Design and Experiment of Capacitive Rice Online Moisture Detection Device

Abstract

:1. Introduction

2. Materials

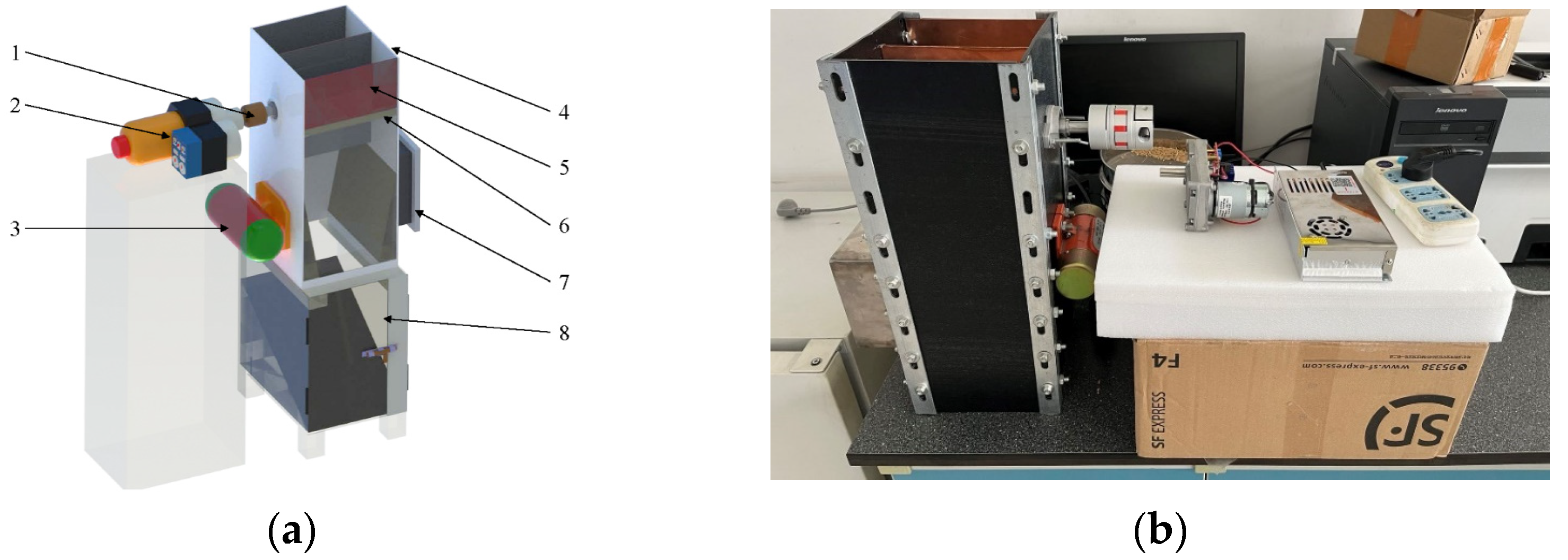

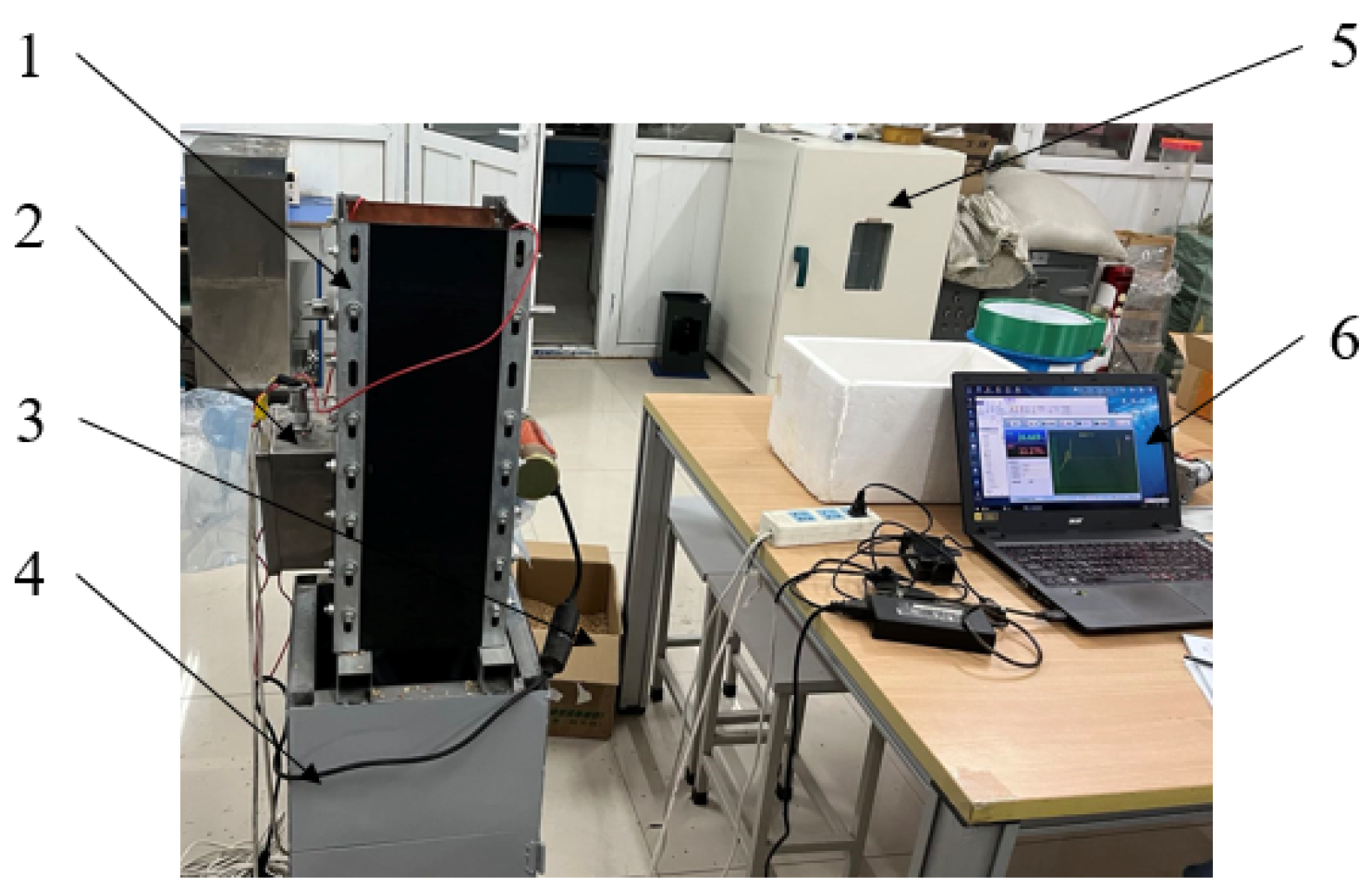

2.1. Design of Dynamic Rice Collection Device

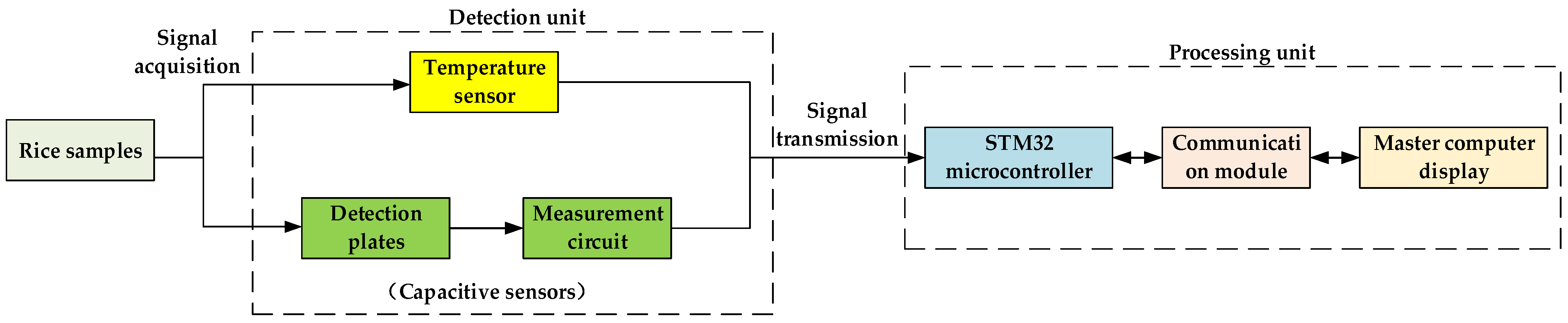

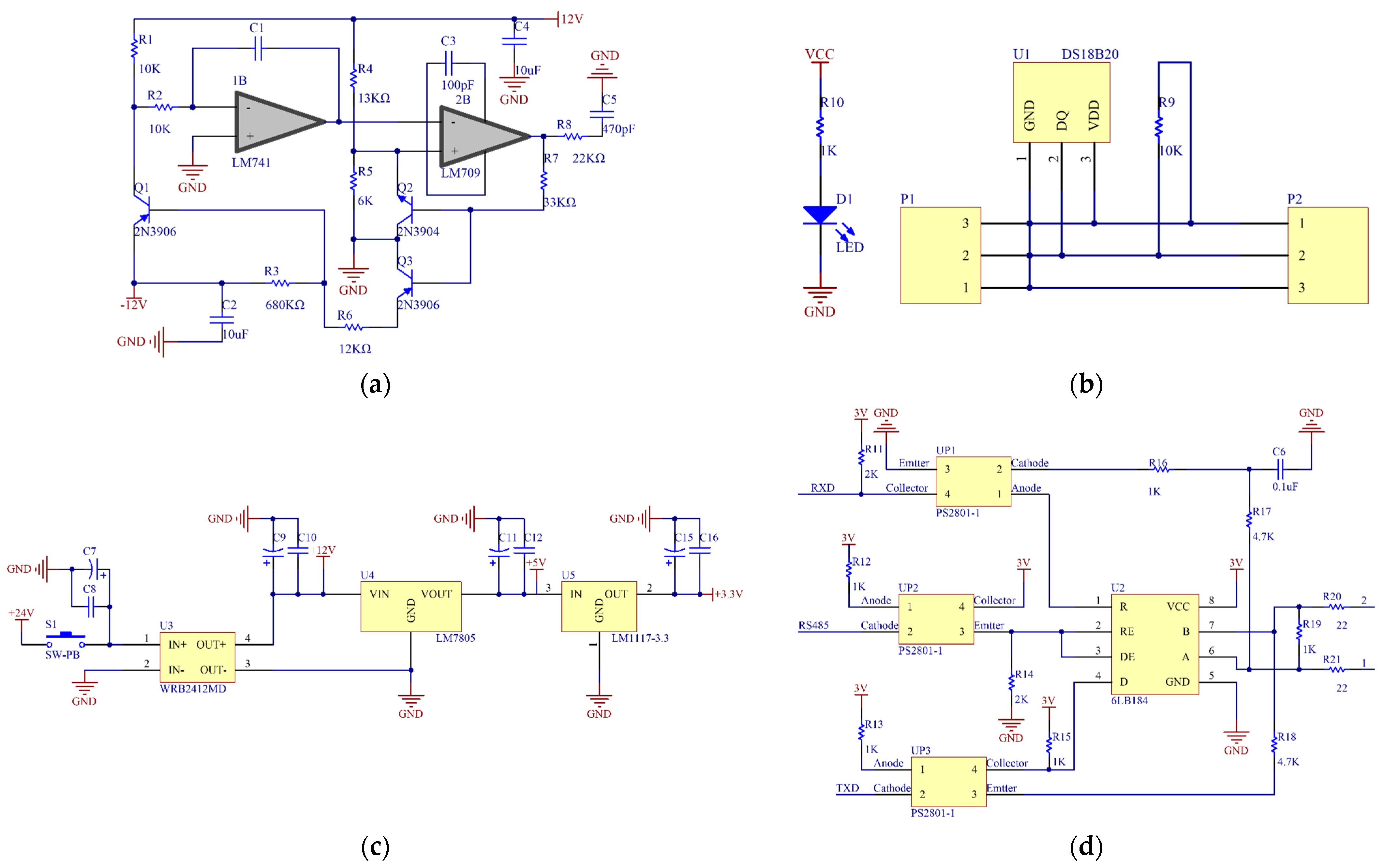

2.2. Hardware Design

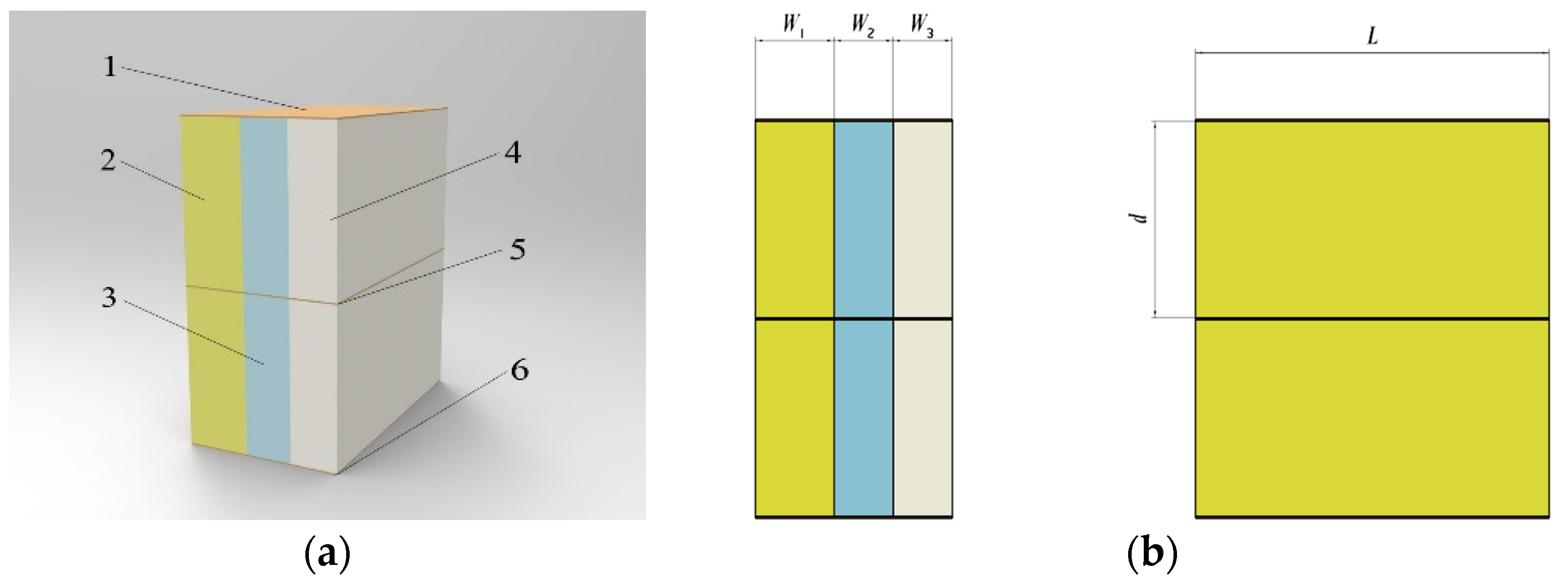

2.2.1. Detection Unit

- Capacitance detection;

- Temperature detection;

2.2.2. Power Supply Unit

2.2.3. Communication Unit

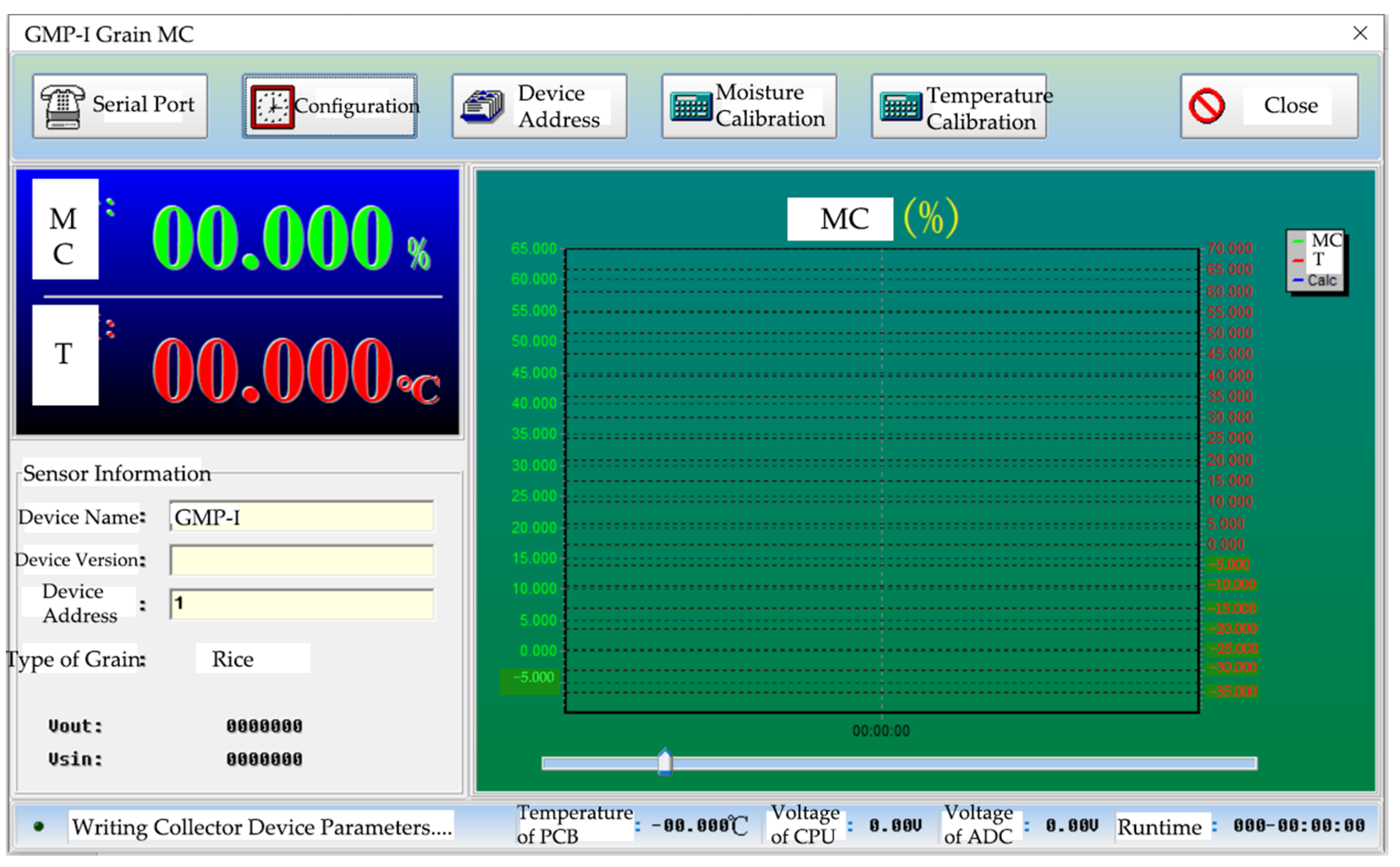

2.3. Software Design

3. Methods

3.1. Detection Principle

3.2. Electrostatic Field Simulation of the Tri-Plate Capacitor

3.2.1. Electrostatic Field Analysis of Capacitor Plate Thickness

3.2.2. Electrostatic Field Analysis of Capacitance Plate Spacing

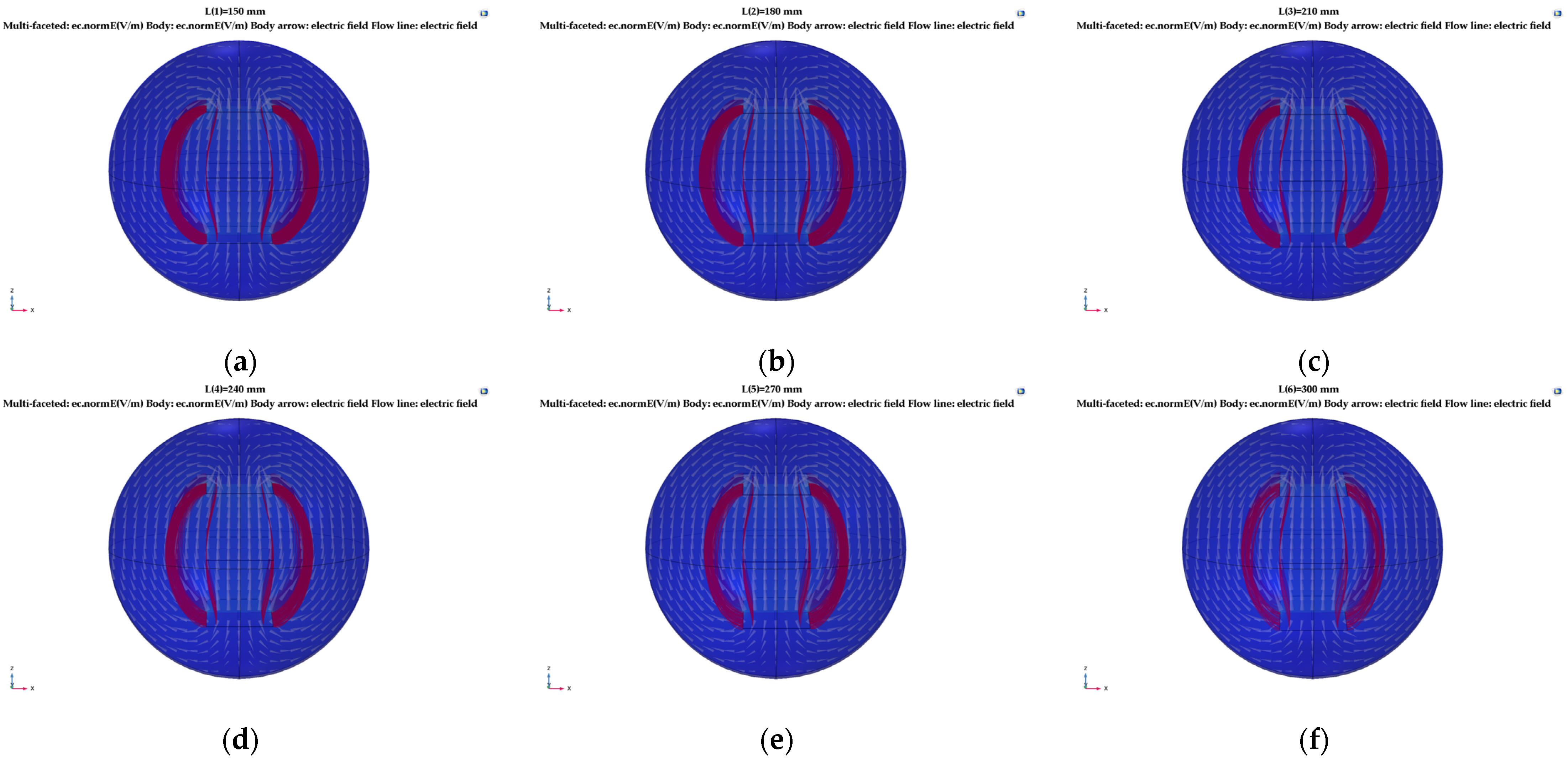

3.2.3. Electrostatic Field Analysis of the Relative Area of Capacitor Plates

3.3. Optimizing the BP Neural Network Prediction Model with the Genetic Algorithm

3.3.1. Data Preparation

3.3.2. Model Building

3.3.3. Evaluation Index

4. Results and Discussion

4.1. Optimization Experiment on the Structural Parameters of the Tri-Plate Capacitor

4.2. Analysis of the Prediction Results

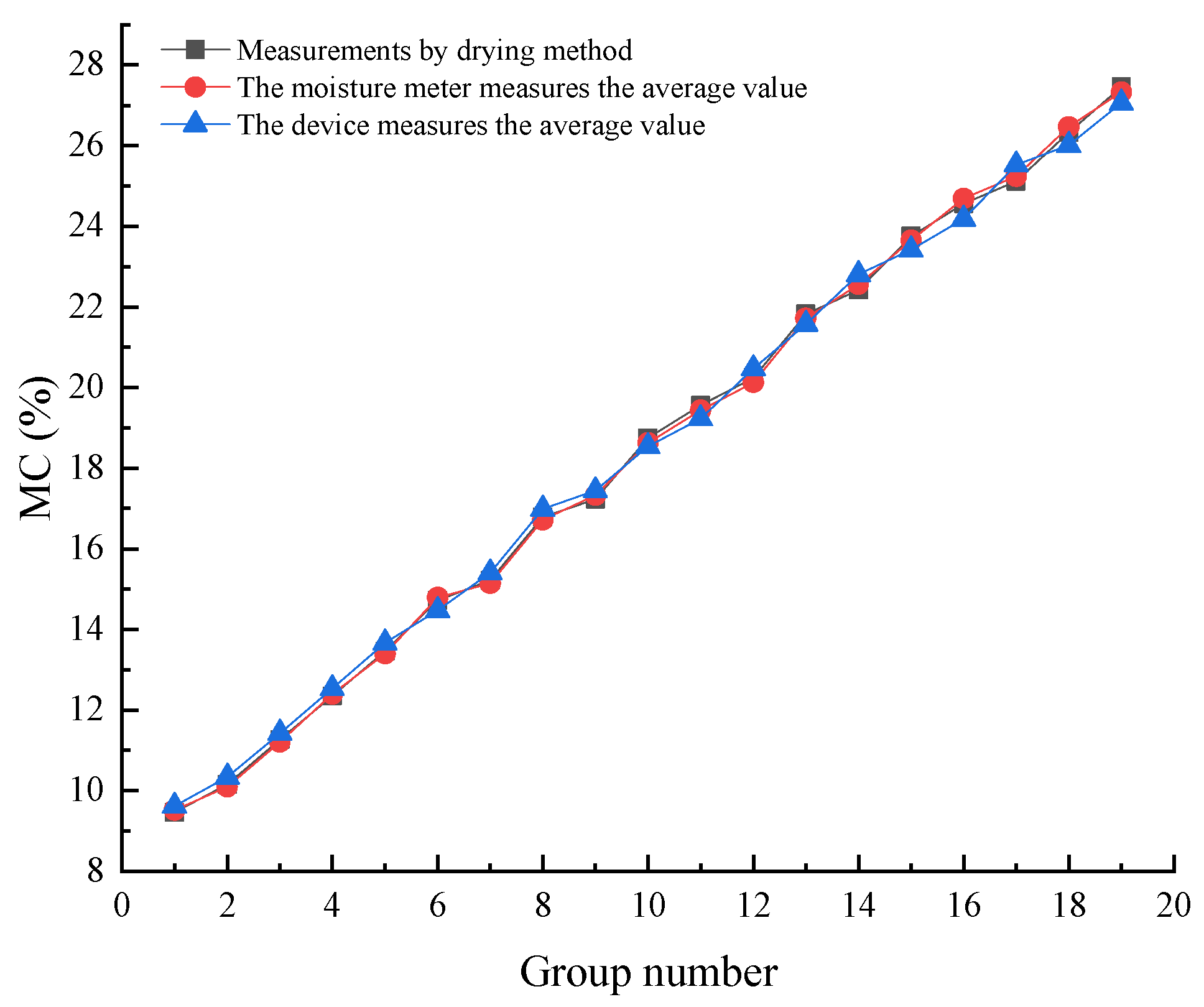

4.3. Indoor Accuracy of the Device

4.4. Indoor Dynamic Experiences of the Device

4.5. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, C.; van Groenigen, K.J.; Yang, H.; Hungate, B.A.; Yang, B.; Tian, Y.; Chen, J.; Dong, W.; Huang, S.; Deng, A.; et al. Global warming and shifts in cropping systems together reduce China’s rice production. Glob. Food Secur. 2020, 24, 100359. [Google Scholar] [CrossRef]

- Cao, D.; Feng, J.Z.; Bai, L.Y.; Xun, L.; Zhang, J.H. Delineating the rice crop activities in Northeast China through regional parametric synthesis using satellite remote sensing time-series data from 2000 to 2015. J. Integr. Agric. 2021, 20, 424–437. [Google Scholar] [CrossRef]

- Niu, Y.; Xie, G.; Xiao, Y.; Liu, J.; Wang, Y.; Luo, Q.; Zou, H.; Gan, S.; Qin, K.; Huang, M. Spatiotemporal patterns and determinants of grain self-sufficiency in China. Foods 2021, 10, 747. [Google Scholar] [CrossRef]

- Li, S.; Lu, Z.; Zhao, J.; Luo, M.; Chen, F.; Chu, Q. Changes in planting methods will change the potential distribution of rice in South China under climate warming. Agric. For. Meteorol. 2023, 331, 109355. [Google Scholar] [CrossRef]

- Scariot, M.A.; Karlinski, L.; Dionello, R.G.; Radünz, A.L.; Radünz, L.L. Effect of drying air temperature and storage on industrial and chemical quality of rice grains. J. Stored Prod. Res. 2020, 89, 101717. [Google Scholar] [CrossRef]

- Trail, P.; Motis, T.; Swartz, S.; Bicksler, A. Low-cost seed storage technologies for development impact of small-scale seed saving entities in tropical climates. Exp. Agric. 2021, 57, 324–337. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, L.; Wang, H.; Ai, L.; Xiong, W. Insight into protein-starch ratio on the gelatinization and retrogradation characteristics of reconstituted rice flour. Int. J. Biol. Macromol. 2020, 146, 524–529. [Google Scholar] [CrossRef] [PubMed]

- Hasan, M.; Gopakumar, D.A.; Olaiya, N.; Zarlaida, F.; Alfian, A.; Aprinasari, C.; Alfatah, T.; Rizal, S.; Khalil, H.A. Evaluation of the thermomechanical properties and biodegradation of brown rice starch-based chitosan biodegradable composite films. Int. J. Biol. Macromol. 2020, 156, 896–905. [Google Scholar] [CrossRef] [PubMed]

- Amanda, M.; Trojahn, N.M.; Vanessa, M.; Carteri, C.P.; de Moraes, R.S.; Samuel, M.; Fernandes, L.A.; Fogliato, P.V.; König, M.C. Rice Drying, Storage and Processing: Effects of Post-Harvest Operations on Grain Quality. Rice Sci. 2022, 29, 16–30. [Google Scholar] [CrossRef]

- Gao, R.L.; Che, G.; Wan, L. Process optimization and quality analysis of rice with negative pressure drying. Cereals Oils 2020, 33, 76–80. [Google Scholar]

- Zhang, H.J. Application of rapid detection technology in grain storage. Food Sci. Technol. Econ. 2020, 45, 59–60. [Google Scholar] [CrossRef]

- Jafari, A.; Tumbleson, M.; Rausch, K.D. Evaluation of grain moisture measurement methods suited for developing countries. J. Stored Prod. Res. 2022, 98, 102001. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, X.L.; Shan, X.X.; Wang, S.; Zhang, P.Z. Optimization of grain and oil moisture testing method. Grain Storage 2020, 49, 45–50. [Google Scholar]

- Tinna, A.; Parmar, N.; Bagla, S.; Goyal, D.; Senthil, V. Design and development of capacitance based moisture measurement for grains. Mater. Today Proc. 2021, 43, 263–267. [Google Scholar] [CrossRef]

- Wu, H.C.; Xie, H.X.; Hu, Z.C.; Gu, F.W.; You, Z.Y.; Wei, H. Design and experiment of continuous single grain typed online grain moisture test apparatus. Trans. CSAE 2017, 33, 282–290. [Google Scholar] [CrossRef]

- Wang, S.B.; Zhao, L.Q.; Zhao, J.; Zhang, Y. Design of needle-punched in-situ corn moisture meter based on resistance method. J. Chin. Agric. Mech. 2019, 40, 159–164. [Google Scholar] [CrossRef]

- Flor, O.; Palacios, H.; Suárez, F.; Salazar, K.; Reyes, L.; González, M.; Jiménez, K. New Sensing Technologies for Grain Moisture. Agriculture 2022, 12, 386. [Google Scholar] [CrossRef]

- Aswani, G.; Islam, T. Capacitive fringing sensor based on PCB for the detection of moisture content in grain. In Proceedings of the 2023 International Conference on Power, Instrumentation, Energy and Control (PIECON), Aligarh, India, 10–12 February 2023; IEEE: Manhattan, NY, USA, 2023; pp. 1–5. [Google Scholar] [CrossRef]

- Surya, S.G.; Yuvaraja, S.; Varrla, E.; Baghini, M.S.; Palaparthy, V.S.; Salama, K.N. An in-field integrated capacitive sensor for rapid detection and quantification of soil moisture. Sens. Actuators B Chem. 2020, 321, 128542. [Google Scholar] [CrossRef]

- Wang, J.W.; Tang, T.Y.; Tang, H.; Xu, C.S.; Zhou, W.Q.; Wang, Q. Design and Experiment of Online Detection Device for Capacitive Paddy Rice Moisture Content of Combine Harvester. Trans. Chin. Soc. Agric. Mach. 2021, 52, 143–152. [Google Scholar] [CrossRef]

- Wan, L.; Tang, H.Y.; Ma, G.Y.; Che, G.; Zou, D.D.; Sun, W.S. Optimization Design and Experiment on Finned Double Plates Rice Moisture Content Measuring Device. Trans. Chin. Soc. Agric. Mach. 2021, 52, 320–328. [Google Scholar] [CrossRef]

- Zhang, B.H.; Qian, C.Q.; Jiao, J.K.; Ding, Z.H.; Zhang, Y.; Cui, H.G.; Liu, C.H.; Feng, L.L. Rice moisture content detection method based on dielectric properties and SPA-SVR algorithm. Trans. CSAE 2019, 35, 237–244. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Y.H.; Lian, Y.; Wang, S.Q.; Liu, X.Y. Development of online monitoring device of grain moisture content in combine harvester with high frequency capacitance. Trans. CSAE 2018, 34, 36–45. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, J.; Zhao, L.Q.; Cheng, X. Design and experiment of online measuring instrument for grain moisture based on dielectric properties. J. Chin. Agric. Mech. 2020, 41, 105–110. [Google Scholar] [CrossRef]

- Li, Z.F.; Jin, C.Q.; Liu, Z.; Yang, T.X.; Chen, M.; Cai, Z.Y. Design and calibration of online moisture detection device for grain combine harvester. J. Chin. Agric. Mech. 2019, 40, 145–151. [Google Scholar] [CrossRef]

- Pan, B.L.; Pan, J.J.; Yan, L.H. The Application of DM510 of Online Moisture Controller in Continuous Grain Dryer. Mod. Food 2016, 3, 20–22. [Google Scholar] [CrossRef]

- Li, C.; Zhang, X.; Meng, M.; Li, B.; Li, C. Capacitive Online Corn Moisture Content Sensor Considering Porosity Distributions: Modeling, Design, and Experiments. Appl. Sci. 2021, 11, 7655. [Google Scholar] [CrossRef]

- Kapic, A.; Tsirou, A.; Verdini, P.G.; Carrara, S. Humidity sensors for high energy physics applications: A review. IEEE Sens. J. 2020, 20, 10335–10344. [Google Scholar] [CrossRef]

- Pathaveerat, S.; Pruengam, P. Low cost measurement of moisture content in long grain paddy. J. Stored Prod. Res. 2020, 89, 101728. [Google Scholar] [CrossRef]

- Putri, R.E.; Pratama, W.E.; Ifmalinda, I. Application of Capacitive Sensor for Measuring Grain Moisture Content Based on Internet of Things. J. Keteknikan Pertan. 2023, 11, 29–40. [Google Scholar] [CrossRef]

- Zhao, D.; Wang, Y.; Shao, J.; Zhang, P.; Chen, Y.; Fu, Z.; Wang, S.; Zhao, W.; Zhou, Z.; Yuan, Y. Temperature and humidity sensor based on MEMS technology. AIP Adv. 2021, 11, 085126. [Google Scholar] [CrossRef]

- Yariv, E. Edge corrections for parallel-plate capacitors. Eur. J. Appl. Math. 2021, 32, 226–241. [Google Scholar] [CrossRef]

- Zhang, H.; Yao, L.; Quan, L.; Zheng, X. Theories for triboelectric nanogenerators: A comprehensive review. Nanotechnol. Rev. 2020, 9, 610–625. [Google Scholar] [CrossRef]

- Guo, Y.; Li, B.; Zhang, Q.; He, X.T.; Sun, J.Y. A Further Theoretical Study of Capacitive Pressure Sensors Based on Thin Film Elastic Deflection and Parallel Plate Capacitor: Refined Closed-Form Solution and Numerical Calibration. Sensors 2022, 22, 2848. [Google Scholar] [CrossRef]

- Anand, G.; Lowe, A.; Jones, R.; Arnold, W.M.; Kalra, A.; Simpkin, R.; Sinno, I.; Budgett, D. Quantification of edge effects in capacitive biopotential sensing. In Proceedings of the TENCON 2021-2021 IEEE Region 10 Conference (TENCON), Auckland, New Zealand, 7–10 December 2021; IEEE: Manhattan, NY, USA, 2021; pp. 1004–1007. [Google Scholar] [CrossRef]

- Oh, Y.; Jang, T.; Ha, H.; Sohn, S. Temporal Change of a Parallel Plate Capacitor’s Voltage after Dielectric Insertion. Phys. Teach. 2022, 60, 124–127. [Google Scholar] [CrossRef]

- Liu, Y.; Abali, B.E.; Yang, H.; Müller, W.H. Plate capacitor problem as a benchmark case for verifying the finite element implementation. Contin. Mech. Thermodyn. 2023, 35, 245–265. [Google Scholar] [CrossRef]

- Cao, X.G.; Yang, Y. The size effect of parallel-plate capacitor. Coll. Phys. 2021, 40, 8–11. [Google Scholar] [CrossRef]

- Xu, L.; Wang, S.X.; Zhang, W.W.; Zheng, P.L.; Huang, Z.Y. Analysis of Fringe Effect on Capacitance Structure Design of Micro Force Measurement Device. Instrum. Tech. Sens. 2020. [Google Scholar] [CrossRef]

- Lei, J. Simulation and Analysis of the Influence of Plate Thickness on Capacitive Edge Effect. Comput. Telecommun. 2013, 15, 52–53. [Google Scholar] [CrossRef]

- Han, J.X.; Ma, M.Y.; Wang, K. Product modeling design based on the genetic algorithm and BP neural network. Neural Comput. Appl. 2021, 33, 4111–4117. [Google Scholar] [CrossRef]

- Zhang, J.; Qu, S.; Lv, Z. Optimization of Backpropagation Neural Network under the Adaptive Genetic Algorithm. Complexity 2021, 2021, 1718234. [Google Scholar] [CrossRef]

- Yang, J.; Hu, Y.; Zhang, K.; Wu, Y. An improved evolution algorithm using population competition genetic algorithm and self-correction BP neural network based on fitness landscape. Soft Comput. 2021, 25, 1751–1776. [Google Scholar] [CrossRef]

- Shen, X.; Zheng, Y.; Zhang, R. A hybrid forecasting model for the velocity of hybrid robotic fish based on back-propagation neural network with genetic algorithm optimization. IEEE Access 2020, 8, 111731–111741. [Google Scholar] [CrossRef]

- Cicek, Z.I.E.; Ozturk, Z.K. Optimizing the artificial neural network parameters using a biased random key genetic algorithm for time series forecasting. Appl. Soft Comput. 2021, 102, 107091. [Google Scholar] [CrossRef]

- Jie, Z.; Qiurui, M. Establishing a Genetic Algorithm-Back Propagation model to predict the pressure of girdles and to determine the model function. Text. Res. J. 2020, 90, 2564–2578. [Google Scholar] [CrossRef]

- Lv, R.W.; Bao, W.L.; Qin, X.L.; Bu, Y.L. Comparative study of moisture measurement method in paddy. Grain Storage 2021, 50, 38–41. [Google Scholar] [CrossRef]

- Che, G.; Chen, Z.F.; Wang, X.; Tang, H.Y.; Wan, L. Design and Experiment on Autonomous Transferring and Quick Measuring Equipment of Moisture Content of Coarse Cereals. Trans. Chin. Soc. Agric. Mach. 2019, 50, 357–366. [Google Scholar] [CrossRef]

| Name | Main Parameters |

|---|---|

| Servo | Rated voltage 12~24 V/DC |

| Power switch | Output voltage: 24 V, AC output current: 10 A, power 250 W |

| Coupling | Plum type aluminum alloy material Size: Outer diameter 55 mm, length 78 mm, hole 12 to 15 mm |

| Normal flat key | Type A 6 × 6 × 180 mm, 304 stainless steel |

| Bearing seat | Rhombic shape KFL004 inner diameter 20 mm |

| Vibrating device | Single 220 V 20 W |

| Grain storage bench | Length, width, and height: 300 × 300 × 500 mm |

| Circuit board package shell | Length, width, and height: 145 × 145 × 75 mm |

| Coded Value | Plate Thickness h/mm | Plate Spacing d/mm | Relative Area A/mm2 |

|---|---|---|---|

| −1.682 | 0.5 | 80 | 18,000 |

| −1 | 0.9 | 84.1 | 20,432 |

| 0 | 1.5 | 90 | 24,000 |

| 1 | 2.1 | 96.0 | 27,568 |

| 1.682 | 2.5 | 100 | 30,000 |

| Test Number | X1 | X2 | X3 | Measured Capacitance Value C1/pF | Theoretical Calculated Capacitance Value C2/pF | Sensitivity Y |

|---|---|---|---|---|---|---|

| 1 | 0 | 0 | 1.682 | 44.8 | 33.68 | 1.33 |

| 2 | 0 | 0 | 0 | 39.63 | 34.16 | 1.16 |

| 3 | 0 | 0 | 0 | 38.94 | 34.16 | 1.14 |

| 4 | 0 | 0 | 0 | 39.28 | 34.16 | 1.15 |

| 5 | −1 | 1 | −1 | 37.21 | 35.1 | 1.06 |

| 6 | 0 | 0 | −1.682 | 36.48 | 25.69 | 1.42 |

| 7 | 0 | −1.682 | 0 | 44.31 | 38.53 | 1.15 |

| 8 | 1.682 | 0 | 0 | 41.13 | 33.44 | 1.23 |

| 9 | 0 | 0 | 0 | 39.39 | 34.16 | 1.23 |

| 10 | 0 | 1.682 | 0 | 43.25 | 35.45 | 1.22 |

| 11 | −1.682 | 0 | 0 | 35.91 | 32.94 | 1.09 |

| 12 | 1 | −1 | −1 | 44.31 | 31.43 | 1.41 |

| 13 | −1 | 1 | 1 | 42.44 | 29.89 | 1.42 |

| 14 | −1 | −1 | 1 | 44.67 | 35.74 | 1.25 |

| 15 | 0 | 0 | 0 | 39.97 | 34.16 | 1.17 |

| 16 | 1 | 1 | 1 | 43.22 | 33.77 | 1.28 |

| 17 | 0 | 0 | 0 | 38.6 | 34.16 | 1.13 |

| 18 | −1 | −1 | −1 | 40.23 | 32.18 | 1.25 |

| 19 | 0 | 0 | 0 | 39.63 | 34.16 | 1.16 |

| 20 | 1 | −1 | 1 | 43.48 | 41.02 | 1.06 |

| 21 | 0 | 0 | 0 | 41.68 | 34.16 | 1.22 |

| 22 | 0 | 0 | 0 | 38.6 | 34.16 | 1.13 |

| 23 | 1 | 1 | −1 | 43.69 | 30.34 | 1.44 |

| Source | Std. Dev. | R2 | Adjusted R2 | Predicted R2 | PRESS |

|---|---|---|---|---|---|

| Linear | 0.1175 | 0.1027 | −0.0389 | −0.5404 | 0.4503 |

| 2FI | 0.0869 | 0.5869 | 0.4320 | −0.1190 | 0.3271 |

| Quadratic | 0.0369 | 0.9394 | 0.8974 | 0.7505 | 0.0729 |

| Cubic | 0.0379 | 0.9559 | 0.8921 | −0.7651 | 0.5160 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 0.2746 | 9 | 0.0305 | 22.38 | <0.0001 |

| X1 | 0.0145 | 1 | 0.0145 | 10.66 | 0.0062 |

| X2 | 0.0089 | 1 | 0.0089 | 6.50 | 0.0243 |

| X3 | 0.0066 | 1 | 0.0066 | 4.88 | 0.0458 |

| X1 X2 | 0.0091 | 1 | 0.0091 | 6.69 | 0.0226 |

| X1 X3 | 0.0946 | 1 | 0.0946 | 69.41 | <0.0001 |

| X2 X3 | 0.0378 | 1 | 0.0378 | 27.74 | 0.0002 |

| X12 | 0.0002 | 1 | 0.0002 | 0.1490 | 0.7057 |

| X22 | 0.0024 | 1 | 0.0024 | 1.80 | 0.2031 |

| X32 | 0.1007 | 1 | 0.1007 | 73.85 | <0.0001 |

| Residual | 0.0177 | 13 | 0.0014 | ||

| Lack of Fit | 0.0071 | 5 | 0.0014 | 1.07 | 0.4431 |

| Pure Error | 0.0106 | 8 | 0.0013 | ||

| Cor Total | 0.2923 | 22 |

| Number of Trainings | Learning Rate | Training Accuracy | Training Function |

|---|---|---|---|

| 1000 | 0.1 | 0.00001 | Levenberg–Marquardt |

| Population Size | Evolutionary Algebra | Crossover Probability | Mutation Probability |

|---|---|---|---|

| 100 | 50 | 0.3 | 0.1 |

| Group Number | Measurements under the Drying Method (%) | Device Measurements (%) | Relative Error (%) |

|---|---|---|---|

| 1 | 18.67 | 19.03 | 1.93 |

| 2 | 17.34 | 17.01 | −1.90 |

| 3 | 16.67 | 17.02 | 2.10 |

| 4 | 16.21 | 15.85 | −2.22 |

| 5 | 15.93 | 15.59 | −2.13 |

| 6 | 15.63 | 16.01 | 2.43 |

| 7 | 15.32 | 15.02 | −1.96 |

| 8 | 15.11 | 15.41 | 1.99 |

| 9 | 14.97 | 14.63 | −2.27 |

| 10 | 14.79 | 14.48 | −2.10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, W.; Wan, L.; Che, G.; Xu, P.; Wang, H.; Qu, T. Design and Experiment of Capacitive Rice Online Moisture Detection Device. Sensors 2023, 23, 5753. https://doi.org/10.3390/s23125753

Sun W, Wan L, Che G, Xu P, Wang H, Qu T. Design and Experiment of Capacitive Rice Online Moisture Detection Device. Sensors. 2023; 23(12):5753. https://doi.org/10.3390/s23125753

Chicago/Turabian StyleSun, Wensheng, Lin Wan, Gang Che, Ping Xu, Hongchao Wang, and Tianqi Qu. 2023. "Design and Experiment of Capacitive Rice Online Moisture Detection Device" Sensors 23, no. 12: 5753. https://doi.org/10.3390/s23125753

APA StyleSun, W., Wan, L., Che, G., Xu, P., Wang, H., & Qu, T. (2023). Design and Experiment of Capacitive Rice Online Moisture Detection Device. Sensors, 23(12), 5753. https://doi.org/10.3390/s23125753