Explainability-Informed Feature Selection and Performance Prediction for Nonintrusive Load Monitoring †

Abstract

1. Introduction

- Using a methodology that enables the codesign with the building owner or householder for a scalable, trustworthy, and privacy-preserving NILM, comprising event detection, feature generation and selection, and DT-based multiclass classification using only smart meter readings as input;

- Leveraging post hoc model-agnostic global and individual explainability of the aforementioned multiclass classifiers’ models to inform feature selection for each appliance and subsequent design of the DT multiclass classifier;

- Explaining how one of more appliances within a multiclass classifier can negatively impact classification of other appliances leading to different multiclassifier models for different sets of appliances;

- Predicting the performance of the trained DT multiclass classifiers for each target appliance via PD and ICE plots, validated during testing by standard; classification performance metrics on unseen data from the same house;

- Predicting the performance of a trained DT multiclass classifier on unseen houses from the same dataset and from another dataset to explore generalisability and transferability.

2. Background and Related Work

2.1. NILM

2.2. DT-Based Multiclass Classifiers for Low-Rate NILM

2.3. Explainability for NILM

3. Explainability-Informed NILM Multilabel Classification

3.1. Automated Event Detection

3.2. DT-Based Multiclass Classification

- Multiclass classifier for classifying the five labels of kettle (K), microwave (M), toaster (T), dishwasher (DW), and washing machine (WM), referred to as DT (K-M-T-WM-DW);

- Multiclass classifier for classifying the three labels of kettle, microwave, and dishwasher, referred to as DT (K-M-DW);

- Multiclass classifier for classifying the two labels of toaster and washing machine, referred to as DT (T-WM).

3.3. Post Hoc Explainability: Predicted and Actual Outcomes

4. Experimental Setup

4.1. Dataset

- Training is carried out on a balance set of edge-pairs (55 edge-pairs per each appliance) selected randomly from the available data of House 2 (except for the test period) and tested on the entire unseen months of October, November, and December 2014 of House 2.

- For generalisability and transferability experiments, the aforementioned trained model from REFIT House 2 is used for testing on unseen REFIT House 6 (the month of October 2014) and UK-DALE House 1 (January 2016 to April 2016).

4.2. Evaluation Metrics

4.3. Detection Performance

4.4. Execution Time

5. Performance Prediction via Explainability Tools

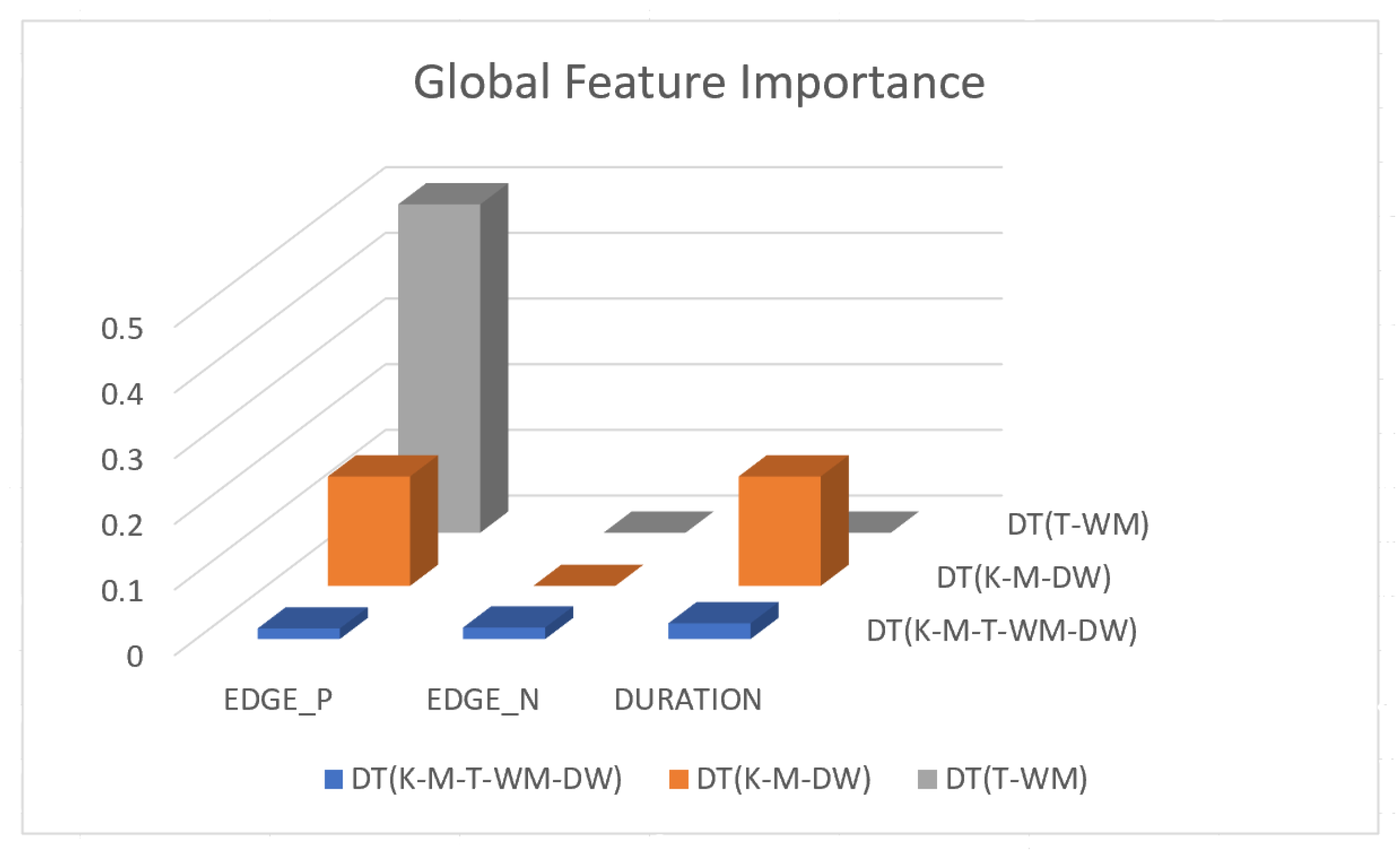

5.1. Global Feature Importance

5.2. DT (K-M-T-WM-DW) Multiclassifier Model

5.3. The DT (K-M-DW) and DT (T-WM) Multiclassifier Models

6. Evaluating Generalisability and Transferability in Relation to the Predicted Outcomes

6.1. Generalisability across the UK REFIT Dataset

6.2. Transferability to UK-DALE Dataset

6.3. Benchmarking

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Angelis, G.F.; Timplalexis, C.; Krinidis, S.; Ioannidis, D.; Tzovaras, D. NILM Applications: Literature review of learning approaches, recent developments and challenges. Energy Build. 2022, 261, 111951. [Google Scholar] [CrossRef]

- Huber, P.; Calatroni, A.; Rumsch, A.; Paice, A. Review on Deep Neural Networks Applied to Low-Frequency NILM. Energies 2021, 14, 2390. [Google Scholar] [CrossRef]

- Kaselimi, M.; Protopapadakis, E.; Voulodimos, A.; Doulamis, N.; Doulamis, A. Towards Trustworthy Energy Disaggregation: A Review of Challenges, Methods, and Perspectives for Non-Intrusive Load Monitoring. Sensors 2022, 22, 5872. [Google Scholar] [CrossRef]

- European Commission. Directorate-General for Communications Networks, Content and Technology, Ethics Guidelines for Trustworthy AI; Publications Office; European Commission: Brussels, Belgium, 2019. [Google Scholar] [CrossRef]

- Murray, D.; Stankovic, L.; Stankovic, V. Transparent AI: Explainability of deep learning based load disaggregation. In Proceedings of the 1st ACM SIGEnergy Workshop of Fair, Accountable, Transparent and Ethical AI for Smart Environments and Energy Systems (FATEsys ’21), Coimbra, Portugal, 17–18 November 2021; pp. 268–271. [Google Scholar] [CrossRef]

- Molnar, C. Interpretable Machine Learning, A Guide for Making Black Box Models Explainable. 2019. Available online: https://christophm.github.io/interpretable-ml-book/ (accessed on 29 March 2023).

- Mollel, S.R.; Stankovic, L.; Stankovic, V. Using Explainability Tools to Inform NILM Algorithm Performance: A Decision Tree Approach. In Proceedings of the 6th International Workshop on Non-Intrusive Load Monitoring (NILM ’22), Hybrid Event, Boston, MA, USA, 11 November 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Goldstein, A.; Kapelner, A.; Bleich, J.; Pitkin, E. Peeking inside the black box: Visualizing statistical learning with plots of individual conditional expectation. J. Comput. Graph. Stat. 2015, 24, 44–65. [Google Scholar] [CrossRef]

- Ribeiro, M.T.; Singh, S.; Guestrin, C. “ Why should i trust you?” Explaining the predictions of any classifier. In Proceedings of the 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, San Francisco, CA, USA, 13–17 August 2016; pp. 1135–1144. Available online: https://arxiv.org/abs/1602.04938 (accessed on 29 March 2023).

- Aas, K.; Jullum, M.; Løland, A. Explaining individual predictions when features are dependent: More accurate approximations to Shapley values. Artif. Intell. 2021, 298, 103502. [Google Scholar] [CrossRef]

- Zhao, B.; Stankovic, L.; Stankovic, V. On a Training-Less Solution for Non-Intrusive Appliance Load Monitoring Using Graph Signal Processing. IEEE Access 2016, 4, 1784–1799. [Google Scholar] [CrossRef]

- Liao, J.; Elafoudi, G.; Stankovic, L.; Stankovic, V. Non-Intrusive Appliance Load Monitoring using Low-Resolution Smart Meter Data. In Proceedings of the 2014 IEEE International Conference on Smart Grid Communications (SmartGridComm), Venice, Italy, 3–6 November 2014; pp. 535–540. [Google Scholar] [CrossRef]

- Vavouris, A.; Garside, B.; Stankovic, L.; Stankovic, V. Low-Frequency Non-Intrusive Load Monitoring of Electric Vehicles in Houses with Solar Generation: Generalisability and Transferability. Energies 2022, 15, 2200. [Google Scholar] [CrossRef]

- He, K.; Jakovetic, D.; Zhao, B.; Stankovic, V.; Stankovic, L.; Cheng, S. A generic optimisation-based approach for improving non-intrusive load monitoring. IEEE Trans. Smart Grid 2019, 10, 6472–6480. [Google Scholar] [CrossRef]

- Sadeghianpourhamami, N.; Ruyssinck, J.; Deschrijver, D.; Dhaene, T.; Develder, C. Comprehensive feature selection for appliance classification in NILM. Energy Build. 2017, 151, 98–106. [Google Scholar] [CrossRef]

- Dash, S.; Sahoo, N.C. Electric energy disaggregation via non-intrusive load monitoring: A state-of-the-art systematic review. Electr. Power Syst. Res. 2022, 213, 108673. [Google Scholar] [CrossRef]

- Pereira, L.; Nunes, N. Performance evaluation in non-intrusive load monitoring: Datasets, metrics, and tools—A review. Wiley Interdiscip. Rev. Data Min. Knowl. Discov. 2018, 8, e1265. [Google Scholar] [CrossRef]

- Altrabalsi, H.; Stankovic, V.; Liao, J.; Stankovic, L. Low-complexity energy disaggregation using appliance load modelling. Aims Energy 2016, 4, 884–905. [Google Scholar] [CrossRef]

- Suthaharan, S. Decision Tree Learning. In Machine Learning Models and Algorithms for Big Data Classification. Integrated Series in Information Systems; Springer: Boston, MA, USA, 2016; pp. 237–269. [Google Scholar] [CrossRef]

- Khazaei, M.; Stankovic, L.; Stankovic, V. Evaluation of low-complexity supervised and unsupervised NILM methods and pre-processing for detection of multistate white goods. In Proceedings of the 5th International Workshop on Non-Intrusive Load Monitoring (NILM’ 20), Virtual Event, 18 November 2020; ACM: New York, NY, USA, 2020; pp. 34–38. [Google Scholar] [CrossRef]

- Machlev, R.; Malka, A.; Perl, M.; Levron, Y.; Belikov, J. Explaining the Decisions of Deep Learning Models for Load Disaggregation (NILM) Based on XAI. In Proceedings of the 2022 IEEE Power & Energy Society General Meeting (PESGM), Denver, CO, USA, 17–21 July 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Amiri, S.S.; Mottahedi, S.; Lee, E.R.; Hoque, S. Peeking inside the black-box: Explainable machine learning applied to household transportation energy consumption. Comput. Environ. Urban Syst. 2021, 88, 101647. [Google Scholar] [CrossRef]

- Tukey, J.W. Exploratory Data Analysis; Addison-Wesley: Reading, MA, USA, 1977; Volume 2, pp. 131–160. [Google Scholar]

- Hu, K. Become Competent within One Day in Generating Boxplots and Violin Plots for a Novice without Prior R Experience. Methods Protoc. 2020, 3, 64. [Google Scholar] [CrossRef] [PubMed]

- Vakharia, V.; Castelli, I.E.; Bhavsar, K.; Solanki, A. Bandgap prediction of metal halide perovskites using regression machine learning models. Phys. Lett. A 2022, 422, 127800. [Google Scholar] [CrossRef]

- Murray, D.; Stankovic, L.; Stankovic, V. An electrical load measurements dataset of United Kingdom households from a two-year longitudinal study. Sci. Data 2017, 4, 160122. [Google Scholar] [CrossRef]

- Kelly, J.; Knottenbelt, W. The UK-DALE dataset, domestic appliance-level electricity demand and whole-house demand from five UK homes. Sci. Data 2015, 2, 150007. [Google Scholar] [CrossRef]

- Makonin, S.; Popowich, F.; Bajic, I.V.; Gill, B.; Bartram, L. Exploiting HMM Sparsity to Perform Online Real-Time Nonintrusive Load Monitoring. IEEE Trans. Smart Grid 2016, 7, 2575–2585. [Google Scholar] [CrossRef]

- Sykiotis, S.; Athanasoulias, S.; Kaselimi, M.; Doulamis, A.; Doulamis, N.; Stankovic, L.; Stankovic, V. Performance-aware NILM model optimization for edge deployment. IEEE Trans. Green Commun. Netw. 2023, 1–26. [Google Scholar] [CrossRef]

- Choudhury, R.; Ahamed, S.R.; Guha, P. Efficient hardware implementation of decision tree training accelerator. SN Comput. Sci. 2021, 2, 360. [Google Scholar] [CrossRef]

- MATLAB Version: 9.14.0.2206163 (R2023a); The MathWorks Inc.: Natick, MA, USA, 2023.

- He, K.; Stankovic, V.; Stankovic, L. Building a graph signal processing model using dynamic time warping for load disaggregation. Sensors 2020, 20, 6628. [Google Scholar] [CrossRef] [PubMed]

| Dataset | Number of Ground-Truth Events | % Events Detected | % Events Due to Unknown Appliances | |

|---|---|---|---|---|

| REFIT H2 | 568 | 92% | 9% | 77% |

| REFIT H6 | 407 | 90% | 15% | 84% |

| UK-DALE H1 | 509 | 96% | 6% | 79% |

| DT Model | No. Features | REFIT H2 | REFIT H2 | REFIT H6 | UK-DALE H1 | ||||

|---|---|---|---|---|---|---|---|---|---|

| Training (2 Months) | No. Samples | Testing (3 Months) | No. Samples | Testing (1 Month) | No. Samples | Testing (4 Months) | No. Samples | ||

| DT (K-M-T-WM-DW) | 3 | 39.15 s | 275 | 3.17 s | 577 | ||||

| DT (K-M-DW) | 2 | 20.37 s | 165 | 3.29 s | 507 | 3.41 s | 394 | 3.95 s | 429 |

| DT (T-WM) | 1 | 25.91 s | 110 | 3.22 s | 126 | 3.32 s | 100 | 3.67 s | 132 |

| Appliance | EDGE_P & EDGE_N | EDGE_P | EDGE_N |

|---|---|---|---|

| & DURATION | & DURATION | & DURATION | |

| Dishwasher | 0.70 | 0.72 | 0.70 |

| Washing Machine | 0.54 | 0.56 | 0.53 |

| Kettle | 0.99 | 0.99 | 0.99 |

| Microwave | 0.88 | 0.90 | 0.87 |

| Toaster | 0.65 | 0.80 | 0.64 |

| (a) Three Features | |||||||

|---|---|---|---|---|---|---|---|

| Predicted Class | |||||||

| DW | K | M | T | WM | Other | ||

| True Class | DW | 47 | 0 | 0 | 0 | 29 | 0 |

| K | 0 | 185 | 0 | 0 | 0 | 0 | |

| M | 0 | 0 | 168 | 22 | 0 | 0 | |

| T | 0 | 0 | 1 | 35 | 0 | 0 | |

| WM | 7 | 0 | 0 | 0 | 27 | 0 | |

| Other | 4 | 3 | 24 | 15 | 10 | 0 | |

| (b) EDGE_P & DURATION Features | |||||||

| Predicted Class | |||||||

| DW | K | M | T | WM | Other | ||

| True Class | DW | 48 | 0 | 0 | 0 | 28 | 0 |

| K | 0 | 185 | 0 | 0 | 0 | 0 | |

| M | 0 | 0 | 184 | 6 | 0 | 0 | |

| T | 0 | 0 | 3 | 33 | 0 | 0 | |

| WM | 6 | 0 | 0 | 0 | 28 | 0 | |

| Other | 4 | 3 | 31 | 8 | 10 | 0 | |

| (c) EDGE_N & DURATION Features | |||||||

| Predicted Class | |||||||

| DW | K | M | T | WM | Other | ||

| True Class | DW | 47 | 0 | 1 | 0 | 28 | 0 |

| K | 0 | 182 | 3 | 0 | 0 | 0 | |

| M | 0 | 0 | 168 | 22 | 0 | 0 | |

| T | 0 | 0 | 1 | 35 | 0 | 0 | |

| WM | 7 | 0 | 1 | 0 | 26 | 0 | |

| Other | 4 | 2 | 24 | 16 | 10 | 0 | |

| Three Features | EDGE_P & DURATION | |||||

|---|---|---|---|---|---|---|

| Appliance | PR | RE | F-Score | PR | RE | F-Score |

| Dishwasher | 0.88 | 1 | 0.94 | 0.88 | 1 | 0.94 |

| Kettle | 0.96 | 1 | 0.98 | 0.96 | 1 | 0.98 |

| Microwave | 0.83 | 1 | 0.91 | 0.83 | 1 | 0.91 |

| Three Features | EDGE_P | |||||

|---|---|---|---|---|---|---|

| Appliance | PR | RE | F-Score | PR | RE | F-Score |

| Washing Machine | 0.67 | 1 | 0.80 | 0.67 | 1 | 0.80 |

| Toaster | 0.48 | 1 | 0.65 | 0.48 | 1 | 0.65 |

| (a) Three Features | ||||

|---|---|---|---|---|

| Predicted Class | ||||

| T | WM | Other | ||

| T | 36 | 0 | 0 | |

| True Class | WM | 0 | 34 | 0 |

| Other | 39 | 17 | 0 | |

| (b) EDGE_P Feature | ||||

| Predicted Class | ||||

| T | WM | Other | ||

| T | 36 | 0 | 0 | |

| True Class | WM | 0 | 34 | 0 |

| Other | 39 | 17 | 0 | |

| (a) Three Features | |||||

|---|---|---|---|---|---|

| Predicted Class | |||||

| DW | K | M | Other | ||

| True Class | DW | 76 | 0 | 0 | 0 |

| K | 0 | 185 | 0 | 0 | |

| M | 0 | 0 | 190 | 0 | |

| Other | 10 | 7 | 39 | 0 | |

| (b) EDGE_P & DURATION Features | |||||

| Predicted Class | |||||

| DW | K | M | Other | ||

| True Class | DW | 76 | 0 | 0 | 0 |

| K | 0 | 185 | 0 | 0 | |

| M | 0 | 0 | 190 | 0 | |

| Other | 10 | 7 | 39 | 0 | |

| Appliance | PR | RE | F-Score |

|---|---|---|---|

| Dishwasher | 0.70 | 1 | 0.82 |

| Kettle | 0.99 | 1 | 0.99 |

| Microwave | 0.74 | 1 | 0.85 |

| (a) EDGE_P & DURATION Features | |||||

| Predicted Class | |||||

| DW | K | M | Other | ||

| True Class | DW | 14 | 0 | 0 | 0 |

| K | 0 | 164 | 0 | 0 | |

| M | 0 | 0 | 154 | 0 | |

| Other | 6 | 1 | 55 | 0 | |

| (b) EDGE_P Feature | |||||

| Predicted Class | |||||

| T | WM | Other | |||

| True Class | T | 32 | 0 | 0 | |

| WM | 0 | 6 | 0 | ||

| Other | 50 | 12 | 0 | ||

| Appliance | PR | RE | F-Score |

|---|---|---|---|

| Washing Machine | 0.33 | 1 | 0.50 |

| Toaster | 0.39 | 1 | 0.56 |

| Appliance | PR | RE | F-Score |

|---|---|---|---|

| Dishwasher | 0.90 | 1 | 0.95 |

| Kettle | 0.98 | 1 | 0.99 |

| Microwave | 0.76 | 1 | 0.87 |

| (a) EDGE_P & DURATION Features | |||||

| Predicted Class | |||||

| DW | K | M | Other | ||

| True Class | DW | 76 | 1 | 0 | 0 |

| K | 0 | 239 | 0 | 0 | |

| M | 0 | 0 | 78 | 0 | |

| Other | 8 | 3 | 24 | 0 | |

| (b) EDGE_P Feature | |||||

| Predicted Class | |||||

| T | WM | Other | |||

| True Class | T | 32 | 0 | 0 | |

| WM | 0 | 65 | 0 | ||

| Other | 20 | 15 | 0 | ||

| Appliance | PR | RE | F-Score |

|---|---|---|---|

| Washing Machine | 0.81 | 1 | 0.90 |

| Toaster | 0.62 | 1 | 0.76 |

| Appliance | K | WM | DW | MW | T |

|---|---|---|---|---|---|

| DT (K-M-T-WM-DW)H2 | 0.99 | 0.56 | 0.72 | 0.90 | 0.80 |

| DT H2 [14] | 0.9 | 0.80 | 0.83 | 0.70 | |

| DT (K-M-DW)H2 | 0.98 | 0.94 | 0.91 | ||

| DT (T-WM)H2 | 0.80 | 0.65 | |||

| DT H2 [20] | 0.52 | 0.77 | |||

| SGSP H2 [32] | 0.87 | 0.64 | 0.63 | 0.68 | 0.58 |

| UGSP H2 [32] | 0.90 | 0.70 | 0.61 | 0.79 | 0.72 |

| DT (K-M-DW)H6 | 0.99 | 0.82 | 0.85 | ||

| DT (T-WM)H6 | 0.50 | 0.56 | |||

| SGSP H6 [32] | 0.79 | 0.57 | 0.63 | 0.45 | |

| UGSP H6 [32] | 0.77 | 0.69 | 0.70 | 0.44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mollel, R.S.; Stankovic, L.; Stankovic, V. Explainability-Informed Feature Selection and Performance Prediction for Nonintrusive Load Monitoring. Sensors 2023, 23, 4845. https://doi.org/10.3390/s23104845

Mollel RS, Stankovic L, Stankovic V. Explainability-Informed Feature Selection and Performance Prediction for Nonintrusive Load Monitoring. Sensors. 2023; 23(10):4845. https://doi.org/10.3390/s23104845

Chicago/Turabian StyleMollel, Rachel Stephen, Lina Stankovic, and Vladimir Stankovic. 2023. "Explainability-Informed Feature Selection and Performance Prediction for Nonintrusive Load Monitoring" Sensors 23, no. 10: 4845. https://doi.org/10.3390/s23104845

APA StyleMollel, R. S., Stankovic, L., & Stankovic, V. (2023). Explainability-Informed Feature Selection and Performance Prediction for Nonintrusive Load Monitoring. Sensors, 23(10), 4845. https://doi.org/10.3390/s23104845