Methods of Passenger Ride Comfort Evaluation—Tests for Metro Cars

Abstract

:1. Introduction

2. Literature Review

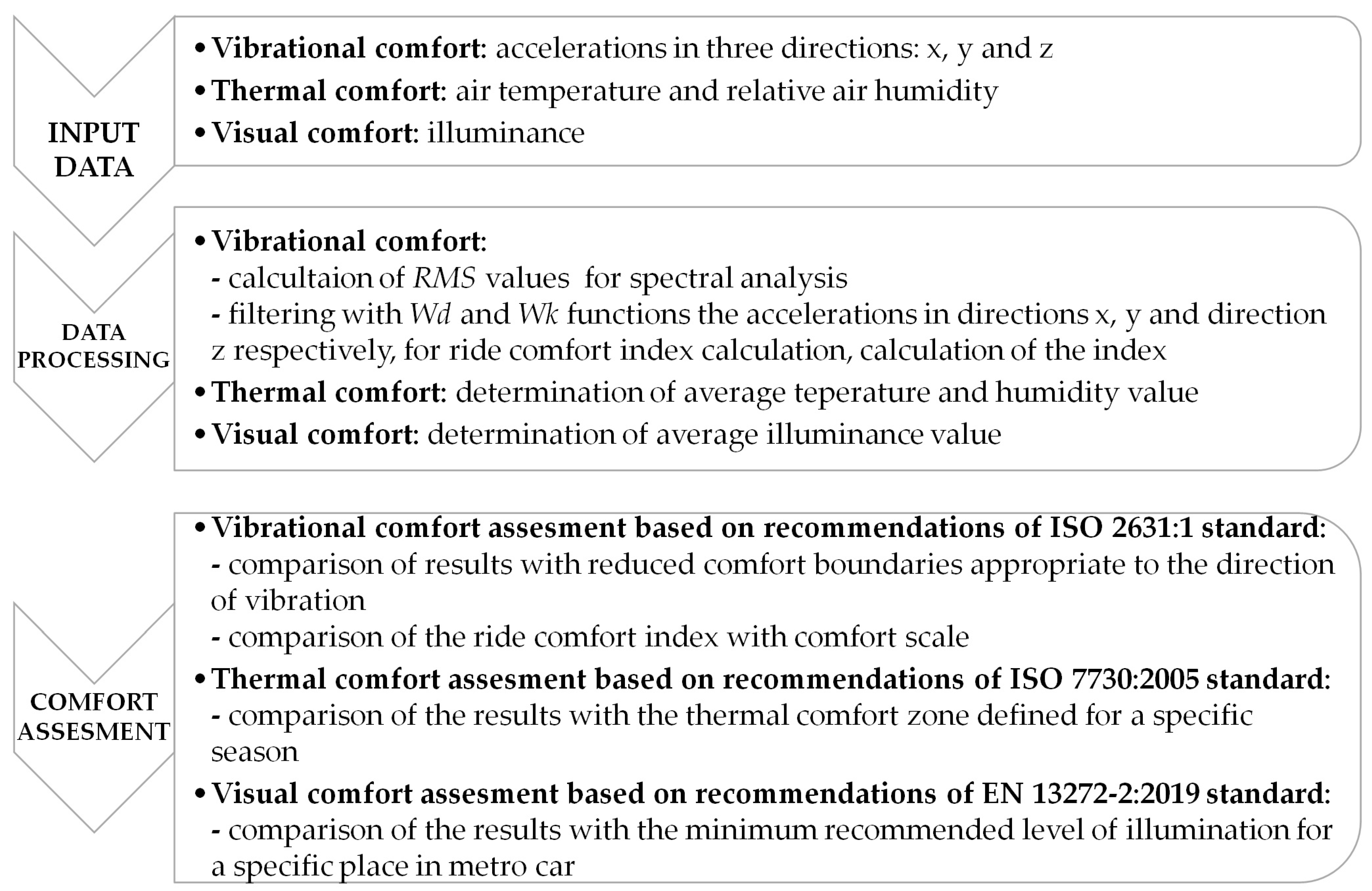

3. Methods for Ride Comfort Assessment

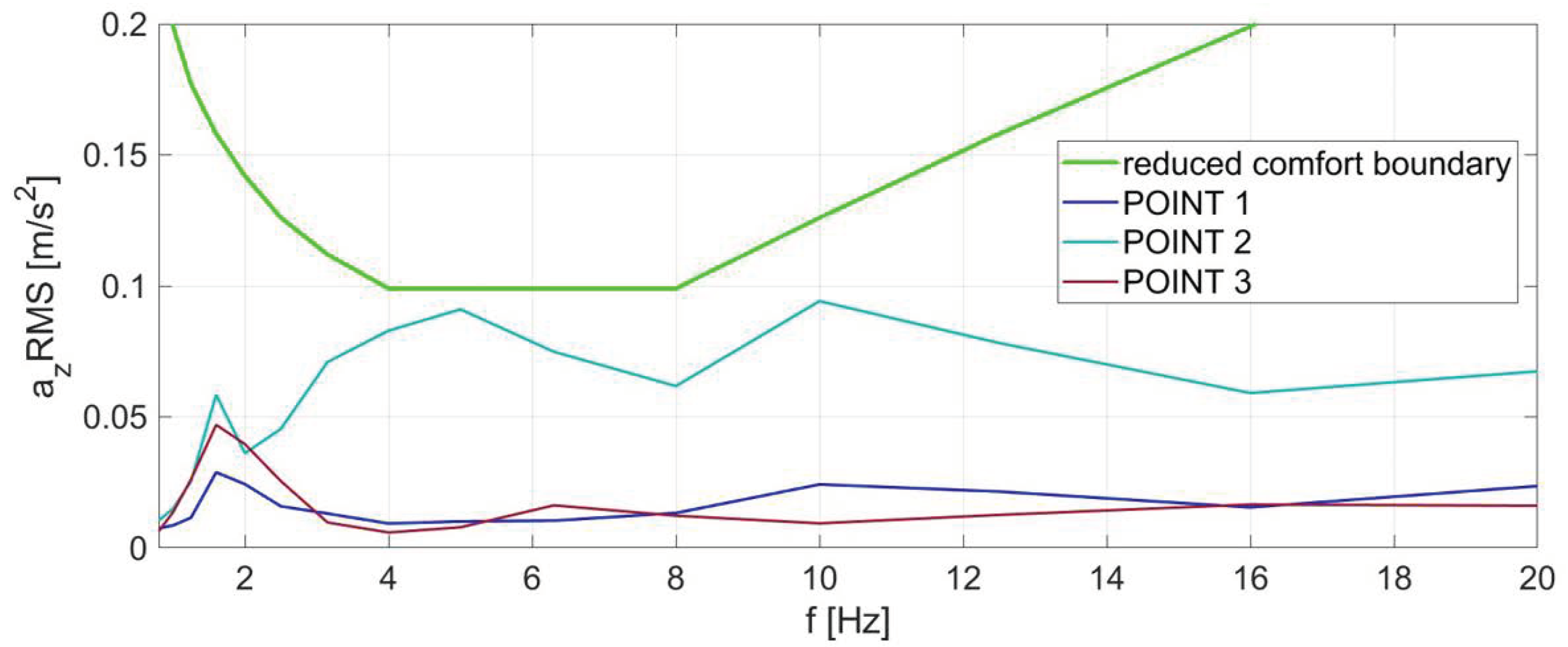

3.1. Mechanical Vibration

- —weight function depending on the center frequency of the one-third octave bands ranging from 0.8 Hz to 80 Hz (n—number of the bands),

- —RMS values of vibration acceleration in the consecutive one-third octave bands in direction X or Y, respectively.

- —averaged RMS value of vibration acceleration for the transverse direction of vibration propagation.

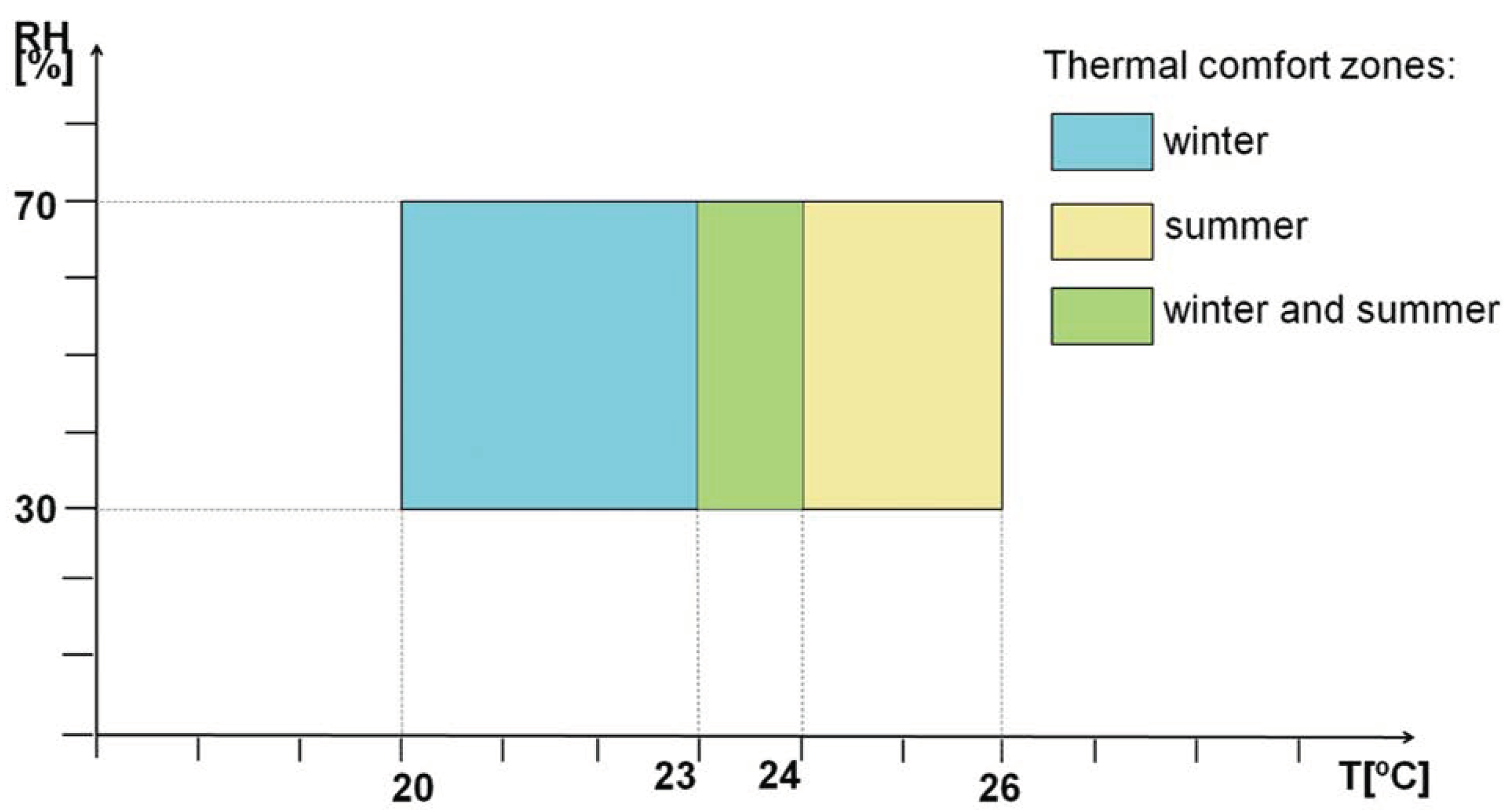

3.2. Air Temperature and Relative Humidity

3.3. Lighting

4. Experimental Research

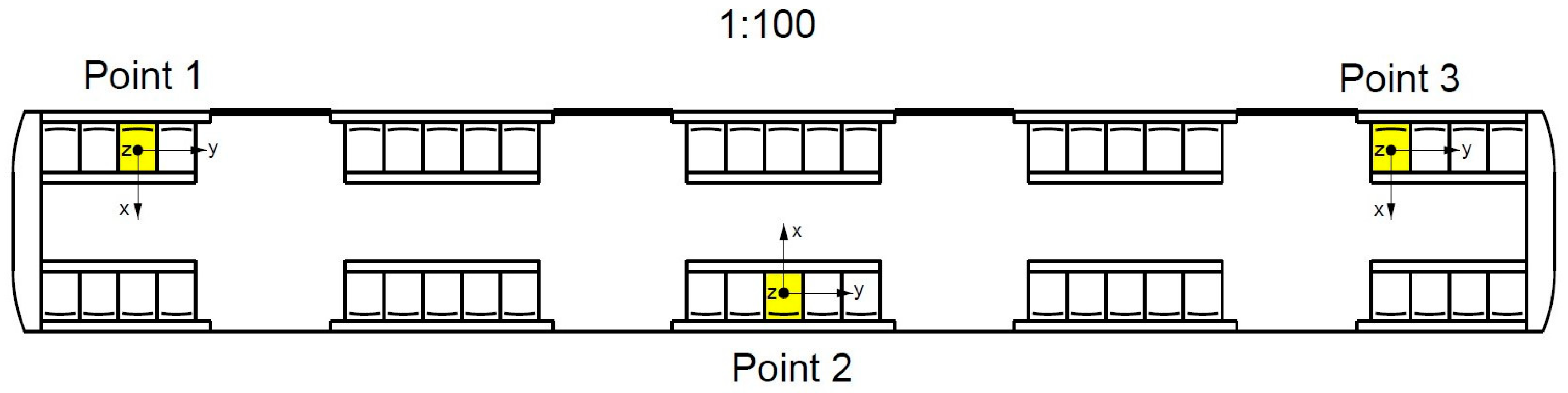

4.1. Description of the Test

4.2. Measuring Equipment

- temperature sensor FXPQ3115 by NXP, with measurement range from −40 to 80 °C, resolution 0.01 °C, and sampling rate up to 10 Hz,

- air humidity sensor HTU21D by MEAS, with measurement range from 0 to 100%, resolution 0.04%, and sampling rate up to 10 Hz,

- illuminance sensor SI1133 by Silicon Labs, with resolution less than 100 mlx, and sampling rate up to 4 Hz.

5. Analysis of the Test Results

5.1. Vibration Comfort Test Results

5.2. Thermal Comfort

5.3. Visual Comfort

6. Summary and Conclusions

- Based on the ride comfort indicators determined by the weighted method, it can be stated that the tested metro car provides “comfortable” conditions, with the lowest synthetic comfort index of 0.111 m/s2 for the first measuring point located at the end of the wagon, and a slightly higher value of 0.113 m/s2 at the front of the wagon. The indicators for the measuring points located at the front and rear of the vehicle reach the lowest values. Slightly worse conditions due to the impact of vibrations are provided by the central part of the vehicle with a rating of “slightly uncomfortable”. The results of the weighted components of effective vibration acceleration indicate the greatest impact of vertical vibration on lower ride comfort level.

- Similar conclusions about vibration comfort can be drawn from a spectral analysis of vibration accelerations. The RMS values of vibration accelerations in the one-third octave bands calculated based on the measured accelerations in the subway car indicate the possibility of lowering the comfort level only in the central part of the vehicle (second measuring point). Exceedances of the reduced comfort boundary occurred only in the case of lateral and longitudinal vibration in the middle frequencies of the one-third octave bands of 1.6 Hz and 2.5 Hz. In these bands, the boundary is 0.070 m/s2 and 0.088 m/s2, respectively. The obtained results are 0.075 m/s2 and 0.110 m/s2. The results for transverse vibration showed overrun in the band with the middle frequency of 1.6 Hz with the RMS value of 0.12 m/s2 and the same boundary as for longitudinal vibration. The vertical vibration did not contribute to passenger discomfort. Given the above, the overall vibration comfort in the tested metro car is at a good level. Particular attention should be paid to low frequency vibration.

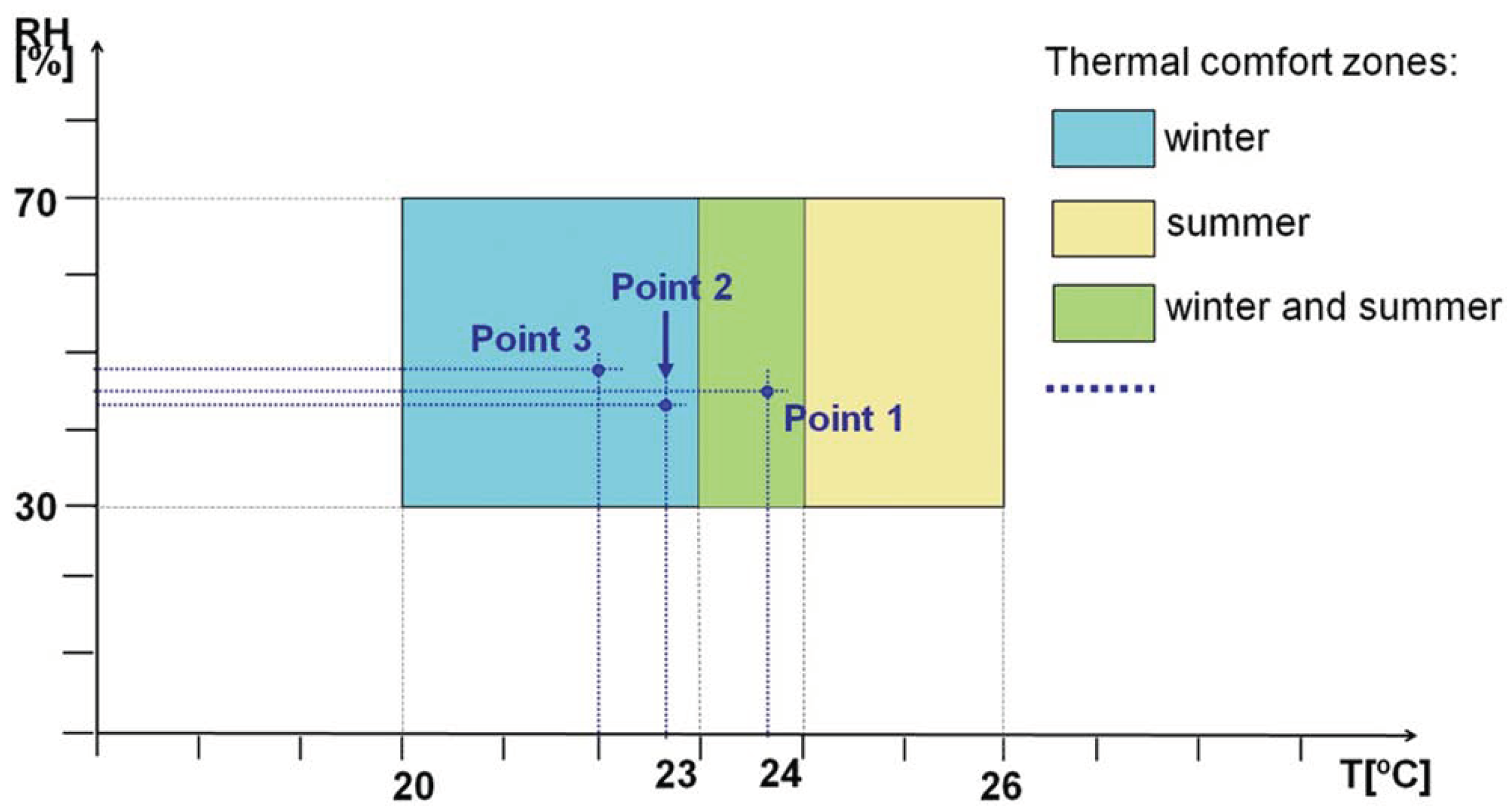

- At every measuring point, passengers were provided with good thermal comfort. The average air temperatures in the wagon ranged from 22.0 °C to 23.6 °C, with the highest temperature at the front part of the wagon (first measuring point). In the case of average values of relative air humidity, larger differences in results were observed. The lowest value of 42.2% was recorded in the center of the wagon, i.e., at the second measuring point. The highest average air humidity was measured at the end of the wagon with the value of 47.1%. The thermal comfort zone defined for winter defines the recommended air temperatures in the range of 20 °C to 24 °C and relative air humidity in the range of 30% to 70%, regardless of the season. Although the average values of air temperature and relative humidity vary depending on the vehicle’s passenger seat, the results fall within the thermal comfort zone. It should be noted that thermal comfort also consists of other factors related to the environment as well as to the individual characteristics of people and their clothing or activity. A more detailed assessment of this type of comfort is recommended especially in areas with demanding climatic conditions.

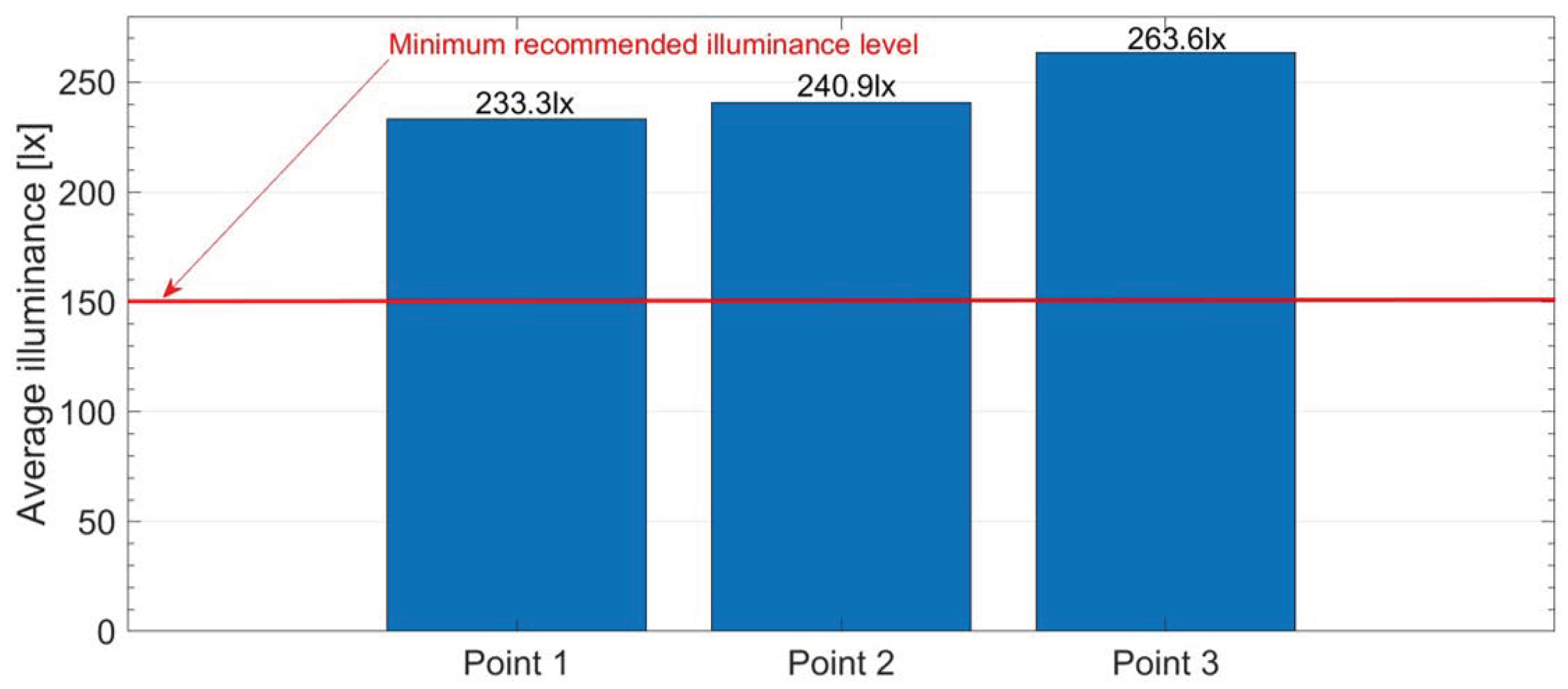

- Illuminance measurements indicate satisfactory visual comfort conditions in the subway car. The average results ranged from 233.3 lx to 263.3 lx, with the highest value recorded at the third measuring point. The minimum requirements of the EN 13272-2:2019 standard [44], which for seating and standing areas should be at least 150 lx, were met in the tested metro car. The lighting environment in the tested metro car shall be sufficient to perform simple visual tasks such as reading. It should be noted, however, that the recommended value of the illuminance level in the standard should only be the initial starting point for comparing lighting conditions in different rail vehicles because the standard does not directly specify the threshold for the sake of comfort.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Passenger Transport. Statistical Portal of the Office of Rail Transport (In Polish). Available online: https://dane.utk.gov.pl/sts/przewozy-pasazerskie/dane-eksploatacyjne/19890,Przewozy-pasazerskie.html (accessed on 15 March 2023).

- Jacyna-Gołda, I.; Gołębiowski, P.; Izdebski, M.; Kłodawski, M.; Jachimowski, R.; Szczepański, E. The evaluation of the sustainable transport system development with the scenario analyses procedure. J. Vibroeng. 2017, 19, 5627–5638. [Google Scholar] [CrossRef] [Green Version]

- EN 13816:2002; Transportation—Logistics and Services—Public Passenger Transport—Service Quality Definition, Targeting and Measurement. European Committee for Standarization: Brussels, Belgium, 2002.

- Kardas-Cinal, E. Statistical Method for Investigating Transient Enhancements of Dynamical Responses due to Random Disturbances: Application to Railway Vehicle Motion. ASME. J. Vib. Acoust. 2020, 142, 061008. [Google Scholar] [CrossRef]

- Zhou, Y.; Chen, S. Vehicle ride comfort analysis with whole-body vibration on long-span bridges subjected to crosswind. J. Wind Eng. Ind. Aerodyn. 2016, 155, 126–140. [Google Scholar] [CrossRef] [Green Version]

- ISO 2631-1:1985 and 1997; Mechanical Vibration and Shock-Evaluation of Human Exposure to Whole-Body Vibration, Part 1: General Requirements. International Organization for Standarization: Genever, Switzerland, 1997.

- Wawryszczuk, R.; Kardas-Cinal, E. Analysis of ride comfort in selected types of rail vehicles. J. KONBiN 2021, 51, 157–183. [Google Scholar] [CrossRef]

- Sekulić, D.; Dedović, V.; Rusov, S.; Obradović, A.; Šalinić, S. Definition and determination of the bus oscillatory comfort zones. Int. J. Ind. Ergon. 2016, 53, 328–339. [Google Scholar] [CrossRef]

- Kırbaş, U.; Karaşahin, M. Discomfort limits provided by railroad crossings to passenger cars. Int. J. Pavement Eng. 2021, 1–12. [Google Scholar] [CrossRef]

- Wu, J.; Qiu, Y. Analysis of ride comfort of the high-speed train based on a train-seat-human model in the vertical direction. Veh. Syst. Dyn. 2021, 59, 1867–1893. [Google Scholar] [CrossRef]

- Bakinowski, Ł.; Firlik, B. Influence of the type of place a tram passenger occupies on the ride comfort. Arch. Transp. 2022, 62, 49–58. [Google Scholar] [CrossRef]

- EN 12299:2009; Railway Applications—Ride Comfort for Passengers—Measurement and Evaluation. European Committee of the Regions: Brussels, Belgium, 2009.

- Ján, D.; Miroslav, B.; Juraj, G.; Leitner, B.; Melnik, R.; Semenov, S.; Mikhailov, E.; Kostrzewski, M. Evaluation of Ride Comfort in a Railway Passenger Car Depending on a Change of Suspension Parameters. Sensors 2021, 21, 8139. [Google Scholar] [CrossRef]

- Park, J.; Lee, J.; Ahn, S.; Jeong, W. Reduced ride comfort caused by beating idle vibrations in passenger vehicles. Int. J. Ind. Ergon. 2017, 57, 74–79. [Google Scholar] [CrossRef]

- Huang, Y.U.; Li, D. Subjective discomfort model of the micro commercial vehicle vibration over different road conditions. Appl. Acoust. 2019, 145, 385–392. [Google Scholar] [CrossRef]

- Barone, V.; Mongelli, D.W.E.; Tassitani, A. Vibrational comfort on board the vehicle: Influence of speed bumps and comparison between different categories of vehicle. Adv. Acoust. Vib. 2016, 2016, 2676021. [Google Scholar] [CrossRef] [Green Version]

- Kardas-Cinal, E. Analysis of the ride comfort of a rail vehicle passenger—A proposal for an indicator depending on vibration frequency. In Selected Issues of Testing Dynamic Interactions in Rail Transport; Kardas-Cinal, E., Korzeb, J., Eds.; Oficyna Wydawnicza Politechniki Warszawskiej: Warsaw, Poland, 2017; pp. 84–91. (In Polish) [Google Scholar]

- Moon, J.H.; Lee, J.W.; Jeong, C.H.; Lee, S.H. Thermal comfort analysis in a passenger compartment considering the solar radiation effect. Int. J. Therm. Sci. 2016, 107, 77–88. [Google Scholar] [CrossRef]

- Yakovenko, Y.; Voichyshyn, Y.; Horbay, O. Analysis of thermal comfort models of users of public urban and intercity transport. Ukr. J. Mech. Eng. Mater. Sci. 2022, 8, 67–74. [Google Scholar] [CrossRef]

- Danca, P.; Vartires, A.; Dogeanu, A. An overview of current methods for thermal comfort assessment in vehicle cabin. Energy Procedia 2016, 85, 162–169. [Google Scholar] [CrossRef] [Green Version]

- Hintea, D.; Kemp, J.; Brusey, J.; Gaura, E.; Beloe, N. Applicability of thermal comfort models to car cabin environments. In Proceedings of the 2014 11th International Conference on Informatics in Control, Automation and Robotics (ICINCO), Vienna, Austria, 1–3 September 2014. [Google Scholar] [CrossRef]

- Pala, U.; Oz, H.R. An investigation of thermal comfort inside a bus during heating period within a climatic chamber. Appl. Ergon. 2015, 48, 164–176. [Google Scholar] [CrossRef]

- Khelf, M.; Boukebbab, S. The effect of noise on the comfort of passengers inside the tramway and its impact on traffic congestion in the urban area. J. Vibroeng. 2018, 20, 530–540. [Google Scholar] [CrossRef] [Green Version]

- Patania, F.; Gagliano, A.; Nocera, F.; Galesi, A. Analysis of acoustic climate on board public transport. Environ. Health Risk VII 2013, 16, 3–10. [Google Scholar] [CrossRef] [Green Version]

- Park, B.; Jeon, J.Y.; Choi, S.; Park, J. Short-term noise annoyance assessment in passenger compartments of high-speed trains under sudden variation. Appl. Acoust. 2015, 97, 46–53. [Google Scholar] [CrossRef]

- Li, T.T.; Bai, Y.H.; Liu, Z.R.; Li, J.L. In-train air quality assessment of the railway transit system in Beijing: A note. Transp. Res. Part D Transp. Environ. 2007, 12, 64–67. [Google Scholar] [CrossRef]

- Schwanitz, S.; Wittkowski, M.; Rolny, V.; Basner, M. Pressure variations on a train–Where is the threshold to railway passenger discomfort? Appl. Ergon. 2013, 44, 200–209. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Xiang, Z.R.; Zhi, J.Y.; Chen, Y.D.; Xu, X.F. Assessment of visual comfort in the lighting environments of subway cabins in China. Int. J. Rail Transp. 2022, 11, 406–427. [Google Scholar] [CrossRef]

- Amador-Jimenez, L.; Christopher, A. A comfort index for public transportation: Case study of Montreal. In Proceedings of the 2016 IEEE International Conference on Intelligent Transportation Engineering (ICITE), Singapore, 20–22 August 2016. [Google Scholar] [CrossRef]

- Xu, J. Build a Comprehensive Ride Comfort Index System for Subway Trains. Converter 2021, 6, 268–277. [Google Scholar]

- Mohammadi, A.; Amador-Jimenez, L.; Nasiri, F. A multi-criteria assessment of the passengers’ level of comfort in urban railway rolling stock. Sustain. Cities Soc. 2020, 53, 101892. [Google Scholar] [CrossRef]

- Sperling, E.; Betzhold, C. Contribution to evaluation of comfortable running of railway vehicles. Bull. Int. Railw. Congr. Assoc. 1956, 34, 672–678. [Google Scholar]

- UIC 513 R; Guidelines for Evaluating Passenger Comfort in Relation to Vibration in Railway Vehicle. International Union of Railways: Paris, France, 1994.

- BS 6841:1987; Guide to measurement and evaluation of human exposure to whole body mechanical vibration and repeated shock. British Standards Institution: London, UK, 1999.

- EN 14750-1:2006; Railway Applications—Air Conditioning for Urban and Suburban Rolling Stock—Comfort Parameters. European Committee for Standardization: Brussels, Belgium, 2006.

- UIC 553; Heating, Ventilation and Air-Conditioning in Coach. International Union of Railways: Paris, France, 2004.

- Fanger, P.O. Thermal Comfort: Analysis and Applications in Environmental Engineering; Danish Technical Press: Copenhagen, Denmark, 1970. [Google Scholar]

- ISO 7730:2005; Ergonomics of the Thermal Environment—Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria. International Organization for Standarization: Genever, Switzerland, 2005.

- ASHRAE Standard 55; Thermal Environmental Conditions for Human Occupancy. American Society of Heating, Refrigerating and Air-Conditioning Engineers: Peachtree Corners, GA, USA, 2020.

- Boyce, P.R. Human Factors in Lighting, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2014; pp. 21–23. [Google Scholar]

- Quek, G.; Wienold, J.; Khanie, M.S.; Erell, E.; Kaftan, E.; Tzempelikos, A.; Andersen, M. Comparing performance of discomfort glare metrics in high and low adaptation levels. Build. Environ. 2021, 206, 108335. [Google Scholar] [CrossRef]

- UIC 651; Layout of Driver’s Cabs in Locomotives, Railcars, Multiple Unit Trains and Driving Trailers. International Union of Railways: Paris, France, 2002.

- EN 13272-1:2019; Railway Applications—Electrical Lighting for Rolling Stock in Public Transport Systems—Part 1: Heavy Rail. International Organization for Standarization: Geneve, Switzerland, 2019.

- EN 13272-2:2019; Railway Applications—Electrical Lighting for Rolling Stock in Public Transport Systems—Part 2: Urban Rail. International Organization for Standarization: Geneve, Switzerland, 2019.

- MATLAB; Version 9.13.0 (R2022b). The MathWorks Inc.: Natick, MA, USA, 2022. Available online: https://www.mathworks.com (accessed on 24 May 2023).

| Standard | Location in the Unit | Height above Floor Level | Minimum Illuminance E |

|---|---|---|---|

| EN13272-1:2019 Heavy and high-speed units | Seating areas where no additional reading lights are provided | Passenger eye level | ≥150 lx |

| Seating areas with reading lights which are switched off | ≥100 lx | ||

| Side corridors and aisles | At floor level | ≥50 lx | |

| At 0.8 m above floor level | ≥75 lx | ||

| Standing areas, multifunctional areas, open gangways | At 0.8 m above floor level | ≥75 lx | |

| EN13272-2:2019 Urban rail vehicles | Seating areas | At 0.8 m above floor level | ≥150 lx |

| Standing areas | At 0.8 m above floor level | ≥150 lx | |

| Open gangways | At floor level | ≥50 lx |

| Comfort Index [m/s2] | Measuring Points | ||

|---|---|---|---|

| Point 1 | Point 2 | Point 3 | |

| ax,RMS-w | 0.045 | 0.202 | 0.068 |

| ay,RMS-w | 0.085 | 0.183 | 0.071 |

| az,RMS-w | 0.055 | 0.206 | 0.057 |

| aRMS-w | 0.111 | 0.342 | 0.113 |

| Comfort level | comfortable | Slightly uncomfortable | comfortable |

| Measuring Point | Average Air Temperature T [°C] | Average Relative Humidity RH [%] | Environment | |

|---|---|---|---|---|

| T [°C] | RH [%] | |||

| Point 1 | 23.6 | 43.8 | 22.3 | 40.7 |

| Point 2 | 22.6 | 42.2 | ||

| Point 3 | 22.0 | 47.1 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wawryszczuk, R.; Kardas-Cinal, E.; Lejk, J.; Sokołowski, M. Methods of Passenger Ride Comfort Evaluation—Tests for Metro Cars. Sensors 2023, 23, 5741. https://doi.org/10.3390/s23125741

Wawryszczuk R, Kardas-Cinal E, Lejk J, Sokołowski M. Methods of Passenger Ride Comfort Evaluation—Tests for Metro Cars. Sensors. 2023; 23(12):5741. https://doi.org/10.3390/s23125741

Chicago/Turabian StyleWawryszczuk, Róża, Ewa Kardas-Cinal, Jerzy Lejk, and Marek Sokołowski. 2023. "Methods of Passenger Ride Comfort Evaluation—Tests for Metro Cars" Sensors 23, no. 12: 5741. https://doi.org/10.3390/s23125741