Recent Progress in Modulated Photothermal Radiometry

Abstract

:1. Introduction

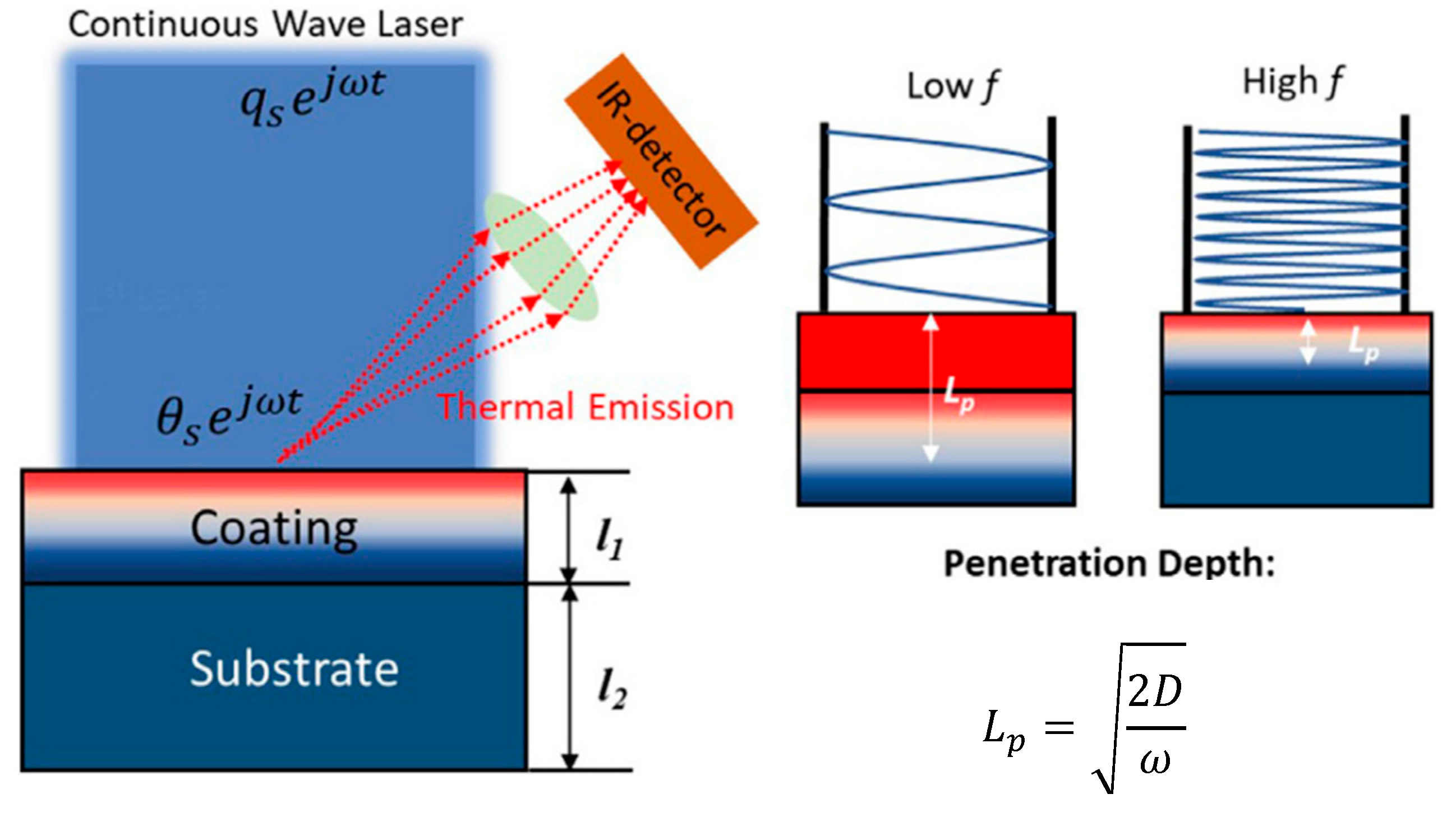

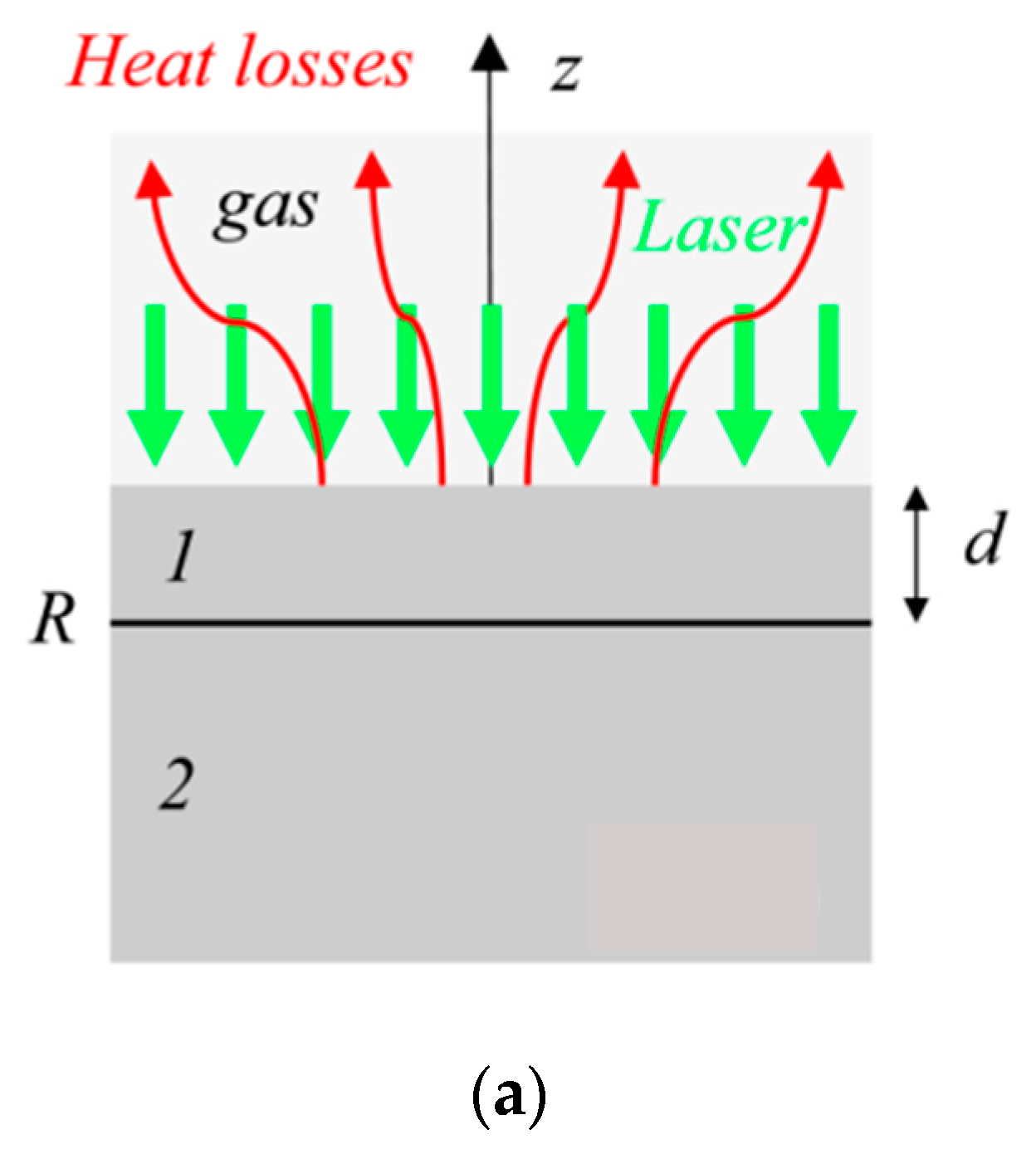

2. Thermodynamic Theory

Theory Simplifications

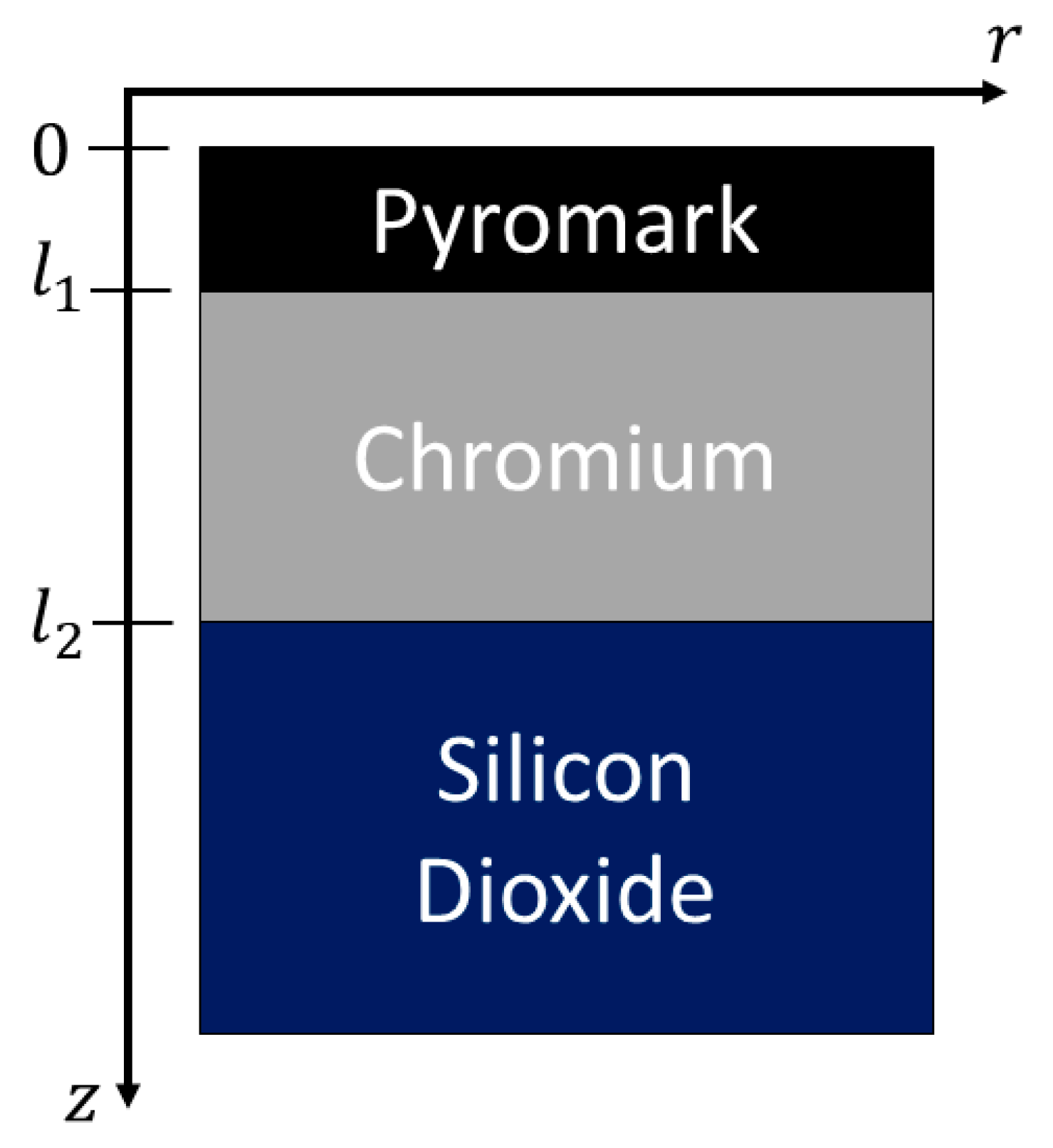

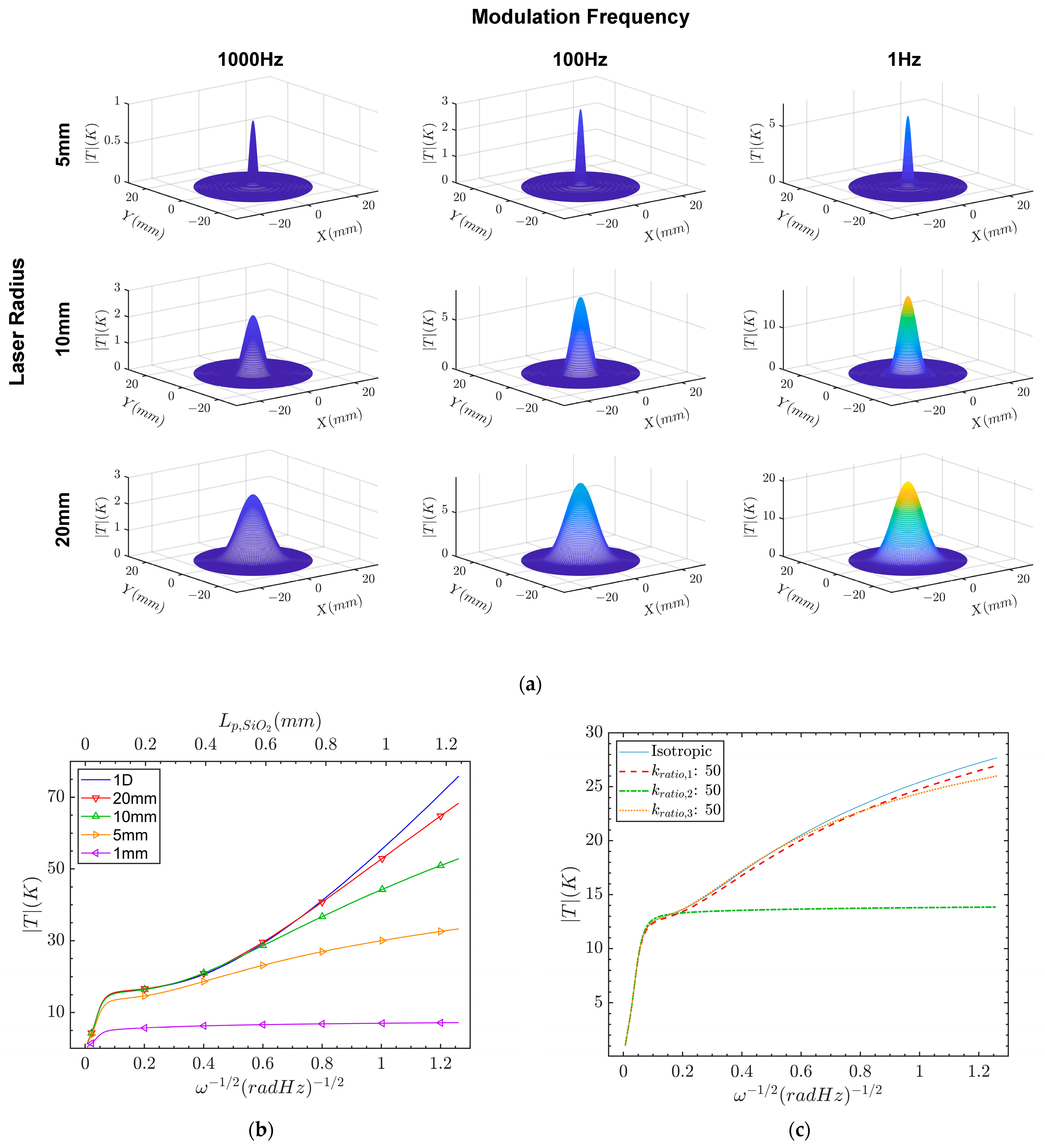

3. Modeling

4. Experimental Setup

4.1. Heat Source

4.2. Radiometric Measurement

4.3. Signal Processing

5. Analysis

6. Applications

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Meyers, R.A. (Ed.) Encyclopedia of Physical Science and Technology, 3rd ed.; Academic Press: San Diego, CA, USA, 2002; ISBN 978-0-12-227410-7. [Google Scholar]

- Kittel, C. Thermal Physics, 2nd ed.; W. H. Freeman: New York, NY, USA, 1980. [Google Scholar]

- Shanks, H.R.; Maycock, P.D.; Sidles, P.H.; Danielson, G.C. Thermal Conductivity of Silicon from 300 to 1400 K. Phys. Rev. 1963, 130, 1743–1748. [Google Scholar] [CrossRef]

- Zhao, D.; Qian, X.; Gu, X.; Jajja, S.A.; Yang, R. Measurement Techniques for Thermal Conductivity and Interfacial Thermal Conductance of Bulk and Thin Film Materials. J. Electron. Packag. 2016, 138, 040802. [Google Scholar] [CrossRef]

- Lee, S.-M.; Cahill, D.G. Heat Transport in Thin Dielectric Films. J. Appl. Phys. 1997, 81, 2590–2595. [Google Scholar] [CrossRef]

- Bauer, M.L.; Norris, P.M. General Bidirectional Thermal Characterization via the 3ω Technique. Rev. Sci. Instrum. 2014, 85, 064903. [Google Scholar] [CrossRef]

- Cahill, D.G. Thermal Conductivity Measurement from 30 to 750 K: The 3ω Method. Rev. Sci. Instrum. 1990, 61, 802–808. [Google Scholar] [CrossRef]

- Paddock, C.A.; Eesley, G.L. Transient Thermoreflectance from Thin Metal Films. J. Appl. Phys. 1986, 60, 285–290. [Google Scholar] [CrossRef]

- Hatori, K.; Taketoshi, N.; Baba, T.; Ohta, H. Thermoreflectance Technique to Measure Thermal Effusivity Distribution with High Spatial Resolution. Rev. Sci. Instrum. 2005, 76, 114901. [Google Scholar] [CrossRef]

- Toberer, E.S.; Baranowski, L.L.; Dames, C. Advances in Thermal Conductivity. Annu. Rev. Mater. Res. 2012, 42, 179–209. [Google Scholar] [CrossRef]

- Nordal, P.-E.; Kanstad, S. Photothermal Radiometry. Phys. Scr. 1979, 20, 659. [Google Scholar] [CrossRef]

- Patel, C.K.N. Continuous-Wave Laser Action on Vibrational-Rotational Transitions of CO2. Phys. Rev. 1964, 136, A1187–A1193. [Google Scholar] [CrossRef]

- Santos, R.; Miranda, L.C.M. Theory of the Photothermal Radiometry with Solids. J. Appl. Phys. 1981, 52, 4194–4198. [Google Scholar] [CrossRef]

- Depriester, M.; Hus, P.; Delenclos, S.; Sahraoui, A.H. New Methodology for Thermal Parameter Measurements in Solids Using Photothermal Radiometry. Rev. Sci. Instrum. 2005, 76, 074902. [Google Scholar] [CrossRef]

- Pawlak, M.; Maliński, M. Minority Carrier Recombination Lifetimes in N-Type CdMgSe Mixed Crystals Measured by Means of the Photothermal Infrared Radiometry. Opto-Electron. Rev. 2014, 22, 31–35. [Google Scholar] [CrossRef]

- Maliński, M.; Pawlak, M.; Chrobak, Ł.; Pal, S.; Ludwig, A. Monitoring of Amorfization of the Oxygen Implanted Layers in Silicon Wafers Using Photothermal Radiometry and Modulated Free Carrier Absorption Methods. Appl. Phys. A 2015, 118, 1009–1014. [Google Scholar] [CrossRef]

- Longo, M.; Cecchi, S.; Selmo, S.; Fanciulli, M.; Wiemer, C.; Battaglia, J.-L.; Saci, A.; Kusiak, A. MOCVD growth and thermal analysis of Sb2Te3 thin films and nanowires. In Proceedings of the 2015 1st Workshop on Nanotechnology in Instrumentation and Measurement (NANOFIM), Lecce, Italy, 24–25 July 2015; pp. 150–154. [Google Scholar]

- Nakamura, H.; Tsubouchi, K.; Mikoshiba, N.; Fukuda, T. Nondestructive and Noncontact Observation of Microdefects in GaAs Wafers with a New Photo-Thermal-Radiation Microscope. Jpn. J. Appl. Phys. 1985, 24, L876–L879. [Google Scholar] [CrossRef]

- Mandelis, A. Laser Infrared Photothermal Radiometry of Semiconductors: Principles and Applications to Solid State Electronics. Solid-State Electron. 1998, 42, 1–15. [Google Scholar] [CrossRef]

- Mandelis, A.; Batista, J.; Shaughnessy, D. Infrared Photocarrier Radiometry of Semiconductors: Physical Principles, Quantitative Depth Profilometry, and Scanning Imaging of Deep Subsurface Electronic Defects. Phys. Rev. B 2003, 67, 205208. [Google Scholar] [CrossRef]

- Batista, J.; Mandelis, A.; Shaughnessy, D. Temperature Dependence of Carrier Mobility in Si Wafers Measured by Infrared Photocarrier Radiometry. Appl. Phys. Lett. 2003, 82, 4077–4079. [Google Scholar] [CrossRef]

- Battaglia, J.-L.; Kusiak, A.; Bamford, M.; Batsale, J.-C. Photothermal Radiometric Characterization of a Thin Deposit Using a Linear Swept-Frequency Heat Flux Waveform. Int. J. Therm. Sci. 2006, 45, 1035–1044. [Google Scholar] [CrossRef]

- Fowles, G.R. Introduction to Modern Optics, 2nd ed.; Dover ed.; Dover Publications: New York, NY, USA, 1989; ISBN 978-0-486-65957-2. [Google Scholar]

- Ulmer, E.A.; Frankl, D.R. Infrared Emission from Free Carriers in Germanium*. J. Opt. Soc. Am. 1969, 59, 1233. [Google Scholar] [CrossRef]

- Adkins, C.J. Equilibrium Thermodynamics, 3rd ed.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 1983; ISBN 978-0-521-25445-8. [Google Scholar]

- Balanis, C.A. Advanced Engineering Electromagnetics, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2012; ISBN 978-0-470-58948-9. [Google Scholar]

- Bergman, T.; Lavine, A.; Incropera, F.; DeWitt, D. Fundamentals of Heat and Mass Transfer, 7th ed.; Wiley: Hoboken, NJ, USA, 2011. [Google Scholar]

- Pham Tu Quoc, S.; Cheymol, G.; Semerok, A. New Contactless Method for Thermal Diffusivity Measurements Using Modulated Photothermal Radiometry. Rev. Sci. Instrum. 2014, 85, 054903. [Google Scholar] [CrossRef] [PubMed]

- Carslaw, H.S.; Jaeger, J.C. Conduction of Heat in Solids, 2nd ed.; Oxford University Press: Oxford, UK, 1986. [Google Scholar]

- Cahill, D.G. Analysis of Heat Flow in Layered Structures for Time-Domain Thermoreflectance. Rev. Sci. Instrum. 2004, 75, 5119–5122. [Google Scholar] [CrossRef]

- Zhu, J.; Tang, D.; Wang, W.; Liu, J.; Holub, K.W.; Yang, R. Ultrafast Thermoreflectance Techniques for Measuring Thermal Conductivity and Interface Thermal Conductance of Thin Films. J. Appl. Phys. 2010, 108, 094315. [Google Scholar] [CrossRef]

- Liu, J.; Zhu, J.; Tian, M.; Gu, X.; Schmidt, A.; Yang, R. Simultaneous Measurement of Thermal Conductivity and Heat Capacity of Bulk and Thin Film Materials Using Frequency-Dependent Transient Thermoreflectance Method. Rev. Sci. Instrum. 2013, 84, 034902. [Google Scholar] [CrossRef] [PubMed]

- Zeng, J.; Chung, K.M.; Wang, Q.; Wang, X.; Pei, Y.; Li, P.; Chen, R. Measurement of High-Temperature Thermophysical Properties of Bulk and Coatings Using Modulated Photothermal Radiometry. Int. J. Heat Mass Transf. 2021, 170, 120989. [Google Scholar] [CrossRef]

- Siegman, A.E. Lasers; Univ. Science Books: Mill Valley, CA, USA, 1986; ISBN 978-0-935702-11-8. [Google Scholar]

- Mandelis, A. Signal-to-noise Ratio in Lock-in Amplifier Synchronous Detection: A Generalized Communications Systems Approach with Applications to Frequency, Time, and Hybrid (Rate Window) Photothermal Measurements. Rev. Sci. Instrum. 1994, 65, 3309–3323. [Google Scholar] [CrossRef]

- Abramowitz, M.; Stegun, I. Handbook of Mathematical Functions with Formulas, Graphs, and Mathematical Tables; NBS Applied Mathematics Series 55; National Bureau of Standards: Washington, DC, USA, 1964. [Google Scholar]

- Zeng, J.; Chung, K.M.; Adapa, S.R.; Feng, T.; Chen, R. In-Situ Thermal Transport Measurement of Flowing Fluid Using Modulated Photothermal Radiometry. Int. J. Heat Mass Transf. 2021, 180, 121767. [Google Scholar] [CrossRef]

- Coventry, J.; Burge, P. Optical Properties of Pyromark 2500 Coatings of Variable Thicknesses on a Range of Materials for Concentrating Solar Thermal Applications; AIP Publishing LLC: Abu Dhabi, United Arab Emirates, 2017; p. 030012. [Google Scholar]

- Hernández-Wong, J.; Rojas-Trigos, J.B.; Nogal, U.; Suárez, V.; Marín, E.; Calderón, A.; Hernández-Wong, J.; Rojas-Trigos, J.B.; Nogal, U.; Suárez, V.; et al. Axisymmetric Modelling of Transient Thermal Response in Solids for Application to Infrared Photothermal Radiometry Technique. Rev. Mex. Física 2019, 65, 54–64. [Google Scholar] [CrossRef]

- Fleurence, N.; Hay, B.; Davée, G.; Cappella, A.; Foulon, E. Thermal Conductivity Measurements of Thin Films at High Temperature Modulated Photothermal Radiometry at LNE: Thermal Conductivity Measurements of Thin Films. Phys. Status Solidi A 2015, 212, 535–540. [Google Scholar] [CrossRef]

- Vogel, M. Masers and Lasers, Second Edition: An Historical Approach, by Mario Bertolotti: Scope: Monograph. Level: Advanced Undergraduate, Postgraduate, Researcher. Contemp. Phys. 2016, 57, 255–256. [Google Scholar] [CrossRef]

- Liu, J.-M. Principles of Photonics; Cambridge University Press: Cambridge, UK, 2016. [Google Scholar]

- Ikari, T.; Salnick, A.; Mandelis, A. Theoretical and Experimental Aspects of Three-Dimensional Infrared Photothermal Radiometry of Semiconductors. J. Appl. Phys. 1999, 85, 7392–7397. [Google Scholar] [CrossRef]

- Borca-Tasciuc, T.; Chen, G. Temperature Measurement of Fine Wires by Photothermal Radiometry. Rev. Sci. Instrum. 1997, 68, 4080–4083. [Google Scholar] [CrossRef]

- Fomina, P.S.; Proskurnin, M.A. Photothermal Radiometry Methods in Materials Science and Applied Chemical Research. J. Appl. Phys. 2022, 132, 040701. [Google Scholar] [CrossRef]

- Balram, K.C.; Davanço, M.I.; Ilic, B.R.; Kyhm, J.-H.; Song, J.D.; Srinivasan, K. Acousto-Optic Modulation and Optoacoustic Gating in Piezo-Optomechanical Circuits. Phys. Rev. Appl. 2017, 7, 024008. [Google Scholar] [CrossRef]

- Rosengren, L.-G. Optimal Optoacoustic Detector Design. Appl. Opt. 1975, 14, 1960. [Google Scholar] [CrossRef]

- Chrobak, Ł.; Korte, D.; Budasheva, H.; Maliński, M.; Rodič, P.; Milošev, I.; Janta-Lipińska, S. Investigations of the Thermal Parameters of Hybrid Sol–Gel Coatings Using Nondestructive Photothermal Techniques. Energies 2022, 15, 4122. [Google Scholar] [CrossRef]

- Battaglia, J.-L.; Kusiak, A.; Ghosh, K. The Use of Photothermal Techniques for Thermal Conductivity and Thermal Boundary Resistance Measurements of Phase-Change Chalcogenides Alloys. J. Appl. Phys. 2021, 129, 055106. [Google Scholar] [CrossRef]

- Ramírez-Rincón, J.A.; Ares-Muzio, O.; Macias, J.D.; Estrella-Gutiérrez, M.A.; Lizama-Tzec, F.I.; Oskam, G.; Alvarado-Gil, J.J. On the Use of Photothermal Techniques for the Characterization of Solar-Selective Coatings. Appl. Phys. A 2018, 124, 252. [Google Scholar] [CrossRef]

- Walker, J.; Halliday, D. Fundamentals of Physics, 8th ed.; Wiley: Hoboken, NJ, USA, 2008; ISBN 978-0-471-75801-3. [Google Scholar]

- Pichler, B.J.; Ziegler, S.I. Chapter 14—Photodetectors. In Emission Tomography; Wernick, M.N., Aarsvold, J.N., Eds.; Academic Press: San Diego, CA, USA, 2004; pp. 255–267. ISBN 978-0-12-744482-6. [Google Scholar]

- Chirtoc, M.; Fleming, A.; Horny, N.; Ban, H. Nonlinear Heterodyne Photothermal Radiometry for Emissivity-Free Pyrometry. J. Appl. Phys. 2020, 128, 153101. [Google Scholar] [CrossRef]

- Alabedra, R.; Rigaud, D. Noise in photodiodes and photoreceiver systems. In Optoelectronic Sensors; Wiley: Hoboken, NJ, USA, 2009; pp. 223–268. ISBN 978-0-470-61163-0. [Google Scholar]

- Piotrowski, J.; Gawron, W. Ultimate Performance of Infrared Photodetectors and Figure of Merit of Detector Material. Infrared Phys. Technol. 1997, 38, 63–68. [Google Scholar] [CrossRef]

- Downs, C.; Vandervelde, T. Progress in Infrared Photodetectors Since 2000. Sensors 2013, 13, 5054–5098. [Google Scholar] [CrossRef] [PubMed]

- Gunapala, S.D.; Rhiger, D.R.; Jagadish, C. Advances in Infrared Photodetectors, 1st ed.; Semiconductors and Semimetals; Academic Press: Amsterdam, The Netherlands; Boston, MA, USA, 2011; ISBN 978-0-12-381337-4. [Google Scholar]

- Pettersson, H.; Trägårdh, J.; Persson, A.I.; Landin, L.; Hessman, D.; Samuelson, L. Infrared Photodetectors in Heterostructure Nanowires. Nano Lett. 2006, 6, 229–232. [Google Scholar] [CrossRef] [PubMed]

- Kolahdouz, M.; Farniya, A.A.; Di Benedetto, L.; Radamson, H.H. Improvement of Infrared Detection Using Ge Quantum Dots Multilayer Structure. Appl. Phys. Lett. 2010, 96, 213516. [Google Scholar] [CrossRef]

- Chen, J.; Wang, J.; Li, X.; Chen, J.; Yu, F.; He, J.; Wang, J.; Zhao, Z.; Li, G.; Chen, X.; et al. Recent Progress in Improving the Performance of Infrared Photodetectors via Optical Field Manipulations. Sensors 2022, 22, 677. [Google Scholar] [CrossRef]

- Scofield, J.H. Frequency-domain Description of a Lock-in Amplifier. Am. J. Phys. 1994, 62, 129–133. [Google Scholar] [CrossRef]

- MODEL SR830—DSP Lock-In Amplifier 1993. Available online: https://www.thinksrs.com/downloads/pdfs/manuals/SR830m.pdf. (accessed on 7 March 2023).

- Semerok, A.; Jaubert, F.; Fomichev, S.V.; Thro, P.-Y.; Courtois, X.; Grisolia, C. Laser Lock-in Thermography for Thermal Contact Characterisation of Surface Layer. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2012, 693, 98–103. [Google Scholar] [CrossRef]

- Nguyen, H.T. Thermal Characterization of In-Sb-Te Thin Films for Phase Change Memory Application. Ph.D. Dissertation, L’Université de Bordeaux, Bordeaux, France, 2015. [Google Scholar]

- Sun, Q.; Melnikov, A.; Mandelis, A. Camera-Based High Frequency Heterodyne Lock-in Carrierographic (Frequency-Domain Photoluminescence) Imaging of Crystalline Silicon Wafers: Frequency-Domain Photoluminescence Imaging of Crystalline Silicon Wafers. Phys. Status Solidi A 2016, 213, 405–411. [Google Scholar] [CrossRef]

- Felice, R.A. The spectropyrometer. In AIP Conference Proceedings; AIP: Chicago, IL, USA, 2003; Volume 684, pp. 711–716. [Google Scholar]

- Hua, Z.; Schley, R.; Hurley, D. Local Measurement of Bulk Thermal Diffusivity Using Photothermal Radiometry. Rev. Sci. Instrum. 2022, 93, 044903. [Google Scholar] [CrossRef]

- Pawlak, M. Simple Method for the Determination of the Effective Infrared Absorption Coefficient of Semiconductor Wafer Using Modulated Photothermal Infrared Radiometry. Infrared Phys. Technol. 2019, 97, 43–47. [Google Scholar] [CrossRef]

- Fuente, R.; Mendioroz, A.; Apiñaniz, E.; Salazar, A. Simultaneous Measurement of Thermal Diffusivity and Optical Absorption Coefficient of Solids Using PTR and PPE: A Comparison. Int. J. Thermophys. 2012, 33, 1876–1886. [Google Scholar] [CrossRef]

- Cui, Y.; Xie, J.; Liu, J.; Wang, J.; Chen, S. A Review on Phase Change Material Application in Building. Adv. Mech. Eng. 2017, 9, 1–15. [Google Scholar] [CrossRef]

- Kusiak, A.; Battaglia, J.-L.; Noé, P.; Sousa, V.; Fillot, F. Thermal Conductivity of Carbon Doped GeTe Thin Films in Amorphous and Crystalline State Measured by Modulated Photo Thermal Radiometry. J. Phys. Conf. Ser. 2016, 745, 032104. [Google Scholar] [CrossRef]

- Gordiz, K.; Henry, A. Phonon Transport at Crystalline Si/Ge Interfaces: The Role of Interfacial Modes of Vibration. Sci. Rep. 2016, 6, 23139. [Google Scholar] [CrossRef]

- Horny, N.; Chirtoc, M.; Fleming, A.; Hamaoui, G.; Ban, H. Kapitza Thermal Resistance Studied by High-Frequency Photothermal Radiometry. Appl. Phys. Lett. 2016, 109, 033103. [Google Scholar] [CrossRef]

- Figueira, R.B.; Silva, C.J.R.; Pereira, E.V. Organic–Inorganic Hybrid Sol–Gel Coatings for Metal Corrosion Protection: A Review of Recent Progress. J. Coat. Technol. Res. 2015, 12, 1–35. [Google Scholar] [CrossRef]

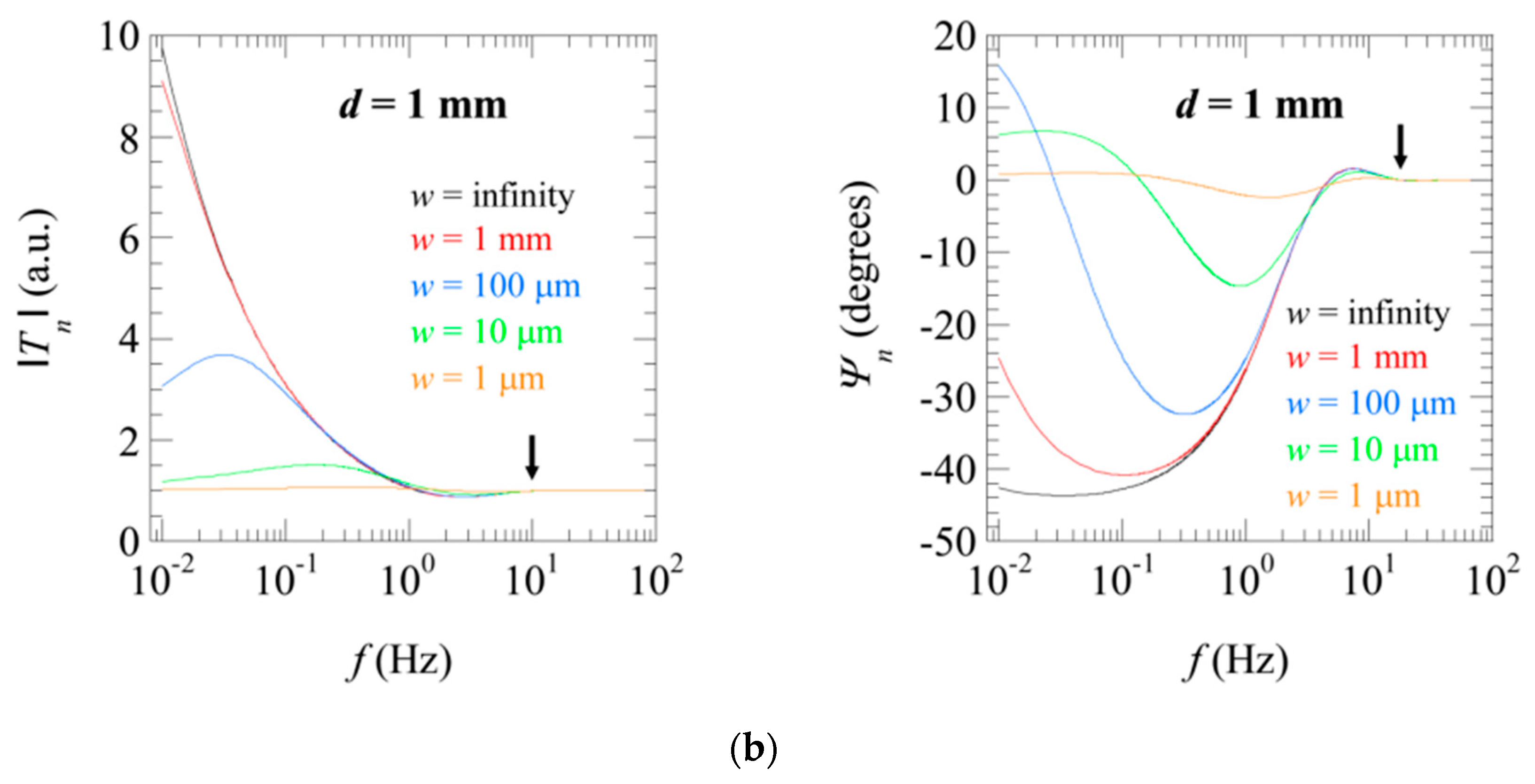

- Salazar, A.; Mendioroz, A. Sizing the Depth and Width of Ideal Delaminations Using Modulated Photothermal Radiometry. J. Appl. Phys. 2022, 131, 085106. [Google Scholar] [CrossRef]

- Corona, J.; Stout, D.; Otanicar, T.P.; Kandadai, N. Characterizing particle-based thermal storage performance using optical methods for use in next generation concentrating solar power plants. In Proceedings of the Nonimaging Optics: Efficient Design for Illumination and Solar Concentration XVIII, San Diego, CA, USA, 21 August 2022; Jiang, L., Winston, R., Koshel, R.J., Eds.; SPIE: Bellingham, WA, USA, 2022; p. 21. [Google Scholar]

- Brace, C.L. Microwave Tissue Ablation: Biophysics, Technology, and Applications. Crit. Rev. Biomed. Eng. 2010, 38, 65–78. [Google Scholar] [CrossRef]

- Kosik, I.; Weersink, R.; Wilson, B. Photoacoustic Methods for Direct Monitoring of Nanoparticle Enhanced Photothermal Ablation in Biological Tissues: Visualizing Scattering, Absorption, and Thermal Effects. In Proceedings of the Novel Optical Systems, Methods, and Applications XXV, San Diego, CA, USA, 22–23 August 2022; SPIE: Bellingham, WA, USA, 2022; Volume 12216, pp. 82–87. [Google Scholar]

- Cheng, J.-X. High-Resolution High-Speed Chemical Imaging through Mid-Infrared Photothermal Microscopy. In Proceedings of the SPIE Photonics West, San Francisco, CA, USA, 28 January–2 February 2023. [Google Scholar]

| Property | Layer 1 Pyromark 1 | Layer 2 Chromium | Layer 3 Silicon Dioxide |

|---|---|---|---|

| Density | - | ||

| Specific Heat | - | ||

| Heat Capacity | |||

| Thermal Conductivity | |||

| Thickness | 600 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Corona, J.; Kandadai, N. Recent Progress in Modulated Photothermal Radiometry. Sensors 2023, 23, 4935. https://doi.org/10.3390/s23104935

Corona J, Kandadai N. Recent Progress in Modulated Photothermal Radiometry. Sensors. 2023; 23(10):4935. https://doi.org/10.3390/s23104935

Chicago/Turabian StyleCorona, Javier, and Nirmala Kandadai. 2023. "Recent Progress in Modulated Photothermal Radiometry" Sensors 23, no. 10: 4935. https://doi.org/10.3390/s23104935