A Wearable Multi-Modal Digital Upper Limb Assessment System for Automatic Musculoskeletal Risk Evaluation

Abstract

:1. Introduction

- Multi-modal wireless wearable sensors are used for digitally computing RULA scores.

- A robust kinematic model has been developed for upper limbs motion tracking.

- Digital implementation of the new method has been validated by comparison with an online RULA calculator.

2. DULA Method

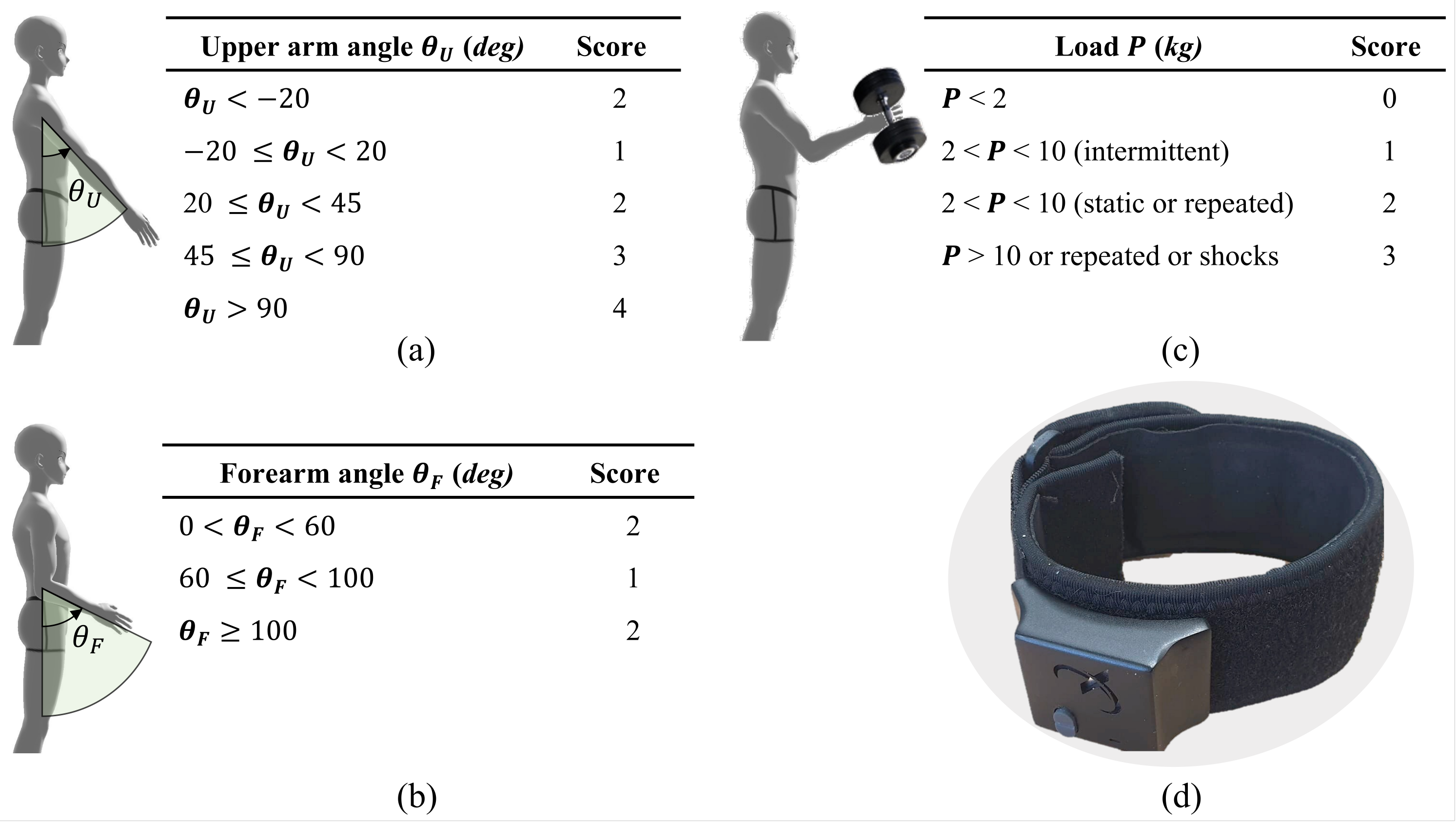

2.1. RULA

2.2. Kinematics for DULA

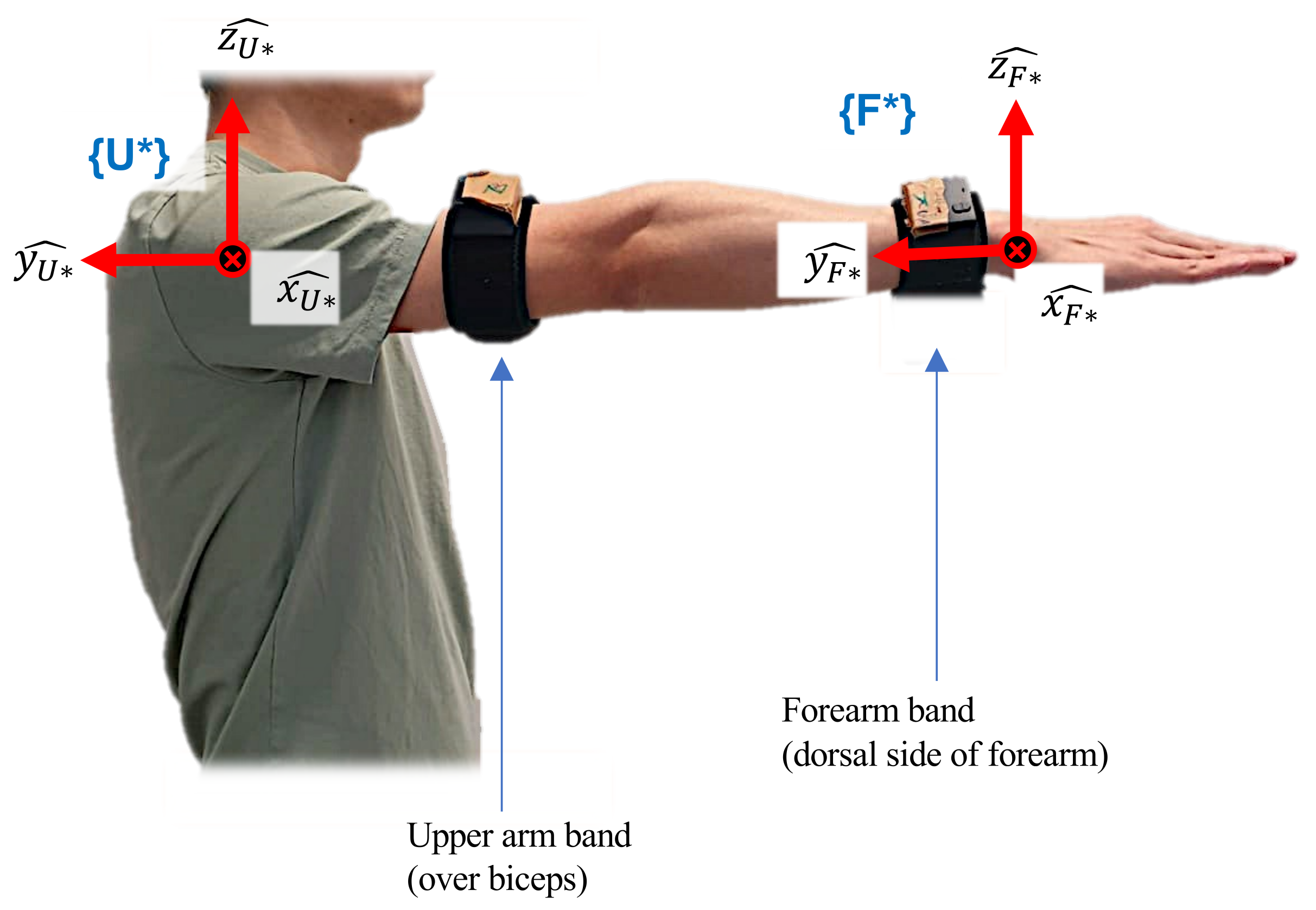

2.2.1. Reference Coordinate Setup

- Stretch the arm forward while the palm is facing downwards. This is considered the right arm base posture.

- Record the gravity vector g at base posture, upon which the for the forearm frame is determined.

- Perform supination motion and record angular velocity during the motion. The for the forearm frame is hence obtained as:

- The cross product of and results in for the forearm frame. However, it is not humanly possible to have and exactly perpendicular to each other, hence, is normalized.

- Finally, is obtained to complete right hand coordinate frame convention.

- Thus, the computed rotation matrix belongs to a special orthogonal group . The forearm reference frame in the IMU frame has the following form:

2.2.2. Frame Transformations

- Record IMU orientation when the arm is in the base posture.

- is computed according the method in Section 2.2.1.

- is continuously acquired from the IMU sensor in real-time.

- To find the forearm orientation with respect to IMU frame, i.e, , the following equations are presented:

- Finally, we find the orientation of the forearm with respect to the forearm reference frame ,

2.2.3. Upper Arm Orientation

2.2.4. Forearm Orientation

- Find the orientations of upper arm base frame and forearm base frame with respect to global reference frame as:where and are upper arm IMU and forearm IMU frames, respectively.

- Compute the relative rotation between both frames and :

- The forearm orientation defined in is mapped in the upper arm reference frame using similarity transformation technique:

- Since both forearm and upper arm orientations are now established in the same coordinate system defined by , the relative rotation matrix is found as:

- The forearm orientation with respect to the upper arm is considered to be formed by the combination of two rotations, the forearm extension/flexion about the current Y, and the forearm pronation/supination about the current Z axis.The composition of orientation is illustrated in Figure 4. Inverse kinematics is used to find the forearm angles:

2.3. Load Identification

3. DULA System Development

3.1. Hardware

3.2. Software

4. Results

5. Discussion

6. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| MSD | Musculoskeletal disorders |

| RULA | Rapid upper limb assessment |

| DULA | Digital upper limb assessment |

| IMU | Inertial measurement unit |

| F or f | Forearm |

| U or f | Upper arm |

References

- Winkel, J.; Mathiassen, S.E. Assessment of physical work load in epidemiologic studies: Concepts, issues and operational considerations. Ergonomics 1994, 37, 979–988. [Google Scholar] [CrossRef]

- Dockrell, S.; O’Grady, E.; Bennett, K.; Mullarkey, C.; Mc Connell, R.; Ruddy, R.; Twomey, S.; Flannery, C. An investigation of the reliability of Rapid Upper Limb Assessment (RULA) as a method of assessment of children’s computing posture. Appl. Ergon. 2012, 43, 632–636. [Google Scholar] [CrossRef] [PubMed]

- Lei, L.; Dempsey, P.G.; Xu, J.G.; Ge, L.N.; Liang, Y.X. Risk factors for the prevalence of musculoskeletal disorders among Chinese foundry workers. Int. J. Ind. Ergon. 2005, 35, 197–204. [Google Scholar] [CrossRef]

- Parent-Thirion, A.; Biletta, I.; Cabrita, J.; Vargas Llave, O.; Vermeylen, G.; Wilczyńska, A.; Wilkens, M. Sixth European Working Conditions Survey–Overview report. Eurofound 2016. [Google Scholar] [CrossRef]

- Hignett, S.; McAtamney, L. Rapid entire body assessment (REBA). Appl. Ergon. 2000, 31, 201–205. [Google Scholar] [CrossRef]

- Sanchez-Lite, A.; Garcia, M.; Domingo, R.; Angel Sebastian, M. Novel ergonomic postural assessment method (NERPA) using product-process computer aided engineering for ergonomic workplace design. PLoS ONE 2013, 8, e72703. [Google Scholar] [CrossRef]

- Moore, J.S.; Vos, G.A. The strain index. In Handbook of Human Factors and Ergonomics Methods; CRC Press: Boca Raton, FL, USA, 2004; pp. 109–114. [Google Scholar]

- Karhu, O.; Kansi, P.; Kuorinka, I. Correcting working postures in industry: A practical method for analysis. Appl. Ergon. 1977, 8, 199–201. [Google Scholar] [CrossRef]

- McAtamney, L.; Corlett, E.N. RULA: A survey method for the investigation of work-related upper limb disorders. Appl. Ergon. 1993, 24, 91–99. [Google Scholar] [CrossRef]

- Basahel, A.M. Investigation of work-related musculoskeletal disorders (MSDs) in warehouse workers in Saudi Arabia. Procedia Manuf. 2015, 3, 4643–4649. [Google Scholar] [CrossRef]

- Bao, S.; Howard, N.; Spielholz, P.; Silverstein, B. Two posture analysis approaches and their application in a modified rapid upper limb assessment evaluation. Ergonomics 2007, 50, 2118–2136. [Google Scholar] [CrossRef]

- Intranuovo, G.; De Maria, L.; Facchini, F.; Giustiniano, A.; Caputi, A.; Birtolo, F.; Vimercati, L. Risk assessment of upper limbs repetitive movements in a fish industry. BMC Res. Notes 2019, 12, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Valentim, D.P.; de Oliveira Sato, T.; Comper, M.L.C.; da Silva, A.M.; Boas, C.V.; Padula, R.S. Reliability, construct validity and interpretability of the Brazilian version of the Rapid Upper Limb Assessment (RULA) and Strain Index (SI). Braz. J. Phys. Ther. 2018, 22, 198–204. [Google Scholar] [CrossRef] [PubMed]

- Balasubramanian, V.; Swami Prasad, G. An EMG-based ergonomic evaluation of manual bar bending. Int. J. Ind. Syst. Eng. 2007, 2, 299–310. [Google Scholar] [CrossRef]

- González, A.; Barrios-Muriel, J.; Romero-Sánchez, F.; Salgado, D.; Alonso, F. Ergonomic assessment of a new hand tool design for laparoscopic surgery based on surgeons’ muscular activity. Appl. Ergon. 2020, 88, 103161. [Google Scholar] [CrossRef]

- Kong, Y.K.; Choi, K.H.; Cho, M.U.; Kim, S.Y.; Kim, M.J.; Shim, J.W.; Park, S.S.; Kim, K.R.; Seo, M.T.; Chae, H.S.; et al. Ergonomic assessment of a lower-limb exoskeleton through electromyography and Anybody modeling system. Int. J. Environ. Res. Public Health 2022, 19, 8088. [Google Scholar] [CrossRef]

- Huang, C.; Kim, W.; Zhang, Y.; Xiong, S. Development and validation of a wearable inertial sensors-based automated system for assessing work-related musculoskeletal disorders in the workspace. Int. J. Environ. Res. Public Health 2020, 17, 6050. [Google Scholar] [CrossRef]

- Moore, J.; Stuart, S.; McMeekin, P.; Walker, R.; Celik, Y.; Pointon, M.; Godfrey, A. Enhancing free-living fall risk assessment: Contextualizing mobility based IMU data. Sensors 2023, 23, 891. [Google Scholar] [CrossRef]

- Akhmad, S.; Arendra, A.; Findiastuti, W.; Lumintu, I.; Pramudita, Y.D. Wearable IMU Wireless Sensors Network for Smart Instrument of Ergonomic Risk Assessment. In Proceedings of the 6th Information Technology International Seminar (ITIS), Surabaya, Indonesia, 14–16 October 2020; pp. 213–218. [Google Scholar]

- Mohamad, D.; Md Deros, B.; Ismail, A.R.; Daruis, D.D.I.; Sukadarin, E.H. RULA analysis of work-related disorder among packaging industry worker using digital human modeling (DHM). In Advanced Engineering Forum; Trans Tech Publications Ltd.: Kuala Lumpur, Malaysia, 2013; Volume 10, pp. 9–15. [Google Scholar]

- Hussain, M.M.; Qutubuddin, S.; Kumar, K.P.R.; Reddy, C.K. Digital human modeling in ergonomic risk assessment of working postures using RULA. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Bangkok, Thailand, 5–7 March 2019; pp. 5–7. [Google Scholar]

- Hu, B.; Ma, L.; Zhang, W.; Salvendy, G.; Chablat, D.; Bennis, F. Predicting real-world ergonomic measurements by simulation in a virtual environment. Int. J. Ind. Ergon. 2011, 41, 64–71. [Google Scholar] [CrossRef]

- Cao, W.; Zhong, J.; Cao, G.; He, Z. Physiological Function Assessment Based on Kinect V2. IEEE Access 2019, 7, 105638–105651. [Google Scholar] [CrossRef]

- Yu, Y.; Yang, X.; Li, H.; Luo, X.; Guo, H.; Fang, Q. Joint-level vision-based ergonomic assessment tool for construction workers. J. Constr. Eng. Manag. 2019, 145, 04019025. [Google Scholar] [CrossRef]

- Forsman, M.; Hansson, G.Å.; Medbo, L.; Asterland, P.; Engström, T. A method for evaluation of manual work using synchronised video recordings and physiological measurements. Appl. Ergon. 2002, 33, 533–540. [Google Scholar] [CrossRef] [PubMed]

- David, G.C. Ergonomic methods for assessing exposure to risk factors for work-related musculoskeletal disorders. Occup. Med. 2005, 55, 190–199. [Google Scholar] [CrossRef] [PubMed]

- Cheng, H.Y.K.; Cheng, C.Y.; Ju, Y.Y. Work-related musculoskeletal disorders and ergonomic risk factors in early intervention educators. Appl. Ergon. 2013, 44, 134–141. [Google Scholar] [CrossRef] [PubMed]

- McDevitt, S.; Hernandez, H.; Hicks, J.; Lowell, R.; Bentahaikt, H.; Burch, R.; Ball, J.; Chander, H.; Freeman, C.; Taylor, C.; et al. Wearables for biomechanical performance optimization and risk assessment in industrial and sports applications. Bioengineering 2022, 9, 33. [Google Scholar] [CrossRef]

- Padilla, B.E.O.; Glushkova, A.; Menychtas, D.; Manitsaris, S. Designing a web-based automatic ergonomic assessment using motion data. In Proceedings of the 12th ACM International Conference on Pervasive Technologies Related to Assistive Environments, Rhodes, Greece, 5–7 June 2019; pp. 528–534. [Google Scholar]

- Balser, F.; Desai, R.; Ekizoglou, A.; Bai, S. A novel passive shoulder exoskeleton designed with variable stiffness mechanism. IEEE Robot. Autom. Lett. 2022, 7, 2748–2754. [Google Scholar] [CrossRef]

- Islam, M.; Bai, S. Payload estimation using forcemyography sensors for control of upper-body exoskeleton in load carrying assistance. Model. Identif. Control (Online) 2019, 40, 189–198. [Google Scholar] [CrossRef]

- Tahir, A.; An, Z.; Bai, S.; Shen, M. Robust payload recognition based on sensor-over-muscle-independence deep learning for the control of exoskeletons. IEEE Trans. Circuits Syst. II Express Briefs 2023. [Google Scholar] [CrossRef]

- Ergonomics, O. RULA—Rapid Upper Limb Assessment. 2019. Available online: https://www.rula.co.uk/assessment.html (accessed on 12 May 2023).

| Reference | Assessment Tool | Data Acquisition Method | Wearable | Non-Obstructive | Load Identification |

|---|---|---|---|---|---|

| [10,11,12,13,23,24] | RULA/Modified RULA/SI | Optical/Self-report | No | No | No |

| [14,15,16] | Muscle activity level | EMG/AnyBody software | Yes | Yes | Yes |

| [20,21,22] | RULA | DHM/VR/CATIA software | Yes | No | No |

| [17,19] | RULA/REBA/NIOSH | Inertial | Yes | Yes | No |

| [18] | Artificial Intelligence based | Inertial and optical | Yes | No | No |

| Our work | RULA | Inertial | Yes | Yes | Yes |

| RULA Score | Action Level | Action |

|---|---|---|

| 1–2 | 1 | Acceptable working pattern; no changes are required. |

| 3–4 | 2 | Working pattern may be changed; hence, further investigations are suggested. |

| 5–6 | 3 | Working pattern will soon require changes; therefore, further investigations are needed. |

| >7 | 4 | Working pattern highly risks health and should be immediately changed. |

| Posture | DULA | RULA | Posture | DULA | RULA |

|---|---|---|---|---|---|

| 1 | 6 | 6 | 6 | 6 | 6 |

| 2 | 5 | 5 | 7 | 7 | 6 |

| 3 | 5 | 4 | 8 | 5 | 5 |

| 4 | 4 | 4 | 9 | 6 | 6 |

| 5 | 6 | 5 | 10 | 7 | 7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tahir, A.; Bai, S.; Shen, M. A Wearable Multi-Modal Digital Upper Limb Assessment System for Automatic Musculoskeletal Risk Evaluation. Sensors 2023, 23, 4863. https://doi.org/10.3390/s23104863

Tahir A, Bai S, Shen M. A Wearable Multi-Modal Digital Upper Limb Assessment System for Automatic Musculoskeletal Risk Evaluation. Sensors. 2023; 23(10):4863. https://doi.org/10.3390/s23104863

Chicago/Turabian StyleTahir, Abdullah, Shaoping Bai, and Ming Shen. 2023. "A Wearable Multi-Modal Digital Upper Limb Assessment System for Automatic Musculoskeletal Risk Evaluation" Sensors 23, no. 10: 4863. https://doi.org/10.3390/s23104863

APA StyleTahir, A., Bai, S., & Shen, M. (2023). A Wearable Multi-Modal Digital Upper Limb Assessment System for Automatic Musculoskeletal Risk Evaluation. Sensors, 23(10), 4863. https://doi.org/10.3390/s23104863