEMFC/Lithium-Ion Batteries/Supercapacitors Hybrid Renewable Power System Using White Shark Optimizer. Sensors 2023, 23, 1534. [Google Scholar] [CrossRef] [PubMed]

- Lahyani, A.; Venet, P.; Guermazi, A.; Troudi, A. Battery/Supercapacitors Combination in Uninterruptible Power Supply (UPS). IEEE Trans. Power Electron. 2013, 28, 1509–1522. [Google Scholar] [CrossRef]

- Choi, J.H.; Noh, J.H.; Choi, C. Highly Elastically Deformable Coiled CNT/Polymer Fibers for Wearable Strain Sensors and Stretchable Supercapacitors. Sensors 2023, 23, 2359. [Google Scholar] [CrossRef]

- Xiao, H.; Qi, N.; Yin, Y.; Yu, S.; Sun, X.; Xuan, G.; Liu, J.; Xiao, S.; Li, Y.; Li, Y. Investigation of Self-Powered IoT Sensor Nodes for Harvesting Hybrid Indoor Ambient Light and Heat Energy. Sensors 2023, 23, 3796. [Google Scholar] [CrossRef] [PubMed]

- Wei, Y.; Ruochen, W. Development and performance evaluation of a comprehensive automotive energy recovery system with a refined energy management strategy. Energy 2019, 189, 116365. [Google Scholar]

- Yibre, M.; Abido, M.A. Supercapacitors for wind power application. In Proceedings of the 2013 International Conference on Renewable Energy Research and Applications (ICRERA), Madrid, Spain, 20–23 October 2013; pp. 418–422. [Google Scholar]

- Simjee, F.I.; Chou, P.H. Efficient Charging of Supercapacitors for Extended Lifetime of Wireless Sensor Nodes. IEEE Trans. Power Electron. 2008, 23, 1526–1536. [Google Scholar] [CrossRef]

- Tian, L.; Liu, X. Study on Control Strategy for Composite Power Supply System of EV. J. Phys. Conf. Ser. 2021, 1748, 052054. [Google Scholar] [CrossRef]

- Chen, J.; Song, Q. A Decentralized Energy Management Strategy for a Fuel Cell/Supercapacitor-Based Auxiliary Power Unit of a More Electric Aircraft. IEEE Trans. Ind. Electron. 2019, 66, 5736–5747. [Google Scholar] [CrossRef]

- Végvári, Z. Supercapacitors and Their Military Applicability. Honvédségi Szle. A Magy. Honvédség Központi Folyóirata 2019, 147, 38–49. [Google Scholar] [CrossRef]

- Gu, S.; Wei, L.; Zhang, Y.; Yao, Y. Review of Nonuniformity Research and Analysis on Supercapacitor. Proc. Chin. Soc. Electr. Eng. 2015, 35, 2862–2869. [Google Scholar]

- Nelms, R.M.; Cahela, D.R.; Newsom, R.L.; Tatarchuk, B.J. A Comparison of Two Equivalent Circuits for Double-Layer Capacitors. Appl. Power Electron. Conf. Expo. 1999, 2, 692–698. [Google Scholar]

- Gualous, H.; Bouquain, D.; Berthon, A.; Kauffmann, J.M. Experimental study of supercapacitor serial resistance and capacitance variations with temperature. J. Power Sources 2003, 123, 86–93. [Google Scholar] [CrossRef]

- Rafik, F.; Gualous, H.; Gallay, R.; Crausaz, A.; Berthon, A. Frequency, thermal and voltage supercapacitor characterization and modeling. J. Power Sources 2007, 165, 928–934. [Google Scholar] [CrossRef]

- German, R.; Sari, A.; Venet, P.; Ayadi, M.; Briat, O.; Vinassa, J.M. Prediction of supercapacitors floating ageing with surface electrode interface based ageing law. Microelectron. Reliab. 2014, 54, 1813–1817. [Google Scholar] [CrossRef]

- Nakamura, M.; Minowa, I. Film DCESR and constriction effect of current in a contact interface. IEEE Trans. Compon. Hybrids Manuf. Technol. 2002, 12, 109–113. [Google Scholar] [CrossRef]

- Minowa, I.; Kanno, M. Measurement of contact DCESR of electric contacts using SQUID galvanometer. Electron. Commun. Jpn. (Part I Commun.) 1984, 67, 93–103. [Google Scholar] [CrossRef]

- Martin, R.; Quintana, J.J.; Ramos, A. Modeling electrochemical double layer capacitor, from classical to fractional impedance. In Proceedings of the MELECON 2008—The 14th IEEE Mediterranean Electrotechnical Conference, Ajaccio, France, 5–7 May 2008; pp. 61–66. [Google Scholar]

- Spyker, R.L.; Nelms, R.M. Discharge characteristics of high energy storage double layer capacitors. In Proceedings of the IECEC-97 Proceedings of the Thirty-Second Intersociety Energy Conversion Engineering Conference (Cat. No.97CH6203), Honolulu, HI, USA, 27 July–1 August 1997; Volume 1, pp. 292–296. [Google Scholar]

- Shukla, A.K.; Sampath, S. Electrochemical Supercapacitors: Energy Storage Beyond Batteries. Currentence 2000, 79, 1656–1661. [Google Scholar]

- Zhao, Y.; Xie, W.; Fang, Z.; Liu, S. A parameters identification method of the equivalent circuit model of the supercapacitor cell module based on segmentation optimization. IEEE Access 2020, 8, 92895–92906. [Google Scholar] [CrossRef]

- Cocchi, A.; Lampasi, A. Modeling non-ideal behaviors of Superca-pacitors’ equivalent capacitance. In Proceedings of the Institute of Electrical and Electronics Engineers and International Conference, Madrid, Spain, 9–12 June 2020; pp. 9–12. [Google Scholar]

- Morandi, A.; Lampasi, A.; Cocchi, A.; Gherdovich, F.; Melaccio, U.; Ribani, P.L.; Rossi, L.; Soavi, F. Characterization and Model Parameters of Large Commercial Supercapacitor Cells. IEEE Access 2021, 9, 20376–20390. [Google Scholar] [CrossRef]

- Zhang, L.; Hu, X.; Wang, Z.; Sun, F.; Dorrell, D.G. A compar-ative study of equivalent circuit models of ultracapacitors for electric vehicles. J. Power Sources 2015, 274, 899–906. [Google Scholar] [CrossRef]

- Burke, A.; Miller, M. Testing of electrochemical capacitors: Capacitance, resistance, energy density, and power capability. Electrochim. Acta 2010, 55, 7538–7548. [Google Scholar] [CrossRef]

- Spyker, R.L.; Nelms, R.M. Classical equivalent circuit parameters for a double-layer capacitor. IEEE Trans. Aerosp. Electron. Syst. 2000, 36, 829–836. [Google Scholar] [CrossRef]

- IEC 62391-1-2015; Fixed Electric Double-Layer Capacitors for Use in Electric and Electronic Equipment—Part 1: Generic Specification. IEC: Geneva, Switzerland, 2015.

- Application Note 1007239; Test Procedures for Capacitance, ESR, Leakage Current and Self-Discharge Characterizations of Ultracapacitors. Maxwell Technologies, Inc.: San Diego, CA, USA, 2015.

- QCT 741-2014; Ultra-Capacitor for Electric Vehicles. Ministry of Industry and Information Technology of the People’s Republic of China: Beijing, China, 2014.

- CAS SCAP Data Sheet SCD3R0R308L29CAZ Electrical Double Layer Capacitor. Available online: https://www.chemi-con.co.jp/en/catalog/pdf/dl-e/dl-sepa-e/dl-summary-e-2020.pdf (accessed on 5 July 2022).

- GMCC CRAMS-Data Sheet C60W-3R0-3000 Ultracapacitors. Available online: http://www.gmccchina.com/product/product_15_1.html (accessed on 9 October 2022).

- Skeleton Technologies-SKELCAP Ultracapacitors. Available online: https://www.skeletontech.com/skelcap-sca-ultracapacitor-cells (accessed on 18 December 2020).

- Hang, G. Research and Optimization of Measurement Method for Electrostatic Capacity and Equivalent Series Internal Resistance of Super Capacitors. Master’s Thesis, Zhejiang University, Hangzhou, China, 2021. [Google Scholar]

- Chu, A.; Braatz, P. Comparison of Commercial supercapacitors and high-power lithium-ion batteries for Power assist applications in hybrid electric vehicles: 1. Initial characterization. J. Power Sources 2002, 112, 236–246. [Google Scholar] [CrossRef]

| Manufacturer | CAS SCAP [32] | GMCC [33] | SKELETON [34] |

|---|---|---|---|

| Product model | SCD3R0308L29CAZ | C60W-3R0-3000 | FSCA3200 |

| Rated Voltage (UR) | 3.0 V | 3.0 V | 2.85 V |

| Rated capacitance (CR) | 3000 F | 3000 F | 3200 F |

| Rated DCESR | 0.23 mΩ | 0.18 mΩ | 0.18 mΩ |

| Rated continuous current (Ir at ∆T = 15 °C) | 144 A | 164 A | 190 A |

| Overall Diameter | 60.5 mm | 60 mm | 60.2 mm |

| Overall Length | 138 mm | 138 mm | 138 mm |

| Model | LBT 21044 |

|---|---|

| Voltage control range | 0–5 V |

| Standard current range | 100 A/10 A/1 A/0.1 A |

| Test accuracy | ±0.02% |

| Resolution ratio | 24 bit |

| Minimum voltage @ maximum current | 0 V @ 100 A |

| Number of standard channels | 8 |

| Capacitance (F) | UR~0.5UR | 0.8UR~0.5UR | 0.8UR~0.4UR | UR~0.1V | 0.8UR~0.1V |

|---|---|---|---|---|---|

| QC/T 741 standard | 3356.1 | 3306.1 | / | / | / |

| Maxwell standard | 3359.6 | 3305.7 | / | / | / |

| IEC 62391 standard | 3384.8 | 3331.0 | 3265.2 | 3111.7 | 3016.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, X.; Li, X.; Xu, J.; Dong, L. Investigation and Improvement of Test Methods for Capacitance and DCESR of EDLC Cells. Sensors 2023, 23, 4717. https://doi.org/10.3390/s23104717

Xie X, Li X, Xu J, Dong L. Investigation and Improvement of Test Methods for Capacitance and DCESR of EDLC Cells. Sensors. 2023; 23(10):4717. https://doi.org/10.3390/s23104717

Chicago/Turabian StyleXie, Xiong, Xu Li, Junqiang Xu, and Lichun Dong. 2023. "Investigation and Improvement of Test Methods for Capacitance and DCESR of EDLC Cells" Sensors 23, no. 10: 4717. https://doi.org/10.3390/s23104717