Drone–Robot to Clean Power Line Insulators

Abstract

:1. Introduction

Review of the State-of-the-Art in Cleaning Insulator Chains

2. Materials and Methods

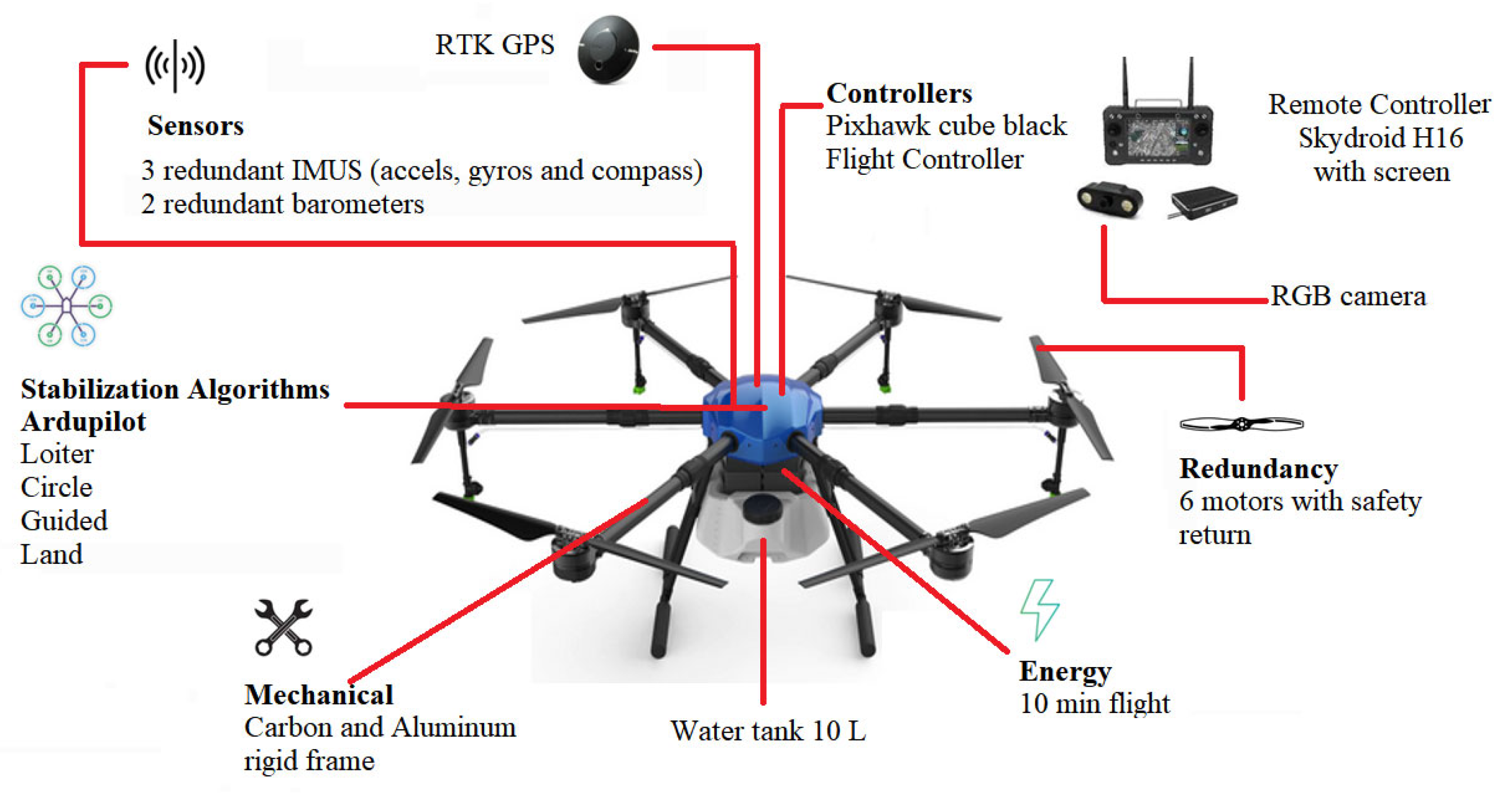

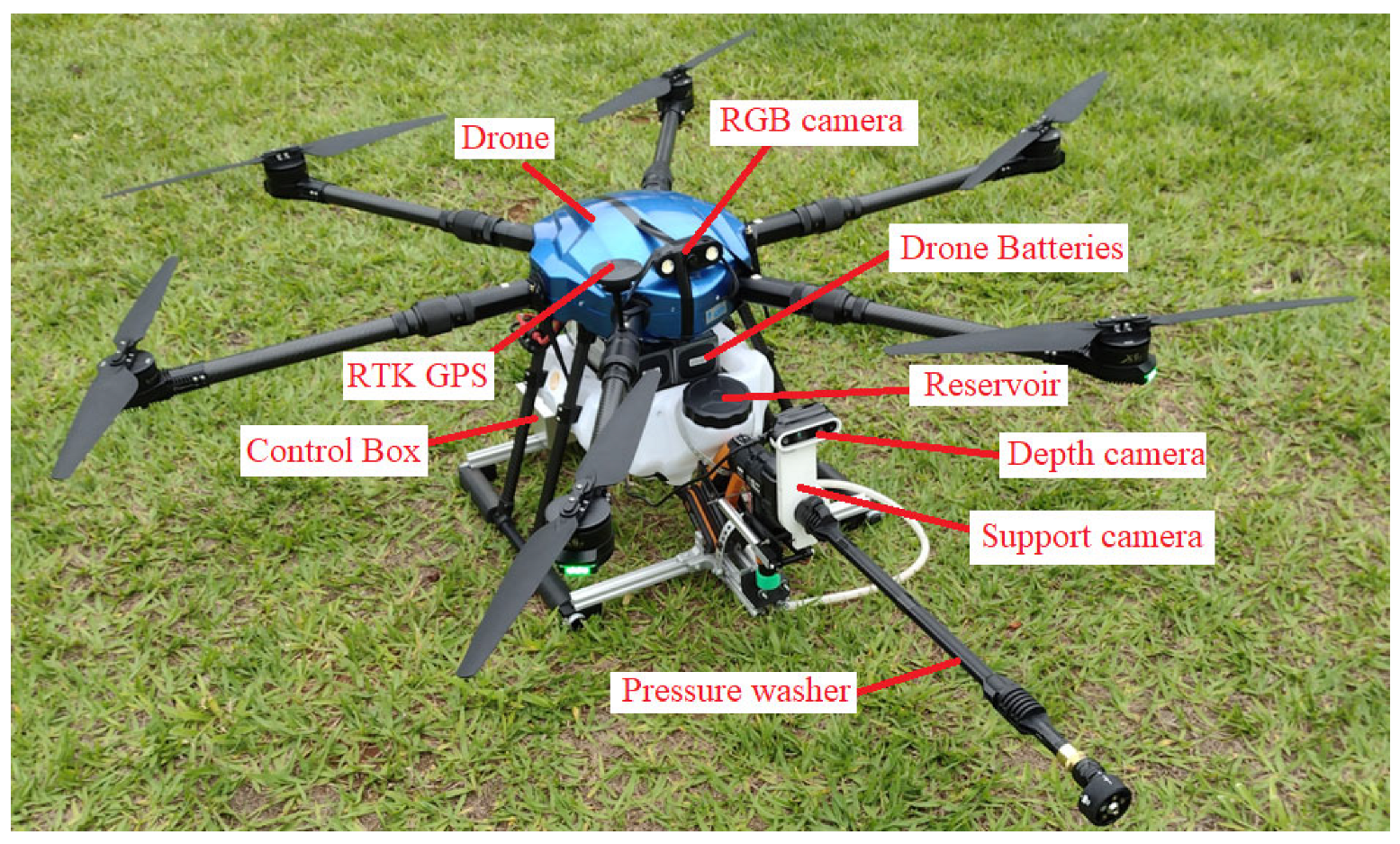

2.1. Drone Description

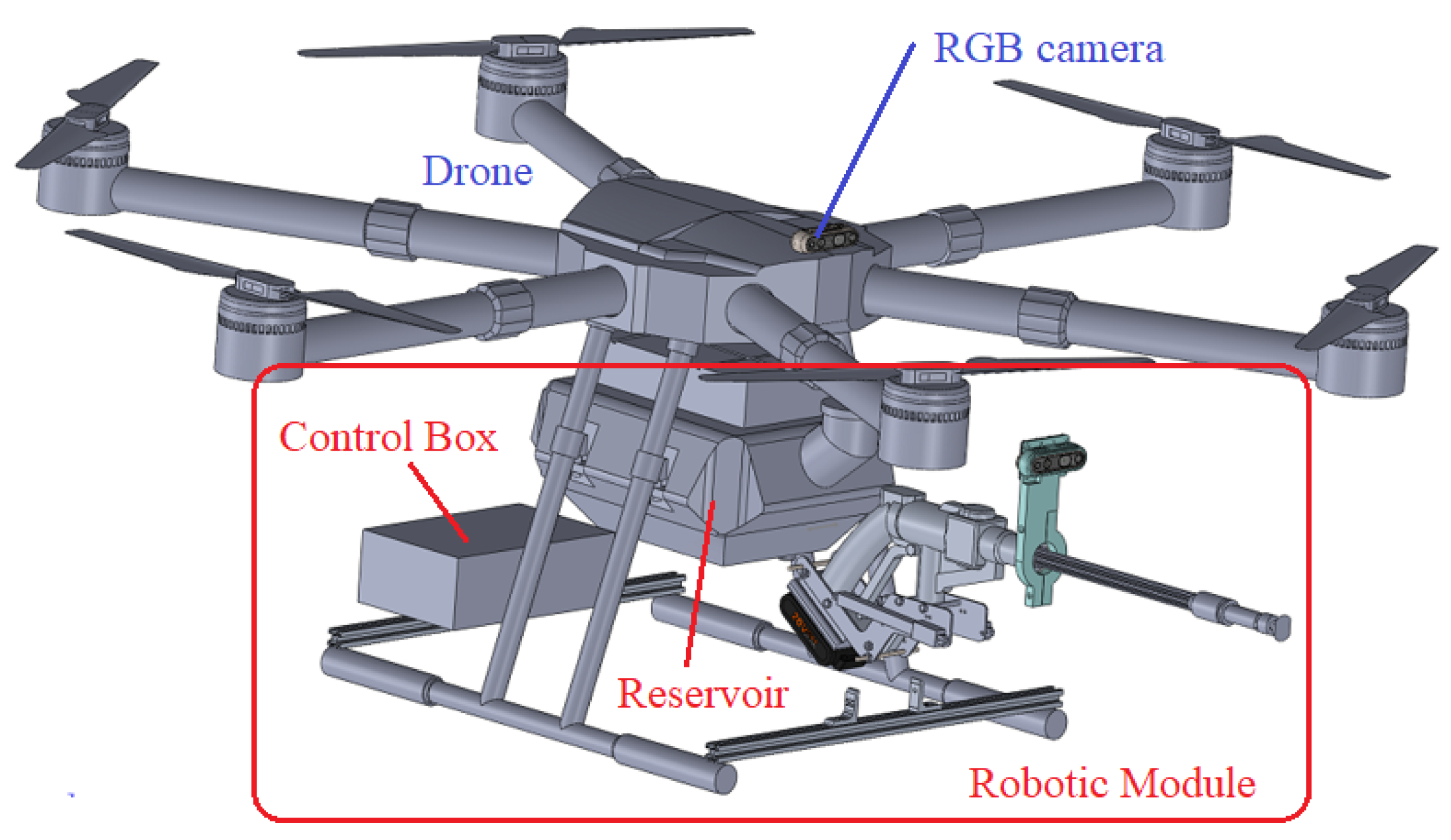

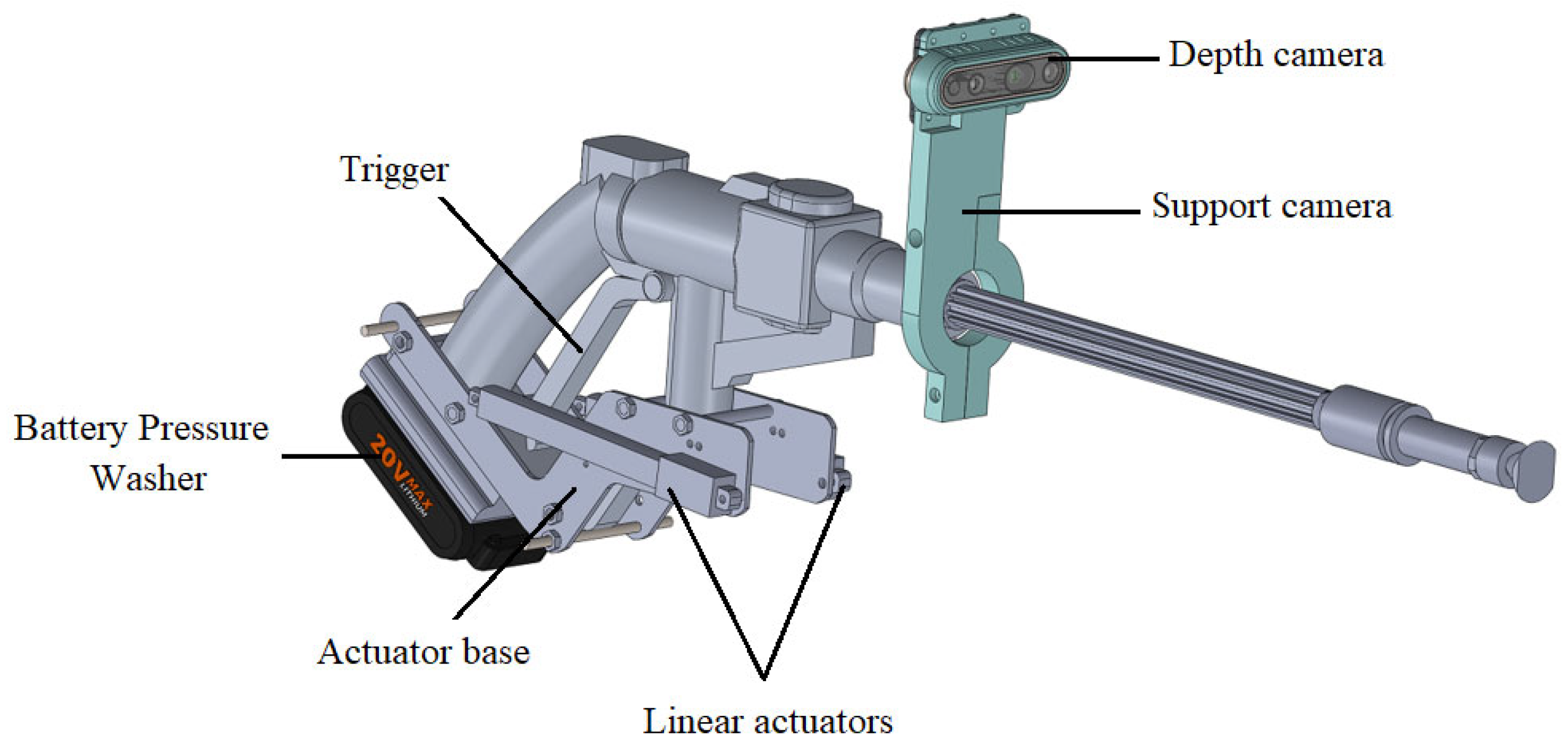

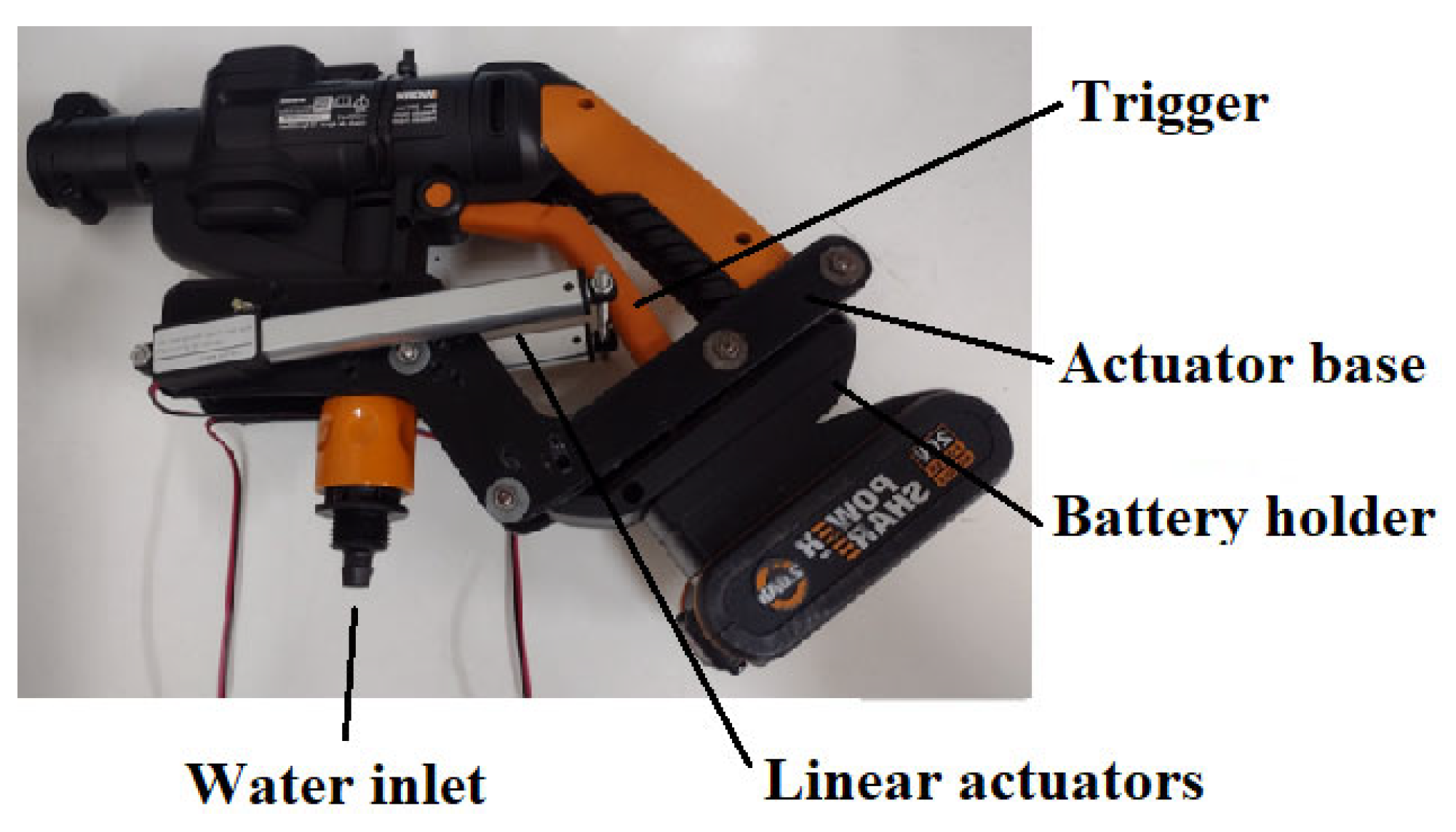

2.2. Robotic Module for Cleaning the Insulator Chain

2.3. Development of Electromagnetic and Electrostatic Shielding for the Drone–Robot

- v = 3 × 108 m/s (speed of electromagnetic waves);

- r = 2.1 m (minimum distance of the source at which the drone controller will be exposed), Figure 6;

- μr = 1 (relative magnetic permeability of aluminum);

- σr = 0.61 (relative conductivity of aluminum);

- t = 0.1 mm = 0.0039 in (shield thickness).

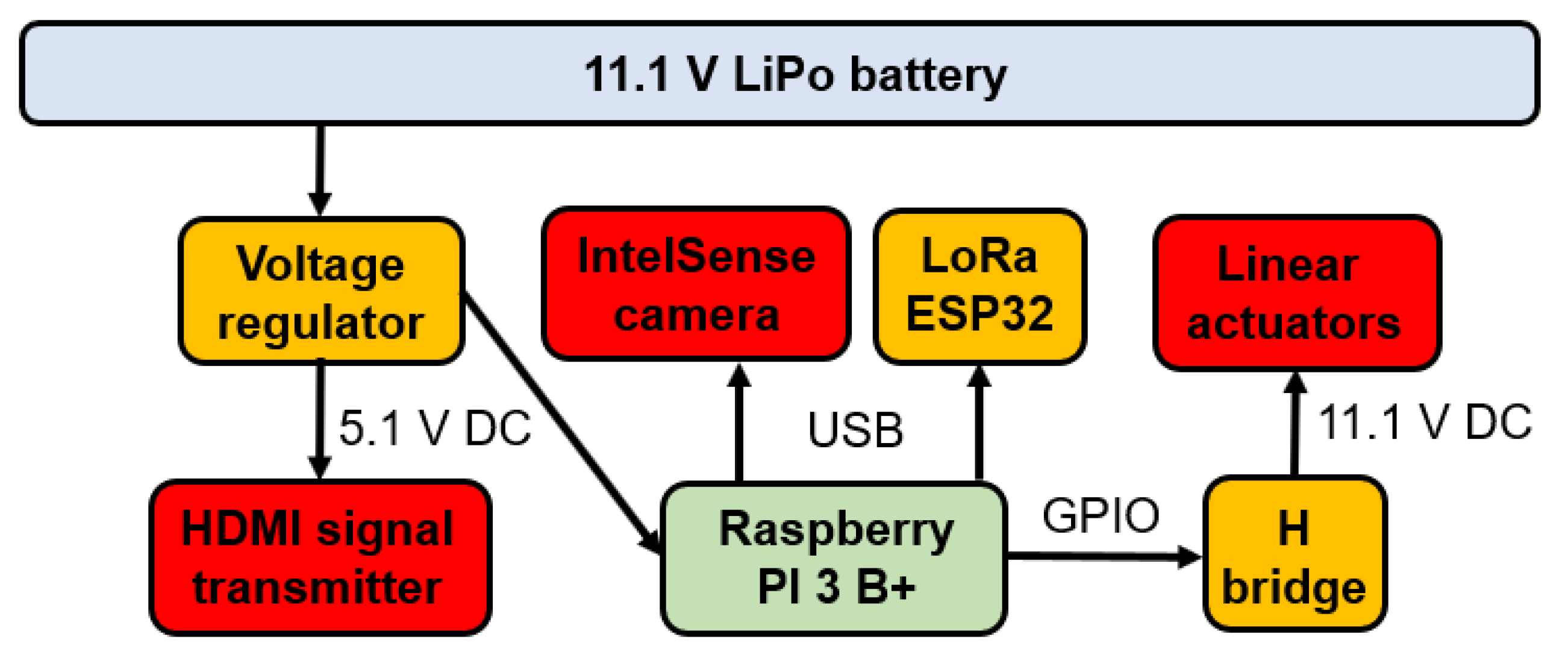

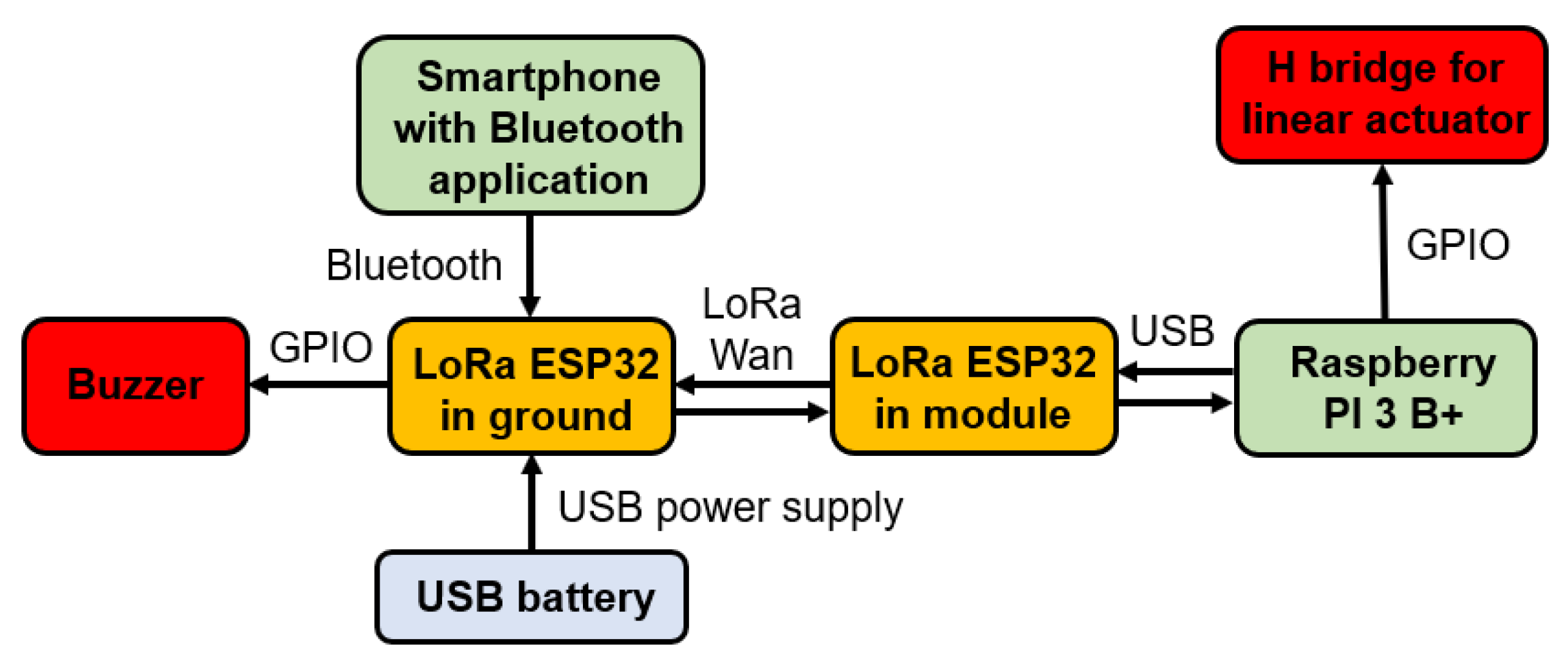

2.4. Electronic System of the Robotic Module

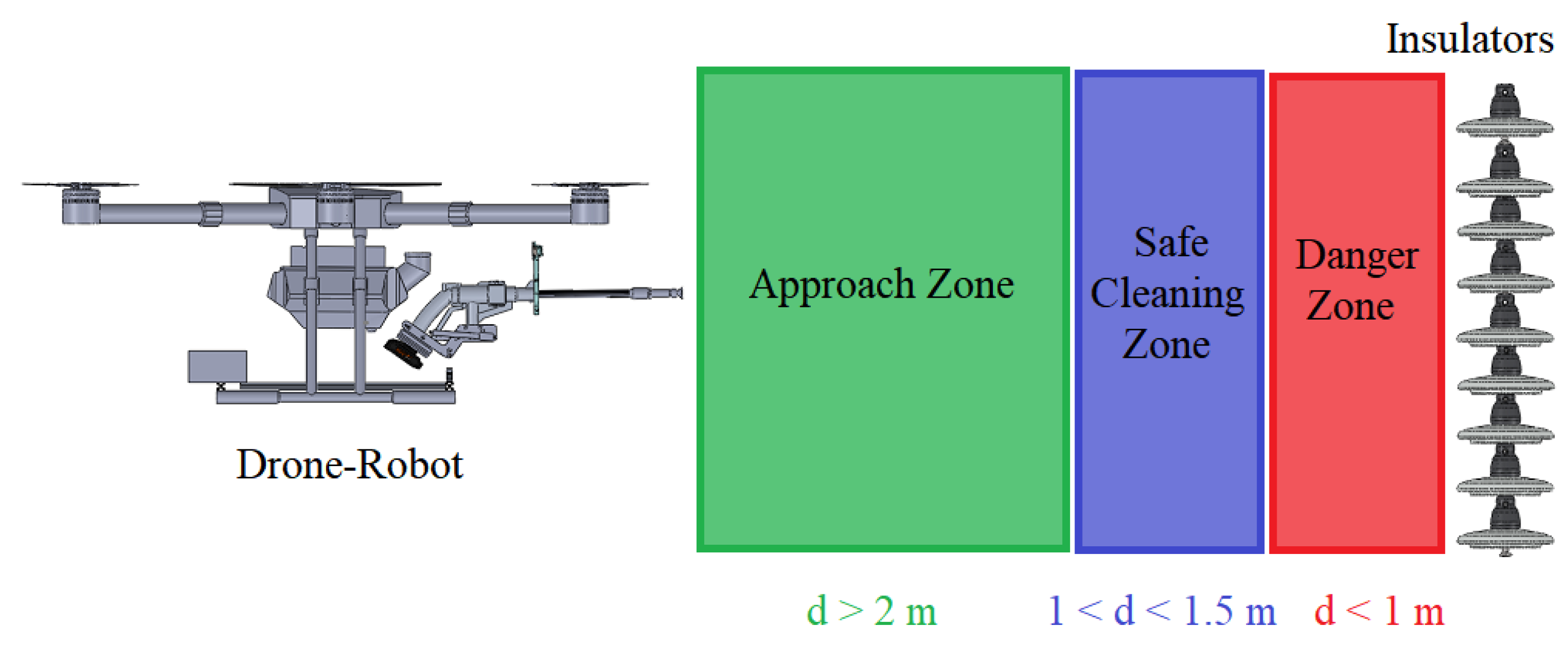

2.5. Robotic Module Distance Detection System

| Algorithm 1: Depth camera image streaming and distance processing to warn drone pilot | |

| 1: | StartCameraStream <- CameraParameters |

| 2: | while (true) do |

| 3: | DepthMatrix ← ImageDepthFrames |

| 4: | Distance1 ← DepthMatrix (ImagePosition1) |

| 5: | Distance2 ← DepthMatrix (ImagePosition2) |

| 6: | Distance3 ← DepthMatrix (ImagePosition3) |

| 7: | Distance4 ← DepthMatrix (ImagePosition4) |

| 8: | Distance5 ← DepthMatrix (ImagePosition5) |

| 9: | if (Distance1 < Distance2, 3, 4 and 5) then |

| 10: | CurrentDistance ← Distance1 |

| 11: | else if (Distance2 < Distance1, D3, D4 and D5) then |

| 12: | CurrentDistance ← Distance2 |

| 13: | else if (Distance3 < Distance1, D2, D4 and D5) then |

| 14: | CurrentDistance ← Distance3 |

| 15: | else if (Distance4 < Distance1, D2, D3 and D5) then |

| 16: | CurrentDistance ← Distance4 |

| 17: | else if (Distance5 < Distance1, D3, D4 and D5) then |

| 18: | CurrentDistance ← Distance5 |

| 19: | if (CurrentDistance ≤ 1 m) then |

| 20: | Buzzer ← ConstantBuzz |

| 21: | else if (CurrentDistance ≥ 1.5 m) then |

| 22: | Buzzer ← Silence |

| 23: | else if (CurrentDistance > 1 m and CurrentDistance < 1.5 m) then |

| 24: | Buzzer ← IntermitentBuzz |

2.6. Drone–Robot Prototype for Cleaning Insulator Chains

3. Results

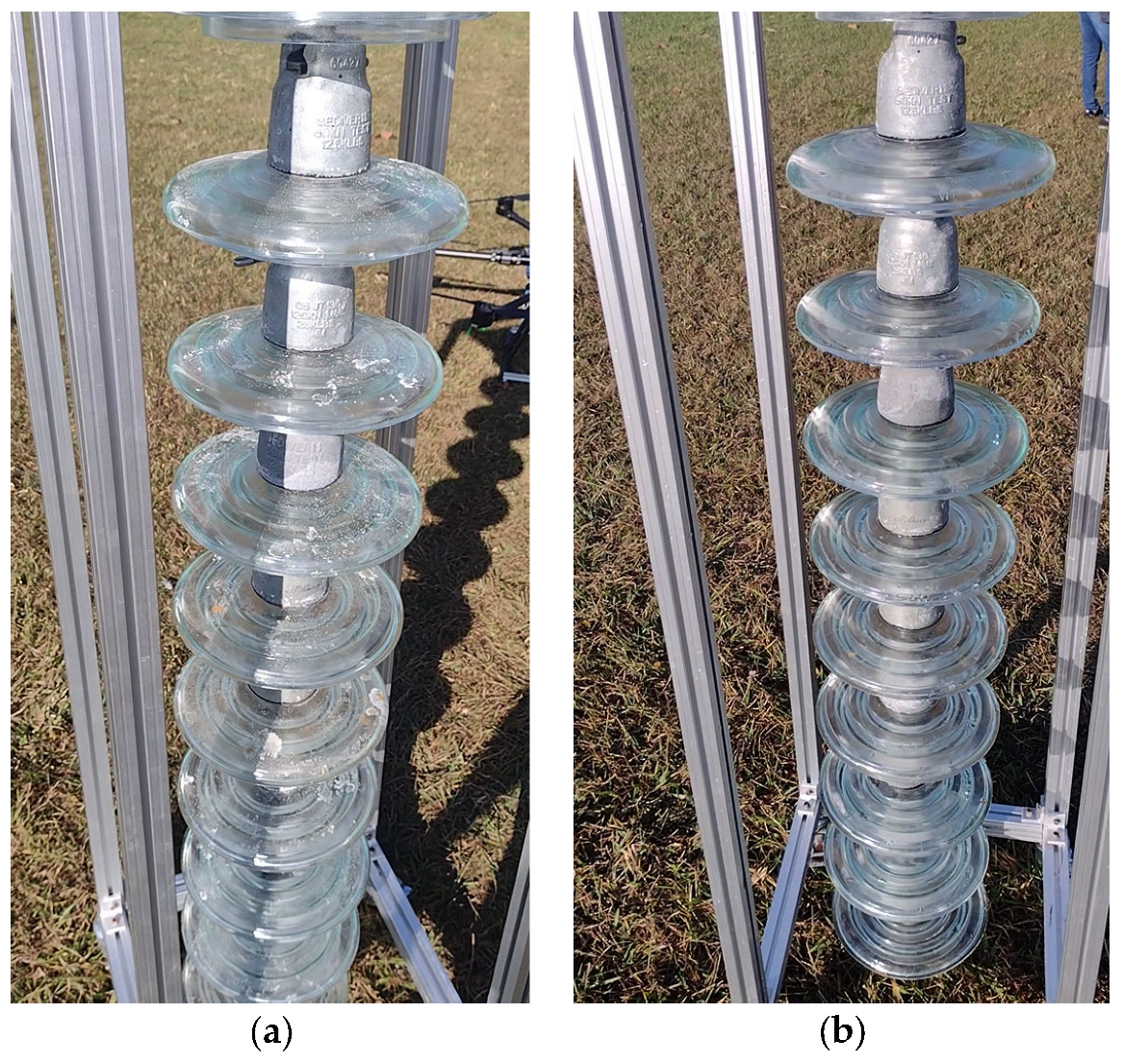

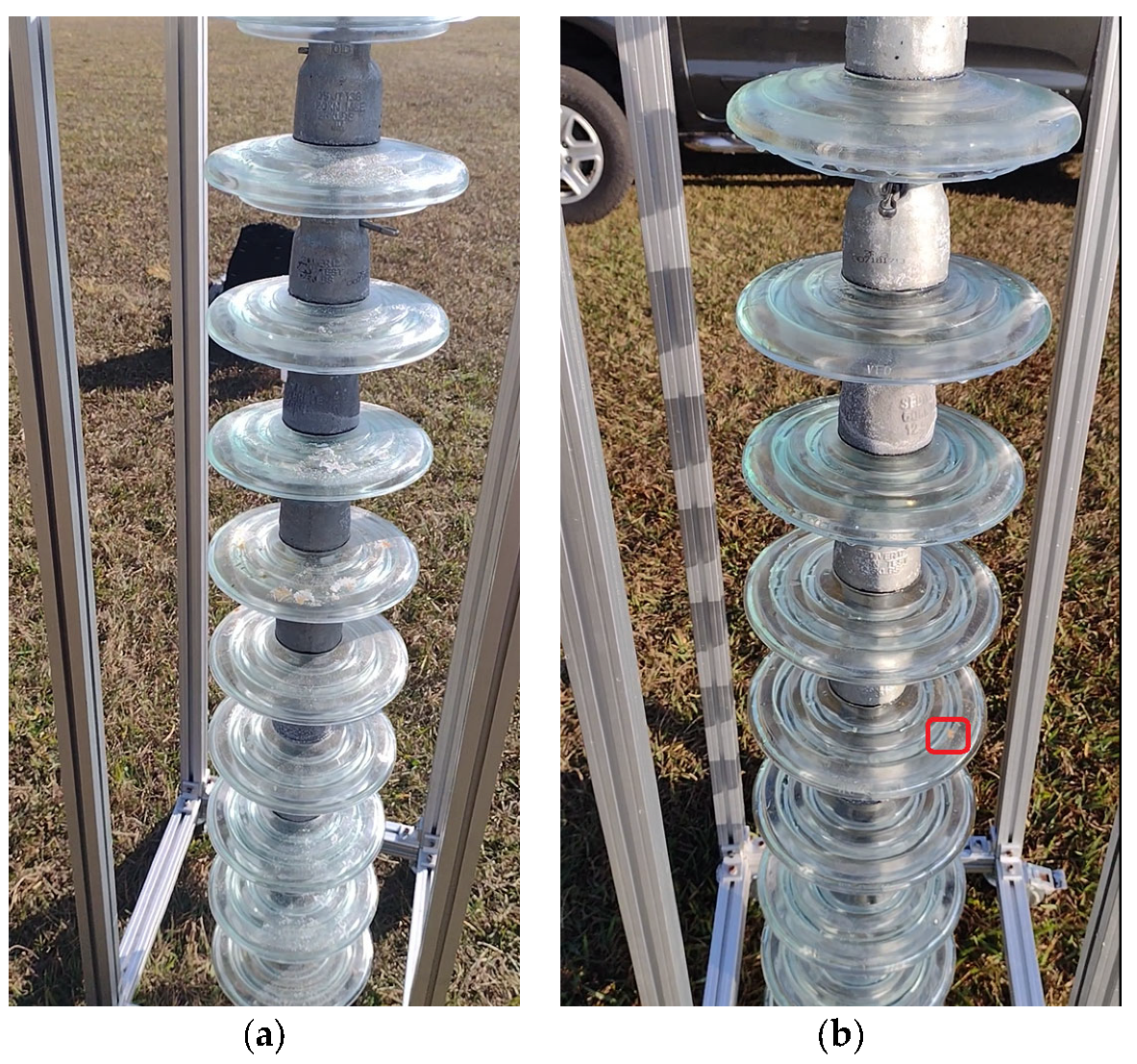

3.1. Simulated Cleaning Tests

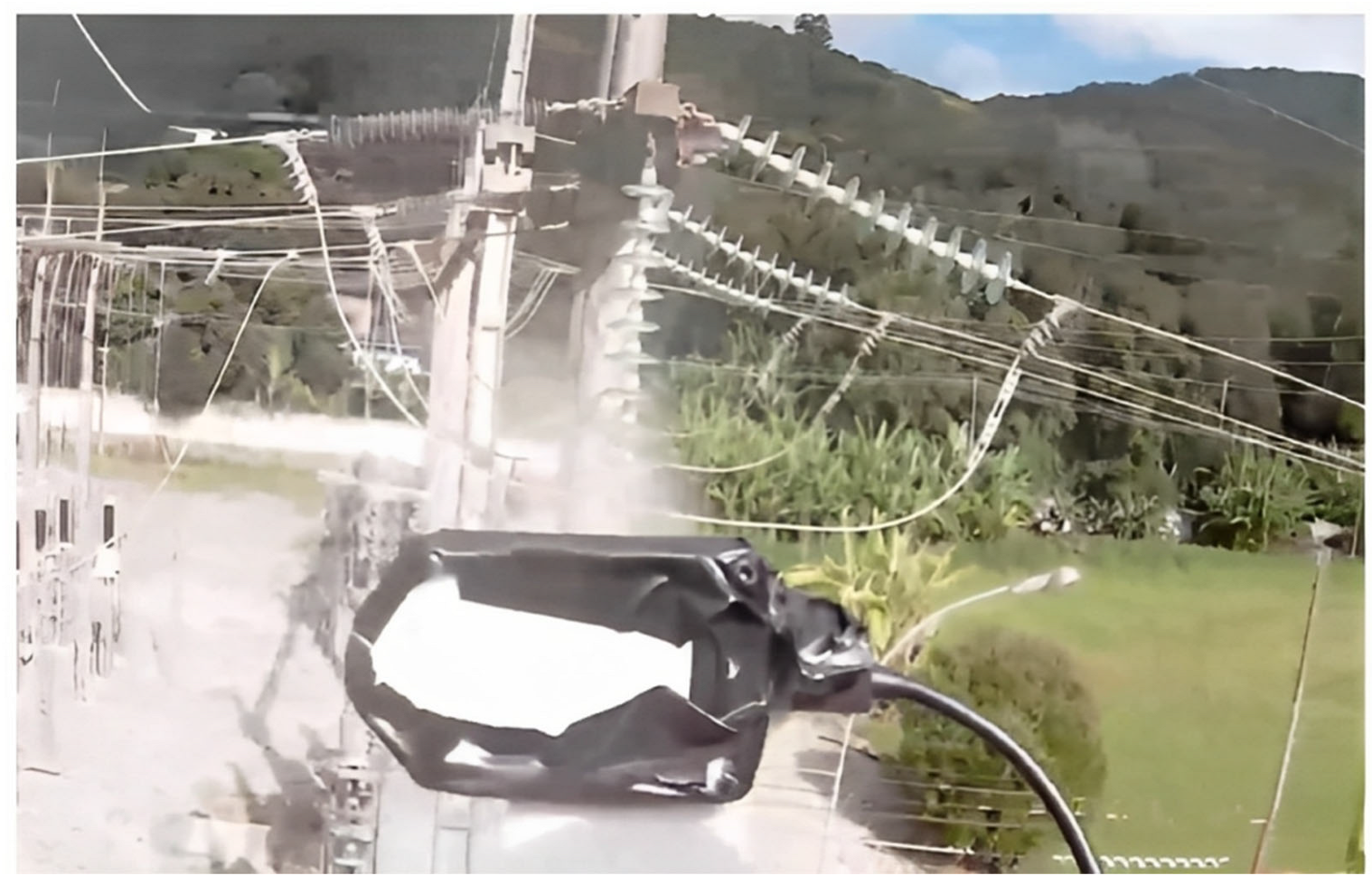

3.2. Field Tests

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hadipour, M.; Shiran, M. Various Pollutions of Power Line Insulators. Majlesi J. Ener. Manag. 2017, 6, 29–38. [Google Scholar]

- COPEL—Maintenance on High Voltage Distribution Lines with Dead Line. Available online: https://docplayer.com.br/111431340-Manutencao-em-linhas-de-distribuicao-em-alta-tensao-com-linha-morta-grupo-gestao-de-seguranca-e-saude-no-trabalho-gsst.html (accessed on 18 May 2023).

- Gonçalves, R.S.; Carvalho, J.C.M. Review and Latest Trends in Mobile Robots Applied in Power Transmission Lines. Int. J. Adv. Robot. Syst. 2013, 10, 408. [Google Scholar] [CrossRef] [Green Version]

- Goncalves, R.S.; Agostini, G.S.; Bianchi, R.A.C.; Homma, R.Z.; Sudbrack, D.E.T.; Trautmann, P.V.; Clasen, B.C. Inspection of Power Line Insulators: State of the Art, Challenges, and Open Issues. In Handbook of Research on New Investigations in Artificial Life, AI, and Machine Learning, 1st ed.; Habib, M.K., Ed.; IGI Global: Hershey, PA, USA, 2022; Volume 1, pp. 462–491. [Google Scholar]

- Gonçalves, R.S.; Souza, F.C.; Homma, R.Z.; Sudbrack, D.E.T.; Trautmann, P.V.; Clasen, B.C. Review: Robots for Inspection and Maintenance of Power Transmission Lines. In Mechanisms and Machine Science, 1st ed.; Carbone, G., Laribi, M.A., Eds.; Robot Design; Springer: Cham, Switzerland; New York, NY, USA, 2022; Volume 123. [Google Scholar]

- Mahouin, A.; Gonçalves, R.S. Design of a Robot Applied to Inspection of Power Transmission Lines. Appl. Mech. Mater. 2014, 590, 551–555. [Google Scholar] [CrossRef]

- Gonçalves, R.S.; Carvalho, J.C.M. A mobile robot to be applied in high-voltage power lines. J. Braz. Soc. Mech. Sci. Eng. 2014, 37, 349–359. [Google Scholar] [CrossRef]

- Wang, L.; Wang, H.; Song, Y.; Pan, X. Development of a Bio-Inspired Live-Line Cleaning Robot for Suspension Insulator Strings. Int. J. Simul. Syst. Sci. Technol. 2016, 17, 24.1–24.9. [Google Scholar] [CrossRef]

- Byun, S.; Cho, B.; Park, J.; Lee, J. Implementation of Control System for Insulator Cleaning Robot. In Proceedings of the SICE-ICASE International Joint Conference, Bexco, Busan, Republic of Korea, 18–21 October 2006. [Google Scholar] [CrossRef]

- Park, J.; Cho, B.; Byun, S.; Lee, J. Development of Cleaning Robot System for Live-Line Suspension Insulator Strings. Int. J. Control Autom. Syst. 2009, 7, 211–220. [Google Scholar] [CrossRef]

- Park, J.; Song, S.; Cho, B.; Byun, S.; Kim, J. Robot Mechanism for Cleaning and Inspection of Live-Line Insulators. U.S. Patent 7,797,781, 21 September 2010. [Google Scholar]

- Jiang, W.; Yan, Y.; Yu, L.; Peng, M.; Li, H.; Chen, W. Research on Dual-Arm Coordination Motion Control Strategy for Power Cable Mobile Robot. Trans. Inst. Meas. Control 2019, 41, 3235–3247. [Google Scholar] [CrossRef]

- Tengfei, S.; Ronghai, L.; Xin, Z.; Zhangqin, W.; Xinliang, G.; Yingchun, Y.; Hongwei, X. Electrified Insulator Cleaning Method based on Unmanned Aerial Vehicle. CN105170523A, 23 December 2015. [Google Scholar]

- Hadipour, M.; Aberomand, N.; Jameii, S. A New Approach for Live Line Insulator Washing with Unmanned Autonomous Mobile Helicopter (UAMH). In Proceedings of the Smolensk, International Conference NESEFF, Moscow, Russia, 20–25 June 2016. [Google Scholar]

- Lopez Lopez, R.; Batista Sanchez, M.J.; Perez Jimenez, M.; Arrue, B.C.; Ollero, A. Autonomous UAV System for Cleaning Insulators in Power Line Inspection and Maintenance. Sensors 2021, 21, 8488. [Google Scholar] [CrossRef] [PubMed]

- IEEE. IEEE Guide for Maintenance Methods on Energized Power-Lines. ANSI/IEEE Std 516 1987, 1988, 7–44. [Google Scholar] [CrossRef]

- Ardupilot Documentation. Available online: https://ardupilot.org/ardupilot/index.html (accessed on 18 May 2023).

- Mission Planner Home. Available online: https://ardupilot.org/planner/ (accessed on 18 May 2023).

- Ott, H. Electromagnetic Compatibility Engineering, 3rd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2009; pp. 238–301. [Google Scholar] [CrossRef] [Green Version]

- Ungureanu, M.; Rusu, A.C.-T.; Baran, I. Field components of the electromagnetic environment related to the presence of the overhead transmission lines. WSEAS Trans. Environ. Dev. 2007, 3, 149–164. [Google Scholar]

- Vasquez-Arnez, R.L.; Jardini, M.G.M.; Masuda, M.; Carita, L.A.; Jardini, J.A. Preventive Inspection of Line Insulators through Corona Emission: A Case Study. In Proceedings of the IEEE PES T&D 2010, New Orleans, LA, USA, 19–22 April 2010; pp. 1–6. [Google Scholar] [CrossRef]

- Liu, J.; Tan, Q.; Zhao, Q.; Gu, Y. The research on Electromagnetic Compatibility of the Autonomous Inspection Robot for Power Transmission Line. In Proceedings of the 2016 International Forum on Energy, Environment and Sustainable Development (IFEESD 2016), Shenzhen, China, 16–17 April 2016; pp. 1091–1094. [Google Scholar] [CrossRef] [Green Version]

- Stewart, J.R.; Dale, S.J.; Klein, K.W. Magnetic field reduction using high phase order lines. IEEE Trans. Power Deliv. 1993, 8, 628–636. [Google Scholar] [CrossRef]

- Pakala, W.E.; Chartier, V.L. Radio Noise Measurements on Overhead Power Lines from 2.4 to 800 KV. IEEE Trans. Power Appar. Syst. 1971, 3, 1155–1165. [Google Scholar] [CrossRef]

- Nor, N.M.; Ramli, A. Electrical properties of dry soil under high impulse currents. J. Electrost. 2007, 65, 500–505. [Google Scholar] [CrossRef]

| Contaminant | Low-Pressure Washing | High-Pressure Washing |

|---|---|---|

| Salt | Yes | Yes |

| Cement/lime | No | No |

| Dirt dust | Yes | Yes |

| Fertilizer dust | Yes | Yes |

| Metallic dust | No | No |

| Coal dust | Yes | Yes |

| Volcanic ash | Yes | Yes |

| Bird droppings | Yes | Yes |

| Chemical | Yes | No |

| Vehicle smoke | Yes | Yes |

| Cooling tower effluent | Yes | Yes |

| Coal smoke/soot | Yes | Yes |

| Organic | Yes | Yes |

| Ice/snow | No | Yes |

| Oil/grease | No | No |

| Cleaning Method | Water Washing |

|---|---|

| Contaminants targeted by washing | Salt |

| Type of insulator to be cleaned | Glass or ceramic |

| Pressure | 320 psi |

| Flow rate | 1.6 L/min |

| Jet shape | Droplets/spray |

| Safety distance | 1.5 m to 1.0 m from chain |

| Maximum wind speed | 8 m/s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gonçalves, R.S.; De Oliveira, M.; Rocioli, M.; Souza, F.; Gallo, C.; Sudbrack, D.; Trautmann, P.; Clasen, B.; Homma, R. Drone–Robot to Clean Power Line Insulators. Sensors 2023, 23, 5529. https://doi.org/10.3390/s23125529

Gonçalves RS, De Oliveira M, Rocioli M, Souza F, Gallo C, Sudbrack D, Trautmann P, Clasen B, Homma R. Drone–Robot to Clean Power Line Insulators. Sensors. 2023; 23(12):5529. https://doi.org/10.3390/s23125529

Chicago/Turabian StyleGonçalves, Rogério Sales, Murilo De Oliveira, Murilo Rocioli, Frederico Souza, Carlos Gallo, Daniel Sudbrack, Paulo Trautmann, Bruno Clasen, and Rafael Homma. 2023. "Drone–Robot to Clean Power Line Insulators" Sensors 23, no. 12: 5529. https://doi.org/10.3390/s23125529

APA StyleGonçalves, R. S., De Oliveira, M., Rocioli, M., Souza, F., Gallo, C., Sudbrack, D., Trautmann, P., Clasen, B., & Homma, R. (2023). Drone–Robot to Clean Power Line Insulators. Sensors, 23(12), 5529. https://doi.org/10.3390/s23125529