Crack-Based Sensor with Microstructures for Strain and Pressure Sensing

Abstract

1. Introduction

2. Materials and Methods

2.1. Fabrication of a Strain and Pressure-Sensing CBS

2.2. Electrical Characterization of a Strain- and Pressure-Sensing Sensor

3. Results

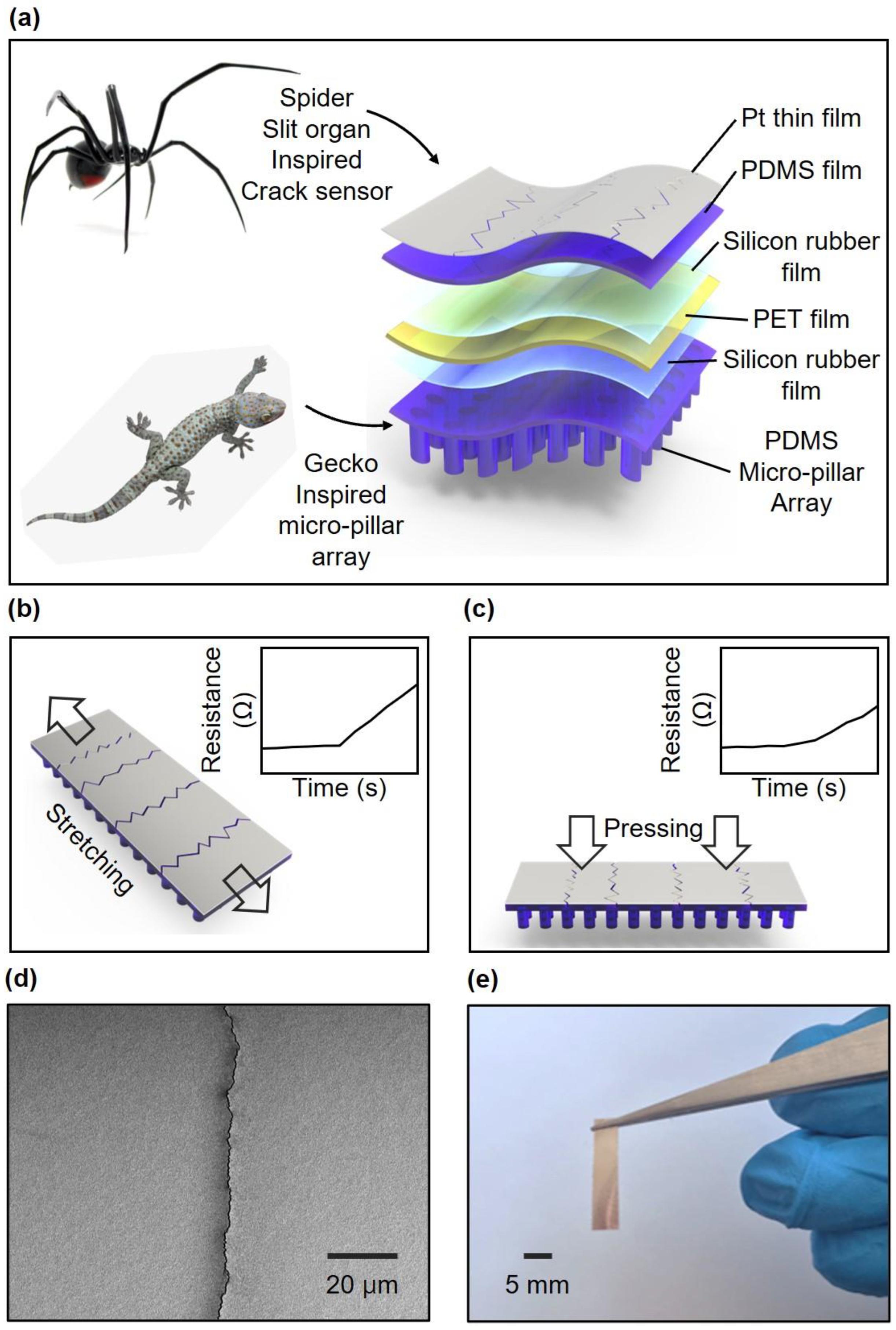

3.1. Crack-Based Strain and Pressure Sensor

3.2. AFM Analysis of Morphology or Crack-Based Strain and Pressure Sensors

3.3. Characterization of a CBS for Strain Sensing

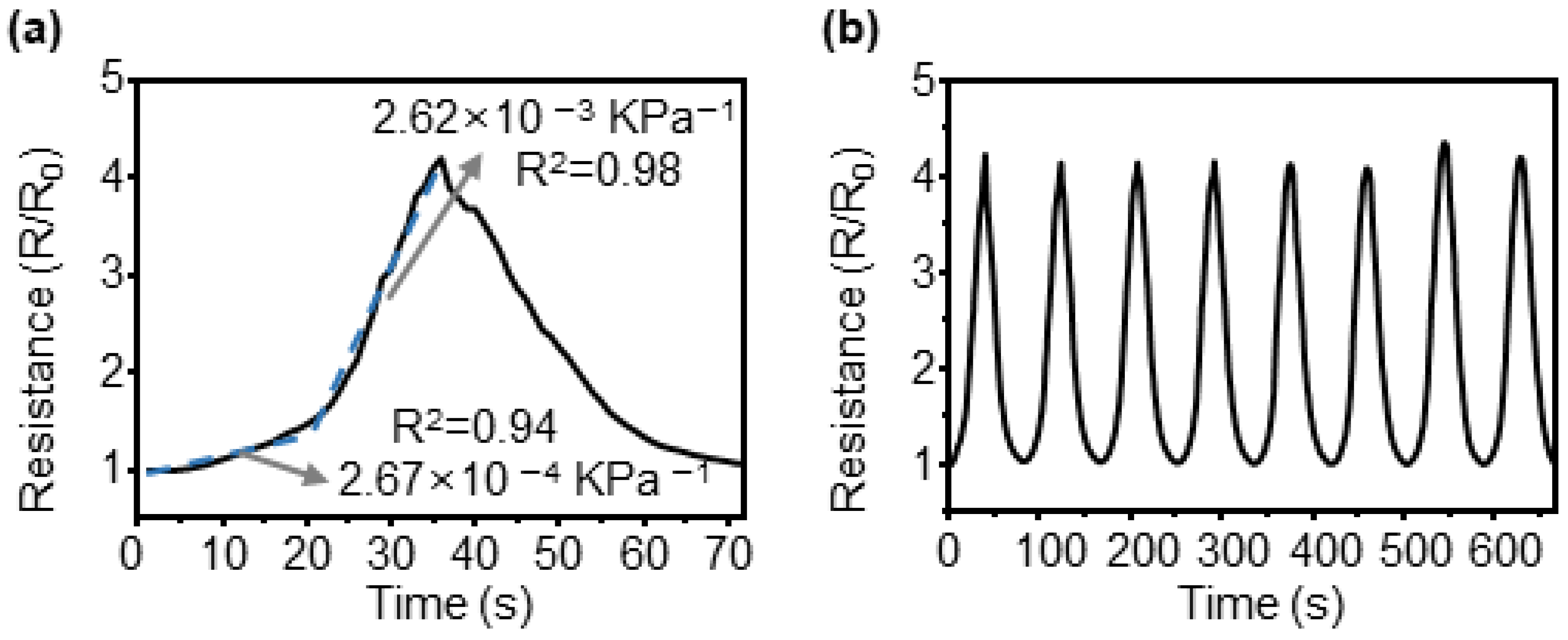

3.4. Characterization of the CBS for Pressure Sensing

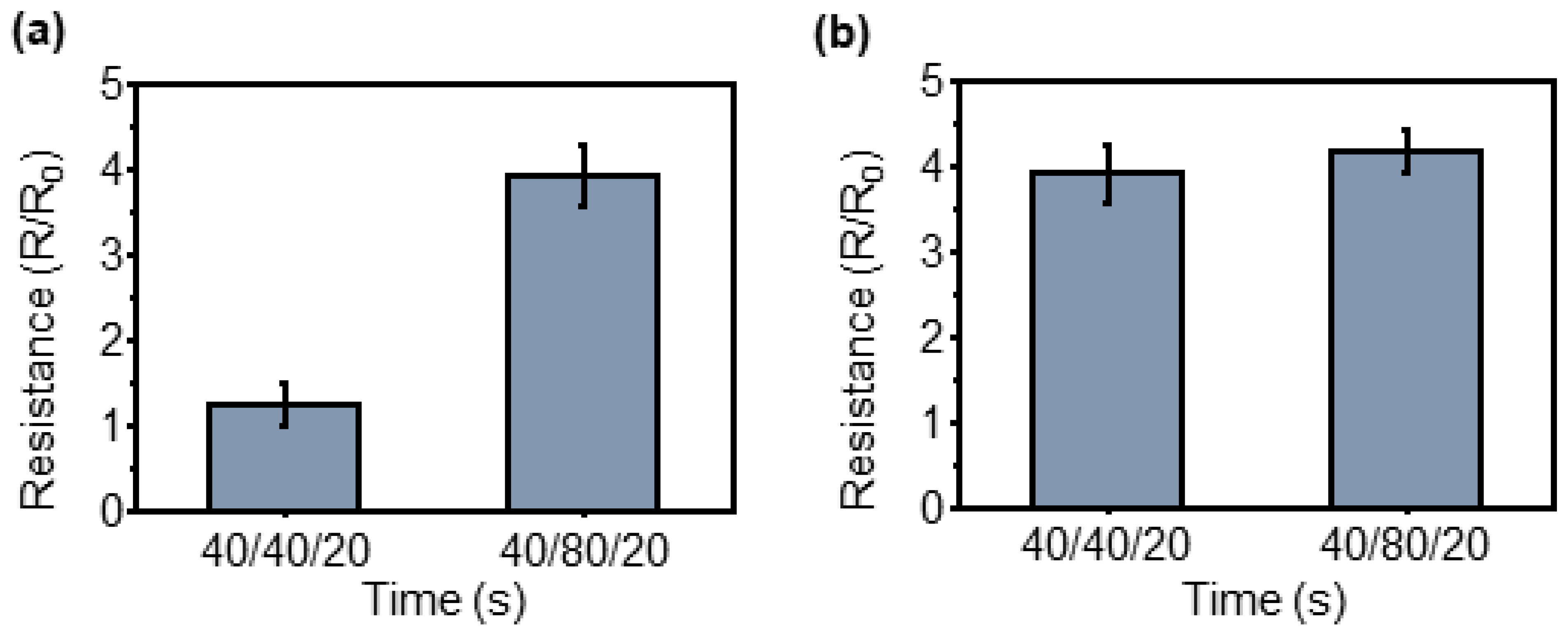

3.5. Sensitivity Comparison Owing to Micropillar Pattern Changes

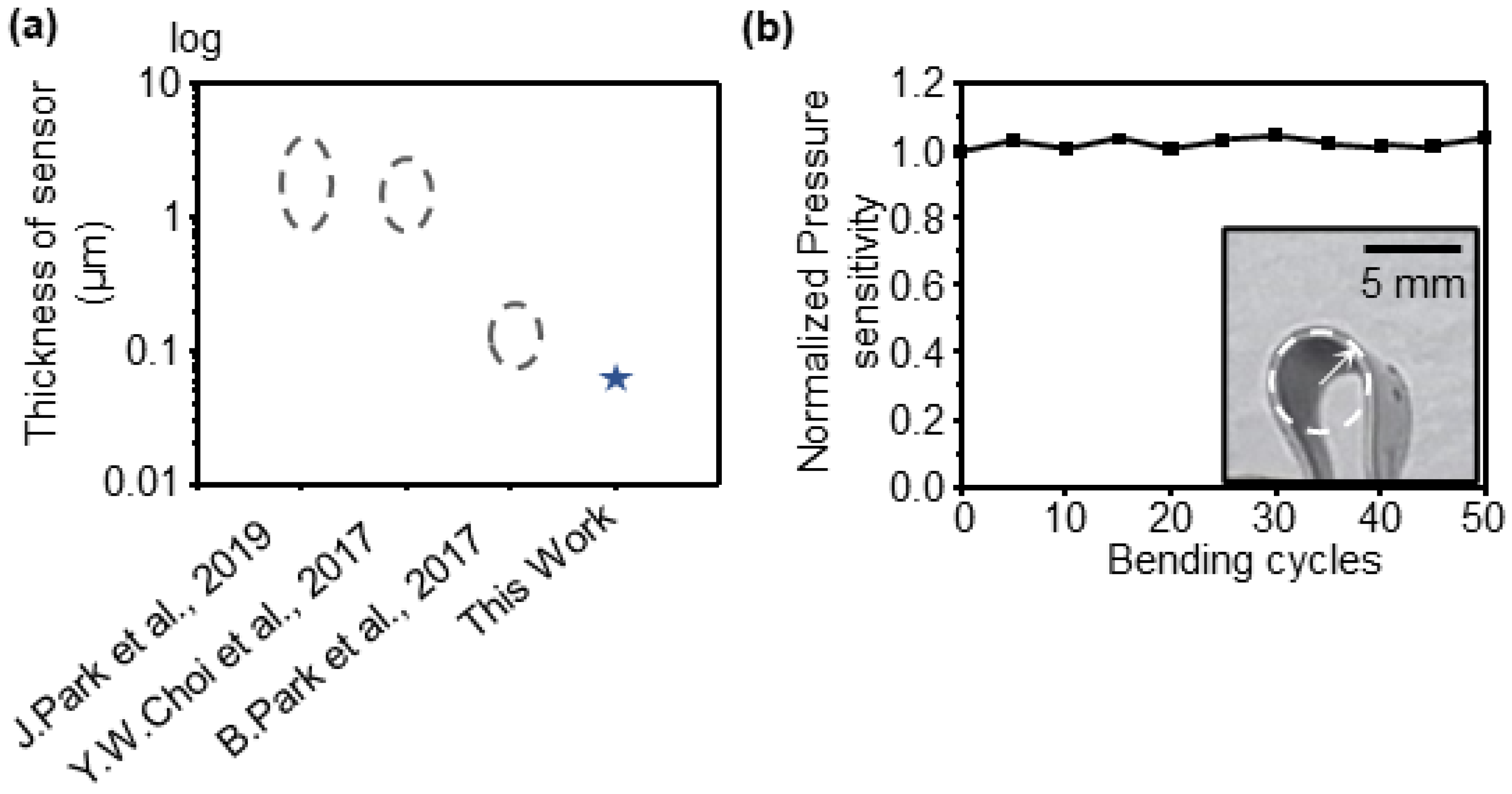

3.6. Thickness Comparison of the Sensor and Bending Test

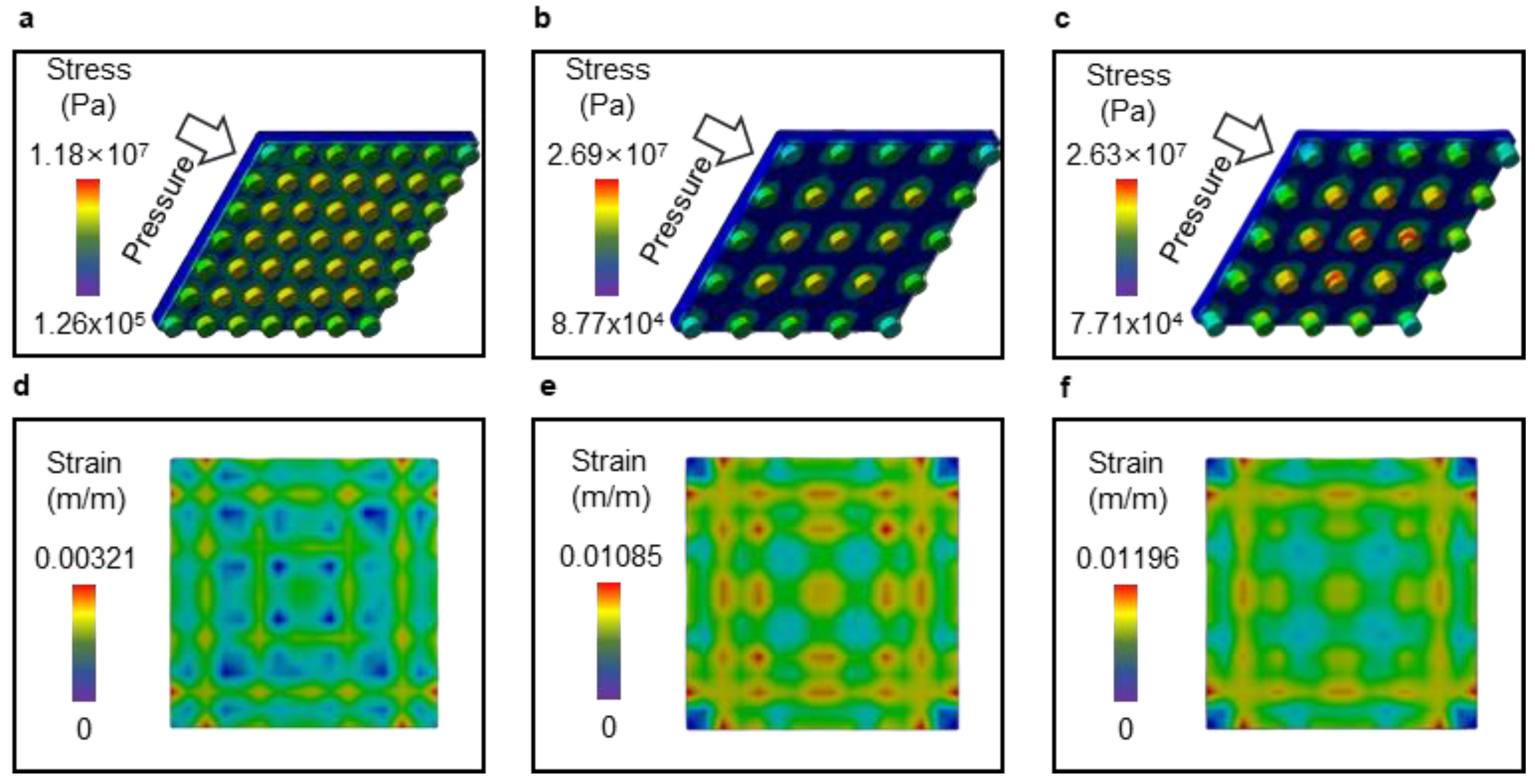

3.7. FEM Simulation Analysis of the Effect of Micropillar Pattern Array Variation

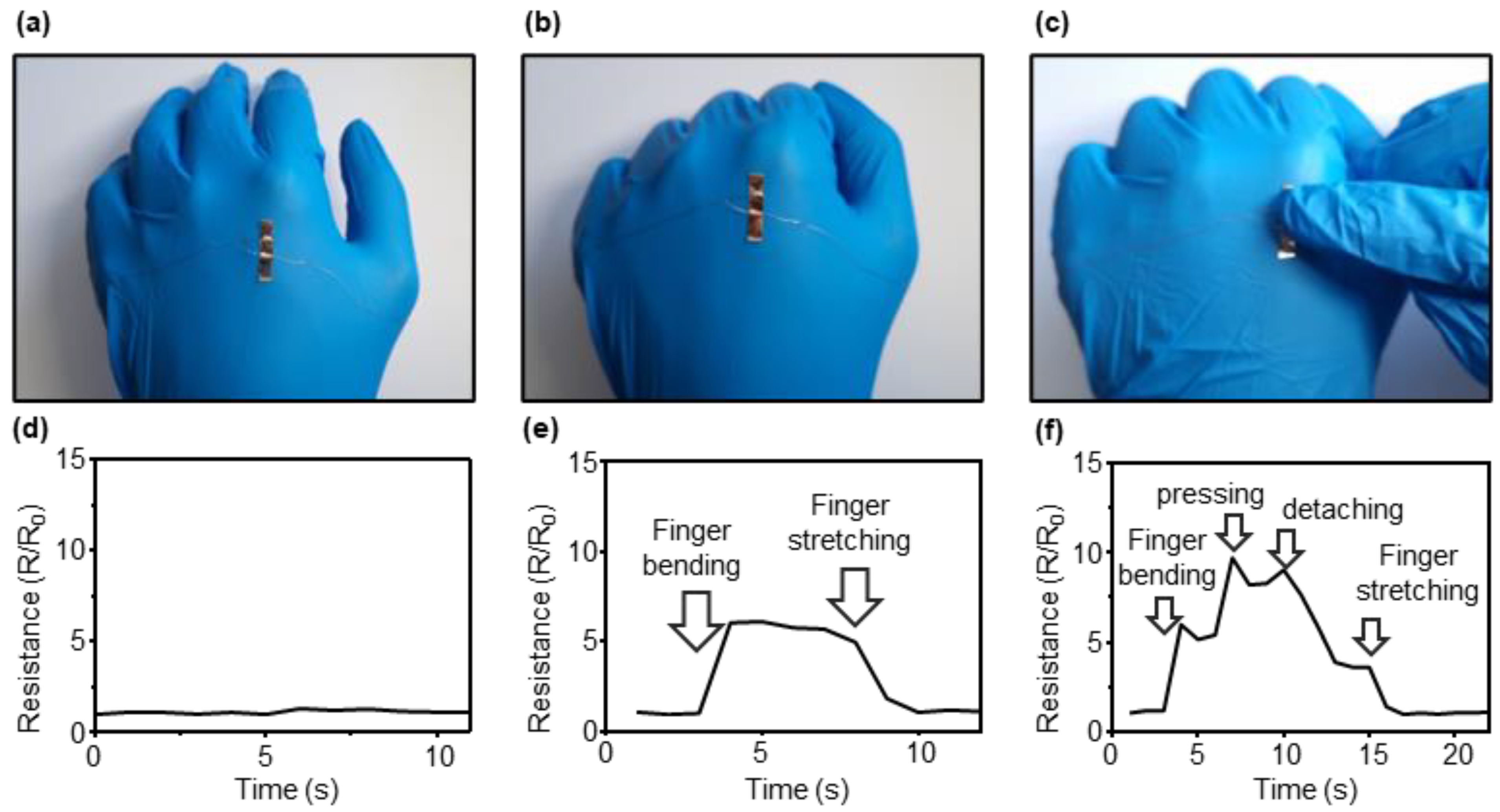

3.8. Applications

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, D.H.; Ghaffari, R.; Lu, N.; Rogers, J.A. Flexible and stretchable electronics for biointegrated devices. Annu. Rev. Biomed. Eng. 2012, 14, 113–128. [Google Scholar] [CrossRef] [PubMed]

- Lim, H.R.; Kim, H.S.; Qazi, R.; Kwon, Y.T.; Jeong, J.W.; Yeo, W.H. Advanced soft materials, sensor integrations, and applications of wearable flexible hybrid electronics in healthcare, energy, and environment. Adv. Mater. 2020, 32, 1901924. [Google Scholar] [CrossRef] [PubMed]

- Jang, H.; Park, Y.J.; Chen, X.; Das, T.; Kim, M.S.; Ahn, J.H. Graphene-based flexible and stretchable electronics. Adv. Mater. 2016, 28, 4184–4202. [Google Scholar] [CrossRef] [PubMed]

- Wu, M.; Luo, J. Wearable technology applications in healthcare: A literature review. Online J. Nurs. Inform. 2019, 23. [Google Scholar]

- Patel, S.; Park, H.; Bonato, P.; Chan, L.; Rodgers, M. A review of wearable sensors and systems with application in rehabilitation. J. Neuroeng. Rehabil. 2012, 9, 1–17. [Google Scholar] [CrossRef]

- Zahid, M.; Zych, A.; Dussoni, S.; Spallanzani, G.; Donno, R.; Maggiali, M.; Athanassiou, A. Wearable and self-healable textile-based strain sensors to monitor human muscular activities. Compos. Part B Eng. 2021, 220, 108969. [Google Scholar] [CrossRef]

- Jones, L.; Deo, N.; Lockyer, B. Wireless physiological sensor system for ambulatory use. In Proceedings of the International Workshop on Wearable and Implantable Body Sensor Networks (BSN’06), Cambridge, MA, USA, 3–5 April 2006; IEEE: Piscataway, NJ, USA, 2006; p. 4. [Google Scholar]

- Yang, T.; Jiang, X.; Zhong, Y.; Zhao, X.; Lin, S.; Li, J.; Li, X.; Xu, J.; Li, Z.; Zhu, H. A wearable and highly sensitive graphene strain sensor for precise home-based pulse wave monitoring. ACS Sens. 2017, 2, 967–974. [Google Scholar] [CrossRef]

- Fu, W.; Sun, L.; Cao, H.; Chen, L.; Zhou, M.; Shen, S.; Zhu, Y.; Zhuang, S. Qualitative and quantitative recognition of volatile organic compounds in their liquid phase based on terahertz microfluidic EIT meta-sensors. IEEE Sens. J. 2023, 1. [Google Scholar] [CrossRef]

- Chen, H.; Li, S. Multi-sensor fusion by CWT-PARAFAC-IPSO-SVM for intelligent mechanical fault diagnosis. Sensors 2022, 22, 3647. [Google Scholar] [CrossRef]

- Chen, H.; Xiong, Y.; Li, S.; Song, Z.; Hu, Z.; Liu, F. Multi-sensor data driven with PARAFAC-IPSO-PNN for identification of mechanical nonstationary multi-fault mode. Machines 2022, 10, 155. [Google Scholar] [CrossRef]

- Huang, K.; Xu, Q.; Ying, Q.; Gu, B.; Yuan, W. Wireless strain sensing using carbon nanotube composite film. Compos. Part B Eng. 2023, 256, 110650. [Google Scholar] [CrossRef]

- Hou, X.; Zhang, L.; Su, Y.; Gao, G.; Liu, Y.; Na, Z.; Xu, Q.; Ding, T.; Xiao, L.; Li, L.; et al. A space crawling robotic bio-paw (SCRBP) enabled by triboelectric sensors for surface identification. Nano Energy 2023, 105, 108013. [Google Scholar] [CrossRef]

- Liu, B.; Peng, Y.; Jin, Z.; Wu, X.; Gu, H.; Wei, D.; Zhu, Y.; Zhuang, S. Terahertz ultrasensitive biosensor based on wide-area and intense light-matter interaction supported by QBIC. Chem. Eng. J. 2023, 462, 142347. [Google Scholar] [CrossRef]

- Jian, M.; Xia, K.; Wang, Q.; Yin, Z.; Wang, H.; Wang, C.; Xie, H.; Zhang, M.; Zhang, Y. Flexible and highly sensitive pressure sensors based on bionic hierarchical structures. Adv. Funct. Mater. 2017, 27, 1606066. [Google Scholar] [CrossRef]

- Wu, P.; Xiao, A.; Zhao, Y.; Chen, F.; Ke, M.; Zhang, Q.; Zhang, J.; Shi, X.; He, X.; Chen, Y. An implantable and versatile piezoresistive sensor for the monitoring of human–machine interface interactions and the dynamical process of nerve repair. Nanoscale 2019, 11, 21103–21118. [Google Scholar] [CrossRef]

- Gong, S.; Schwalb, W.; Wang, Y.; Chen, Y.; Tang, Y.; Si, J.; Shirinzadeh, B.; Cheng, W. A wearable and highly sensitive pressure sensor with ultrathin gold nanowires. Nat. Commun. 2014, 5, 3132. [Google Scholar] [CrossRef]

- Yu, J.; Hou, X.; Cui, M.; Shi, S.; He, J.; Sun, Y.; Wang, C.; Chou, X. Flexible PDMS-based triboelectric nanogenerator for instantaneous force sensing and human joint movement monitoring. Sci. China Mater. 2019, 62, 1423–1432. [Google Scholar] [CrossRef]

- Yu, P.; Liu, W.; Gu, C.; Cheng, X.; Fu, X. Flexible piezoelectric tactile sensor array for dynamic three-axis force measurement. Sensors 2016, 16, 819. [Google Scholar] [CrossRef]

- Park, K.-I.; Son, J.H.; Hwang, G.-T.; Jeong, C.K.; Ryu, J.; Koo, M.; Choi, I.; Lee, S.H.; Byun, M.; Wang, Z.L.; et al. Highly-efficient, flexible piezoelectric PZT thin film nanogenerator on plastic substrates. Adv. Mater. 2014, 26, 2514–2520. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, Z.; Li, X.; Lin, Y.; Luo, N.; Long, M.; Zhao, N.; Xu, J.-B. Flexible piezoelectric-induced pressure sensors for static measurements based on nanowires/graphene heterostructures. Acs Nano 2017, 11, 4507–4513. [Google Scholar] [CrossRef]

- Hu, W.; Zhang, C.; Wang, Z.L. Recent progress in piezotronics and tribotronics. Nanotechnology 2018, 30, 042001. [Google Scholar] [CrossRef] [PubMed]

- Zhong-Hua, Z.; Bao-Yuan, S.U.N.; Min, Q. Influence of Multiple Piezoelectric Effects on Static Performance of Piezoelectric Sensors. Piezoelectr. Acoustoopt. 2009, 31, 360–363. [Google Scholar]

- Li, T.; Luo, H.; Qin, L.; Wang, X.; Xiong, Z.; Ding, H.; Gu, Y.; Liu, Z.; Zhang, T. Flexible capacitive tactile sensor based on micropatterned dielectric layer. Small 2016, 12, 5042–5048. [Google Scholar] [CrossRef] [PubMed]

- Heikenfeld, J.; Jajack, A.; Rogers, J.; Gutruf, P.; Tian, L.; Pan, T.; Li, R.; Khine, M.; Kim, J.; Wang, J.; et al. Wearable sensors: Modalities, challenges, and prospects. Lab Chip 2018, 18, 217–248. [Google Scholar] [CrossRef]

- Yang, J.; Luo, S.; Zhou, X.; Li, J.; Fu, J.; Yang, W.; Wei, D. Flexible, tunable, and ultrasensitive capacitive pressure sensor with microconformal graphene electrodes. ACS Appl. Mater. Interfaces 2019, 11, 14997–15006. [Google Scholar] [CrossRef]

- Fan, F.R.; Tian, Z.Q.; Wang, Z.L. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Liu, Z.; Li, H.; Shi, B.; Fan, Y.; Wang, Z.L.; Li, Z. Wearable and implantable triboelectric nanogenerators. Adv. Funct. Mater. 2019, 29, 1808820. [Google Scholar] [CrossRef]

- Liu, Z.; Ma, Y.; Ouyang, H.; Shi, B.; Li, N.; Jiang, D.; Li, Z. Transcatheter self-powered ultrasensitive endocardial pressure sensor. Adv. Funct. Mater. 2019, 29, 1807560. [Google Scholar] [CrossRef]

- Iqra, M.; Anwar, F.; Jan, R.; Mohammad, M.A. A flexible piezoresistive strain sensor based on laser scribed graphene oxide on polydimethylsiloxane. Sci. Rep. 2022, 12, 4882. [Google Scholar] [CrossRef]

- Kang, D.; Pikhitsa, P.V.; Choi, Y.W.; Lee, C.; Shin, S.S.; Piao, L.; Park, B.; Suh, K.Y.; Kim, T.I.; Choi, M. Ultrasensitive mechanical crack-based sensor inspired by the spider sensory system. Nature 2014, 516, 222–226. [Google Scholar] [CrossRef]

- Park, B.; Kim, J.; Kang, D.; Jeong, C.; Kim, K.S.; Kim, J.U.; Yoo, P.J.; Kim, T.I. Dramatically enhanced mechanosensitivity and signal-to-noise ratio of nanoscale crack-based sensors: Effect of crack depth. Adv. Mater. 2016, 28, 8130. [Google Scholar] [CrossRef]

- Wang, S.; Xiao, P.; Liang, Y.; Zhang, J.; Huang, Y.; Wu, S.; Kuo, S.W.; Chen, T. Network cracks-based wearable strain sensors for subtle and large strain detection of human motions. J. Mater. Chem. C 2018, 6, 5140. [Google Scholar] [CrossRef]

- Lee, J.; Kim, S.; Lee, J.; Yang, D.; Park, B.C.; Ryu, S.; Park, I. A stretchable strain sensor based on a metal nanoparticle thin film for human motion detection. Nanoscale 2014, 6, 11932–11939. [Google Scholar] [CrossRef]

- Li, P.; Zhao, Y.; Ma, J.; Yang, Y.; Xu, H.; Liu, Y. Facile fabrication of ultraflexible transparent electrodes using embedded copper networks for wearable pressure sensors. Adv. Mater. Technol. 2020, 5, 1900823. [Google Scholar] [CrossRef]

- Guo, Y.; Guo, Z.; Zhong, M.; Wan, P.; Zhang, W.; Zhang, L. A flexible wearable pressure sensor with bioinspired microcrack and interlocking for full-range human–machine interfacing. Small 2018, 14, 1803018. [Google Scholar] [CrossRef]

- Hua, Q.; Liu, H.; Zhao, J.; Peng, D.; Yang, X.; Gu, L.; Pan, C. Bioinspired Electronic Whisker Arrays by Pencil-Drawn Paper for Adaptive Tactile Sensing. Adv. Electron. Mater. 2016, 2, 1600093. [Google Scholar] [CrossRef]

- Liu, X.; Zhu, Y.; Nomani, M.W.; Wen, X.; Hsia, T.Y.; Koley, G. A highly sensitive pressure sensor using a Au-patterned polydimethylsiloxane membrane for biosensing applications. J. Micromech. Microeng. 2013, 23, 025022. [Google Scholar] [CrossRef]

- Shi, J.; Li, H.; Sun, B.; Zhao, X.; Ding, G.; Yang, Z. A flexible pressure sensor based on low-cost electroplated-Ni film induced cracking for wearable devices application. In Proceedings of the 2018 IEEE 13th Annual International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Singapore, 22–26 April 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 432–435. [Google Scholar]

- Won, C.; Lee, S.; Jung, H.H.; Woo, J.; Yoon, K.; Lee, J.; Kwon, C.; Lee, M.; Han, H.; Mei, Y.; et al. Ultrasensitive and Stretchable Conductive Fibers Using Percolated Pd Nanoparticle Networks for Multisensing Wearable Electronics: Crack-Based Strain and H2 Sensors. ACS Appl. Mater. Interfaces 2020, 12, 45243–45253. [Google Scholar] [CrossRef]

- Sarkar, B.; Satapathy, D.K.; Jaiswal, M. Nanostructuring mechanical cracks in a flexible conducting polymer thin film for ultra-sensitive vapor sensing. Nanoscale 2019, 11, 200–210. [Google Scholar] [CrossRef]

- Wang, Q.; Tong, J.; Wang, N.; Chen, S.; Sheng, B. Humidity sensor of tunnel-cracked nickel@ polyurethane sponge for respiratory and perspiration sensing. Sens. Actuators B Chem. 2021, 330, 129322. [Google Scholar] [CrossRef]

- Yu, Y.; Peng, S.; Blanloeuil, P.; Wu, S.; Wang, C.H. Wearable temperature sensors with enhanced sensitivity by engineering microcrack morphology in PEDOT: PSS–PDMS sensors. ACS Appl. Mater. Interfaces 2020, 12, 36578–36588. [Google Scholar] [CrossRef] [PubMed]

- Luo, C.; Jia, J.; Gong, Y.; Wang, Z.; Fu, Q.; Pan, C. Highly sensitive, durable, and multifunctional sensor inspired by a spider. ACS Appl. Mater. Interfaces 2017, 9, 19955–19962. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Ma, Z.; Wu, Z.; Peng, L.; Su, B. Magnetic-Sensitive Crack Sensor with Ultrahigh Sensitivity at Room Temperature by Depositing Graphene Nanosheets upon a Flexible Magnetic Film. Adv. Electron. Mater. 2021, 7, 2100335. [Google Scholar] [CrossRef]

- Park, J.; Kim, M.; Hong, I.; Kim, T.; Lee, E.; Kim, E.-A.; Ryu, J.-K.; Jo, Y.; Koo, J.; Han, S.; et al. Foot plantar pressure measurement system using highly sensitive crack-based sensor. Sensors 2019, 19, 5504. [Google Scholar] [CrossRef]

- Choi, Y.W.; Kang, D.; Pikhitsa, P.V.; Lee, T.; Kim, S.M.; Lee, G.; Tahk, D.; Choi, M. Ultra-sensitive pressure sensor based on guided straight mechanical cracks. Sci. Rep. 2017, 7, 40116. [Google Scholar] [CrossRef]

- Park, B.; Lee, Y.; Jung, W.; Scott, D.K.; Aalto, D.; Chung, H.J.; Kim, T.I. Deterministically assigned directional sensing of a nanoscale crack based pressure sensor by anisotropic Poisson ratios of the substrate. J. Mater. Chem. C 2021, 9, 5154–5161. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, N.; Yun, D.; Hwang, I.; Yoon, G.; Kang, S.M.; Choi, Y.W. Crack-Based Sensor with Microstructures for Strain and Pressure Sensing. Sensors 2023, 23, 5545. https://doi.org/10.3390/s23125545

Kim N, Yun D, Hwang I, Yoon G, Kang SM, Choi YW. Crack-Based Sensor with Microstructures for Strain and Pressure Sensing. Sensors. 2023; 23(12):5545. https://doi.org/10.3390/s23125545

Chicago/Turabian StyleKim, Nakung, Daegeun Yun, Injoo Hwang, Gibaek Yoon, Seong Min Kang, and Yong Whan Choi. 2023. "Crack-Based Sensor with Microstructures for Strain and Pressure Sensing" Sensors 23, no. 12: 5545. https://doi.org/10.3390/s23125545

APA StyleKim, N., Yun, D., Hwang, I., Yoon, G., Kang, S. M., & Choi, Y. W. (2023). Crack-Based Sensor with Microstructures for Strain and Pressure Sensing. Sensors, 23(12), 5545. https://doi.org/10.3390/s23125545